Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

162results about How to "Improve dechlorination effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

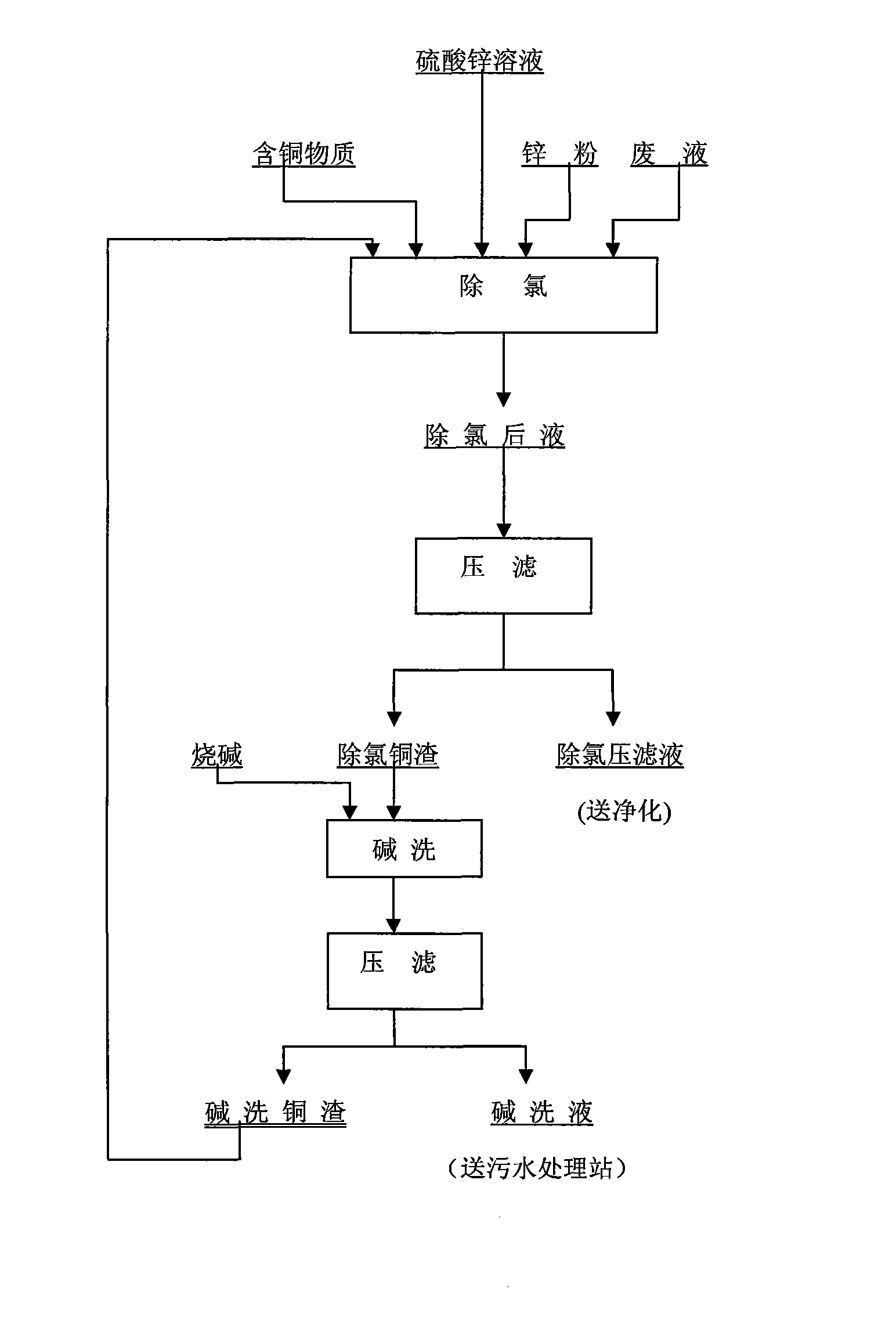

Method for circularly removing chlorine in zinc sulphate solution by copper slag

InactiveCN101633982ATake advantage ofReduce consumptionProcess efficiency improvementZincCopper sulfate

The invention relates to a method for circularly removing chlorine in a zinc sulphate solution by copper slag. The method comprises the following steps: copper ions, zinc powders and a zinc sulphate solution are added into a continuous reaction groove and react in a stirring state to obtain the zinc sulphate solution containing Cl<-> equal to or less than0.3g / l, and a CuCl precipitate generated in the reaction enters slag; a mixture of the zinc sulphate solution and the slag are treated by liquid-solid separation to obtain a dechlorinated zinc sulphate solution and copper slag; the separated copper slag is washed with alkali to remove chlorine ions; the copper slag after being washed with the alkali is returned to the continuous reaction groove for carrying out a circular reaction; and when the copper ions are deficient, a certain copper sulfate is added at proper time for replenishment. The invention utilizes the zinc powders as a reducer for reacting with the copper ions in the zinc sulphate solution to generate a CuCl copper slag precipitate, Cl<-> is eluted with the alkali, Cu2O is also obtained and is returned to react with the Cl<-> in the solution for circular dechlorination, copper sulfate does not need to be added or a little copper sulfate is only added in the dechlorination process, the consumption of raw materials is little, and the cost is low; compared with a method that the copper slag which can be changed is added continuously, the interference of external factors to a dechlorination technique is little, the process is easy to control, and the dechlorination effect is stable and reliable.

Owner:蒙自矿冶有限责任公司

Method for removing chlorine from solution of zinc sulfate

The invention discloses a method for chlorine from solution of zinc sulfate, which mainly comprises the following: 1, a step of extraction, in which tributylamine is used as an extractant, kerosene or para-octanol is used as diluent, clear liquid of zinc sulfate is mixed with an organic phase for extraction, and chlorine in a water phase is transferred to an organic phase; 2, a step of back extraction, in which back extraction is performed by using ammonia water or solution of sodium hydroxide, chlorine in the organic phase is retransferred to the water phase, and the organic phase is recycled; 3, a step of organic phase regeneration, in which 5 to 10 percent solution of sodium hydroxide is mixed with the organic phase which ages after being used for a certain period of time in a ratio of 1:0.9 to 1:2.5, and the mixture is stirred by an electromagnetic siterr at a high speed for 8 to 15 minutes for regenerating the organic phase; and 4, a step of deoiling, in which raffinate is subjected to active carbon absorption or ultrasonic demulsification so as to remove the organic phase in the raffinate. In the invention, the organic phase and the raffinate can be used circularly, the dechlorination rate is over 85 percent, the electrolytic operation environment is improved, the process flow is simple, and the method can be used for dechlorinating solution of zinc sulfate from wet-method zinc smelting plants and can also be used for dechlorinating wastewater.

Owner:ZHUZHOU SMELTER GRP

Material and apparatus for filtering tap water, and method for mfg. said apparatus

InactiveCN1751772AExtend the life cycleEasy to useStationary filtering element filtersMolecular sieveActivated carbon

A filtering material for removing the harmful substance from running water is proportionally prepared from activated carbon, KDFT, calcium sulfite, zeolite molecular sieve, and Ag carried phosphate. Its filter apparatus is a multi-layer hollow structure composed of internal non-woven fabric layer, activated carbon mixed core layer, external non-woven fabric layer and plastic mesh layer. Its manufacture method features that its both ends are blocked by polyethene covers and its core layer is prepared from multiple substances through mixing and screw extruding out to become a hollow cylinder.

Owner:VITOP BIOENERGY SCI & TECH

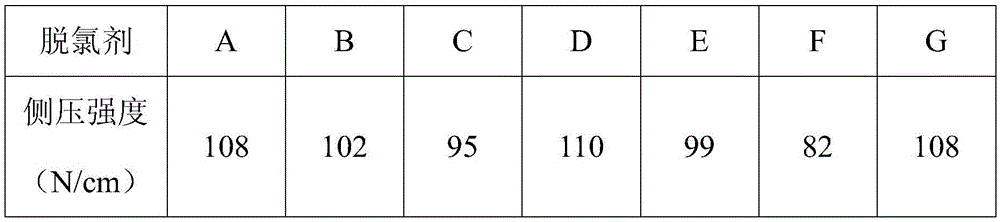

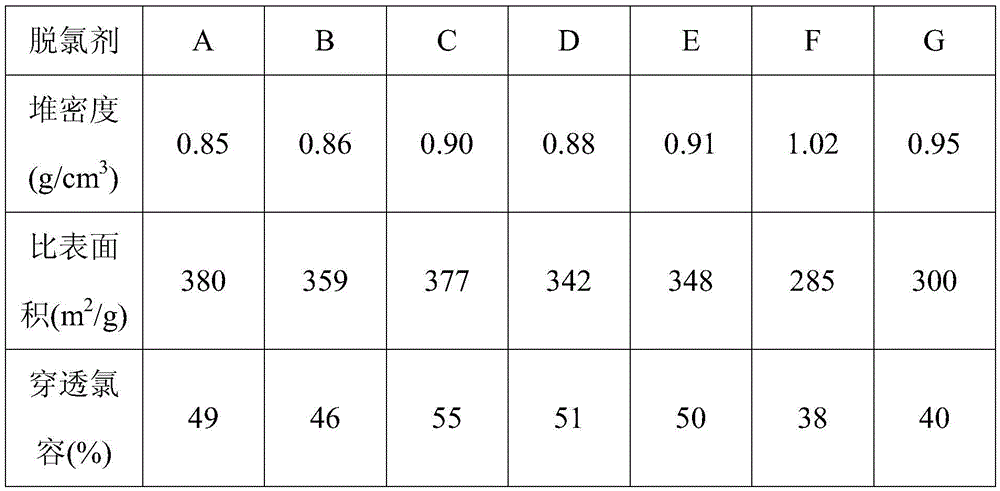

Normal-temperature dechlorinating agent

ActiveCN103127903ARegular crystal formImprove dechlorination effectOther chemical processesDispersed particle separationCopper oxideImpurity

The invention discloses a normal-temperature dechlorinating agent. The normal-temperature dechlorinating agent is mainly prepared from 20-30 parts of ferrous sulfate, 20-40 parts of CaO and 10-25 parts of attapulgite clay in parts by weight and further comprises 15-25 parts of waste catalyst, wherein active components of the waste catalyst include copper oxide and zinc oxide. According to the normal-temperature dechlorinating agent, the ferrous sulfate has weak acidity and can react with calcium carbonate impurity in calcium oxide to enable the crystal form of the calcium oxide to be more regular, and meanwhile, ferrous ions are continuously oxidized into iron oxide to enable the crystal forms of the calcium oxide and the iron oxide to be mutually doped, so that the dechlorinating effect of the dechlorinating agent is improved; and according to a preparation method of dechlorinating agent disclosed by the invention, a roasting process is not needed, the energy consumption is reduced, devices used in the preparation process are decreased, the preparation step is simplified, and the preparation cost is lowered.

Owner:SHENYANG SANJUKAITE CATALYST

Method for removing chlorine in manganese electrolyte or zinc electrolyte

InactiveCN102839283ASimple processEasy to operatePhotography auxillary processesProcess efficiency improvementElectrolysisDechlorinator

The invention relates to a method for removing chlorine in manganese electrolyte or zinc electrolyte. The method comprises the steps of: adding a certain quantity of bismuth (III)-containing antichlor into chloridion-containing manganese electrolyte or chloridion-containing zinc electrolyte by means of continuous stirring; adjusting the pH value of the solution at 1.0-5.0, so that the trivalent bismuth ions are hydrolyzed to generate insoluble bismuth oxychloride precipitate on the premise of chloridion; filtering, wherein the filter liquor is used for the follow-up electrolysis production technology; and regenerating filter residue bismuth oxychloride precipitate by an alkaline solution to generate bismuth hydroxide for recycling, and timely adding a small quantity of antichlor in the process of recycling to compensate the loss in the process of regeneration.

Owner:JISHOU UNIVERSITY

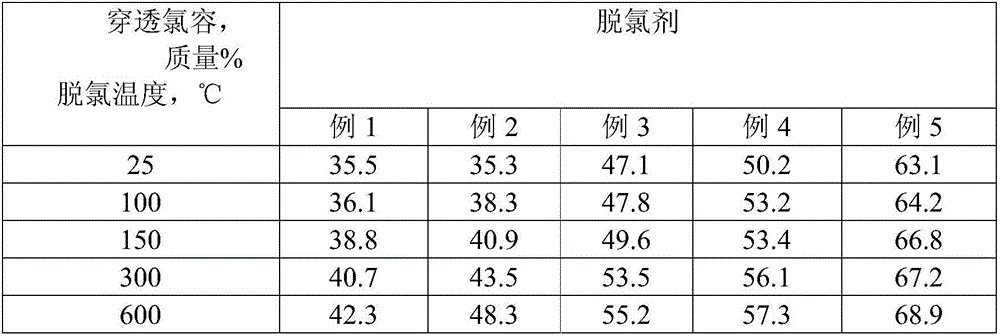

Novel efficient dechlorinating agent and preparation method thereof

ActiveCN106268832AImprove dechlorination effectIncrease profitOther chemical processesDispersed particle separationCatalytic reformingHigh concentration

The invention discloses a novel efficient dechlorinating agent and a preparation method thereof. The novel efficient dechlorinating agent is prepared from active components selected from one or more of Na2CO3, CaCO3, CaO, MgO, CuO, ZnO and derivatives thereof, NH4CO3 serving as a porous auxiliary as well as carriers and auxiliaries selected from at least one of Al2O3, zultanite, kaolin or carclazyte by adding a modified Zn salt and a Ca salt as synergistic auxiliaries, adding an appropriate quantity of water according to the proportion, blending and mixing prior to extrusion molding, drying and roasting. The novel efficient dechlorinating agent has the advantages that the novel efficient dechlorinating agent is high in adsorption rate of both high-concentration HCl and low-concentration HCl at the normal temperature and high in dechlorinating presicion, and chlorine capacity is above 35%; the novel efficient dechlorinating agent is capable of subjecting HCl gas in every work section to efficient deep removal and catalytic reforming at the temperature of 300-600 DEG C, and breakthrough chlorine capacity can be above 65%; the solid dechlorinating agent is free of toxicity and corrosiveness and convenient and safe to operate manually, and treatment of the waste dechlorinating agent causes no pollution or damage to the environment.

