Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

50results about How to "Excellent finished appearance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Water-based intercoating composition and method of forming multilayered coating film

InactiveUS20060121204A1Improve propertiesGood lookingLiquid surface applicatorsPolyurea/polyurethane coatingsPolymer sciencePolyol

A water-based intermediate coating composition which contains a water-dispersible polyurethane composition is used. Here, the water-dispersible polyurethane composition is obtained from: a polyisocyanate component containing diisocyanate as an essential component; a polyol component containing polycarbonatediol with an average molecular weight of 500 to 5,000 and carboxyl group-containing diol as essential components; an amine component containing a monoamine compound as an essential component; a carboxyl group-neutralizing component; and water. A three-layered coating film including the water-based intermediate coating, a water-based base coating and a clear coating is formed through a wet-on-wet process on a material onto which an electrodeposited coating film is formed. Thereafter, the three coating films are baked and cured at the same time, thereby forming a multilayer coating film.

Owner:NIPPON PAINT CO LTD

Aqueous two-package type clear coating composition and process for the formation of multilayer finish coating film

ActiveUS20090274846A1Remarkable effectExcellent film performancePretreated surfacesPolyurea/polyurethane coatingsAcrylic resinGlass transition

The present invention provides an aqueous two-package type clear coating composition comprising: (A) an aqueous dispersion of a hydroxyl group- and acid group-containing acrylic resin having a hydroxyl value of 30 to 200 mg KOH / g, an acid value of 5 to 50 mg KOH / g, a weight average molecular weight of 3,000 to 30,000, and a glass transition temperature of −30 to +40° C. obtained by radical polymerization of 10 to 50 mass % of a secondary hydroxyl group-containing monomer (a) and 50 to 90 mass % of at least one other unsaturated monomer (b); and (B) a polyisocyanate curing agent obtained by mixing (c) a polyisocyanate compound and (d) a compound containing an anionic functional group, a polyoxyethylene group, and a hydrocarbon group, and a process for forming a multilayer topcoat film using the same.

Owner:KANSAI PAINT CO LTD

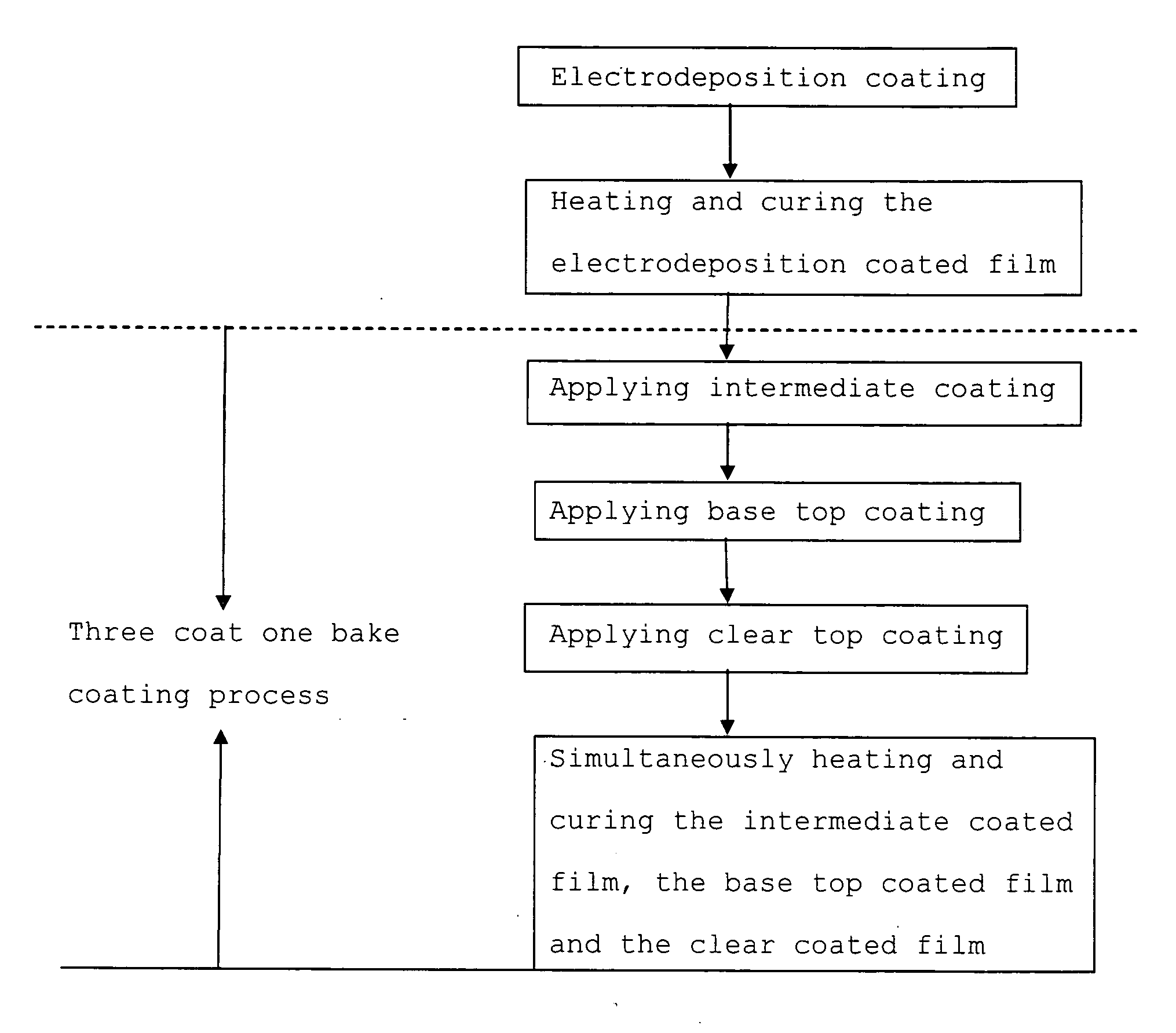

Process for forming multi layered coated film and multi layered coated film

InactiveUS20050161330A1Save energyLow costElectrolysis componentsVolume/mass flow measurementVolumetric Mass DensityCoating

The present invention provides a process for forming a multi layered coated film having good finished appearance. The present invention relates to a process for forming a multi layered coated film comprising the steps of conducting electrodeposition coating with a cationic electrodeposition coating composition on a substrate, and then heating and curing it to form an cured electrodeposition coated film on the substrate, applying an intermediate coating composition on the cured coated film to form an uncured intermediate coated film, applying a base top coating composition on the uncured intermediate coated film to form an uncured base coated film, applying a clear top coating composition on the uncured base coated film to form an uncured clear coated film, and simultaneously heating and curing the three uncured coated films, wherein the cured electrodeposition coated film has specified ranges of Ra and Pa; or has specified ranges of Tg and crosslinking density.

Owner:NIPPON PAINT CO LTD

Method for forming multilayer coating film

ActiveUS20150218405A1Improve curing effectImprove waterproof performanceSynthetic resin layered productsPretreated surfacesTime conditionOrganometallic catalysis

An object of the present invention is to provide a method for forming a multilayer coating film, capable of achieving excellent curability under low-temperature, short-time conditions, and forming a multilayer coating film having excellent chipping resistance and an excellent finished appearance. This method comprises sequentially applying an aqueous first colored coating composition (X), an aqueous second colored coating composition (Y), and a clear coating composition (Z) to a substrate, and simultaneously bake-curing the resulting multilayer coating film. In this method, the aqueous first colored coating composition (X) comprises an aqueous film-forming resin (A) and a specific blocked polyisocyanate compound (B), and the clear coating composition (Z) comprises a hydroxy-containing acrylic resin (K) having a hydroxy value in a specific range, a polyisocyanate compound (L), and an organometallic catalyst (M) containing a metal compound (M1) selected from a specific range and an amidine compound (M2).

Owner:KANSAI PAINT CO LTD

Water-based coating composition and method for forming multilayer coating film

InactiveUS20120107619A1Prevent roughness of surfacePrevents formationSynthetic resin layered productsPretreated surfacesPolycarbonateIsocyanate

This invention relates to an aqueous coating composition comprising an acrylic or polyester resin (A); a curing agent (B); and a blocked isocyanate group-containing urethane resin emulsion (C) having a weight average molecular weight of 2,000 to 50,000, which is prepared using a polyisocyanate component and a polyol component as starting materials, the polyisocyanate component comprising an alicyclic diisocyanate, and the polyol component comprising a polycarbonate diol in an amount of 50 mass % or more, based on the total amount of the polyol component; (i) when the component (A) is an acrylic resin, the aqueous coating composition comprising the component (C) in an amount of, as solids content, 20 to 60 mass %, based on the total solids content of the components (A), (B) and (C); and (ii) when the component (A) is a polyester resin, the aqueous coating composition comprising the component (C) in an amount of, as solids content, 10 to 50 mass %, based on the total solids content of the components (A), (B) and (C).

Owner:KANSAI PAINT CO LTD

Automobile body-coating method

InactiveUS20030201182A1Safely and stably and continuouslyExcellent finished appearanceElectrolysis componentsVolume/mass flow measurementWater basedMaterials science

An automobile body-coating method which comprises optionally subjecting an aluminum material in the automobile body to a surface treatment, followed by subjecting to an oxidizing film treatment, essentially or optionally, respectively and successively forming a curable electrodeposition coating film, a water based chipping primer coating film, an intercoat coating film, and a curable topcoat coating film, or comprises applying a film racing material onto an aluminum material or coating film-coated aluminum material, and comprises forming respective multi-layer coating films onto the steel material in the automobile body respectively.

Owner:KANSAI PAINT CO LTD

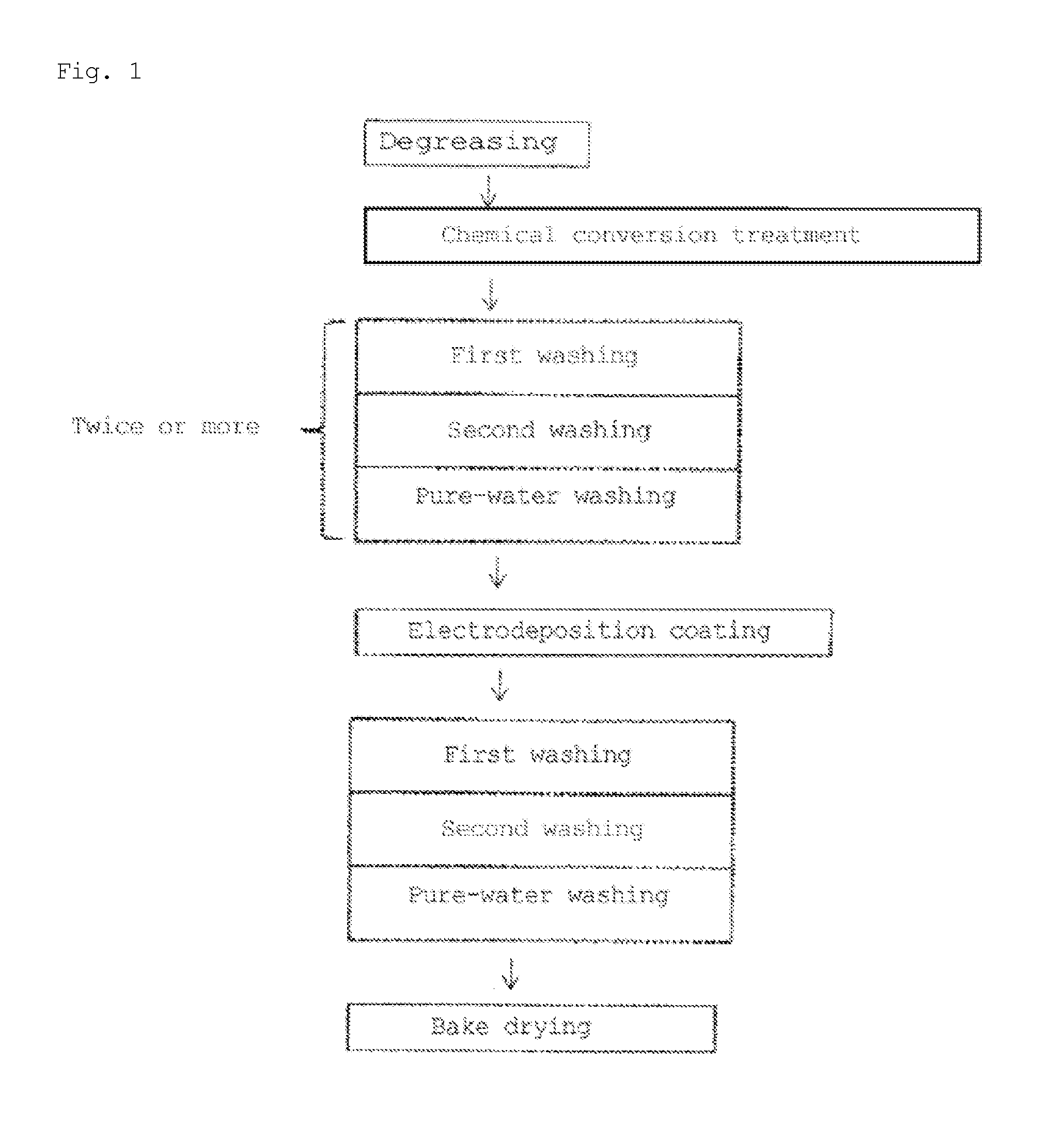

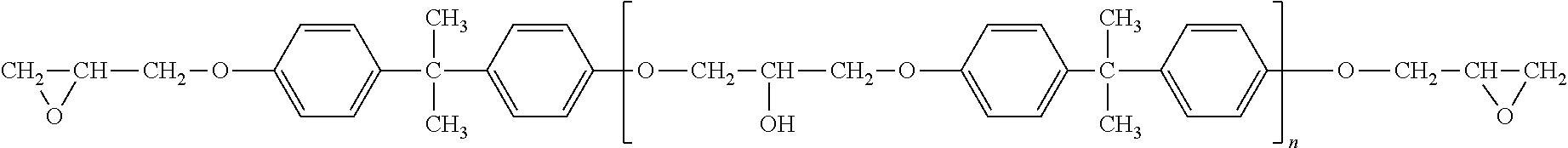

Electrodeposition coating composition, coating method and coated article

InactiveUS20060211831A1Improve corrosion resistanceExcellent finished appearanceSynthetic resin layered productsSurface reaction electrolytic coatingIonTungsten

A coated article is obtained by electrodeposition coating using an electrodeposition coating composition, which comprises: (A) a resin component obtained by reacting an epoxy resin, an amino compound and / or a phenolic compound; (B) a resin component having a specific structural unit; (C) a blocked polyisocyanate compound; and (D) at least one rust inhibiting component selected from the group consisting of metal ions selected from zirconium, titanium, cobalt, vanadium, tungsten and molybdenum, oxymetal ions of the metal, and fluorometal ions of the metal.

