Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

766 results about "M-Phenylenediamine" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

M-Phenylenediamine, also called 1,3-diaminobenzene, is an organic compound with the formula C₆H₄(NH₂)₂. It is an isomer of o-phenylenediamine and p-phenylenediamine. It is a colourless solid.

Preparation method of aromatic polyamide film modified by ZIF-8 type metal-organic framework material

InactiveCN104209021AIncrease fluid channelFacilitate water permeation membraneSemi-permeable membranesPolymer scienceMetal-organic framework

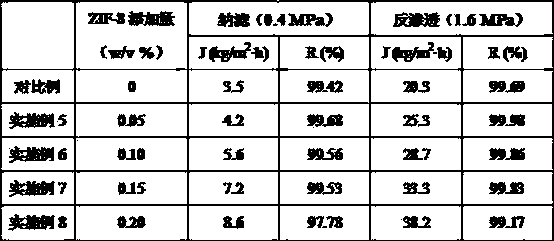

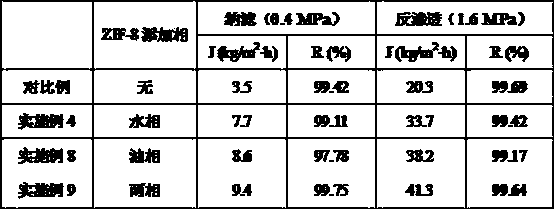

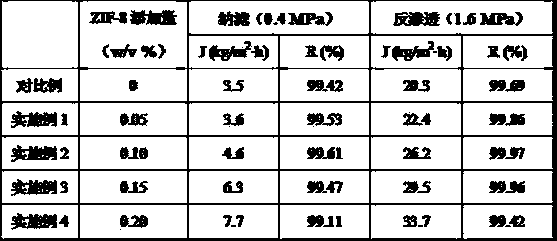

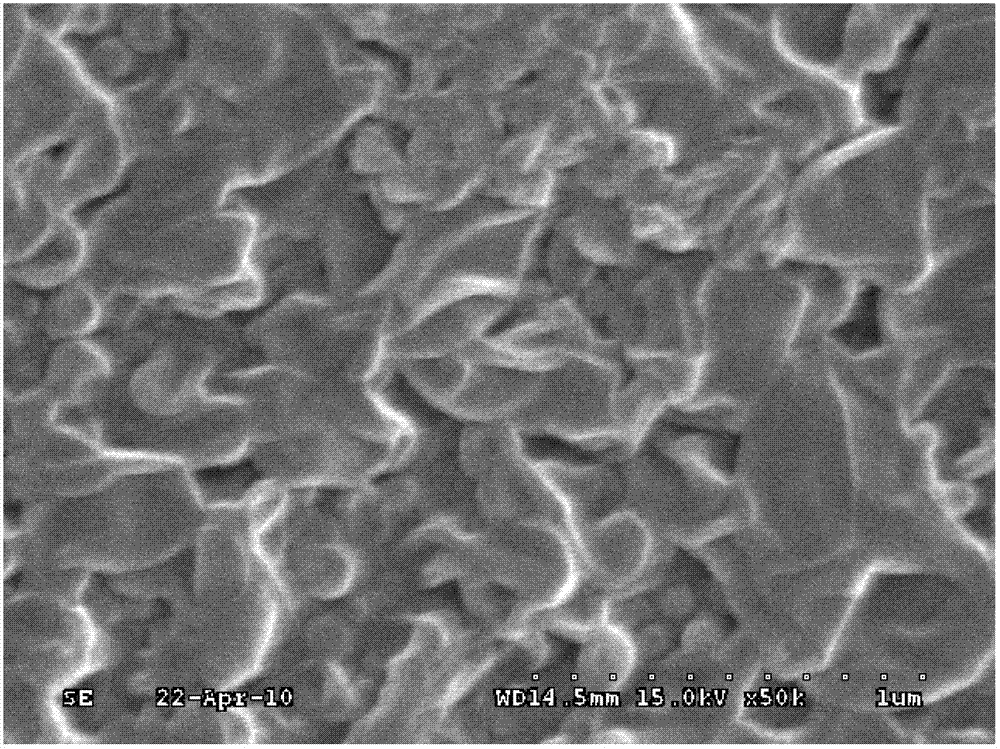

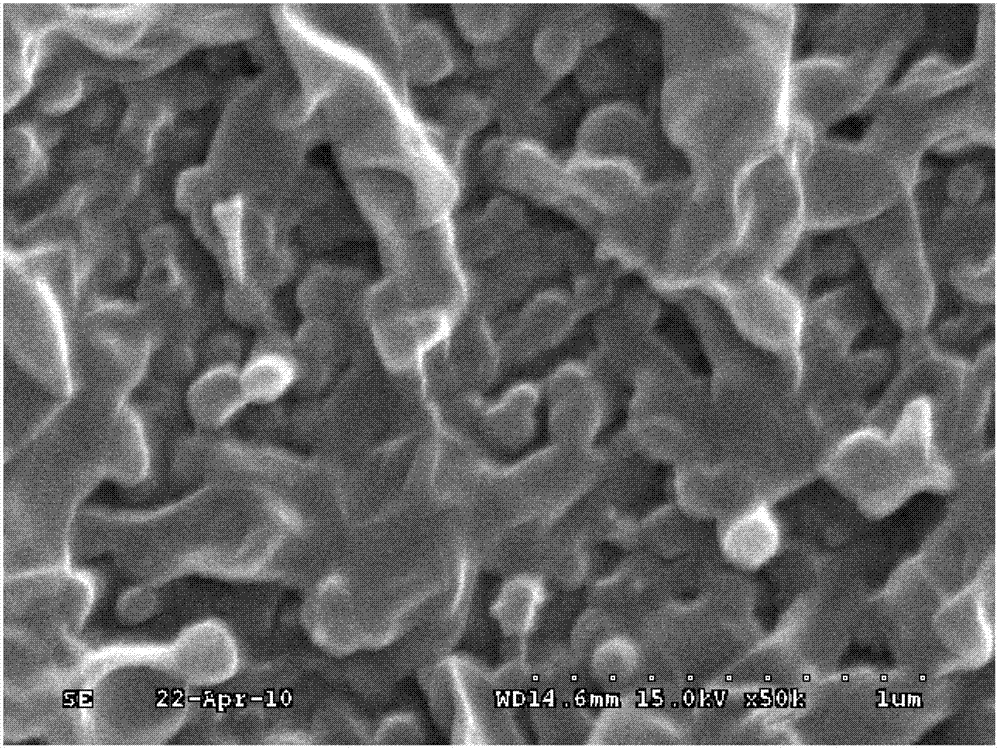

The invention discloses a preparation method of an aromatic polyamide film modified by a ZIF-8 type metal-organic framework material. A ZIF-8 filling polyamide composite film is prepared on an ultrafiltration bottom film by an interfacial polymerization method, wherein nano-grade ZIF-8 particles are added into an m-phenylenediamine aqueous solution and / or a trimesoyl hexane solution; a polyamide ultrathin skin layer, to which ZIF-8 is added, is formed through interfacial polymerization. The preparation method has the advantages that by the use of a ZIF-8 nano-grade aperture and a three-dimensional multi-hole structure, the selectivity or the permeability of the aromatic polyamide film is improved; the prepared ZIF-8 filling polyamide composite film can serve as a nanofiltration or reverse osmosis film for removing organic matters from the aqueous solution; when the adding ratio of an organic phase or water phase solution, to which ZIF-8 is added, is 0.05-0.15% (w / v), the performance of the film is the highest, and the permeation flux and the retention rate can be increased at the same time; furthermore, the nanofiltration or reverse osmosis performance of the two-phase adding film is higher than that of a single-phase adding film.

