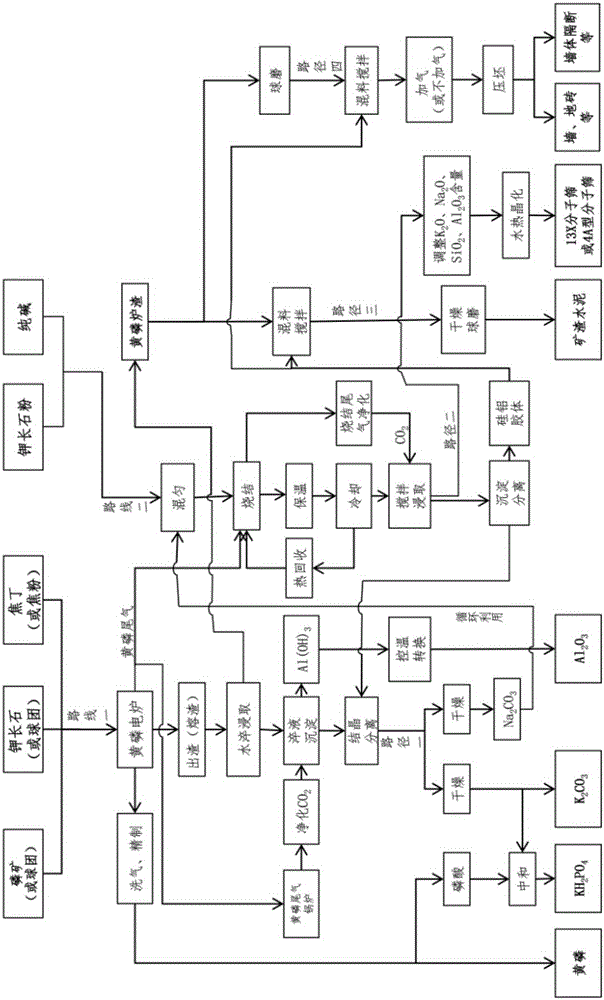

Circular clean production method for yellow phosphorus with co-production of potassium salt, aluminium oxide, molecular sieve, blast furnace slag cement and architectural profile

A slag cement and clean production technology, applied in the chemical industry, can solve the problems of insufficient utilization of heat, inability to produce high-quality yellow phosphorus, and incompatibility with yellow phosphorus enterprises, and achieve outstanding economic benefits and energy-saving effects, and comprehensive production costs. The effect of thermal decomposition energy consumption and material consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0070] A company's phosphating factory has 3 yellow phosphorus electric furnaces, with capacities of 35000KVA, 31500KVA and 12500KVA respectively, with a total capacity of 79000KVA. with P 2 o 5 The content is 29.05%, SiO 2 content of 14.66%, CaO content of 42.03%, CO 2 Phosphorus concentrate pellets with a content of 2.39%, plus silica and coke to produce yellow phosphorus. The consumption of yellow phosphorus raw materials per ton is 8.48t of phosphorous concentrate pellets, 1.46t of coke and 1.91t of silica, and the power consumption is 14215kwh. The total annual consumption of phosphorous concentrate pellets is 300,000 tons, the production of yellow phosphorus is 35,385 tons, and the by-product of yellow phosphorus slag is 279,800 tons.

[0071] According to technical route (technical scheme) of the present invention, use K 2 O content is 13.0%, Na 2 Potassium feldspar particles (3-25 mm) with O content of 2.0% replace the added silica and combine with P 2 o 5 The ...

Embodiment 2

[0075] A phosphorus industry company has 2 yellow phosphorus electric furnaces with a capacity of 2×25000KVA. with P 2 o 5 The content is 29%, SiO 2 content of 11%, CaO content of 42%, CO 2 Phosphate rock (3-25mm) with a content of 10%, plus silica and coke to produce yellow phosphorus. The raw material consumption of yellow phosphorus per ton is 8.68t of phosphate rock, 1.69t of coke and 1.97t of silica, and the power consumption is 14893kwh. The total annual consumption of phosphate rock is 182,500 tons, the production of yellow phosphorus is 21,000 tons, and the by-product of yellow phosphorus slag is 167,000 tons.

[0076] According to technical route (technical scheme) of the present invention, use K 2 O content is 13.0%, Na 2 O content of 1.0% potassium feldspar particles (3 ~ 25mm) instead of silica, and with P 2 o 5 The content is 29%, SiO 2 content of 11%, CaO content of 42%, CO 2 Phosphate rock (3-25mm) with a content of 10% and coke (3-25mm) with a fixed c...

Embodiment 3

[0080] A yellow phosphorus enterprise has a yellow phosphorus electric furnace with a capacity of 20,000KVA. with P 2 o 5 The content is 30.02%, SiO 2 content of 9.81%, CaO content of 42.03%, CO 2 Phosphorus concentrate pellets with a content of 2.39%, plus silica and coke to produce yellow phosphorus. The consumption of yellow phosphorus raw materials per ton is 8.20t of phosphorous concentrate pellets, 1.46t of coke and 2.27t of silica, and the power consumption is 14263kwh. The total annual consumption of phosphorus concentrate pellets is 80,000 tons, the production of yellow phosphorus is 9,750 tons, and the by-product of yellow phosphorus slag is 77,957 tons.

[0081] According to technical route (technical scheme) of the present invention, use K 2 O content is 14.0%, Na 2 Potassium feldspar particles (3-25mm) with O content of 1.3% replace the added silica and combine with P 2 o 5 The content is 30.02%, SiO 2 content of 9.81%, CaO content of 42.03%, CO 2 Phosph...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| decomposition efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com