Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

338results about How to "High specific modulus" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

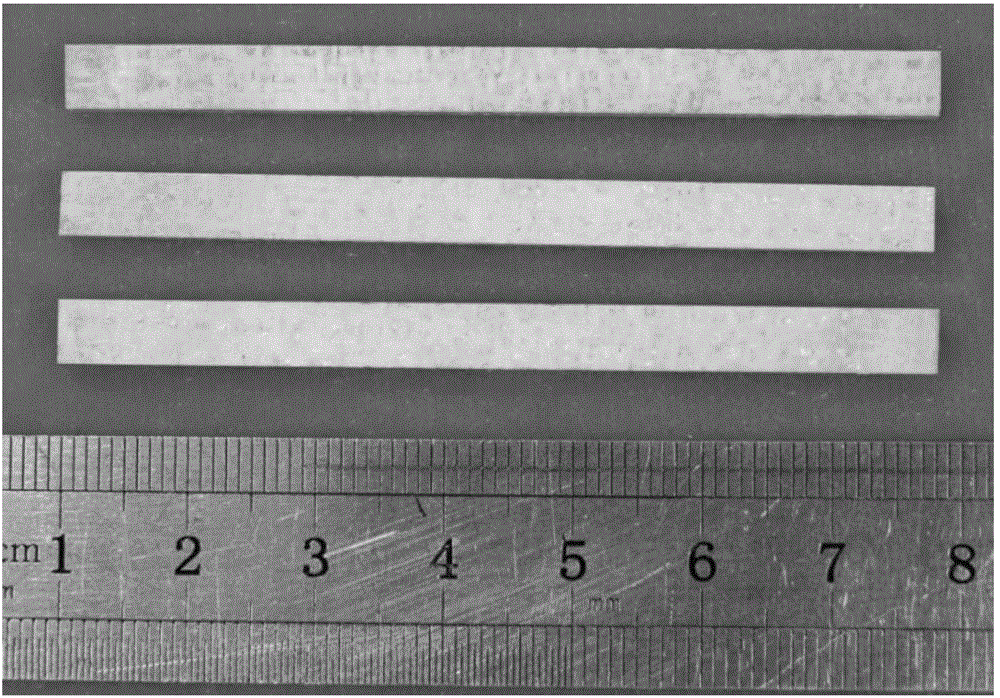

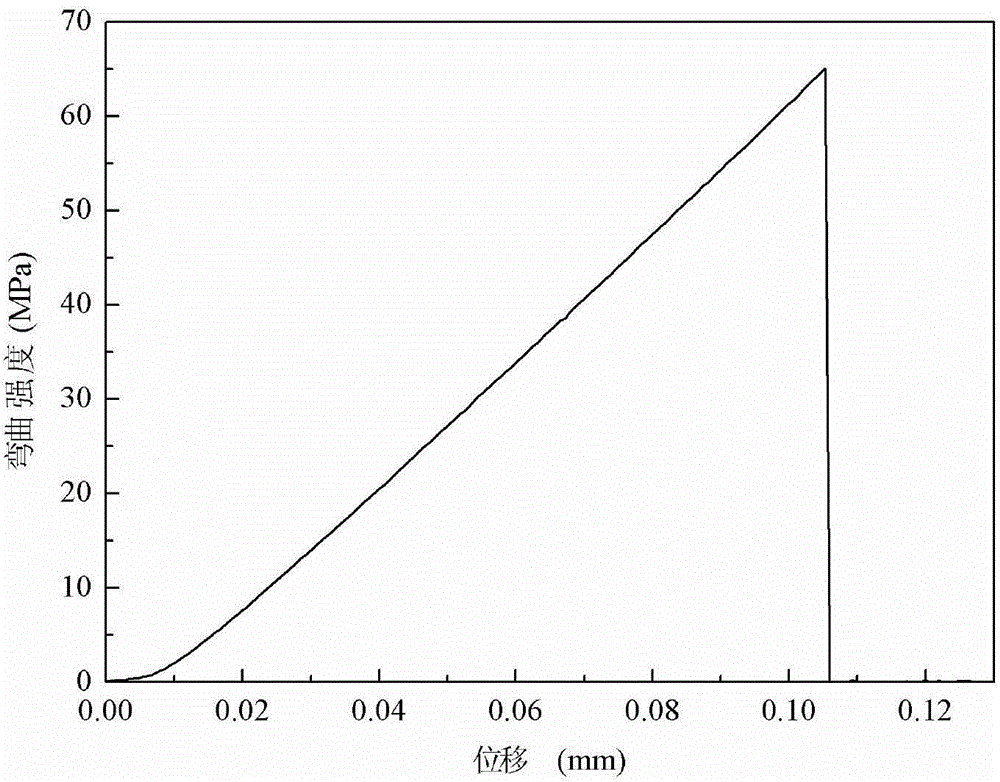

Light-weight and high-strength plastic steel sandwich board and its making method

ActiveCN102991046ALight in massQuality improvementSynthetic resin layered productsLaminationThermoplasticAdhesive

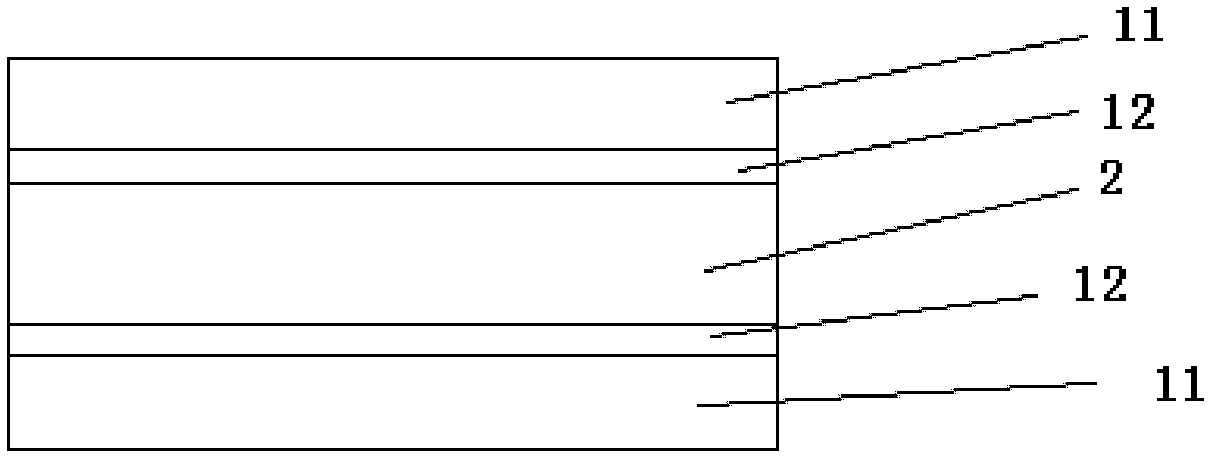

The invention belongs to the technical field of building decoration and transportation, and discloses a light-weight and high-strength plastic steel sandwich board and its making method. The plastic steel sandwich board comprises two panels and a sandwich layer fixed between the two panels. The making method of the plastic steel sandwich board comprises the following steps: placing the sandwich layer between the two panels, and respectively bonding the two panels with the right and wrong surfaces of the sandwich layer through an adhesive to prepare the plastic steel sandwich board, wherein each of the panel is obtained through compounding one side of a continuous fiber reinforced thermoplastic plastic board with a non-woven fabric through hot-press molding. The plastic steel sandwich board has the advantages of light weight, high strength, heat insulation, fire resistance, moisture resistance, corrosion resistance and the like.

Owner:滁州格美特科技有限公司

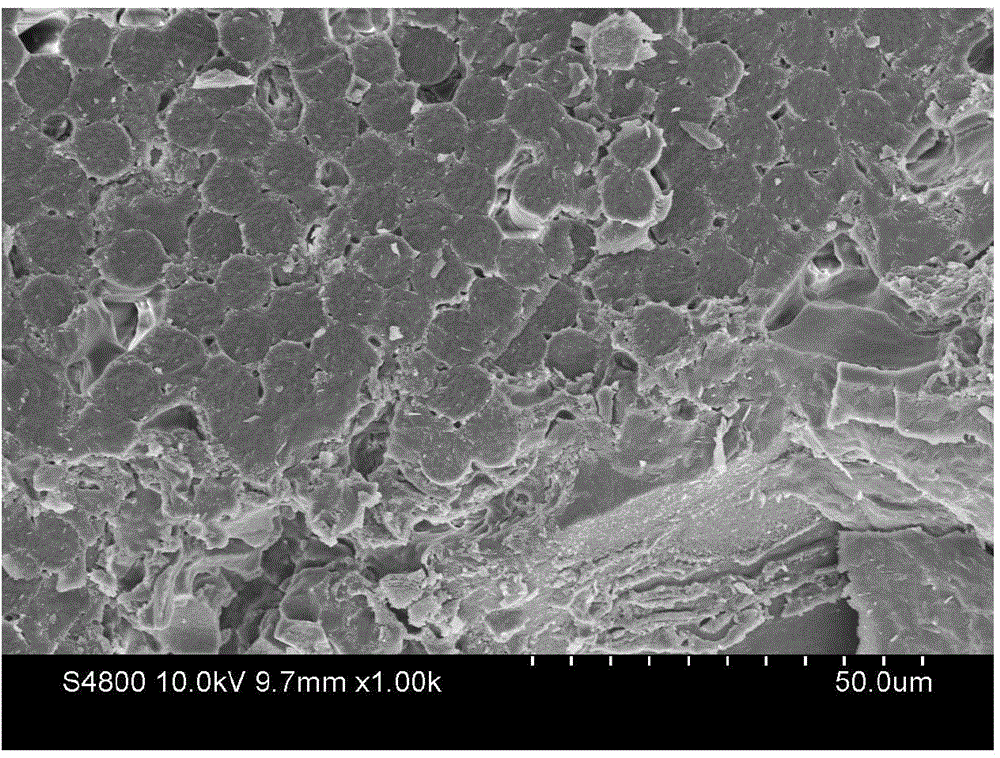

Aluminum-base alloy self-lubricating material and preparation method thereof

A aluminum-based alloy self-lubricating materials and method for making same relates to the technology for preparing composite metal materials. Aimming at the evil of large gas cavity amount in aluminum-based alloy self-lubricating materials, there is disclosed a aluminum-based alloy self-lubricating materials and method for making same. Said scheme is as follows: selecing aluminium alloy as a basal body alloy, adding a slipping agent into the aluminium alloy fused mass, wherein said slipping agent is composed of one of copper facing mineral carbon or one mixture of copper facing mineral carbon and copper facing carbon fabric or one mixture of copper facing mineral carbon and nickel plating carbon fibre and is prepared through stirring-mixing, vacuum outgassing and casting, and the basal body aluminium alloy comprises (based on mass percent) Si of 6.5-9.0, Mg of 0.8-1.2, Mn of 0.1-0.5, Ti of 0.1-0.25, Zn of not more than 0.3, Fe of not more than 0.5, Cu of not more than 0.3, Ni of not more than 0.1, in which the allowance is Al. The weight of the added substance is 7-12%, 10-18% and 10-17 of the total weight of the aluminum-based alloy respectively when copper facing mineral carbon, the mixture of copper facing mineral carbon and copper facing carbon fabric and the mixture of copper facing mineral carbon and nickel plating carbon fibre are adopted. There is less gas cavities existing in said material.