Owner:BEIJING FORESTRY UNIVERSITY

Compound reverse osmosis membrane with interpenetrating network desalting layer and preparation method of membrane

ActiveCN102921314AImprove throughputHigh desalinationSemi-permeable membranesPolyamideReverse osmosis

The invention discloses a compound reverse osmosis membrane with interpenetrating network desalting layer and a preparation method of the membrane. The desalting layer consists of a stereoscopic network which is formed by interpenetrating macromolecule nanogel and polyamide. The preparation method comprises the following steps of: pre-adding hydrophilic and / or oleophylic macromolecule nanogel with good dispersion into a solvent of solution A and / or B, preparing a water phase A solution containing m-phenylenediamine and / or p-phenylenediamine, preparing an organic phase B solution containing trimesoyl chloride, enabling the solution A and the solution B to fully contact on a porous support carrier for interface reaction, rinsing by using deionized water, carrying out moisturizing treatment by using glycerol, and drying. The compound reverse osmosis membrane disclosed by the invention has a sodium chloride removal rate of not less than 99% and a flux of not less than 25GFD (Geophysical Fluid Dynamics) under a pressure of 225psi; the microstructure and the charge property of the desalting layer can be regulated and controlled through the macromolecule nanogel so that the reverse osmosis membrane with high anti-pollution capability is prepared; and the compound reverse osmosis membrane can further be used for developing novel low-pollution reverse osmosis membranes.