Owner:WUHAN TEXTILE UNIV +2

Method for preparing chlorine-removal alkali residue mixture by utilizing alkali residues through ammonia-soda process and application of chlorine-removal alkali residue mixture

ActiveCN104190690AImprove dechlorination effectReduce Chloride ContentSolid waste managementSolid waste disposalChlorideEthyl Chloride

The invention discloses a method for preparing a chlorine-removal alkali residue mixture by utilizing alkali residues through an ammonia-soda process. The method comprises the following steps: step 1, crushing returned sand and returned stones, and grinding to obtain returned sand and returned stone powder; step 2, soaking the returned sand and returned stone powder in water for 0.5-14 days, digesting overburnt calcium oxide, mixing the digested returned sand and returned stone powder, alkali residues and water, wherein a ratio of dry mass of the digested returned sand and returned stone powder to the alkali residues is 2:8 to 5:5 based on the mass percentage of the materials, and the total mass of the water is 1.5 to 8 times that of total dry mass of the digested returned sand and returned stone powder and alkali residues; or mixing the returned sand and returned stone powder, the alkali residues and water, soaking the mixture for 0.5-14 days, and digesting the overburnt calcium oxide; and step 3, performing filter pressing treatment, thereby obtaining the chlorine-removal alkali residue mixture of which the chloride ion content is lower than 0.30 percent of the total mass of solids in the mixture. The invention also discloses application of the chlorine-removal alkali residue mixture. The method and application disclosed by the invention are good in chlorine removal effect, simple in process, energy-saving and environmentally friendly.

Owner:SOUTH CHINA UNIV OF TECH

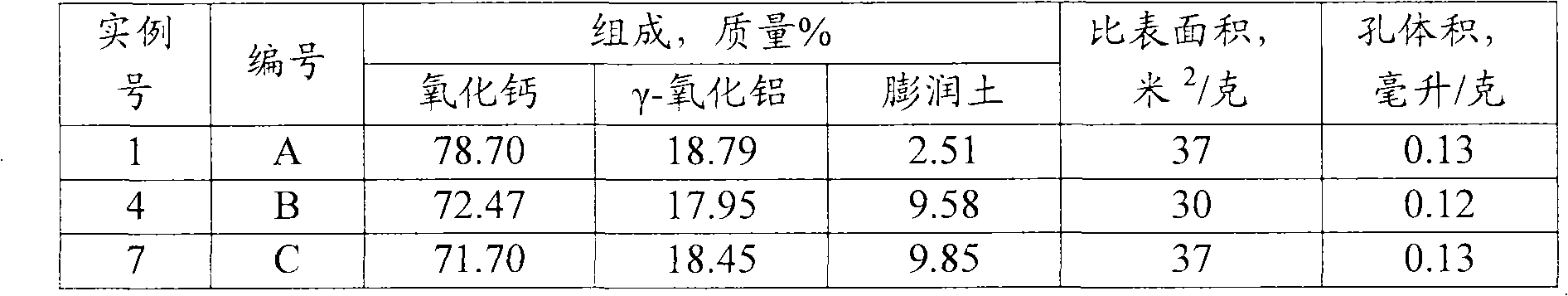

Method for dechlorinating gas discharged from continuous reforming regenerator

ActiveCN101569830AImprove stabilityNot easy to slimeCatalytic naphtha reformingDispersed particle separationSodium BentoniteEnvironmental engineering

The invention relates to a method for dechlorinating gas discharged from a continuous reforming regenerator, comprising the following steps: absorbing chloride in gas discharged from a coke-burning zone and an oxychlorination zone of the continuous reforming regenerator through a bed for catalyst to be regenerated and a bed for solid dechlorinating agent, wherein the bed for catalyst to be regenerated and the bed for solid dechlorinating agent are arranged between a gas-solid separator and a regenerator in sequence; eliminating one part of gas discharged from the bed for catalyst to be regenerated from a system, and returning the other part of the gas to the coke-burning zone of the continuous reforming regenerator; enabling gas discharged from a roasting zone of the continuous reforming regenerator to enter another dechlorinating pot filled with solid dechlorinating agent to absorb chloride therein and eliminating the gas from the system, wherein the solid dechlorinating agent comprises 50-88 percent of alkaline earth oxide by weight, 10-40 percent of alumina by weight and 2-30 percent of bentonite by weight. With the method for dechlorinating gas discharged from a continuous reforming regenerator, the gas discharged from the continuous reforming regenerator can be dechlorinated, and agent to be regenerated can absorb a certain amount of chlorine to reduce the amount of chlorine injected in the regeneration process.

Owner:CHINA PETROLEUM & CHEM CORP +1

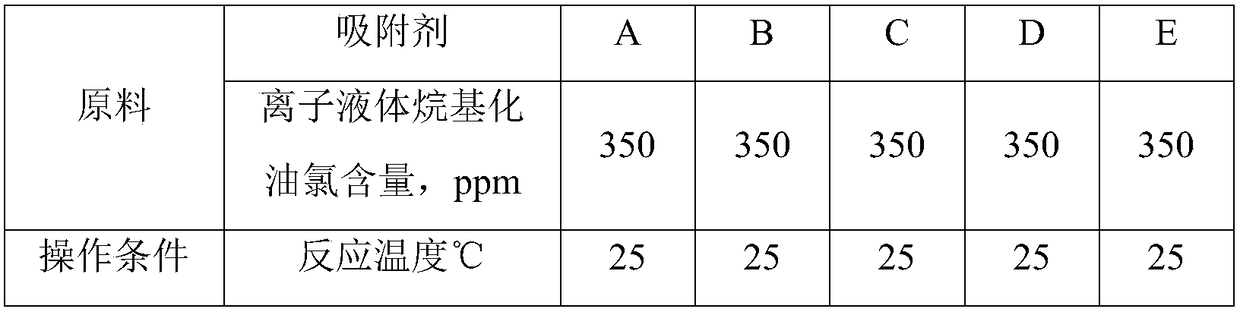

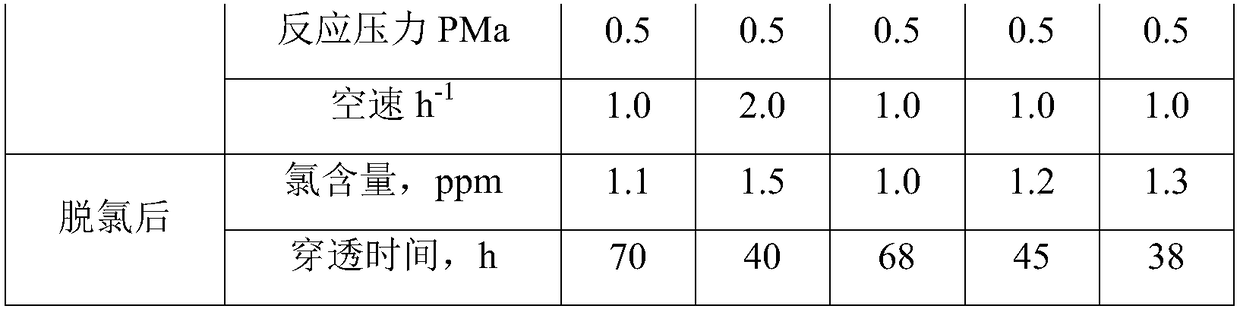

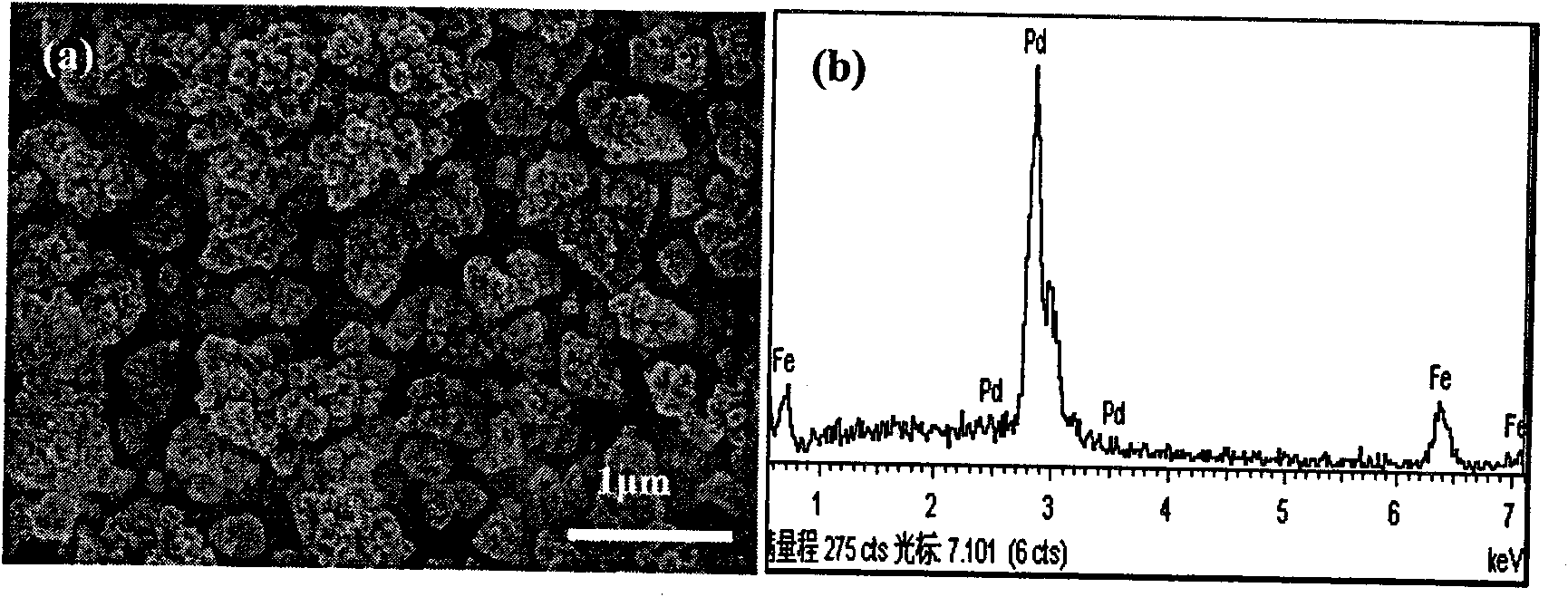

Adsorbent loaded with alkali active components, preparation method of adsorbent loaded with alkali active components and deep dechlorination method

ActiveCN108636348AHigh adsorption capacityHighly selective adsorptionOther chemical processesHydrocarbon oils refiningSorbentIonic liquid

The invention provides an adsorbent loaded with alkali active components, a preparation method of the adsorbent loaded with alkali active components and a deep dechlorination method. In percentage byweight, per 100% of the adsorbent loaded with alkali active components comprise 30-70% of molecular sieve, 10-50% of active alumina and the balance of alkali active metal components. The preparation method of the adsorbent loaded with alkali active components comprises the following steps of mixing the molecular sieve, an adhesive-bonding agent and a pore-forming agent, molding the mixture by performing kneading, and carrying out drying and calcining so as to obtain an adsorbent carrier; immersing the adsorbent carrier in an aqueous solution of alkali active metal components, and carrying outfiltering, drying and calcining so as to obtain the adsorbent loaded with alkali active components. Being applied during dechlorination process of ionic liquid alkylated oil adopting fixed bed technology, the adsorbent loaded with alkali active components provided by the invention shows excellent dechlorination effects; moreover, regeneration process of the adsorbent is simple, effective, low in energy consumption and free of hydrogen. Ionic liquid alkylated oil underwent dechlorination according to the process can be directly used as gasoline-blending oil.

Owner:CHINA UNIV OF PETROLEUM (BEIJING) +1

Antichlor used for purifying reforming regeneration gas and preparation method of antichlor

ActiveCN105478000AHigh reactivityIncrease acidityGas treatmentDispersed particle separationMass ratioAntichlor

The invention provides an antichlor used for purifying reforming regeneration gas. The antichlor is prepared from, by mass, 85-90wt% of a composite oxide carrier and 10-15wt% of alkaline earth metal oxide. The composite oxide carrier is a mixture formed by Al2O3, SiO2 and ZrO2 at the mass ratio of 80:(80-100):(1-3), the specific surface area of the composite oxide carrier is 310-340 m<2> / g, and the total acid content is 0.31-0.45 mmol / g. According to the antichlor, composite oxide with a specific composition is adopted as the carrier, the total acid content of the carrier can be easily controlled within a proper range so that the bonding force between metal active components and the carrier can be regulated and controlled to be moderate, accordingly, it is guaranteed that the antichlor has both high chlorine capacity and high anti-hardening capability, and thus the antichlor has broad industrialized application prospects.