Owner:TOYOTA JIDOSHA KK

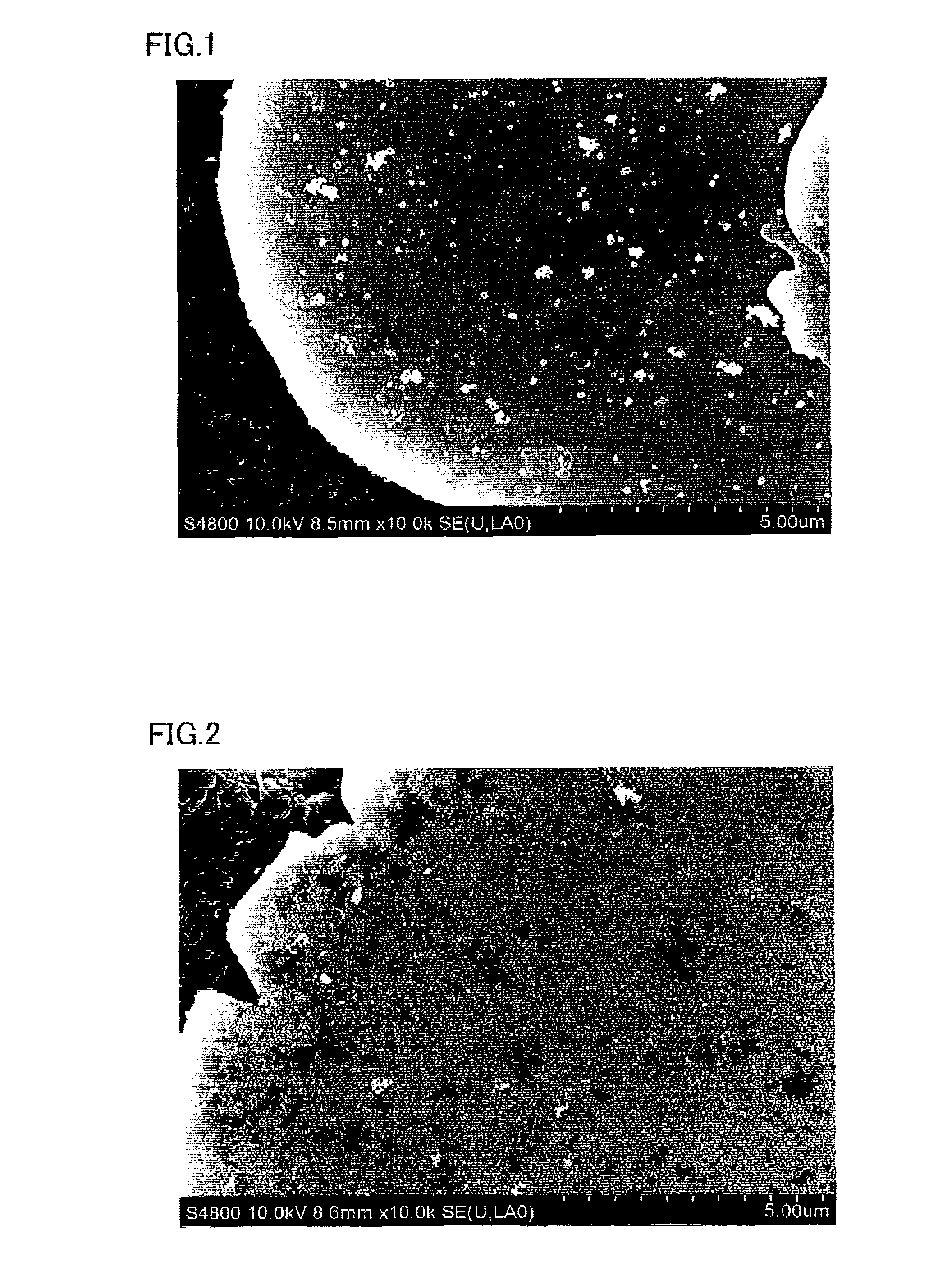

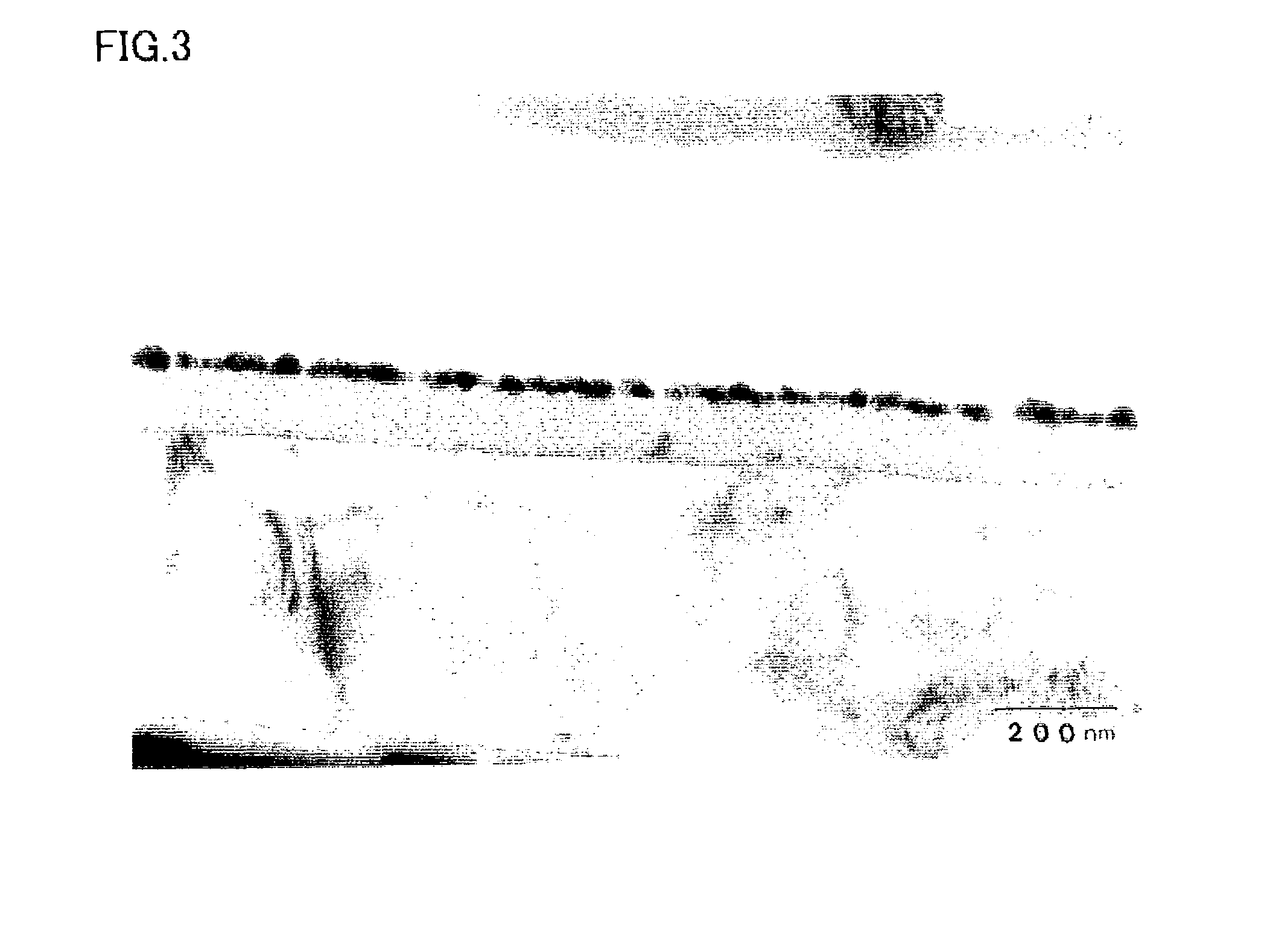

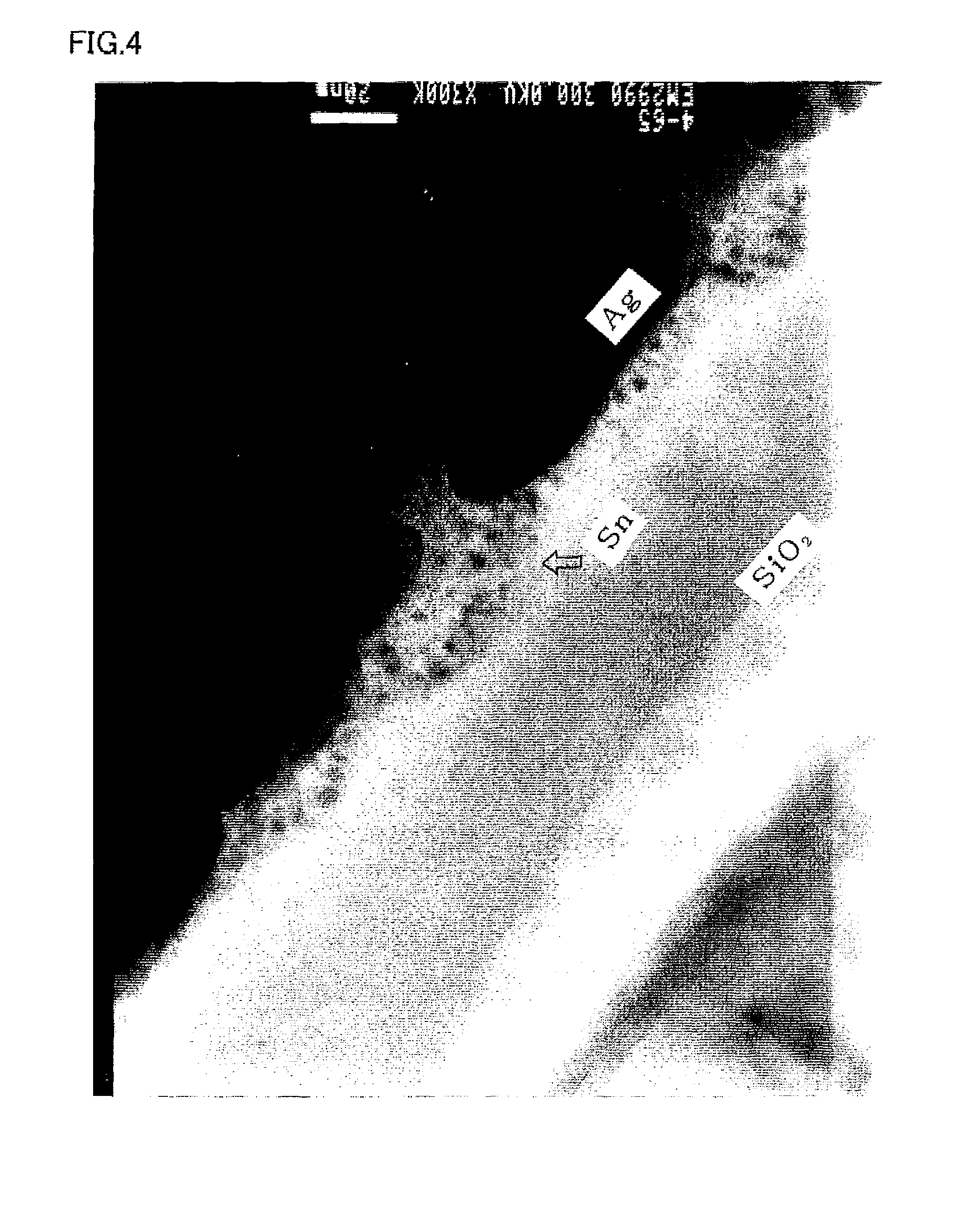

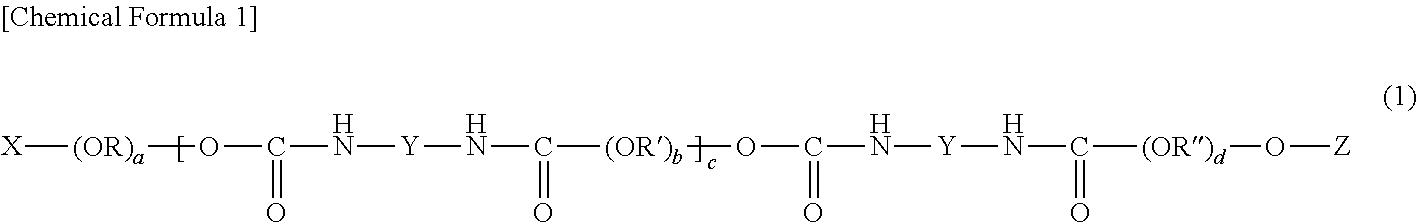

Colored metallic pigment, process for producing the same, and coating composition and cosmetic preparation containing said colored metallic pigment

ActiveUS7998266B2Excellent finished appearanceLight resistanceCosmetic preparationsLiquid surface applicatorsInterference colorNonferrous metal

This invention provides a colored metallic pigment, which can develop a variety of colors and varied interference colors while maintaining good lightfastness, weatherfastness and hiding power, a process for producing the same, a coating composition containing the colored metallic pigment and capable of providing a coating film having excellent finished appearance, and a cosmetic preparation containing the colored metallic pigment, having excellent hiding power, and capable of providing sharp hue. The colored metallic pigment comprises at least a metallic pigment, an amorphous silicon oxide film layer provided on the surface of the metallic pigment, a metal layer provided on the surface of the amorphous silicon oxide film layer, and metallic particles provided on the surface of the metal layer. The metallic particles are provided so as to directly cover a part of the surface of the metal layer. In the colored metallic pigment, the metal layer preferably comprises at least one metal selected from Sn, Pd, Pt and Au. The metallic particle preferably comprises at least one metal selected from Cu, Ni and Ag.

Owner:TOYO ALUMINIUM KK

Color metallic pigment, method for producing same, and coating composition and cosmetic containing same

ActiveUS20130131187A1Excellent obliterate powerSimpleBiocideCosmetic preparationsSilicon oxideMaterials science

A color metallic pigment according to the present invention contains at least a metallic pigment, an amorphous silicon oxide film layer that is formed on the surface of the metallic pigment, a metal oxide layer that is formed on the surface of the amorphous silicon oxide film layer and contains a metal oxide other than silicon oxide, and metal particles that are formed on the surface of the metal oxide layer, wherein the metal particles are so formed as to directly cover a part of the metal oxide layer.

Owner:TOYO ALUMINIUM KK

Aqueous coating composition and method for forming multilayer coating film

ActiveUS20110117378A1Excellent finished appearanceImprove surface smoothnessSynthetic resin layered productsPretreated surfacesCarbon numberPolymer science

An object of the present invention is to provide an aqueous coating composition capable of forming a coating film having a superior finishing appearance. The present invention provides an aqueous coating composition comprising a polyester resin containing a predetermined or greater amount of long chain, straight-chain dicarboxylic acid and / or straight-chain diols having a predetermined or greater carbon number and having hydroxy groups and acid values within predetermined ranges; a urethane-associated thickener having a hydrophobic group and / or a polyacrylic acid-based thickener having a hydrophobic group; a curing agent; and a hydrophobic solvent, wherein the contents of the thickener and the hydrophobic solvent are within a specific range based on the gross amount of the polyester resin and the curing agent. The present invention also provides a method for forming a multilayer coating film using the aqueous coating composition.