Owner:VONTRON TECH CO LTD

Composite nanofiltration membrane based on hydrophilic modified polyolefin microporous substrate and preparation method thereof

InactiveCN106975371AImprove surface hydrophilicityLow membrane resistanceMembranesReverse osmosisPolyolefinOil phase

The invention discloses a composite nanofiltration membrane based on a hydrophilic modified polyolefin microporous substrate and a preparation method thereof. The composite nanofiltration membrane comprises a substrate and a selective cortex formed on the substrate through an interfacial polymerization reaction, and the substrate is a polyolefin microporous membrane subjected to hydrophilic modification through sedimentation; the selective cortex is formed by the interfacial polymerization reaction of an aqueous phase monomer and an oil phase monomer on the surface of the substrate; the aqueous phase monomer is at least one of piperazine, m-phenylenediamine and o-phenylenediamine; and the oil phase monomer is trimesoyl chloride. The substrate of the composite nanofiltration membrane is the polyolefin microporous membrane subjected to the hydrophilic modification through the sedimentation, a formed hydrophilic layer is thin and uniform, the surface topography of the substrate is unchanged, and the selective cortex formed on the hydrophilic layer through the interfacial polymerization is dense, uniform and defect-free, so that water flux of the composite nanofiltration membrane is large; the polyolefin microporous substrate has good tolerance for organic solvents, so that the use range of the composite nanofiltration membrane is improved.

Owner:ZHEJIANG UNIV

Novel coupling components

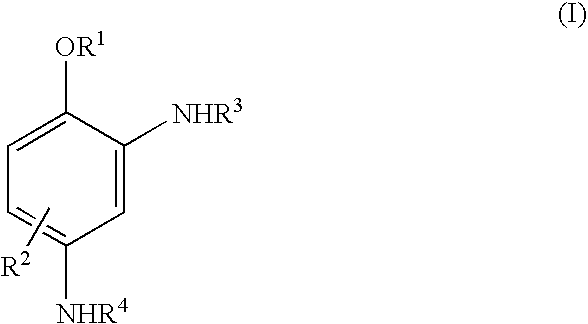

InactiveUS20060000032A1High color intensityHigh fastnessCosmetic preparationsHair cosmeticsFiberCoupling

Keratin fibers are colored by an agent comprising a coupler which is a m-phenylenediamine derivative of the formula (I) wherein R1 is a C1-C4 alkyl group or a C1-C4 monohydroxyalkyl group; R2 is a methyl or an ethyl group; each of R3 and R4 is independently a branched or unbranched C2-C6 hydroxyalkyl group; and a cosmetically acceptable carrier. These couplers exhibit improved toxicological and dermatological properties and permit hair colorations in a broad color spectrum with good fastness properties.

Owner:HENKEL KGAA

Preparation of low salt-containing aramid fiber 1313spinning solution and process for spinning fibre by wet method

ActiveCN101285214AWell mixedHigh molecular weightWet spinning methodsSpinning solutions preparationPolymer scienceDry heat