Owner:SHENYANG SANJUKAITE CATALYST

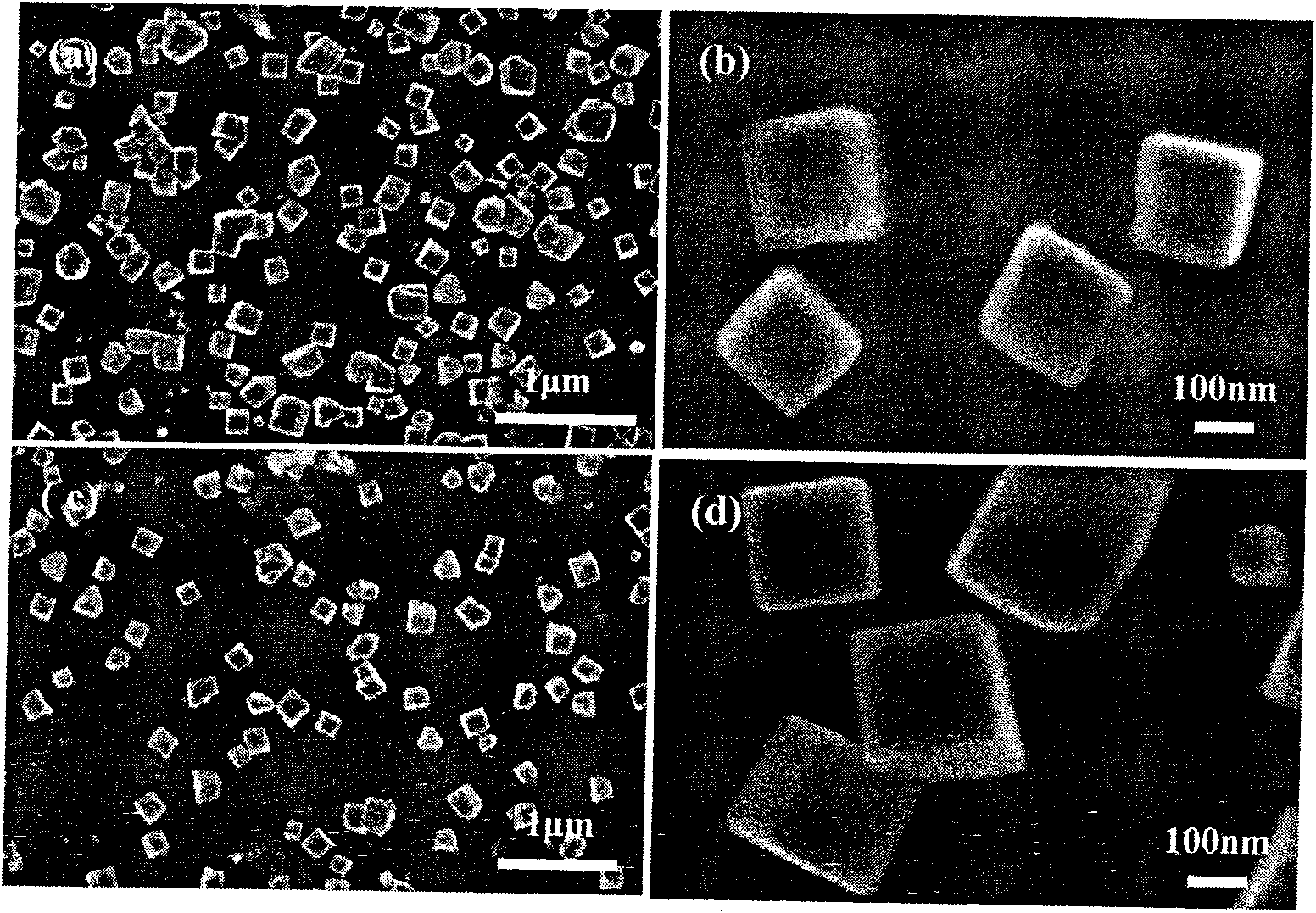

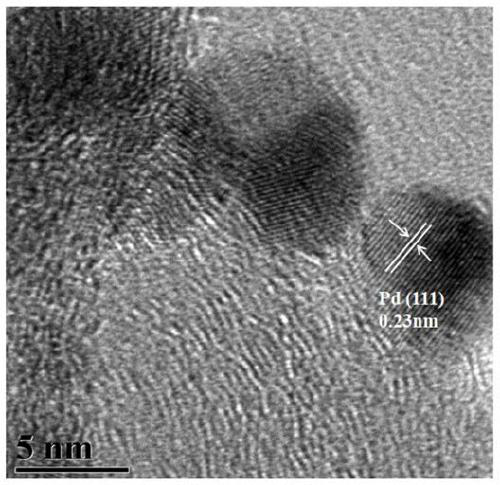

Palladium catalyst for processing chlorinated organics in water and method for preparing same

InactiveCN101711981AThe preparation method is simple and environmentally friendlySimple preparation processWater contaminantsCatalyst activation/preparationDispersityPalladium catalyst

The invention discloses a palladium catalyst for processing chlorinated organics and a method for preparing the same, which belong to the technical field of environment. The catalyst of the invention comprises a carbonaceous carrier and metal palladium, wherein the ratio of the metal palladium to the carbonaceous carrier in part by weight is 0.1-10:100. The method of the invention comprises the following steps: firstly performing acid pretreatment on the carbonaceous carrier; and loading the metal palladium on the carbonaceous carrier by an oxidation reduction method. Active metallic components Pd prepared by the method of the invention are uniformly distributed on the surface of the carbonaceous carrier in an amorphous state, have size distribution less than 5 nm and have the characteristics of strong adhesion, high dispersity and high effective utilization ratio. When in use as an electrochemical cathode catalyst, the multifunctional Pd-loaded catalyst not only endows the chlorinated organics with electroreduction dechlorination capacity (hydrogen is introduced), but also can produce H2O2 through electroreduction (air is introduced). Cathode electroreduction dechlorination and oxidization are combined to treat chlorinated organics wastewater so as to fulfill the aims of full decontamination, energy consumption reduction and decontamination efficiency improvement.

Owner:BEIJING FORESTRY UNIVERSITY

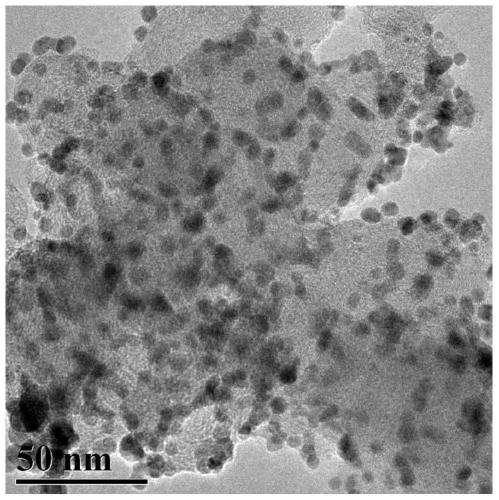

Dechlorination agent and preparation method thereof

InactiveCN1768905AImprove dechlorination effectDispersed particle separationOrganochloridePhysical chemistry

The invention provides a dechlorinating agent and it's preparing method. Said dechlorinating agent uses the nanometer ferro-calcium composite metallic oxide superfine powder as active component while its components comprises: CaO and Ca2Fe2O5, or Fe2O3 and CaFe2O4. And the mol ratio between calcium and iron atom is 6:1-1:1. The preparing method is that using NaOH, KOH or dense NH3 as titrant, to titrate the mixture of ferric iron salt and calcium salt in water-bath and 30-100Deg. C, to be completely deposited, and washing, filtering, drying and milling the deposition to be sintered at 500-900Deg. C. Said invention has high effect, lower cost and simple operation which can apply removing chlorine in variable organic chloride.

