Apparatus and testing method for testing sample creep property in ultra high temperature environment

A creep performance and ultra-high temperature technology, which is applied in the direction of applying stable tension/pressure to test the strength of materials, can solve the problems of test data accuracy, machining difficulties, and test result errors that affect deflection, and achieve simple processing and testing Accuracy improvement, the effect of improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Now in conjunction with embodiment, accompanying drawing, the present invention will be further described:

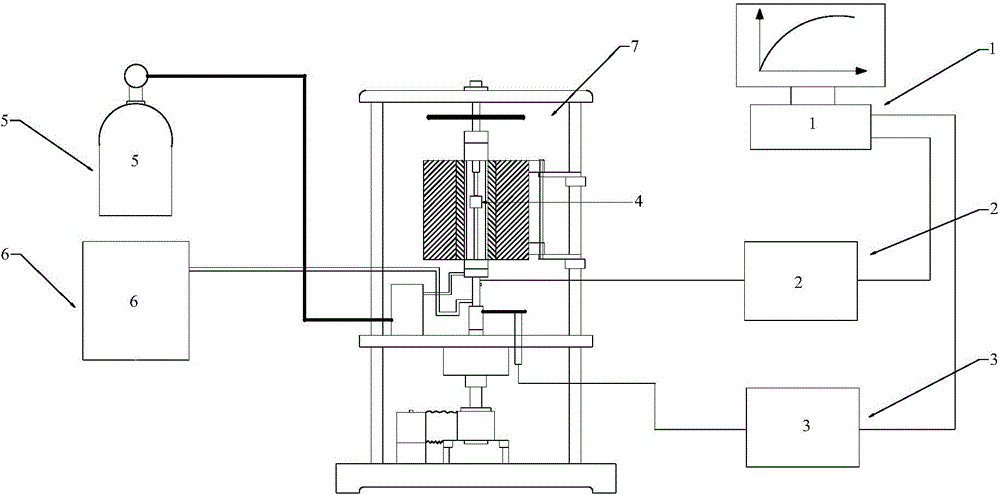

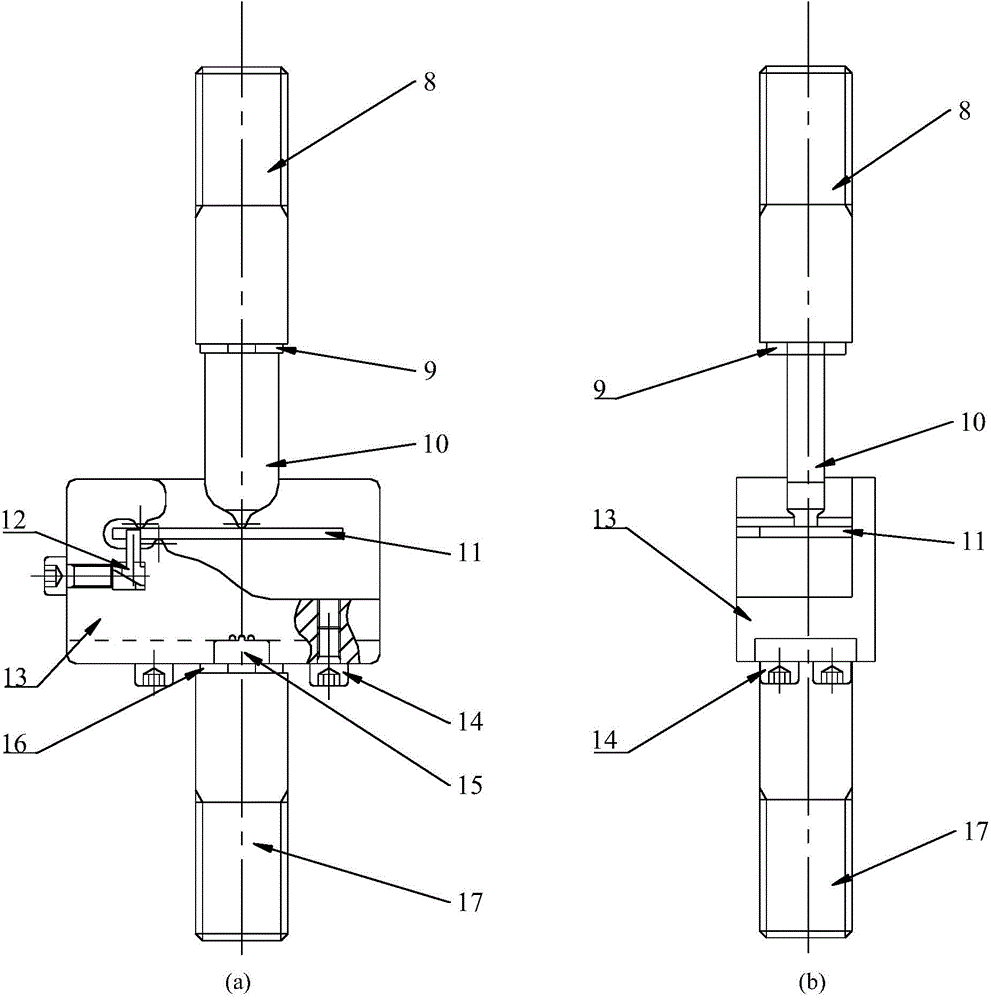

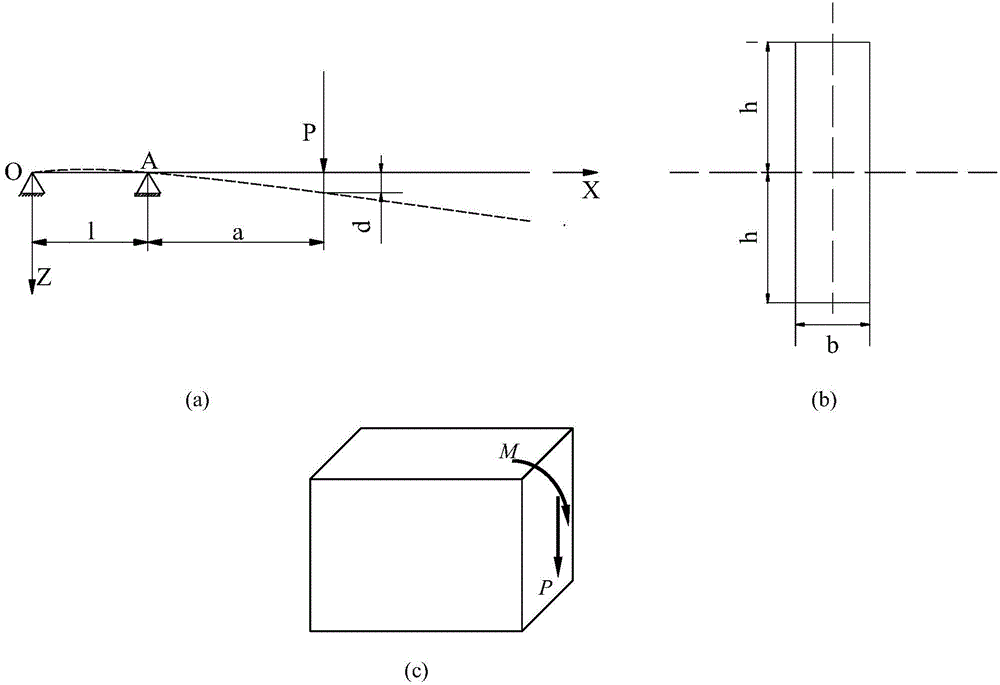

[0031] figure 1 Shown is the block diagram of the composition of the ultra-high temperature creep performance tester provided by the present invention, a computer 1, the computer is installed with the control software of the electro-hydraulic servo fatigue testing machine; an input terminal is electrically connected to the temperature controller 2 of the computer; A measurement controller 3 whose input terminal is electrically connected to the computer; an electro-hydraulic servo testing machine 7; a gas cylinder 5 filled with inert gas; a water cooling system 6 used to ensure the safety of the test device; a simply supported bending test device 4.

[0032] In this embodiment, the software installed on the computer is FT console and SAX (single Axis Max), the temperature range that can be controlled by the temperature controller is 0-2000°C, and the driving devi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com