Nanolevel zero-valent iron particle coated with oleic acid-Pluronic and synthetic method thereof

A Pluronic package and Pluronic technology, applied in the field of oleic acid-Pluronic coating of nano-scale zero-valent iron particles and their synthesis, can solve the problems of decreasing specific surface area, affecting reactivity, affecting movement, etc. Easy to operate, reproducible, and simple to synthesize effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] 1) Weigh 3.75 grams of FeSO 4 ·7H 2 O and 1.20 g NaBH 4 , were dissolved in 50 ml deoxygenated deionized water, and the NaBH 4 aqueous solution was added dropwise to FeSO 4 ·7H 2 Black nano-sized zero-valent iron particles are generated in the O aqueous solution, and the stirring is continued for 10 minutes, and then the N 2 The nanoscale zero-valent iron particles were washed 3 times with deoxygenated deionized water under certain conditions;

[0019] 2) The nanoscale zero-valent iron particles prepared in step 1) are made into 150 milliliters of suspensions with deoxygenated deionized water, and the pH value is adjusted to 9 with a concentration of 0.5 mol / liter of NaOH aqueous solution, and 0.1 milliliters of oleic acid is added, at 80 Stirring and reacting at ℃ for 0.5 hours, performing solid-liquid separation with a centrifuge, washing the obtained solid three times with absolute ethanol and deoxygenated deionized water successively, to obtain nano-sized zero-...

Embodiment 2

[0024] 1) with step 1) among the embodiment 1;

[0025] 2) Prepare 150 ml of suspension of the nanoscale zero-valent iron particles prepared in step 1) with deoxygenated and deionized water, add 0.2 ml of oleic acid, stir and react at 30° C. for 3 hours, and use a centrifuge to separate the solid and liquid. Washing the obtained solid three times with absolute ethanol and deoxygenated deionized water successively to obtain nano-scale zero-valent iron particles coated with oleic acid;

[0026] 3) Make 150 ml suspension of oleic acid-coated nano-scale zero-valent iron particles prepared in step 2) with deoxygenated deionized water, add 0.2 g of Pluronic F-127, and stir at 30°C for 10 hours , the obtained solid was ultrasonically washed 6 times with deoxygenated deionized water, and then dried in a vacuum oven at 50° C. for 3 hours to obtain nano-sized zero-valent iron particles coated with oleic acid-pluronic.