Owner:RES CENT FOR ECO ENVIRONMENTAL SCI THE CHINESE ACAD OF SCI

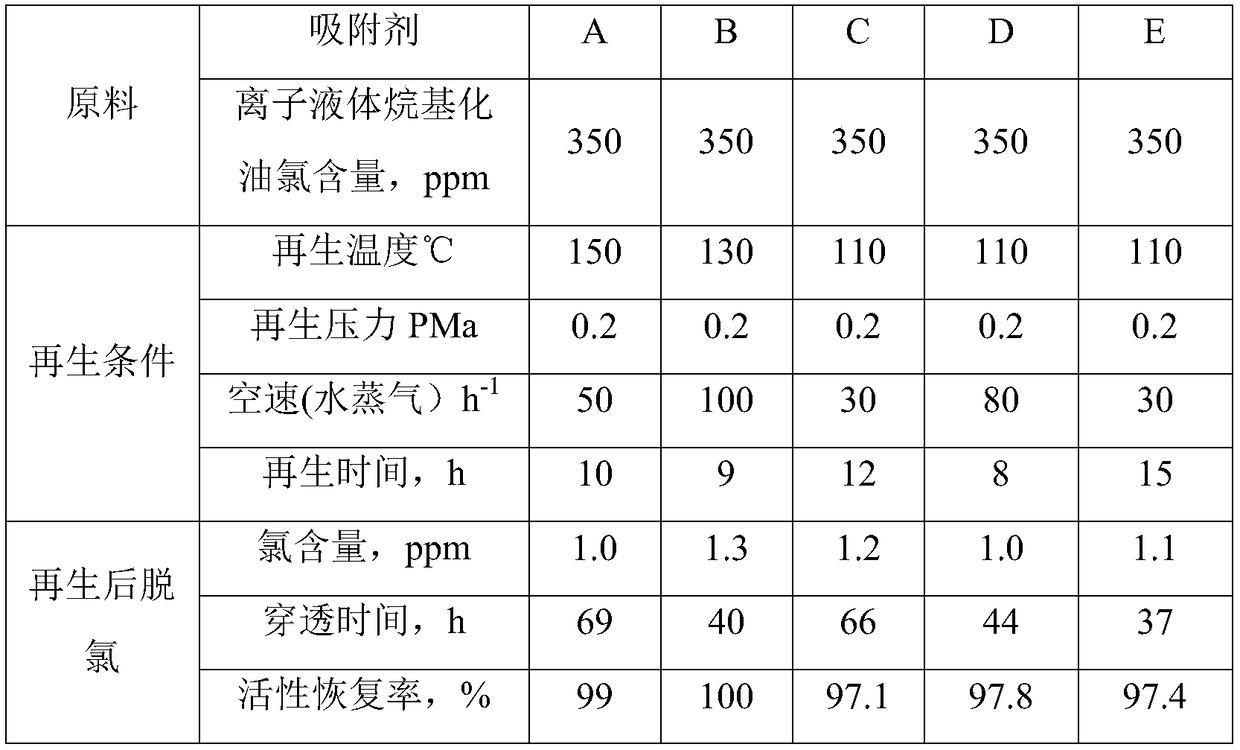

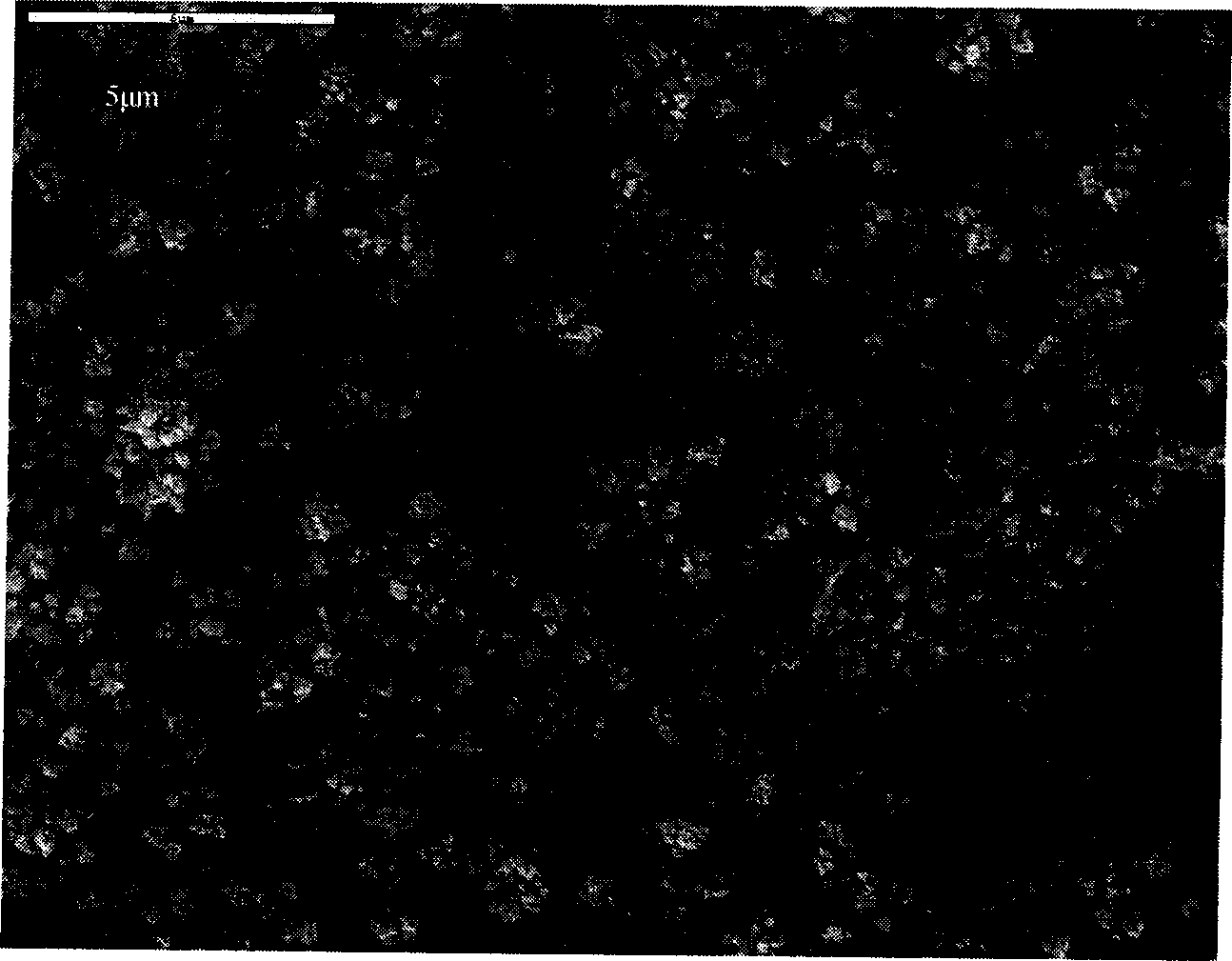

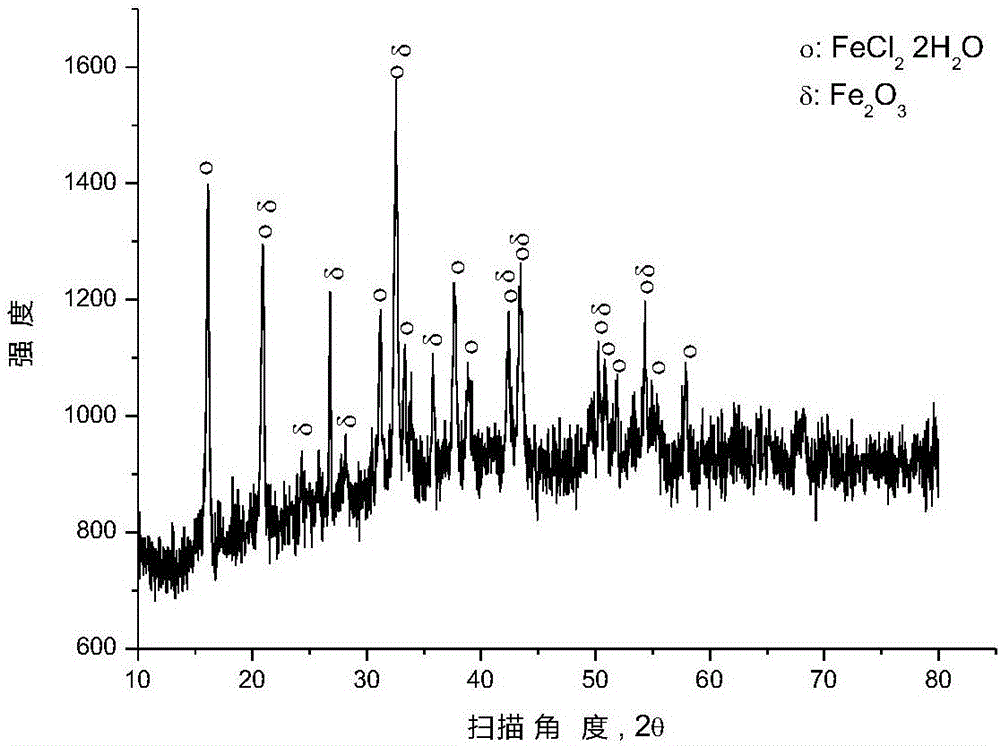

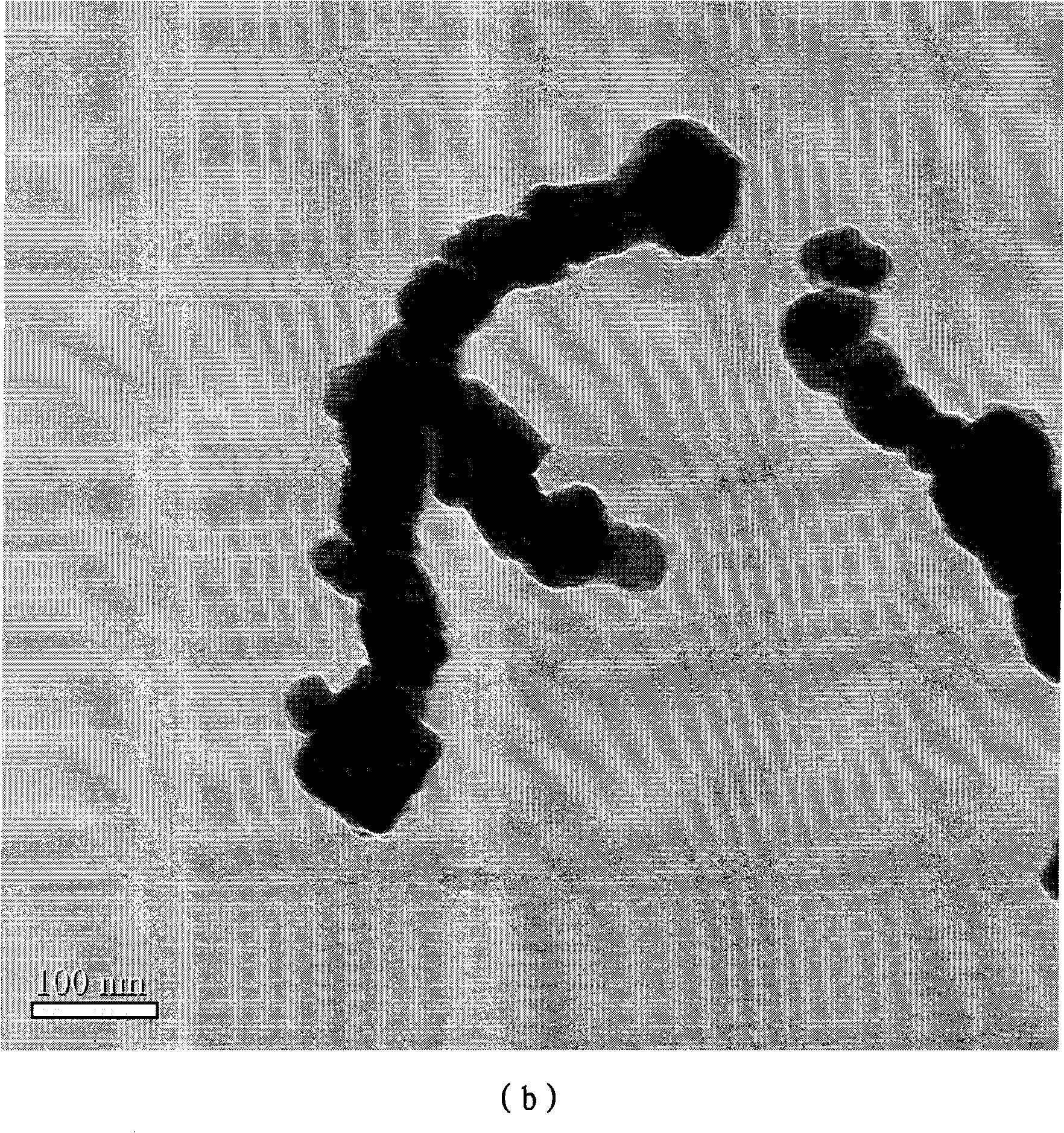

Preparation method of core-shell Fe/Pd bimetallic nano-catalyst

InactiveCN101642714AIncrease profitFree from pollutionWater contaminantsCatalyst activation/preparationNano catalystCore shell

The invention discloses a preparation method of a core-shell Fe / Pd bimetallic nano-catalyst. In the preparation method, glassy carbon electrodes are used as working electrodes, nano-Fe is firstly deposited on the electrodes by an electrochemical deposition method, then the nano-Fe is dipped into a certain quantity of palladium chloride ion solutions for appropriate time so that the noble metal ions and the nano-Fe are partially replaced, and then residual liquid on the surfaces of the electrodes is washed out. The method has simple steps and is easily operated and can conveniently control theload and the appearance of the Fe deposited on the surfaces of the glassy carbon electrodes by controlling the growth time of finished core-core and the concentration of Fe ions in deposit liquid. Theprepared core-shell Fe / Pd bimetallic nano-catalyst has high catalytic activity and favorable effect on dechlorination for contaminants such as organic chloro compounds, and the like.

Owner:SHANDONG UNIV

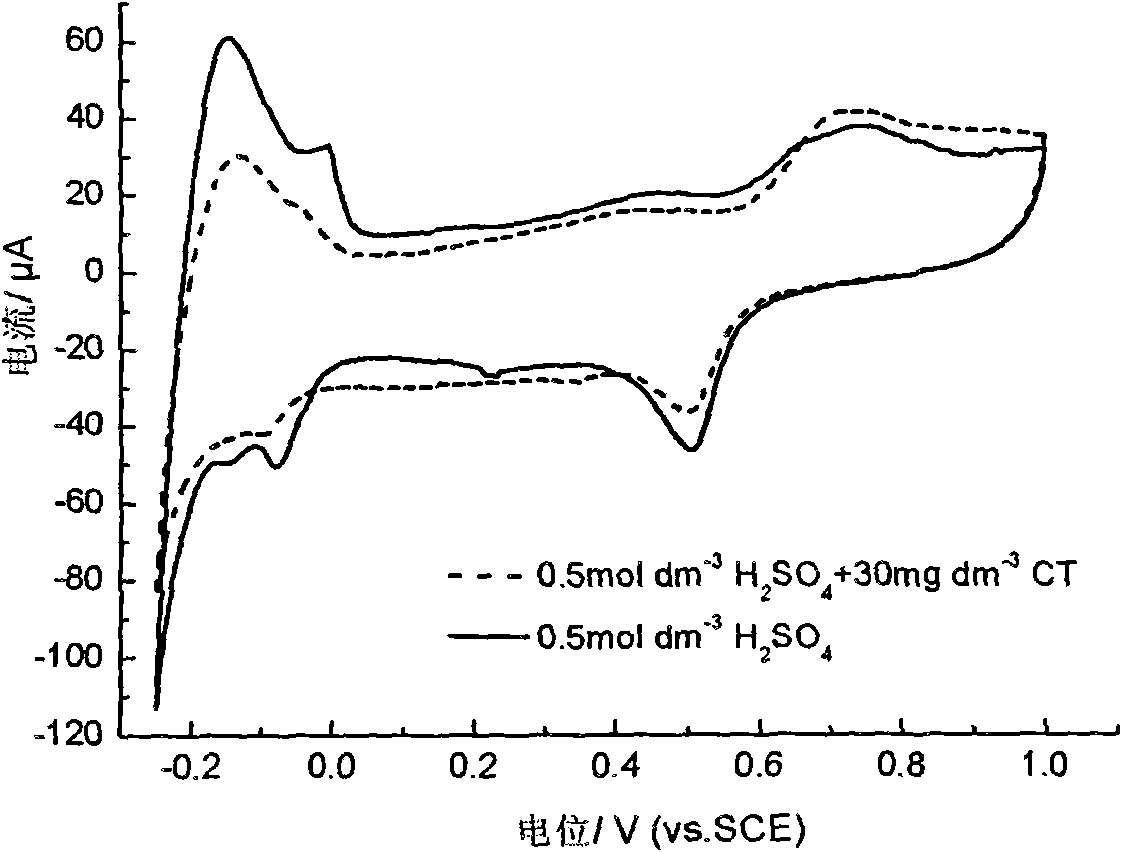

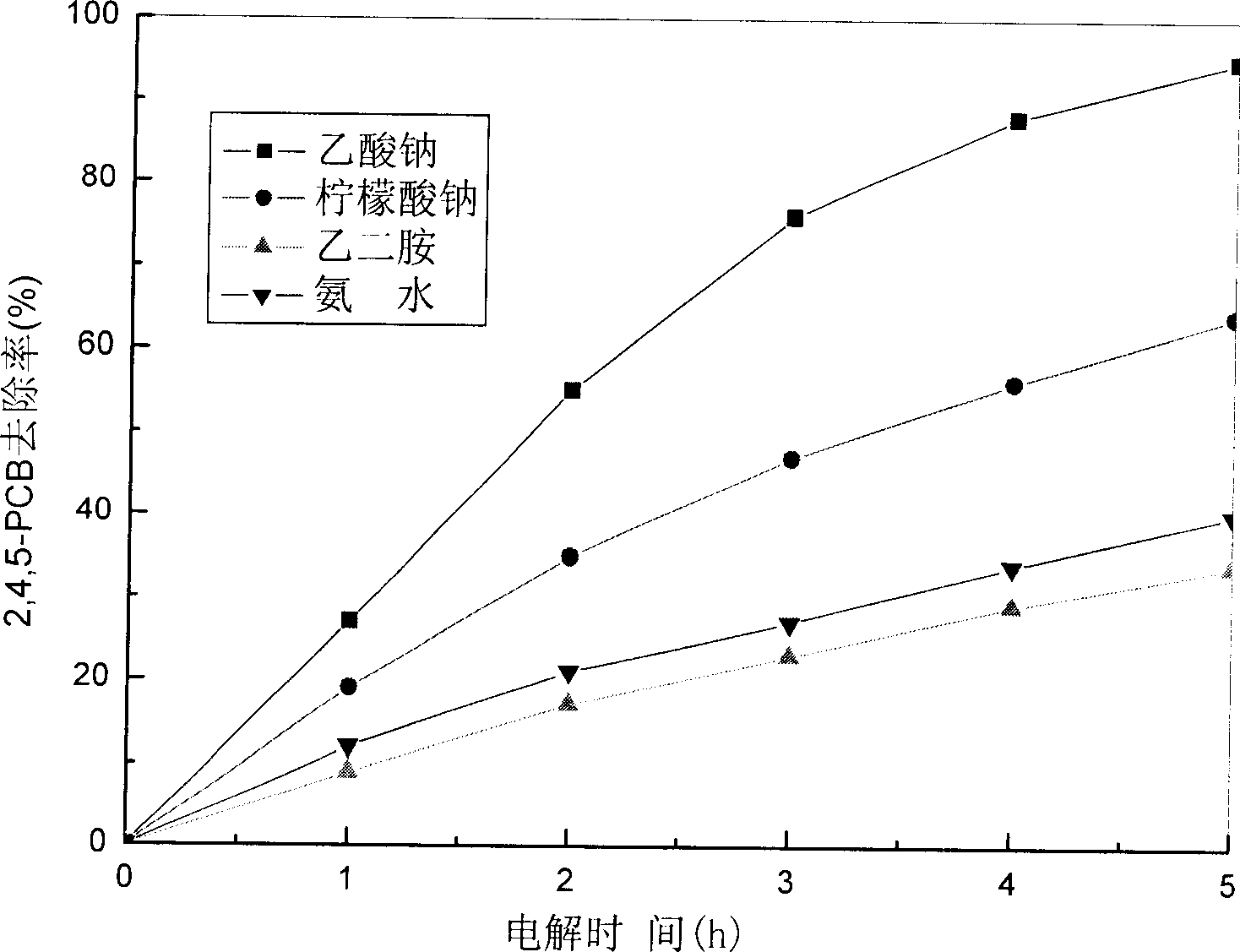

Method for preparing palladium carried metal-based electrode used for electro-catalysis of chlore-aromatics for dechlorination

InactiveCN1831197AHigh catalytic activityImprove dechlorination effectElectrodesSodium acetateElectricity

The invention discloses a manufacture method for Pb load metal base electrode using for dechloridizing in chloroaryl hydrocarbons electrocatalysis. It includes electric sediment liquid mixing process and sediment process. Pouring palladium chloride and sodium acetate into pure water to make mixing sediment liquid of 5mM palladium solution and 50mM-100mM sodium acetate solution, taking heating super sound dissolving to make the color turning to nigger-brown from yellow, adding the liquid and metal base into tri-electrode system single room electric settling basin to take heating and whisking, taking low current sediment for several times and each changing the surface, the electrode loading Pb would be formed and could be taken out to use. The invention has simple technology process, and high controllability.

