Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

67 results about "Bismuth hydroxide" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Bismuth hydroxide (Bi(OH)₃) is non-fully characterised chemical compound of bismuth. It is produced as white flakes when alkali is added to a solution of a bismuth salt and is usually described as bismuth oxide hydrate or bismuth hydrate. Bismuth hydrate is a component used in milk of bismuth which is used in gastrointestinal disorders as a protective agent. Aqueous ammonia reacts with bismuth(III) ions to precipitate white bismuth hydroxide.

Novel Ethynylation Catalyst And Method Of Making Same

ActiveUS20140275639A1Convenient coatingOrganic compound preparationHeterogenous catalyst chemical elementsCopperBismuth hydroxide

A novel catalyst useful in the ethynylation of formaldehyde to butynediol is formed by precipitating copper and bismuth from a salt solution of such metals, utilizing an alkali metal hydroxide as the precipitating agent to deposit copper and bismuth hydroxide as a coating around a siliceous carrier particle.

Owner:BASF CORP

Electrodeposition paint

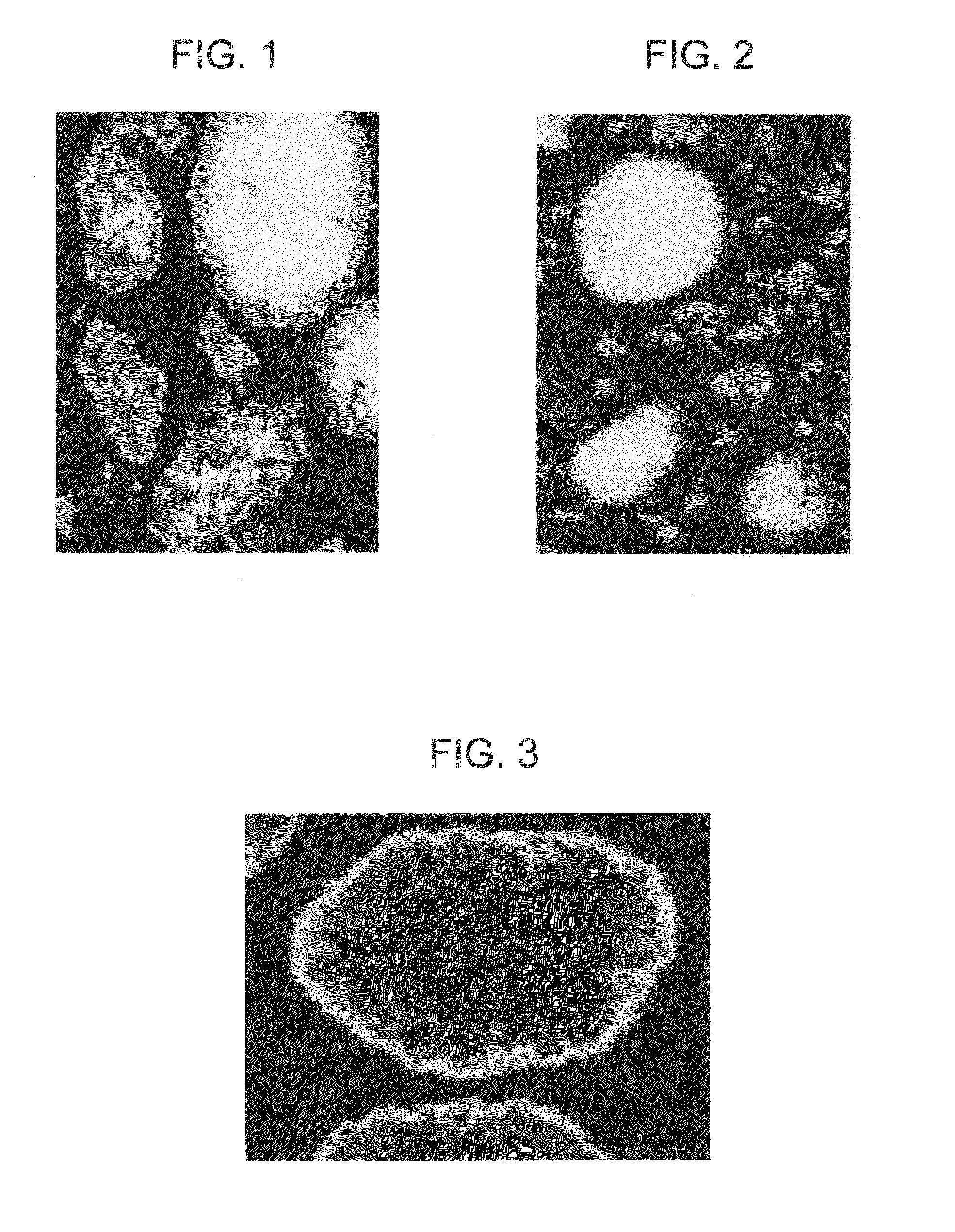

InactiveUS20070149655A1Improve corrosion resistanceExcellent finished appearanceSurface reaction electrolytic coatingPolyurea/polyurethane coatingsBismuth hydroxideMetal

This invention provides an electrodeposition paint comprising particles of at least one metallic compound selected from bismuth hydroxide, zirconium compound and tungsten compound, said particles of the metallic compound having an average particle diameter of 1-1,000 nm. The electrodeposition paint forms coating film excelling in corrosion resistance, finished appearance, paint stability and so on.

Owner:KANSAI PAINT CO LTD

Method for removing chlorine in manganese electrolyte or zinc electrolyte

InactiveCN102839283ASimple processEasy to operatePhotography auxillary processesProcess efficiency improvementElectrolysisDechlorinator

The invention relates to a method for removing chlorine in manganese electrolyte or zinc electrolyte. The method comprises the steps of: adding a certain quantity of bismuth (III)-containing antichlor into chloridion-containing manganese electrolyte or chloridion-containing zinc electrolyte by means of continuous stirring; adjusting the pH value of the solution at 1.0-5.0, so that the trivalent bismuth ions are hydrolyzed to generate insoluble bismuth oxychloride precipitate on the premise of chloridion; filtering, wherein the filter liquor is used for the follow-up electrolysis production technology; and regenerating filter residue bismuth oxychloride precipitate by an alkaline solution to generate bismuth hydroxide for recycling, and timely adding a small quantity of antichlor in the process of recycling to compensate the loss in the process of regeneration.

Owner:JISHOU UNIVERSITY

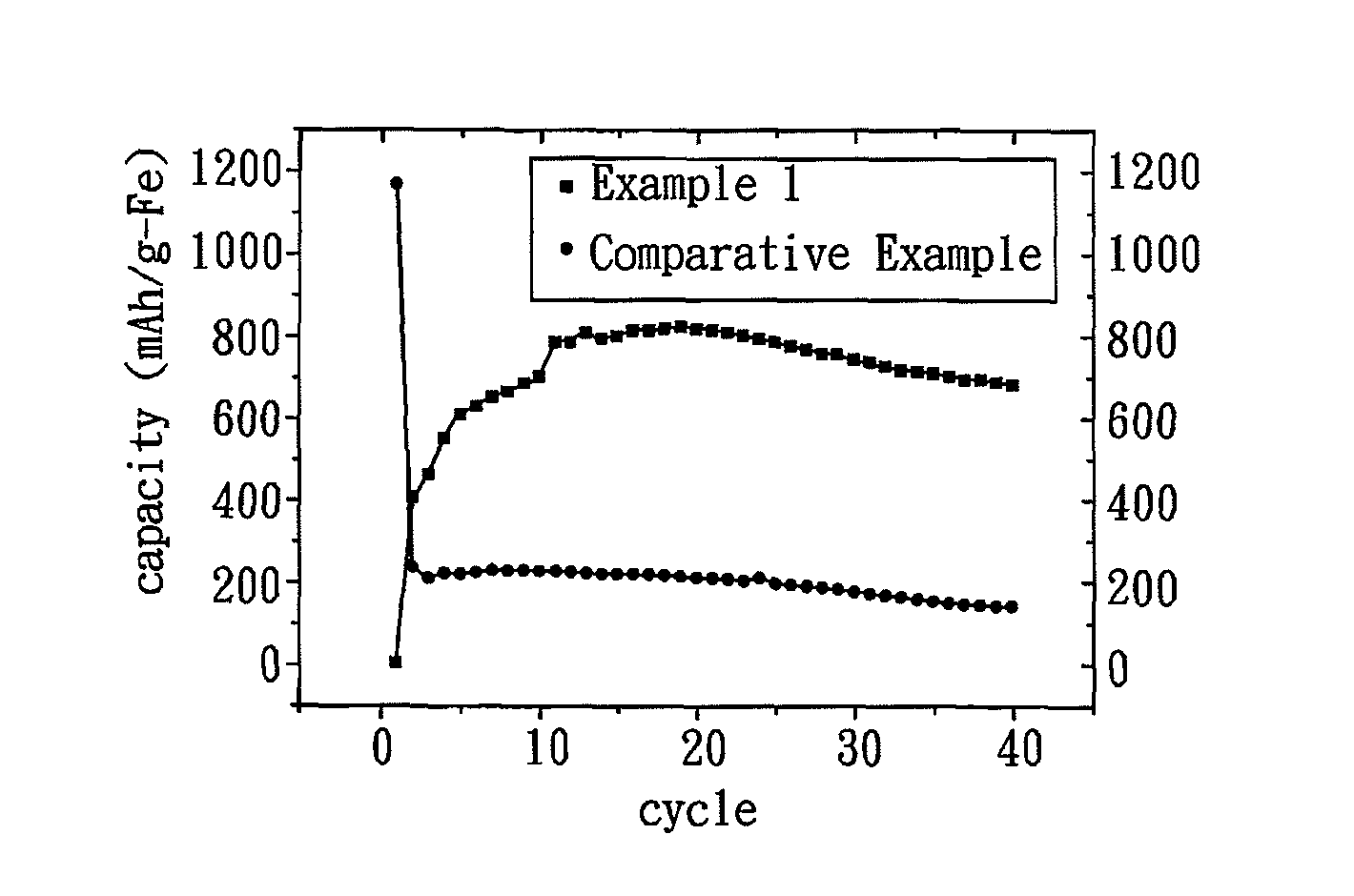

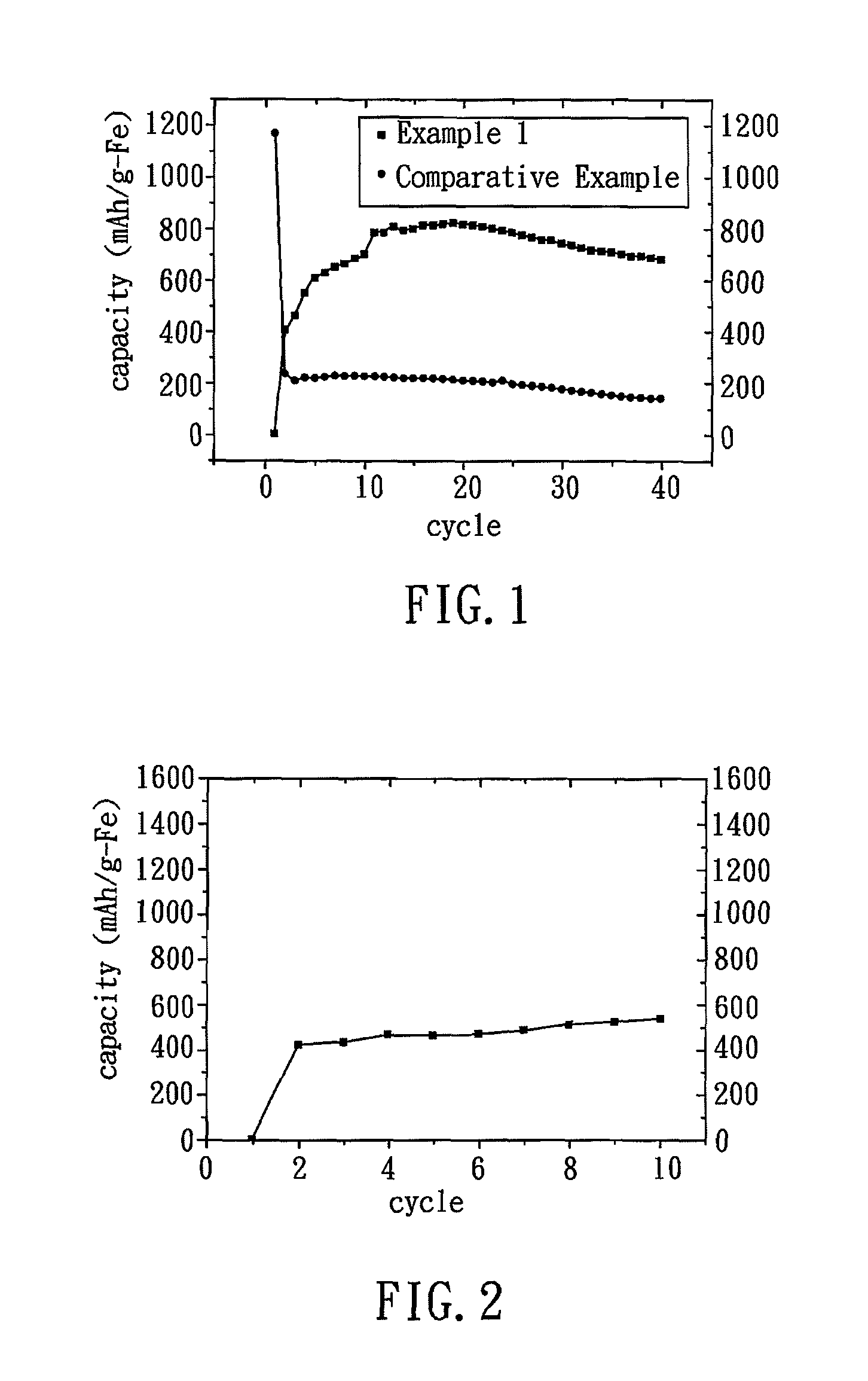

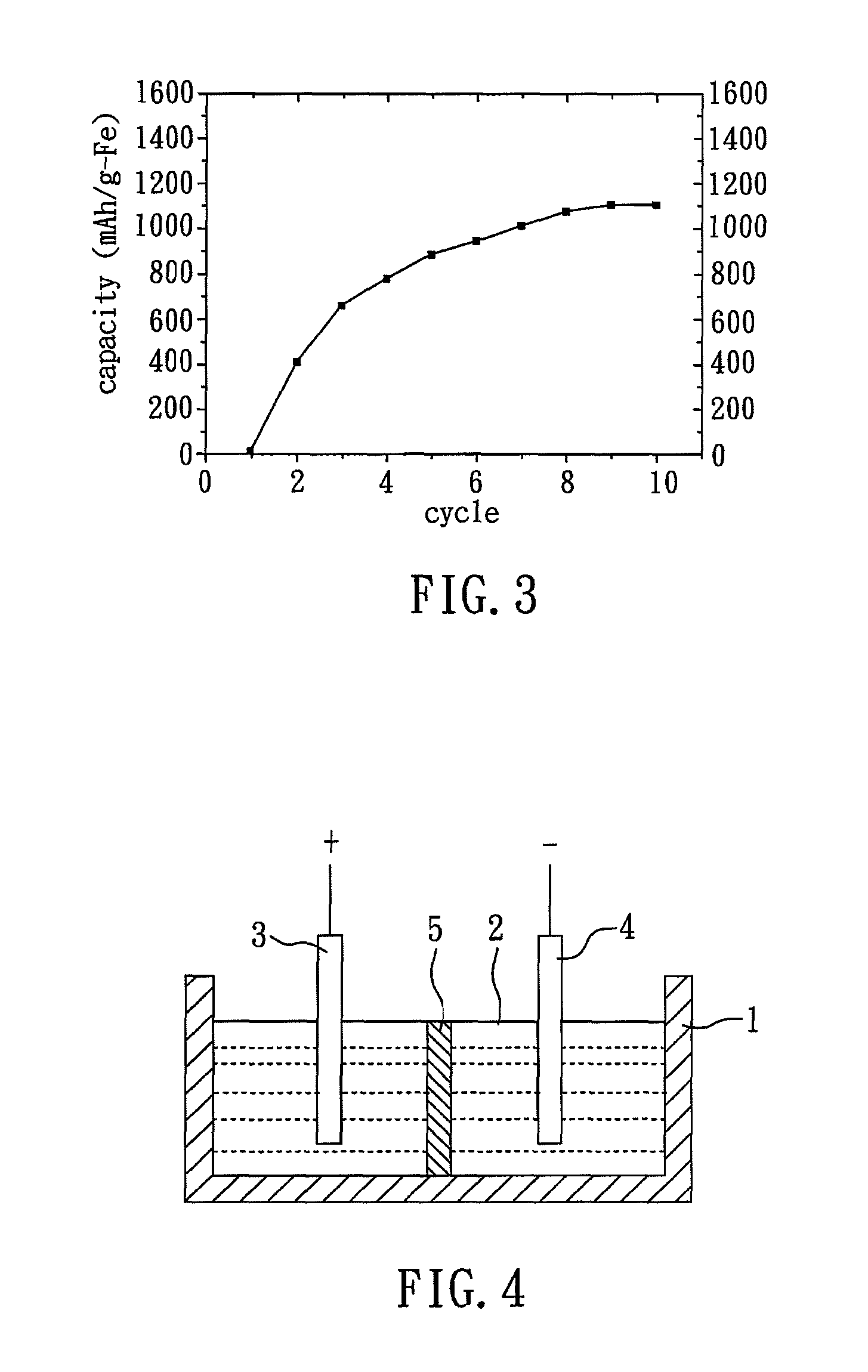

Cathode electrode composite material and preparation method thereof and electrochemical device applying same

