Method for preparing palladium carried metal-based electrode used for electro-catalysis of chlore-aromatics for dechlorination

A chlorinated aromatic hydrocarbon and electrocatalysis technology, which is applied to electrodes, electrolysis processes, electrolysis components, etc., can solve the problems of simple process, inability to effectively control palladium deposition morphology, electrocatalytic electrode fabrication, etc., and achieve high catalytic activity and improve economy. and practicality, the effect of simple and easy process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

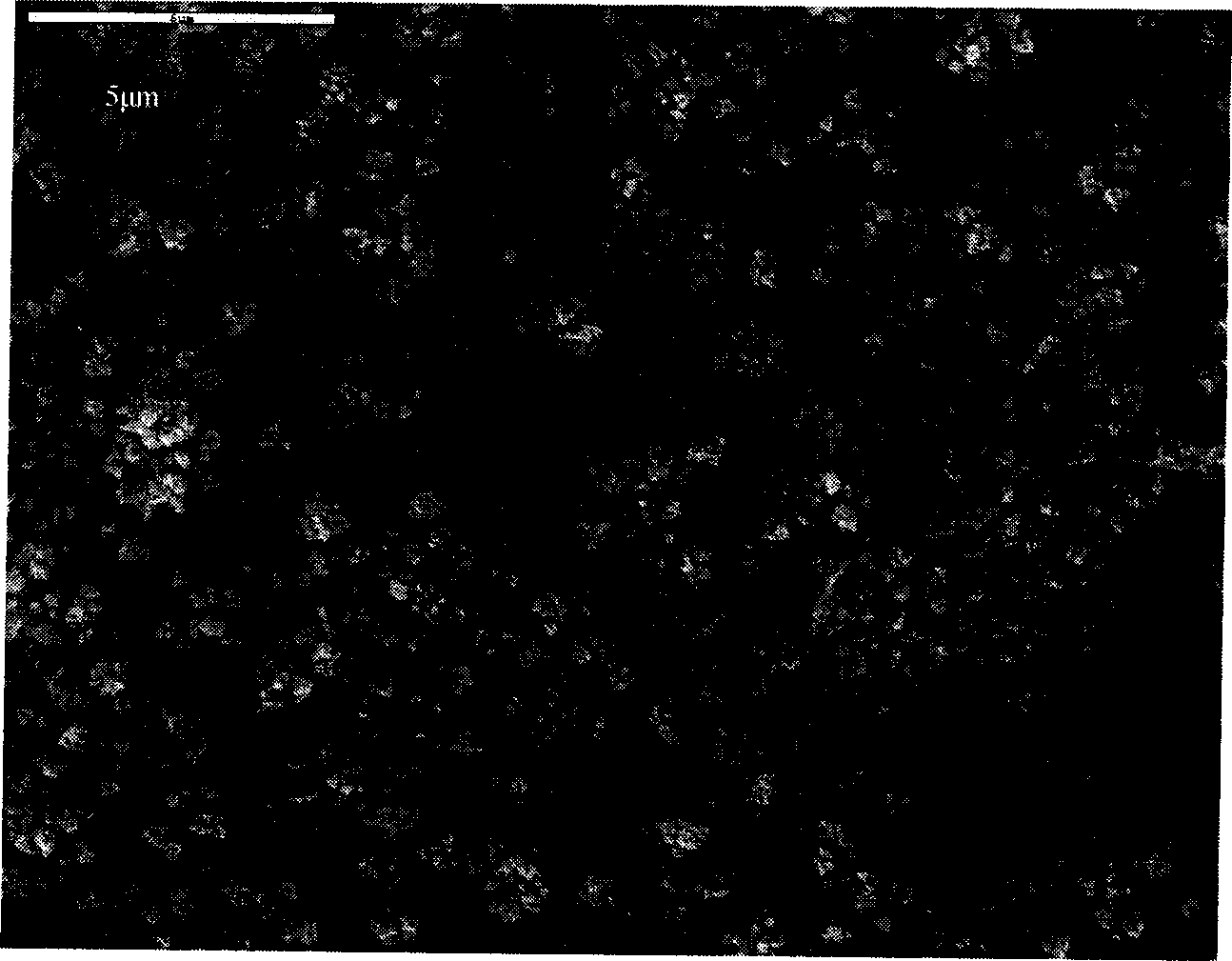

[0029] Embodiment one: palladium loading of foamed nickel base material

[0030] The cutting size is 1.6mm thick and the specific surface area is 1.35×10 6 m 2 / m 3 Nickel foam is loaded according to the following steps:

[0031] 1) Prepare a mixed deposition solution of palladium chloride with a concentration of 5mM and sodium acetate with a concentration of 50mM at a molar ratio of 1:10, in a water bath at 60°C, ultrasonic for about 1 hour, the color of the solution changes from yellow to dark brown at last , and then moved to a single-chamber electrolytic cell using a three-electrode system. Put it into acetone solution for 40 minutes to remove oil, take it out, rinse it with water, put it into 80g / L sulfuric acid solution for ultrasonic etching for 30s, take it out, wash it with water and drain it, and then use it as the working electrode of the three-electrode system. In the deposition solution, and connect the counter electrode (platinum black) and reference electrode...

Embodiment 2

[0033] Embodiment two: palladium loading of foamed copper matrix material

[0034] The cutting size is 1.6mm thick and the specific surface area is 1.35×10 6 m 2 / m 3 The foamed copper matrix material is loaded according to the following steps:

[0035] 1) Prepare a mixed deposition solution of palladium chloride with a concentration of 5mM and sodium acetate with a concentration of 75mM at a molar ratio of 1:15. Under a water bath at 60°C, ultrasonically for about 1 hour, the color of the solution changes from yellow to dark brown at the end , and then moved to a single-chamber electrolytic cell using a three-electrode system. Put it into acetone solution for 40min to remove oil, take it out, rinse it with clean water, put it into 80g / L sulfuric acid solution for 5s etching, take it out, wash it with clean water and drain it, and then use it as the working electrode of the three-electrode system for immersion deposition solution, and connect the counter electrode (platinu...

Embodiment 3

[0037] Embodiment three: palladium loading of industrial titanium mesh matrix material

[0038] Cut out an industrial titanium mesh with a size of 40 mesh and a wire diameter of 0.17mm, and load it according to the following steps:

[0039] 1) Prepare a mixed deposition solution of palladium chloride with a concentration of 5mM and sodium acetate with a concentration of 100mM at a molar ratio of 1:20. Under a water bath at 60°C, ultrasonically for about 1 hour, the color of the solution changes from yellow to dark brown at last , and then moved to a single-chamber electrolytic cell using a three-electrode system, the amount of liquid added is based on the final metal substrate that can be completely immersed in the desired deposition, and kept stirring and heating (40 ° C), during which the industrial titanium mesh substrate material to be loaded Put into 5% (mass percentage) Na 2 CO 3 Boil in the solution for 30 minutes to remove oil, take it out, rinse it with clean water,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com