Owner:NORTHEASTERN UNIV

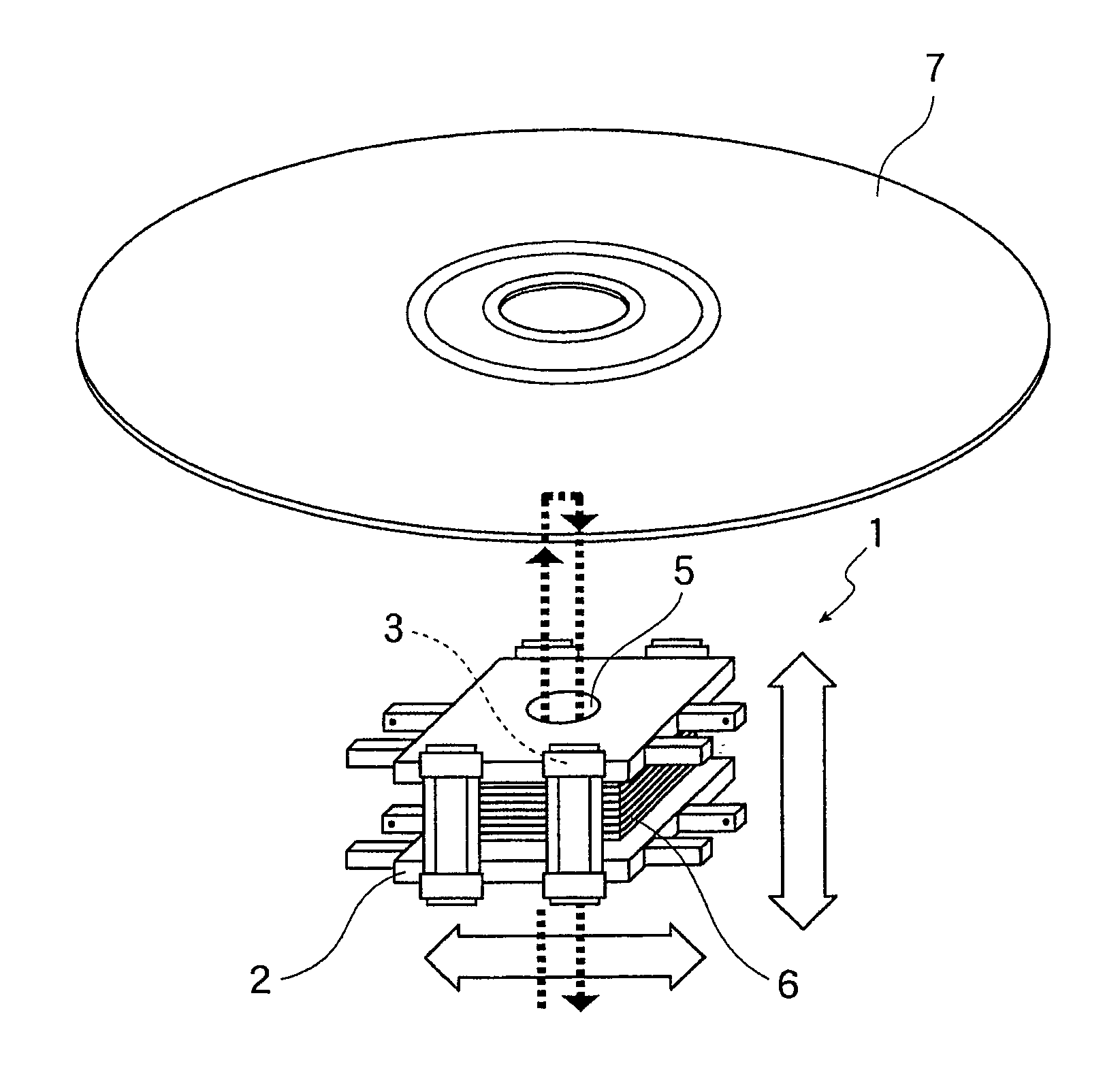

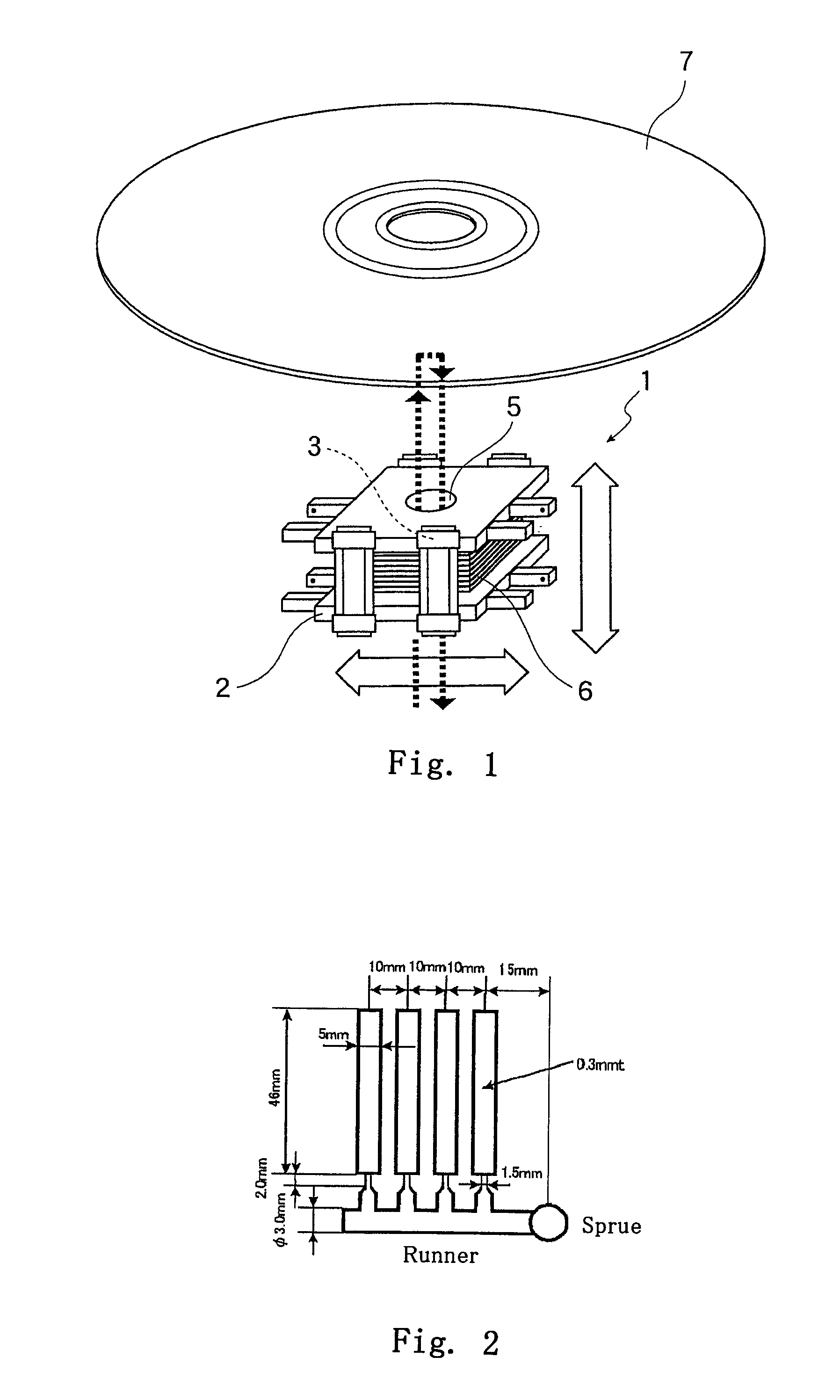

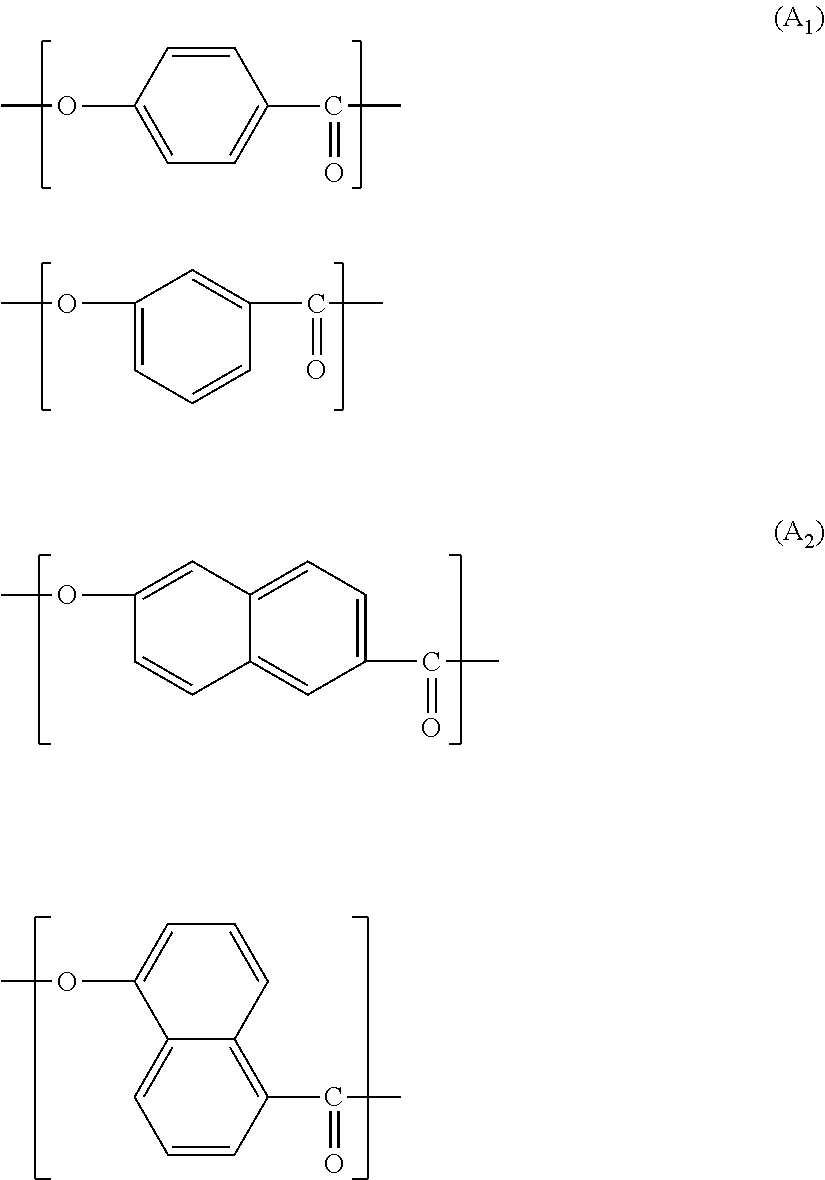

Liquid crystalline polyester resin composition, molded article and holder for optical pickup lenses

A liquid crystalline polyester resin composition is provided, by which a molded article with an enhanced specific modulus can be produced. The liquid crystalline polyester resin composition comprises mica fillers in an amount of 15 to 30 parts by mass and carbon fibers with specific volume resistance of 108 Ωcm or more in an amount of 5 to 20 parts by mass with respect to 100 parts by mass of the liquid crystalline polyester.

Owner:SUMITOMO CHEM CO LTD

Aramid fiber enhanced wood-plastic composite material and preparation method thereof

InactiveCN101629022AImprove mechanical propertiesImprove thermal stabilityFibre treatmentChemical LinkageThermoplastic

The invention relates to aramid fiber enhanced wood-plastic composite material and a preparation method thereof, relating to fiber enhanced wood-plastic composite material and the preparation method thereof. The invention solves the problem that the existing wood-plastic composite material has bad comprehensive mechanical property. The wood-plastic composite material comprises thermoplastic, wood fiber material, lubricant, bulking agent and graft modification aramid fiber. The preparation method of the invention is as follows: 1. weighing raw materials; 2. preparing premixing materials; 3. melting, extruding and molding the premixing materials to obtain the fiber enhanced wood-plastic composite material. The preparation method utilizes carbon-carbon double bond and silane alkyl on the surface of modified aramid fiber and polyolefin and wood flour to form chemical bonds so that aramid fiber and polyolefin has good compatibility, and effectively enhances the interface binding force of the composite materials; the aramid fiber enhanced wood-plastic composite material simultaneously has high strength, high tenacity, and good comprehensive mechanical property. The method can be used for producing the wood-plastic composite material with high performances such as structural engineering materials, etc.

Owner:NORTHEAST FORESTRY UNIVERSITY +1

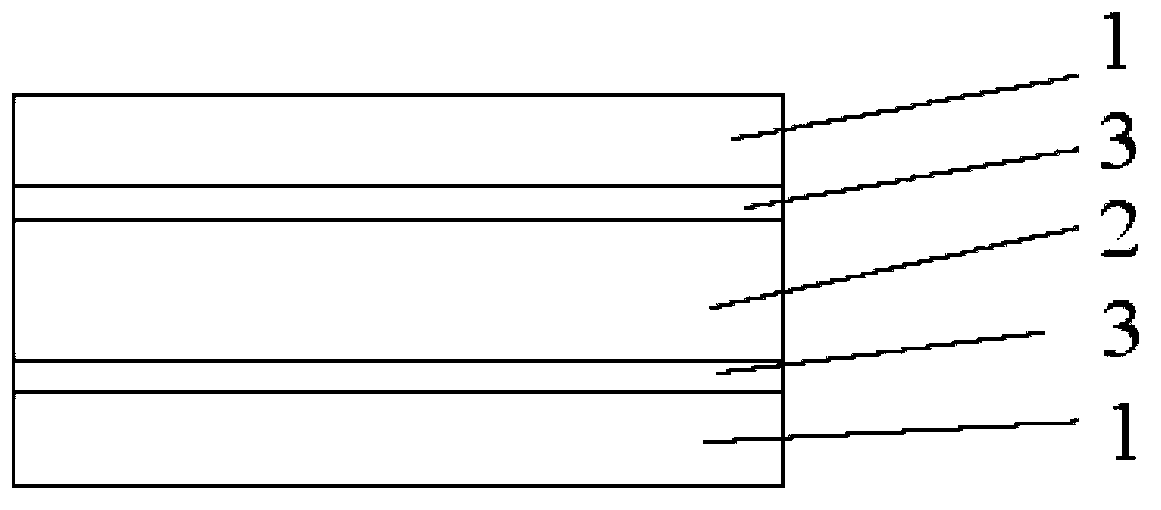

Light-weight and high-strength thermoplastic composite material sandwich board and production method thereof

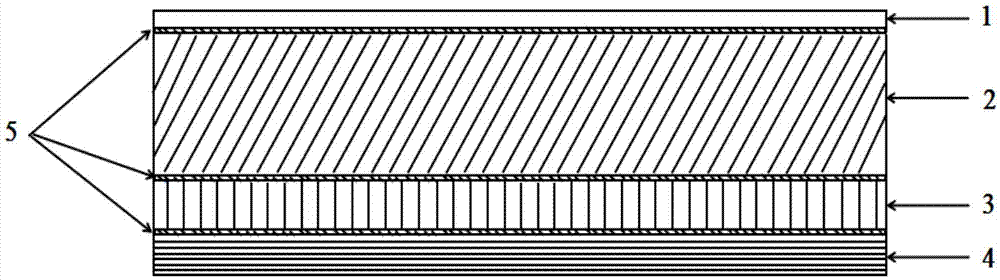

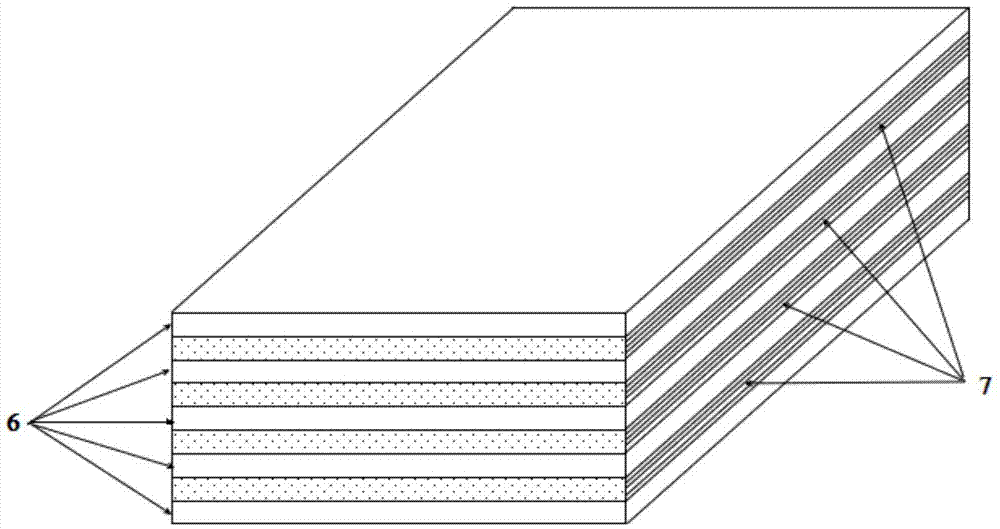

InactiveCN103568396ALight in massLightweight and high-strength qualitySynthetic resin layered productsLaminationSandwich boardHoneycomb

The invention relates to a light-weight and high-strength thermoplastic composite material sandwich board and a production method thereof. The light-weight and high-strength thermoplastic composite material sandwich board comprises two panels and a sandwich layer, wherein the sandwich layer is fixedly arranged between the two panels. The preparation method comprises the following steps: putting the sandwich layer between the two panels; and sticking the two panels on the front and rear faces of the sandwich layer by a thermoplastic glue film through a hot pressing process and a cold pressing process to produce the thermoplastic composite material sandwich board. The panels are continuous fiber enhanced thermoplastic composite material boards and the sandwich layer is made of a honeycomb aluminum material. Compared with the prior art, the thermoplastic composite material sandwich board has the advantages of light weight, high strength, heat preservation, fireproof prevention, moisture prevention, corrosion prevention and the like.

Owner:SHANGHAI GENIUS ADVANCED MATERIAL (GRP) CO LTD

Aluminum silicate fiber reinforced oxide ceramic and preparation method thereof

The invention relates to aluminum silicate fiber reinforced oxide ceramic. The aluminum silicate fiber reinforced oxide ceramic adopts one or a mixture of more of mullite, aluminum silicate, aluminum oxide and silicon oxide as a ceramic substrate and adopts aluminum silicate fiber as a reinforcing phase. The preparation method comprises the steps: carrying out heat treatment for an aluminum silicate fiber fabric, and removing adhesive on the surface of the fiber; taking oxide sol as a precursor, vacuum impregnating the pretreated aluminum silicate fiber fabric, then carrying out the gelatination, carrying out high-temperature ceramization, and completing primary compacting process; repeating the steps for at least ten times, so as to prepare the aluminum silicate fiber reinforced oxide ceramic. The product is excellent in mechanical property and antioxidant property and has the advantages of short preparation period, low cost, capability of realizing near-net shape and the like.

Owner:NAT UNIV OF DEFENSE TECH

Shape memory polymer composite body with spatially-expanded three-wing beam and its preparation method

InactiveCN101055344AHigh specific strengthHigh specific modulusLamination ancillary operationsSynthetic resin layered productsElectrical resistance and conductancePolymer science

A space expanded three-wing-beam shaped remember polymer compound and the preparation thereof relates to a space expanded three-wing-beam shaped remember polymer and the preparation thereof, and to solve the problems of large material weight, complicated expanded mechanical performance, unsteady controlling of the expanding-telescoping procedure, and complicated fabrication technology in the existing space expanded beam structure design procedure. The compound material layer of the shaped remember polymer compound is shaped as superposition and the electric resistance silk screen is located therein. The inner of the compound material layer bending part of the shaped remember polymer compound is connected with a yalloy material layer, the preparation of which comprises the steps of: sorting, confect material, curing. The invention has the advantages of: high specific strength, small material weight, strong controlling ability for beam expanding, simple mechanical performance of the space beam expanding. Moreover, the invention has the characteristic of shaped remember and simple technological operation of the preparation.