InactiveCN102214822ASimple processReduce manufacturing costAlkaline accumulator electrodesNickel accumulatorsIndiumNickel salt

The invention discloses a cathode electrode composite material, which comprises a plurality of ferriferous oxide particles and a conductive aid which is selected from copper, cobalt, nickel, tin, antimony, bismuth, indium, silver, gold, lead, cadmium, carbon black, graphite, cupric salt, cobalt salt, nickel salt, tin salt, antimonic salt, bismuth salt, indium salt, silver salt, gold salt, lead salt, cadmium salt, cupric hydroxide, cobalt hydroxide, nickel hydroxide, tin hydroxide, stibine hydroxide, bismuth hydroxide, indium hydroxide, silver hydroxide, gold hydroxide, lead hydroxide, cadmium hydroxide and a group consisting of the combinations. When applied to an electrochemical device, the cathode electrode composite material can show high charging and discharging characteristics and high electric capacity. Moreover, the invention provides a preparation method of the cathode electrode composite material and an electrochemical device applying the same.

Owner:NATIONAL TSING HUA UNIVERSITY

Method for establishing photo-Fenton system for tetracycline degradation based on composite bismuth ferrite material

InactiveCN106242015AIncrease profitImprove degradation efficiencyWater/sewage treatment by irradiationWater treatment compoundsDissolutionControllability

Owner:TONGJI UNIV

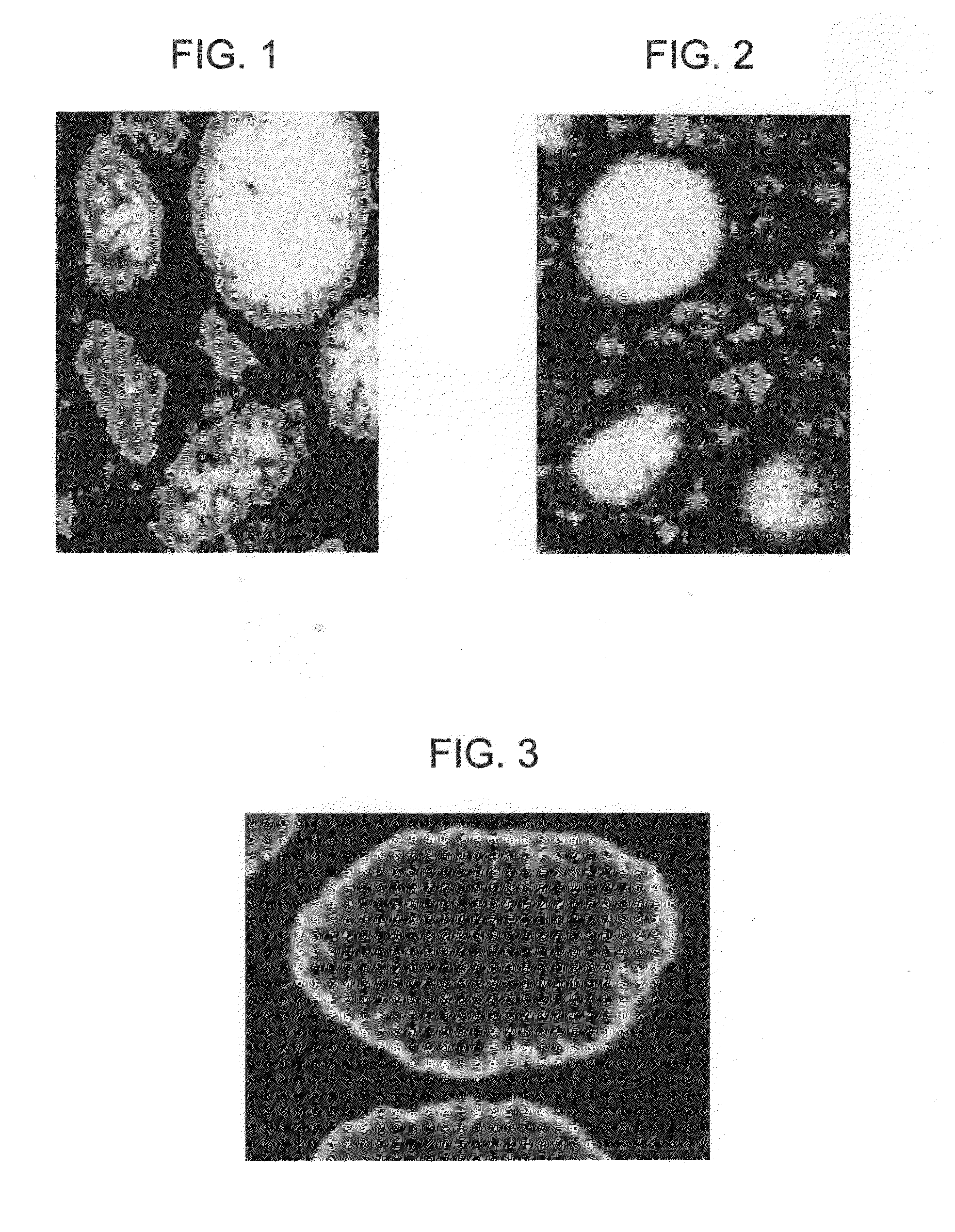

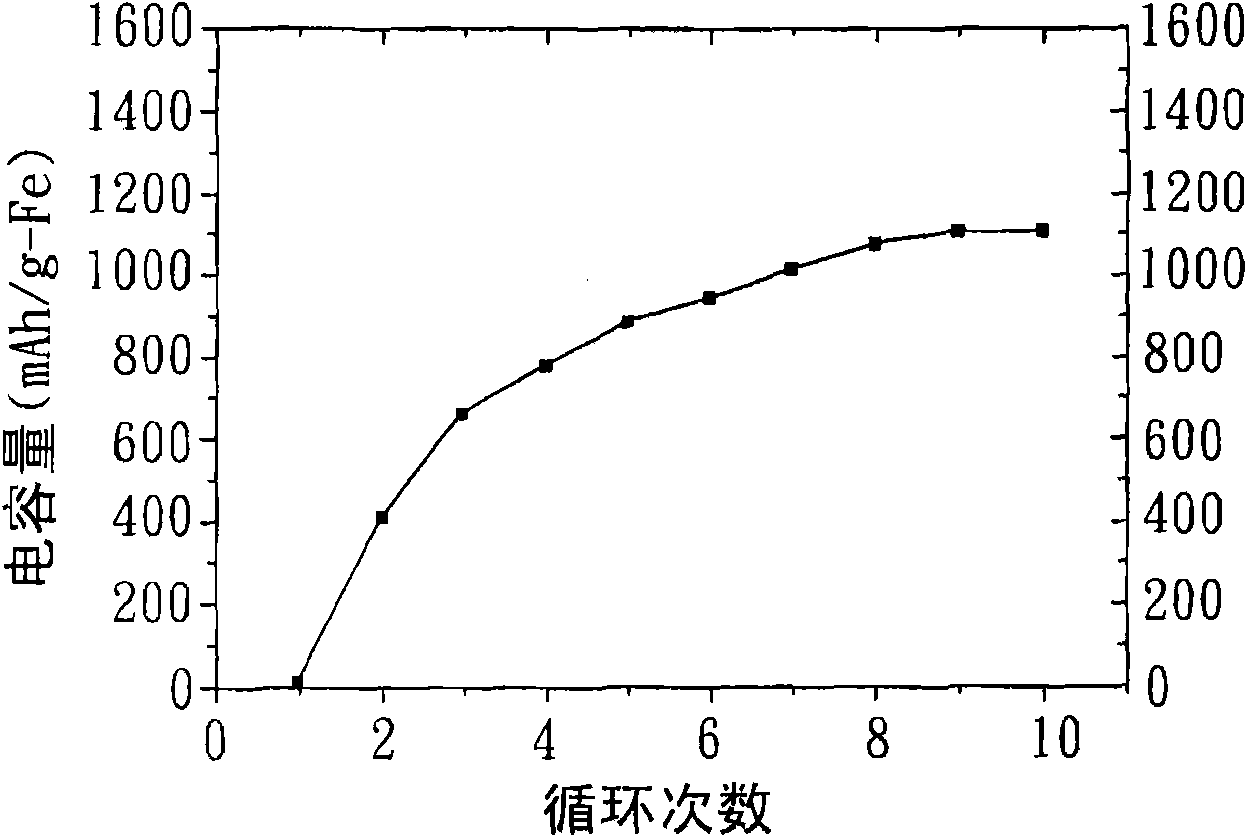

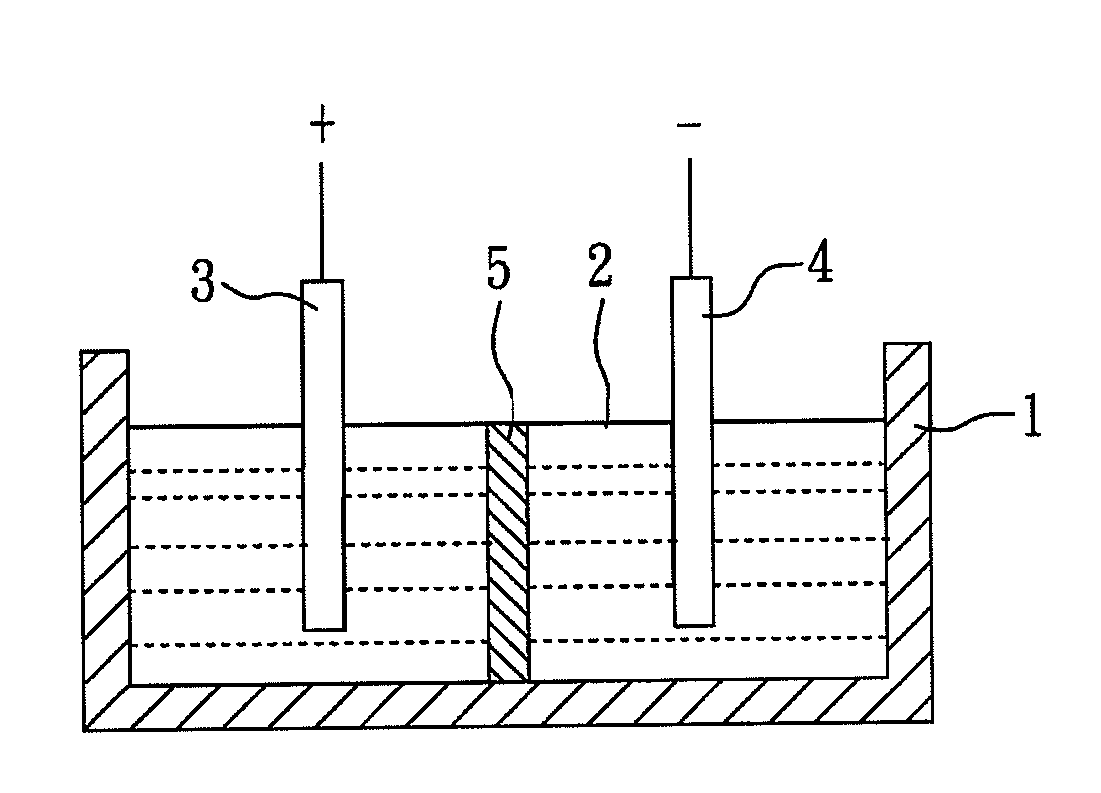

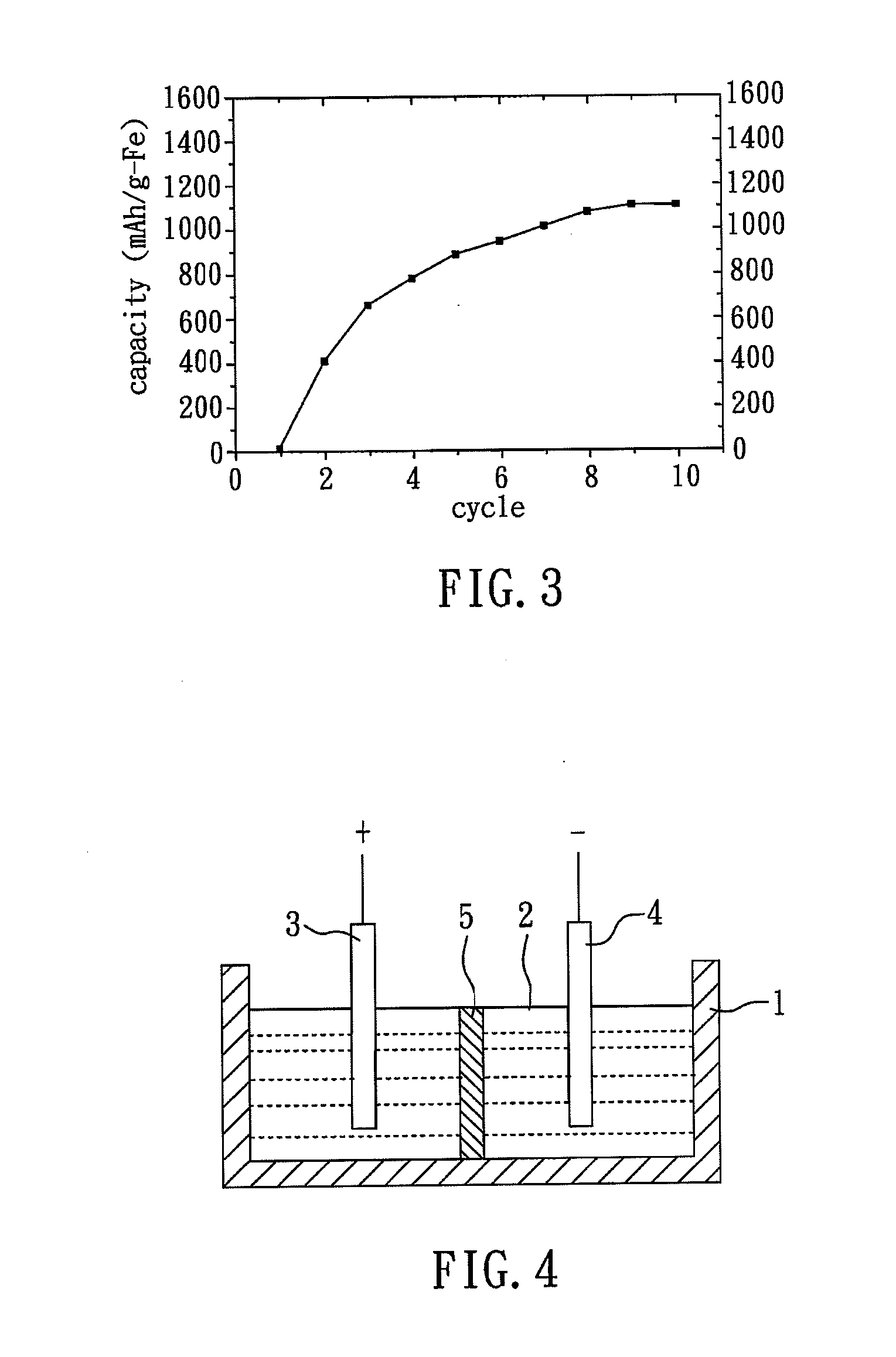

Composite material for negative electrode, method for fabricating the same and electrochemical device using the same

