High-performance jute fiber reinforced polypropylene composite and preparation method thereof

A jute fiber and composite material technology, which is applied in the field of fiber composite materials, can solve the problems of large proportion of plastic particles, differences in fiber content, and small proportion of jute fiber, and achieve high specific modulus, improved binding force, and low price.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

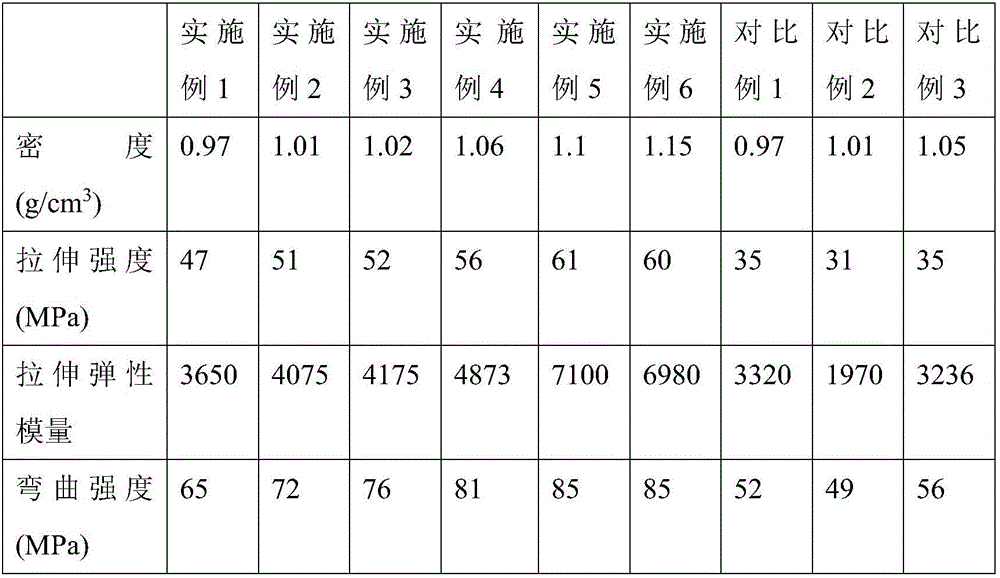

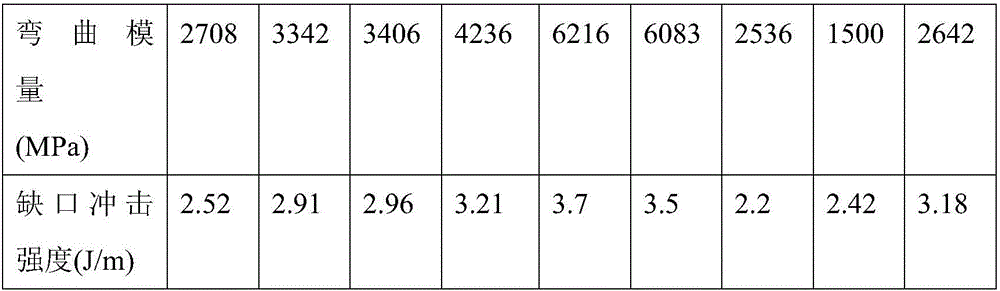

Examples

Embodiment 1

[0031] Weigh 75.7 parts of polypropylene, 20 parts of jute fiber, 3 parts of polypropylene grafted maleic anhydride, 0.5 parts of KH5500, 0.3 part of antioxidant DSTP, 0.1 part of antioxidant 1010, 0.2 part of antioxidant 168 by mass percentage , 0.2 part of calcium stearate, mixed in a high-speed mixer for 5 minutes, after the jute fiber was treated with 5% NaOH solution and coupling agent, it was added to the mixer of the internal mixer together with the prepared polypropylene and each component additive mixture. In the mixing room, the mixing and fusion treatment is carried out through the rotation of the rotor of the internal mixer. The rotor speed is 24r / min, the temperature of the mixing room is set at 185°C, and the mixing time is 45min. The material is immediately transferred to the double-arm feeding port, and is extruded, air-cooled, and granulated by the single-screw extruder. The single-screw extruder is divided into three sections to control the temperature, from t...

Embodiment 2

[0033] Weigh 65.7 parts of polypropylene, 30 parts of jute fiber, 3 parts of polypropylene grafted maleic anhydride, 0.5 parts of KH5500, 0.3 part of antioxidant DSTP, 0.1 part of antioxidant 1010, 0.2 part of antioxidant 168 by mass percentage , 0.2 part of calcium stearate, mixed in a high-speed mixer for 5 minutes, after the jute fiber was treated with 5% NaOH solution and coupling agent, it was added to the mixer of the internal mixer together with the prepared polypropylene and each component additive mixture. In the mixing room, the mixing and fusion treatment is carried out through the rotation of the rotor of the internal mixer. The rotor speed is 24r / min, the temperature of the mixing room is set at 185°C, and the mixing time is 45min. The material is immediately transferred to the double-arm feeding port, and is extruded, air-cooled, and granulated by the single-screw extruder. The single-screw extruder is divided into three sections to control the temperature, from t...

Embodiment 3

[0035] Weigh 63.2 parts of polypropylene, 30 parts of jute fiber, 5 parts of polypropylene grafted maleic anhydride, 1 part of KH5501, 0.3 part of antioxidant DSTP, 0.1 part of antioxidant 1010, 0.2 part of antioxidant 168, hard Calcium fatty acid 0.2 parts, mixed in a high-speed mixer for 5 minutes, jute fibers were treated with 5% NaOH solution and coupling agent, and added to the mixing chamber of the internal mixer together with the prepared polypropylene and the mixture of various component additives , through the rotation of the rotor of the internal mixer, it is mixed and fused. The rotor speed is 24r / min, the temperature of the mixing chamber is set at 185°C, and the mixing time is 45min. It is transferred to the double-arm feeding port, extruded, air-cooled, and granulated by the single-screw extruder. The single-screw extruder is divided into three sections to control the temperature, from the feeding port to the head The temperatures are 180°C, 185°C, and 185°C in s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com