Modified PP (polypropylene) material with long carbon fiber and reinforced conductivity and preparation method thereof

A technology of long carbon fiber and conductive enhancement, which is applied in the field of long carbon fiber conductive reinforced modified PP material and its preparation, and can solve the problems of weak conductivity of PP

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

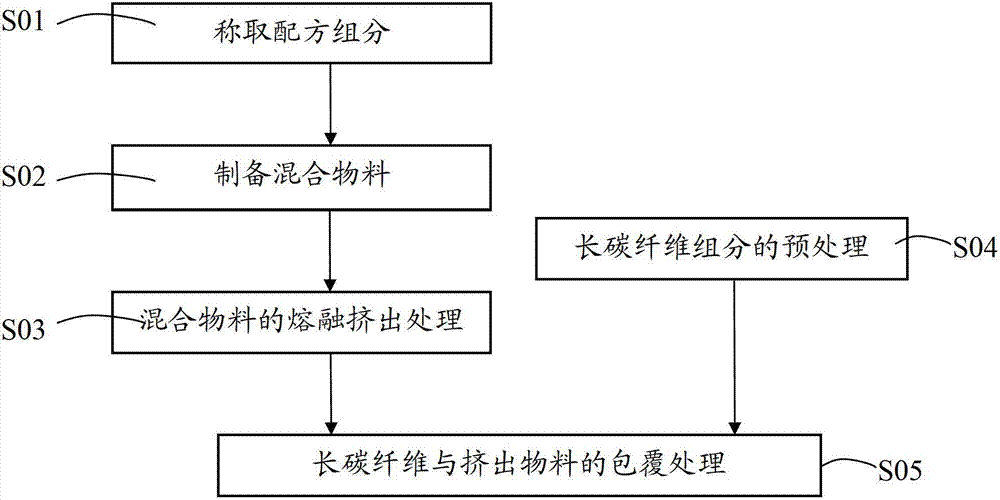

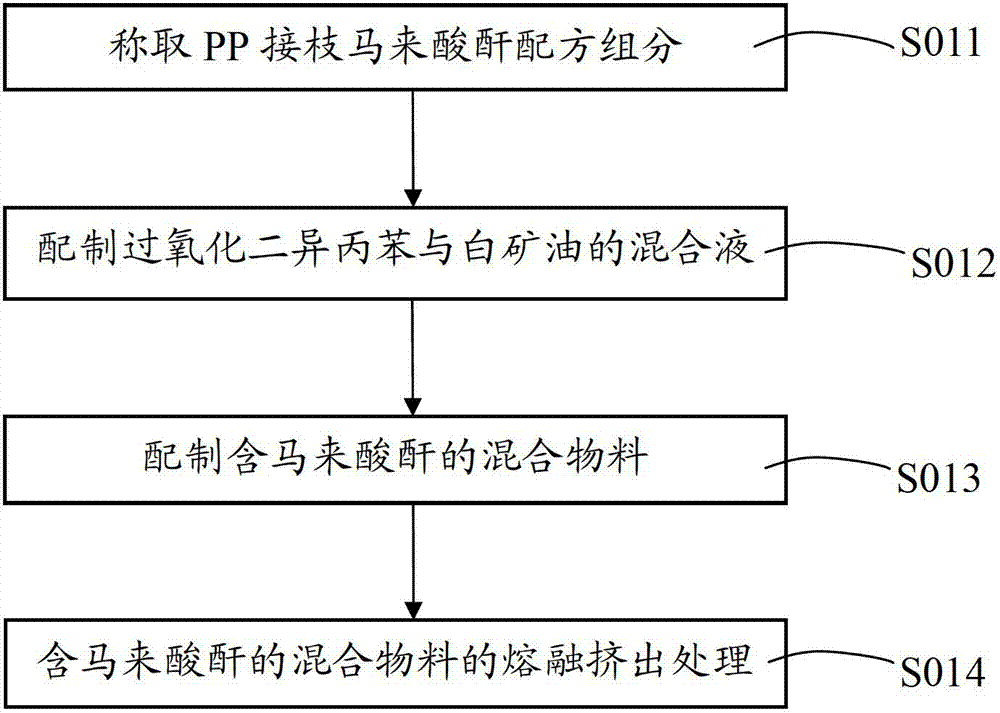

[0039] Correspondingly, the embodiment of the present invention also provides a preparation method of the above-mentioned long carbon fiber conductive reinforced modified PP material, the process flow is as follows figure 1 shown. The method comprises the steps of:

