Preparation method of nanometer ZrO2/BiOCl composite powder

A nano-composite powder and colloid technology, applied in nanotechnology, nanotechnology, chemical instruments and methods, etc., can solve the problems of poor thermal stability of single bismuth oxychloride, uneven composition of composite powder, complicated preparation process, etc. To achieve the effect of good pearl effect, low cost and simple synthesis process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

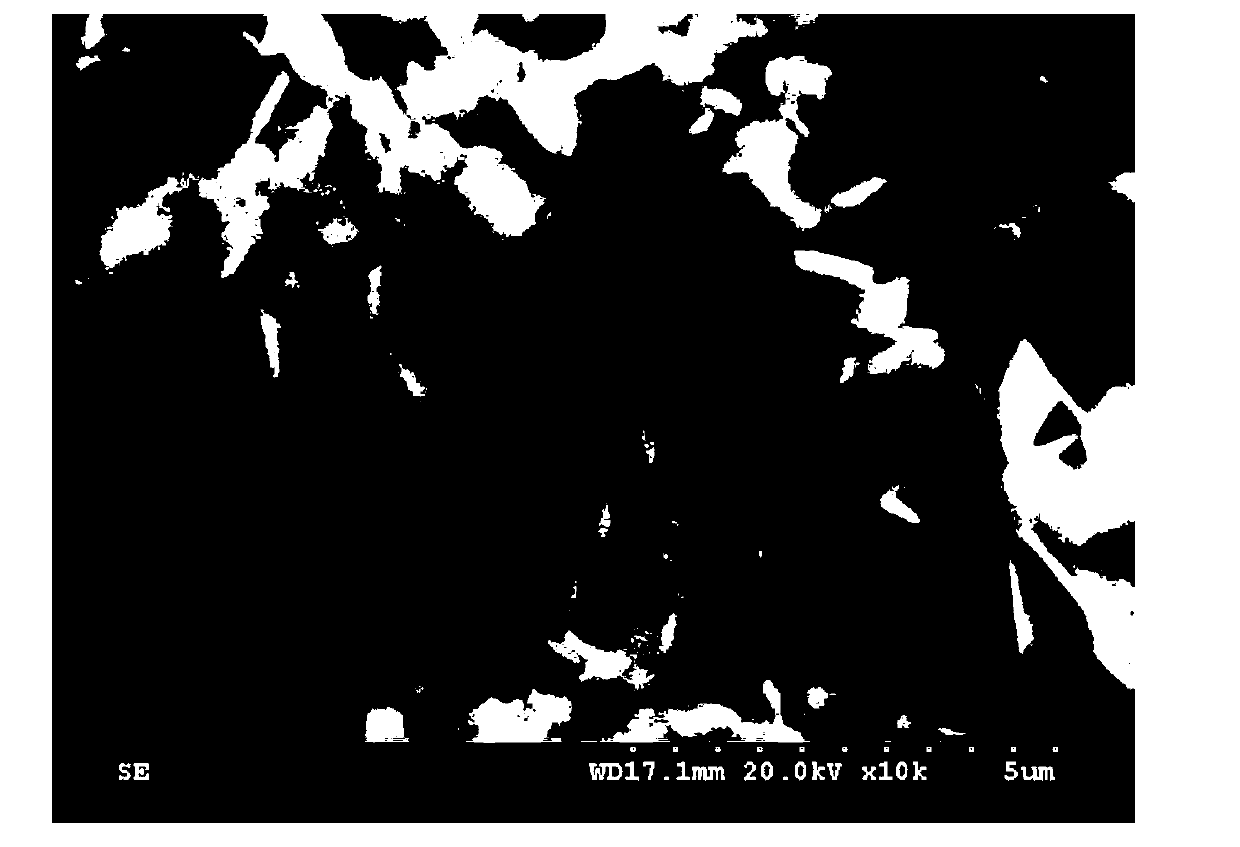

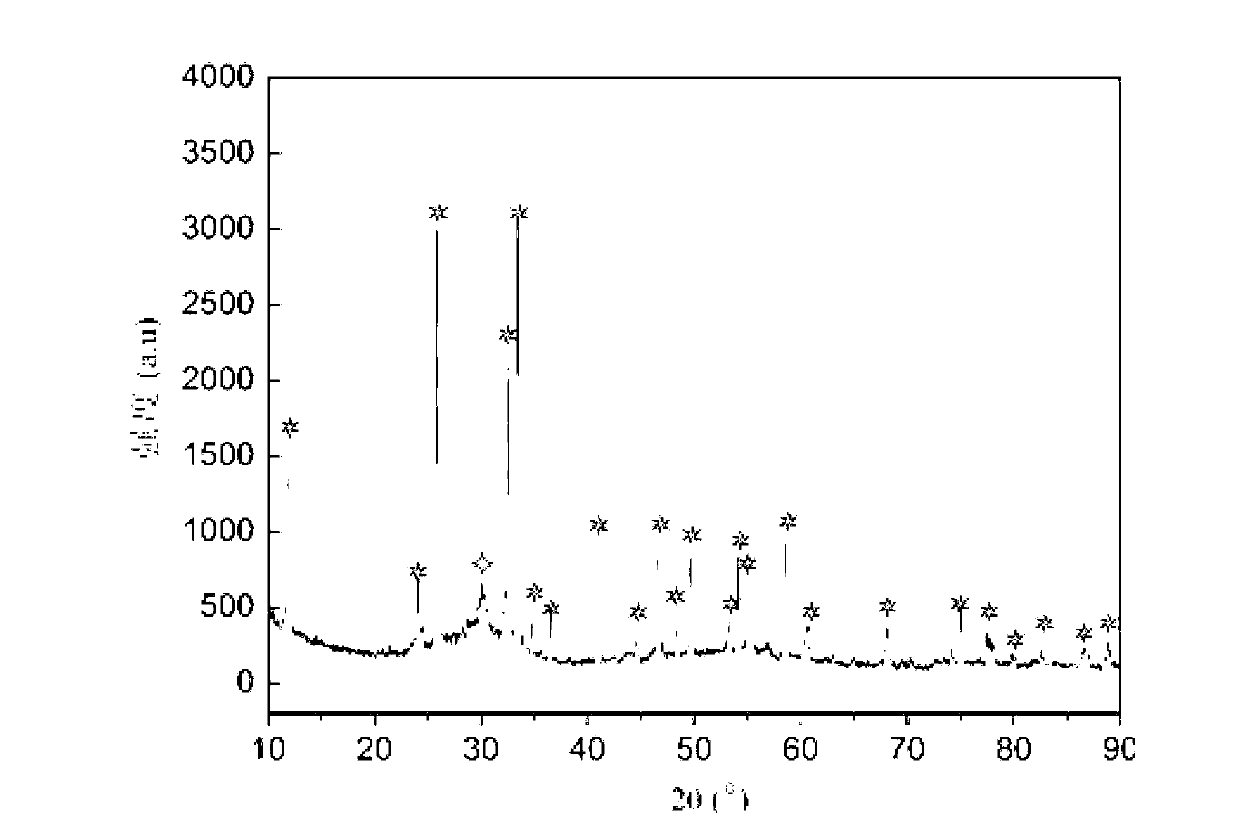

Image

Examples

specific Embodiment approach 1

[0015] Specific implementation mode one: ZrO in this implementation mode 2 The preparation method of / BiOCl nanocomposite powder is carried out according to the following steps:

[0016] 1. Dissolving bismuth nitrate in nitric acid, stirring evenly, adding water to dilute to obtain bismuth nitrate solution, the concentration of bismuth nitrate in the bismuth nitrate solution is 0.0001-0.02mol / L, and the concentration of nitric acid is 0.02-10mol / L;

[0017] 2. Prepare an ammonia solution with a concentration of 0.001-2mol / L;

[0018] 3. Add ammonia water and bismuth nitrate solution dropwise into a container containing water while stirring, and control the pH value of the system during the dropwise addition process, the pH value is 7-10, and bismuth hydroxide colloid is obtained;

[0019] 4. Dissolving zirconium oxychloride into water to obtain a zirconium oxychloride solution with a concentration of 0.0001 to 1 mol / L;

[0020] 5. Polyethylene glycol is dissolved in water to...

specific Embodiment approach 2

[0022] Embodiment 2: This embodiment differs from Embodiment 1 in that the concentration of bismuth nitrate in the bismuth nitrate solution in step 1 is 0.001-0.015 mol / L, and the concentration of nitric acid is 0.015-9 mol / L. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0023] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that the concentration of bismuth nitrate in the bismuth nitrate solution in step 1 is 0.0018-0.012 mol / L, and the concentration of nitric acid is 0.5-8 mol / L. Others are different from the first or second specific embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com