Owner:KANSAI PAINT CO LTD

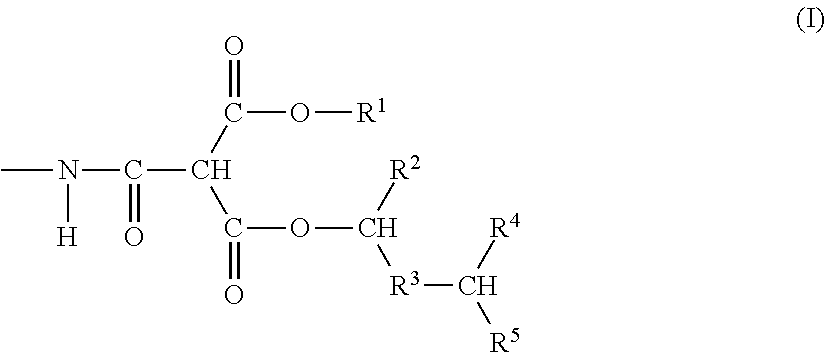

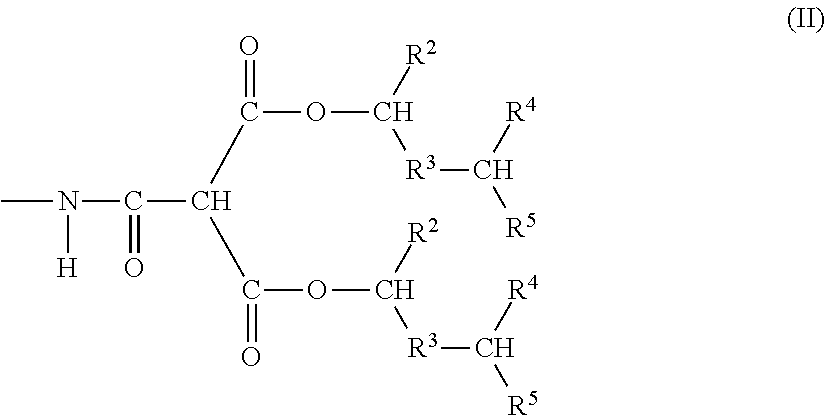

Paint composition and coating film formation method

InactiveUS20110293844A1Excellent finished appearanceImprove compatibilityLiquid surface applicatorsOrganic dyesAcrylic resinCarboxylic acid

An object of the present invention is to provide a coating composition capable of forming a cured coating film with excellent scratch resistance, acid resistance, stain resistance, and finished appearance.The present invention provides coating composition comprising (A) carboxy-containing polymer, (B) epoxy-containing acrylic resin, and (C) carboxy-containing reaction product with an acid value of 50 to 200 mg KOH / g and a number average molecular weight of 600 to 5,000 obtained by a half-esterification reaction of an acid anhydride with a polycarbonate polyol having three or more hydroxyl groups per molecule.

Owner:KANSAI PAINT CO LTD

Polyester resin and thermosetting water-borne coating compositions

ActiveUS20090197094A1Improve waterproof performanceExcellent finished appearanceSynthetic resin layered productsCellulosic plastic layered productsMonomer compositionPolymer science

The invention discloses specific polyester resins which are obtained by the technique of reacting polyesterpolyol oligomer of specific monomeric composition further with polyvalent carboxylic acid (anhydride) and the like; thermosetting water-borne coating compositions using the polyester resins, and coating film-forming methods using the thermosetting water-borne coating compositions.

Owner:KANSAI PAINT CO LTD

Preparation method for efficient crystal silicon passivated emitter rear contact (PERC) solar cell

InactiveCN106057971AImprove battery efficiencyImprove uniformityFinal product manufacturePhotovoltaic energy generationScreen printingProtection layer

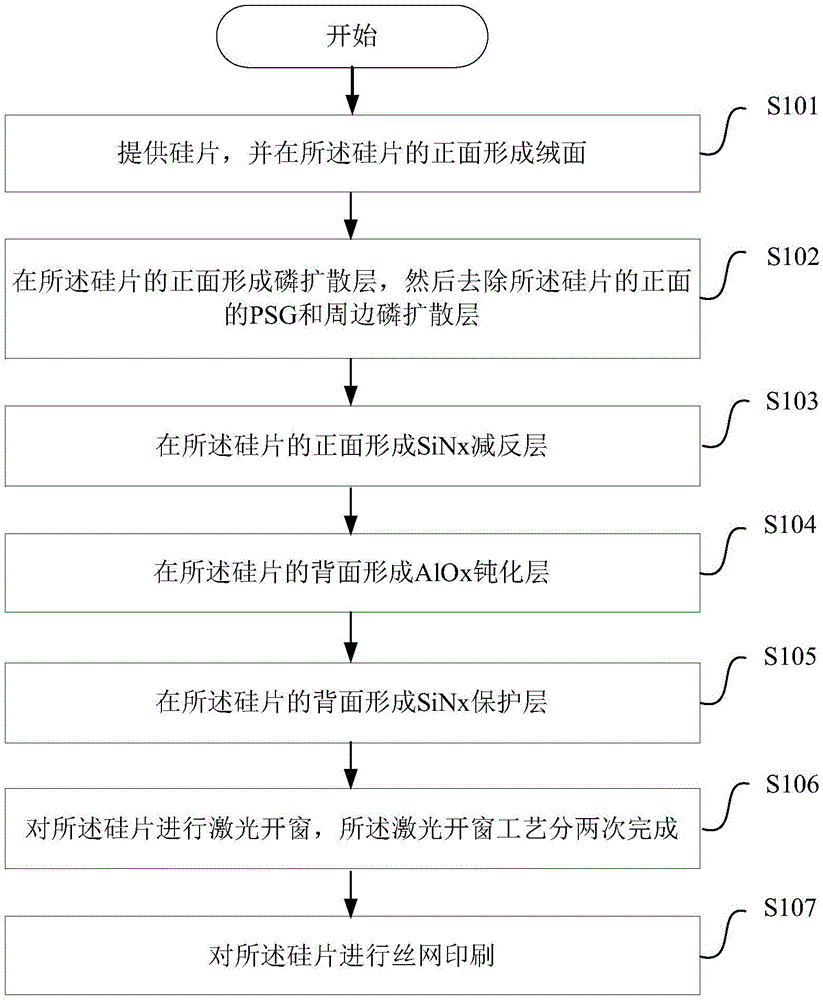

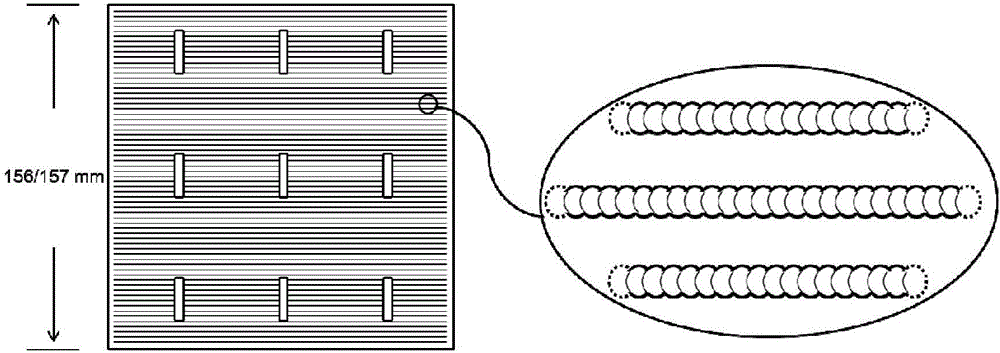

The invention discloses a preparation method for an efficient crystal silicon passivated emitter rear contact (PERC) solar cell. The production method comprises the steps of providing a silicon wafer, and forming a textured surface on the front surface of the silicon wafer; forming a phosphorus diffusion layer on the front surface of the silicon wafer, and then removing PSG and peripheral phosphorus diffusion layer on the front surface of the silicon wafer; forming an SiNx antireflection layer on the front surface of the silicon wafer; forming an AlOx passivation layer on the back surface of the silicon wafer; forming an SiNx protection layer on the back surface of the silicon wafer; windowing the silicon wafer by a laser, wherein the laser windowing process is completed in two times; and implementing silk-screen printing on the silicon wafer. Correspondingly, the invention also provides the efficient crystal silicon PERC solar cell, which is prepared by using the preparation method provided by the invention. The preparation method provided by the invention is simple in technology and low in cost, and the acquired crystal silicon PERC solar cell is high in efficiency and good in appearance.

Owner:ZHEJIANG ASTRONERGY

Aqueous coating composition and method for forming multilayer coating film

ActiveUS8436084B2Excellent finished appearanceImprove surface smoothnessSynthetic resin layered productsPretreated surfacesCarbon numberAcid value

An object of the present invention is to provide an aqueous coating composition capable of forming a coating film having a superior finishing appearance. The present invention provides an aqueous coating composition comprising a polyester resin containing a predetermined or greater amount of long chain, straight-chain dicarboxylic acid and / or straight-chain diols having a predetermined or greater carbon number and having hydroxy groups and acid values within predetermined ranges; a urethane-associated thickener having a hydrophobic group and / or a polyacrylicacid-based thickener having a hydrophobic group; a curing agent; and a hydrophobic solvent, wherein the contents of the thickener and the hydrophobic solvent are within a specific range based on the gross amount of the polyester resin and the curing agent. The present invention also provides a method for forming a multilayer coating film using the aqueous coating composition.

Owner:KANSAI PAINT CO LTD

Polyester resin and thermosetting water-borne coating compositions

ActiveUS8309229B2Improve waterproof performanceExcellent finished appearanceSynthetic resin layered productsCellulosic plastic layered productsOligomerPolyol

The invention discloses specific polyester resins which are obtained by the technique of reacting polyesterpolyol oligomer of specific monomeric composition further with polyvalent carboxylic acid (anhydride) and the like; thermosetting water-borne coating compositions using the polyester resins, and coating film-forming methods using the thermosetting water-borne coating compositions.

Owner:KANSAI PAINT CO LTD

Paint composition and method for forming multi-layered coating film

ActiveUS20150284585A1Reduce molecular weightReduce the impactSynthetic resin layered productsPretreated surfacesPolyolPolymer chemistry

