Anti-yellowing meta-aramid fibrid and preparation method and application thereof

A technology of aramid fiber precipitation and anti-yellowing, which is applied in the field of polymers and can solve the problems of large loss of additives, fast settling speed, and low utilization efficiency, so as to achieve good combination, increase permittivity, and increase effective use rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

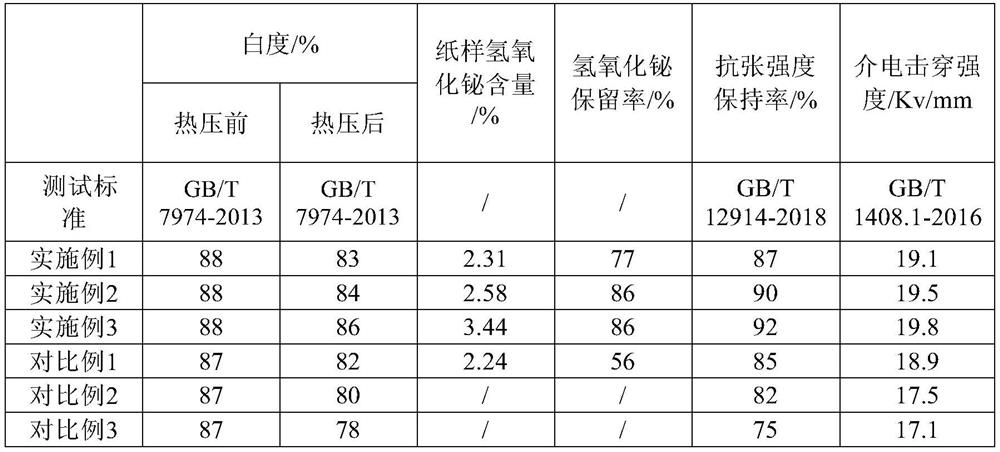

Examples

preparation example Construction

[0027] The preparation method of the meta-aramid filtrate fiber of a specific embodiment of the present invention comprises the following steps:

[0028] (1) Preparation of anti-yellowing additive: bismuth hydroxide, DMAc (dimethylacetamide), and silane coupling agent are formulated into a suspension, and the suspension is ground with a nano sand mill as an anti-yellowing Dosage spare.

[0029] Preferably, DMAc is 10 to 30 times the mass of bismuth hydroxide, more preferably 20 to 25 times. One or more of KH-550, KH-540, KH-551, KH-901, KH-791 is selected as the silane coupling agent, more preferably one or more of KH-550, KH-540, KH-551 . The silane coupling agent is 0.1-3% of the mass of bismuth hydroxide, more preferably 1-2.5%, more preferably 1.8-2.2%. The particle size of bismuth hydroxide after grinding is 0.1-10 μm, more preferably 0.5-2 μm. The average width of the precipitated fiber is 30-50 μm. If the particle size of bismuth hydroxide is too large, the adsorpti...

Embodiment 1

[0039] Dissolve a mol m-phenylenediamine in DMAc, gradually add b mol isophthaloyl chloride, then add c mol 1,3,5-benzenetricarboxylic acid chloride, and finally add d mol tetramethylpiperidinamine, where b +c=a, b:a=0.99, d:c=2, the meta-aramid resin solution is obtained, the inherent viscosity is controlled to be 1.7, and calcium hydroxide is added for neutralization, and the pH value of the resin solution at the end of neutralization is 7.2 , After neutralization, dilute the resin solution with DMAc to a kinematic viscosity of 1500mpa·s.

[0040]Weigh bismuth hydroxide according to 6% of the mass of the polymer in the resin solution, add DMAc 20 times the mass of bismuth hydroxide and silane coupling agent KH-550 with 1.5% mass of bismuth hydroxide, and stir to form a suspension. Grind the suspension with a nano-sand mill. After grinding, the particle size of bismuth hydroxide is 1 μm. The ground suspension is added to the resin solution as an anti-yellowing agent, stirred ...

Embodiment 2

[0044] Dissolve a mol m-phenylenediamine in DMAc, gradually add b mol isophthaloyl chloride, then add c mol 1,3,5-benzenetricarboxylic acid chloride, and finally add d mol tetramethylpiperidinamine, where b +c=a, b:a=0.99, d:c=2, the meta-aramid resin solution is obtained, the inherent viscosity is controlled to be 1.7, and calcium hydroxide is added for neutralization, and the pH value of the resin solution at the end of neutralization is 7.2 , After neutralization, dilute the resin solution with DMAc to a kinematic viscosity of 1500mpa·s.

[0045] Weigh bismuth hydroxide according to 6% of the mass of the polymer in the resin solution, add DMAc 20 times the mass of bismuth hydroxide and silane coupling agent KH-550 with 2% mass of bismuth hydroxide, and stir to form a suspension. Grind the suspension with a nano-sand mill. After grinding, the particle size of bismuth hydroxide is 1 μm. The ground suspension is added to the resin solution as an anti-yellowing agent, stirred a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com