Owner:TSINGHUA UNIV

Chlorine removal agent, and method and application for removing chlorine from waste acid wastewater by using same

InactiveCN110255799ALow priceEasy to getWater contaminantsWaste water treatment from metallurgical processIonChemistry

The invention belongs to the technical field of waste water and waste liquid treatment and recycling, and particularly relates to a chlorine removal agent, and a method and an application for removing chlorine from waste acid wastewater by using same. The method comprises the following steps: firstly, heating the acid wastewater to a certain temperature, then adding a proper amount of a dechlorinating agent, continuously heating and stirring the system for a certain time to efficiently remove chloride ions in the waste acid wastewater, and absorbing chlorine generated in the reaction process by using alkali liquor. The reaction principle is different from that of the prior art: chlorine ions in the contaminated acid wastewater are oxidized into chlorine by means of the principle of oxidation reduction and the high oxidation potential of a chlorine removal agent or an intermediate product in the reaction process, and the chlorine is volatilized due to the fact that the chlorine is not dissolved in an acidic solution. The concentration of chloride ions in the waste acid wastewater treated by the method is lower than 20 mg / L, so that the concentration of chloride ions in the waste acid wastewater meets the recycling requirement. The method not only solves the problem of removal of chloride ions in the acid wastewater, but also has low requirements on equipment, and realizes resource recovery of chlorine in the wastewater.

Owner:RES CENT FOR ECO ENVIRONMENTAL SCI THE CHINESE ACAD OF SCI

Preparation method of Cu/Pd alloy modified TiO2 catalyst for reductive dechlorination materials

ActiveCN107224982AAchieving Visible Light ResponseExcellent catalytic dechlorination effectWater/sewage treatment by irradiationWater contaminantsAlloyLight response

The invention relates to the technology of preparation of catalytic materials, and aims to provide a preparation method of a Cu / Pd alloy modified TiO2 catalyst for reductive dechlorination materials. The method comprises the following steps: preparing a nano-sheet-like TiO2 catalyst by using tetrabutyl titanate as a titanium precursor and utilizing corrosion performance of HF(hydrogen fluoride) through hydrothermal reaction; preparing a Cu / Pd alloy co-modified TiO2 catalyst through an immersion-reducing atmosphere calcination method. Complex Cu and Pd salt solutions and the catalyst are mixed and immersed, and after vacuum drying, calcination under a hydrogen reducing atmosphere is carried out. According to the preparation method disclosed by the invention, visible light response of the catalyst is realized, and high-efficient reductive hydrogenation dechlorination in aqueous solutions under visible light can be carried out by utilizing a synergistic effect of Cu / Pd alloys, and a catalytic dechlorination effect of the catalyst is superior to that of a commercialized P25 / Pd individually-loaded TiO2 catalyst. By the formation of the Cu / Pd alloys, the catalyst has the advantages that the using amount of precious metals is reduced while the good dechlorination effect is achieved, and practical application of reductive dechlorination under visible light is facilitated.

Owner:JIANGSU ANQIER WASTE GAS PURIFICATION

Dechlorination method for chlorine-containing plastic

ActiveCN106349500AHigh economic valueGood dechlorination effectPlastic recyclingChemical industryChemistry

The invention belongs to the field of chemical industry, and particularly relates to a dechlorination method for chlorine-containing plastic. The method comprises the following steps: a), performing a pyrolysis reaction on an alkaline matter and the chlorine-containing plastic, so as to obtain chlorine salt and hydrocarbon, wherein the alkaline matter comprises one or more of ferriferous oxide, alkali metal oxide, alkali metal hydrate, alkali-earth metal oxide and alkali-earth metal hydrate, and the chlorine-containing plastic comprises polyvinyl chloride. During a pyrolysis process of the chlorine-containing plastic, the specific alkaline matter is added, so that chlorine elements in the chlorine-containing plastic produce non-gaseous chlorine salt, and gaseous chlorine hydride and secondary pollution to atmospheric environment are not produced on the premise of ensuring smooth dechlorination of the chlorine-containing plastic. Experimental results indicate that when the method provided by the invention is adopted to perform dechlorination on the chlorine-containing plastic, the chlorine elements in the plastic are nearly completely fixed to the chlorine salt.

Owner:SUZHOU UNIV

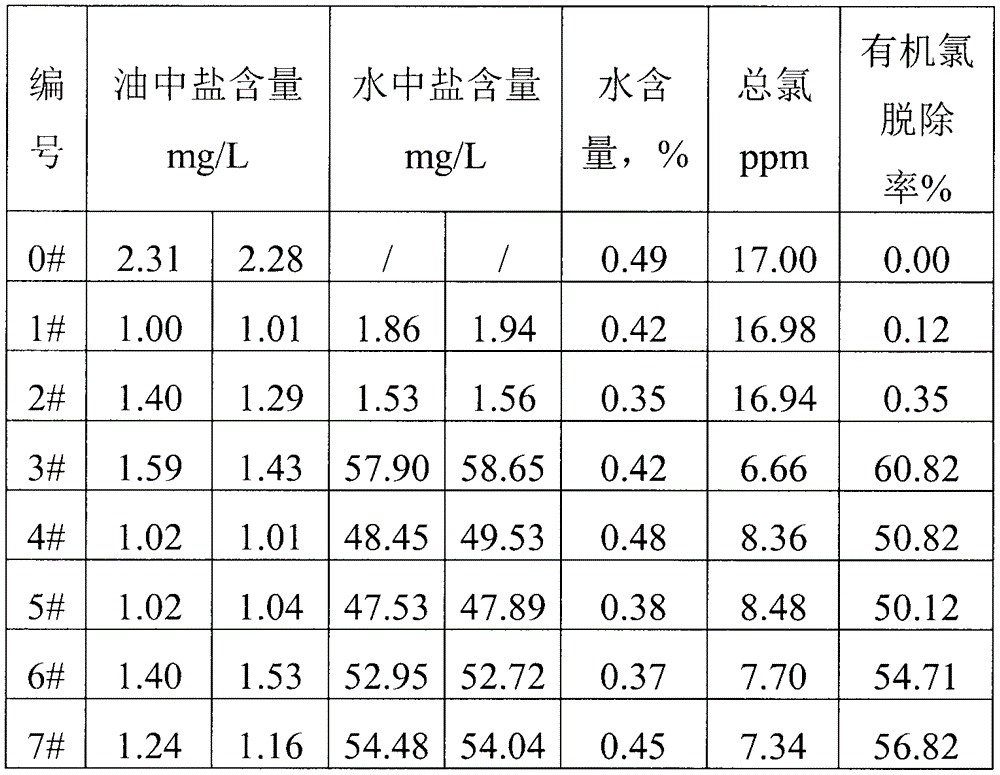

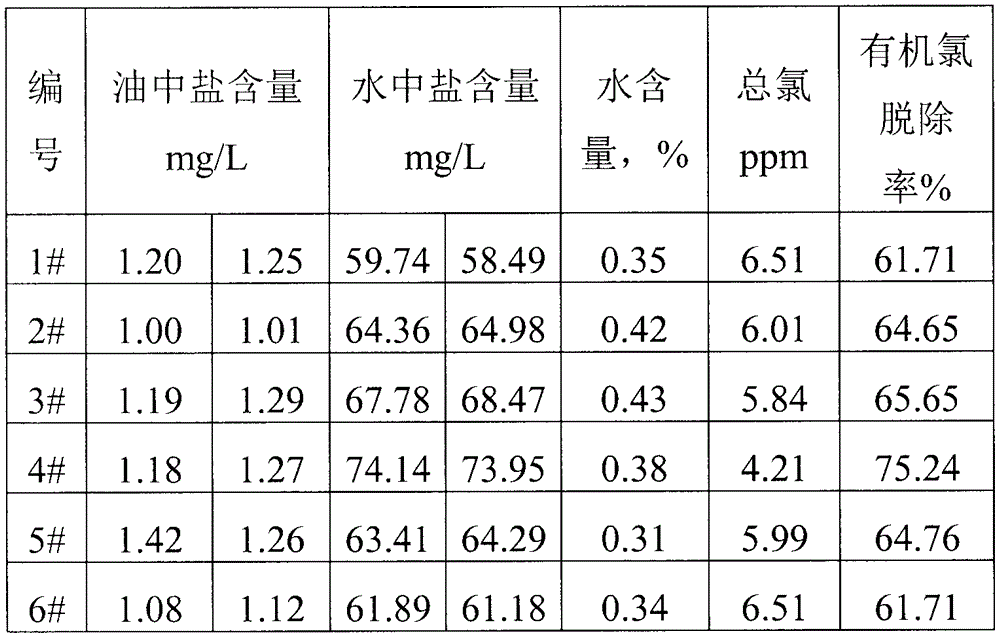

Organic chloride removing method for waste cooking oil

InactiveCN105368580AIncrease reaction rateImprove dechlorination effectFatty acid chemical modificationFatty-oils/fats refiningChemistryElectricity

The invention discloses an organic chloride removing method for waste cooking oil. The organic chloride removing method aims at eliminating the harm of organic chloride to subsequent processing equipment and comprises the steps that at least one stage of electric desalting is conducted on the waste cooking oil; then 6-15% by weight of water is added into the waste cooking oil subjected to electric desalting to be mixed with the oil, and a dechlorination agent is added to perform dechlorination reaction, wherein the dechlorination reaction conditions are described as: the reaction temperature is 90-150 DEG C, the reaction time is 45-120 minutes, the stirring rate is 100-600 r / min, and the agent-chlorine mass ratio is 2-20:1 generally; a reaction product obtained after dechlorination reaction is subjected to electric desalting again to obtain organic chlorine removed cooking oil. The organic chloride in waste cooking oil can be efficiently removed by using the method at low cost.

Owner:LUOYANG PETROCHEMICAL ENG CORP SINOPEC +1

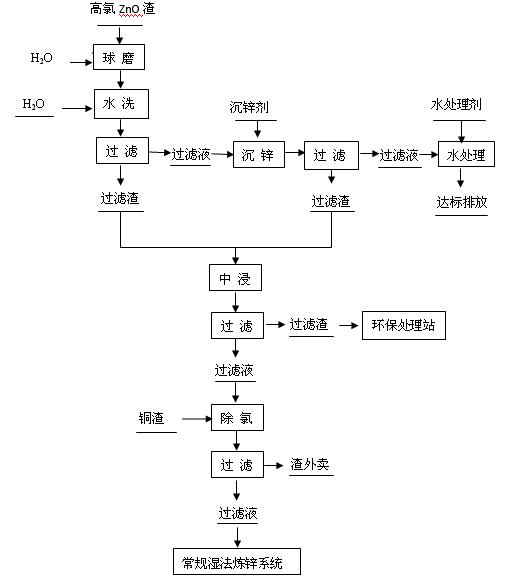

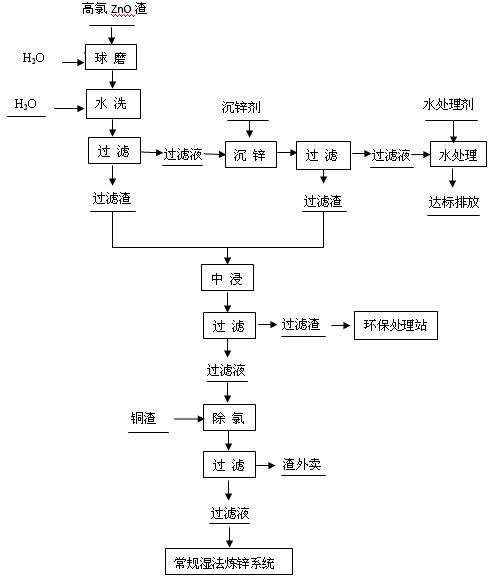

Method for zinc raw material dechlorination in zinc hydrometallurgy

InactiveCN102230080AHigh recovery rateQuality improvementProcess efficiency improvementDechlorinatorHydrometallurgy

The invention relates to a method for zinc raw material dechlorination in zinc hydrometallurgy. The method comprises the following steps: 1, ball-grinding: ball-grinding raw materials into a slurry with a particle size of less than 80 meshes; 2, washing: adding water to the slurry, washing, filtering, allowing a filtrate to enter into a zinc precipitation process, and allowing a filter residue toenter into a neutral leaching process; 3, precipitating zinc: adding a zinc precipitant to the filtrate obtained in step 2, precipitating zinc, filtering, allowing a filtrate to enter into a waste water processing process, and allowing a filter residue to enter into a neutral leaching process; 4, carrying out neutral leaching: adding an electrolytic waste liquid and sulfuric acid to the filter residue obtained in the step 2, adding the zinc precipitation filter residue obtained in step 3, stirring, filtering, allowing a filtrate to enter into an advanced dechlorination process, and sending a filter residue to an environmental protection processing station; 5, carrying out advanced dechlorination: adding a cooper residue dechlorination agent and sulfuric acid to the filtrate obtained in step 4, reacting, filtering, allowing a filtrate to enter into a zinc hydrometallurgy process, and selling a filter residue outside; and 6, processing waste water: carrying out environmental processing on the filtrate obtained in the step 3, and discharging when standards are reached. The method has the characteristics of good dechlorination effect, low cost, strong operability, substantial economicbenefit and the like.

