A continuous casting anti-clogging submerged nozzle

An immersion-type, anti-clogging technology, applied in casting equipment, casting melt containers, metal processing equipment, etc., can solve the problems of side hole nodulation, nozzle nodulation, blockage, etc., to prevent nodulation and blockage, improve casting Billet quality, ease of manufacture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

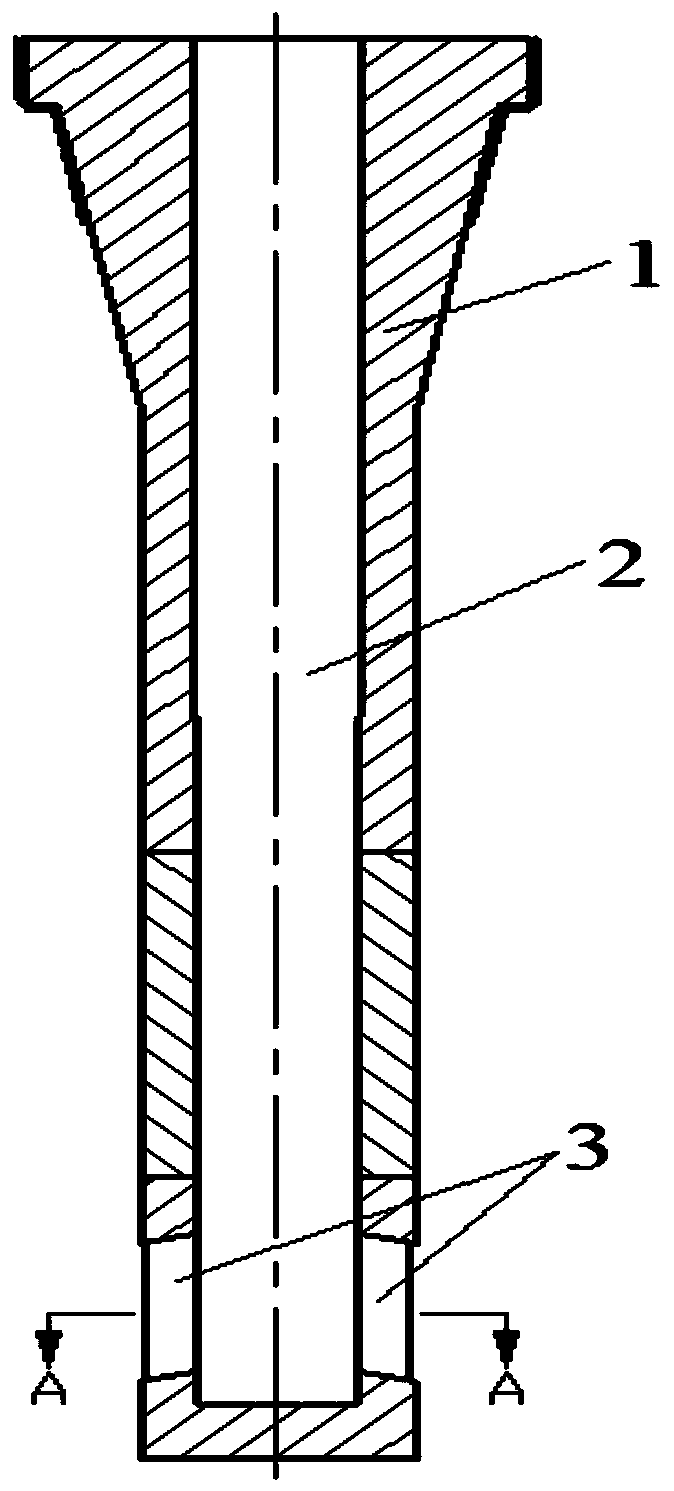

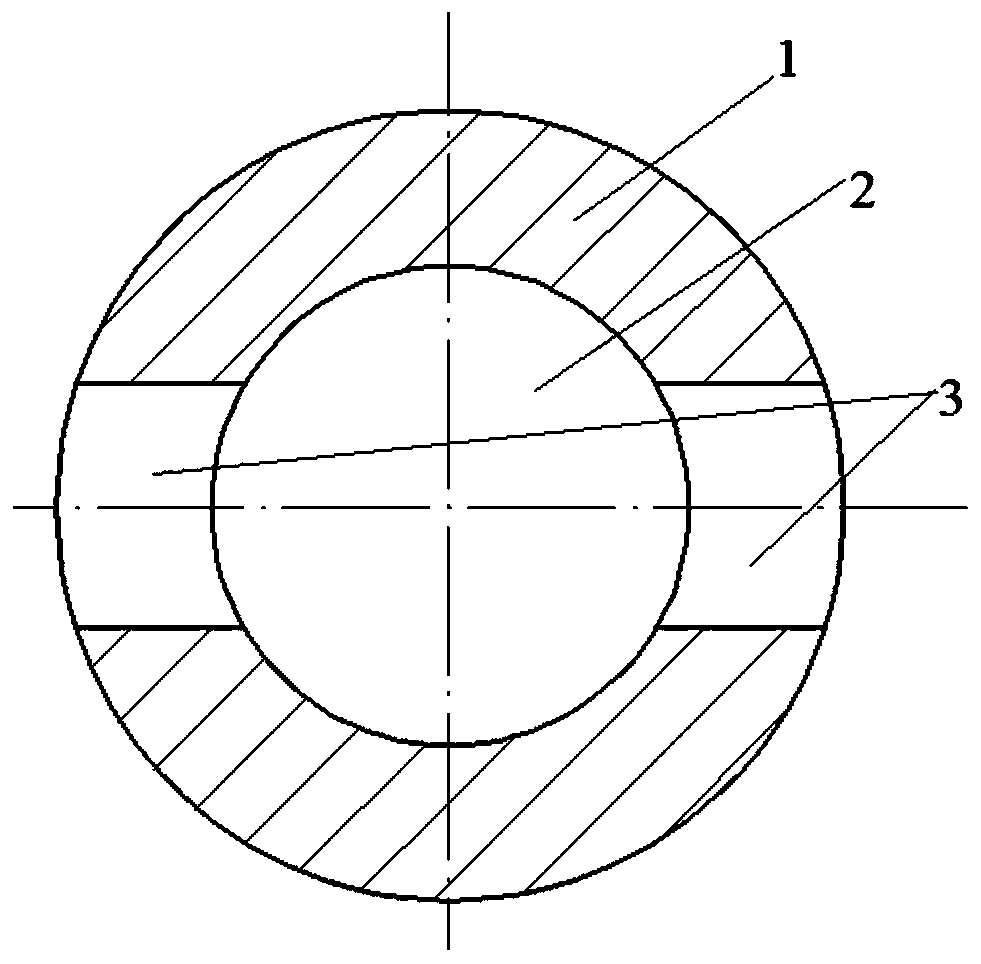

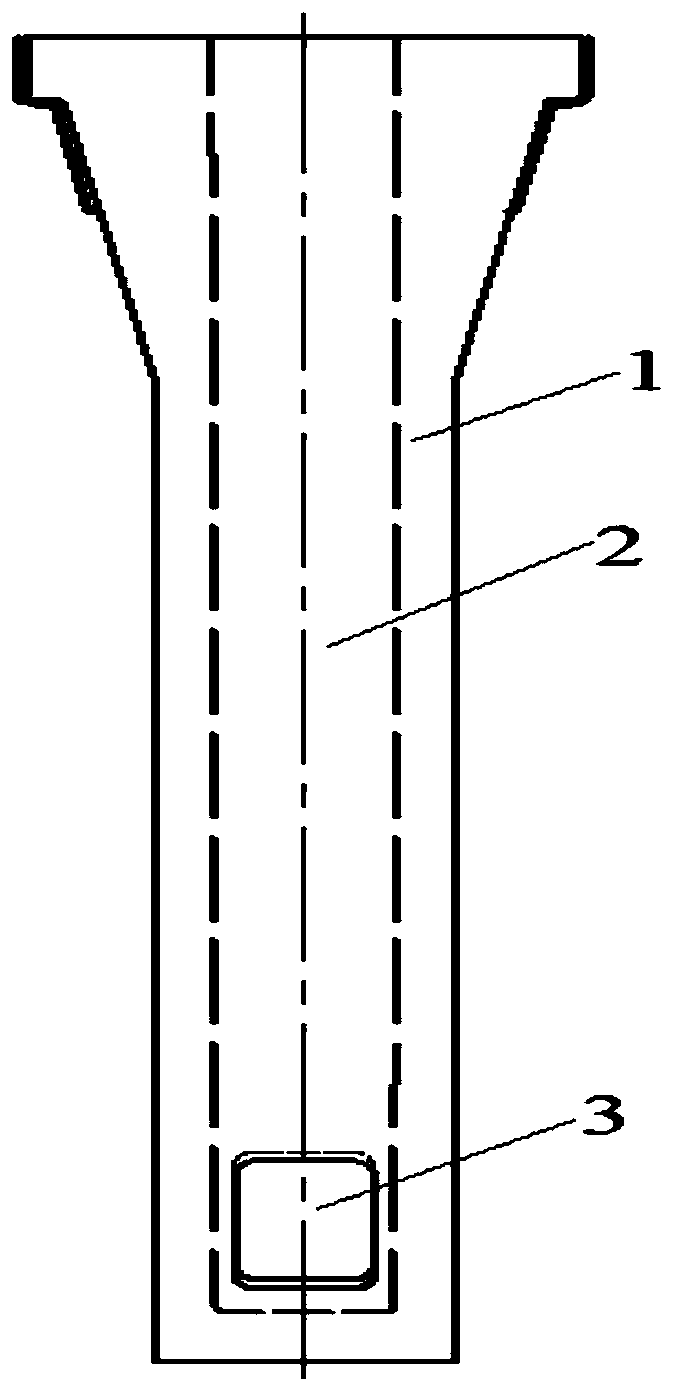

[0041] Such as Figure 4 , Figure 5 , Figure 6 As shown, the two side holes 3 of the anti-clogging submerged nozzle of the present invention are rectangular. The submerged nozzle is composed of a body 1, a main hole 2 and two rectangular holes 3 at the lower part of the