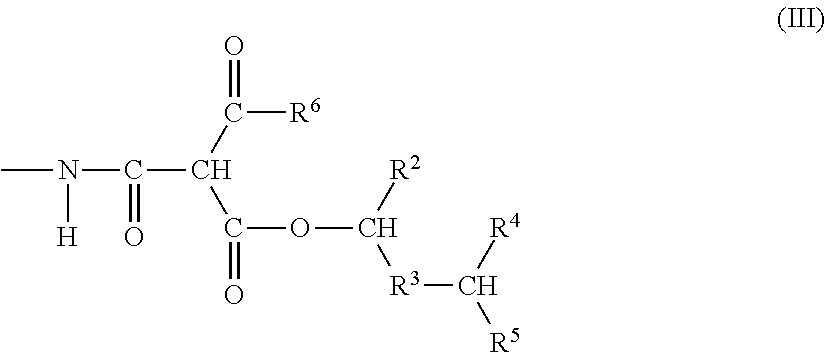

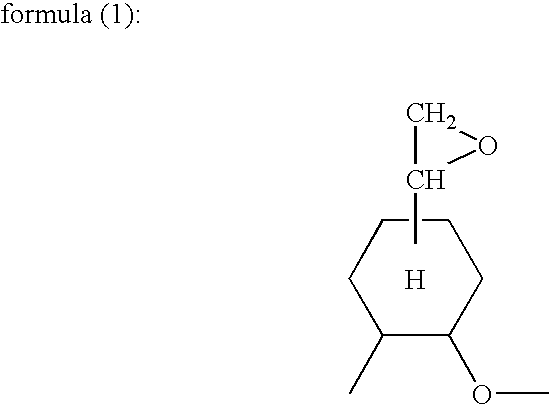

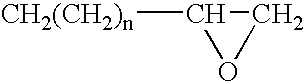

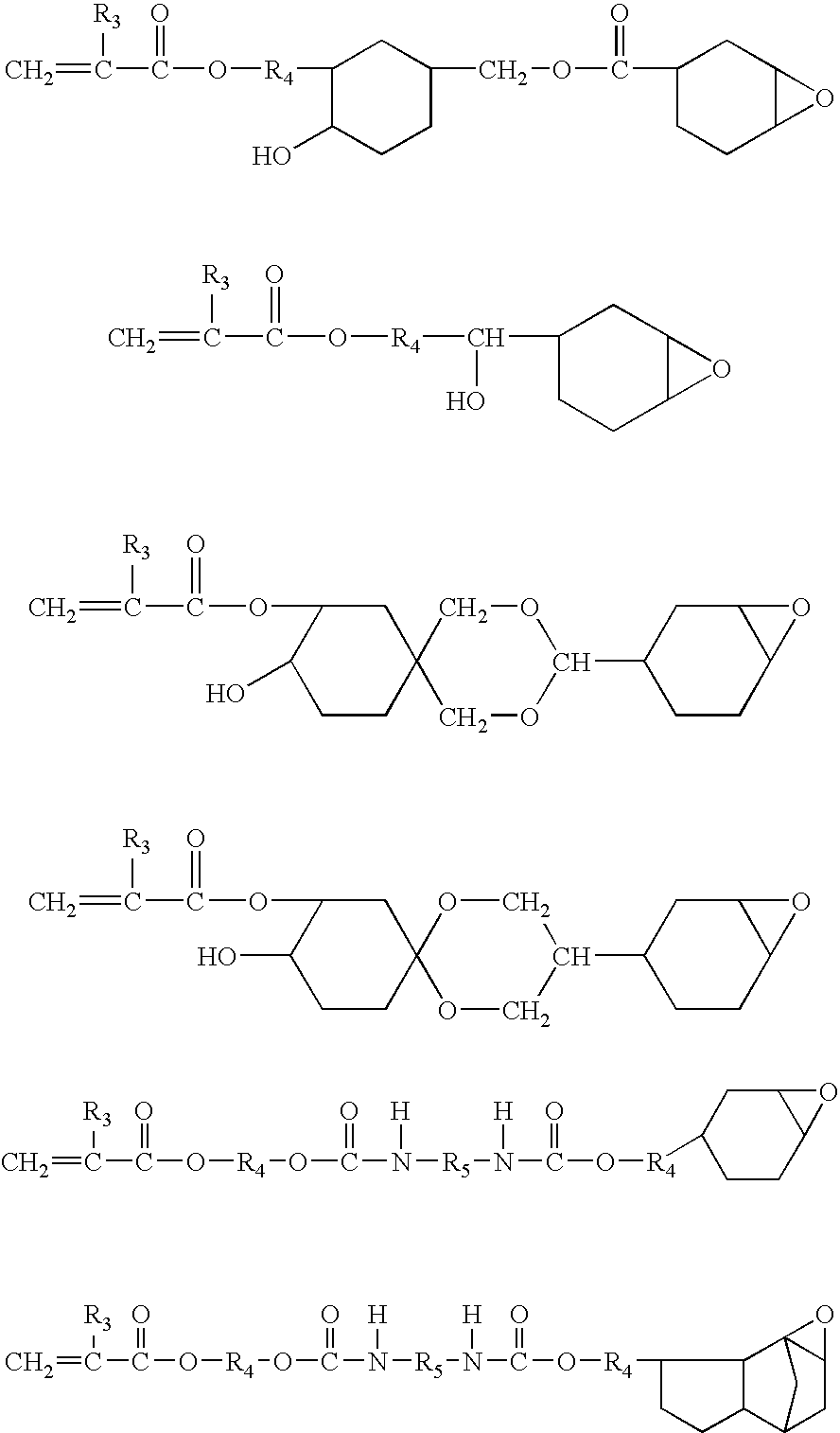

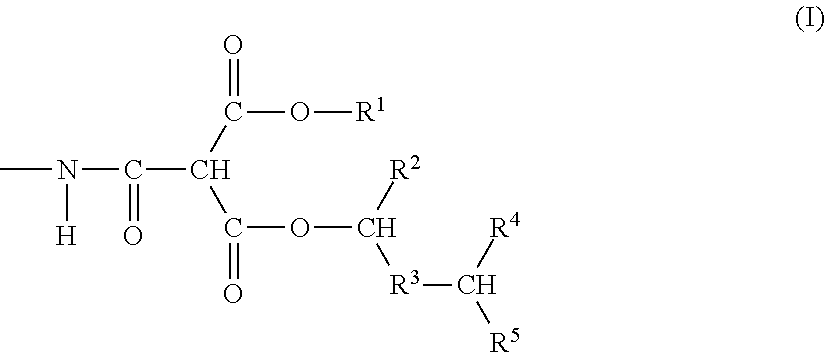

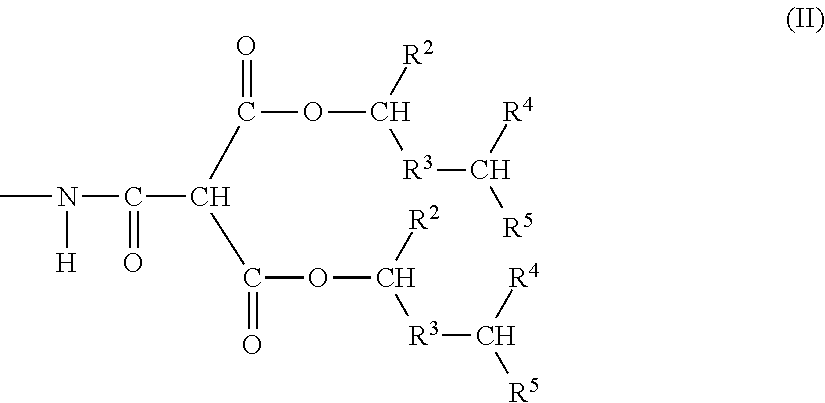

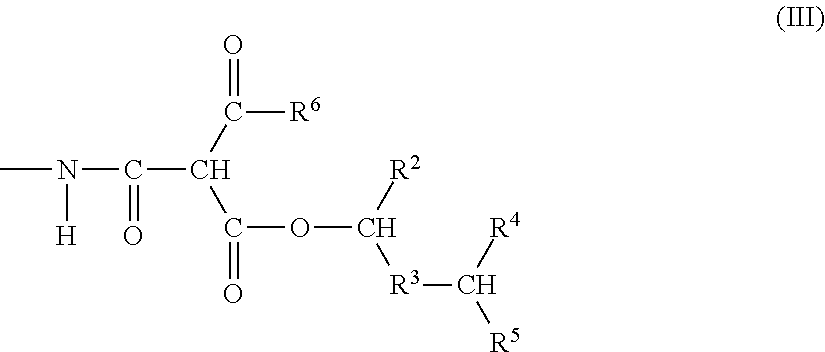

This invention relates to a coating composition comprising a carboxy-containing compound (A), a polyepoxide (B), and a specific polyol (C) having a number average molecular weight of 300 to 1,500, and a method for forming a multilayer coating film using the coating composition as a clear coating composition, the method comprising sequentially applying an aqueous first colored coating composition, an aqueous second colored coating composition, and the clear coating composition to a substrate, and heat-curing the resulting coating films all at once to form the multilayer coating film.

Owner:KANSAI PAINT CO LTD

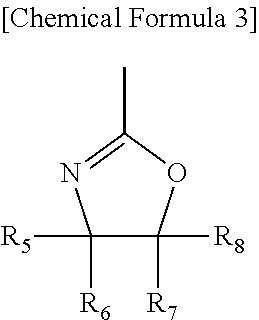

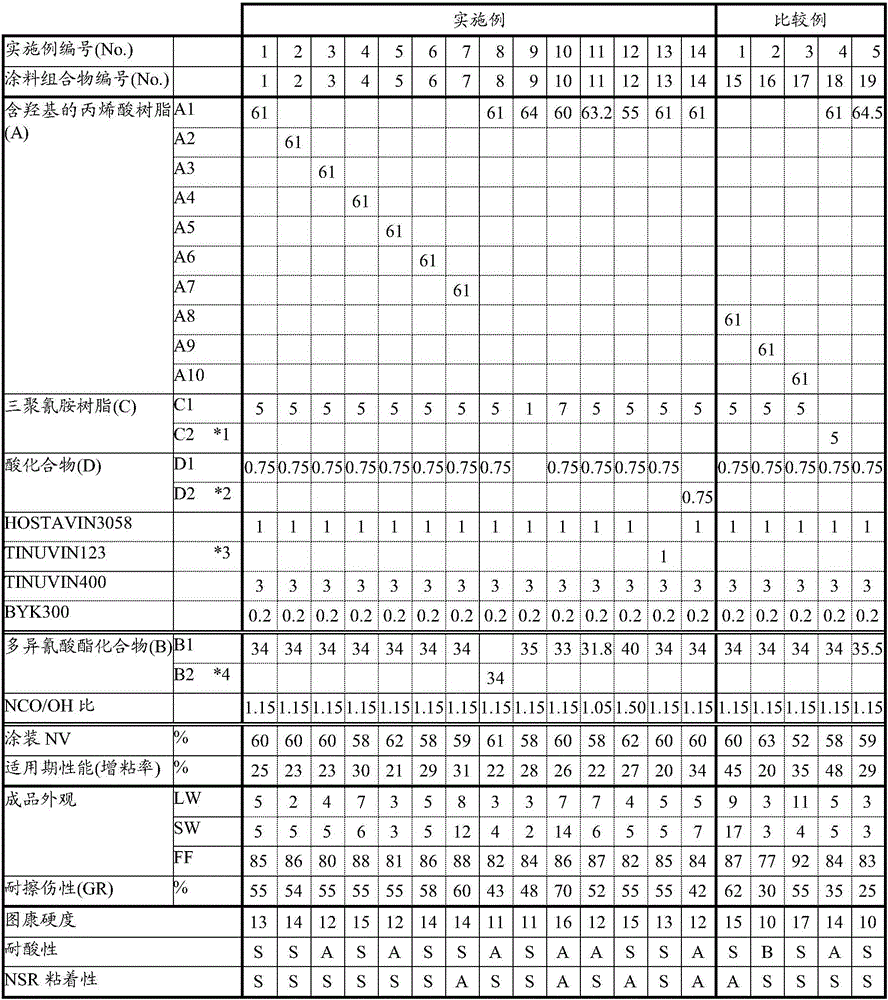

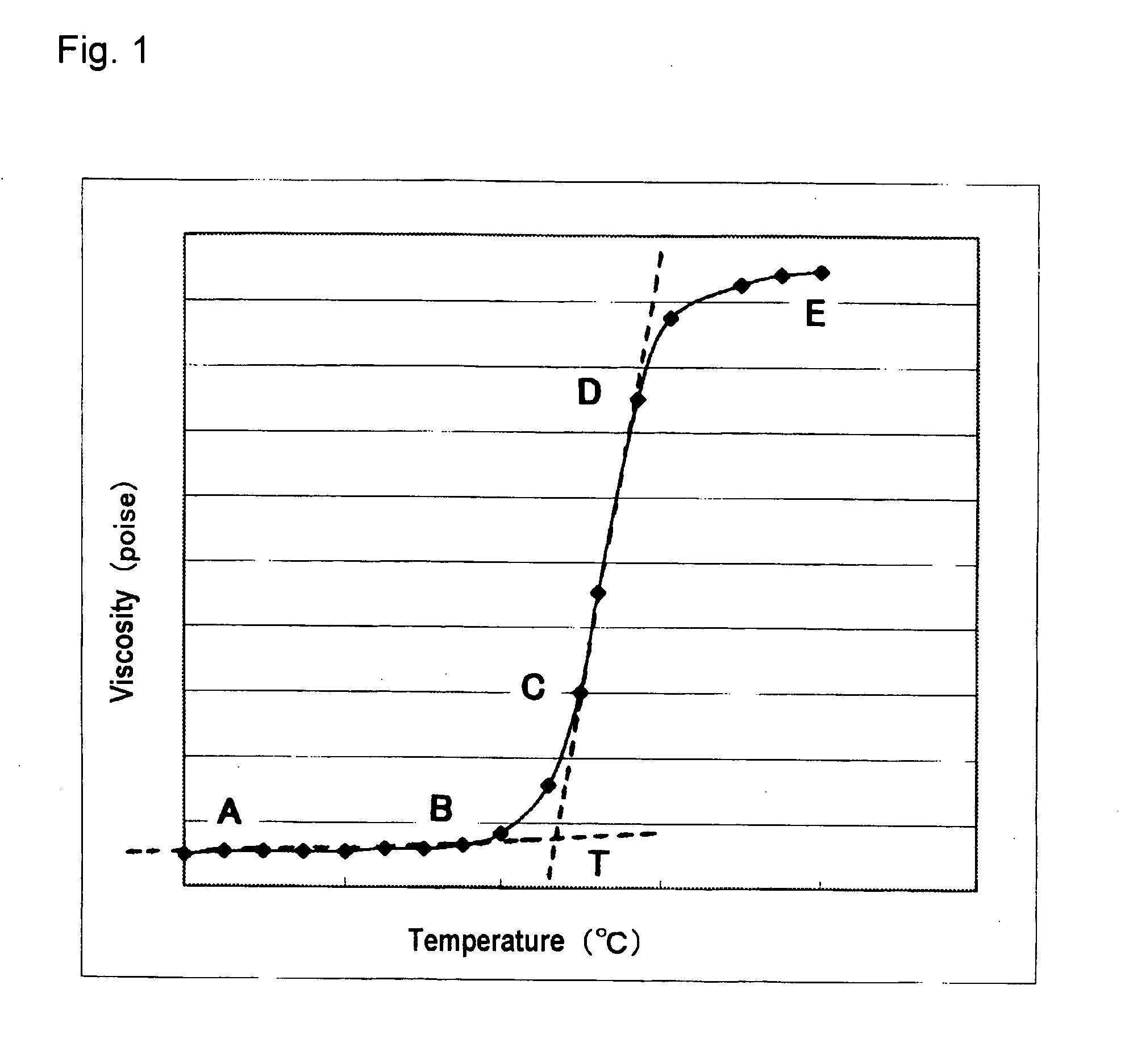

High-solid coating composition

InactiveCN107177294AImprove acid resistanceImprove scratch resistancePolyurea/polyurethane coatingsAcrylic resinPhosphoric acid

The invention provides a high-solid coating composition and a multilayer paint film forming method employing the same, wherein the high-solid coating composition is capable of obtaining a coating film excellent in pot life, excellent in scratch resistance, acid resistance, and finished appearance (moisture-resistant property). The high-solid coating composition comprises (A) acrylic resin containing secondary hydroxyl having a weight-average molecular weight of 3000-7000, (B) an aliphatic polyisocyanate compound and / or a derivative thereof, (C) an alkyl etherified melamine resin having a weight-average molecular weight of 1,000 or less, and (D) a sulfonate compound and / or a phosphate compound, wherein the amount of the component (C) to the total amount of the component (B) is within a range of 1.5 to 20% by mass.

Owner:KANSAI PAINT CO LTD

Cationic electrodeposition coating composition

InactiveUS20050282936A1Low specular glossExcellent finished appearanceSynthetic resin layered productsPretreated surfacesIsocyanateEmulsion

The present invention provides a cationic electrodeposition coating composition which can provide an electrodeposition coating film having low specular gloss and excellent finished appearance. The present invention relates to a cationic electrodeposition coating composition comprising a cationic emulsion (A) which comprises (a) a cationic epoxy resin and (c) a blocked isocyanate curing agent, and a cationic emulsion (B) which comprises (b) at least one resin selected from the group consisting of a cation-modified acrylic resin and a cationic epoxy resin other than the cationic epoxy resin (a) and (d) a blocked isocyanate curing agent, wherein a difference ΔδA-B between a solubility parameter δA of a resin component in the cationic emulsion (A) and a solubility parameter δB of a resin component in the cationic emulsion (B) is within a range of from 0.5 to 1.5, and a difference ΔTA-B between a curing-initiation temperature (TA) of the cationic emulsion (A) and a curing-initiation temperature (TB) of the cationic emulsion (B) is within a range of from 20° C. to 60° C.