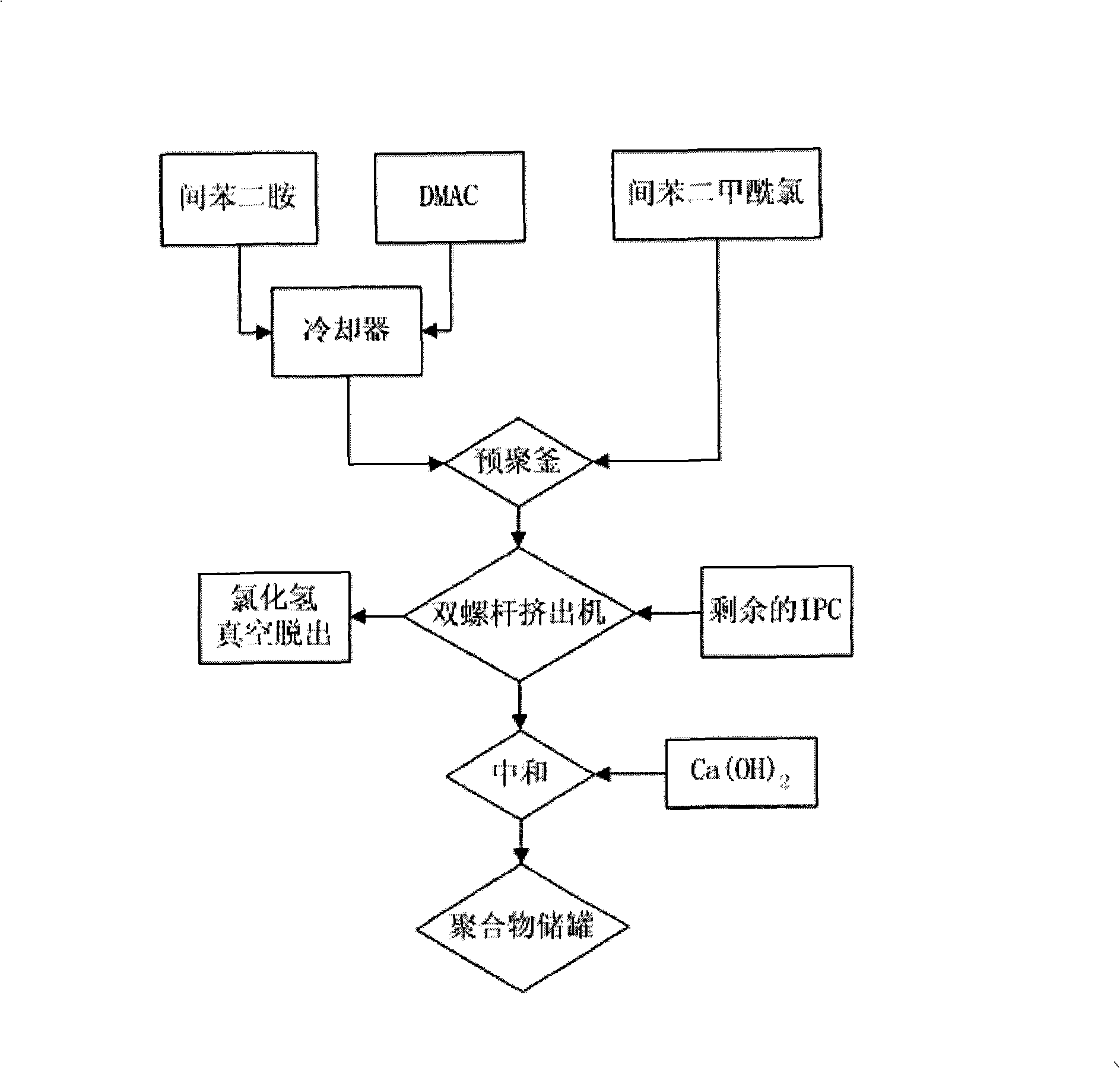

The invention relates to a method for spinning aramid fiber 1313 with low salt content by wet spinning. The method comprises the following steps of: prepolymerizing m-phenylenediamine (MPD) and part m-phthaloyl chloride (IPC); adding the preformed polymer and the rest m-phthaloyl chloride into a double-screw extruder to extrude the aramid fiber 1313 containing chlorine hydride; extruding spinning dope into a aqueous coagulation bath after neutralizing the chlorine hydride with calcium hydroxide; crimping and cutting coagulated tows into the required fiber length via hot water drawing, water rinsing, drying, dry-heat drawing and heat setting after being taken out of the coagulation bath to receive a finished fiber. The method is convenient and simple, can improve the molecular weight of products and the evenness of polycondensate, and reduce the salt content of the final spinning solution.