ActiveUS20110236747A1Large capacityLarge scaleSilver accumulatorsNon-metal conductorsIndiumNickel salt

The present invention relates to a composite material for a negative electrode, including: a plurality of iron oxide particles; and a conductivity improver, which is selected form the group consisting of copper, cobalt, nickel, tin, antimony, bismuth, indium, silver, gold, lead, cadmium, carbon black, graphite, copper salt, cobalt salt, nickel salt, tin salt, antimony salt, bismuth salt, indium salt, silver salt, gold salt, lead salt, cadmium salt, copper hydroxide, cobalt hydroxide, nickel hydroxide, stannic hydroxide, antimony hydroxide, bismuth hydroxide, indium hydroxide, silver hydroxide, gold hydroxide, lead hydroxide, cadmium hydroxide and the combination thereof. In the case of applying the composite material for a negative electrode according to the present invention in an electrochemical device, the improved charge / discharge characteristics and high capacity can be achieved. In addition, the present invention further provides a method for fabricating the above-mentioned composite material for a negative electrode and an electrochemical device using the same.

Owner:NATIONAL TSING HUA UNIVERSITY

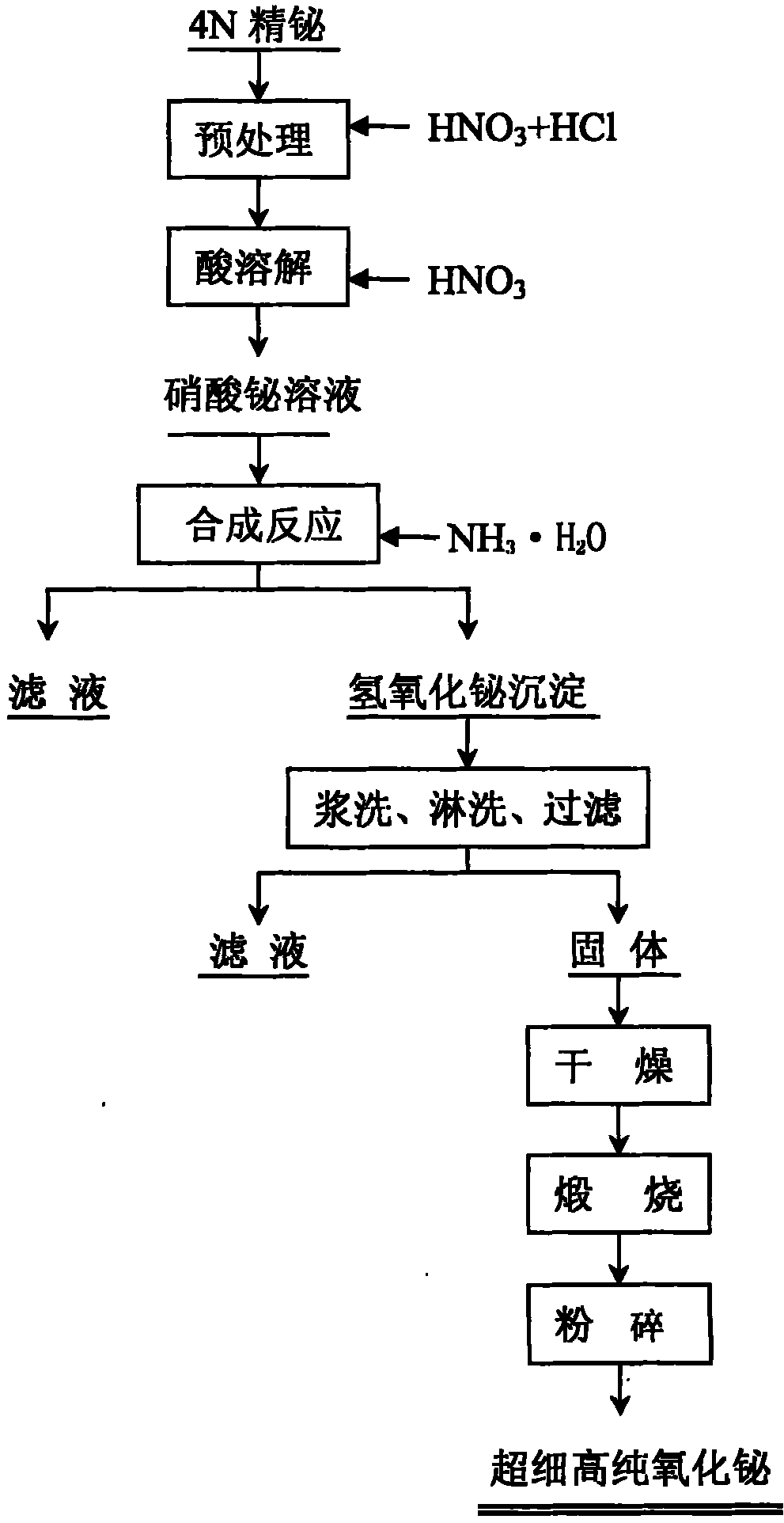

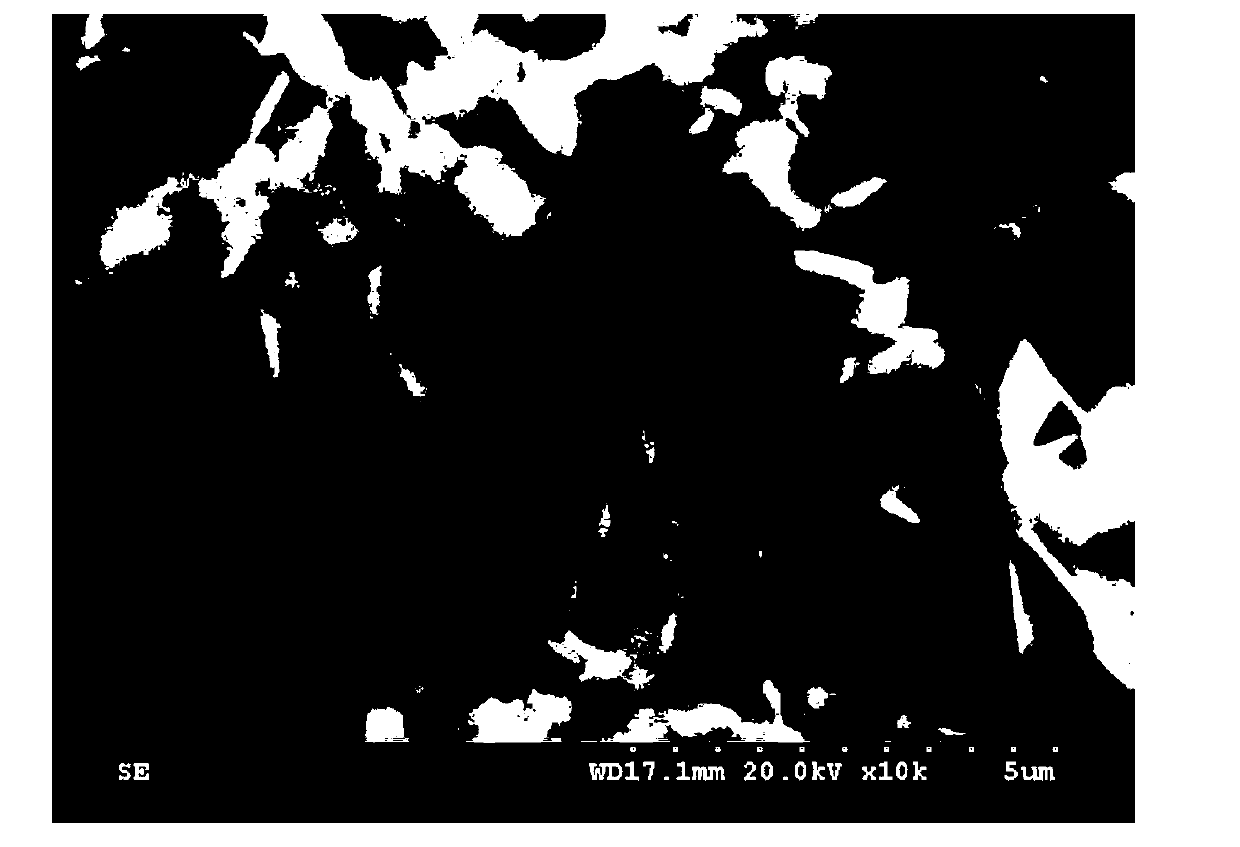

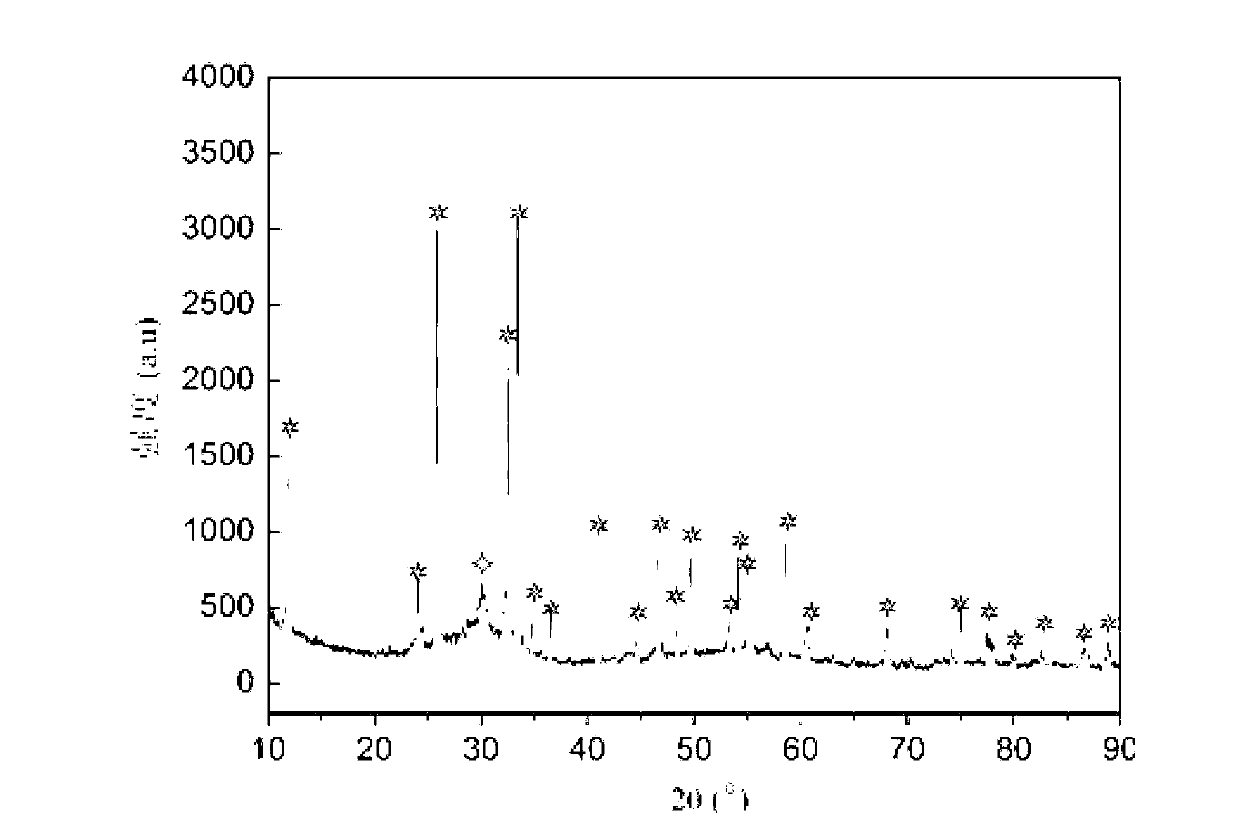

Superfine and high-purity bismuth oxide and preparation method thereof

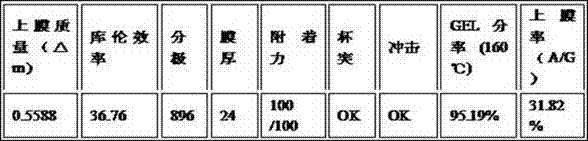

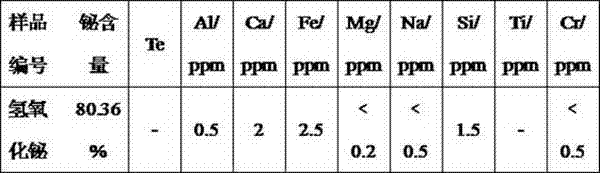

InactiveCN101811732AProcess conditions are easy to controlImprove uniformityBismuth compoundsHydrogen NitrateGranularity

The invention relates to a superfine and high-purity bismuth oxide with the granularity of 10-1000nm and a preparation method thereof. The method takes the solid bismuth with the purity of 4N as a raw material to synthesize the superfine and high-purity bismuth oxide, and is characterized in comprising the following steps of: firstly, soaking the solid bismuth with the purity of 4N into mixed acid solution which is prepared by hydrogen nitrate and muriatic acid; taking out the soaked solid bismuth, and enabling the soaked solid bismuth to react with hydrogen nitrate solution to obtain the bismuth nitrate solution and keep the excessive status of the hydrogen nitrate; mixing the bismuth nitrate solution with the ammonia water solution to perform synthetic reaction; filtrating to obtain white bismuth hydroxide deposition; and washing, drying, calcining and preparing powder according to a conventional method to obtain the superfine and high-purity bismuth oxide with the phase of alpha-Bi2O3, the granularity of 10-100nm and the purity of 5N. The technological condition is easily controlled, has good product homogeneity, and does not need to an add dispersing agent, thereby being capable of obtaining the superfine bismuth oxide powder with even granularity, preventing impurity from being induced, and reducing the preparation cost.

