High-solid coating composition

A technology of high solid content and composition, applied in the direction of polyurea/polyurethane coatings, coatings, etc., can solve the problems of insufficient acid resistance of the coating film and difficult differentiation of high solids, and achieve excellent pot life, excellent appearance of finished products, and pot life. excellent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

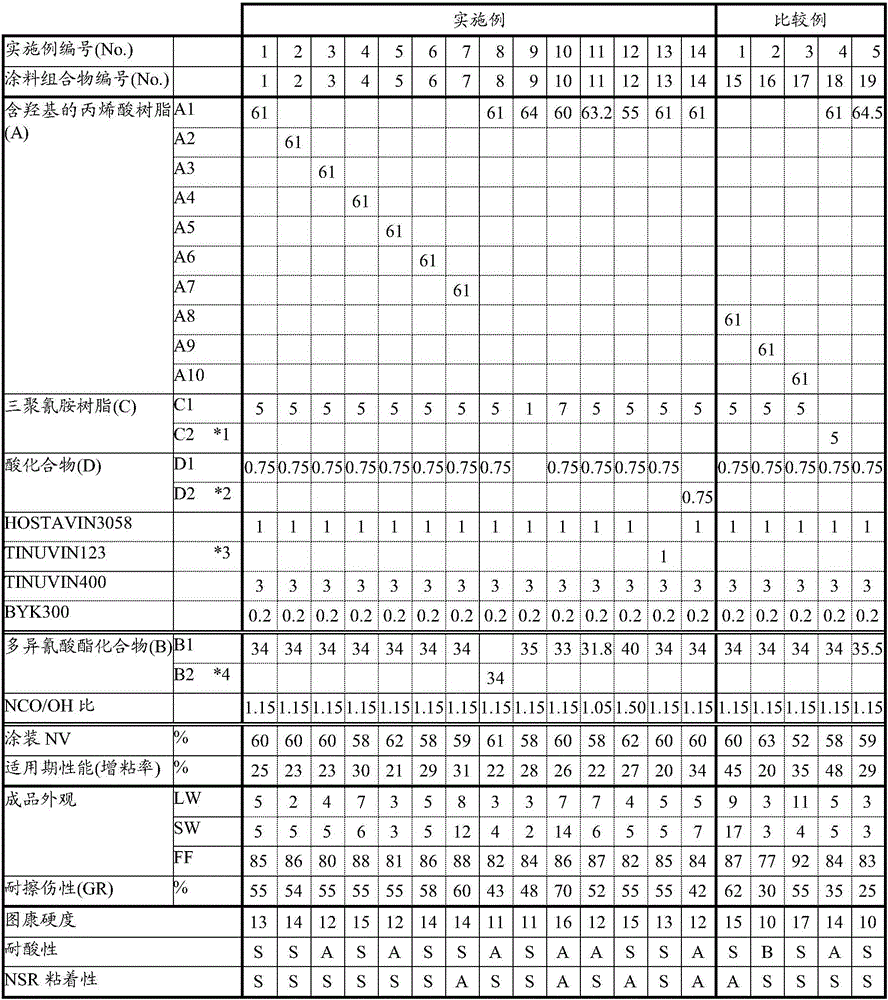

Examples

Embodiment

[0173] Hereinafter, the present invention will be described more concretely with reference to Examples and Comparative Examples. However, the present invention is not limited to these Examples. In addition, "parts" and "%" are based on mass.

[0174] Production of secondary hydroxyl-containing acrylic resin (A)

manufacture example 1

[0176] In an acrylic resin reaction tank equipped with a stirrer, a thermometer, and a reflux condenser, 27 parts of Swasolve 1000 (aromatic solvent, manufactured by Cosmo Oil Co., Ltd.) and methoxypropyl acetate (KH Neochem Co., Ltd. (manufactured by KH Neochem Co., Ltd., ester solvent) 5 parts, heated and stirred under nitrogen gas, and stopped feeding nitrogen gas after reaching 150 ° C. 20 parts of styrene, 2-hydroxypropyl acrylate 32.5 part, 46.8 parts of isobornyl acrylate, 0.7 part of acrylic acid and 6.0 parts of di-t-amyl peroxide (polymerization initiator) were added dropwise over 4 hours.

[0177] Then, after aging at 150 degreeC for 1 hour, it cooled, and further added and diluted 21 parts of isobutyl acetates, and obtained the hydroxyl group containing acrylic resin (A1) of 65 mass % of solid content concentration. The weight-average molecular weight of the hydroxyl-containing acrylic resin (A1) was 5500, the hydroxyl value was 139 mgKOH / g, the acid value was 5.5 ...

manufacture example 2 to 10

[0179] In Production Example 1, except that the monomer mixture was set to a monomer mixture having the composition shown in Table 1, the same operation was carried out as in Production Example 1 (adjustment was made so that the amount of the polymerization initiator became the desired weight average molecular weight) to obtain hydroxyl-containing acrylic resins (A2) to (A10). Table 1 also shows the weight average molecular weight, hydroxyl value, acid value, and glass transition temperature (Tg (° C.)) calculated from the monomer composition.

[0180] In addition, hydroxyl group-containing acrylic resins (A8) to (A10) are acrylic resins for comparative examples.

[0181] Table 1

[0182] Manufacturing example number (No.)

[0183]

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com