Nonionic waterborne epoxy resin emulsion, nonionic waterborne epoxy curing agent, preparation method of nonionic waterborne epoxy resin emulsion and nonionic waterborne epoxy curing agent and waterborne epoxy resin varnish

A water-based epoxy emulsion and non-ionic emulsifier technology, applied in epoxy resin coatings, latex paints, coatings, etc., to achieve the effects of expanding the scope of application, good water resistance, and simple synthesis process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0067] A kind of nonionic water-based epoxy emulsion, the preparation steps are as follows:

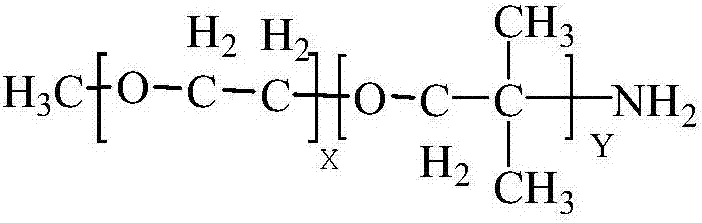

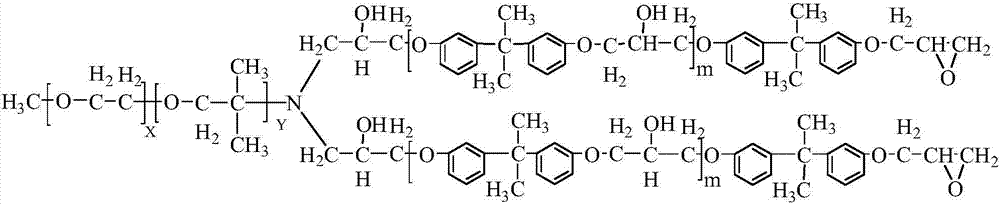

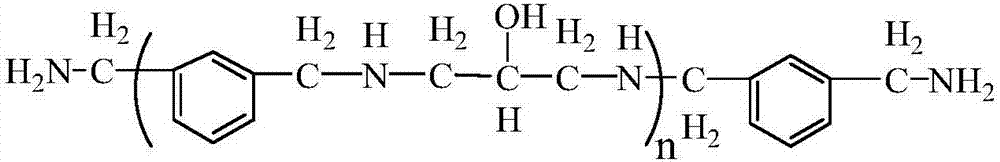

[0068] (1) Preparation of emulsifier

[0069] Add 200.0g polyetheramine L200 (0.10mol, molecular weight 2000g / mol) into a 500ml three-necked round bottom flask equipped with a stirrer and a thermometer, and then heat it to a temperature of 65°C; 78.4g epoxy resin E51 (0.20mol, molecular weight 392g / mol) was dissolved in 70.0g propylene glycol methyl ether, and was added dropwise to the above-mentioned flask through a 125ml constant pressure dropping funnel, and the dropwise addition was completed within 1h, and the stirring reaction was continued for 3h to obtain a light yellow transparent solution with a solid content of 80%. Liquid, non-ionic emulsifier.

[0070] (2) Preparation of epoxy resin emulsion

[0071] In the 500ml three-necked round-bottom flask that is equipped with stirrer, thermometer, add respectively the nonionic emulsifier (solid content is 80%) that 30g step (1) p...

Embodiment 2

[0073] A kind of nonionic water-based epoxy emulsion, the preparation steps are as follows:

[0074] (1) Preparation of emulsifier

[0075] Add 200.0g polyetheramine L200 (0.10mol, molecular weight 2000g / mol) into a 500ml three-necked round bottom flask equipped with a stirrer and a thermometer, and then heat it to a temperature of 65°C; 117.6g epoxy resin E51 (0.30mol, molecular weight 392g / mol) was dissolved in 80.0g propylene glycol methyl ether, and was added dropwise to the above-mentioned flask through a 125ml constant pressure dropping funnel, and the dropwise addition was completed within 1h, and the stirring reaction was continued for 3h to obtain a light yellow transparent mixture with a solid content of 80%. Liquid, non-ionic emulsifier.

[0076] (2) Preparation of epoxy resin emulsion

[0077] In the 500ml three-necked round bottom flask that is equipped with stirrer, thermometer, add respectively the emulsifier (solid content 80%) that 30g step (1) prepares, 84....

Embodiment 3

[0080] The preparation of epoxy emulsion, the epoxy resin that prepares emulsifier and emulsion is identical, and step is as follows:

[0081] Add 20.0g of polyetheramine L200 (0.010mol, molecular weight 2000g / mol) to a 500ml three-necked round-bottomed flask equipped with a stirrer and a thermometer, and then heat to a temperature of 65°C; 149.0g of epoxy resin E51 (0.38mol), Molecular weight 392g / mol) was dissolved in 30.0g propylene glycol methyl ether, and was added dropwise into the above-mentioned flask through a 125ml constant pressure dropping funnel, and the dropwise addition was completed within 1h, and the stirring reaction was continued for 3h.

[0082] Slowly add 108.3 g of deionized water in 5 batches under high-speed stirring, and stir for 40 minutes to obtain a milky white stable epoxy resin emulsion.

[0083] The prepared epoxy resin had a solid content of 55%, a viscosity of 1099 mPas, and a particle size of 382 nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com