Owner:ZHUZHOU SMELTER GRP

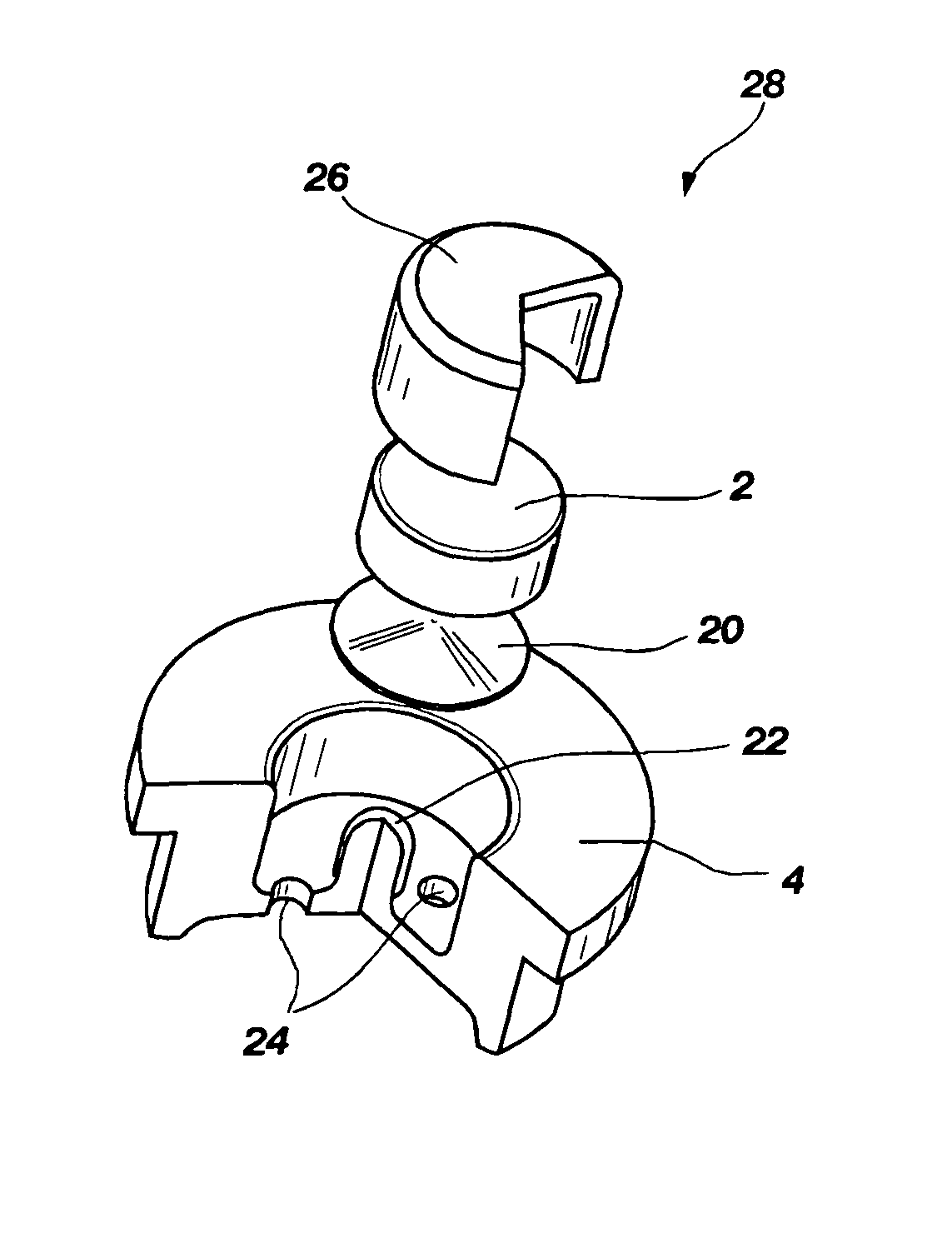

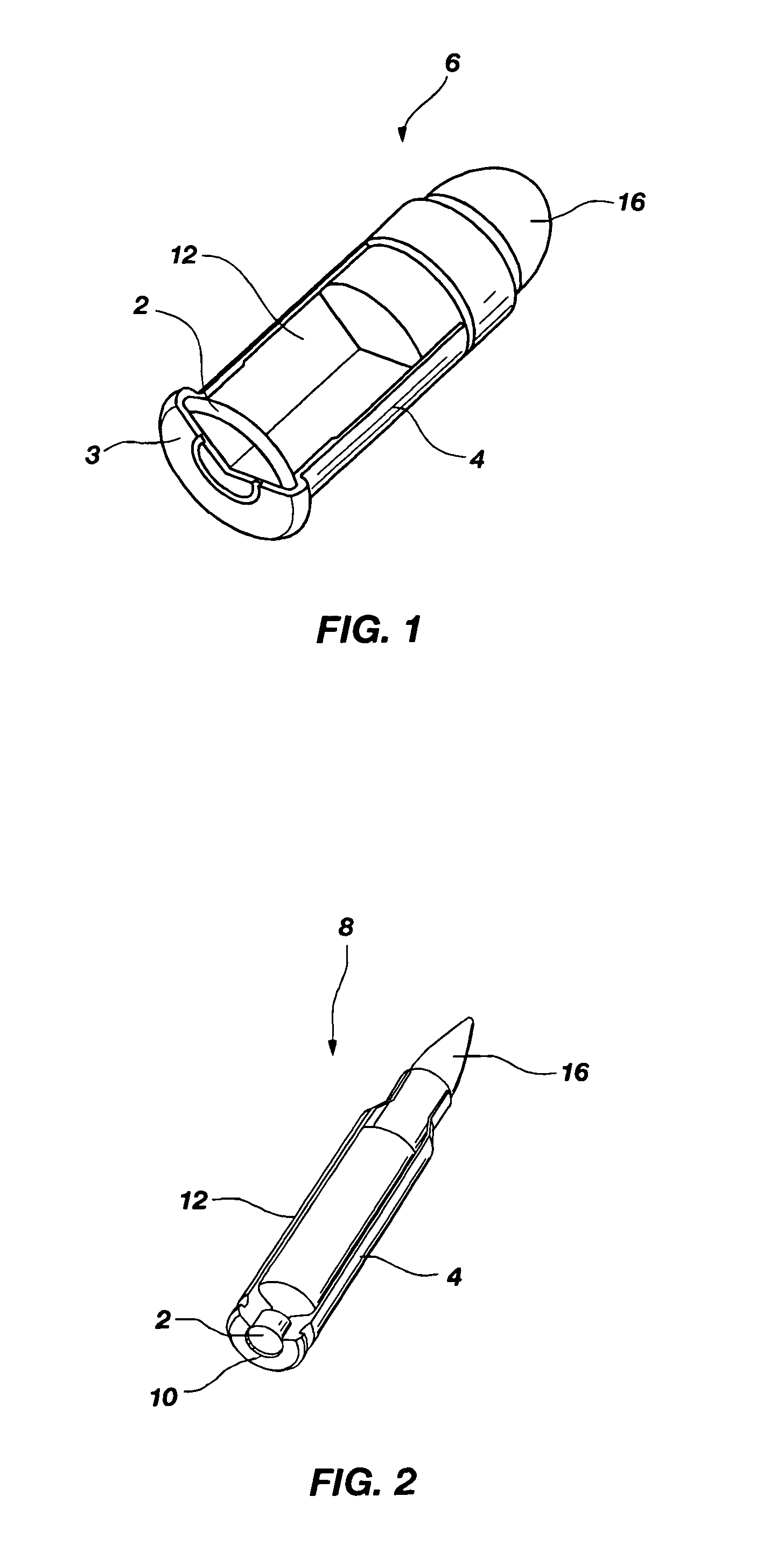

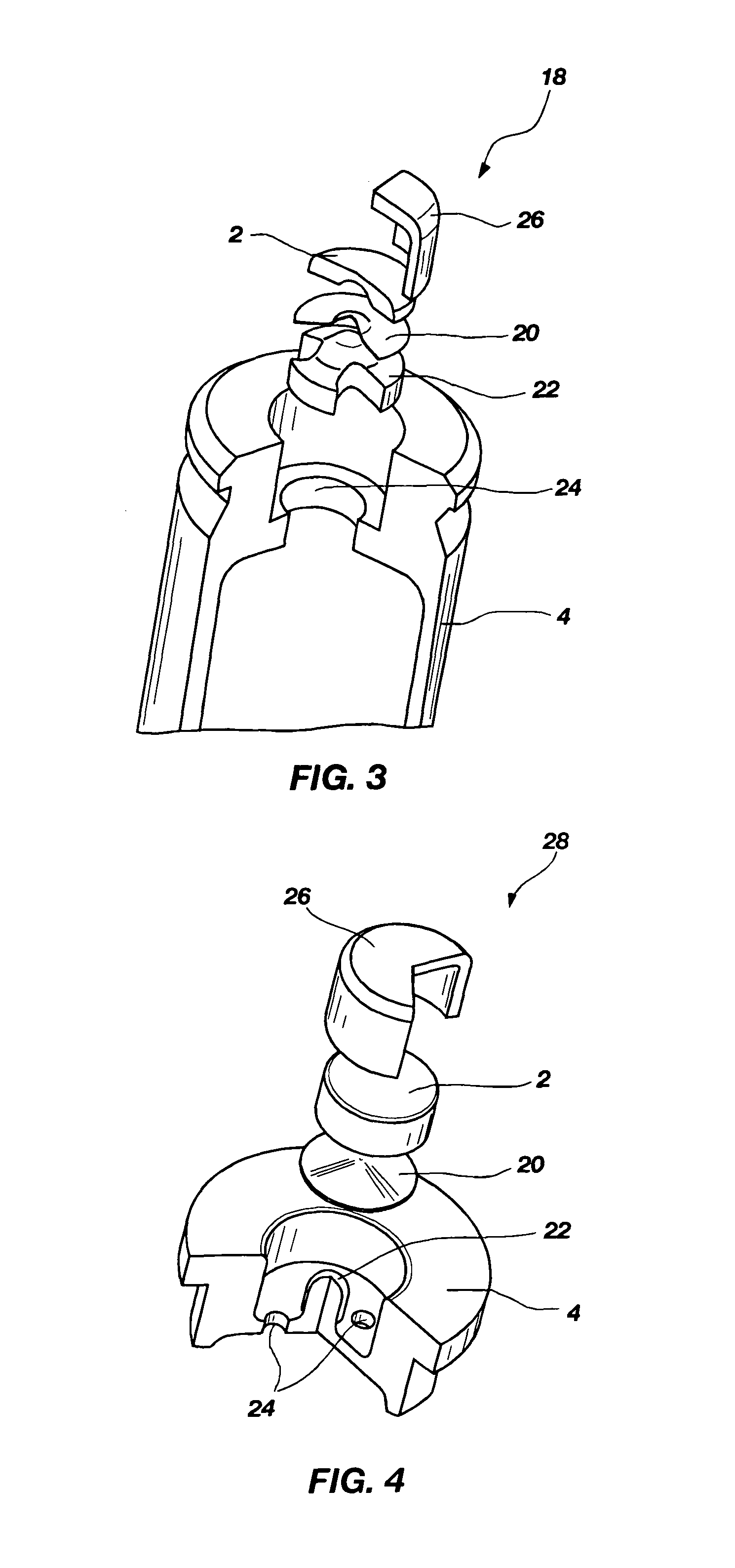

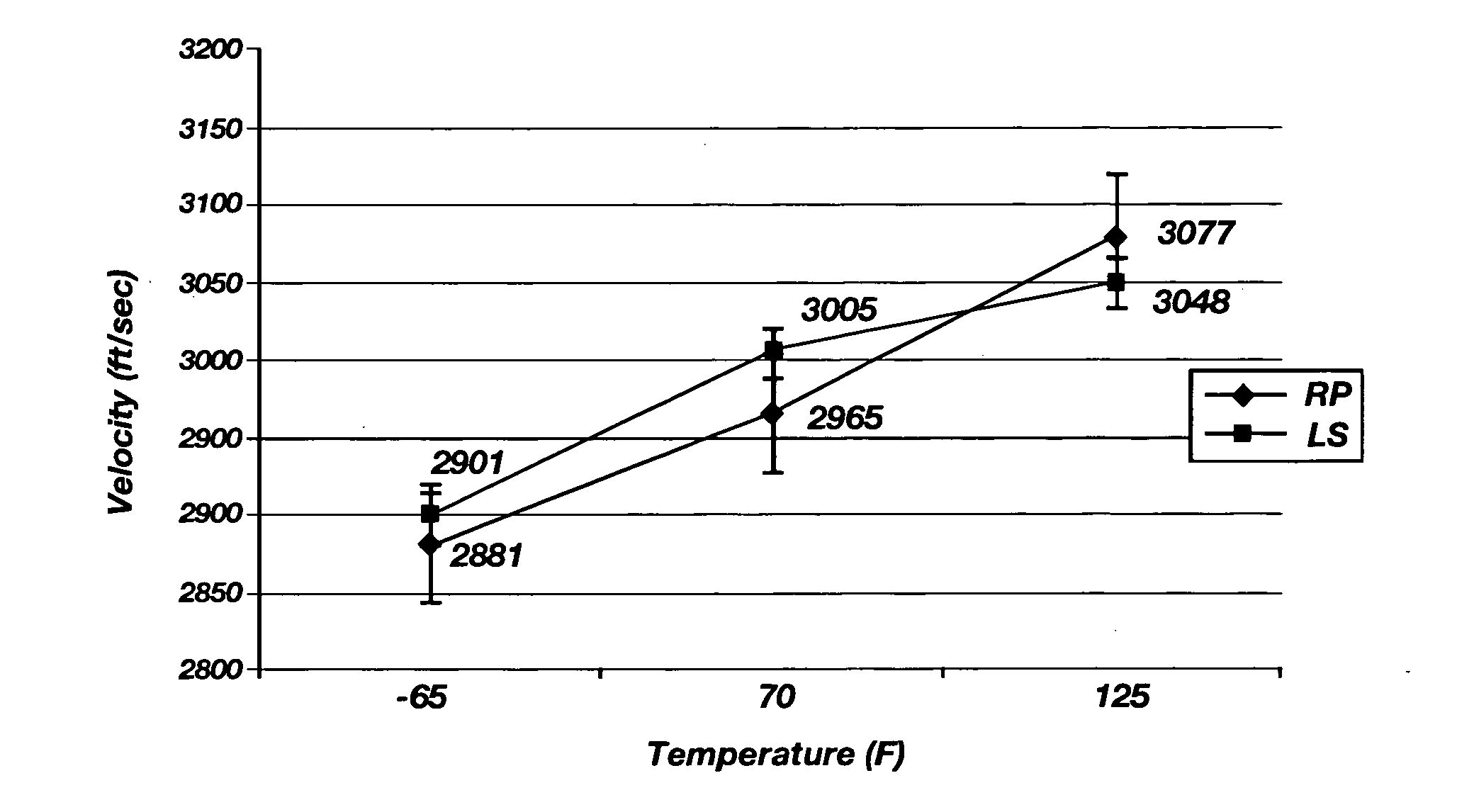

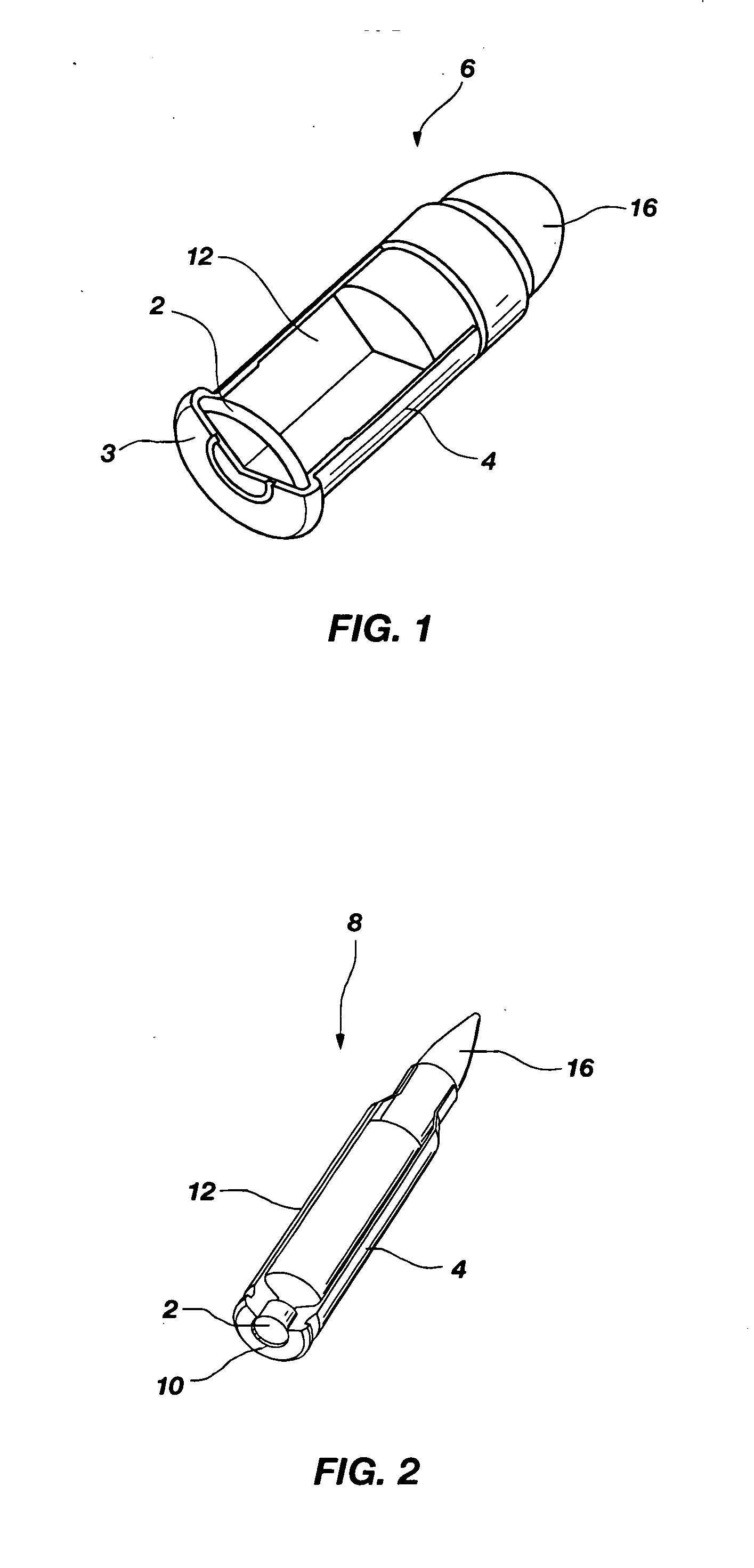

Nontoxic, noncorrosive phosphorus-based primer compositions

A primer composition that includes stabilized, encapsulated red phosphorus, at least one oxidizer, at least one secondary explosive composition, at least one light metal, and at least one acid resistant binder. The stabilized, encapsulated red phosphorus may include particles of red phosphorus, a metal oxide coating, and a polymer layer. The metal oxide coating may be a coating of aluminum hydroxide, bismuth hydroxide, cadmium hydroxide, cerium hydroxide, chromium hydroxide, germanium hydroxide, magnesium hydroxide, manganese hydroxide, niobium hydroxide, silicon hydroxide, tin hydroxide, titanium hydroxide, zinc hydroxide, zirconium hydroxide, or mixtures thereof. The polymer layer may be a layer of epoxy resin, melamine resin, phenol formaldehyde resin, polyurethane resin, or mixtures thereof. A percussion cap primer that includes the primer composition, a tertiary explosive composition, and a cup is also disclosed, as are ordnance devices including the primer composition.

Owner:NORTHROP GRUMMAN SYST CORP

Multi-layer coating film-forming method

InactiveUS6730203B2Improving substrate-opacifying propertyMaintain good propertiesLiquid surface applicatorsElectrolysis componentsWater basedTitanium oxide

A multi-layer coating film-forming method which comprises coating a cationic electrodeposition coating composition (A) containing a blocked polyisocyanate compound as a crosslinking agent and bismuth hydroxide to form a non-cured electrodeposition coating film, coating a water based intercoat coating composition (B1) containing a hydroxyl group and carboxyl group-containing base resin, a blocked polyisocyanate crosslinking agent, a fine aluminum powder and a titanium oxide white pigment onto the non-cured electrodeposition coating film to form a non-cured intercoat coating film, followed by heat curing both coating films simultaneously.

Owner:KANSAI PAINT CO LTD

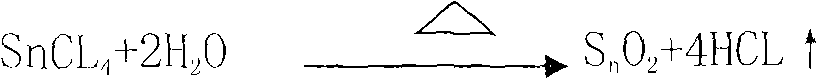

Method for manufacturing high-temperature resistant transparent electric heating film

ActiveCN102065589AWide temperature rangeSolution to short lifeHeating element materialsBarium titanateSolvent