Owner:HARBIN INST OF TECH

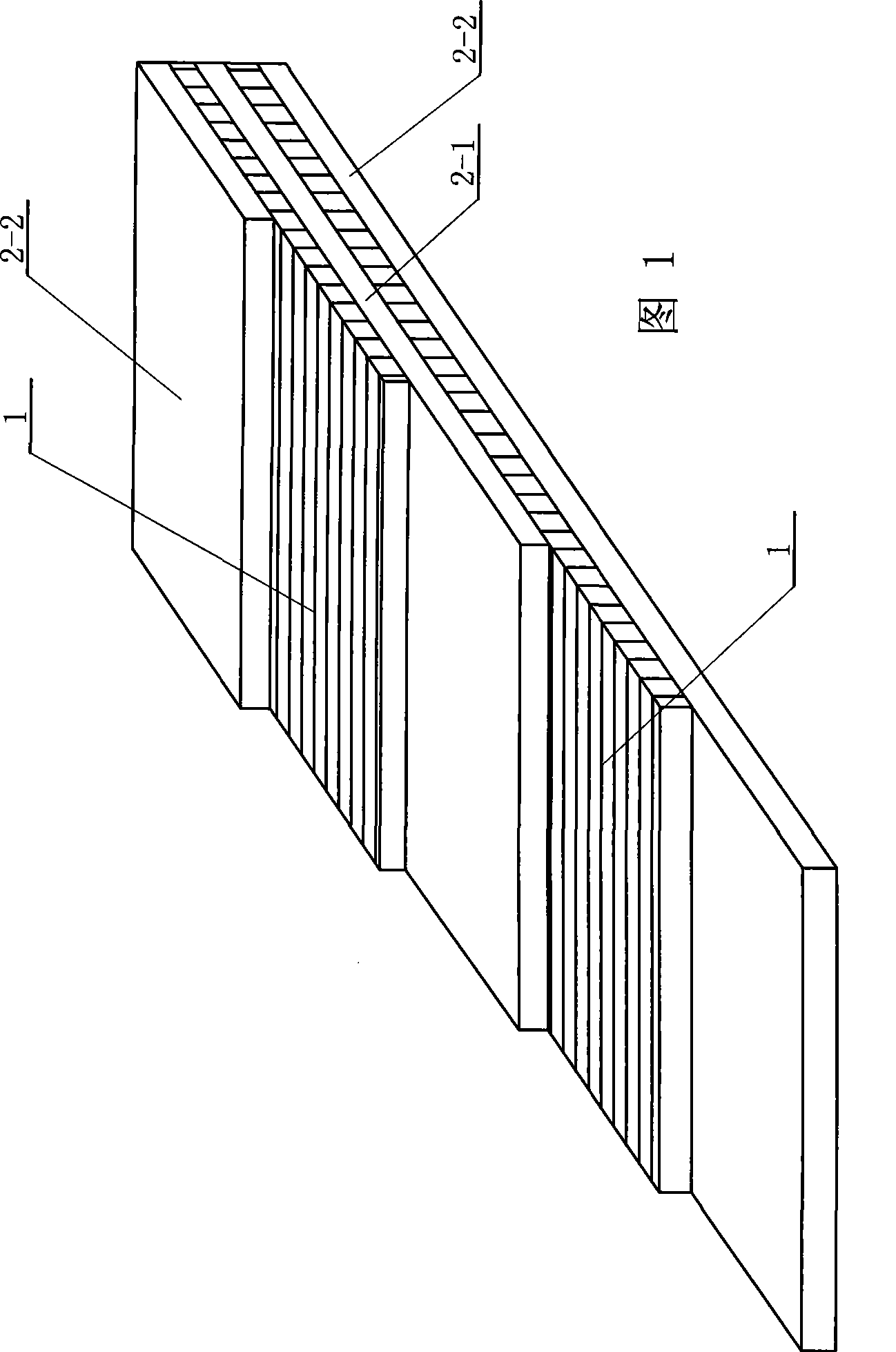

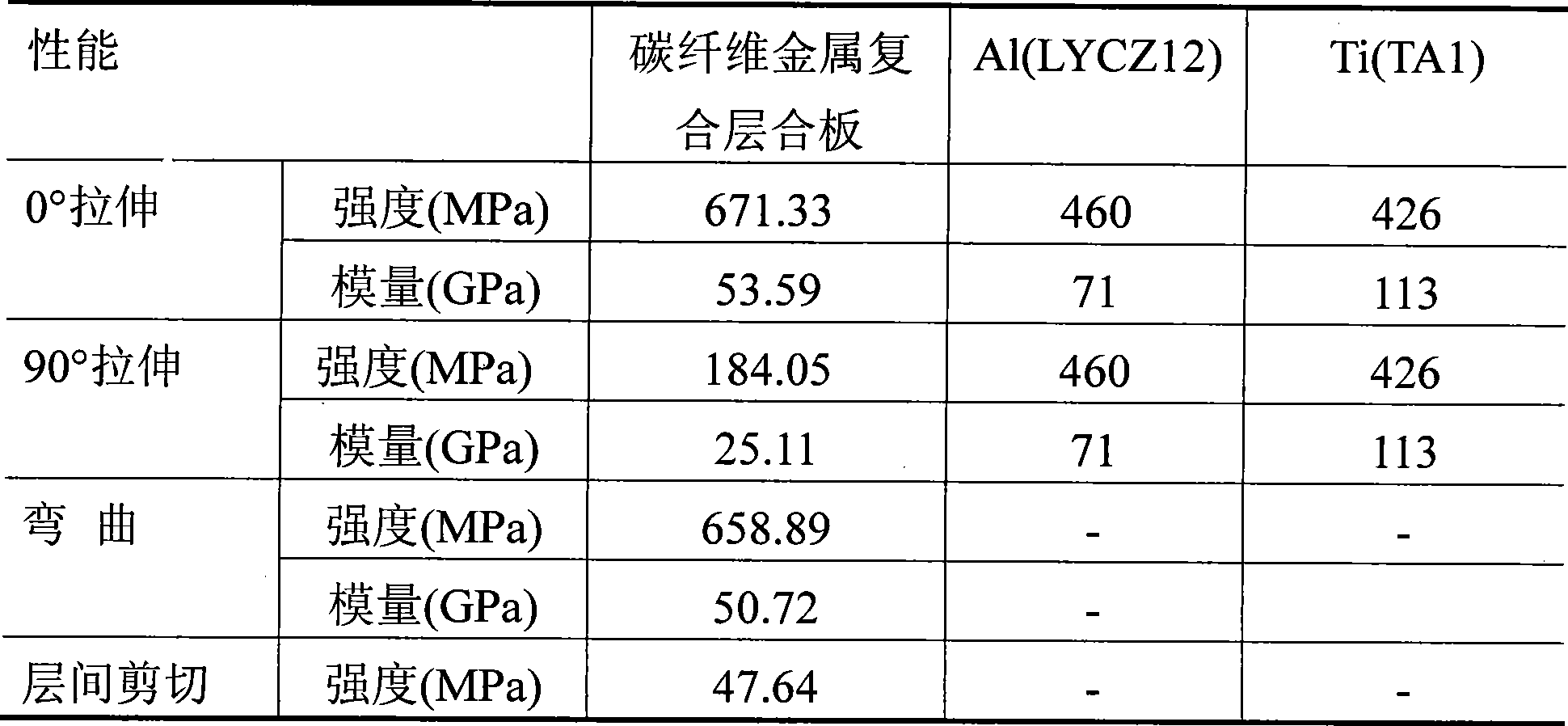

Manufacture method of carbon fiber metal composite laminated plate

InactiveCN101417524AFlame retardantImpact resistantLamination ancillary operationsLaminationFiberEpoxy

A manufacturing method of a carbon fiber metal composite laminated plate relates to a manufacturing method of a fiber metal composite laminated plate. The method aims at solving the problems that no manufacturing methods for manufacturing aircraft structural material with high specific stiffness, high specific strength, tenacity and workability exist in China. The method comprises the following steps of: carrying out surface treatment to three pieces of metal plates; winding a carbon fiber composite material layer which is soaked in liquid cement on one of the metal plates, wherein, the liquid cement is prepared by epoxy resin, a metaphenylene diamine curing agent and an anhydrous alcohol solvent according to the mass ratio of 1:0.1 to 0.18:0.15 to 0.2; fixedly arranging another two metal plates on the upper surface and the lower surface of the carbon fiber composite material layer so as to be integrally put into a mould, and then treated with mould assembling, drying, solidification by adopting the method of gradient temperature increasing, and demoulding. The manufacturing method of the invention is simple and is easy for operation. The carbon fiber metal composite laminated plate manufactured by the method of the invention has the advantages of high specific stiffness, high specific strength, also high tenacity and workability of metal material, good fatigue property, and good damage tolerance capability.