side wall of the body, and the two side walls of the rectangular hole expand outwards with a straight side 6 with an angle α=20°, as shown in Figure 6 shown.

[0042] The bottom 4 of the side hole expands downward in an arc shape with a radius of R=50mm, and forms the lower side hole of the submerged nozzle with the top 7 of the side hole at a downward angle b=15°, such as Figure 4 shown.

Embodiment 2

[0044] Such as Figure 4 , Figure 5 , Figure 7 As shown, the two side holes 3 of the anti-clogging submerged nozzle of the present invention are rectangular. The submerged nozzle is composed of a main body 1, a main hole 2 and two rectangular side holes 3 at the bottom of the side wall of the body. Figure 7 ) expands outward, and the bottom of the side hole 4 ( Figure 4 ) expands downward in an arc with a radius of R=60mm, and is connected with the top 7 of the side hole at a downward angle b=14° ( Figure 4 ) constitute the lower side hole of the submerged nozzle.

Embodiment 3

[0046] Such as Figure 4 , Figure 8 , Figure 6 As shown, the two side holes 3 at the lower part of the anti-clogging submerged nozzle of the present invention are oval. The submerged nozzle is composed of a body 1, a main hole 2 and two oval holes 3 at the lower part of the side wall of the body. Figure 6 ) expands outward, and the bottom of the side hole 4 ( Figure 4 ) expands downward in an arc with a radius of R=40mm, and is connected with the top 7 of the side hole at a downward angle b=15° ( Figure 4 ) constitute the lower side hole of the submerged nozzle.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com