The invention relates to a method for manufacturing a high-temperature resistant transparent electric heating film. The method comprises the following steps of: preparing a surface modification solution; purifying a substrate; carrying out surface modification; manufacturing an electrode; and carrying out an electrifying and aging procedure. The method is characterized in that the surface medication solution comprises the following components: 300-500g of stannic chloride as a main material, 3-5g of ruthenium trichloride, 4-7g of bismuth hydroxide as a high-temperature resistance stabilizer, 4-7g of barium titanate as a high-voltage resistance stabilizer, 2-4g of fluoboric acid as a doping agent, a proper quantity of hydrofluoric acid as a doping cosolvent, a proper quantity of hydrochloric acid as a cosolvent and 300-500g of absolute alcohol as a solvent. The method has the advantages of high temperature resistance, antioxidation, dry burning in air, wide using temperature range, long service life, slow attenuation and wide application. The method is suitable for manufacturing a high-temperature resistant transparent electric heating film.

Owner:宁波高新区健坤电热技术有限公司

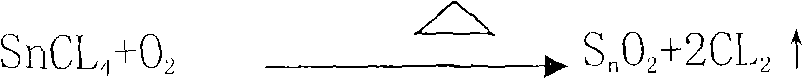

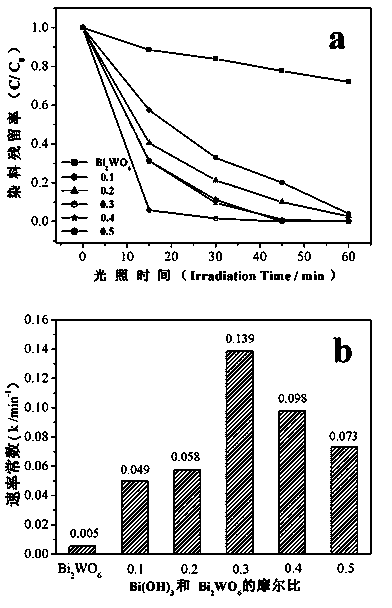

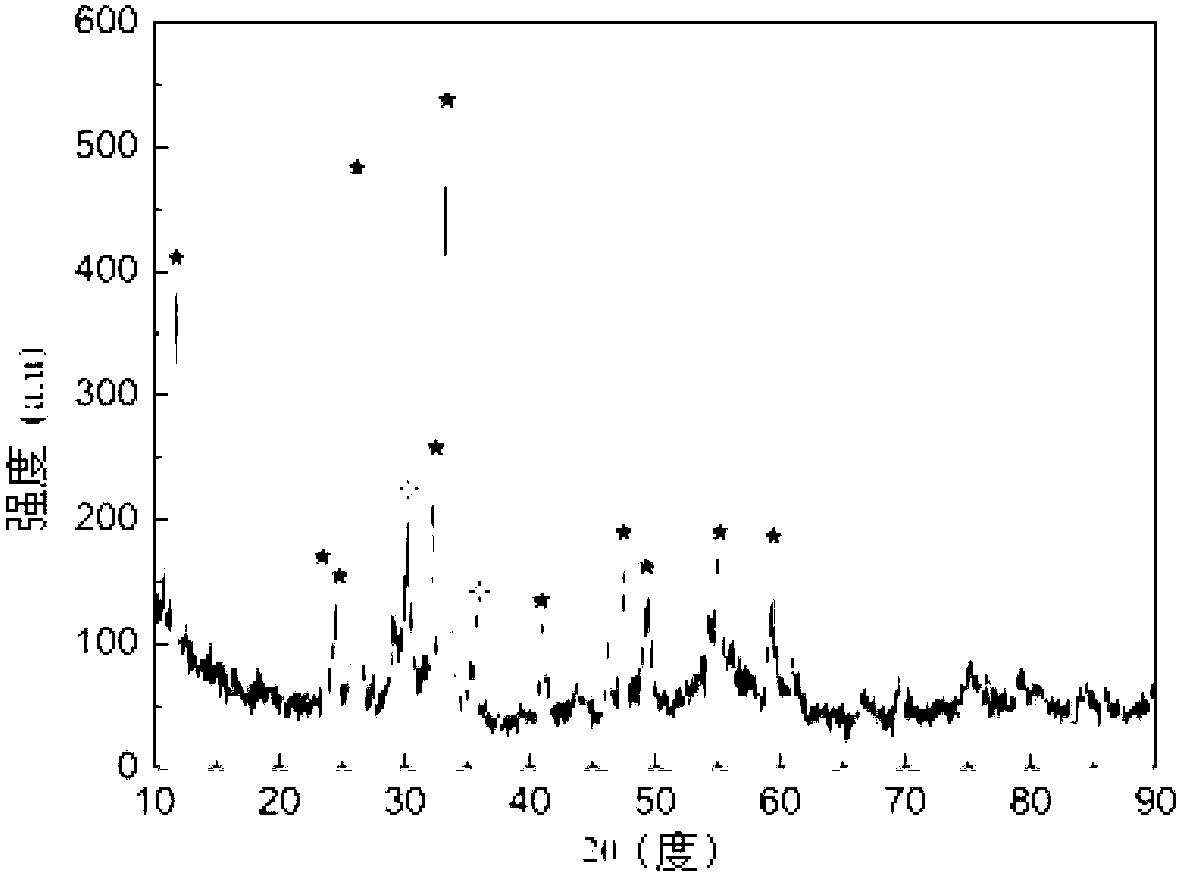

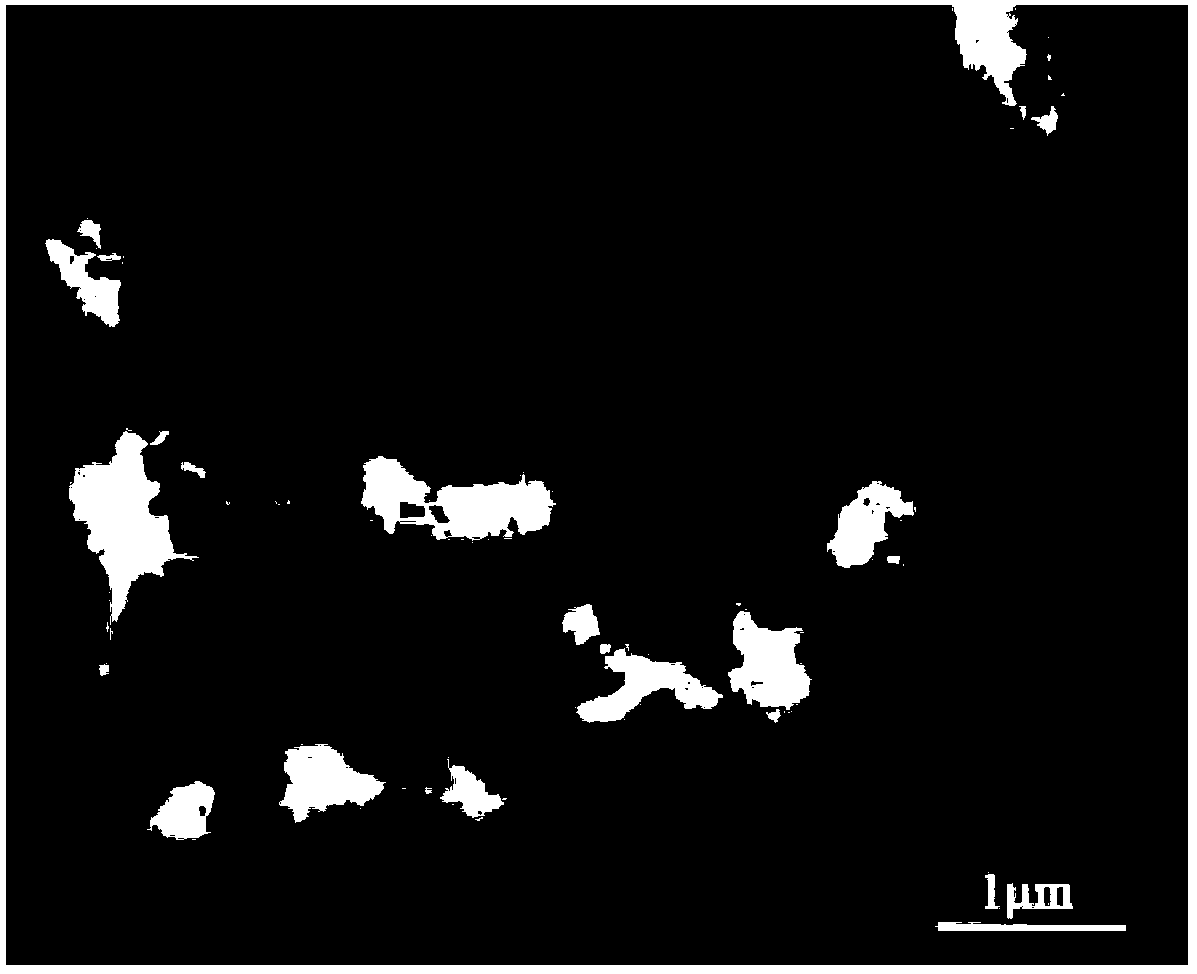

Method for preparing bismuth hydroxide/bismuth tungstate compound photo-catalyst by heating one-pot solvent

InactiveCN104209118AEasy and economical to makeEasy to scale up productionWater/sewage treatment by irradiationEnergy based wastewater treatmentPhoto catalyticAlcohol

The invention discloses a method for preparing a bismuth hydroxide / bismuth tungstate compound photo-catalyst by heating an one-pot solvent. A novel Bi(OH)3 / Bi2WO6 visible responsive photo-catalyst is prepared by taking ethanol and water as a mixed solvent, heating the one-pot solvent, and only excessively using and dissolving one bismuth source Bi (NO3)3.5H2O. The photocatalytic activity of the product is systematically researched under the impact of ethanol content, reaction temperature and time, Bi(OH)3 compound content and other experiment parameters, and the optimal conditions for preparing Bi (OH)3) / Bi2WO6 include alcohol-water volume ratio of 9 : 8, solvent hot temperature of 200 degrees centigrade, reaction time of 6 hours, and Bi (OH)3) compound mole ratio of 0.3. The preparation method has the characteristics of simpleness, low cost and energy saving, the prepared compound photo-catalyst has the excellent photocatalytic performance, thereby solving the problem that the present pure bismuth tungstate is relatively weak in catalytic performance and restricted in actual application.