Owner:HARBIN INST OF TECH

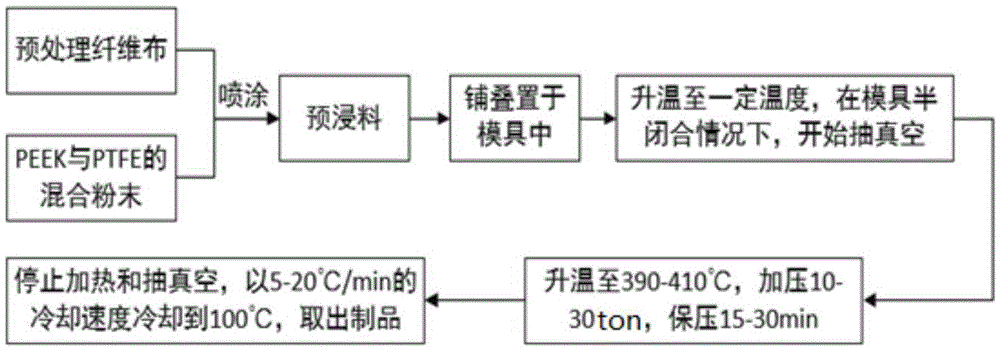

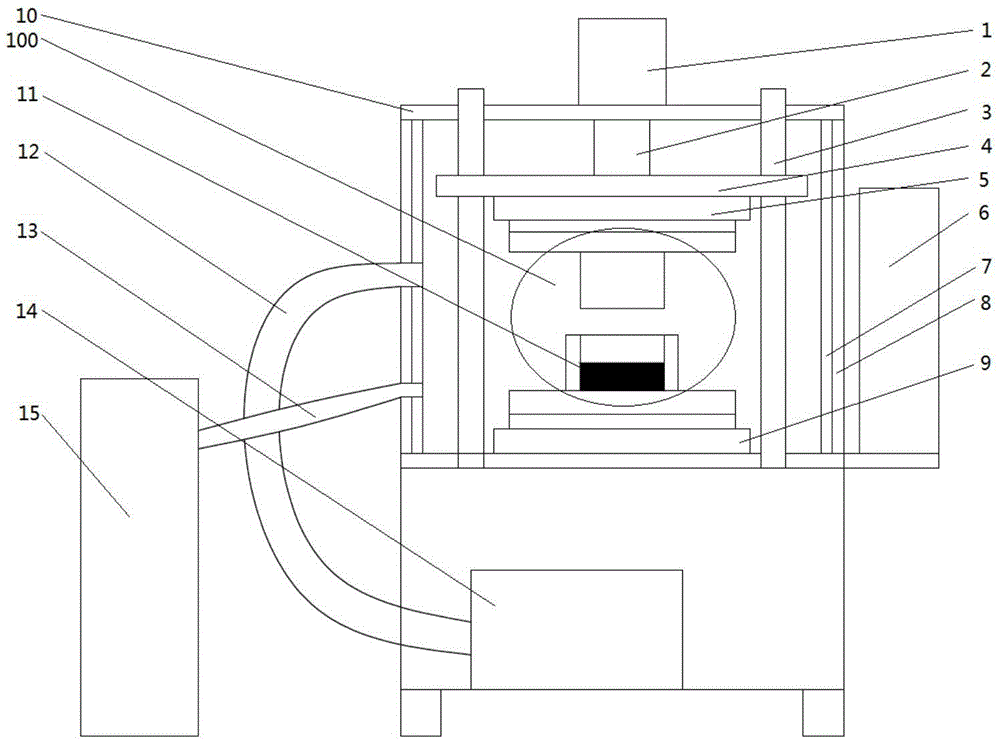

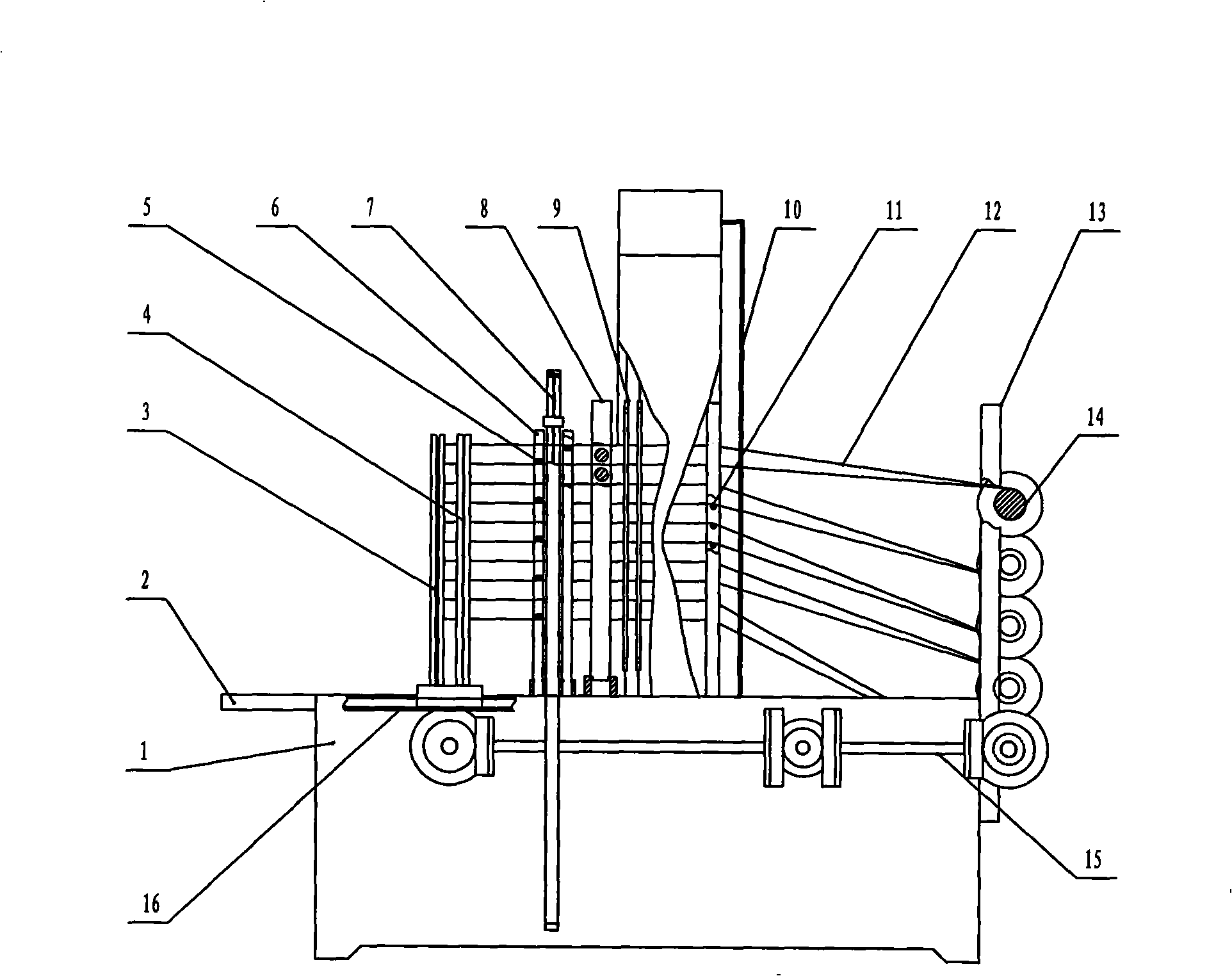

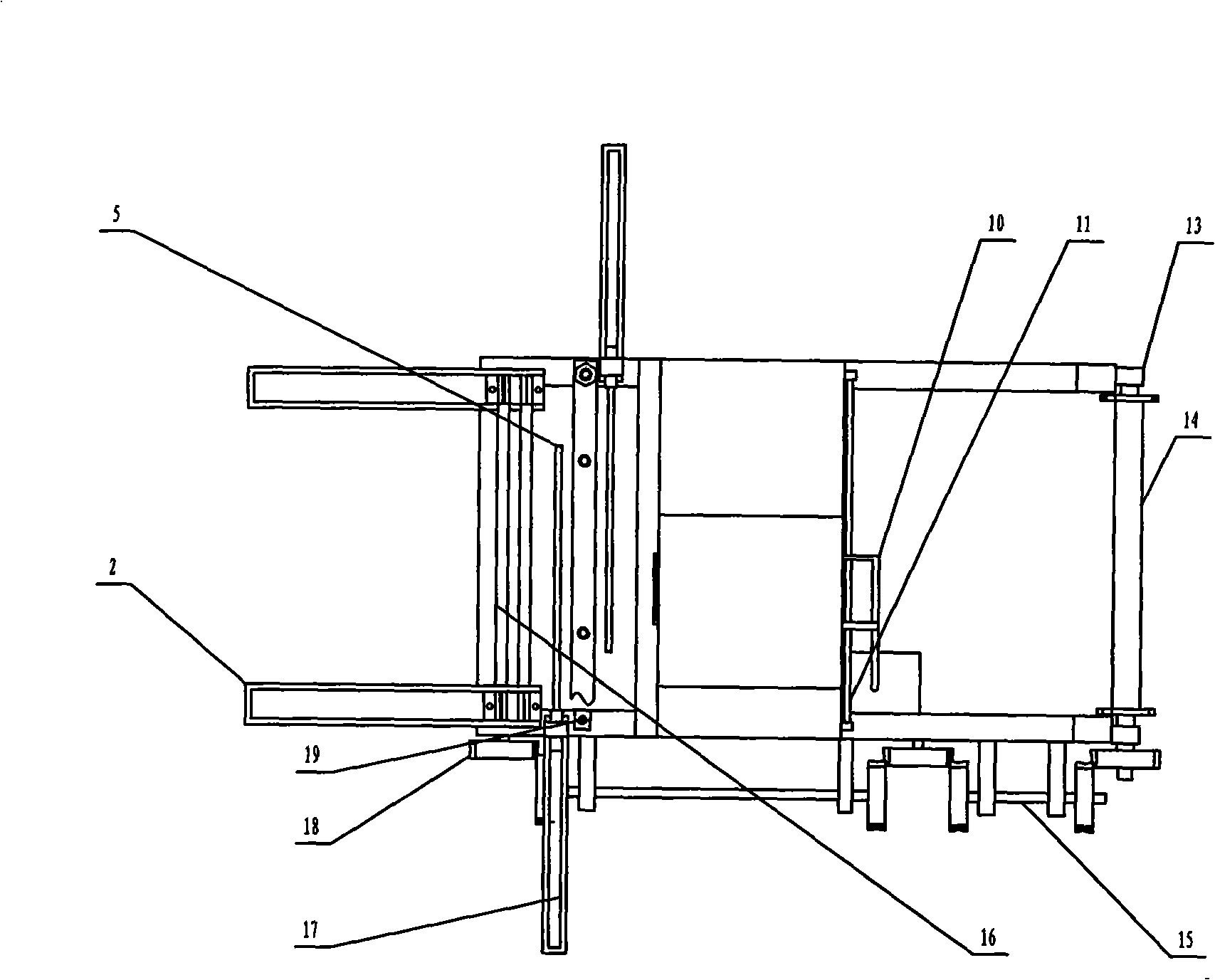

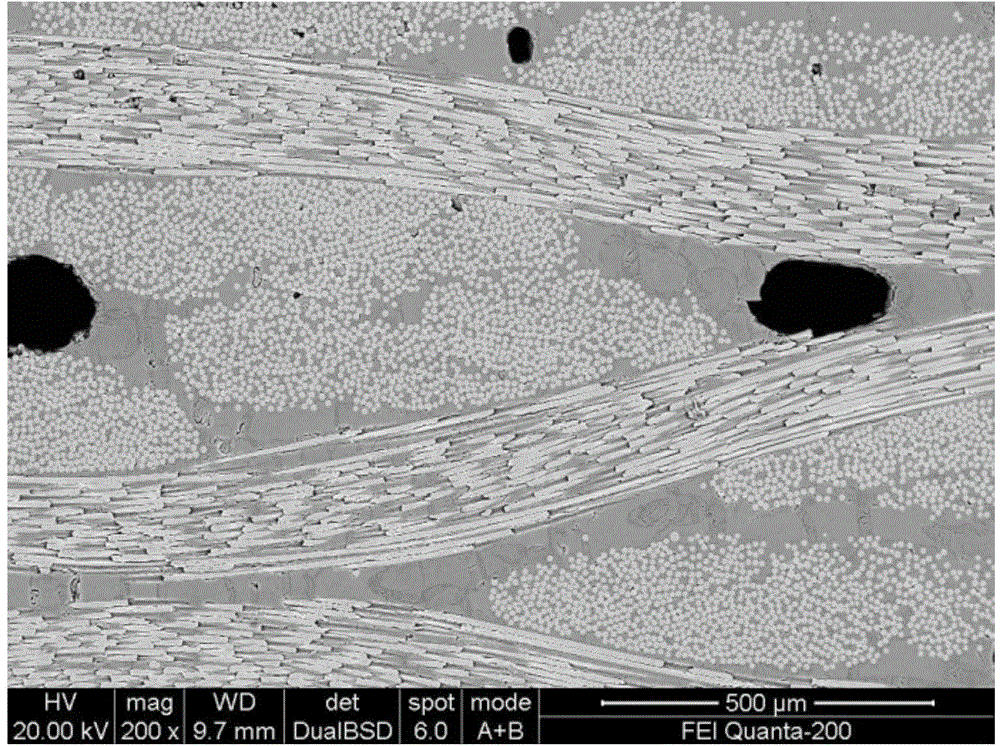

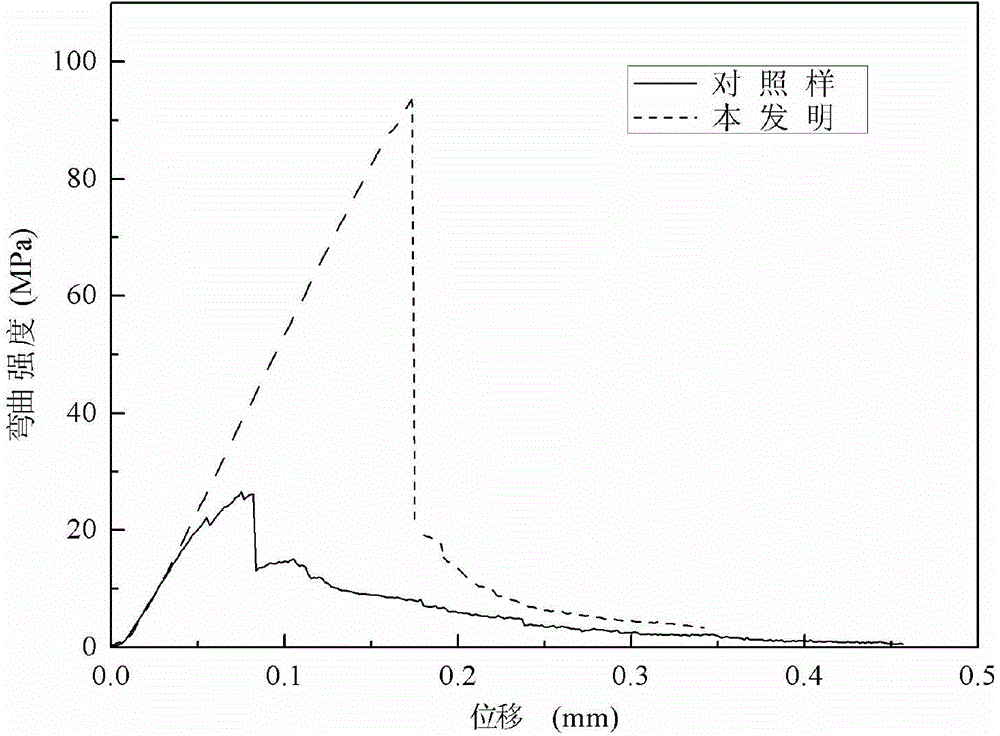

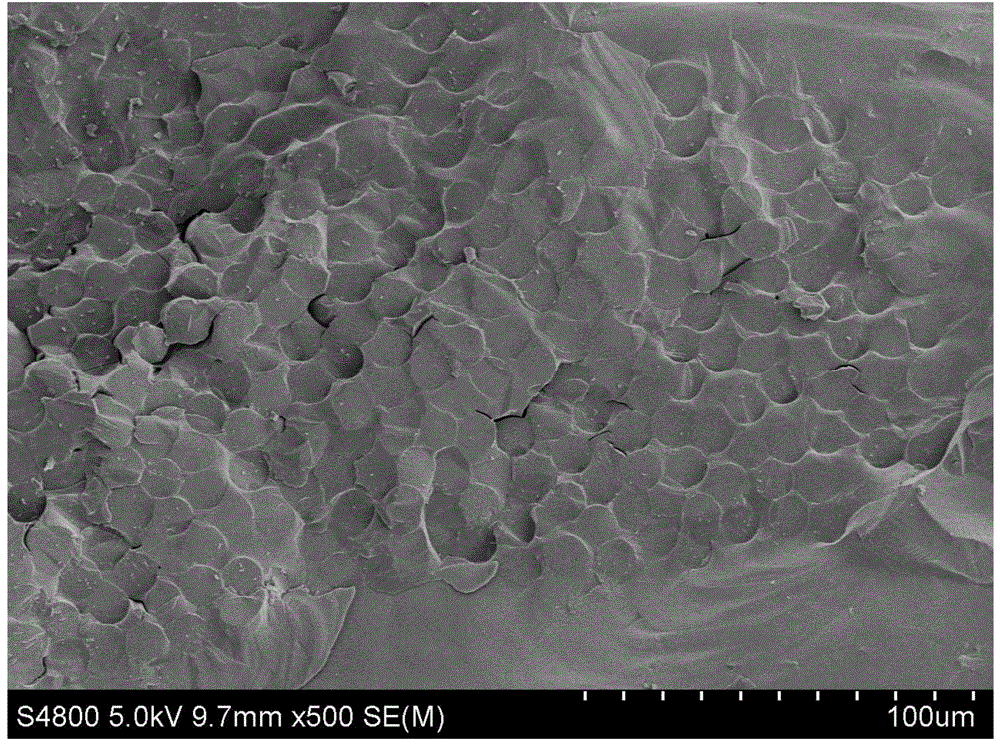

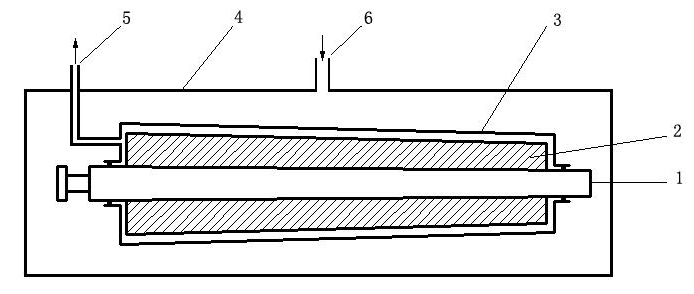

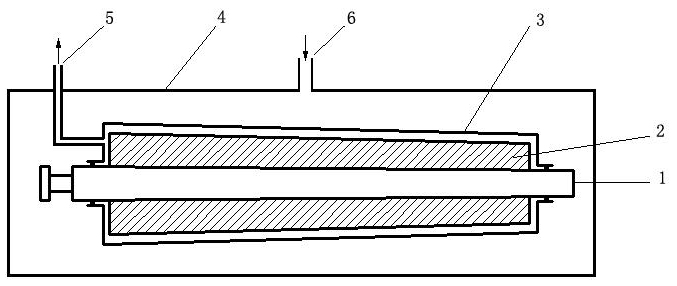

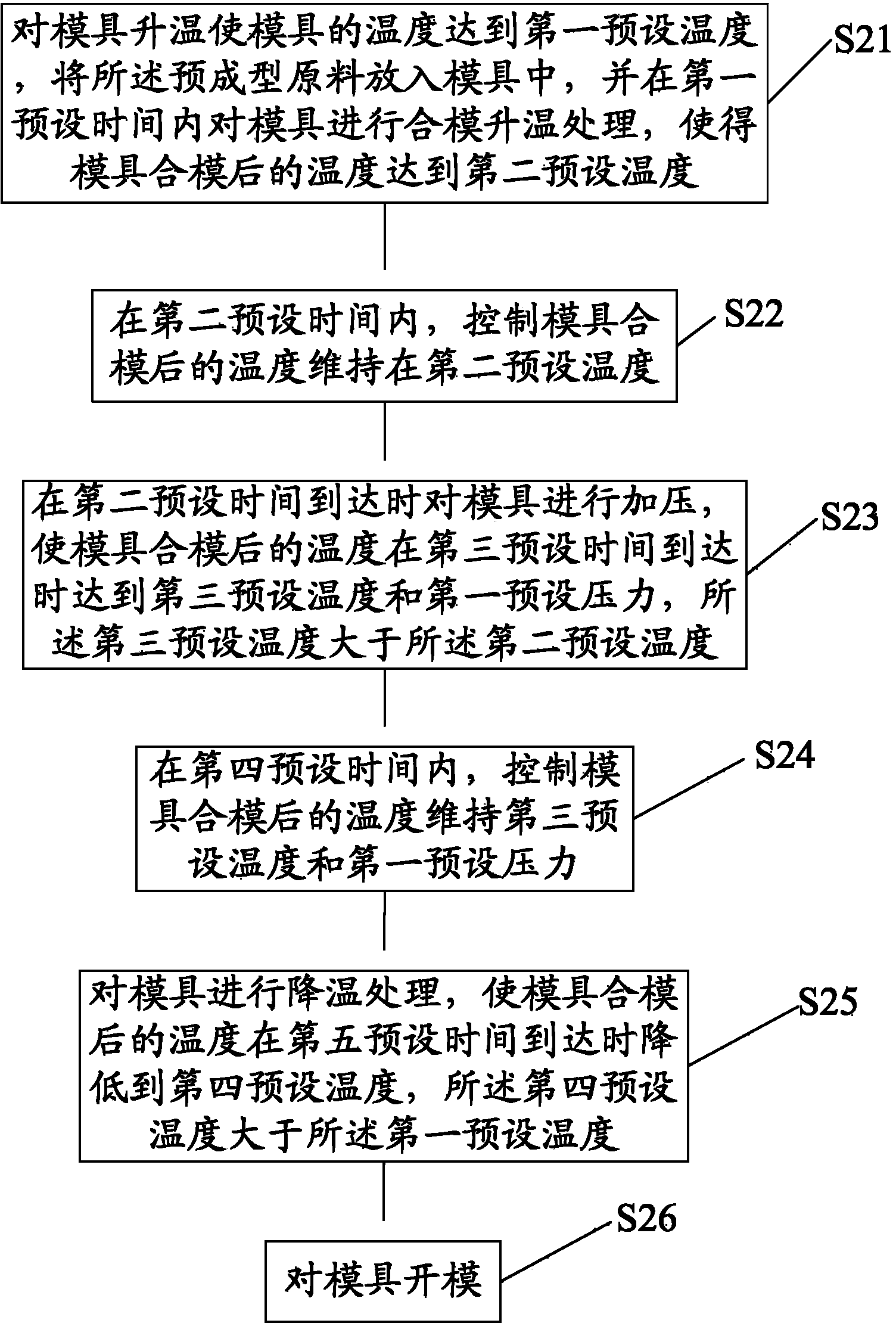

Hot press molding device for carbon fiber enhanced polyether-ether-ketone (PEEK) composite material and technological method thereof

The invention provides a hot press molding device for a carbon fiber enhanced polyether-ether-ketone (PEEK) composite board. The hot press molding device comprises a hydraulic machine, a molding die and a vacuum system. According to the device, a heating unit is separated from the hydraulic machine, and a heating pipe is used for heating the die to achieve a high temperature hot pressing function; by carrying out hot press molding in a vacuum environment, the content of bubbles in resin can be greatly reduced, and the test piece surface smoothness and workpiece performances are improved; a cooling unit is arranged in the die, and cooling speed is regulated by regulating the flow and temperature of high pressure cold air, so as to control the crystallinity of matrix resin and realize flexible selection between high strength and high toughness. Correspondingly, the invention also provides a hot press molding method for the carbon fiber enhanced polyether-ether-ketone (PEEK) composite board. A carbon fiber enhanced polyether-ether-ketone (PEEK) composite board produced by adopting the device and the method disclosed by the invention through hot press molding is simple in production equipment and solves the problems that material internal porosity is large, resin impregnation fiber is insufficient, test piece performance is insufficient, molding cycle is long and the like during production of polyether-ether-ketone resin with high melting point and high viscosity.