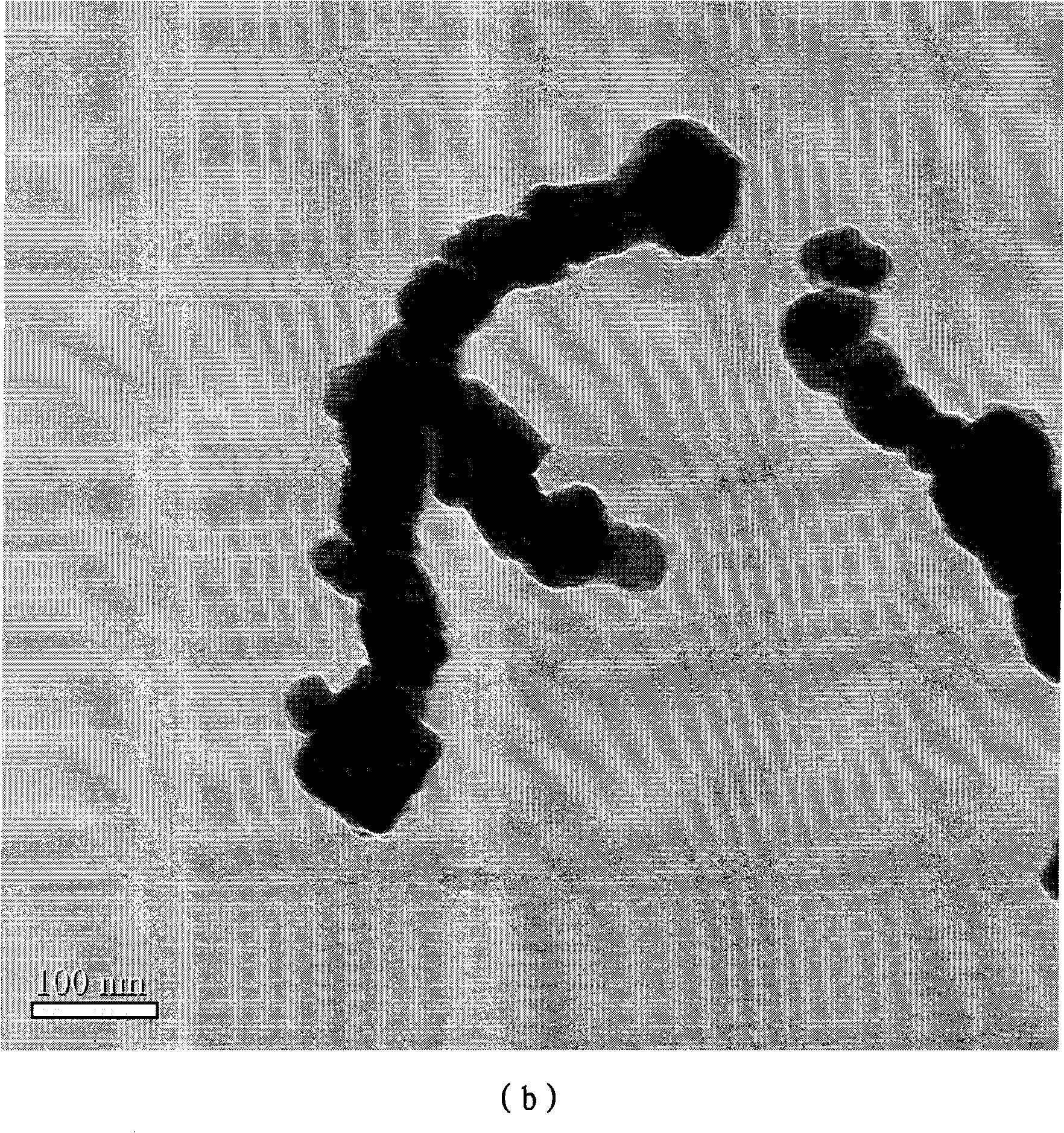

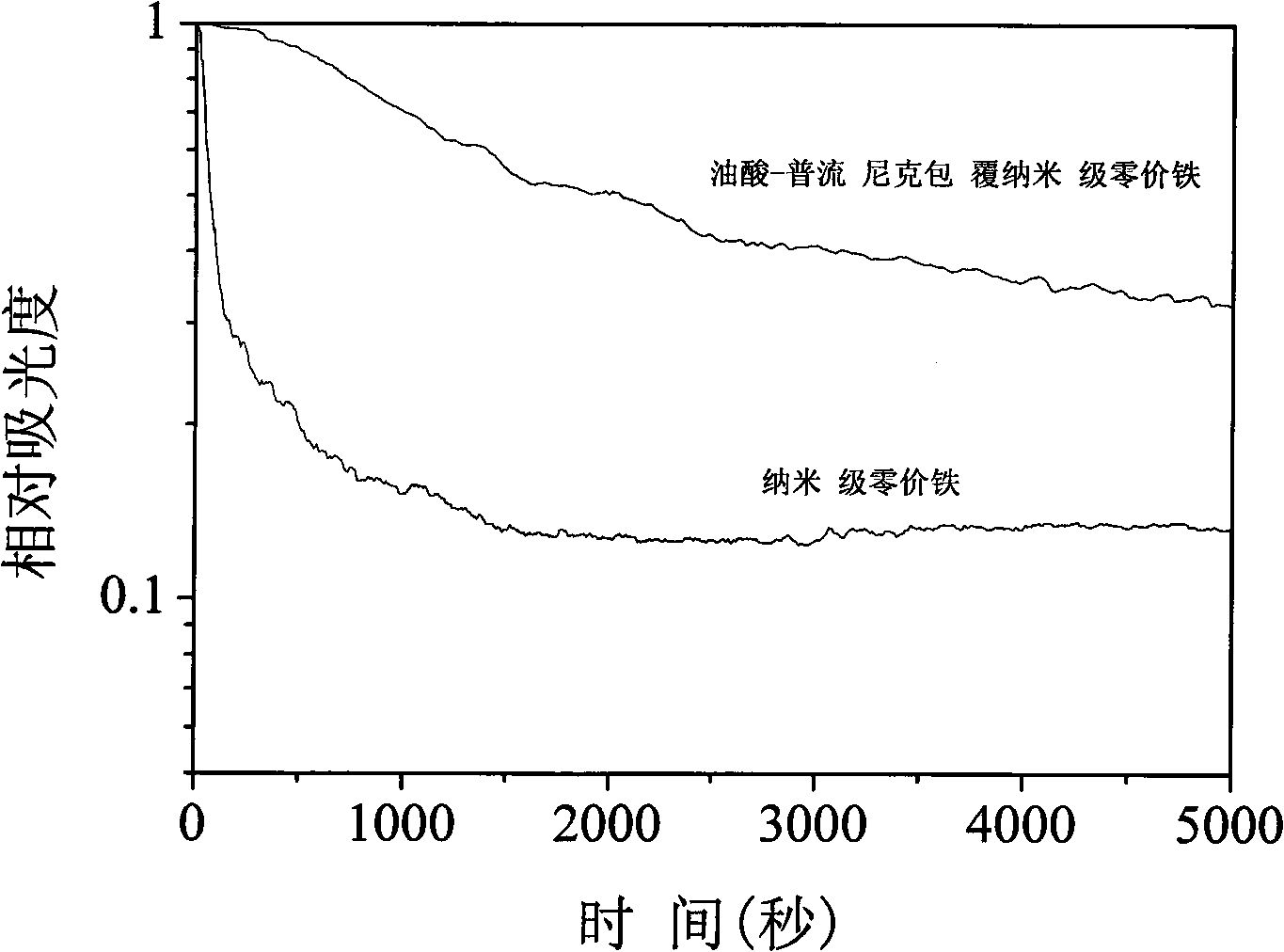

[0027] Depend on image 3 It can be seen that the nanoscale zero-...

Embodiment 3

[0029] 1) with step 1) among the embodiment 1;

[0030] 2) The nanoscale zero-valent iron particles prepared in step 1) were made into 150 ml of suspension with deoxygenated deionized water, and 0.17 ml of oleic acid was added, stirred and reacted at room temperature for 3 hours, and solid-liquid separation was carried out with a centrifuge. The obtained solid was washed three times with absolute ethanol and deoxygenated deionized water successively to obtain nano-scale zero-valent iron particles coated with oleic acid;

[0031] 3) The oleic acid-coated nano-scale zero-valent iron particles prepared in step 2) were used to make 150 ml of suspension with deoxygenated deionized water, and after adding 0.15 g of Pluronic F-127, the reaction was stirred at room temperature for 10 hours, The obtained solid was ultrasonically washed 6 times with deoxygenated deionized water, and then dried in a vacuum oven at room temperature for 24 hours to obtain nano-sized zero-valent iron partic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com