Owner:TIANJIN NORMAL UNIVERSITY

Preparation method of Fe2O3/BiOCl nano-composite powder

InactiveCN103241775AThe synthesis process is simpleLow costMaterial nanotechnologyFerric oxidesPolyethylene glycolColloid

The invention relates to a preparation method of composite powder, and in particular relates to a preparation method of Fe2O3 / BiOCl nano-composite powder. The preparation method aims to solve the technical problem that when Fe2O3 or BiOCl is separately applied to catalyzing organics and serves as a coating additive, the pearl effect is not obvious. The method comprises the following steps of: 1, dissolving bismuth nitrate in nitric acid, uniformly stirring, diluting with water to obtain a bismuth nitrate solution; 2, preparing an ammonia water solution; 3, preparing a bismuth hydroxide colloid; 4, preparing a ferric chloride solution; 5, dissolving polyethylene glycol in water to obtain a polyethylene glycol water solution; and 6, mixing the bismuth hydroxide colloid, the ferric chloride solution and the polyethylene glycol water solution, pouring the mixture into a hydrothermal kettle, holding the temperature and obtaining the Fe2O3 / BiOCl nano-composite powder after naturally cooling. The Fe2O3 / BiOCl nano-composite powder obtained by adopting the method is simple in synthesis process, low in cost and good in pearl effect and can be recycled when serving as a photocatalyst.

Owner:HARBIN UNIV OF SCI & TECH

Powdery eye shadow block

InactiveCN101804020ANon-irritatingNo other side effectsCosmetic preparationsMake-upSide effectIrritation

The invention discloses a powdery eye shadow block comprising the following materials in parts by weight: 50-60 parts of kaolin, 10-20 parts of ultramarine, 3-5 parts of titanium dioxide, 15-25 parts of bismuth hydroxide, 2-5 parts of beeswax, 4-8 parts of isopropyl palmitate, 0.5-1 part of glycerin monostearate and 0.3-0.6 part of essence. Compared with the prior art, the invention has good gloss and easy inunction without irritation on skin and eyes and any other side effect, can not be afraid of being soaked by rainwater, tears and sweats and has proper drying property.

Owner:任芳芳

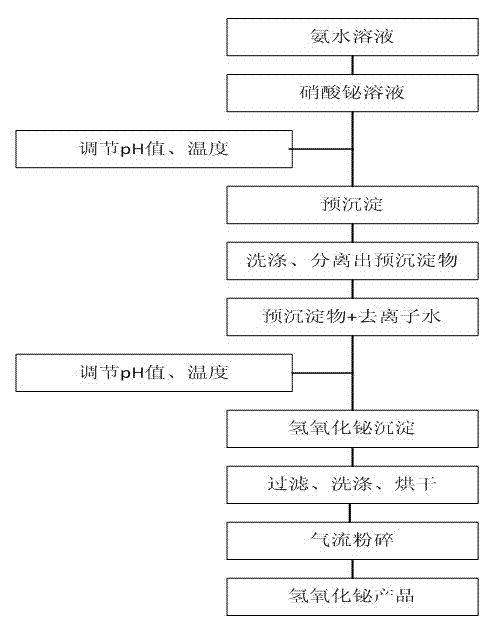

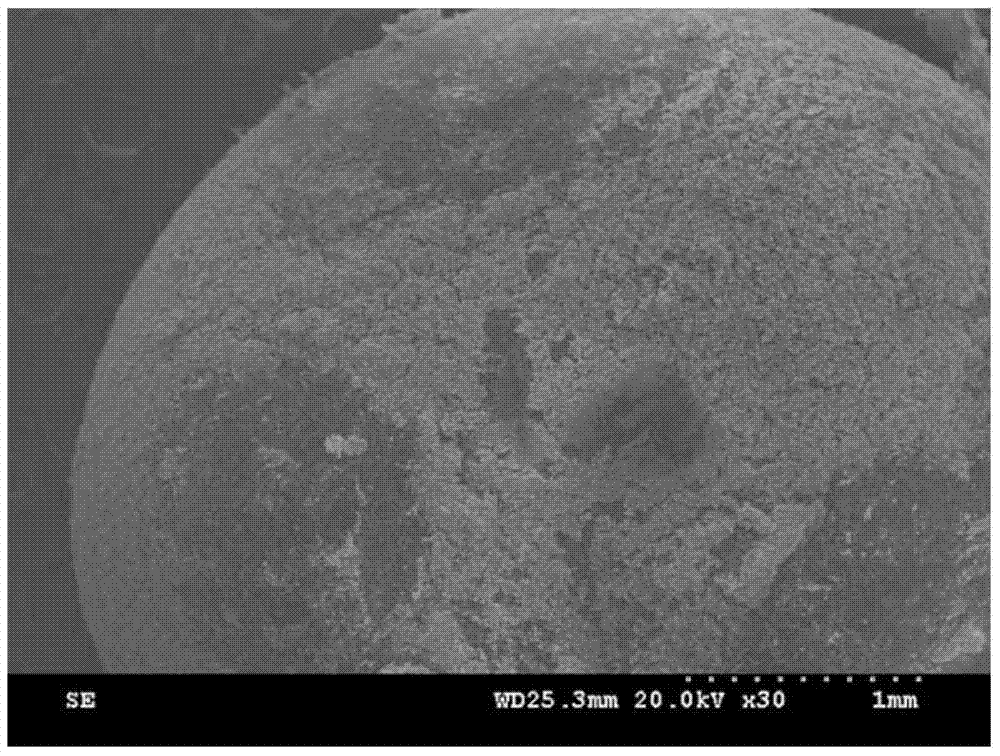

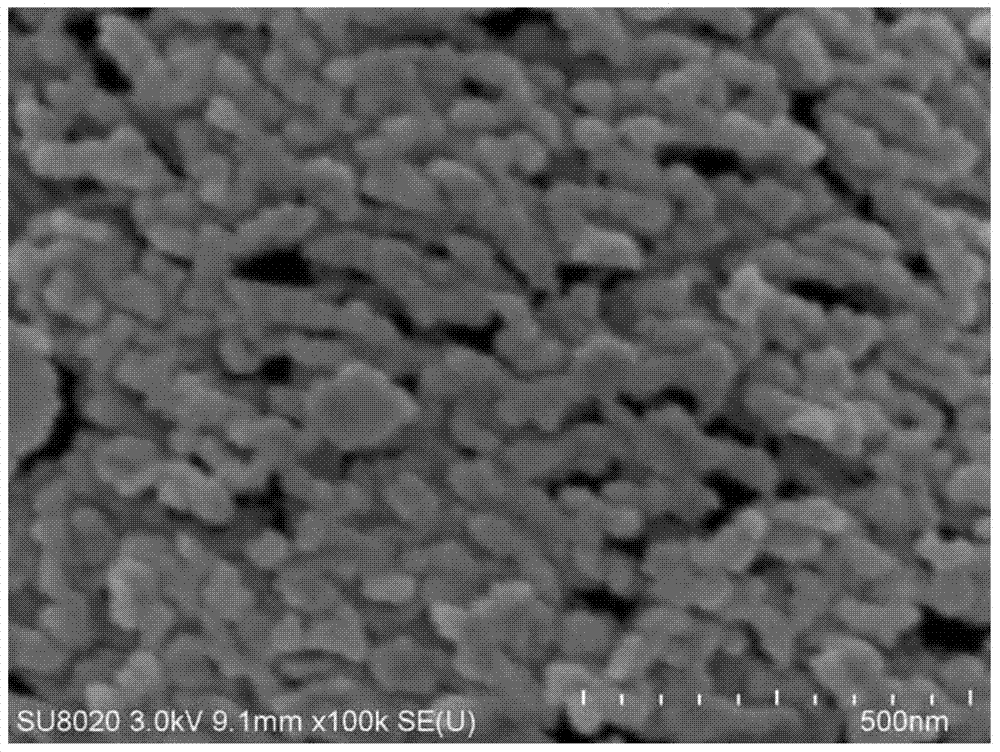

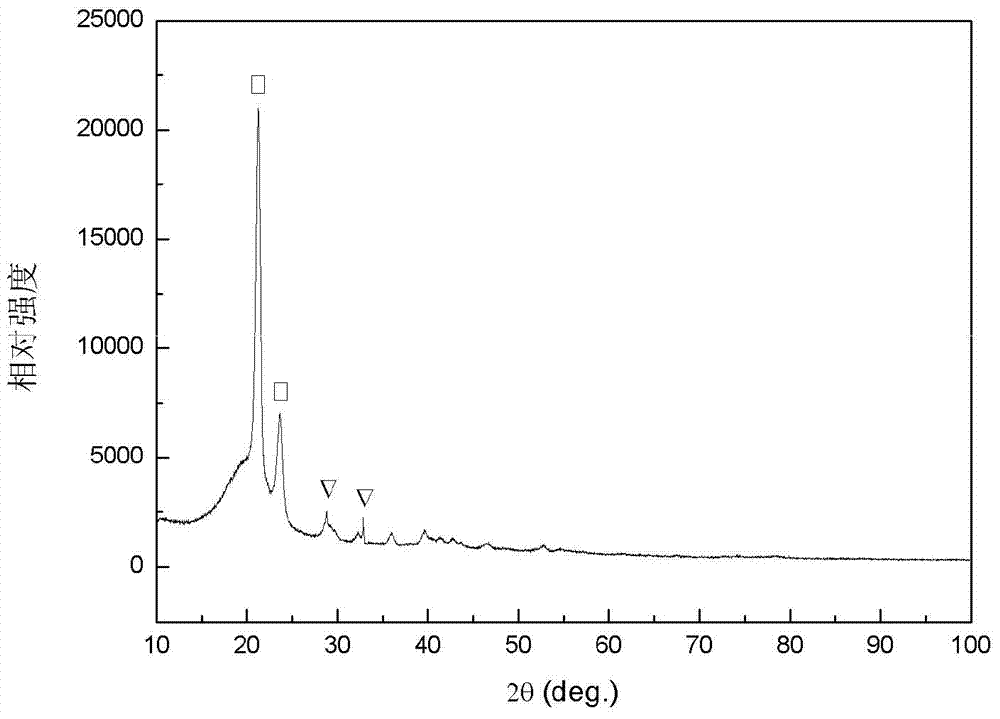

Preparation method of bismuth hydroxide

ActiveCN103112893ASmall granularityNarrow particle size distributionBismuth compoundsMetal/metal-oxides/metal-hydroxide catalystsHydrogenAmmonia

The invention discloses a preparation method of bismuth hydroxide; the preparation method comprises the following steps of: firstly, confecting bismuth nitrate Bi(NO3)3 solution, ammonia water solution and dispersing agent solution; then adding the dispersing agent solution into the bismuth nitrate Bi(NO3)3 solution, stirring, adding water to dilute the bismuth nitrate Bi(NO3)3 solution, adding ammonia water solution to adjust the pH (potential of hydrogen) of the bismuth nitrate Bi(NO3)3 solution, stirring, filtering, depositing and washing pre-precipitating at the end of the reaction; confecting the washed pre-precipitate to be suspension, keeping on adding ammonia water solution to adjust the pH, stirring; sanding and ageing after the reaction, washing, separating and drying bismuth nitrate Bi(NO3)3 precipitate after ageing, so as to obtain dry bismuth hydroxide Bi(OH)3 powder, carrying out fluid energy milling on the dry powder, thus obtaining the bismuth hydroxide Bi(OH)3 product. The bismuth hydroxide prepared by the method is low in impurity content and is excellent in catalyzing property.

Owner:FIRST RARE MATERIALS CO LTD

Preparation method of nanometer bismuth hydroxide/polyethylene flame-retardant composite material

InactiveCN103788459AImprove flame retardant performanceEvenly dispersedPlastic/resin/waxes insulatorsInsulated cablesWater bathsSynthesis methods

The invention relates to a preparation method of a nanometer bismuth hydroxide / polyethylene flame-retardant composite material, and relates to a flame-retardant composite material which contains an inorganic flame retardant and a preparation method of the flame-retardant composite material. The invention aims at solving the technical problem that the bismuth hydroxide is nonuniformly grown on the surface of polyethylene in a water bath synthetic method. The method comprises the following steps of dissolving the bismuth hydroxide and the polyethylene into alcohol, mixing, and then pouring into a ball milling jar for ball milling, wherein the mass ratio of mill balls to materials is 15:1; then regulating a pH value, pouring into a hydro-thermal synthesis reaction kettle for heat preservation; pouring powder from the hydro-thermal synthesis reaction kettle, washing the powder by using alcohol, drying, then placing the powder into a flat vulcanizing machine for hot press forming, and cooling to room temperature to obtain the nanometer bismuth hydroxide / polyethylene flame-retardant composite material. According to the invention, the generated bismuth hydroxide is coated on the surface of the polyethylene through a solvent thermal synthesis method, nanometer particles contained in the prepared nanometer particle / polyethylene composite material are uniformly dispersed, the bismuth hydroxide outstandingly enhances the flame-retardant property of the polyethylene, and the carbon forming amount of the polyethylene is greatly increased. The invention belongs to the field of preparation of flame-retardant composite materials.

Owner:HARBIN UNIV OF SCI & TECH

Electrodeposition paint

InactiveUS7625477B2Excellent in corrosion resistance and finished appearance and paint stabilityImprove corrosion resistanceSurface reaction electrolytic coatingPolyurea/polyurethane coatingsBismuth hydroxideMaterials science

This invention provides an electrodeposition paint comprising particles of at least one metallic compound selected from bismuth hydroxide, zirconium compound and tungsten compound, said particles of the metallic compound having an average particle diameter of 1-1,000 nm. The electrodeposition paint forms coating film excelling in corrosion resistance, finished appearance, paint stability and so on.

Owner:KANSAI PAINT CO LTD

Ethynylation catalyst and method of making same

ActiveUS9006129B2Convenient coatingOrganic compound preparationHeterogenous catalyst chemical elementsCopperBismuth hydroxide

A novel catalyst useful in the ethynylation of formaldehyde to butynediol is formed by precipitating copper and bismuth from a salt solution of such metals, utilizing an alkali metal hydroxide as the precipitating agent to deposit copper and bismuth hydroxide as a coating around a siliceous carrier particle.

Owner:BASF CORP

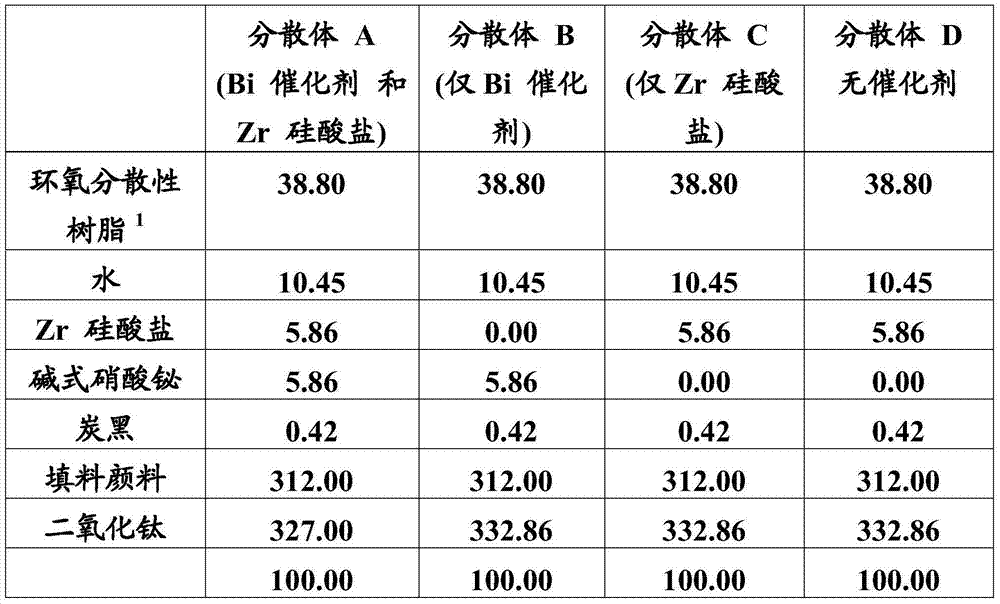

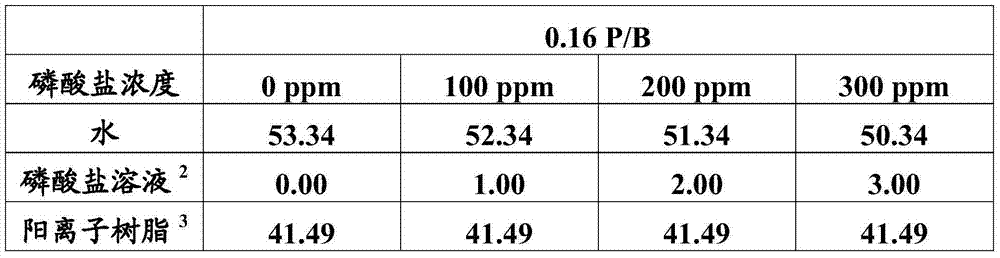

Method for improving coating cure for article coated in phosphate-contaminated electrocoat coating composition and electrocoat coating composition

ActiveCN104769051AElectrophoretic coatingsPaints for electrolytic applicationsPhosphate ionBismuth compound

An electrocoat coating composition contaminated with phosphate ions is treated by adding zirconium silicate to the coating composition. Aqueous electrocoat coating compositions including (1) a bismuth compound and that is free of tin compounds and free of bismuth hydroxide or (2) having a catalyst consisting essentially of a member selected from the group consisting of bismuth compounds and mixtures of these also include zirconium silicate.