Owner:HUAZHONG UNIV OF SCI & TECH

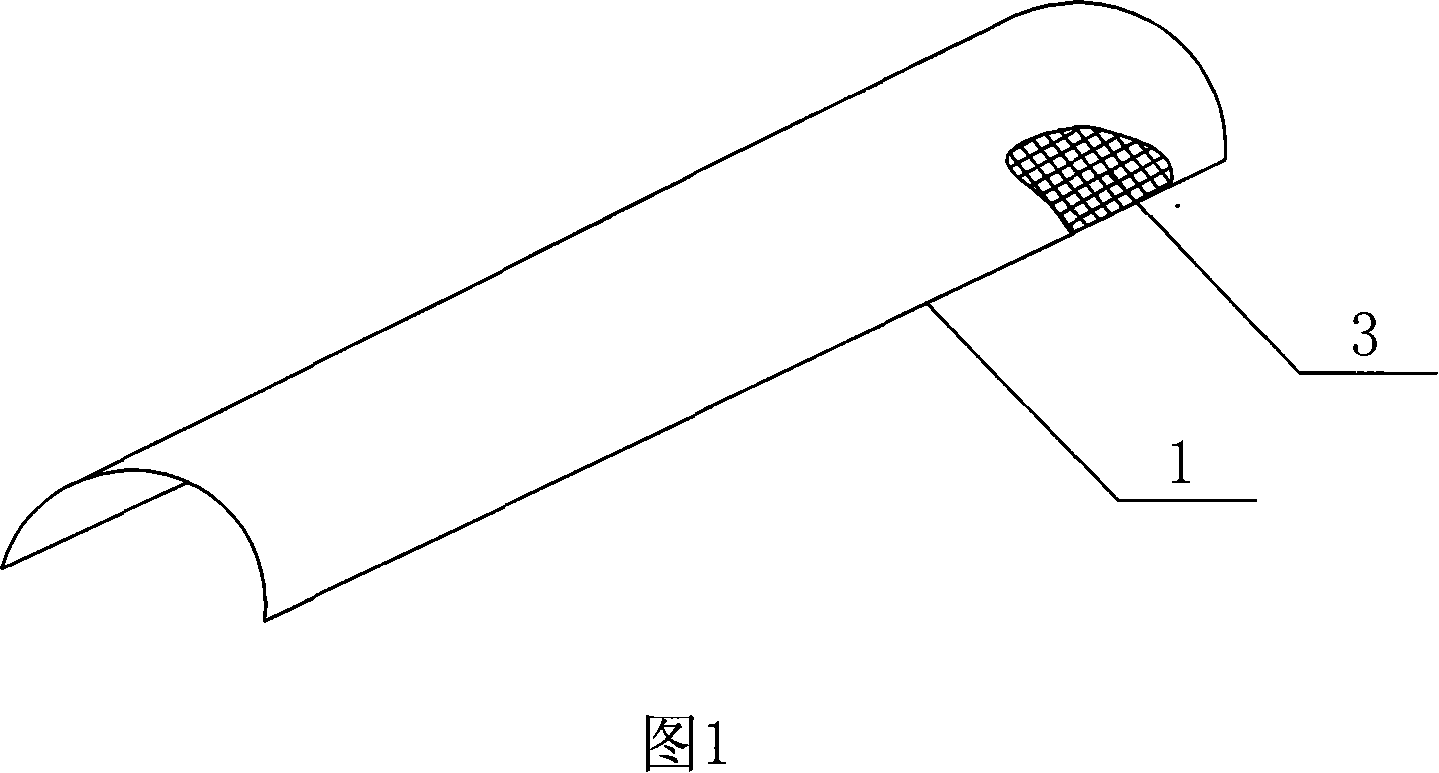

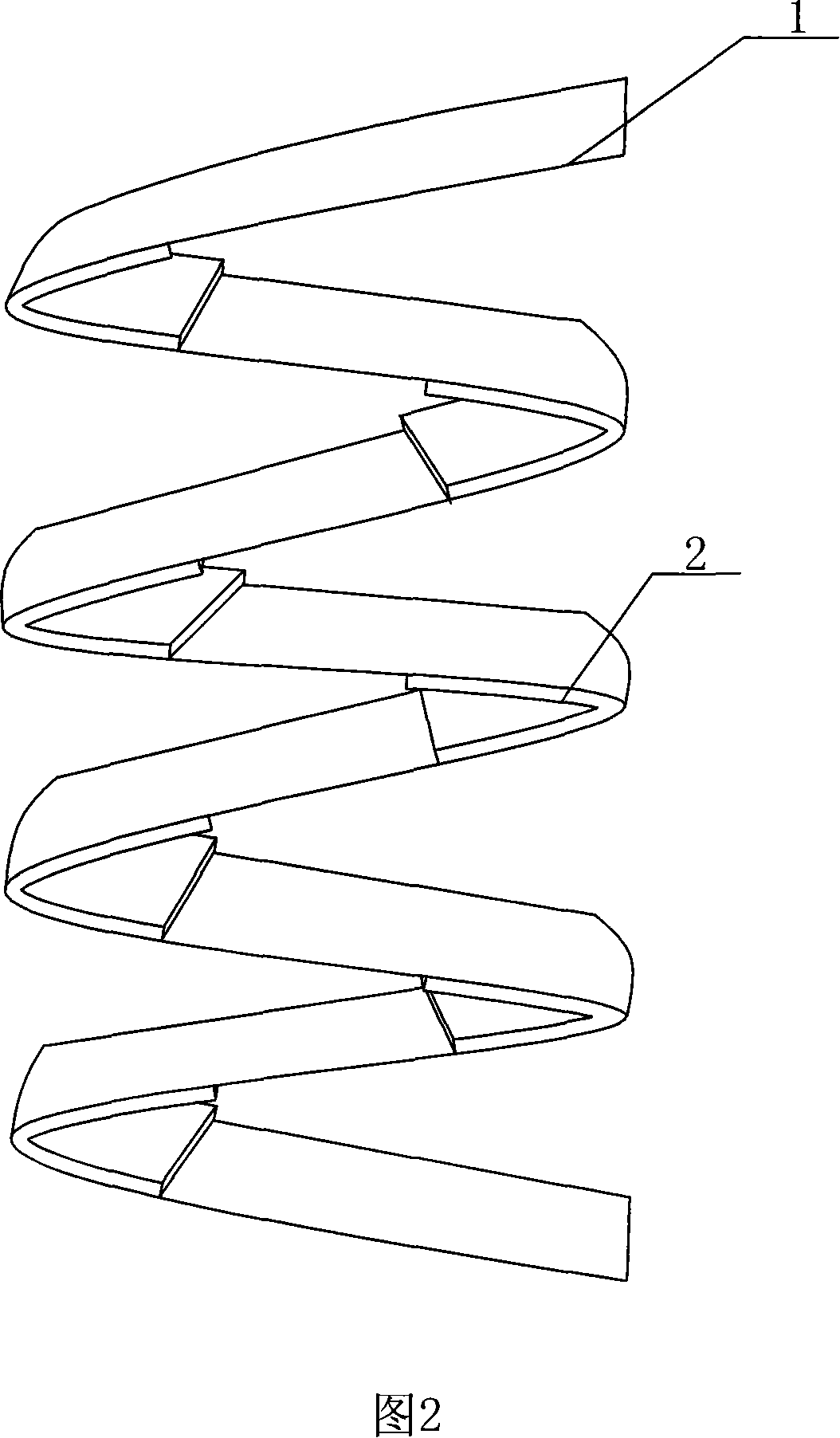

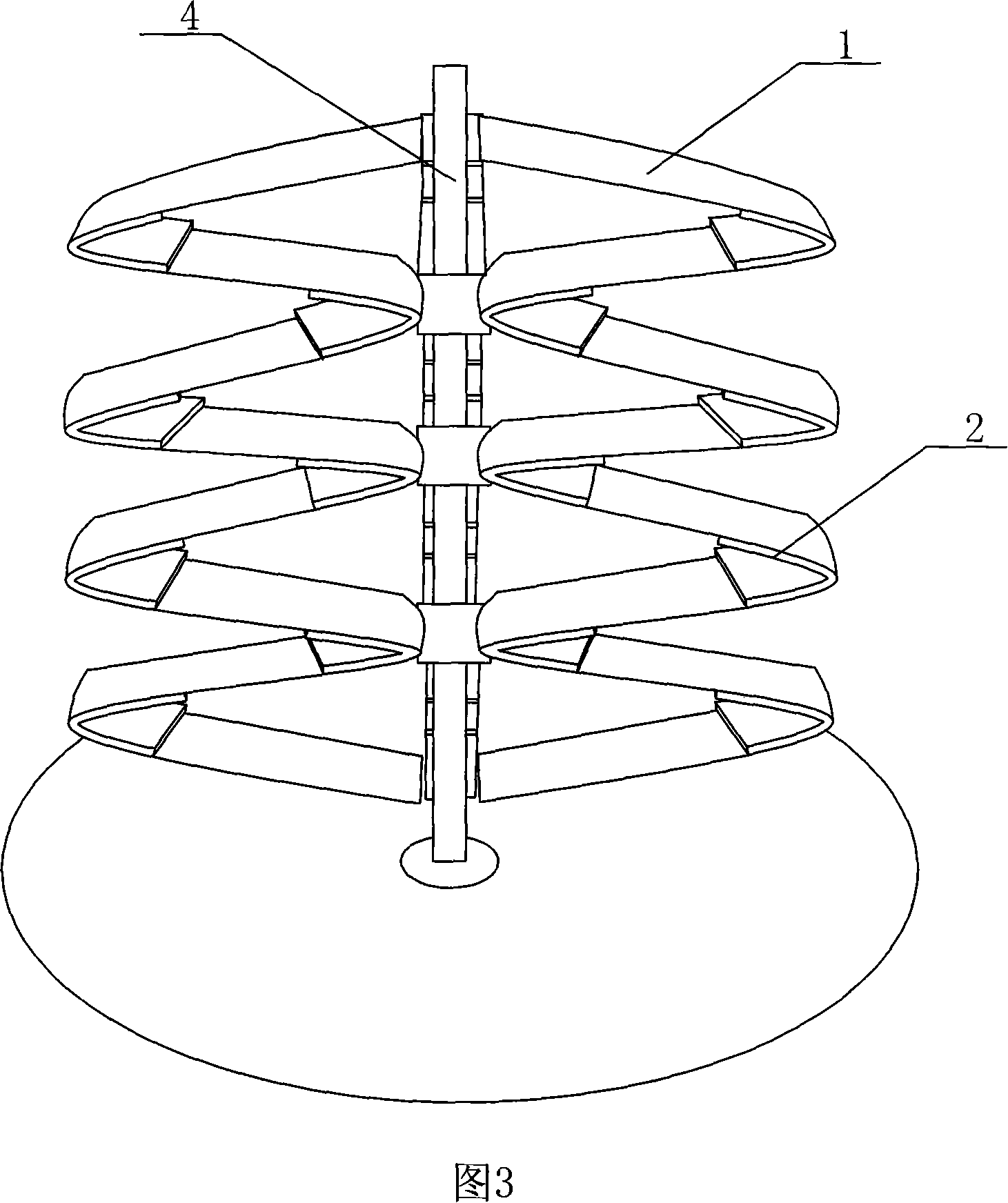

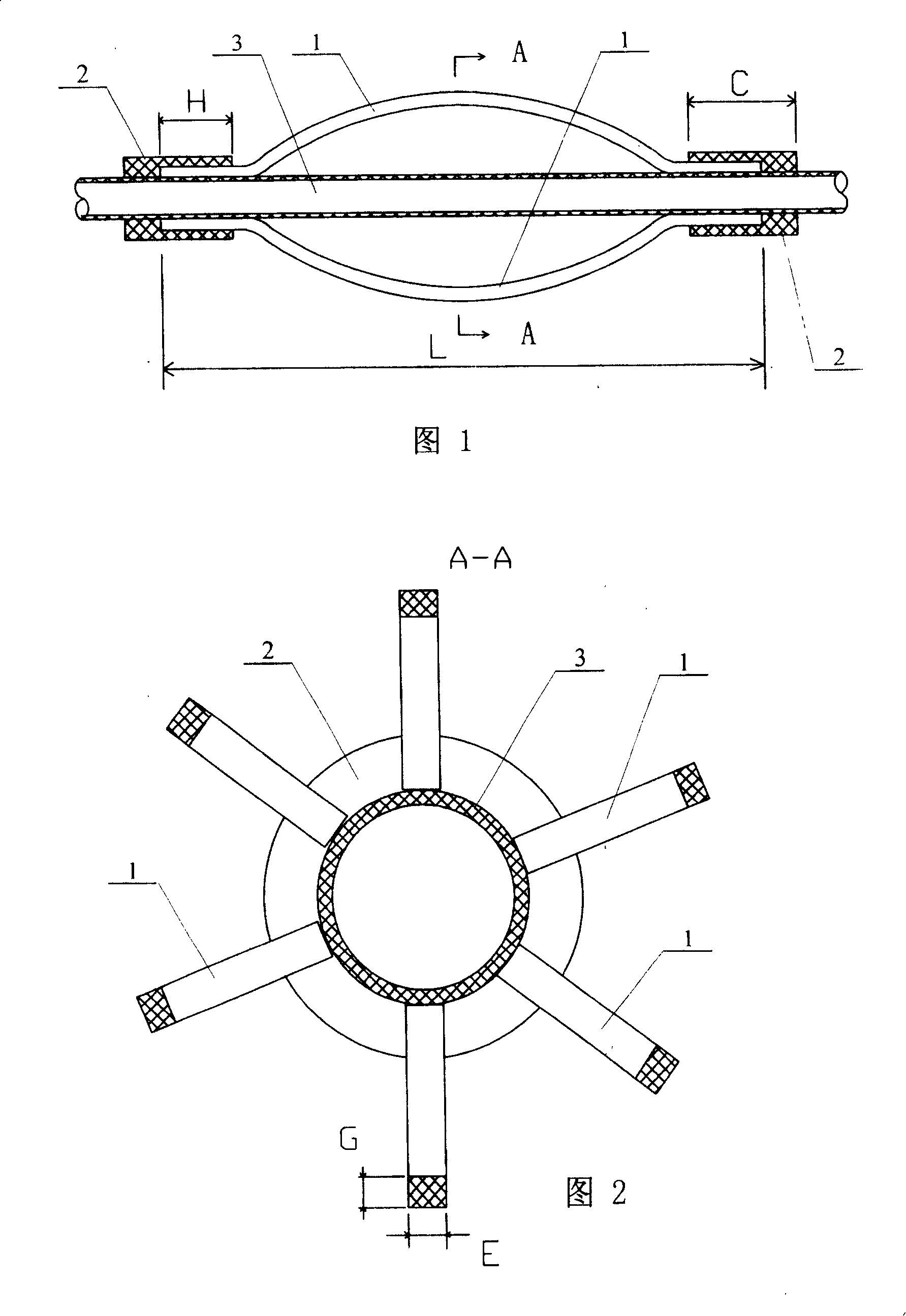

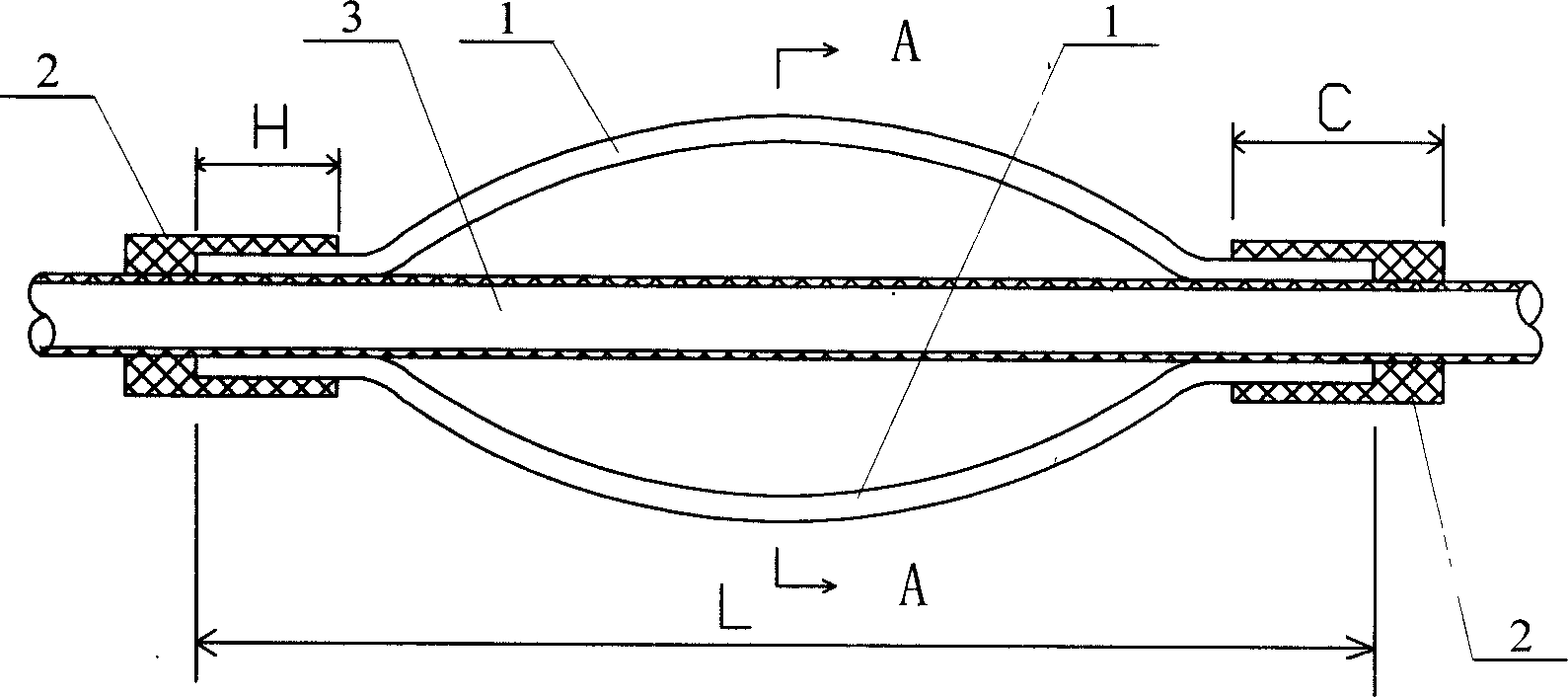

Glass fiber reinforced plastic centralizer

ActiveCN100404784CReduce weightImprove corrosion resistanceDrilling rodsDrilling casingsGlass fiberMetal

The invention relates to a glass steel stabilizer. Wherein, two glass steel fixing rings (2) are individually mounted on two ends of 4-12 glass steel arc bars (1). The producing method comprises: making the arc back of said glass steel arc bars (1) outward to be distantly radial fixed on the surface of mould; coiling the continuous glass fiber immerged with thermosetting resin on two ends of glass steel arc bars (1), to be solidified to fix the bars (1) and the fixing rings (2), or directly fixing the glass steel stabilizer on the glass steel tube or glass steel oil tube via said method. The invention has lower weight, simple process and lower cost.