Owner:NIPPON PAINT CO LTD

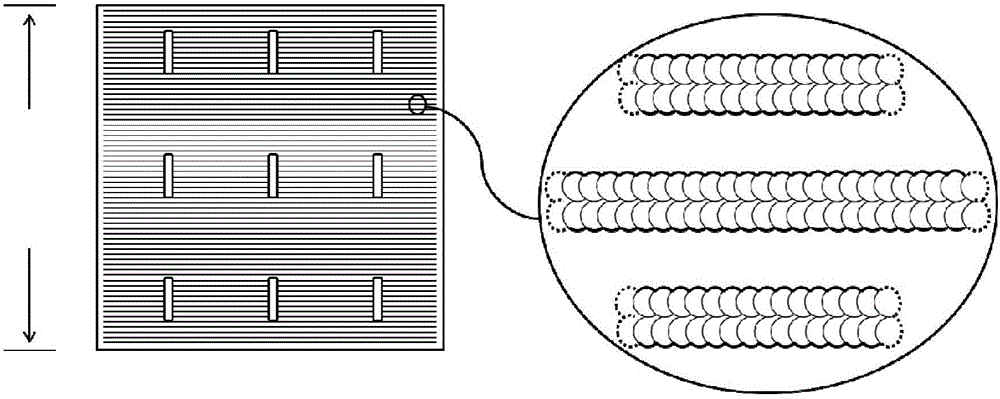

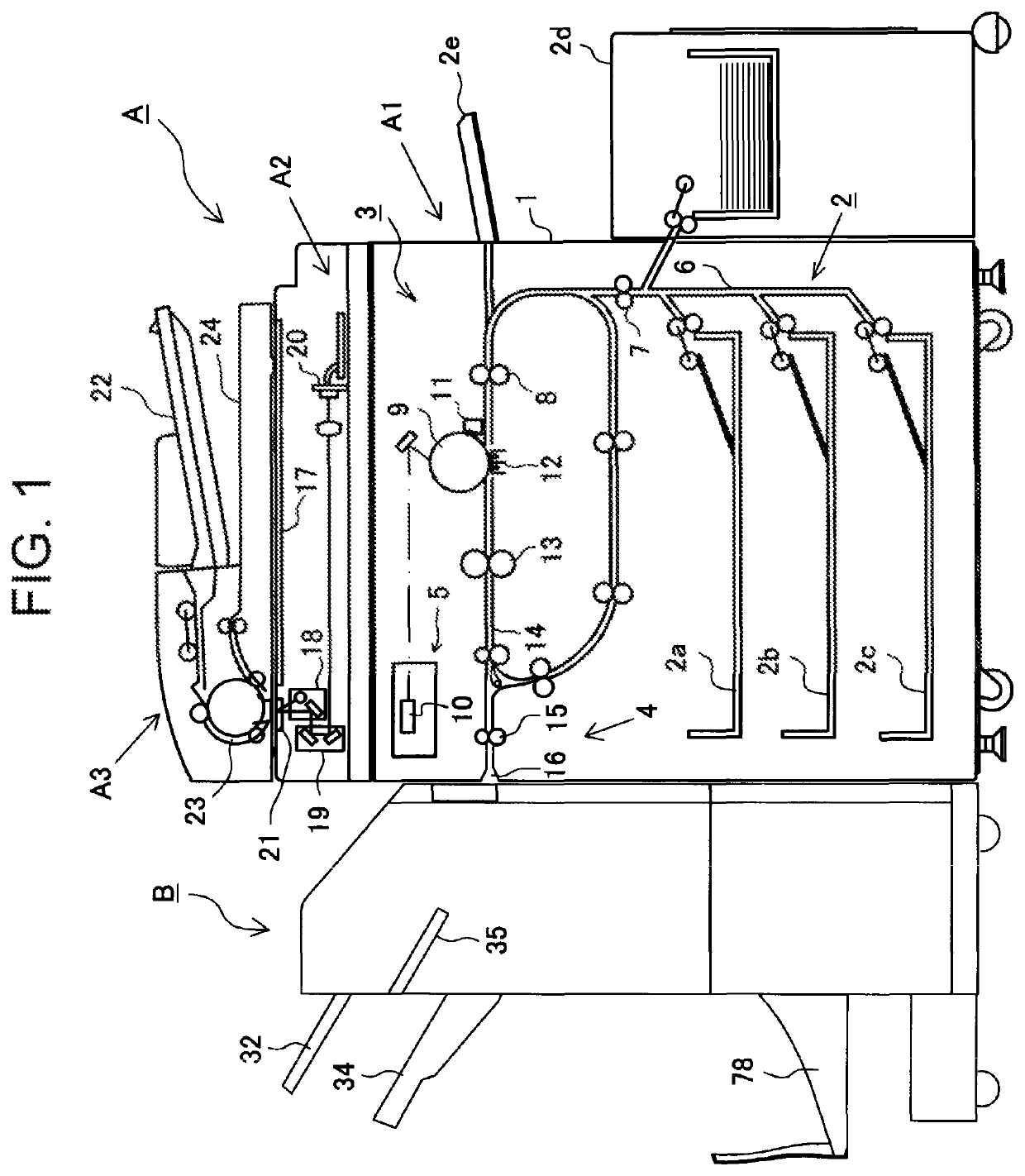

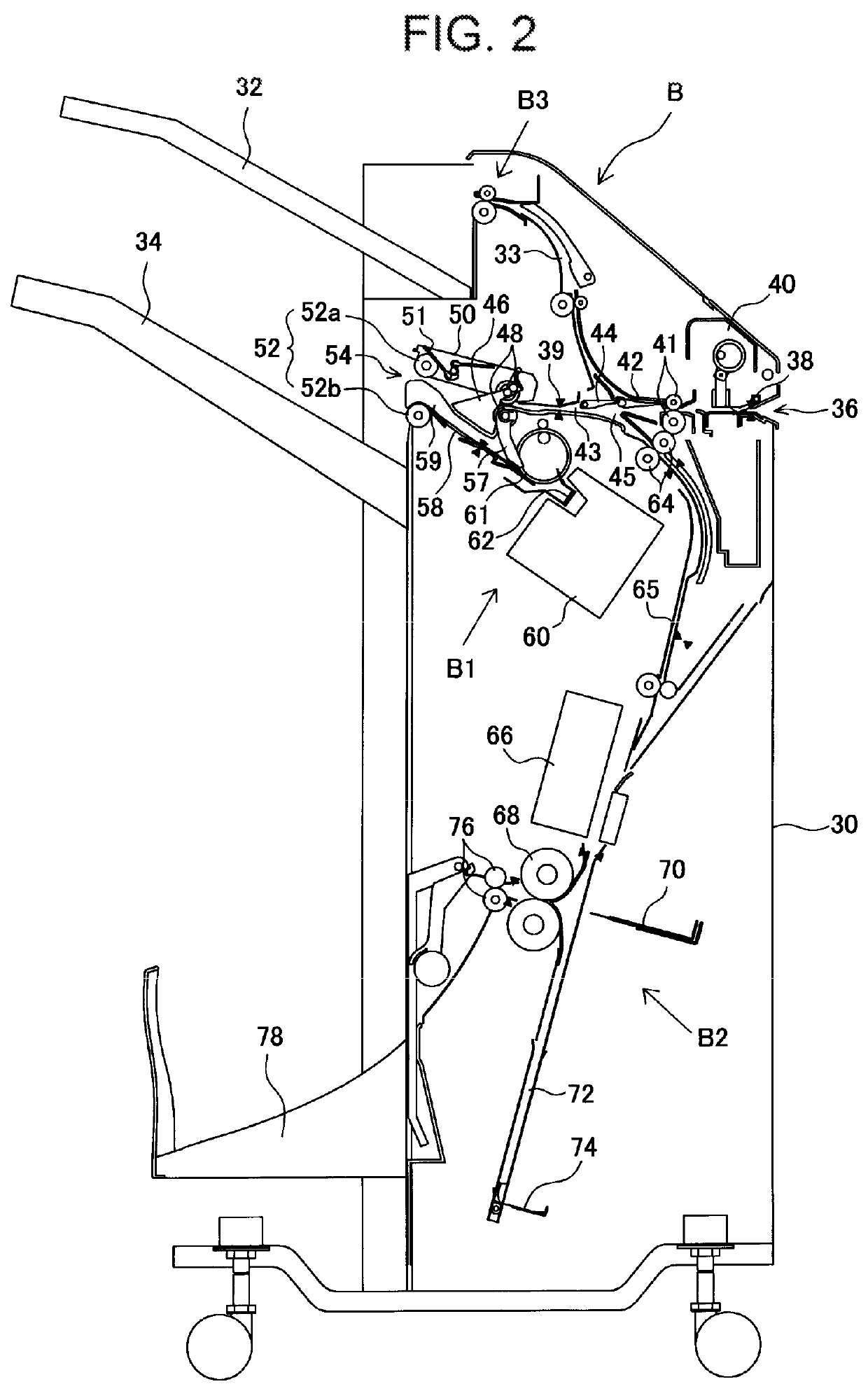

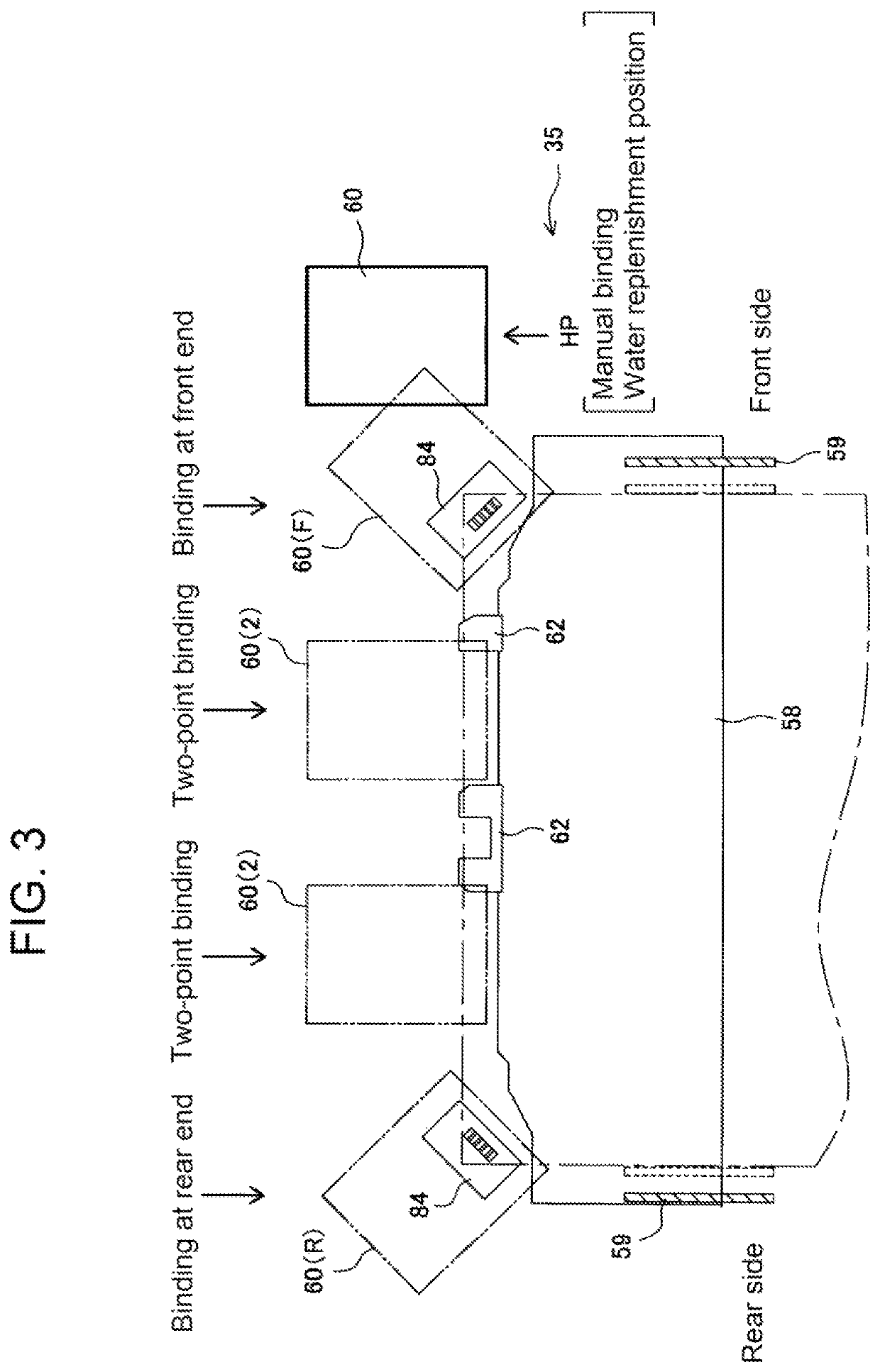

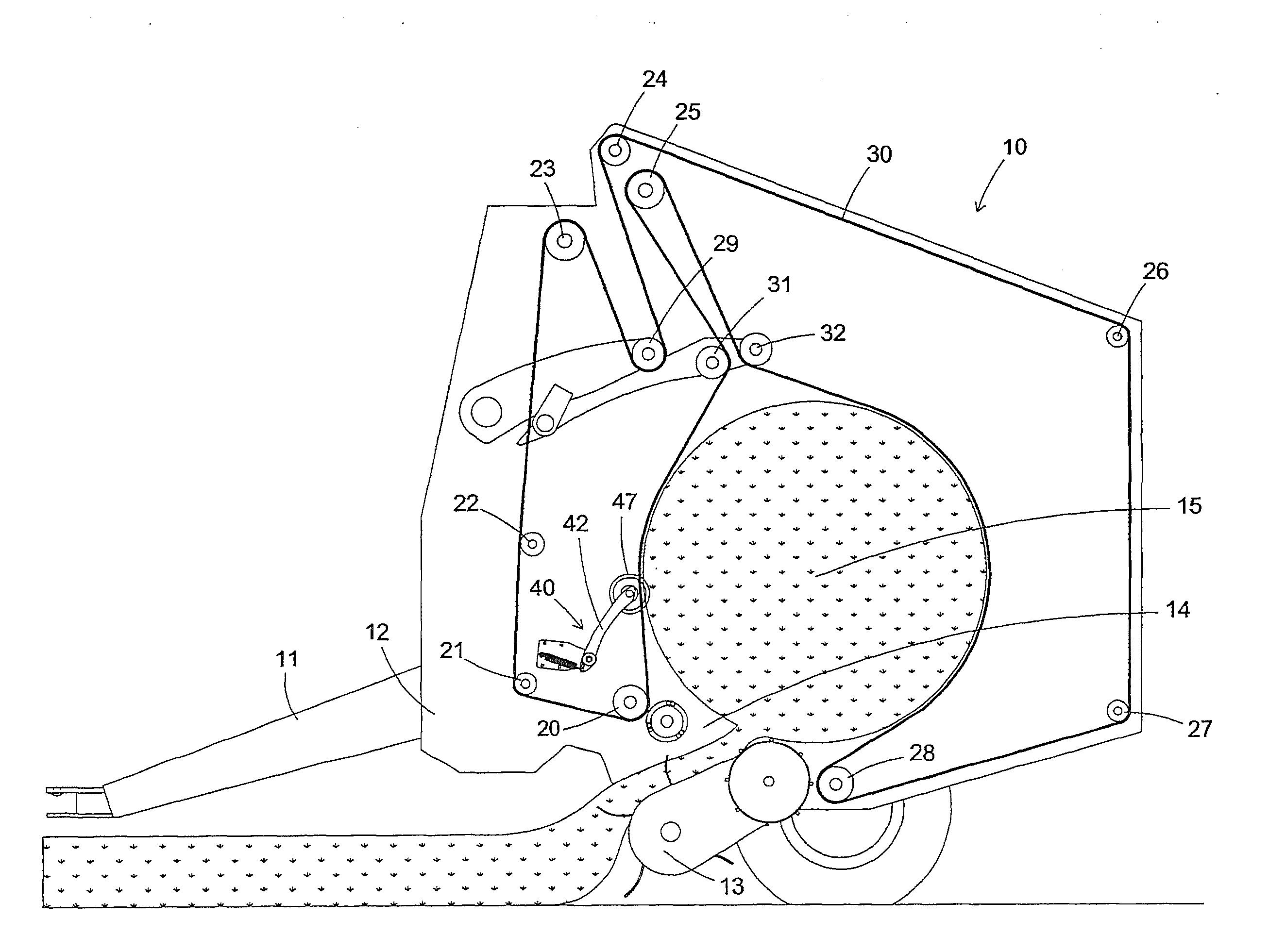

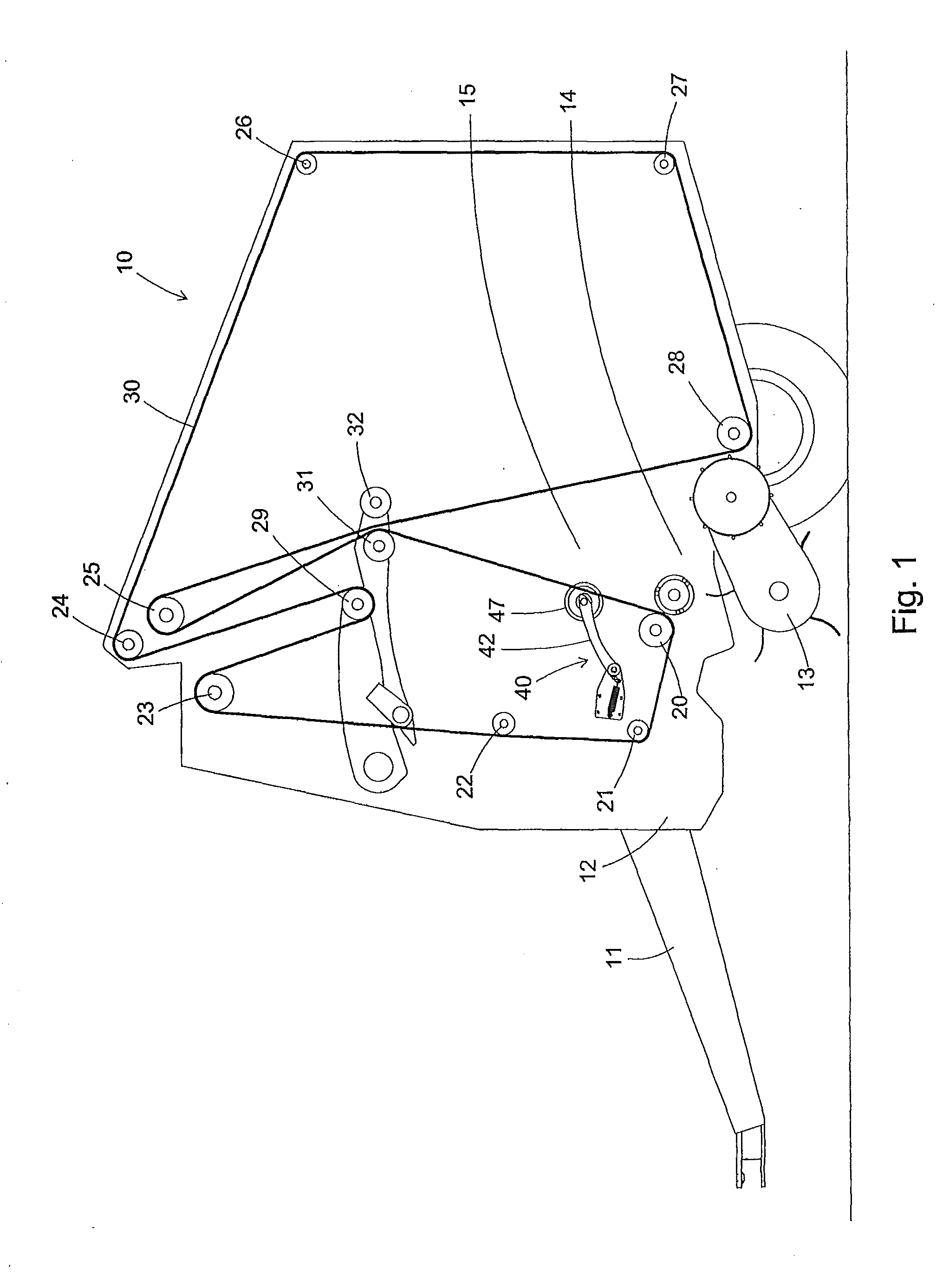

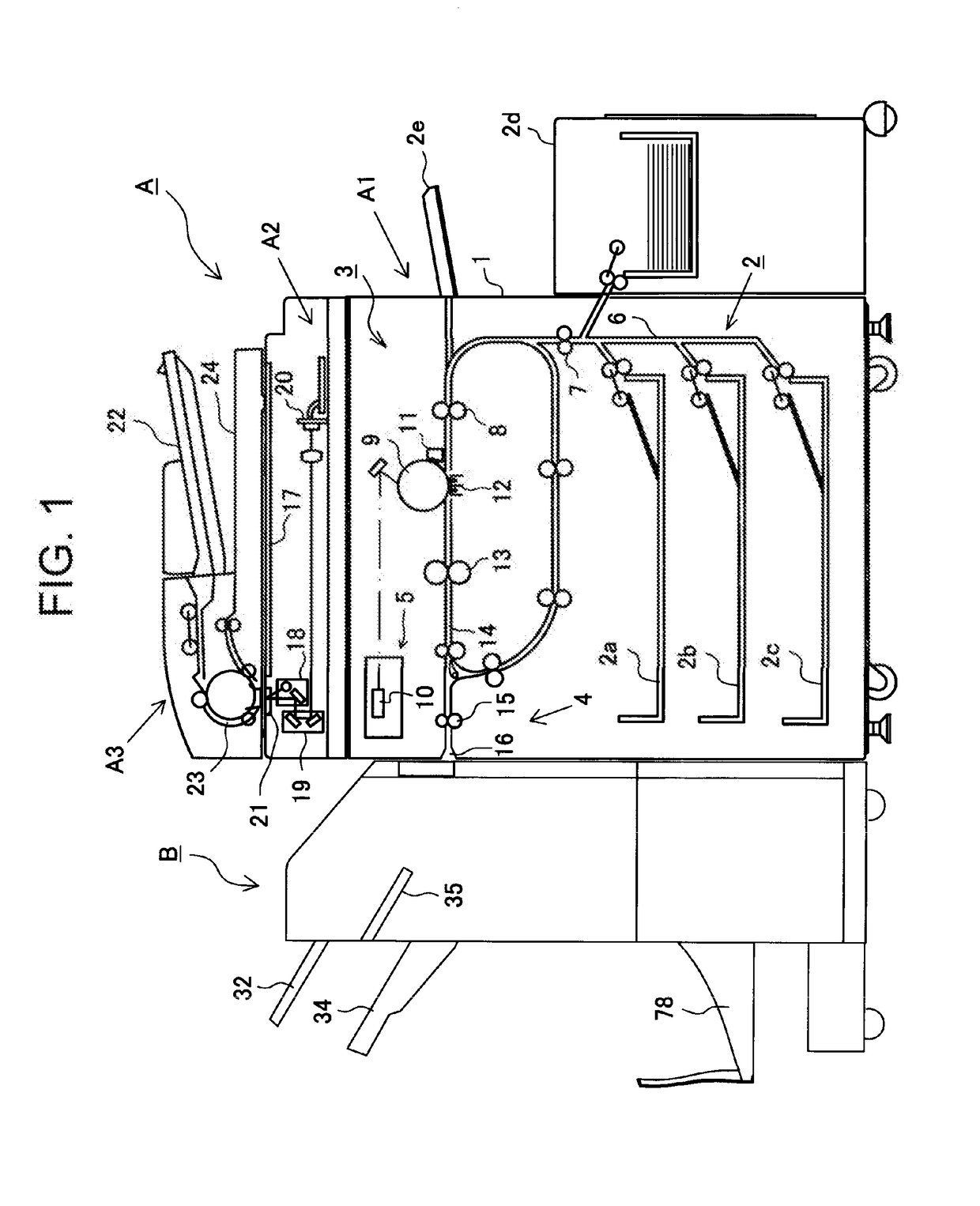

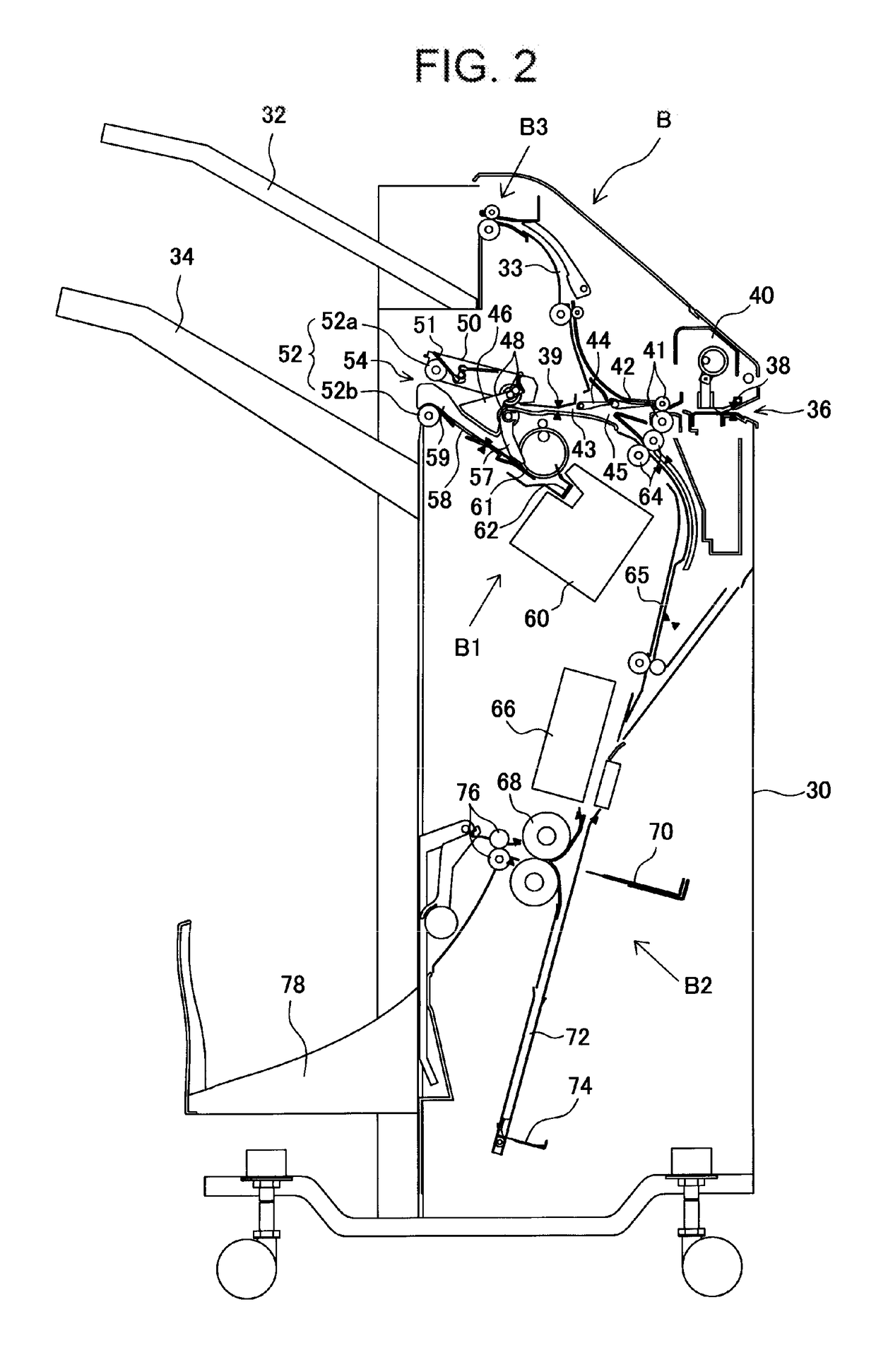

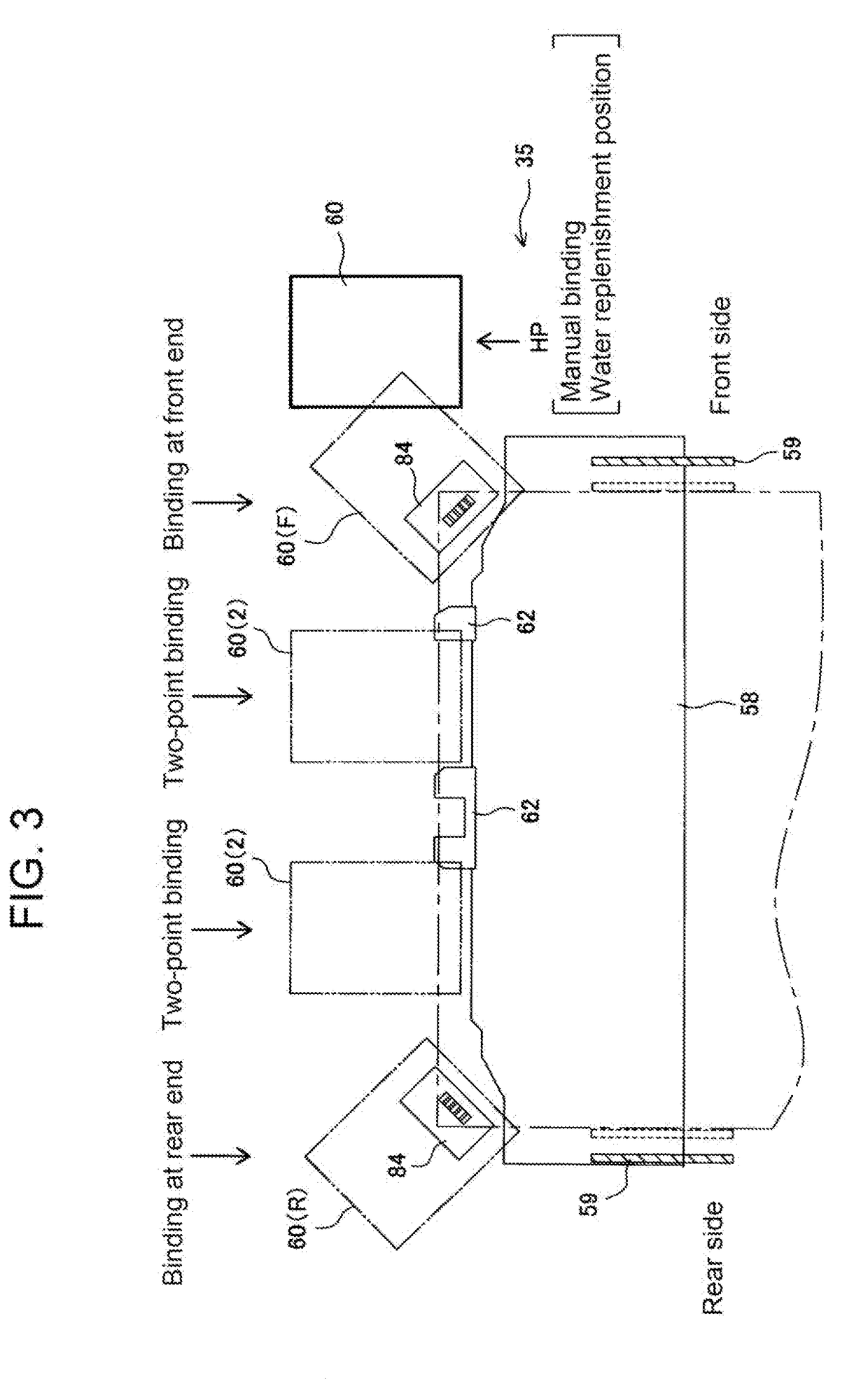

Binding unit, sheet processing device, and image forming device provided with them

ActiveUS10654240B2Prevent twisting and warpingExcellent finished appearanceMechanical working/deformationBook making processesImage formationPaper sheet

A sheet processing device has a binding unit that applies water to a crimping range of sheets and then crimps the sheets. The sheet processing device includes a processing tray on which sheets are placed, a pair of pressure teeth (pressure teeth and receiving teeth) that crimps the sheets placed on the processing tray at a crimping position with the sheets interposed therebetween, and a water application member (cylinder and piston) that applies water to the crimping position before crimping by the pressure teeth. When the number of sheets placed on the processing tray is equal to or less than a predetermined number, the sheets are crimped by the pressure teeth without water application; while when the number of sheets placed on the processing tray exceeds the predetermined number, the sheets are crimped by the pressure teeth after water application.