Owner:BASF COATINGS GMBH

Aqueous dispersion system and method for etching polysilicon wafer

The invention discloses an aqueous dispersion system used for etching a polysilicon wafer. The aqueous dispersion system comprises the following components based on the total weight of the aqueous dispersion system: an aqueous medium as well as 0.0001-0.5 mol / L bismuth hydroxide and 1-5000 ppm at least one anionic or nonionic surfactant which are dispersed in the aqueous medium. The invention also discloses a method for etching the polysilicon wafer by utilizing the aqueous dispersion system and a solar polysilicon wafer cell obtained by using the method.

Owner:EI DU PONT DE NEMOURS & CO

Preparation method of honeycomb-shaped porous bismuth oxide

InactiveCN107199030AAvoid affecting shapeHigh porosityWater/sewage treatment by irradiationWater contaminantsMicro structurePorosity

The invention discloses a preparation method of honeycomb-shaped porous bismuth oxide, which belongs to the technical field of the preparation of a semiconductor functional material. The preparation method comprises the following steps: by adopting dilute nitric acid as a solvent, adopting bismuth nitrate pentahydrate as a bismuth source and adopting a urea solution as a precipitant, stirring and reacting, then filtering, washing and vacuum freeze drying to prepare a precursor material containing porous bismuth hydroxide, then stirring and mixing the precursor material and organic matters such as starch, standing and molding the mixed material in a greenhouse to obtain mold slurry, mixing the mold slurry and ethanol solution, fermenting in the presence of oxygen, introducing ozone into the system, after microorganisms are dormant, collecting surface-layer flotage of a fermenting tank, washing and drying, and then calcining, thus obtaining the honeycomb-shaped porous bismuth oxide. The porous bismuth oxide is of a honeycomb-shaped micro structure, and is high in porosity, large in specific surface area and excellent in photocatalytic performance and reusability.

Owner:薛向东

Composite material for negative electrode, method for fabricating the same and electrochemical device using the same

ActiveUS8486563B2Large capacityLarge scaleSilver accumulatorsNon-metal conductorsGold(III) hydroxideIndium

Owner:NATIONAL TSING HUA UNIVERSITY

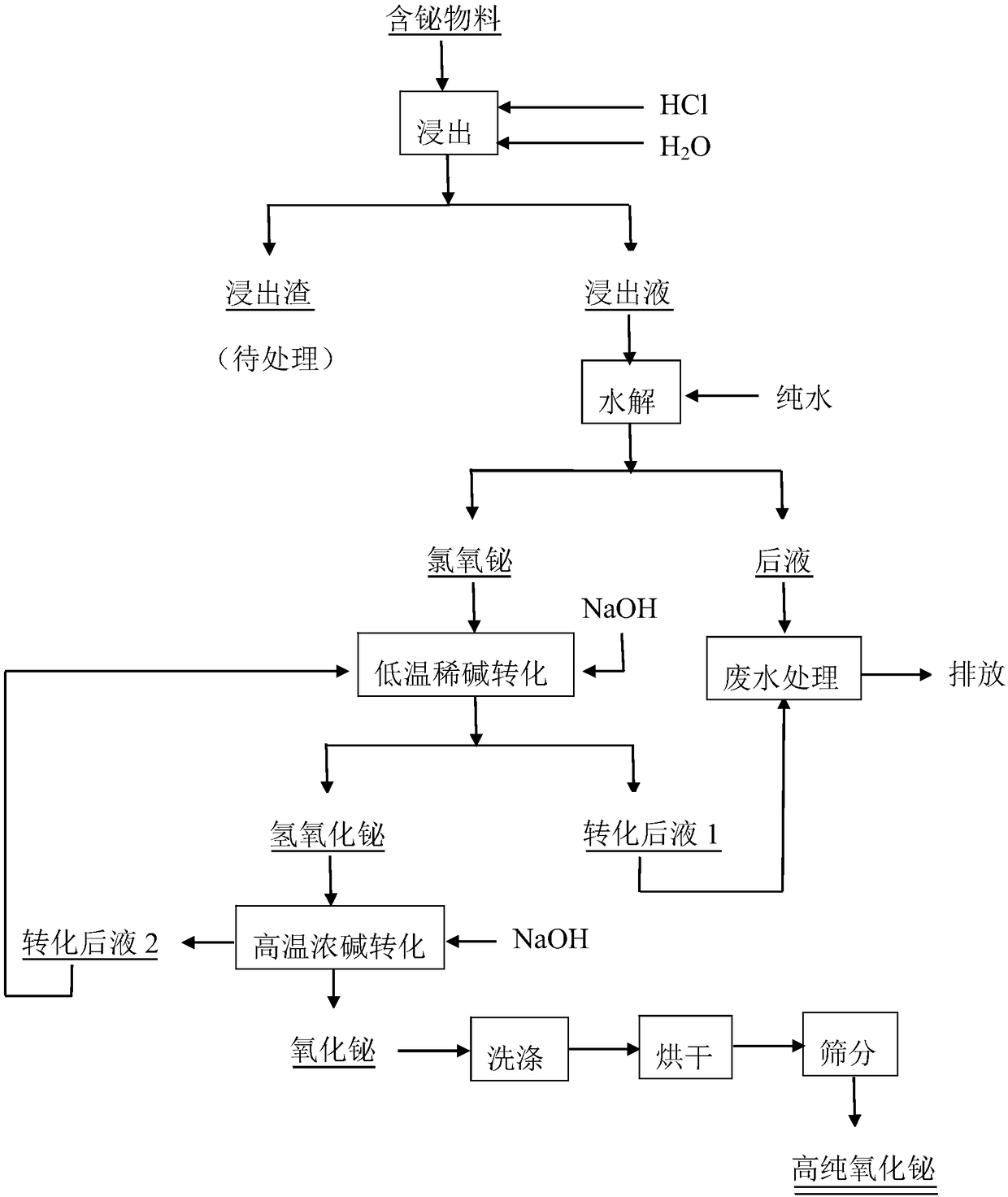

Method for producing high-purity bismuth oxide from bismuth-containing materials

ActiveCN108557881AReduce consumptionThe method flow is simpleBismuth compoundsBismuth oxychlorideHydrolysis

The invention discloses a method for producing high-purity bismuth oxide from bismuth-containing materials. The method includes the steps that firstly, a bismuth-containing material and a hydrochloricacid solution are subjected to a leaching reaction, so that bismuth in the bismuth-containing materials enter the solution in a bismuth chloride form, and leachate and leaching residues are separated; secondly, pure water is added into the leachate, and a hydrolysis reaction is carried out on the bismuth chloride to precipitate bismuth oxychloride; thirdly, the precipitated bismuth oxychloride isseparated out, a dilute alkali solution is added, and the bismuth oxychloride is converted into bismuth hydroxide under the condition of low-temperature dilute alkali; fourthly, a concentrated alkalisolution is added into the filtered bismuth hydroxide, and the bismuth hydroxide is converted into bismuth oxide by using high-temperature concentrated alkali; finally, the generated bismuth oxide iswashed, dried and screened to obtain the high-purity bismuth oxide. According to the method, the bismuth-containing materials serve as the raw materials, so that bismuth enters the solution in the bismuth chloride form and then is hydrolyzed into bismuth oxychloride, and bismuth oxide is generated through low-temperature dilute alkali conversion and high-temperature concentrated alkali conversion. The method is simple in procedure, the consumption of reagents is small, and impurities such as Fe, Pb, Sb and As can be deeply purified and separated.

Owner:俞淼

High-purity colloidal bismuth pectin compound and confirmation of structural formula, molecular formula and molecular weight thereof

InactiveCN107118285AOrganic active ingredientsInorganic active ingredientsBismuth / pectinStructural formula

The invention discloses a preparation method of a high-purity colloidal bismuth pectin compound, confirmation of a chemical structural formula, a molecular formula and the molecular weight thereof, and an application technology. The compound is different from a compound prepared by a colloidal bismuth pectin preparation method (patent) disclosed and implemented previously. According to the original patent process, due to reasons of raw materials in an intermediate liquid pectin and a bismuth salt solution for the production of colloidal bismuth pectin and the preparation method thereof, the product contains lots of organic impurities (sorbitol, pectin, etc.) and inorganic impurities (nitrate and bismuth hydroxide), purity of the product is low (only 80%), quality standard level is low, and curative effect is poor. The invention provides several preparation methods for preparation of a high-purity (98%) colloidal bismuth pectin compound, including five optimization methods. Through spectrometry and analysis, the structural formula, the molecular formula and the molecular weight of the compound are determined. A novel medicinal preparation prepared from the high-purity compound has obvious clinical advantages.

Owner:于学敏

Preparation method of graphene oxide-based catalytic material

InactiveCN107398265AEvenly dispersedImprove photocatalytic activityMetal/metal-oxides/metal-hydroxide catalystsPolyethylene glycolNitrogen atmosphere

The invention discloses a preparation method of a graphene oxide-based catalytic material. The preparation method comprises the following steps: (1) adding deionized water and polyethylene glycol into graphene oxide, stirring the mixture, and ball-milling the same for 10-15min to obtain paste graphene oxide; (2) mixing the paste graphene oxide with bismuth nitrate pentahydrate in a weight ratio of 1: (1-3), ball-milling the mixture for 2-10h, adding a sodium hydroxide solution to adjust the pH value to 9-10, leaving the mixture to stand, filtering the same, collecting a precipitate and washing the precipitate, and drying the precipitate to obtain a graphene oxide-bismuth hydroxide compound; and (3) calcining the graphene oxide-bismuth hydroxide compound for 1-2h at 300-600 DEG C in a nitrogen atmosphere to obtain the graphene oxide-bismuth trioxide catalytic material. According to the graphene oxide-based catalytic material disclosed by the invention, bismuth trioxide can be uniformly dispersed on the surface of graphene oxide, so that the graphene oxide-based catalytic material has relatively good photocatalytic activity.

Owner:张家港市汇鼎新材料科技有限公司

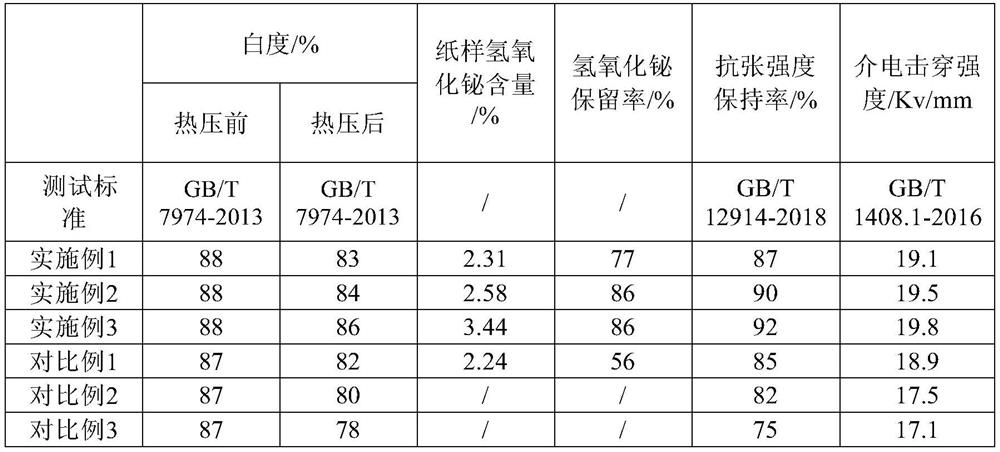

Aramid paper and preparation method thereof

ActiveCN107653735AHigh tensile strengthEasy to tearSpecial paperPaper/cardboardWater vaporPapermaking

The invention discloses a preparation method of aramid paper, comprising the following steps: 30-70 wt% of aramid fibrid containing an anti-oxidant (which is an oxide of bismuth or bismuth hydroxide)and 30-70 wt% of aramid chopped fiber are mixed for papermaking to form raw paper; then, the obtained raw paper undergoes hot-pressing treatment, wherein one of two pressure rollers is a soft roller and the other one of the two pressure rollers is a hot-hard roller; as for heat treatment, a high-temperature negative-pressure vacuum-pumping calendering technology is adopted for calendaring of the raw paper, wherein there are many round bulges on the surface of the soft roller. With the addition of the anti-oxidant, the paper is avoided from being oxidized and yellowed during the papermaking process. With the addition of the chopped fiber, dispersion of fiber in water can be enhanced, and some slightly large gaps in the paper can be filled up during the papermaking process. In the hot-pressing process, extrusion of the small bulges on the surface of the soft roller is beneficial to discharge of water vapor inside the paper.