Owner:辐基斯(青岛)复合材料管道有限公司

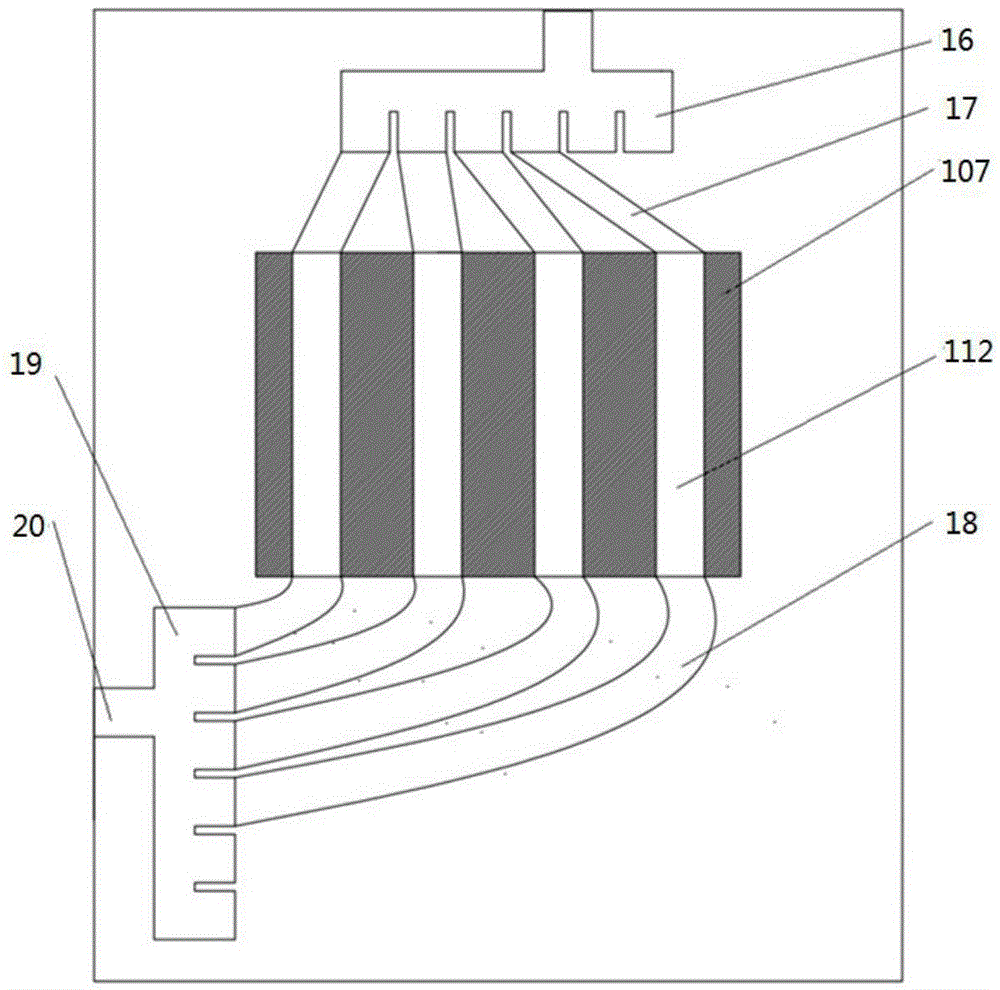

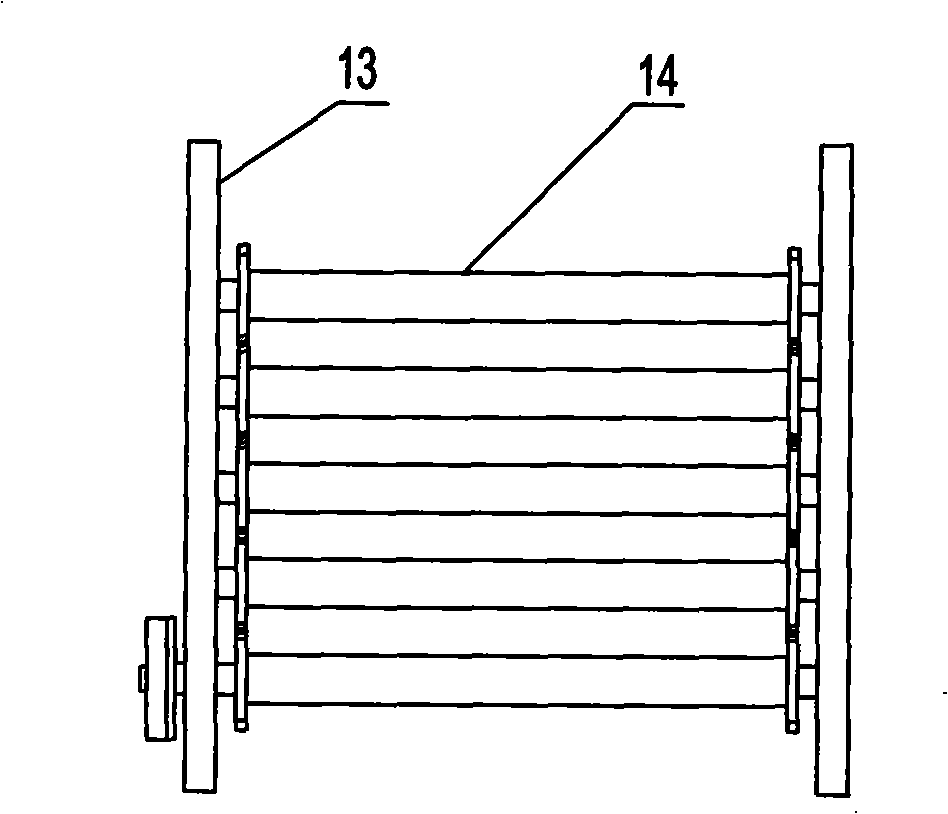

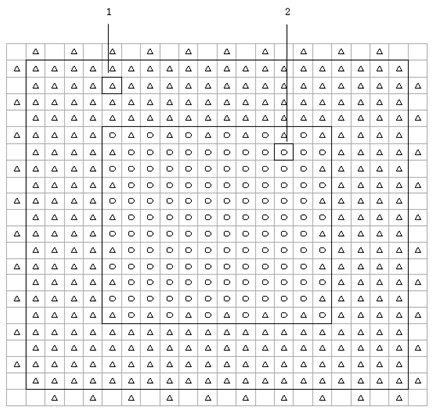

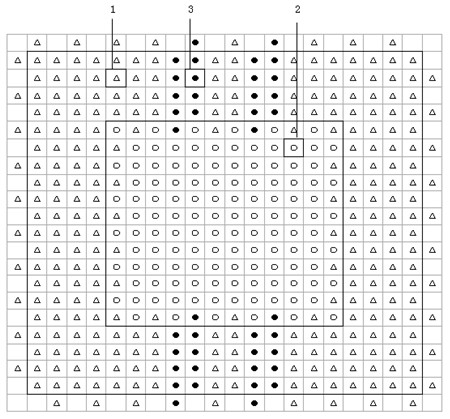

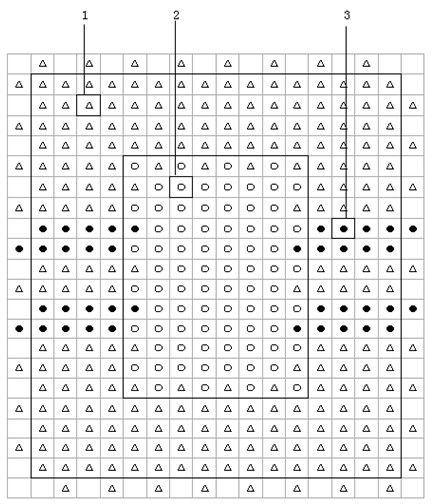

Novel three-dimensional weaving machine

InactiveCN101294327AGood interlaminar shear strengthGood resistance to impact damageLoomsKnittingWoven fabricYarn

The invention belongs to the field of textile machinery, in particular to a novel 3D loom capable of producing 3D textile composite material skeleton. The novel 3D loom comprises a frame and a transmission portion, and is characterized in that the loom also includes a 3D woven fabric winding mechanism arranged on the front end of the frame, a multilayer warp let-off mechanism arranged on the tailend of the frame, and a Y-direction opening, a Z-direction weft inserting mechanism, a Z-direction opening and a Y-direction weft inserting mechanism, which are sequentially arranged between the winding mechanism and the let-off mechanism. The 3D loom has the advantages that (1) the loom can weave completely and has good stability, the woven fabrics have various structures, and the produced textile composite material has excellent performance; (2) four different fabrics can be woven; (3) the integrity of the fabric can be ensured; (4) the pitch between yarns can be better controlled to combine with the looseness of the 3D woven fabrics, and the loom obviates the need of a beating up mechanism; and (5) the loom has simple structure and operation and convenient maintenance by fully utilizing electromechanical integration technology.

Owner:FOSHAN CIHUI TONGDA SCI & TECH

Interface-phase-including alumina fibrous fabric reinforced SiOC (silicon oxycarbide) ceramic and preparation method thereof

The invention discloses an interface-phase-including alumina fibrous fabric reinforced SiOC (silicon oxycarbide) ceramic. The interface-phase-including alumina fibrous fabric reinforced SiOC ceramic uses a SiOC ceramic as a matrix and three-dimensional alumina fibrous fabric as a reinforcement, and a sacrificial carbon interface phase is formed between the matrix and the reinforcement. A preparation method of the interface-phase-including alumina fibrous fabric reinforced SiOC ceramic comprises the following steps of first, putting the alumina fibrous fabric into a muffle furnace for carrying out high-temperature oxidation to remove impurities; afterwards, preparing a cracking carbon coating on the surface of the alumina fibrous fabric by utilizing a chemical vapor deposition technique; preparing a precursor solution, carrying out vacuum impregnation on the alumina fibrous fabric coated with the cracking carbon coating with the precursor solution, taking out the vacuum-impregnated alumina fibrous fabric out for air-drying, carrying out low-temperature crosslinking on the air-dried alumina fibrous fabric, and then completing a one-time compaction process through high-temperature ceramization; repeatedly carrying out compaction for at least five times to prepare a SiOC ceramic intermediate product; finally, carrying out subsequent oxidation to sacrifice cracking carbon, so as to prepare a final product. The product provided by the invention is excellent in room-temperature and high-temperature mechanical properties, high in inoxidizability and low in cost, and can be molded in a near-net-size manner.

Owner:NAT UNIV OF DEFENSE TECH

Burster block of composite structure and manufacturing method of burster block

InactiveCN105444622AImprove fracture toughnessImprove impact resistanceSynthetic resin layered productsCeramic layered productsEnergy absorptionHardness

The invention relates to a burster block of a composite structure and a manufacturing method of the burster block. The burster block comprises a protection layer, a ceramic layer, an energy absorption layer and a supporting layer, wherein the protection layer, the ceramic layer, the energy absorption layer and the supporting layer are sequentially stacked from outside to inside and bonded together through bonding agents. The surface density of the whole block is 50-80 kg / m<2>. The supporting layer is a fiber metal composite material laminated plate which is formed by alternately applying at least three metal plates and at least two layers of fiber prepreg in a combined mode. According to the burster block of the composite structure, the fiber metal composite material laminated plate serves as the supporting layer, shock resistance and multi-hit resistance of the fiber metal composite material laminated plate are far superior to those of a pure fiber reinforced resin composite material laminated plate or a metal plate, good rigid supporting can be provided for the ceramic layer, the high hardness characteristic of ceramic is given into play, bullets are broken to the greatest extent, impact energy is dispersed, and the protection capacity is greatly improved. The burster block of the composite structure can be widely applied to the field of light bulletproof armors.

Owner:THE QUARTERMASTER EQUIPMENT RESEARCH INSTITUTE OF THE GENERAL LOGISITIC DEPARTME +1

Preparation method of para-aramid paper honeycomb core

InactiveCN106696360AHigh specific strengthHigh specific modulusPaper/cardboard articlesMaterials preparationHoneycomb

The invention belongs to the technical field of composite material preparation, and relates to a preparation method of a para-aramid paper honeycomb core. The preparation method of the para-aramid paper honeycomb core is used for preparing a sandwich-structure composite material, and comprises the four treatment process steps of sequentially gluing and pressing para-aramid paper, stretching and setting the para-aramid paper, glue dipping and solidifying the para-aramid paper, and slicing processing the para-aramid paper. A para-aramid paper honeycomb prepared through the preparation method provided by the invention has higher specific strength and specific modulus, and a more excellent heat-resisting property; and under the same design requirement, the weight of a composite material component can be further reduced. The para-aramid paper honeycomb core prepared by adopting the method provided by the invention has higher strength and modulus, under the same mechanical property design requirement, the weight of the high-performance para-aramid paper honeycomb is reduced greatly, and the para-aramid paper honeycomb core can be widely applied in high-end fields such as aerospace.

Owner:AVIC COMPOSITES

Preparation method of continuous fiber-toughened silicon carbide ceramic bullet-proof plate

ActiveCN108253843AHigh hardnessReduce hardnessLamination ancillary operationsLaminationShock resistanceHigh pressure

The invention relates to a preparation method of a bullet-proof plate, particularly to a preparation method of a continuous fiber-toughened silicon carbide ceramic bullet-proof plate. The preparationmethod has the beneficial effects that the continuous fiber-toughened silicon carbide ceramic provided by the invention inherits high hardness and abrasion resistance advantages of a silicon carbide ceramic material, exerts the continuous fiber reinforcing and toughening principle, and overcomes the inherent defects, of pure silicon carbide ceramic, that inherent toughness is poor and external shock load resistance performance is poor, so that the continuous fiber-toughened silicon carbide ceramic has the characteristics like low density, high specific strength, high specific modulus, high hardness and shock resistance, and bullet-proof performance, particularly multi-bullet-proof performance, of the bullet-proof plate can be effectively improved; a continuous fiber-toughened silicon carbide ceramic material is prepared through a polymer high-pressure impregnation pyrolysis technology, the technology is simple, and preparation cost is low; and a setting method provided by the inventionis simple and flexible, and size customization of the bullet-proof plate is facilitated.

Owner:AVIC BASIC TECH RES INST

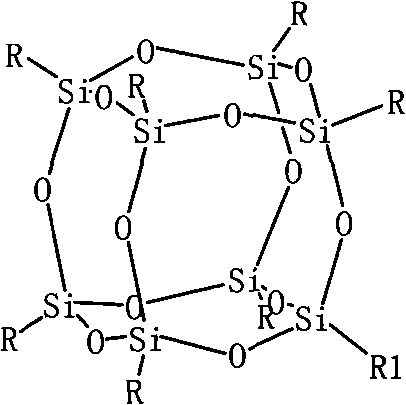

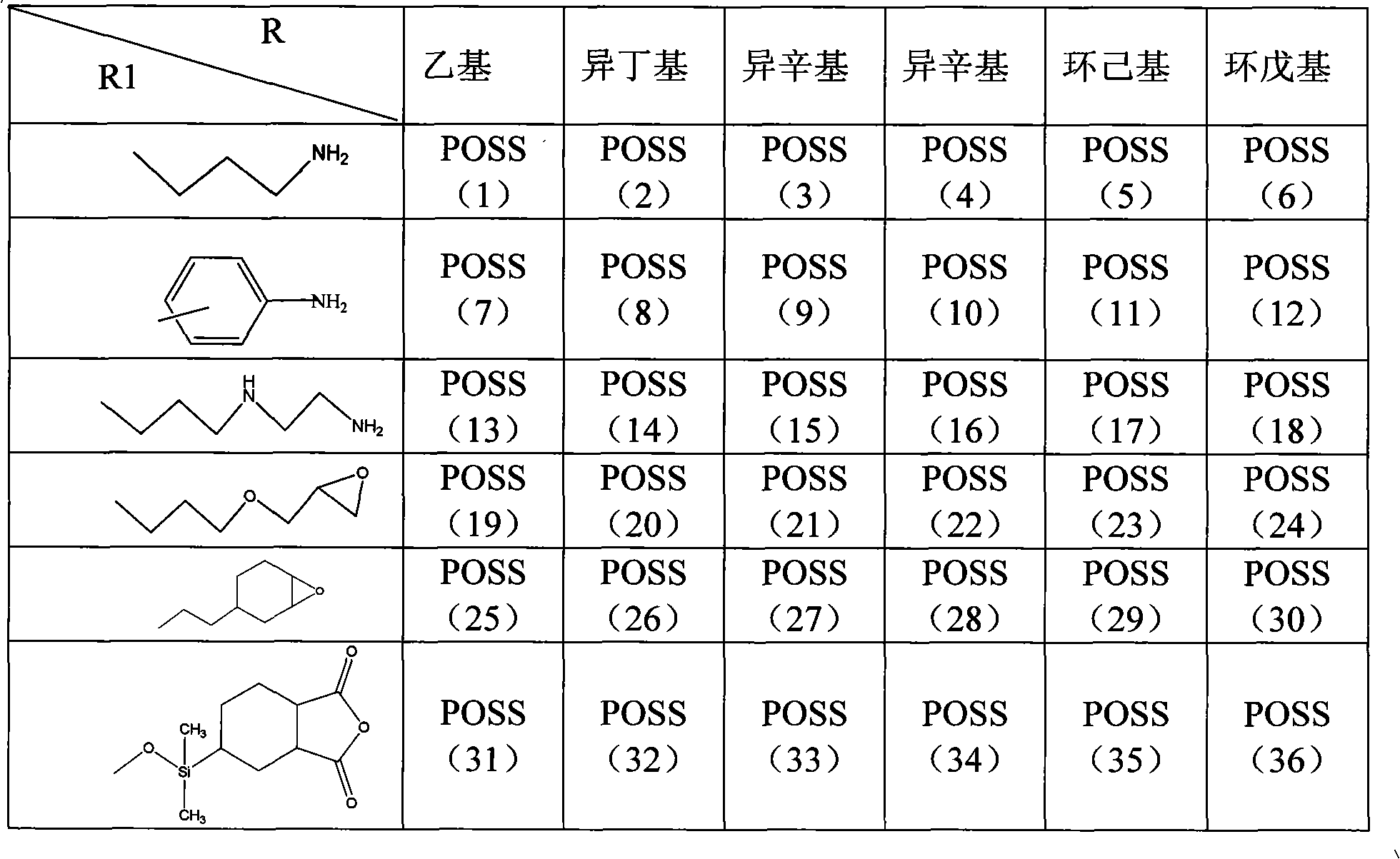

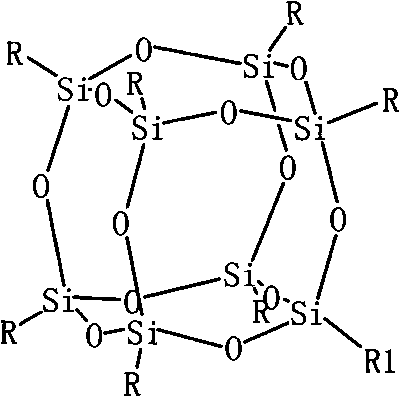

Epoxy/POSS/carbon fiber nanometer composite material for light sports equipment and preparation method thereof

The invention relates to a nanometer composite material, in particular to an epoxy / POSS / carbon fiber nanometer composite material for light sports equipment and a preparation method thereof. The nanometer composite material comprises 20-60 percent of carbon fibers, 0.5-20 percent of POSS and 30-70 percent of cured epoxy resin. The preparation method comprises the following steps: reacting the POSS and the epoxide resin or a firming agent to obtain modified POSS; impregnating the carbon fibers in a butanone solution which is stoichiometrically prepared by the epoxide resin, the firming agent and the modified POSS to obtain a carbon fiber mesh surface coated by epoxy and POSS; then, coiling the mesh surface in the shape of a designed product to place in a die for solidification; and demolding to obtain the epoxy / POSS / carbon fiber nanometer composite material. Due to the addition of the mesh surface, a substrate effectively improves shock resistance, elasticity modulus, hardness, resistance to abrasion, fatigue and aging, shock absorption, and the like. The epoxy / POSS / carbon fiber nanometer composite material has various mechanical performance indexes superior to the prior epoxy carbon fiber composite material.

Owner:XIAMEN UNIV +1

Method for manufacturing carbon fiber arm support for concrete pump truck

The invention relates to a method for manufacturing a carbon fiber arm support for a concrete pump truck, which comprises the following steps of: arranging a hollow core mold, laying a raw material for manufacturing the carbon fiber arm on the external surface of the core mold, coating the exterior of the raw material by using a vacuum film, sealing both ends of the vacuum film on both ends of the core mold, arranging air exhaust holes on the vacuum film, putting the entire mold in an autoclave, pressurizing by using compression air, and curing to form by using an electric heating tube to heat. The carbon fiber arm support for a concrete pump truck, processed by using the method, fully exerts the advantages of high specific strength, large specific modulus, fatigue resistance and corrosion resistance of a carbon fiber reinforced epoxy resin composite material, so that the pump truck arm support has excellent performance, and the weight of the arm support can be reduced by 40-60%. Meanwhile, because no outer mold is used in the invention, the investment to molds, tooling and equipment is greatly reduced, and the product design can be changed conveniently. Meanwhile, the method can also be applied to the fields of fire truck arm supports, suspension arms of hoisting equipment, transmission poles, communication poles and the like.

Owner:WEIHAI GUANGWEI COMPOSITES +1

Preparation method of polyurethane pervaporation phenol/water separating membrane compounded by inorganic particles

InactiveCN103084077AHigh temperature resistantHigh temperature resistanceDistillationFiberDiphenylmethane

The invention discloses a preparation method of a polyurethane pervaporation phenol / water separating membrane compounded by inorganic particles, and belongs to the field of pervaporation membrane separation. The polyurethane membrane basic material is obtained by polymerizing and mixing monomer hydroxyl-terminated polybutadiene, toluene diisocynate, 4,4'-diamine diphenylmethane solution, cyclodextrin and silica or carbon fiber powder. The preparation method comprises the following steps: reacting hydroxyl-terminated polybutadiene with toluene diisocynate to obtain blocked prepolymer, then adding 4,4'-diamine diphenylmethane solution and cyclodextrin as chain extenders to perform the chain extension, and adding inorganic modified particle silica or carbon fiber powder (using N,N-dimethylacetamide as solvent) to obtain prepolymer solution of polyurethane; casting the solution on a polyfluortetraethylene plate to form a membrane, solidifying for 1-1.5 hours at room temperature, and moving the membrane to an oven at 80 DEG C to thermally treat to obtain the polyurethane membrane compounded by inorganic particles. The preparation method disclosed by the invention is simple in process, and the prepared membrane has good heat and chemical stability and mechanical property.