Owner:DONGHUA UNIV +1

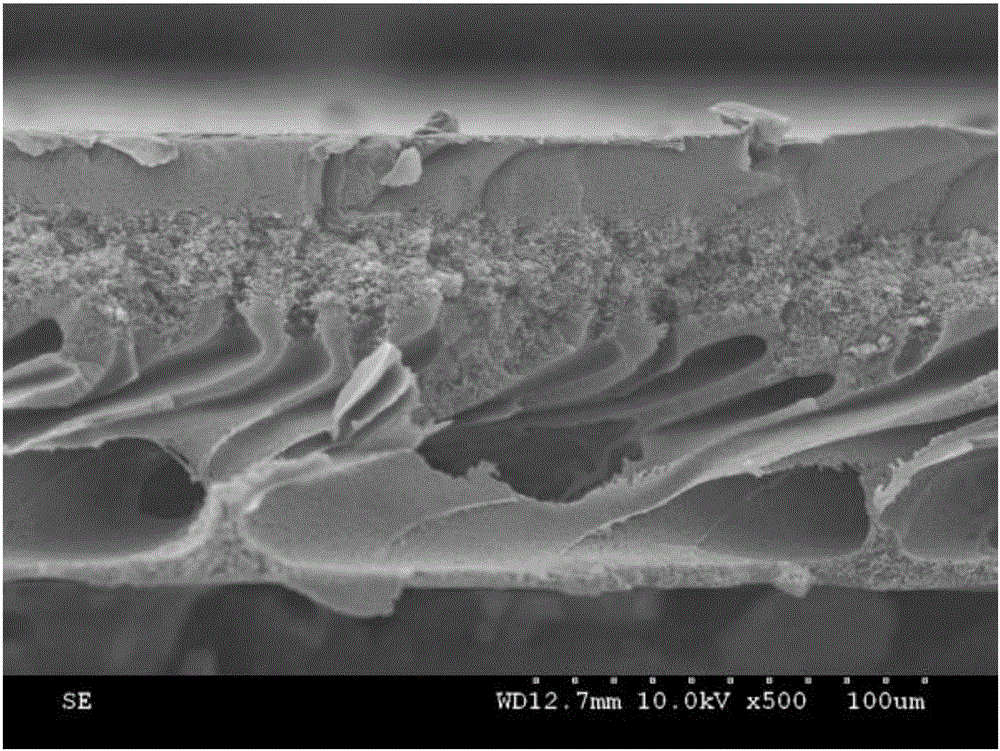

Method for preparing graphene aerogel and application thereof

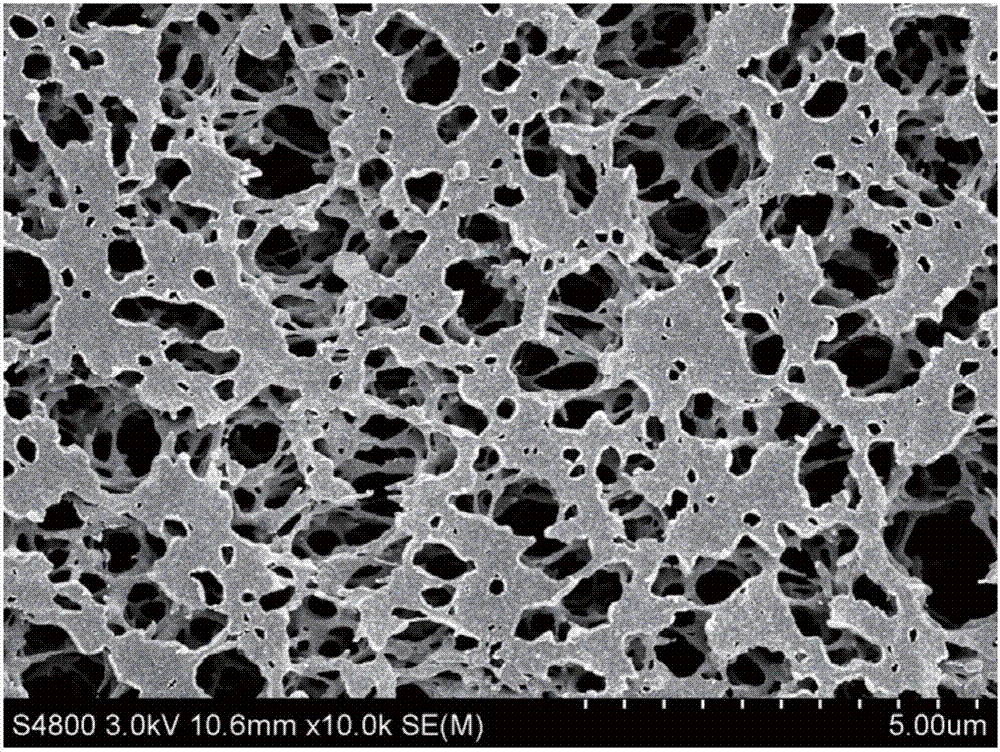

The invention discloses a method for preparing graphene aerogel and application thereof, and relates to the technical field of graphene materials. The method includes steps of uniformly mixing graphene oxide dispersion liquid and amine curing agents with one another to obtain graphene oxide mixed liquid; hermetically heating the obtained graphene oxide mixed liquid to obtain the graphene aerogel. The amine curing agents are one type of or a plurality of types of diaminodiphenyl-methane, diamino diphenyl sulfone, diethylenetriamine, triethylenetetramine, diethylaminopropylamine and m-phenylenediamine. The graphene aerogel prepared by the aid of the method can be applied to epoxy resin, so that graphene aerogel / epoxy resin composite materials with high conductivity and excellent mechanical properties can be obtained. The method and the application have the advantages that the graphene aerogel prepared by the aid of the method is internally of a uniform macroporous structure and is high in porosity; the amine curing agents are adopted in preparation procedures, accordingly, the epoxy resin interface bonding can be improved, and the conductivity and the mechanical properties of the epoxy resin can be enhanced.

Owner:BEIJING UNIV OF CHEM TECH

Preparation method of polyamide reverse osmosis membrane

ActiveCN104474926ALow total unreacted amine residueGentle rinse processSemi-permeable membranesReverse osmosisPolyamide

The invention discloses a preparation method of a reverse osmosis membrane, and more particularly relates to a high-desalting-rate and high-flux reverse osmosis membrane with extreme convenience in rinsing treatment and a preparation method of the high-desalting-rate and high-flux reverse osmosis membrane. According to the invention, a porous polysulfone support layer is provided with a functional compact composite layer which is a m-phenylenediamine aqueous solution formed by organic acid or an aquo-complex thereof, which contains one or more than one hydroxyl, and organic alkali in a buffer salt system, and the