Owner:孙位成

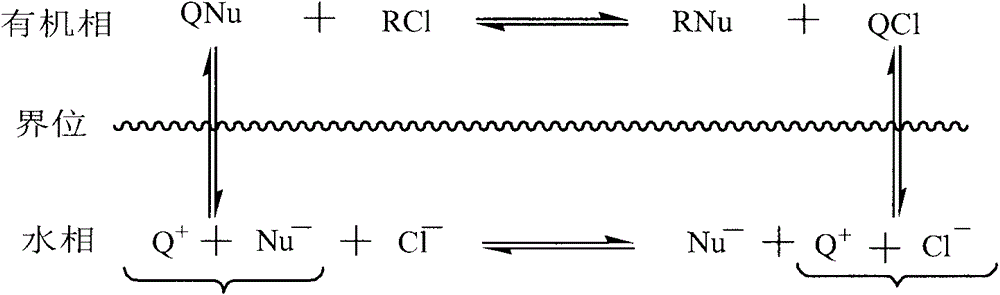

Method for removing chlorine-containing organic compounds in waste oil

InactiveCN109181759AMore active moleculesImprove responseTreatment with plural serial refining stagesHydrocarbon oils treatment productsWaste oilOil phase

The invention provides a method for removing chlorine-containing organic compounds in waste oil, and belongs to the technical field of waste oil recycling. An organochlorine transfer agent is preparedby adding benzyltriethylammonium chloride and an alkali agent to anhydrous ethanol and carrying out a reaction, and hydroxyl anions in the organochlorine transfer agent and carbon cations of the chlorine-containing organic compounds undergo a nucleophilic substitution reaction to convert the oil-soluble chlorine-containing organic compounds into water-soluble chlorine-containing compounds, so water can be added to the product to dissolve the formed water-soluble chlorine-containing compounds in water in order to remove the water-soluble chlorine-containing compounds from an oil phase, and theseparated oil phase is oil free from the chlorine-containing compounds. The method has the advantages of low cost, high dechlorination rate, good dechlorination effect, mild reaction conditions and no secondary pollution.

Owner:NINGBO ZHONGXUN ENVIRONMENTAL TECH CO LLC

Quaternary ammonium salt modified Pd/C electrocatalyst as well as electrode and preparation and application thereof

ActiveCN110184623AWeaken electrostatic repulsionPromote adsorptionOrganic-compounds/hydrides/coordination-complexes catalystsCatalyst activation/preparationChemistryPollutant

The invention discloses a quaternary ammonium salt modified Pd / C electrocatalyst as well as an electrode and preparation and application thereof. The electrocatalyst comprises carbon dust and Pd nanoparticles, wherein the Pd nanoparticles are supported by the carbon dust to form a nano Pd / C composite material; and quaternary ammonium salt is adhered to the surface of the nano Pd / C composite material. The quaternary ammonium salt is adopted to modify Pd / C, by virtue of the electropositivity and the complexing effect (with pollutants) of the quaternary ammonium salt, the electrostatic repulsiveinteraction of chlorine-containing pollutants with cathode electrodes can be alleviated, adsorption of the chlorine-containing pollutants can be enhanced, and dechloridation efficiency can be improved.

Owner:CHONGQING TECH & BUSINESS UNIV

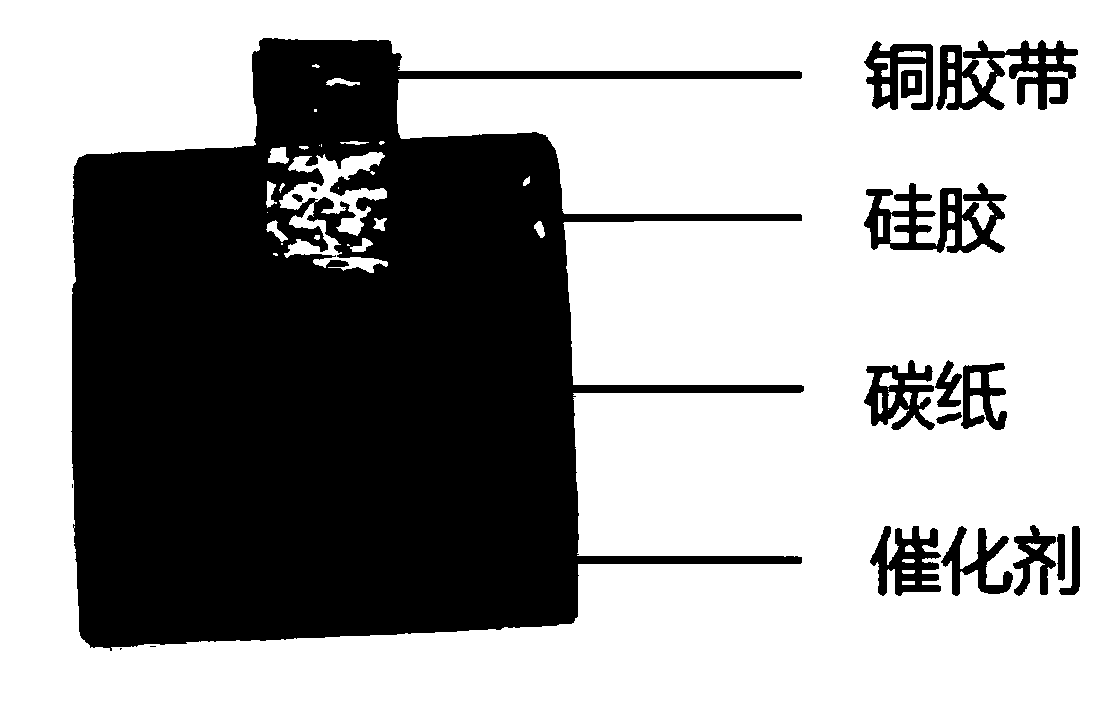

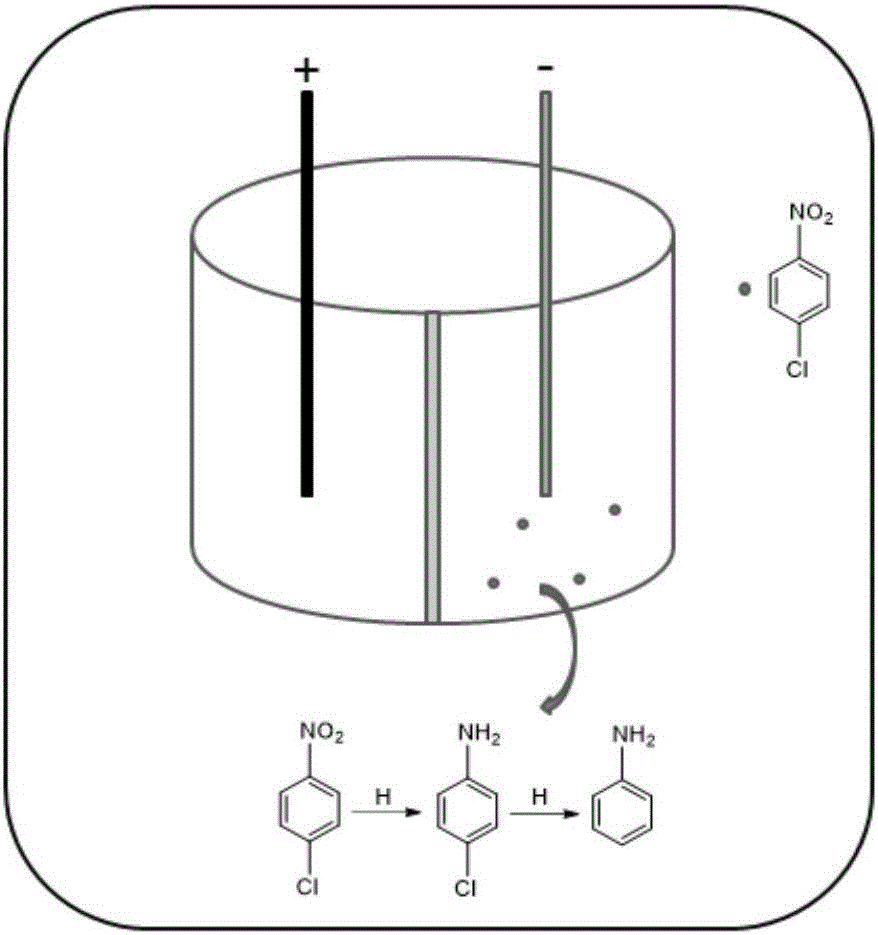

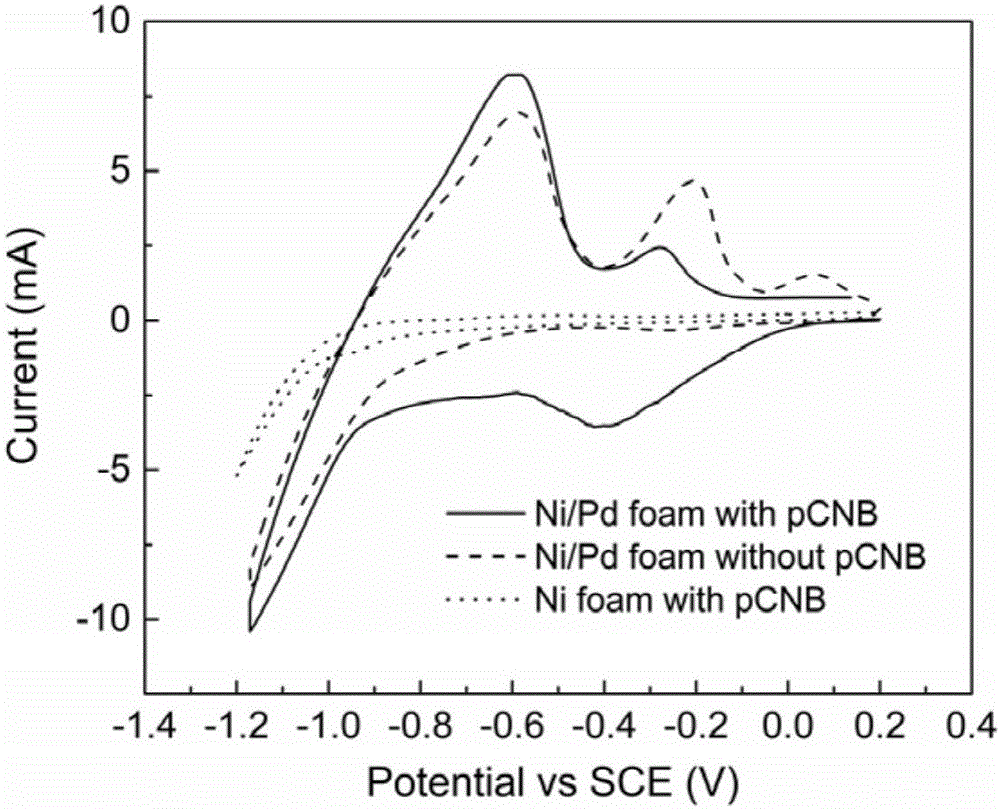

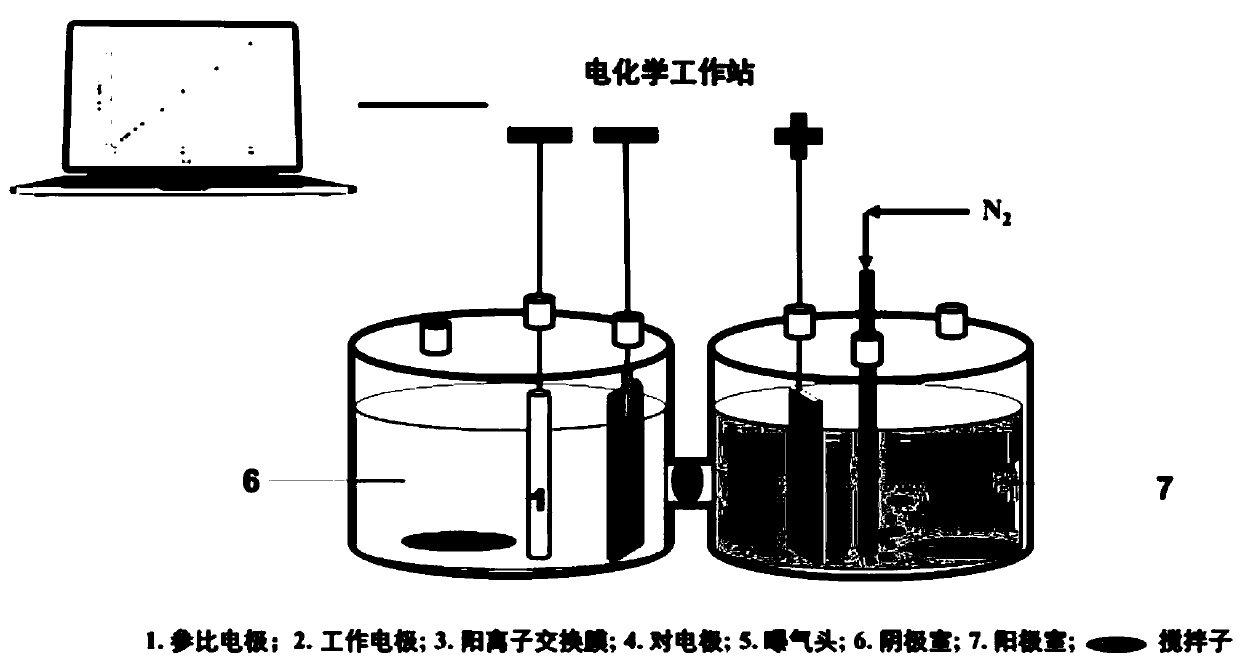

Electrocatalytic dechlorination method for parachloronitrobenzene

InactiveCN105712447AAchieve one-time removalGood dechlorination effectWater contaminantsWater/sewage treatmentChemical treatmentNitrobenzene

The invention discloses an electrocatalytic dechlorination method for parachloronitrobenzene. The method comprises the following steps: loading precious metal palladium on a foam nickel material with a three-dimensional structure by an impregnation method to obtain a cathode of an electrocatalytic reactor; and introducing parachloronitrobenzene-containing wastewater into the electrocatalytic reactor to fill the whole reactor, wherein electrochemical treatment is started under constant current, the parachloronitrobenzene experiences a reduction reaction in a cathode chamber and is reduced into parachloroaniline under the effect of hydrogen radical, and then a dechlorination effect can be realized to form aniline due to the excellent performance of the palladium-containing foam nickel electrode. In the invention, metal reduction is replaced by electrocatalytic reduction, the problems of easy passivation and low mass transfer efficiency of metals are solved, the difficulty in dechlorination of parachloronitrobenzene in the traditional electrode is overcome, and the chlorine group of chloronitrobenzene is effectively removed.

