Hot-melting jig

A technology of hot-melt jig and hot-melt sleeve, which is applied in the field of hot-melt jigs to prevent hot-melt adhesive from overflowing, can solve the problems of irregular shape of covering layer, influence on production efficiency, unsightly appearance, etc., and achieve regular shape and improve Production yield and efficiency, effects of spill prevention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

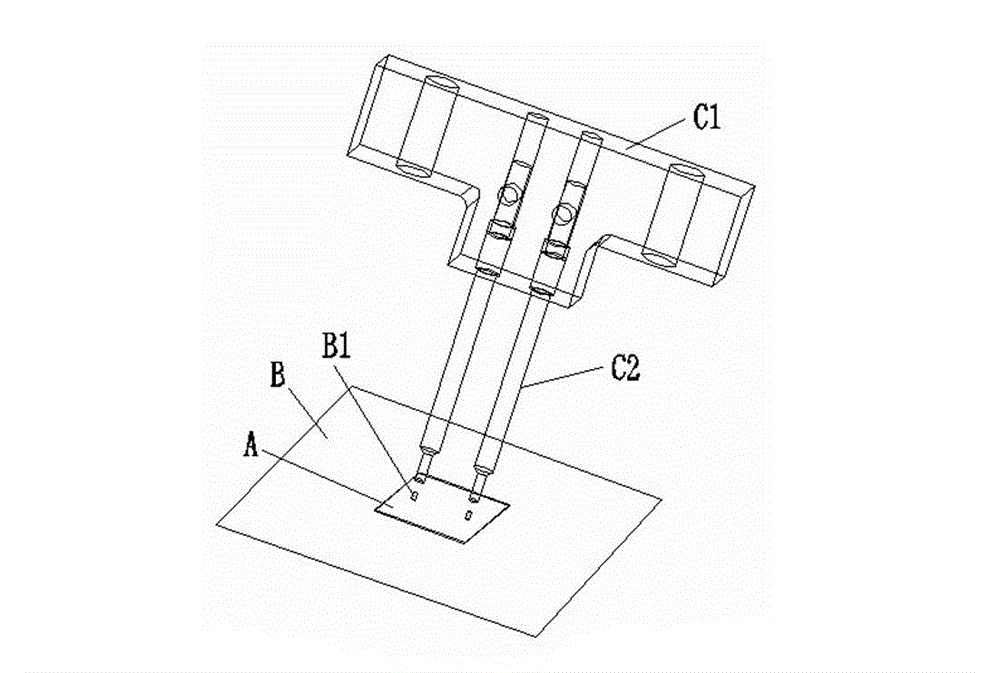

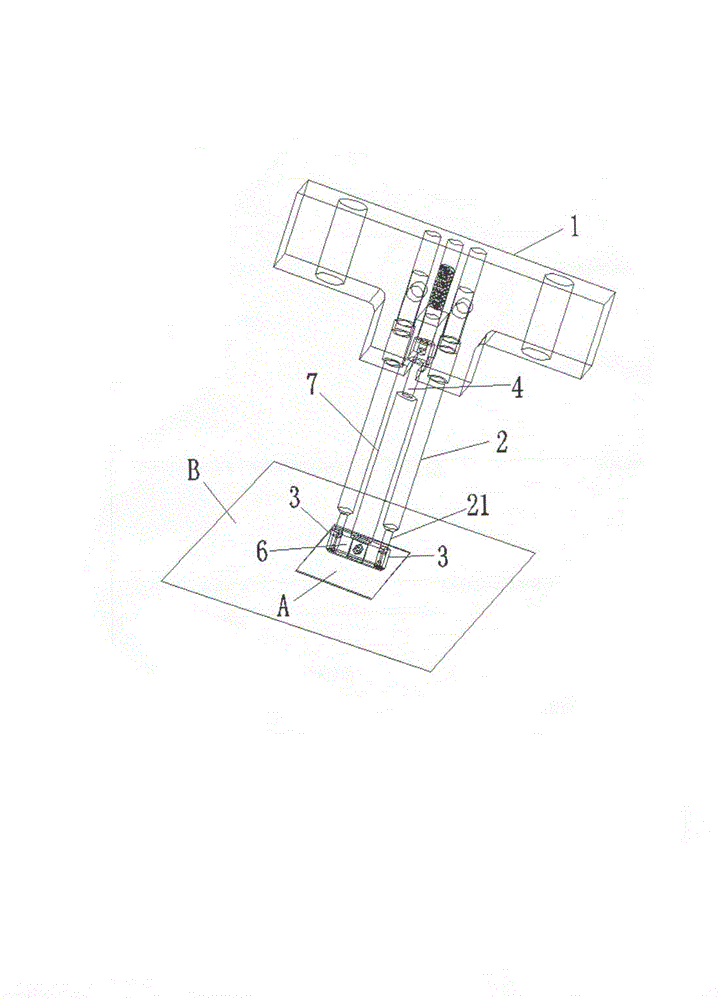

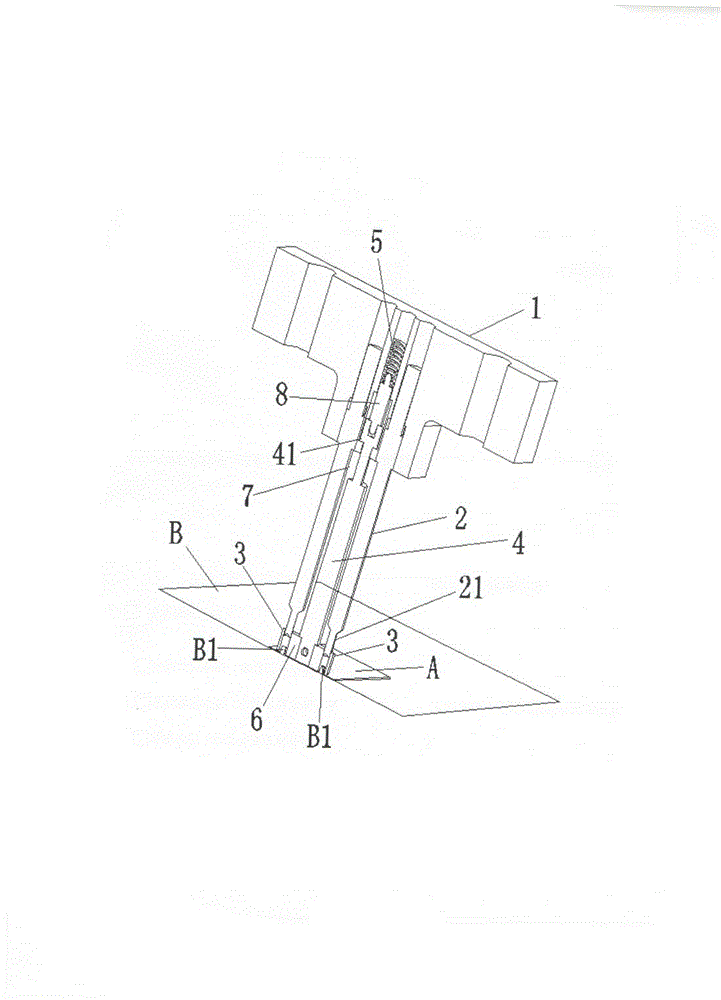

[0016] Embodiment: A hot-melt jig, including a fixed seat 1 and several hot-melt columns 2 connected to the fixed seat, the lower end of the hot-melt column is a welding joint 21, and a hot-melt joint is provided directly below each of the welding joints. Sleeve 3, the hot-melt sleeve 3 is a hollow cylinder whose upper and lower ends are open, the hot-melt sleeve 3 is located on the periphery of the welding joint 21, and the hot-melt sleeve can be set on the body of the welding piece The periphery of the welding column B1 on B is provided with a movable connecting rod 4 and a spring 5, the spring has longitudinal flexibility, the spring 5 is fixed on the fixed seat 1, and a connecting block 6 is provided. The sidewall of the hot-melt sleeve 3 connects several hot-melt sleeves as a whole, and the connecting block 6 is integrated with the hot-melt sleeve 3 . The lower end of the movable connecting rod 4 is connected with the connecting block 6, and the outer sleeve of the movabl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com