porous polysulfone support layer is subjected to polycondensation together with an organic solvent solution of trimesoyl chloride containing a certain amount of additives on the surface of the porous polysulfone support layer. The preparation method of the reverse osmosis membrane has the advantages that the required rinsing treatment technology is mild, simple and efficient; the total residual amount of the unreacted amine in the membrane after rinsing is low, and industrial continuous rapid preparation can be realized easily.

Owner:HANGZHOU WATER TREATMENT TECH DEV CENT

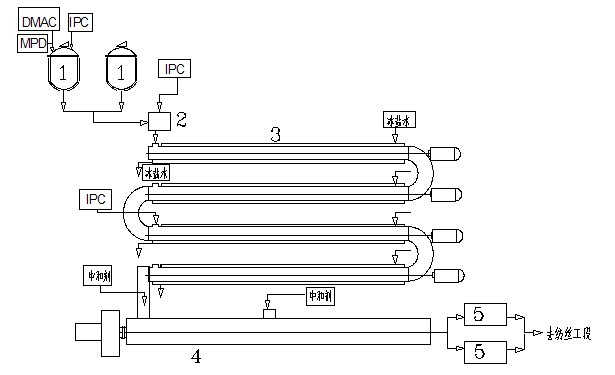

Method for producing polymetaphenylene isophthamide spinning solution

InactiveCN101876092AAvoid lostAvoid the effect of molecular weightSpinning solutions preparationMonocomponent polyamides artificial filamentCalcium hydroxideSpinning

The invention relates to a tube-type continuous method for producing polymetaphenylene isophthamide spinning solution, which is characterized in that a method for serially connecting a self-cleaning tubular reactor serving as a condensation reactor and a twin-screw kneading machine serving as a neutralization reactor is adopted for preparing the polymetaphenylene isophthamide spinning solution. The self-cleaning tubular reactor solves the problems that side reactions are increased due to quick generation of heat in the reaction and the polymer molecular weight cannot be improved; and the twin-screw kneading machine solves the problem of poor dissolution of solid granules in the spinning solution caused by nonuniform liquid / solid kneading in the neutralization process. The preparation method comprises the steps of pre-condensation, condensation, neutralization, and forced extrusion and filtration. The solid content of the final spinning solution is 14 to 20 percent; and calcium hydroxide is adopted for neutralization by one step, and the calcium chloride content is 6.5 to 9.3 percent. If the calcium hydroxide and sodium hydroxide are adopted for neutralization by two steps, the calcium chloride content can be less than 3 percent. Therefore, the method is also suitable for producing spinning solution for a high salt method and a low salt method.