Owner:NANJING UNIV

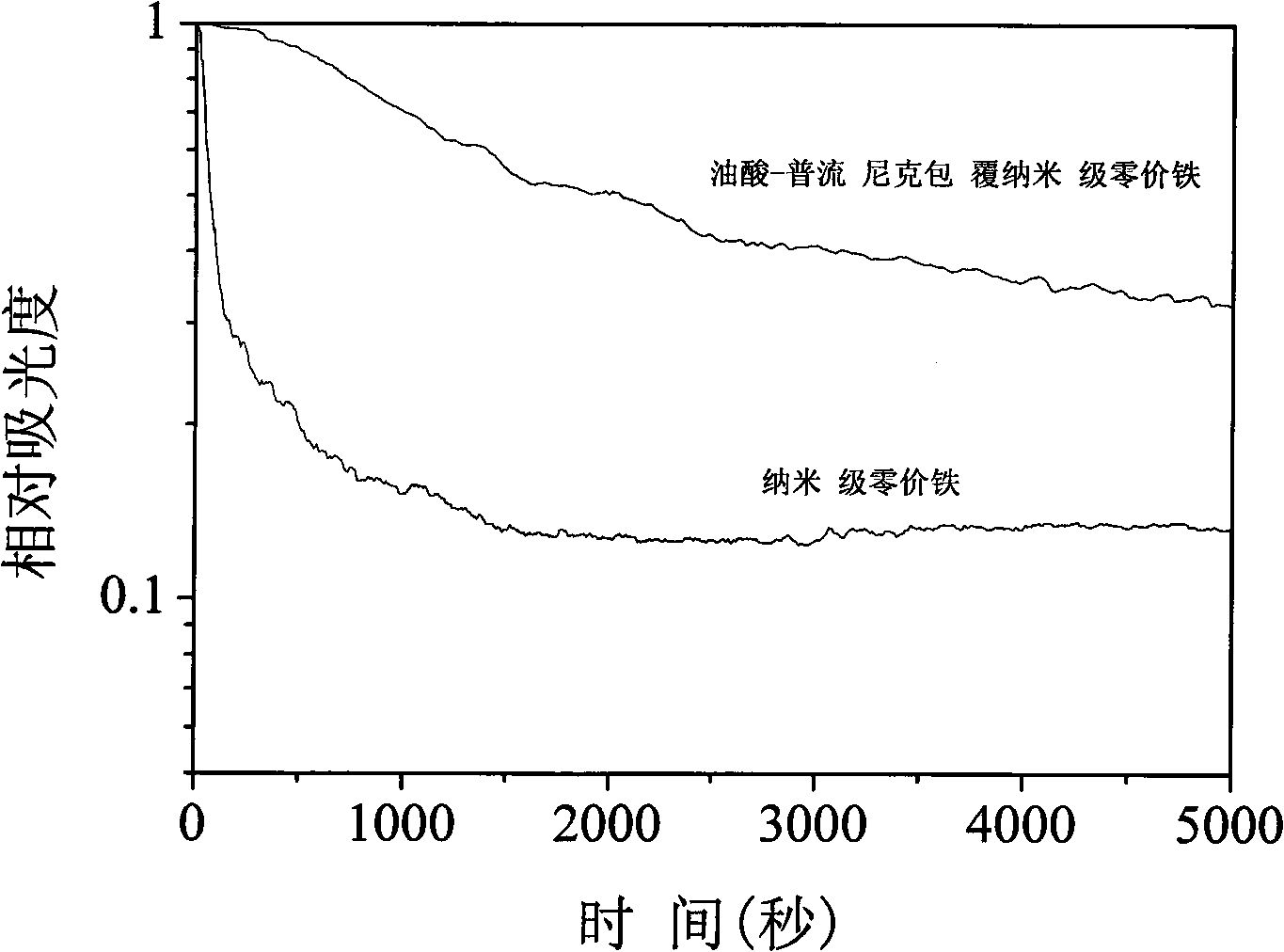

Nanolevel zero-valent iron particle coated with oleic acid-Pluronic and synthetic method thereof

InactiveCN101554661AGood suspensionImprove dechlorination effectCoatingsGroundwater remediationMass ratio

The invention relates to a nanolevel zero-valent iron particle coated with oleic acid-Pluronic and a synthetic method thereof, belonging to the technical field of environmental materials. The invention aims at providing a nanolevel zero-valent iron particle coated with oleic acid-Pluronic which can form stable suspending liquid in water and a synthetic method thereof. The synthetic method comprises the following steps: 1) the nanolevel zero-valent iron particle and the oleic acid with the mass ratio of 4.0:1 to 8.5:1 react for 0.5 to 3 hours under the temperature of room temperature to 80 DEG C to obtain the nanolevel zero-valent iron particle coated with oleic acid; and 2) the nanolevel zero-valent iron particle coated with oleic acid and Pluronic F-127 with the mass ratio of 4.5:1 to 6.5:1 react for 9 to 10 hours under the temperature of the room temperature to 30 DEG C to obtain the nanolevel zero-valent iron particle coated with oleic acid-Pluronic. The invention has the advantages of simple synthetic method and easy operation and repeat and the like; and the obtained nanolevel zero-valent iron particle coated with oleic acid-Pluronic has application prospect in the field of underground water remediation.

Owner:BEIJING UNIV OF CHEM TECH

Method for removing organochlorine in waste lubricating oil

InactiveCN112920842AAvoid harmImprove reaction efficiencyTreatment with plural serial refining stagesLubricant compositionPtru catalystProcess engineering

The invention relates to a method for removing organochlorine in waste lubricating oil. The method comprises the following steps of: dehydrating and purifying the waste lubricating oil containing the organochlorine, adding the waste lubricating oil into a reactor, adding a dechlorinating agent into the reactor, and effectively removing the organochlorine in the waste lubricating oil at a proper temperature and a normal pressure by taking transition metal as an accelerant. The method is mild in conditions, simple and easy to operate, and capable of efficiently removing the organochlorine in the waste lubricating oil at low cost, so the problems of corrosion, pipeline blockage and catalyst poisoning caused by the organochlorine in the waste lubricating oil to a subsequent hydrogenation device are solved.

Owner:WUHAN KELIN FINE CHEM

Preparation and regeneration method of circulating copper salt dechlorinating agent

InactiveCN110747344AGuaranteed purityImprove dechlorination effectProcess efficiency improvementSulfate zincChloric acid

The invention relates to the technical field of wet smelting, and specifically relates to a preparation and regeneration method of a circulating copper salt dechlorinating agent. The preparation and regeneration method comprises the following steps: 1) preparation; 2) alkali washing; 3) rinsing; 4) dechlorination; 5) acid pickling; 6) regeneration; 7) copper deposition; 8) oxidation; and 9) leaching. The invention aims to provide the method for preparing the regenerated copper salt dechlorinating agent to solve the problems of process defects and deficiencies of an existing dechlorination technology of a chlorine-containing zinc sulfate solution, low dechlorination efficiency of a copper slag dechlorination method, insufficient self-yield of copper slag and copper salt and the like. The method can recycle the main component copper metal of the copper salt dechlorinating agent infinitely, and achieves the advantages of low production cost, relatively simple operation, recycling of the dechlorinated copper salt, good dechlorination effect and the like, so as to solve the deficiencies in the prior art.

Owner:GREENNOVO ENVIRONMENTAL TECH CO LTD

Gaseous phase dechlorinating agent and preparation method thereof

ActiveCN105617853AImprove dechlorination activityHigh strengthGas treatmentDispersed particle separationDesorptionNuclear chemistry

The invention provides a gaseous phase dechlorinating agent. The gaseous phase dechlorinating agent is prepared from the following components in percentage by weight: 15 to 30 weight percent of calcium carbonate, 10 to 35 weight percent of magnesium carbonate, 7.2 to 10.8 weight percent of calcium oxide and 48 to 65 weight percent of aluminate cement. According to the dechlorinating agent provided by the invention, by using the characteristic that the calcium carbonate and the magnesium carbonate are used to generate a regular sandwich structure, chlorine is adsorbed more favorably, the dechlorinating activity is improved, and the breakthrough chlorine content of the dechlorinating agent at 300DEG C is as high as 55 percent; in addition, the strength can be improved, and the side pressure strength of the dechlorinating agent when clay is not used is as high as 110N / cm, so that the clay is prevented from being used and further the sintering of the dechlorinating agent is effectively prevented; meanwhile, by using high hygroscopicity of calcium oxide, the calcium oxide absorbs water and is converted into calcium hydroxide with higher alkalinity, so that the absorbing ability for hydrogen chloride is promoted, the dechlorinating precision is improved, the desorption of chlorine from the dechlorinating agent is hindered, the condition that water and metal chloride generated by chlorine absorption of the dechlorinating agent generate a coordination reaction is prevented, the damage to a dechlorinating agent structure and the blockage of an internal pore canal are avoided, and the chlorine capacity of the dechlorinating agent is effectively improved.

Owner:SHENYANG SANJUKAITE CATALYST

Technological method of removing hydrogen chloride through powder injection of blast furnace gas pipeline and device of removing hydrogen chloride through powder injection of blast furnace gas pipeline

ActiveCN111378801AImprove uniformityImprove sufficiencyBlast furnace detailsIncreasing energy efficiencyChemistryPulverizer

The invention discloses a technological method of removing hydrogen chloride through powder injection of a blast furnace gas pipeline and a device of removing hydrogen chloride through powder injection of the blast furnace gas pipeline. The device utilizing the technology of adopting blast furnace gas pipeline powder injection to remove hydrogen chloride adopts the dry type blast furnace gas injecting dechloridation technology to remove hydrogen chloride; a dechlorination agent bag-type dust collector hopper, a pulverizer and a draught fan are sequentially mounted on a pipeline behind a dry process coarse dust remover and in front of the bag-type dust collector of the existing device; and the condition of blast furnace gas in an outlet pipeline of the dry process coarse dust remover is set; through grinding, the dechlorination agent obtains a larger specific surface area, and the ground dechlorination agent is directly injected in the blast furnace gas pipeline for dechloridation reaction through the powder injection manner. With adoption of the technical scheme, the one-time investment is less, the occupied area is small, and the system is simple in operation and convenient to maintain. The technology can effectively improve the contact uniformity and sufficiency of the dechlorination agent and blast furnace gas, improves the dry process dechlorination effect, is low in heat loss of blast furnace gas and does not affect later application of TRT.