Owner:BEIJING TECHNOLOGY AND BUSINESS UNIVERSITY

High-performance jute fiber reinforced polypropylene composite and preparation method thereof

The invention discloses a high-performance jute fiber reinforced polypropylene composite and a prepration method thereof. The high-performance jute fiber reinforced polypropylene composite comprises the following raw materials of, by weight, 20-60 parts of jute fibers, 30-80 parts of polypropylene, 1-10 parts of a compatilizer, 0.5-2 parts of a coupling agent, 0.1-1 part of antioxidants, and 0.2-1 part of lubricants. The polypropylene composite used for vehicles is prepared by adoption of the jute fibers which are low in price, rich in source, high in specific modulus, low in density and small in effect on the environment, the production cost can be lowered, and the composite accords with the development trend of low-weight, environment-friendly and recyclable automobiles; and meanwhile, the natural fibers are treated by adoption of an alkaline solution, the coupling agent and the compatilizer, the hygroscopicity of the jute fibers is reduced, and the bonding force between the jute fibers and polypropylene particles is increased at the same time.

Owner:CHONGQNG PRET NEW MATERIAL +4

Sheet laminating preparation method for sisal fiber reinforced polypropylene composite material

The present invention adopts the sisal hemp fiber as fiber raw material, and uses the nonwoven fabric of thermoplastic resin PP, film, powder material and its fiber as resin base body, and adopts thefollowing steps: pretreating sisal hemp fiber and making it into fiber felt, hot-pressing and forming, selecting and using a certain number of fiber felts, delaminating and sand wiching pp nonwoven fabric or film, under the condition of a certain temp. and pressure hot-pressing and forming or mixing PP fiber (PP powder) directly with sisal hemp fibre, making them into fiber felt and then hot-pressing and forming so as to obtain the invented sisal hemp fiber reinforced polypropylene composite material.

Owner:SUN YAT SEN UNIV

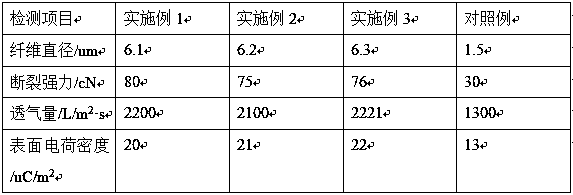

Preparation method of electret polylactic acid meltblown nonwoven material

ActiveCN109914034AAvoid reunionIncreased charge storage capacityNon-woven fabricsMonocomponent polyesters artificial filamentTetrafluoroethyleneNano silicon

The invention relates to a preparation method of an electret polylactic acid meltblown nonwoven material, and belongs to the technical field of textile materials. According to the method, an inorganicelectret material nano silicon nitride and a polymer polytetrafluoroethylene are compounded to serve as a filler by means of a mechanical dispersion method, the charge storage capacity of the compound material can be effectively improved under a high-temperature or humid environment, the occurrence of an electret agglomeration phenomenon is avoided, and the service life of the product is prolonged; the compound filler and polylactic acid are meltblown and then subjected to treatment such as opening, impurity removal, combing, lapping, pre-needling, spunlacing and hot rolling, and the nonwovenmaterial is prepared. The method has the advantages that the inorganic electret material nano silicon nitride and the polymer polytetrafluoroethylene are compounded to serve as the filler by means ofthe mechanical dispersion method, and the charge storage capacity of the compound material can be effectively improved under the high-temperature or humid environment; the electret filler and the polylactic acid are compounded, so that the electrostatic potential of the surface of the polylactic acid nonwoven material is increased, and the charge storage capacity is improved.

Owner:广东东沁新材料科技有限公司

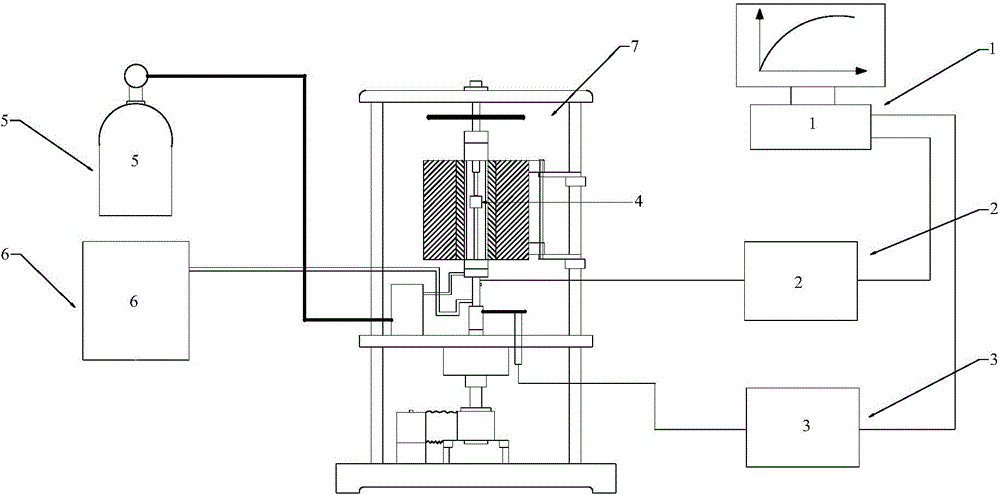

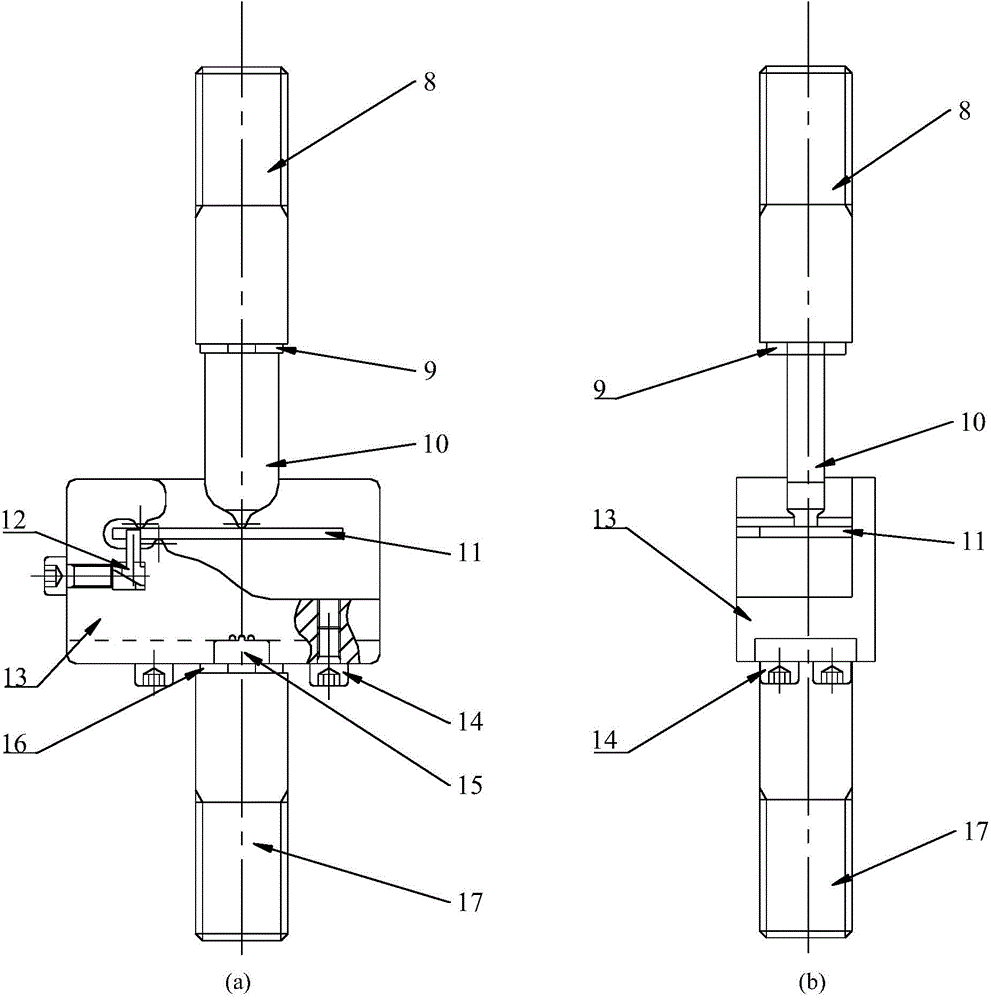

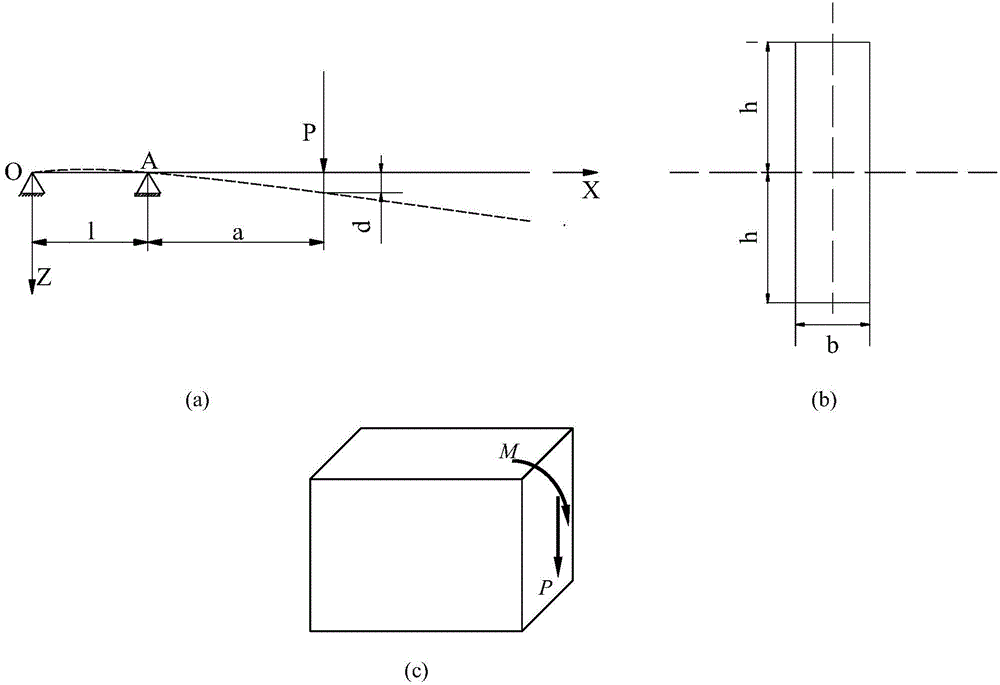

Apparatus and testing method for testing sample creep property in ultra high temperature environment

InactiveCN103954510AEasy to processSimple and fast operationMaterial strength using tensile/compressive forcesTest designTest sample

The present invention relates to an apparatus for testing sample creep property in an ultra high temperature environment. The apparatus is characterized in that a simply supported bending testing device is arranged between the upper clamping block and the lower clamping block of an electro-hydraulic servo testing machine, and the maximum stress position and the maximum deflection position are not at the same place during a testing process, such that the testing precision is increased at the test design level. According to the apparatus and the mechanical property testing method, characteristics of low sample manufacturing requirements, easy processing and easy operation are provided, and the apparatus and the method can be used for the thermal barrier coating system, can be provided for researching creep properties of various coatings, and provide test technology supports and theoretical guidance for engineering application so as to provide important theoretical research values and wide engineering application prospects.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Oxide/silicate mineral fiber nano composite air-sensitive film and preparation method thereof

InactiveCN101609059AAvoid breakingEnhanced gas adsorption capacityMaterial resistanceFiberPalygorskite

The invention discloses an oxide / silicate mineral fiber nano composite air-sensitive film and a preparation method thereof, belonging to the technical field of functional composite material. The oxide / silicate mineral fiber nano composite air-sensitive film comprises silicate mineral fiber nano material substrate and a nano oxide powder layer coated on the surface of the silicate mineral fiber nano material substrate; wherein silicate mineral fiber nano material is any one in the minerals such as chrysotile, amphibole, meerschaum and palygorskite; and nano oxide powder is any one of nano stannic oxide, nano ferric oxide, nano zinc oxide and nano copper oxide. Compared with the prior art, the oxide / silicate mineral fiber nano composite air-sensitive film obtained by adopting the method has the tensile strength being improved from 10-50MPa to 100-3000MPa and the fracture toughness be enhanced from 3-5MPa.m1 / 2 to 100-500MPa.m1 / 2; the air-sensitive stability and the service life are improved by 80-100%.

Owner:SOUTHWEAT UNIV OF SCI & TECH

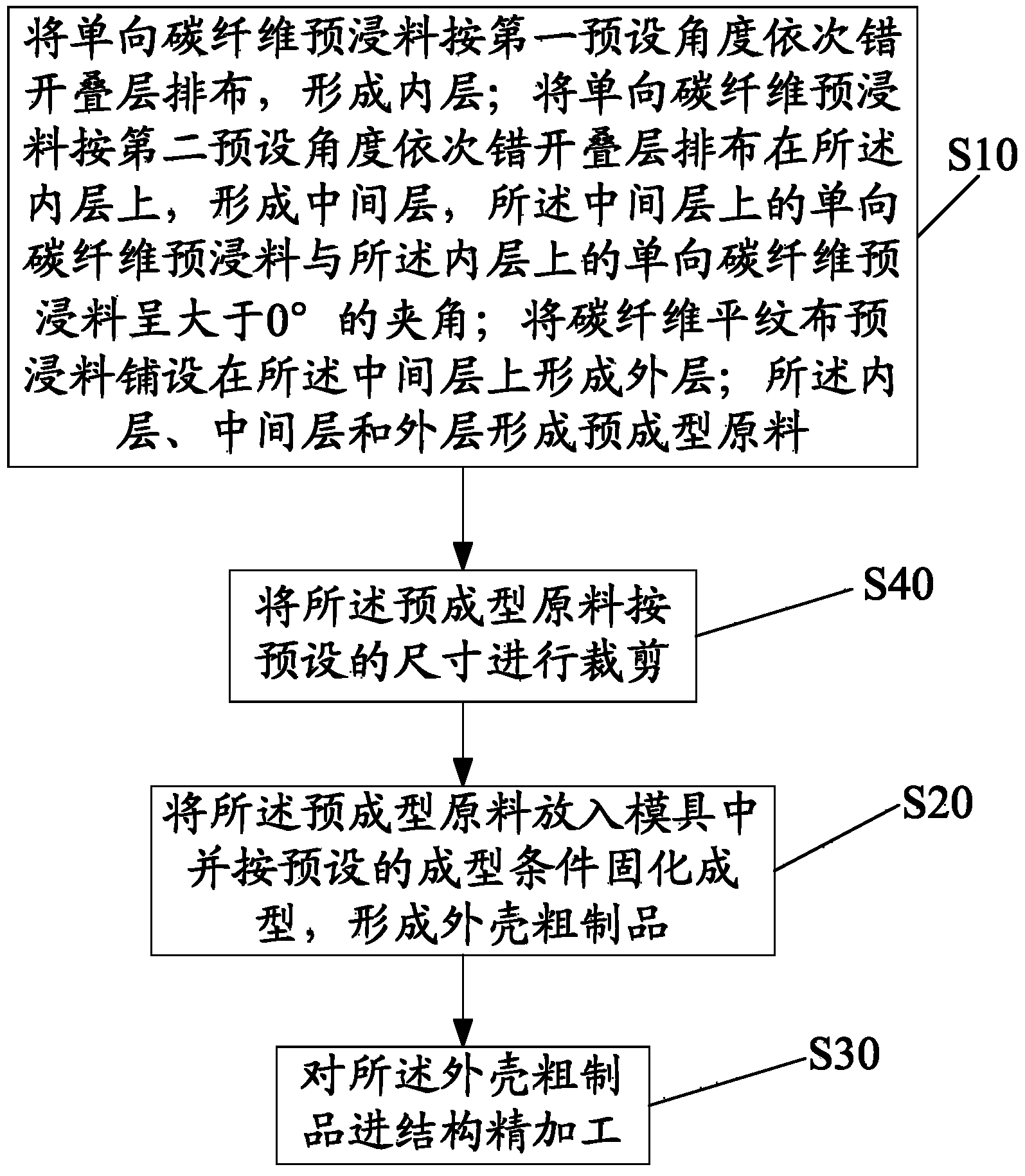

Carbon fiber housing making method

The invention discloses a carbon fiber housing making method which comprises the following steps: forming an inner layer and an intermediate layer by laminated arrangement of a uni-directional carbon fiber prepreg with an included angle of the uni-directional carbon fiber prepreg on the intermediate layer and the inner layer uni-directional carbon fiber prepreg on the inner layer being greater than 0 degree; laying a carbon fiber plain cloth prepreg on the intermediate layer to form an outer layer; forming a pre molding raw material on the inner layer, the intermediate layer and the outer layer; putting the pre molding raw material into a mold for curing molding according to preset curing molding conditions to form a rough housing product; and performing structural finish machining on the rough housing product. The material of a carbon fiber housing prepared by the carbon fiber housing making method is a carbon fiber epoxy resin composite, so that the carbon fiber housing is high in specific strength, light in self weight, beneficial for the lightweight design of a display device, high in specific modulus, large in stiffness, strong in falling resistance, good in corrosion resistance, good in high temperature resistance, good in anti fatigue performance and not easy to deform.