Owner:四川辉腾科技股份有限公司

Cross-linked sulfonated polysulfone/polyether sulfone-sulfonated polysulfone composite membrane and manufacturing method thereof

InactiveCN104524993AImprove hydrophilicityImprove performanceSemi-permeable membranesCross-linkFiltration

The invention relates to a cross-linked sulfonated polysulfone / polyether sulfone-sulfonated polysulfone composite membrane and a manufacturing method of the cross-linked sulfonated polysulfone / polyether sulfone-sulfonated polysulfone composite membrane. Polyhydroxyl or multi-amino or hyperbranched substances are selected, a polyether sulfone / sulfonated polysulfone blended ultra-filtration base membrane is coated with a cross-linked sulfonated polysulfone solution to manufacture the composite membrane, a composite membrane separation layer of which the thickness is 1 micrometer-10 micrometers is formed on the surface of the base membrane, the water contact angle of the surface of the composite membrane separation layer ranges from 40 degrees to 90 degrees, and the composite membrane separation layer has good osmosis and separation properties. The manufacturing method includes the steps that sulfonated polysulfone of different concentrations and sulfonation degrees, m-phenylenediamine, polyethylene glycol, dopamine, H30 and other cross-linking agents are dissolved in solvent to manufacture the coating solution, with the polyether sulfone / sulfonated polysulfone blended ultra-filtration being the base membrane, the composite membrane separation layer is manufactured under vacuum conditions, and finally the cross-linked sulfonated polysulfone / polyether sulfone-sulfonated polysulfone composite membrane which is hydrophilic is obtained. The manufactured composite membrane has the good osmosis and separation properties, and can be used for nanofiltration and forward osmosis processes and membrane separation processes including seawater desalting, waste water treatment, domestic water treatment and bio-separation.

Owner:张一琛

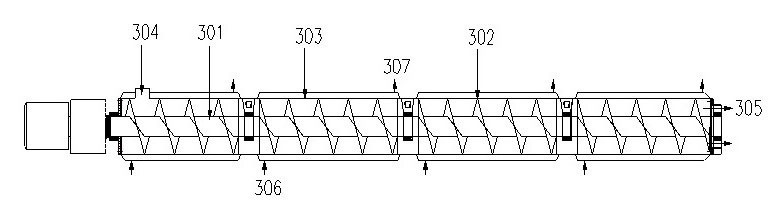

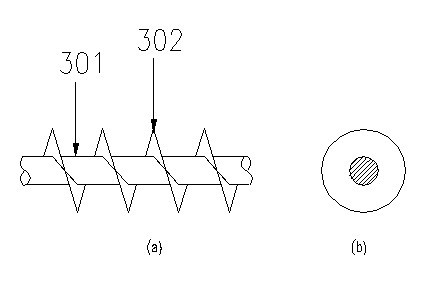

Device and method for continuously preparing polyisophthaloyl metaphenylene diamine spinning solution

ActiveCN102797048AEasy dischargeNo accumulation phenomenonSpinning solutions preparationMonocomponent polyamides artificial filamentFiberPolymer science

Owner:上海舟汉纤维材料科技股份有限公司

Process for preparing resorcinol

InactiveCN1830933ANo emissionsSolve pollutionOrganic chemistryOrganic compound preparationMeta-aminophenolResorcinol

Owner:HUIFENG CHEM PLANT WUJIANG CITY

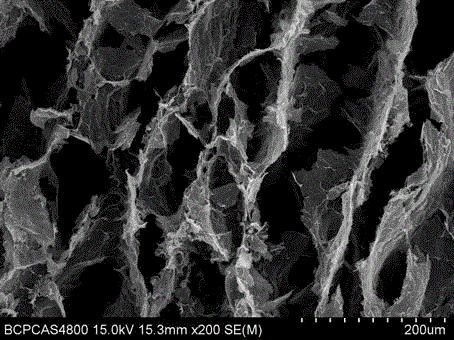

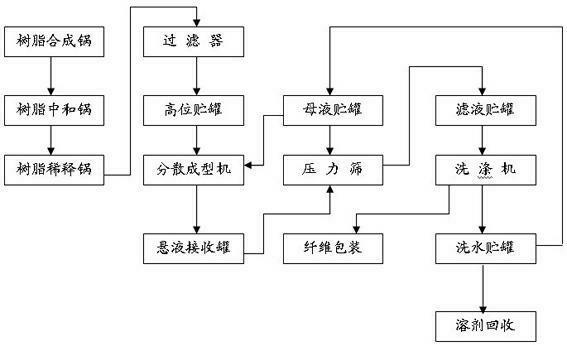

Production method of meta-position aramid paper fibrid

InactiveCN102660795AEasy to shapeGood dispersionSynthetic cellulose/non-cellulose material pulp/paperMonocomponent polyamides artificial filamentChlorideFiber suspension

