Superfine and high-purity bismuth oxide and preparation method thereof

A technology of bismuth oxide and high fineness, which is applied in chemical instruments and methods, inorganic chemistry, bismuth compounds, etc., can solve the problems of unreached product particle size, complicated process, complicated separation procedure, etc., and achieve high purity and good product uniformity , the effect of controlling the reaction speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

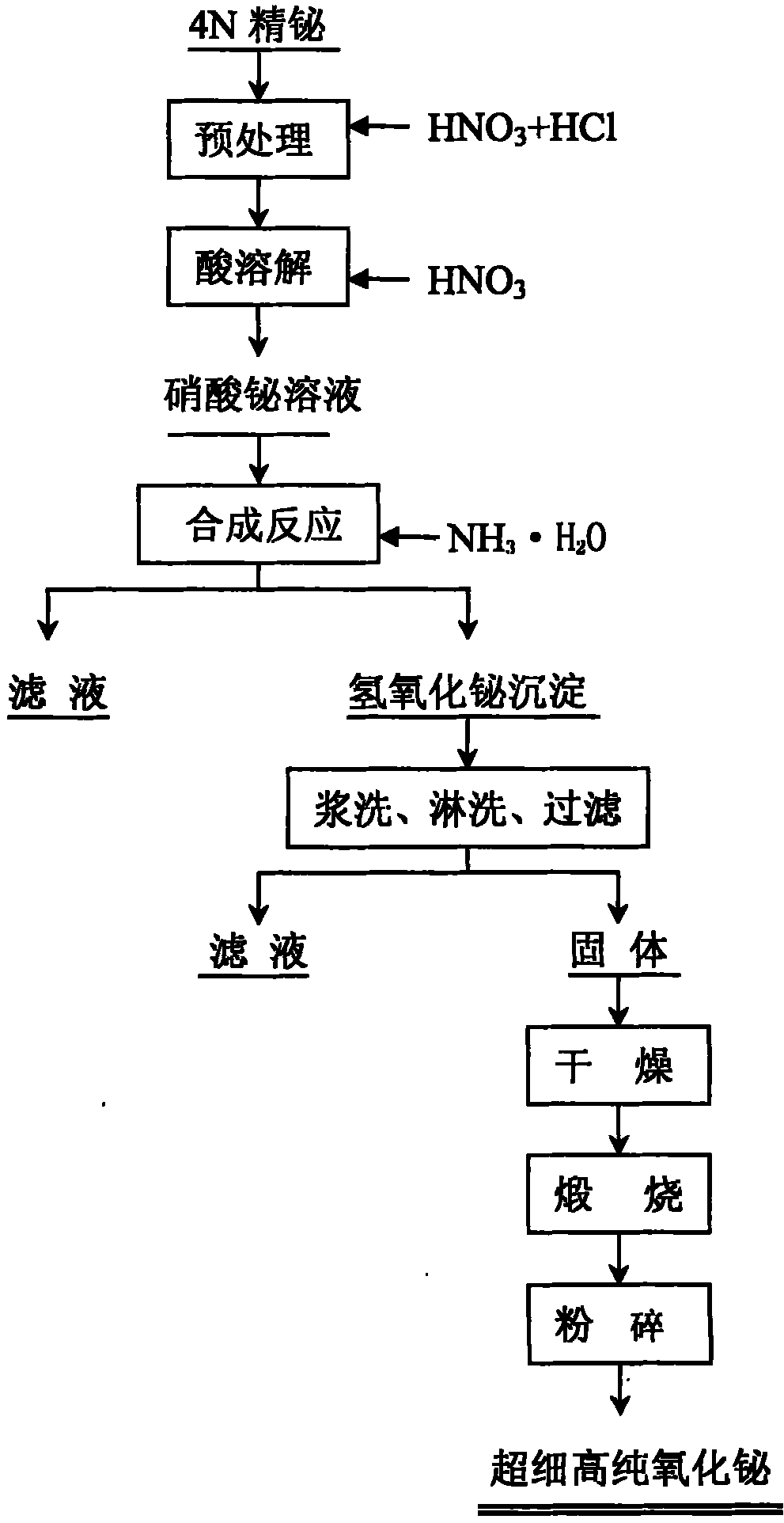

Method used

Image

Examples

Embodiment 1

[0039] A preparation method of ultra-fine and high-purity bismuth oxide, which uses solid bismuth with a purity of 4N as raw material. It pretreats 500g of 4N bismuth with a mixed solution of 2g / L nitric acid and 3g / L hydrochloric acid, that is, the soaking time is 50 minutes Then take it out and react with nitric acid, that is, slowly add about 900 mL of nitric acid with a concentration (wt%) of 60% under constant stirring, and add an appropriate amount of soluble SiO with a conductivity of less than 500us / cm 2 Distilled water less than 0.02mg / L to obtain a bismuth nitrate solution, add 0.001 times the volume of bismuth nitrate solution to the obtained bismuth nitrate solution; cm, soluble SiO 2 Distilled water of less than 0.02 mg / L is prepared at a volume ratio of 1:1 to obtain an aqueous ammonia solution with a mass percentage concentration of 12.8%. Add the above-mentioned bismuth nitrate solution and aqueous ammonia solution under constant stirring conditions with conducti...

Embodiment 2

[0041] A preparation method of ultra-fine and high-purity bismuth oxide, which uses 4N solid bismuth as raw material to synthesize ultra-fine and high-purity bismuth oxide. It pretreats 500g 4N solid bismuth with 3g / L nitric acid and 5g / L hydrochloric acid solution. That is, the immersion time is 40 minutes and then take it out to react with nitric acid, that is, slowly add about 1050 mL of nitric acid with a concentration (wt%) of 50% under constant stirring, and add an appropriate amount of soluble SiO with a conductivity of less than 500us / cm 2 Deionized water less than 0.02mg / L, the obtained bismuth nitrate solution is treated with sulfuric acid 0.002 times the volume of the bismuth nitrate solution; 450mL ammonia water with a mass percentage of 27% and 900mL conductivity less than 500us / cm, soluble SiO 2 The deionized water of less than 0.02 mg / L is prepared with a volume ratio of 1:2 to obtain an ammonia aqueous solution with a concentration of 8.3% by mass. The above-menti...

Embodiment 3

[0043] A preparation method of ultra-fine and high-purity bismuth oxide. It uses 4N solid bismuth as raw material to synthesize ultra-fine and high-purity bismuth oxide. It pretreats 500g of 4N solid bismuth with 4g / L nitric acid and 5g / L hydrochloric acid solution. That is, the immersion time is 30 minutes and then take it out to react with nitric acid, that is, slowly add about 1300 mL of nitric acid with a concentration (wt%) of 40% under constant stirring, and add an appropriate amount of soluble SiO with a conductivity of less than 500us / cm 2 Distilled water less than 0.02mg / L, the obtained bismuth nitrate solution is treated with sulfuric acid 0.002 times the volume of the bismuth nitrate solution; 450mL ammonia water with a mass percentage concentration of 27% and 900mL conductivity less than 500us / cm, soluble SiO 2 Distilled water of less than 0.02 mg / L is prepared with a volume ratio of 1:2 to obtain an ammonia aqueous solution with a mass percentage concentration of 8.3%...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com