Owner:SHENZHEN TCL NEW-TECH CO LTD

Net-size preparation method of three-dimensional woven pyramid sleeve

The invention relates to a net-size preparation method of a three-dimensional woven pyramid sleeve, which comprises the steps of: arranging yarns into a square shape on a chassis of a weaving machine, and on the basis of the four-step square three-dimensional weaving process, weaving a cross beam part and a longitudinal beam part of the pyramid sleeve respectively; and the net-size preparation method is characterized in that the yarns are moved and reduced for at least once in the weaving process to obtain an equal-wall-thickness three-dimensional pyramid sleeve. The net-size preparation method of the three-dimensional woven pyramid sleeve can realize net-size forming of the pyramid sleeve, and reduce the working procedures; and the prepared products have higher specific strength, fatigue resistance and impact damage tolerance, and can totally avoid damage to the sleeve layer by layer.

Owner:DONGHUA UNIV

Automobile body part and production method thereof

The invention provides an automobile body part and a production method thereof. The invention has the technical scheme that: the automobile body part is made from a composite carbon fiber material, wherein the composite carbon fiber material comprises the following components in percentage by mass: 30-40% of carbon fiber and 60-70% of resin. The production method of the automobile body part comprises the following steps of: cleaning a mould with a cleaning agent; coating a layer of demoulding agent inside the mould and then coating a layer of gel coat; spreading carbon fiber cloth in the mould; spreading demoulding cloth and a diversion net on the spread carbon fiber cloth; spreading a vacuum bag film and sticking with the edge of the mould and sealing, and vacuumizing; leading the resin into a mould cavity through a diversion pipe; heating the product in the mould or curing at a normal temperature; stripping off the vacuum bag material, and demoulding the product. Through the processing method provided by the invention, the body part made from the composite material with excellent properties is prepared, and the automobile body part can maintain the anti-collision performance while reducing the body mass.

Owner:CHERY AUTOMOBILE CO LTD

Glass fiber reinforced plastic centralizer

ActiveCN1837572AReduce weightWeight optimizationDrilling rodsDrilling casingsGlass fiberMaterials science

The invention relates to a glass steel stabilizer. Wherein, two glass steel fixing rings (2) are individually mounted on two ends of 4-12 glass steel arc bars (1). The producing method comprises: making the arc back of said glass steel arc bars (1) outward to be distantly radial fixed on the surface of mould; coiling the continuous glass fiber immerged with thermosetting resin on two ends of glass steel arc bars (1), to be solidified to fix the bars (1) and the fixing rings (2), or directly fixing the glass steel stabilizer on the glass steel tube or glass steel oil tube via said method. The invention has lower weight, simple process and lower cost.

Owner:辐基斯(青岛)复合材料管道有限公司

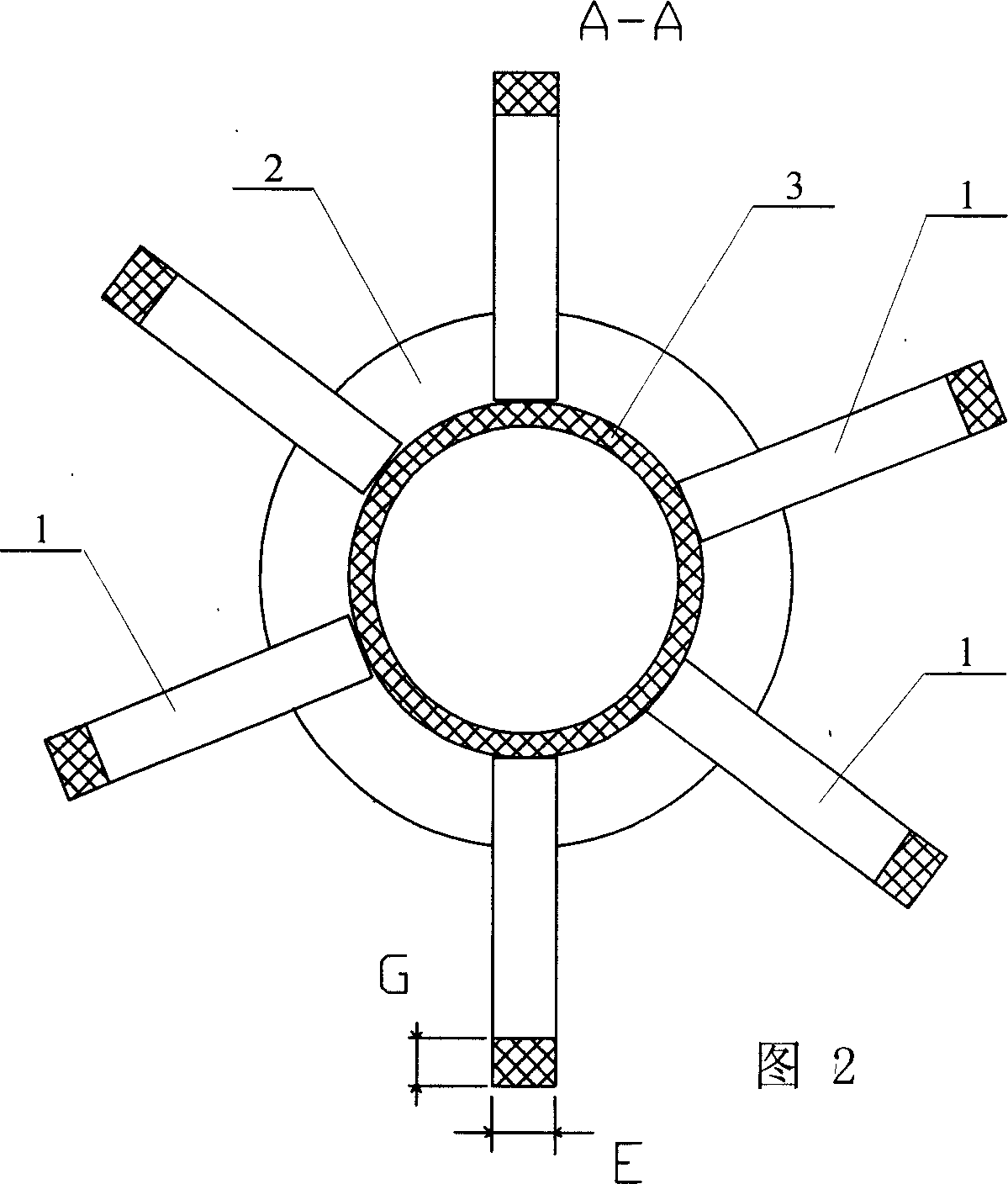

Preparation method of carbon fiber and fiberglass-combined reinforced composite

A preparation method of a carbon fiber and fiberglass-combined reinforced composite relates to the field of a composite technology. The preparation method comprises the following steps: a, blending of base materials: weighing 1-15 wt% of carbon fiber, 45-70 wt% of fiberglass and 30-45 wt% of resin according to the weight ratio and uniformly mixing; b, preparation of a prepreg; c, spraying of a mold release agent for a mold; d, laying of the prepreg; and e, compression molding; and f, demolding. The prepared composite has light weight, high specific strength, high specific modulus, fatigue resistance, corrosion resistance, high temperature resistance and good dimensional stability, and has high cost performance. In addition, the method has few processes, is simple to operate, has high market promotion and application value, and can be used to significantly reduce weight of pure fiberglass reinforced composite parts and greatly enhance carrying capacity of aeronautics and astronautics devices.

Owner:AVIC GUIZHOU AIRPLANE

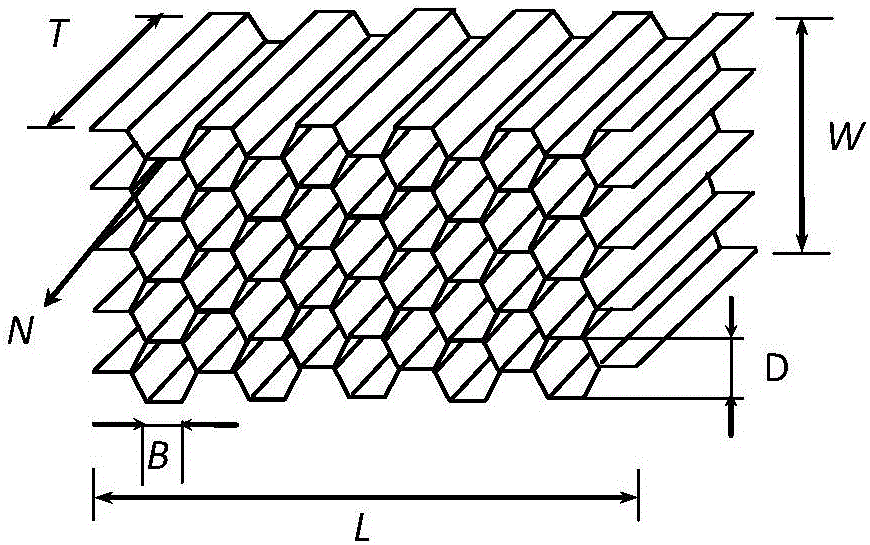

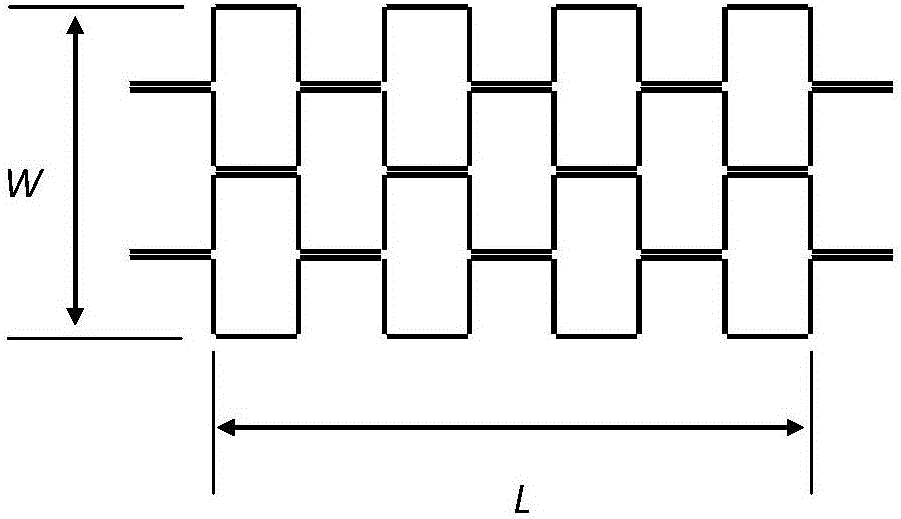

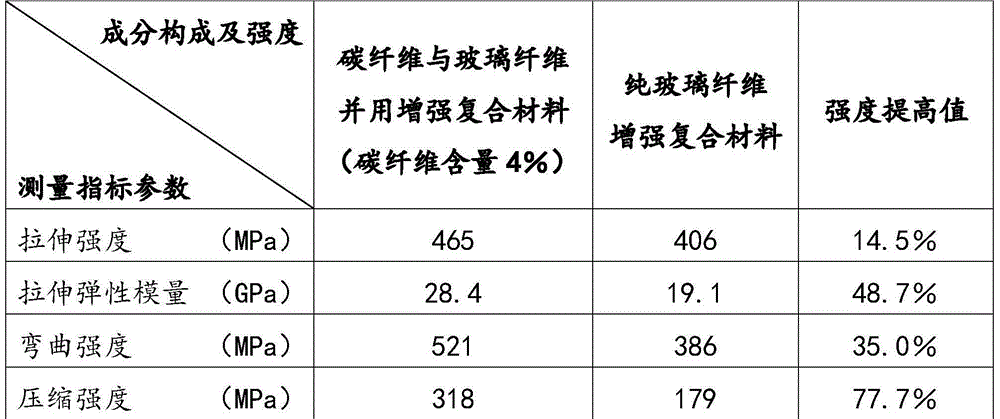

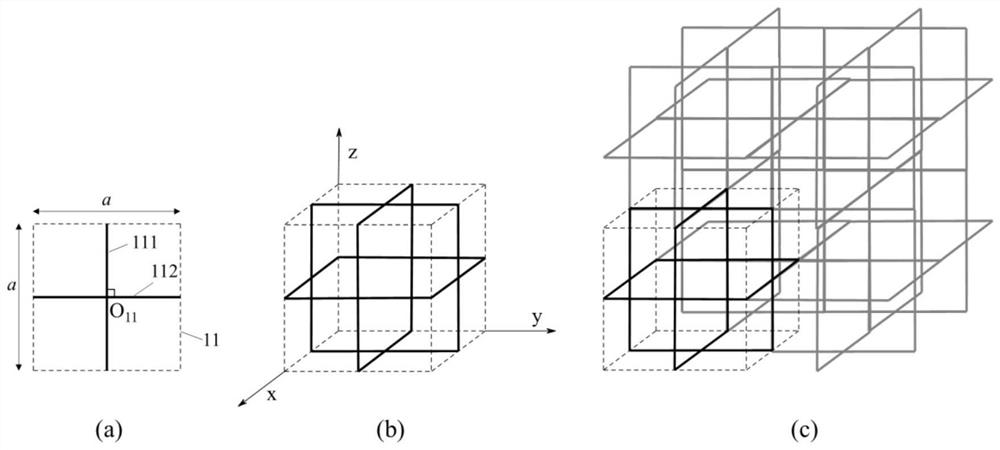

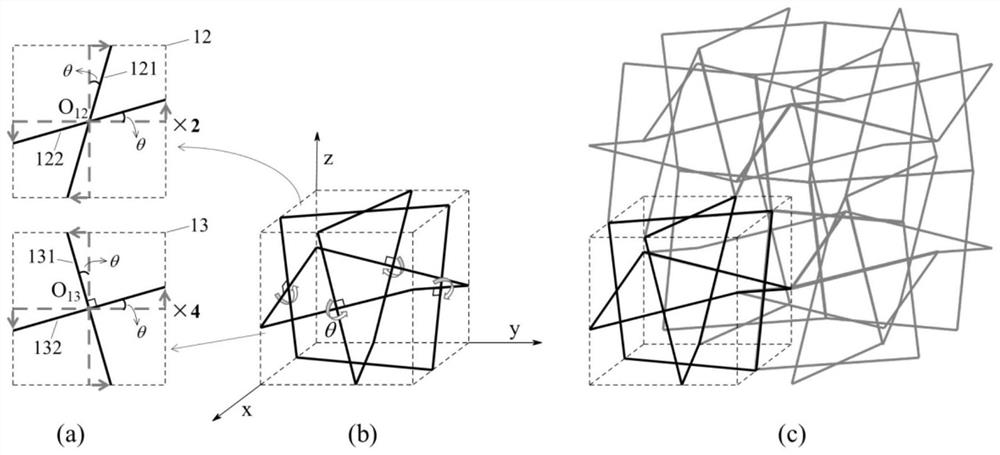

Impact-resistant and high-energy-absorption lattice sandwich structure with negative poisson ratio characteristic

PendingCN112140647AResistance to compressive loadsLight structureLayered productsHigh energySpecific modulus

The invention discloses an impact-resistant and high-energy-absorption lattice sandwich structure with a negative poisson ratio characteristic. The lattice sandwich structure is formed on the basis ofa high-performance negative poisson ratio lattice core material. The negative poisson ratio lattice core material is obtained by changing an included angle between a supporting column and a coordinate axis through a three-dimensional cubic structure. When the included angle between the supporting column and the coordinate axis is not equal to zero, the negative poisson ratio lattice core materialis obtained. The negative poisson ratio lattice material and two thin plates form a novel negative poisson ratio lattice sandwich structure, and the structure has the characteristics of a traditionalauxetic lattice structure and a traditional lattice sandwich structure at the same time, that is, the structure has the characteristics of the negative poisson ratio and the same-direction curvature;meanwhile, has excellent mechanical properties such as ultra-light weight, high specific modulus, high specific strength, impact resistance and high energy absorption. In addition, the sandwich structure has high adjustability, and the mechanical property of the lattice sandwich structure can be adjusted and controlled within a large range by adjusting the deflection angle of the supporting column and the relative density of the lattice material. The lattice sandwich structure has a great application prospect in the field of aerospace.

Owner:BEIHANG UNIV

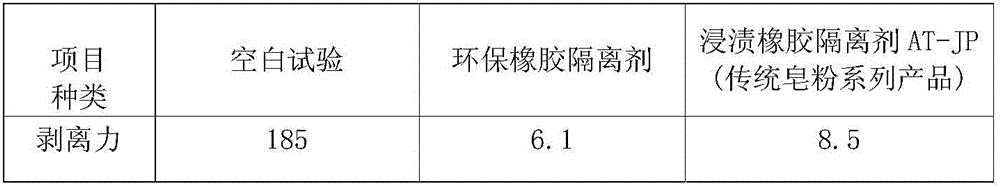

Environment-friendly rubber isolation agent

The invention discloses an environment-friendly rubber isolation agent. The isolation agent comprises the following components in parts by weight: 24-36 parts of polyoxyethylene sorbitan monooleate, 2-4 parts of waterborne polyamide wax, 30-38 parts of calcium stearate, 18-30 parts of hydrated silicon dioxide, 8-14 parts of potassium stearate, 2-5 parts of silicone oil defoaming agents and 2-6 parts of sodium carboxymethylcellulose. The isolation agent is excellent in compatibility, long in actual effect and low in addition amount, and is green and environmentally friendly; the preparation process of the environment-friendly rubber isolation agent is simple and feasible; the cost is low.

Owner:JIANGSU KAOU CHEM

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com