Novel efficient dechlorinating agent and preparation method thereof

A dechlorination agent and high-efficiency technology, applied in the field of dechlorination of oil products, can solve the problems of restricting the industrial application and production preparation of dechlorination agents, strict temperature conditions, and insufficient lateral pressure strength of dechlorination agents, so as to improve the use of Value, improvement of utilization rate, effect of improvement of dechlorination effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

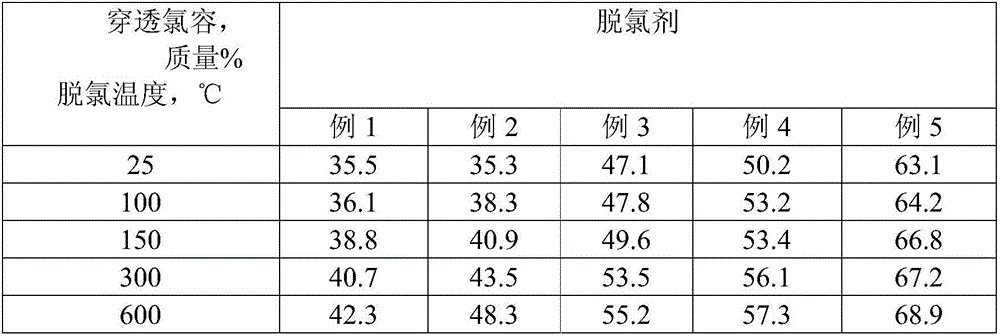

Examples

Embodiment 1

[0028] Weigh 37gAlCl 3 ·6H 2 O, 18gCaCl 2 , 10.2gZnCl 2 and 29g NaOH; first dissolve NaOH with 1kg of 298K deionized water, pour it into the reactor and place it in a 298K water bath, then dissolve and mix the above-mentioned weighed metal salt with 0.4kg of deionized water, and slowly add it dropwise to the previous configuration In the lye, stir vigorously, filter after the reaction is completed, wash with a solution mixed with ethanol and deionized water at a mass ratio of 1:1 until the filtrate is neutral, and dry it naturally for use.

[0029] Weigh 150gCaCO 3 , 60gNa 2 CO 3 , 24.5gCuO, 7gNH 4 HCO 3 , 225g clay; put the above powder and the dried filter cake into a vibrating grinder for grinding and mixing, and pass through a 200-mesh sieve, take the sieved mixed powder, add 150g water, and grind it in a kneader at 30r / min After kneading for 10 minutes, the material was in the form of paste. Take out the above paste material and extrude it with a 3mm round hole d...

Embodiment 2

[0031] Weigh 56gAlCl 3 ·6H 2 O, 27gCaCl 2 , 10.2gZnCl 2 and 125g of ammonia water; first dissolve the ammonia water with 0.9kg of 298K deionized water, pour it into the reactor and place it in a 318K water bath, then dissolve and mix the above-mentioned weighed metal salt with 0.6kg of deionized water, and slowly add it dropwise to In the previously prepared lye, stir vigorously, filter after the reaction is completed, wash with a solution mixed with ethanol and deionized water at a mass ratio of 3:1 until the filtrate is neutral, and dry it naturally for use.

[0032] Weigh 200gCaCO 3 , 40gNa2 CO 3 , 10gMgO, 3gCuO, 3gZnO, 8gNH 4 HCO 3 , 115g clay, 100g boehmite; the above powder and the dried filter cake are put into a vibrating grinder to grind and mix evenly, and pass through a 200 mesh sieve, take the sieved mixed powder, add 175g water, and knead After kneading in the machine at 30r / min for 10min, the material is in the form of paste. Take out the above paste mate...

Embodiment 3

[0034] Weigh 56gAlCl 3 6H2O, 27g CaCl 2 , 20.4gZnCl 2 and 96.6gNaHCO 3 ; First NaHCO 3 Dissolve with 1.3kg of 333K deionized water, pour it into the reactor and place it in a 353K water bath, then dissolve and mix the above-mentioned weighed metal salt with 0.65kg of deionized water, and slowly add it dropwise to the previously prepared lye, Stir vigorously, filter after the reaction is complete, wash with ethanol and deionized water at a mass ratio of 3:1 for several times until the filtrate is neutral, and dry it naturally for use.

[0035] Weigh 180gCaCO 3 , 40gNa 2 CO 3 , 10gMgO, 3gCuO, 20gZnO, 10gNH 4 HCO 3 , 115g white clay, 100g pseudo-boehmite; the above powder and the dried filter cake are put into a vibratory grinder to grind and mix evenly, and pass through a 200 mesh sieve, take the sieved mixed powder, add 180g water, and After kneading at 40r / min for 8min in the kneader, the material is in the form of paste. Take out the above paste material and extrude...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com