Owner:COPYER

Water-based coating composition and method for forming multilayer coating film

InactiveUS20150225596A1Suppress surface roughnessInhibit swellingPretreated surfacesPolyurea/polyurethane coatingsWater basedTotal solid content

This invention relates to an aqueous coating composition comprising an acrylic or polyester resin (A); a curing agent (B); and a blocked isocyanate group-containing urethane resin emulsion (C) having a weight average molecular weight of 2,000 to 50,000, which is prepared using a polyisocyanate component and a polyol component as starting materials, the polyisocyanate component comprising an alicyclic diisocyanate, and the polyol component comprising a polycarbonate diol in an amount of 50 mass % or more, based on the total amount of the polyol component; (i) when the component (A) is an acrylic resin, the aqueous coating composition comprising the component (C) in an amount of, as solids content, 20 to 60 mass %, based on the total solids content of the components (A), (B) and (C); and (ii) when the component (A) is a polyester resin, the aqueous coating composition comprising the component (C) in an amount of, as solids content, 10 to 50 mass %, based on the total solids content of the components (A), (B) and (C).

Owner:KANSAI PAINT CO LTD

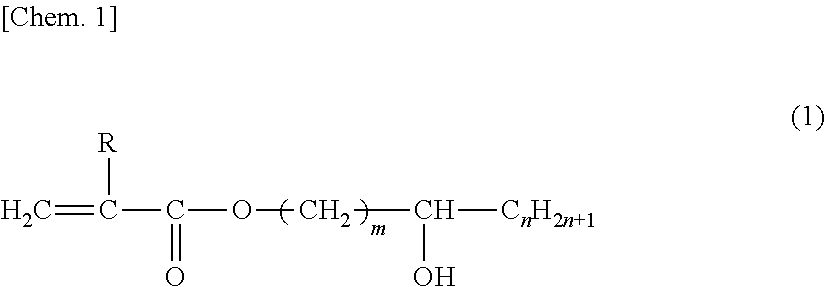

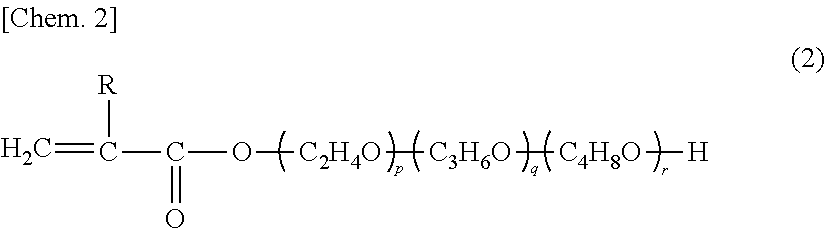

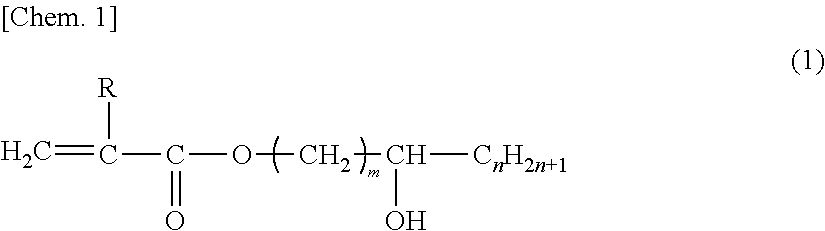

Aqueous coating composition

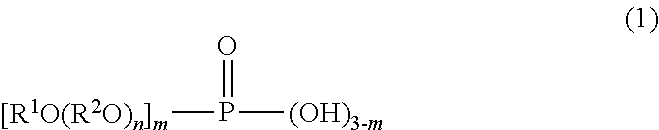

ActiveUS20170369732A1Excellent finished appearanceGood storage stabilityLiquid surface applicatorsEmulsion paintsPhosphoric acidDistinctness of image

The problem to be solved by the present invention is to provide an aqueous coating composition having an excellent finished appearance, such as smoothness and distinctness of image, as well as metallic feel and no metallic mottling when the composition comprises an effect pigment; excellent coating film performance, such as water resistance; and excellent storage stability. The present invention provides an aqueous coating composition comprising (A) acrylic resin particles, (B) a water-soluble acrylic resin, and (C) a phosphoric acid compound represented by a specific formula and having hydrocarbon (and optionally polyoxyalkylene); and also provides a method for forming a coating film, comprising applying the aqueous coating composition, as well as an article coated with the aqueous coating composition.

Owner:KANSAI PAINT CO LTD

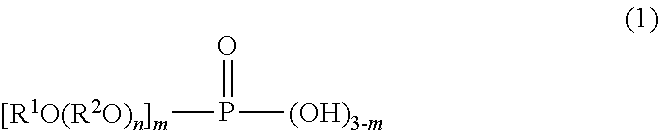

Method for forming multi-layered coating film

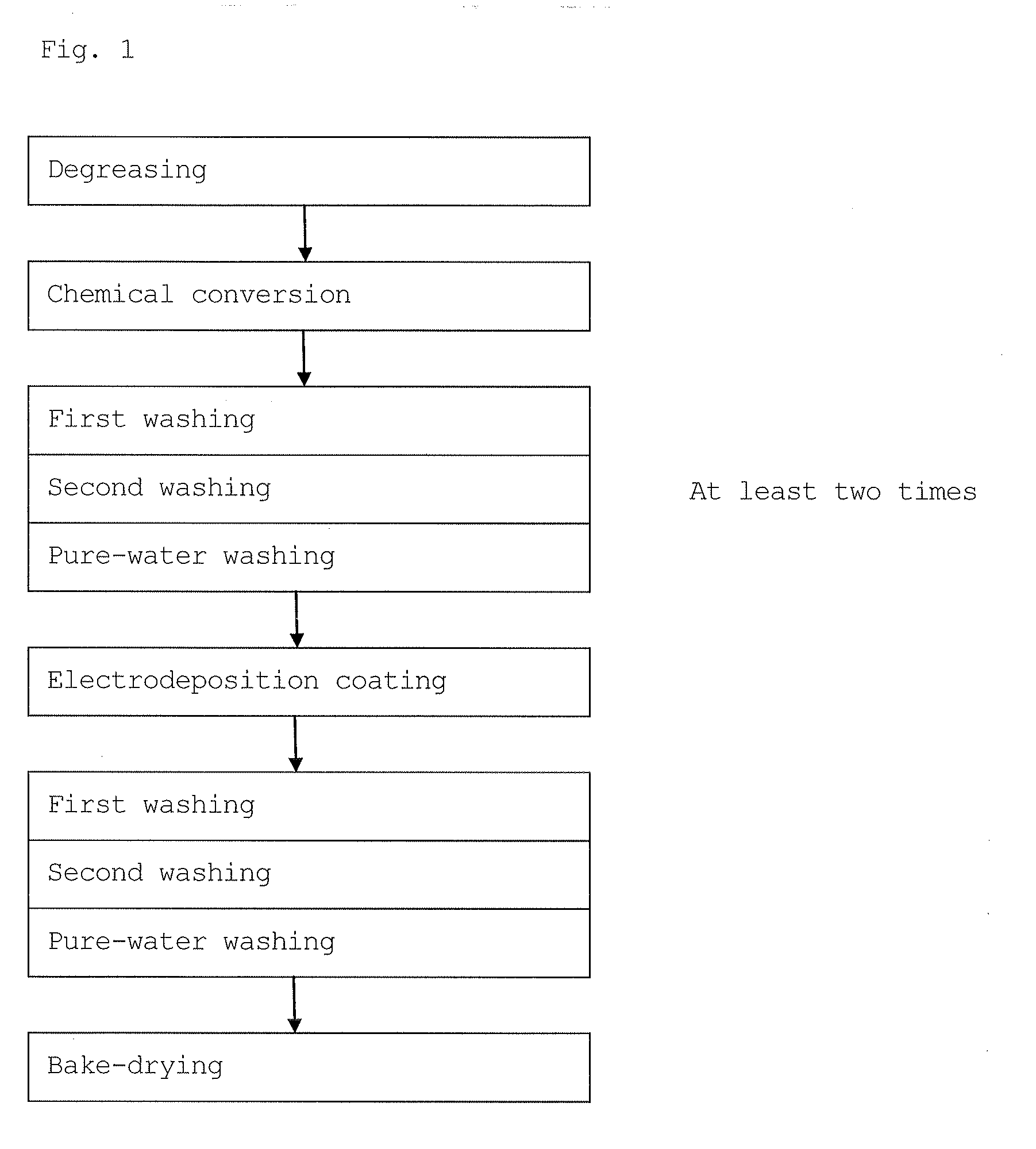

ActiveUS20150292103A1Improve corrosion resistanceSave the processElectrolysis componentsVolume/mass flow measurementMetallic substrateChemical conversion

An object of the present invention is to provide a method for forming a multilayer coating film, the method capable of achieving excellent finished appearance and excellent corrosion resistance without affecting electrodeposition coatability even when a part or all of the water-washing step is omitted after chemical conversion treatment, and to provide a coated article. The invention provides a method for forming a multilayer coating film, comprising forming a chemical conversion coating film and an electrodeposition coating film on a metal substrate by Step 1 of immersing a metal substrate in a chemical conversion treatment solution to form a chemical conversion coating film, and Step 2 of omitting a part or all of the water-washing step, and performing electrodeposition coating on the metal substrate using a cationic electrodeposition coating composition to form an electrodeposition coating film, wherein the chemical conversion treatment solution contains less than 500 ppm of sodium ions on a mass basis.

Owner:KANSAI PAINT CO LTD

Aqueous paint composition and method for forming coating

ActiveUS9701866B2Improve adhesionEnhance the imagePolyurea/polyurethane coatingsSpecial surfacesAcrylic resinPolymer chemistry

The present invention provides an aqueous coating composition for use as an aqueous first colored coating composition in a multilayer coating-forming method, the coating composition containing an aqueous film-forming resin (A), a crosslinking agent (B), and acrylic urethane resin composite particles (C). The acrylic resin of the acrylic urethane resin composite particles (C) is obtained by using, as constituent monomers, 30 to 80 mass % of a polymerizable unsaturated monomer (c-1-1) having one polymerizable unsaturated group per molecule and having a C4-22 alkyl group, 1 to 20 mass % of a polymerizable unsaturated monomer (c-2) having two or more polymerizable unsaturated groups per molecule, and 0 to 69 mass % of a polymerizable unsaturated monomer (c-1-2) having one polymerizable unsaturated group per molecule and being other than the polymerizable unsaturated monomer (c-1-1).

Owner:KANSAI PAINT CO LTD

Cationic electrodeposition coating composition and coated article

ActiveUS20140042031A1Excellent corrosion resistanceExcellent finish appearanceDuplicating/marking methodsActive material electrodesIsocyanateChemistry

The present invention provides a cationic electrodeposition coating composition comprising: a specific amino group-containing modified epoxy resin (A); a blocked polyisocyanate curing agent (B); a water-soluble zirconium compound (C); and sulfamic acid, wherein the water-soluble zirconium compound (C) is present in an amount of 10 to 10,000 ppm, calculated as the mass of the elemental zirconium, relative to the mass of the cationic electrodeposition coating composition.

Owner:TOYOTA JIDOSHA KK +1

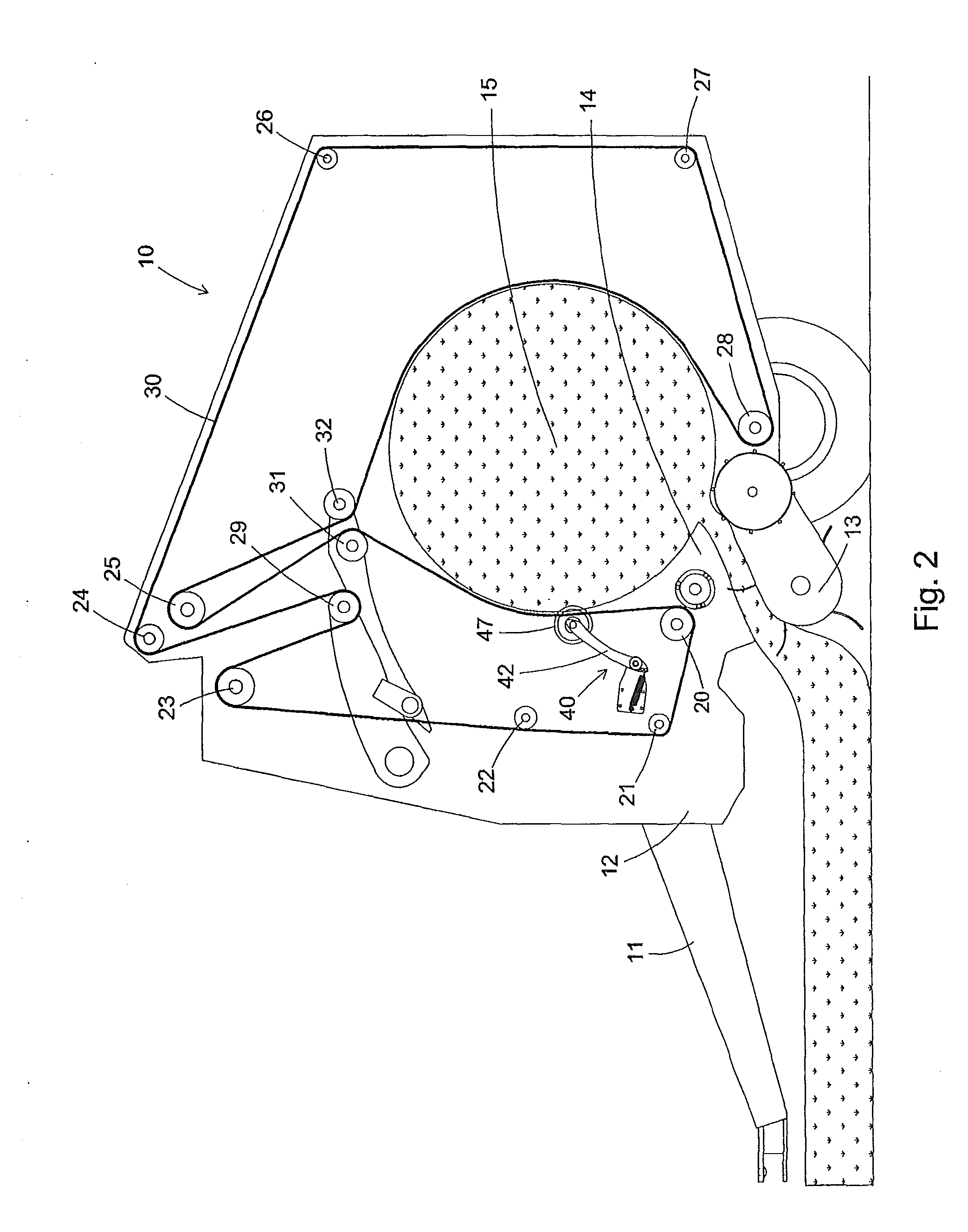

Rotary hay wedge for round balers

Owner:FORAGE INNOVATIONS

Coating composition and coated article

ActiveUS20140200305A1Excellent curabilitySatisfactory pot lifePolyurea/polyurethane coatingsOrganometallic catalysisBismuth

An object of the present invention is to provide a coating composition that has excellent curability at low temperatures and in a short period of time, and that also has satisfactory pot life (usable life) and makes it possible to obtain a cured coating film with an excellent finished appearance. The present invention provides a coating composition comprising a secondary hydroxy-containing acrylic resin (A), which is a copolymer of monomer components comprising 20 to 50% by mass of secondary hydroxy-containing polymerizable unsaturated monomer (a) and 50 to 80% by mass of at least one other polymerizable unsaturated monomer (b); a polyisocyanate compound (B); and an organometallic catalyst (C) containing a metallic compound (C1) in which the metal is a member selected from the group consisting of zinc, tin, zirconium, bismuth, lead, cobalt, manganese, titanium, aluminum and molybdenum, and an amidine compound (C2).