[0040] S01. Weigh the formula components: weigh each component according to the formula of the above-mentioned long carbon fiber conductive reinforced modified PP material;

[0041] S02. Preparation of mixed material: After mixing the PP resin, compatibilizer and coupling agent weighed in step S01, add conductive carbon black, toughening agent, plastic processing aid to continue the mixing process to obtain the mixture material;

[0042] S03. Melt extrusion processing of the mixed material: melt and extrude the mixed material in step S02 to obtain the extruded material;

[0043]S04. Pretreatment of long carbon fiber components: preheating the long carbon fibers weighed in step S01 at 100-110° C. and then perfor...

Embodiment 1

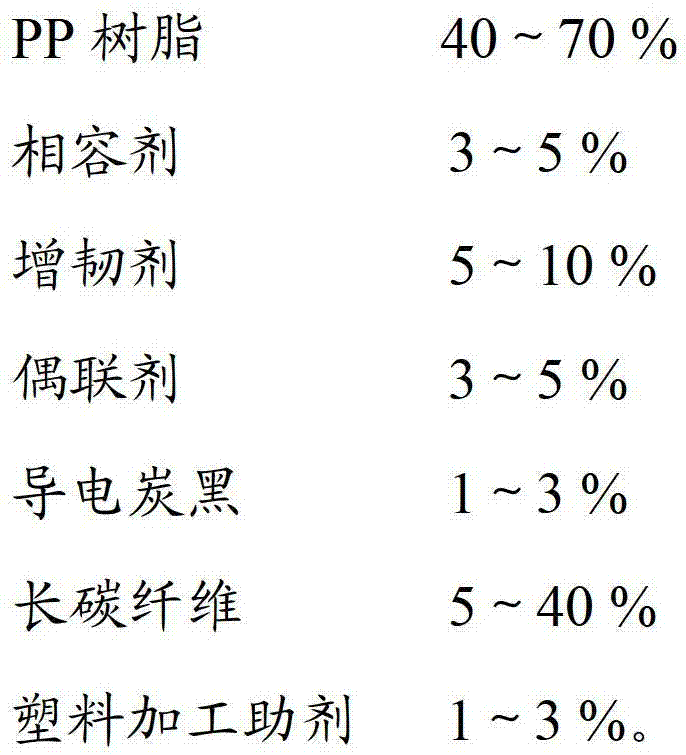

[0063] The weight percent formulation components of the long carbon fiber conductive reinforced modified PP material of the present embodiment are as follows:

[0064] 70% PP resin; 15% long carbon fiber; 4% compatibilizer; 3% toughening agent; 3.5% coupling agent; 3% conductive carbon black; 1.5% plastic processing aid.

[0065] Its preparation method is as follows:

[0066] Step 1. Weigh each component according to the above-mentioned weight percentage, and carry out drying treatment on each component taken; specifically, drying treatment can be carried out by using a dryer;

[0067] Step 2. Put the dried PP resin, compatibilizer and coupling agent in a high-speed mixer or blender and pre-mix for 3 minutes, then add conductive carbon black, toughener, and plastic processing aids and continue mixing for 10 minutes;

[0068] Step 3. Add the mixed material in step 2 into the hopper of the twin-screw extruder, undergo melting reaction, kneading, and flow to the cross dipping he...

Embodiment 2

[0074] The weight percent formulation components of the long carbon fiber conductive reinforced modified PP material of the present embodiment are as follows:

[0075] 50% PP resin; 30% long carbon fiber; 3% compatibilizer; 10% toughening agent; 3% coupling agent; 3% conductive carbon black; 1% plastic processing aid.

[0076] Its preparation method is as follows:

[0077] Step 1. Weigh each component according to the above-mentioned weight percentage, and carry out drying treatment on each component taken; specifically, drying treatment can be carried out by using a dryer;

[0078] Step 2. Put the dried PP resin, compatibilizer and coupling agent in a high-speed mixer or blender and pre-mix for 3 minutes, then add conductive carbon black, toughener, and plastic processing aids and continue mixing for 10 minutes;

[0079] Step 3. Add the mixed material in step 2 into the hopper of the twin-screw extruder, undergo melting reaction, kneading, and flow to the cross dipping head;...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com