Owner:丁秀臣 +1

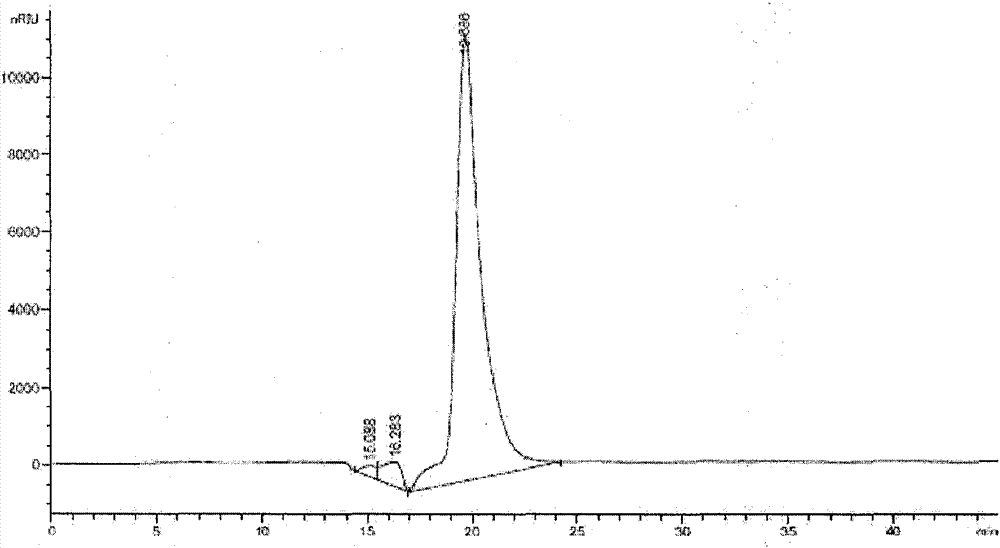

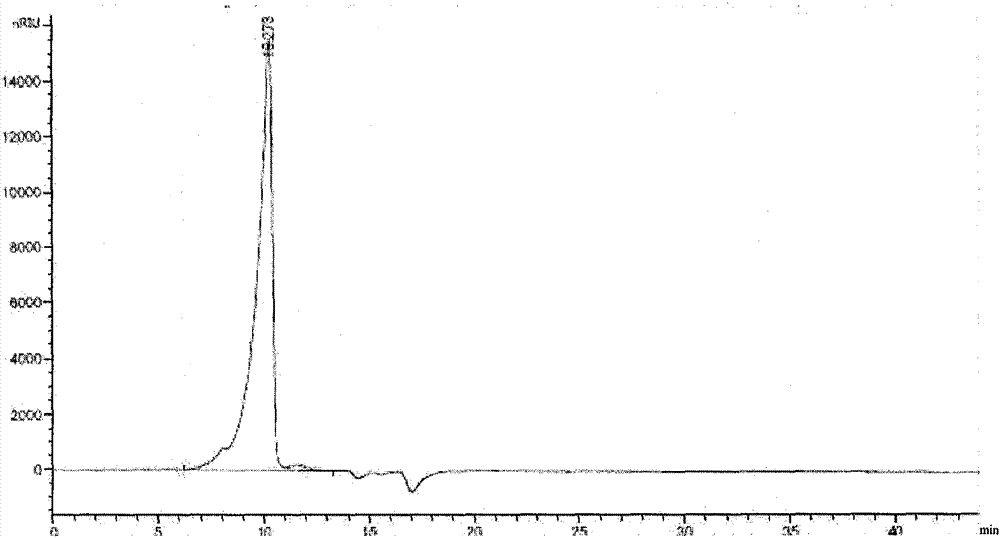

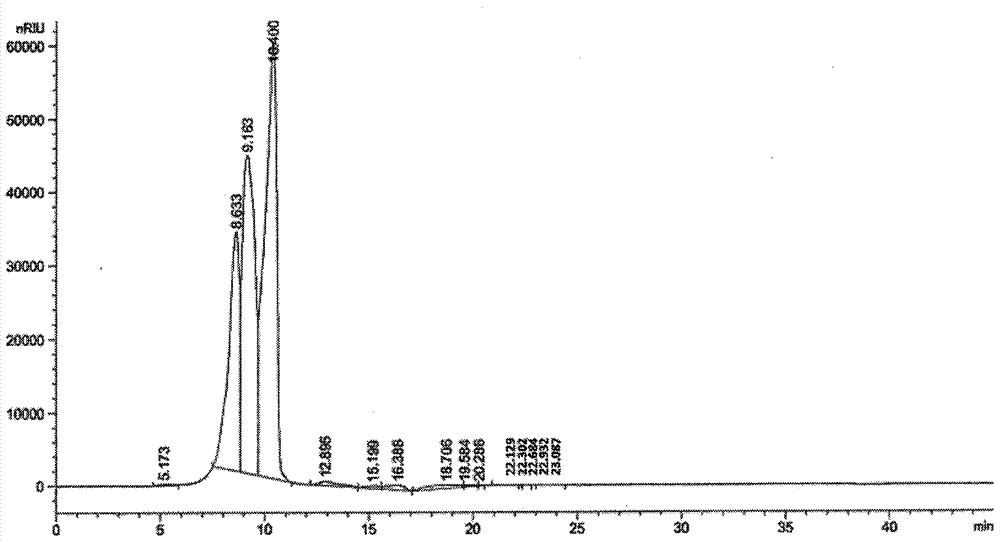

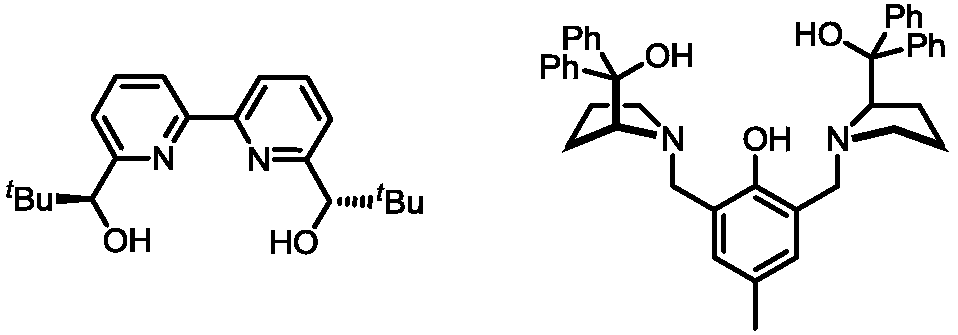

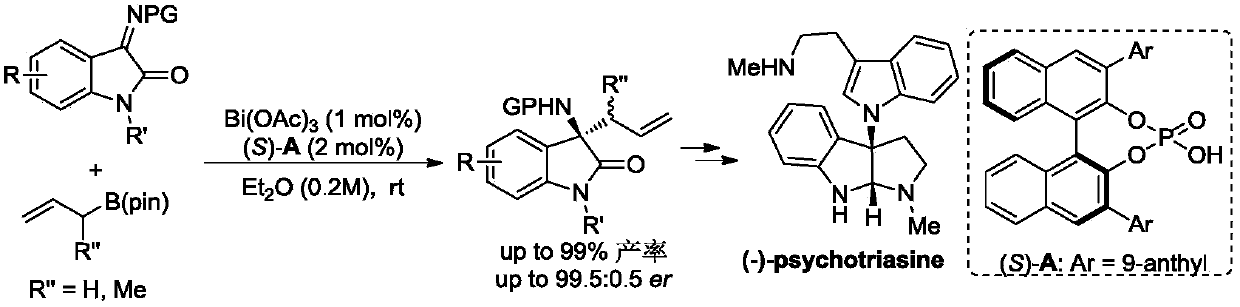

Asymmetric bismuth catalysis system, preparation method and application thereof

ActiveCN109590024AAchieve activationTo achieve the purpose of activationOrganic chemistryOrganic-compounds/hydrides/coordination-complexes catalystsOxonium ionPhosphoric acid

The invention provides an asymmetric bismuth catalysis system, a preparation method and an application thereof, relates to the technical field of asymmetric catalysis and provides an asymmetric bismuth catalysis system. By adoption of the asymmetric bismuth catalysis system, the problem of high Substrate specificity of the bismuth catalysis system is solved. The asymmetric bismuth catalysis systemcomprises a metal activity center and a chiral ligand, wherein the metal activity center is selected from one or more of bismuth acetate, bismuth hydroxide, bismuth bromide or bismuth iodide; the chiral ligand is selected from chiral phosphoric acid. The asymmetric bismuth catalysis system is used for catalyzing multiple types of asymmetric transformations such as asymmetric allylation of ketoneand imine, asymmetric allylation of oxonium ions and asymmetric reaction of imine and phenolic substrates and the like.

Owner:NANKAI UNIV

Preparation method of nanometer ZrO2/BiOCl composite powder

InactiveCN103274464AThe synthesis process is simpleLow costMaterial nanotechnologyBismuth compoundsPolyethylene glycolZirconium oxychloride

The invention discloses a preparation method of nanometer ZrO2 / BiOCl composite powder, relating to a method for preparing the nanometer ZrO2 / BiOCl composite powder through a hydrothermal method. The invention aims to solve the technical problems of complex preparation process, uneven contents of composite powder, high cost and poor thermal stability of single bismuth oxychloride during the preparation of pearlescent pigment composite powder coated by an oxide. The method comprises the following steps of: (1) dissolving bismuth nitrate into nitric acid, evenly stirring and then adding water for dilution to acquire a bismuth nitrate solution; (2) preparing an aqueous ammonia solution; (3) preparing bismuth hydroxide colloid; (4) preparing a zirconium oxychloride solution; (5) dissolving polyethylene glycol into water to acquire a polyethylene glycol solution; (6) mixing the bismuth hydroxide colloid, the zirconium oxychloride solution and the polyethylene glycol solution and pouring the mixture into a hydrothermal reactor and preserving the heat, and naturally cooling to acquire the nanometer ZrO2 / BiOCl composite powder. The preparation method of the nanometer ZrO2 / BiOCl composite powder is simple in synthetic process, low in cost, favorable in pearl effect of the composite powder and good in stability and is applied to the fields of primers for a car, cosmetics and paintings.

Owner:HARBIN UNIV OF SCI & TECH

Anti-yellowing meta-aramid fibrid and preparation method and application thereof

InactiveCN112195529AImprove bindingImprove effective utilizationSynthetic cellulose/non-cellulose material pulp/paperCorrosion-inhibiting/anti-oxidant agent additionArylEndcapping

The invention discloses an anti-yellowing meta-aramid fibrid and a preparation method and application thereof. The preparation method comprises the following steps that isophthaloyl dichloride is gradually added into an m-phenylenediamine solution, then aryl ternary acyl chloride is added, finally tetramethyl piperidine amine is added for terminating, and a meta-aramid resin solution is obtained;after the meta-aramid resin solution is neutralized, an anti-yellowing agent is added, and stirring is carried out to obtain a precipitation resin stock solution; the anti-yellowing agent is preparedby grinding bismuth hydroxide and a silane coupling agent in a solvent; and precipitation molding is carried out on the precipitation resin stock solution, and washing is carried out to obtain the meta-aramid fibrid. Macromolecular chains of the fibrid prepared by the method are terminated by the tetramethyl piperidine amine, bismuth hydroxide is adhered to the surface of the fibrid and is well combined with the meta-aramid fibrid, and prepared aramid paper is bright in surface, uniform and compact and has excellent yellowing resistance, thermal oxidation resistance and insulating property.

Owner:ZHUZHOU TIMES NEW MATERIALS TECH

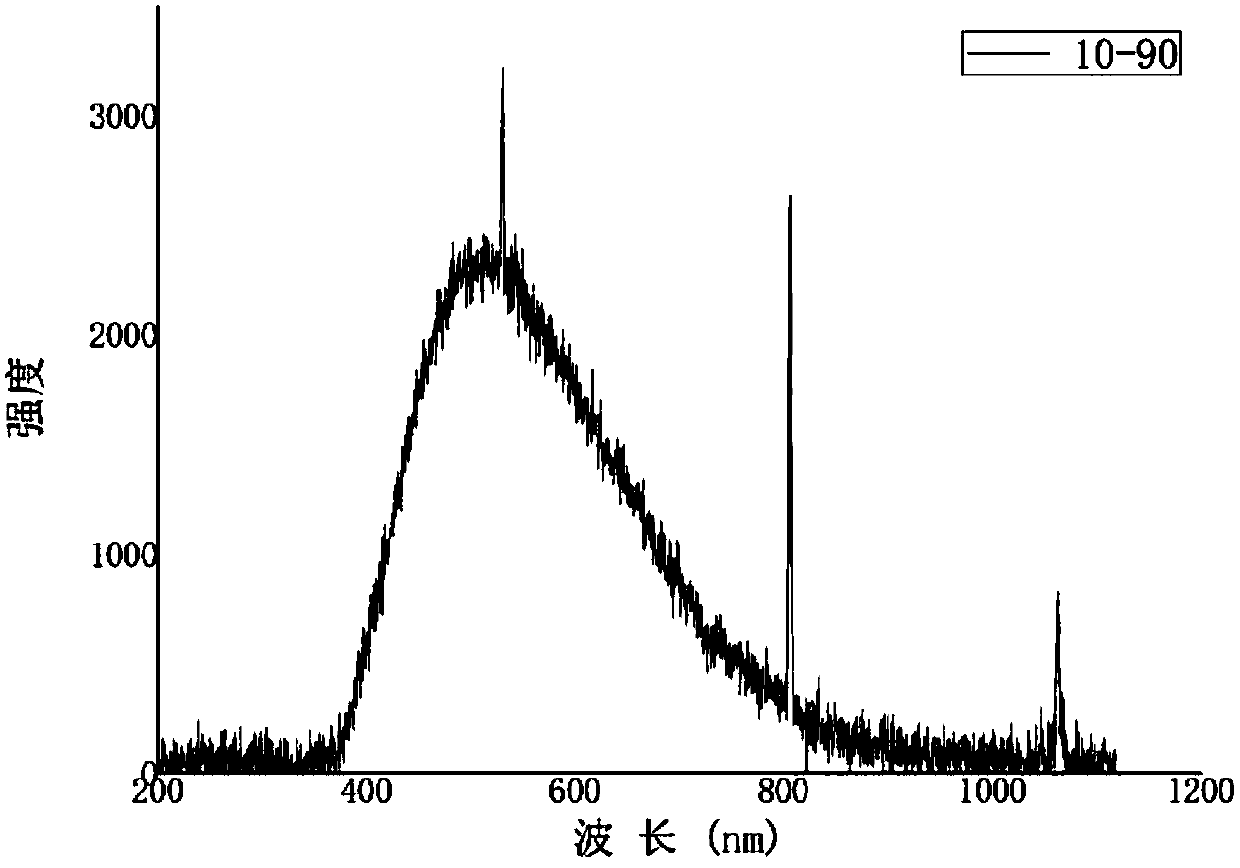

Glass-ceramic containing a bismuth germanate crystal phase, and preparation method thereof

InactiveCN107698165AEasy to processImprove performanceLuminescent compositionsFull width at half maximumBismuth germanate

The present invention relates to a glass-ceramic containing a bismuth germanate crystal phase, and a preparation method thereof, wherein the microcrystalline phase of the glass-ceramic is bismuth germanate, and the preparation raw materials of the glass-ceramic comprise bismuth trioxide, germanium dioxide and bismuth hydroxide according to a molar ratio of 10-40:60-90:3-10. The specific preparation method comprises: (1) preparing raw materials according to a certain ratio, and grinding the raw materials; (2) mixing the grinded raw materials, and carrying out high temperature melting to preparea glass; and (3) annealing the prepared glass, and cooling to obtain the glass-ceramic containing the bismuth germanate crystal phase. According to the present invention, the scintillating glass-ceramic material has the light-emitting property similar to the crystal material with the full width at half maximum of about 200 nm, has good processability so as to be widely used in ray detection, further has advantages of excellent glass material performance, stable size, simple preparation process, designable performance and low production cost, and can be welded to metals.

Owner:TONGJI UNIV

Nontoxic, noncorrosive phosphorus-based primer compositions

A primer composition that includes stabilized, encapsulated red phosphorus, at least one oxidizer, at least one secondary explosive composition, at least one light metal, and at least one acid resistant binder. The stabilized, encapsulated red phosphorus may include particles of red phosphorus, a metal oxide coating, and a polymer layer. The metal oxide coating may be a coating of aluminum hydroxide, bismuth hydroxide, cadmium hydroxide, cerium hydroxide, chromium hydroxide, germanium hydroxide, magnesium hydroxide, manganese hydroxide, niobium hydroxide, silicon hydroxide, tin hydroxide, titanium hydroxide, zinc hydroxide, zirconium hydroxide, or mixtures thereof. The polymer layer may be a layer of epoxy resin, melamine resin, phenol formaldehyde resin, polyurethane resin, or mixtures thereof. A percussion cap primer that includes the primer composition, a tertiary explosive composition, and a cup is also disclosed, as are ordnance devices including the primer composition.

Owner:NORTHROP GRUMMAN SYST CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com