Owner:KANSAI PAINT CO LTD

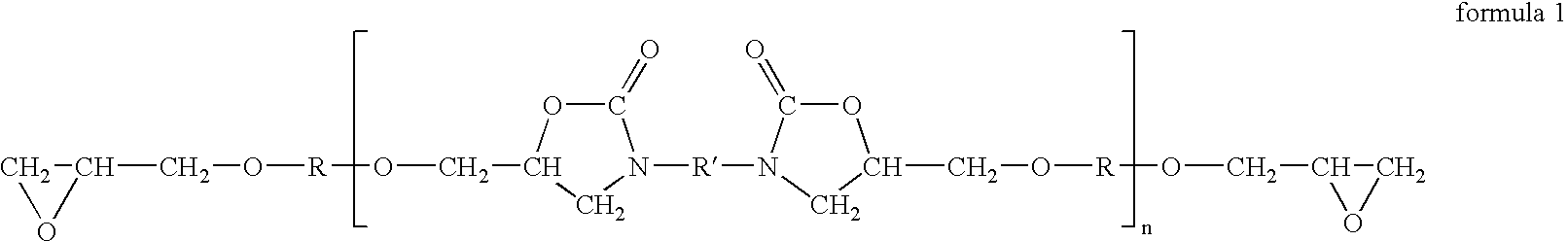

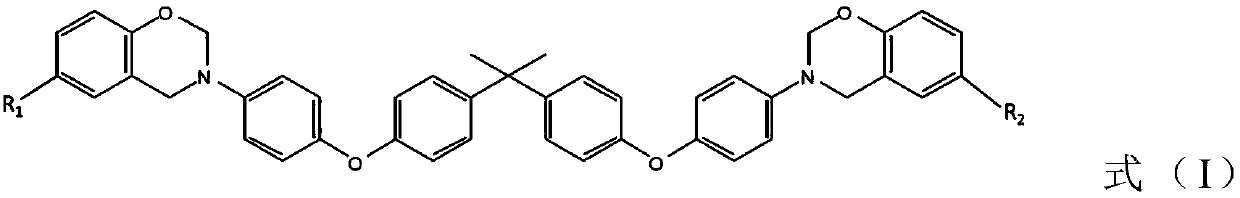

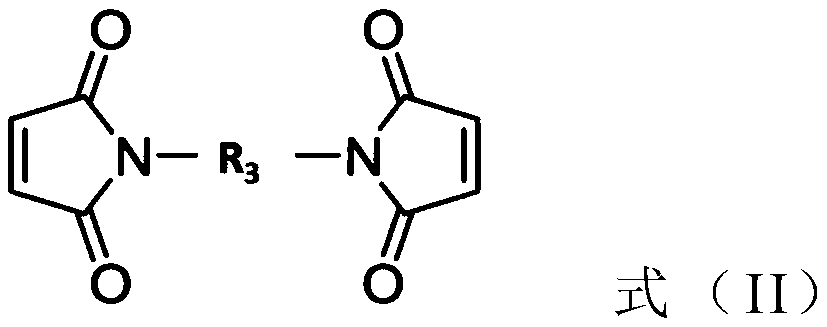

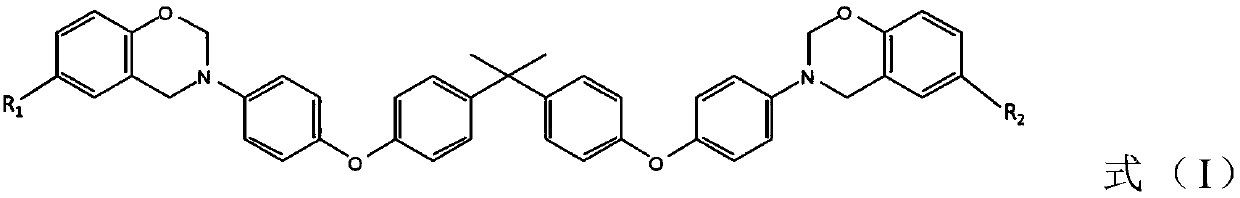

Resin composition, and prepreg, metal-clad laminate, and printed circuit board using the same

ActiveCN110591298AImprove heat resistanceExcellent dielectric propertiesWeather/light/corrosion resistanceHigh frequency circuit adaptationsEpoxyPrinted circuit board

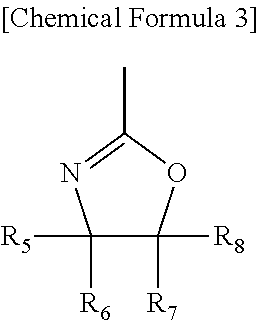

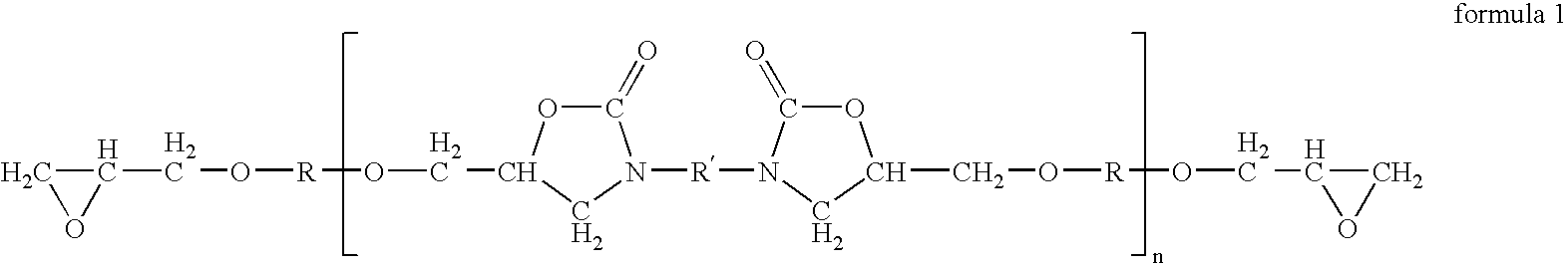

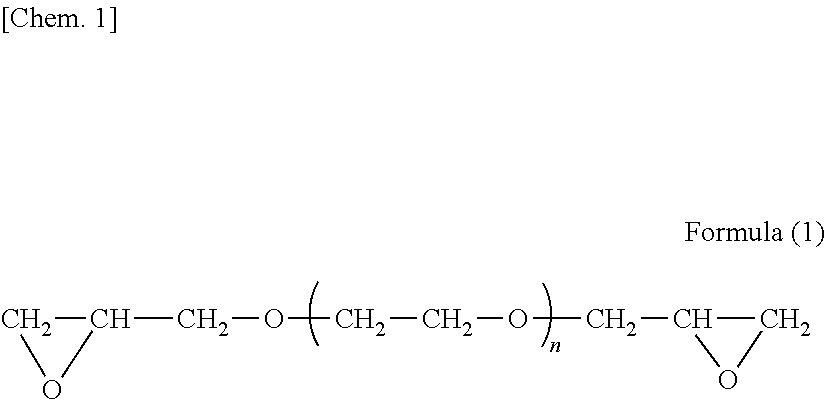

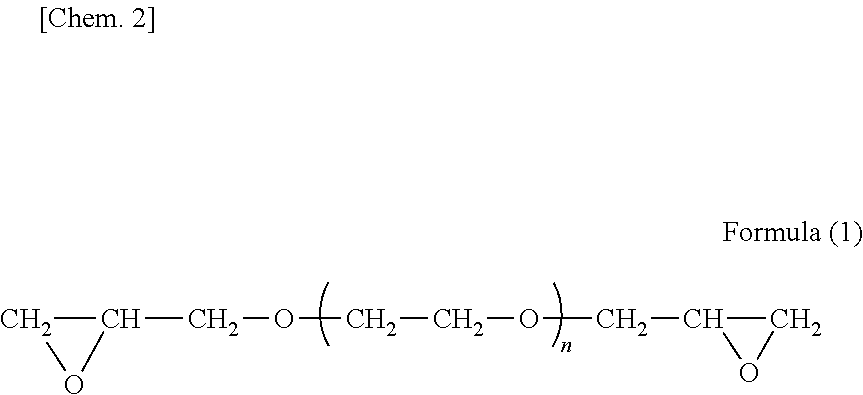

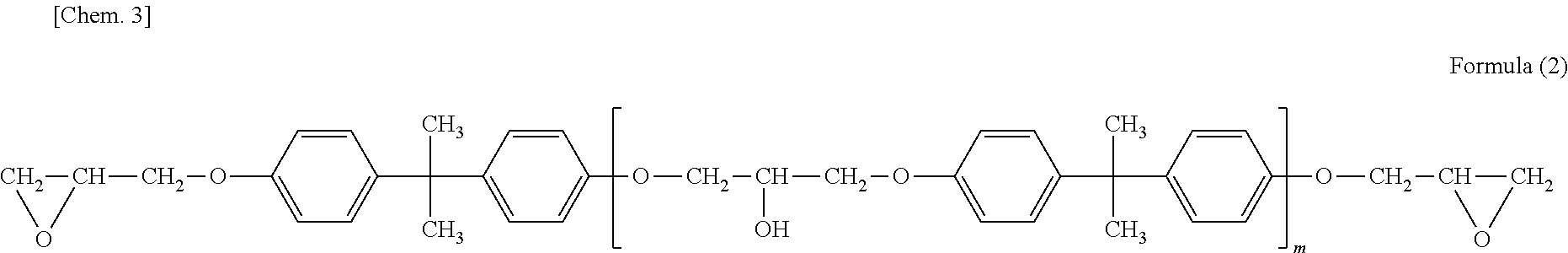

The invention provides a resin composition, which comprises following components: (A) epoxy resin; (B) a compound represented by a formula (I), wherein in the formula (I), R1 and R2 individually represent -H, -CH3, or -C(CH3)3; and (C) an optional filling material.

Owner:TAIWAN POWDER TECH CO LTD

Multi-layered coating film formation method

ActiveUS20160153107A1Improve corrosion resistanceSmall sizeSynthetic resin layered productsElectrophoretic coatingsMetallic substrateMetal substrate

A problem to be solved by the present invention is to provide a method for forming a multilayer coating film, the method being capable of achieving excellent finished appearance and excellent corrosion resistance without affecting electrodeposition coatability even when a part or all of the water-washing step is omitted after chemical conversion treatment, and to provide a coated article. The invention provides a method for forming a multilayer coating film, comprising forming a chemical conversion coating film and an electrodeposition coating film on a metal substrate by Step 1 of immersing a metal substrate in a chemical conversion treatment solution to form a chemical conversion coating film, and Step 2 of omitting a part or all of the water-washing step, and performing electrodeposition coating on the metal substrate using a cationic electrodeposition coating composition to form an electrodeposition coating film, wherein when the electrodeposition coating is performed in Step 2, the solution adhered to and / or deposited on the metal substrate has an electrical conductivity of less than 10,000 μS / cm.

Owner:KANSAI PAINT CO LTD

Binding unit, sheet processing device, and image forming device provided with them

ActiveUS20180339484A1Prevent twisting and warpingExcellent finished appearanceMechanical working/deformationBook making processesEngineeringPiston

A sheet processing device has a binding unit that applies water to a crimping range of sheets and then crimps the sheets. The sheet processing device includes a processing tray on which sheets are placed, a pair of pressure teeth (pressure teeth and receiving teeth) that crimps the sheets placed on the processing tray at a crimping position with the sheets interposed therebetween, and a water application member (cylinder and piston) that applies water to the crimping position before crimping by the pressure teeth. When the number of sheets placed on the processing tray is equal to or less than a predetermined number, the sheets are crimped by the pressure teeth without water application; while when the number of sheets placed on the processing tray exceeds the predetermined number, the sheets are crimped by the pressure teeth after water application.

Owner:COPYER

Coating composition and method for forming coating film

InactiveUS8664327B2Excellent finished appearanceModerate curabilityLiquid surface applicatorsSpecial tyresMeth-Acrylic resin

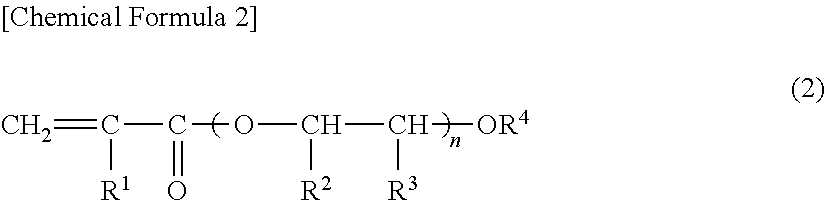

The present invention provides a coating composition that is excellent in application workability, and that can form a cured coating film excellent in coating film performances such as scratch resistance, acid resistance, stain resistance, finished appearance, sagging resistance, etc. Specifically, the present invention provides a coating composition comprising an acrylic resin (A), a polyisocyanate compound (B) and a specific non-aqueous dispersion-type acrylic resin (C), wherein: the acrylic resin (A) is obtainable by copolymerization of a specific secondary hydroxyl group-containing monomer (a-1), a secondary hydroxyl group-containing polyoxyalkylene mono(meth)acrylate monomer (a-2), an isobornyl (meth)acrylate monomer (a-3) and at least one other copolymerizable unsaturated monomer (a-4), the unsaturated monomer (a-1) being used in an amount (mass) greater than that of the monomer (a-2).

Owner:KANSAI PAINT CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com