Owner:BEIJING PEKING UNIV PIONEER TECH

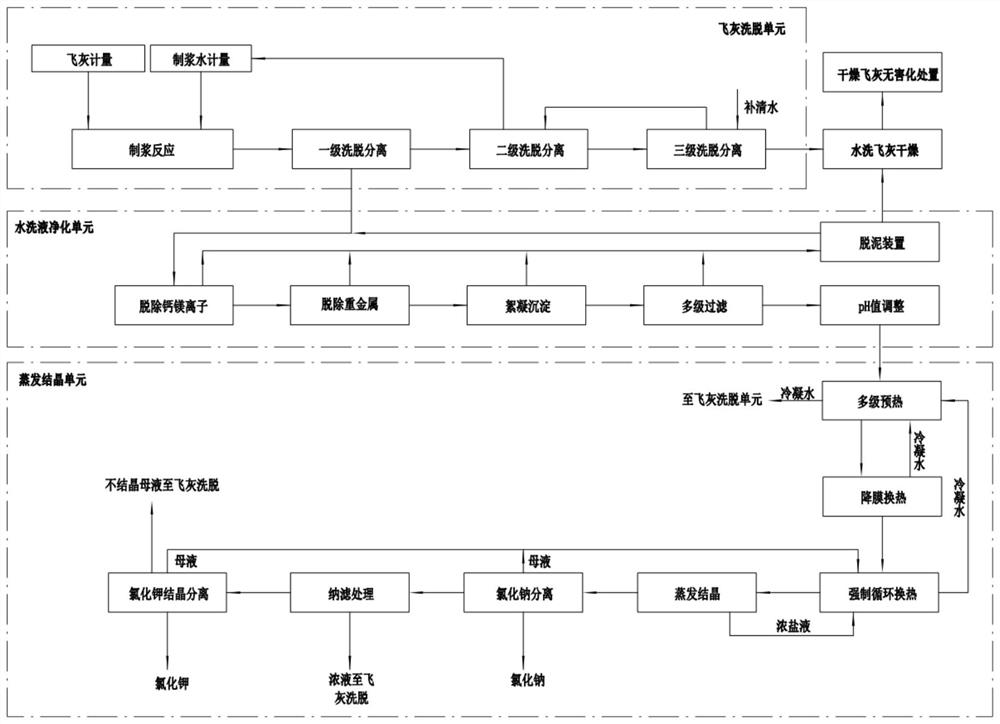

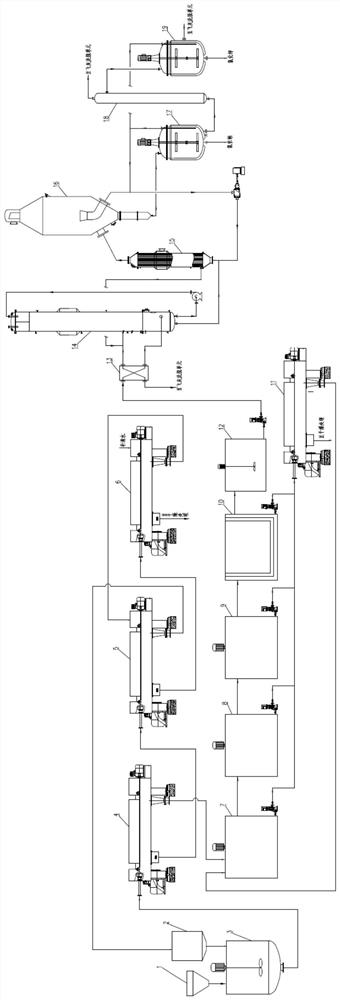

Treatment method and system for washing and dechlorinating waste incineration fly ash and evaporating, grading and crystallizing washing liquid

PendingCN113105138ALow leaching rateReduce water consumptionAlkali metal chloridesNanofiltrationAlkaline water

The invention discloses a treatment method and system for washing and dechlorinating waste incineration fly ash and evaporating, grading and crystallizing washing liquid. The method comprises the following steps: pulping the waste incineration fly ash, and performing multi-stage elution to obtain washed fly ash and washing liquid; purifying the water washing liquid to obtain clear liquid and precipitated slurry; adjusting the pH value of the clear liquid to obtain an evaporation raw material liquid, and sequentially carrying out preheating, falling film heat exchange, forced circulation heat exchange, evaporative crystallization treatment, sodium chloride crystallization separation, nanofiltration membrane treatment and potassium chloride crystallization separation to obtain potassium chloride and sodium chloride products; and obtaining sludge and clear liquid through desliming treatment of the sediment slurry, and obtaining fly ash through drying the sludge and the washed fly ash. The multi-stage countercurrent and alkaline water washing technology is adopted, water consumption is low, raised dust is avoided, the dechlorination effect is good, and the heavy metal leaching rate is low; divalent ions in feed liquid are intercepted by adopting a and nanofiltration membrane treatment technology, so that the quality of crystalline salt is effectively improved, long-term stable operation of the system can be ensured, and cyclic utilization and zero emission of process water are realized while the consumption of clear water is reduced.

Owner:BEIJING ZKGR ENVIRONMENTAL PROTECTION TECH CO LTD

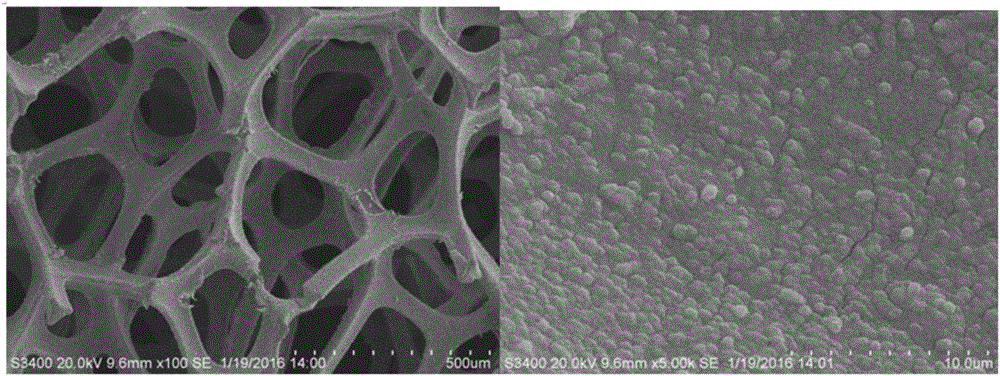

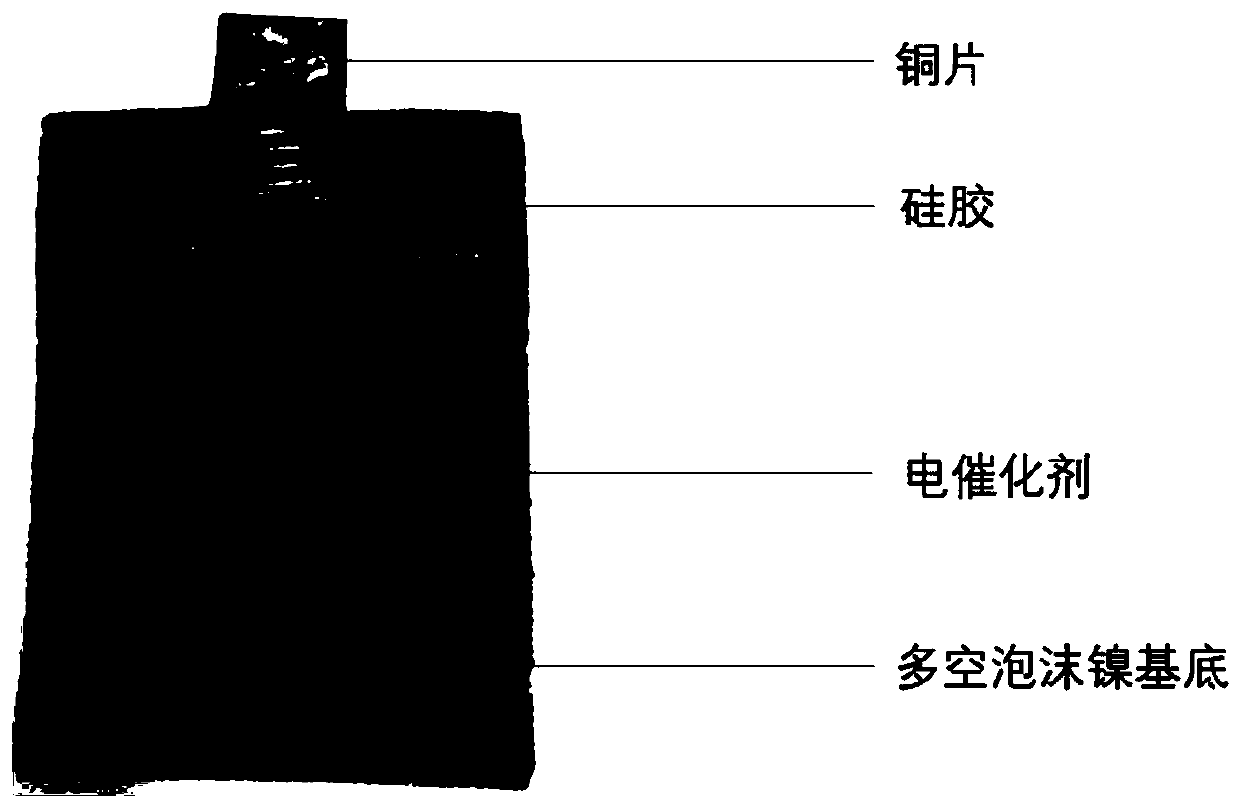

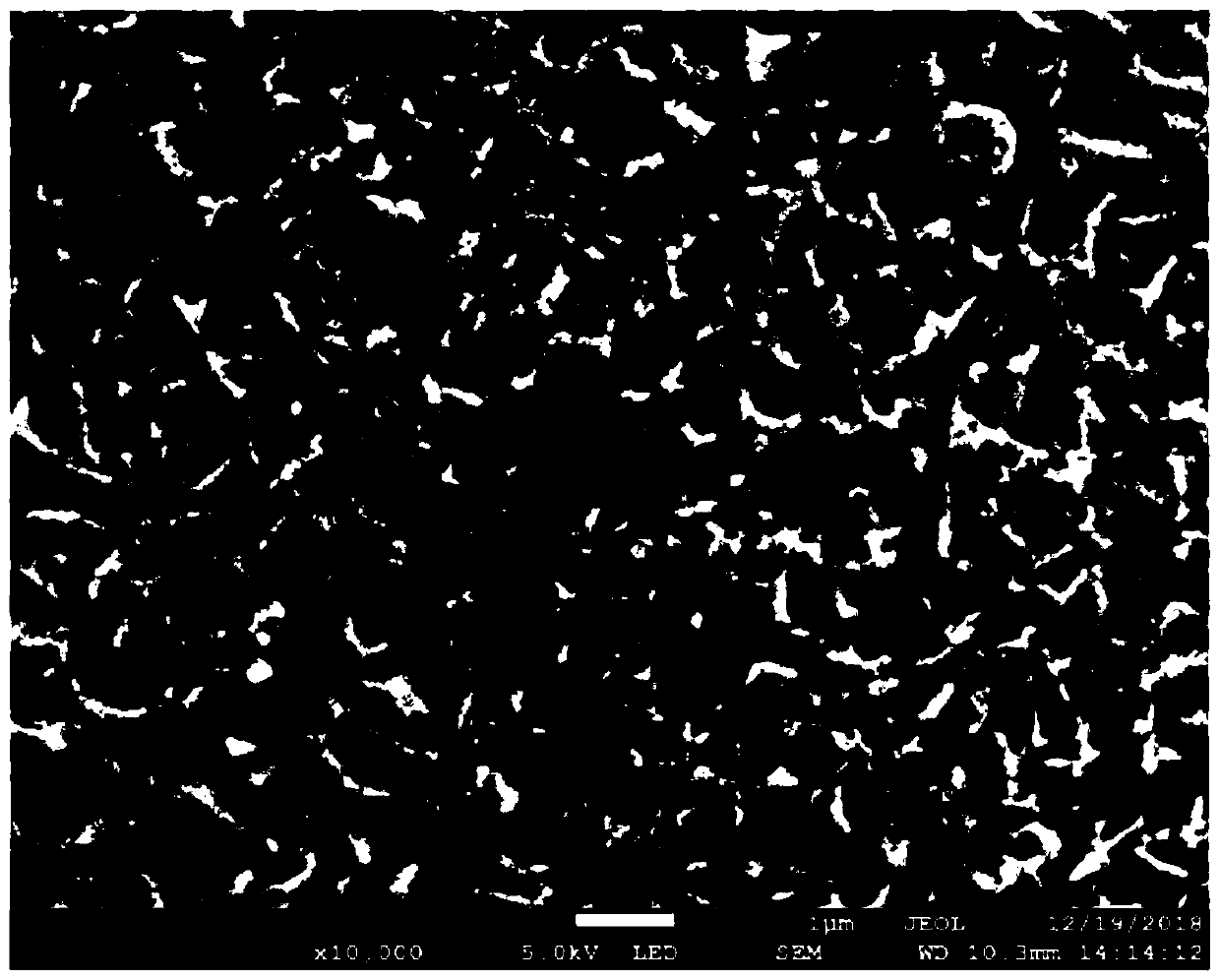

Pd/MnO2-Ni electrode as well as preparation method and application thereof

ActiveCN110713233ASmall particle sizeIncrease active exposure areaWater contaminantsWater/sewage treatmentPd nanoparticlesNanoparticle

The invention discloses a Pd / MnO2-Ni electrode as well as a preparation method and application thereof. The Pd / MnO2-Ni electrode takes porous foamed nickel as an electrode substrate, and MnO2 and Pd nanoparticles are loaded on the porous foamed nickel. According to the Pd / MnO2-Ni electrode, the use amount of Pd is reduced while the catalytic efficiency is improved, compared with a traditional Pd / Celectrode and a Ni / Pd electrode, the Pd / MnO2-Ni electrode has obviously improved activity and remarkably improved dechlorination effect.

Owner:CHONGQING TECH & BUSINESS UNIV

Dechlorinating Agent for Blast Furnace Top Gas

InactiveUS20160271586A1Long breakthrough timeHigh primary breakthrough chlorine contentGas treatmentOther chemical processesWater useSodium Bentonite

A dechlorinating agent for blast furnace top gas prepared by the steps of: Selecting industrial limestone, commercial sodium carbonate and potassium hydroxide; Soaking the raw industrial limestone in a potassium hydroxide solution, wherein the concentration of the potassium hydroxide solution is 10%-15%; Heating the soaked limestone at 700° C. for calcination; Grinding the light-burned limestone obtained by calcining the limestone and sodium carbonate until the particle size is below 20 μm; Mixing the light-burned limestone and the sodium carbonate at a proportion of 30-70:70-30 for 10-15 min; Grinding the resultant mixture by milling process until the particle sizes of all powders are less than 80 μm; Adding 3% bentonite in the prepared mixing powder and fully mix the mixture; Pelletizing the mixture with atomized water using a disc pelletizer; and selecting pellets of 3-10 mm in size; Drying the said pellet naturally or at a temperature below 100° C.

Owner:NORTH CHINA UNIVERSITY OF SCIENCE AND TECHNOLOGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com