The invention discloses a production method of a meta-position aramid paper fibrid. The production method comprises the following steps of: polymerizing m-phenylenediamine and isophthaloyl chloride in DMAC (M, N-dimethylacetamide) to form PMIA (polyisophthaloyl metaphenylene diamine) resin); producing hydrogen chloride gas by a neutralization reaction; diluting the resin, dispersing in a mother liquor and precipitating to obtain a fibrid suspending liquid in accordance with the manufacturing conditions of the meta-position aramid paper; pumping the fibrid suspending liquid and deionized water into a washing and filtering machine, and removing the solvent, additive and moisture containing in the fibrid to obtain the fibrid in accordance with the manufacturing conditions of the meta-position aramid paper. The method has advantages of low cost, high efficiency, stable process, simple used equipment and suitability for sustainable industrial production.

Owner:SICHUAN YUNTONG CHEM IND CO LTD

Epoxy phenolic-titanium-structure amine nano composite heatproof heavy-duty anti-corrosive paint and preparation

The invention relates to epoxy-phenolic-titanium-structure amine nanometer compound temperature resistant heavy anti-corrosive paint and a preparation method thereof. The paint has the following formulation: 30-40 parts of epoxy phenolic resin, 5-10 parts of nanometer compound mother solution, 6-8 parts of intensified carbon fiber, 20-23 of titanium pigment, 9-12 parts of ceramic powder, 15-25 parts of mixed solvent which are well mixed according to the proportion, dispersed and ground till grain diameter is under 40mum to prepare the component A; compound firming agent comprising 4, 4'-diamino sulfobenzide, lentine and phenol-aldehyde amine and mixed solvent are prepared to form the component B; and then the component A and the component B are blended, heated and solidified for 1-3 hours to form the heavy anti-corrosive nanometer compound paint. The coating with the 0.1-1.0 mm thickness can resist the corrosion destruction of strong corrosive medium containing sulfureted hydrogen, sulfur dioxide, carbon dioxide, chloride and the like in the temperature of 80-150 DEG C and in the 1-40 high atmospheric pressure, solves the problems of high temperature acidity deep-etching in industries such as petrifaction, metallurgy, electrical powder and coal and the like, and effectively protect metal materials.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

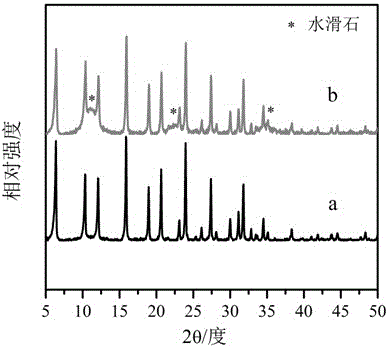

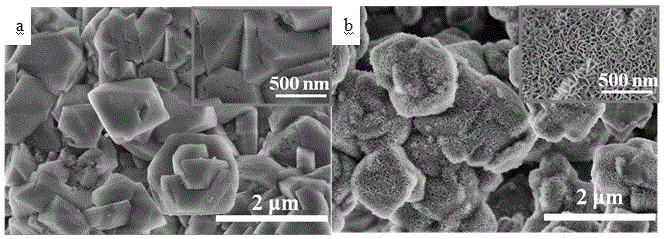

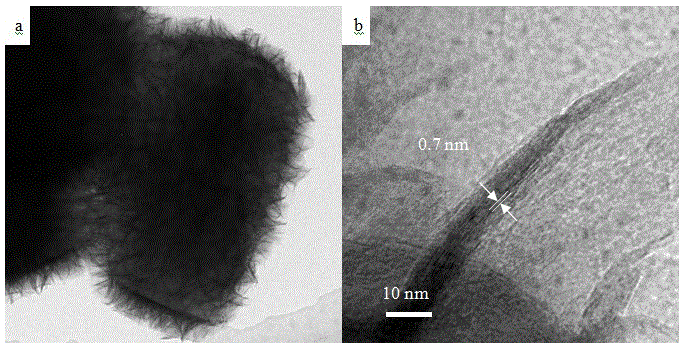

Core shell catalyst by taking hydrotalcite as shell and molecular sieve as core as well as preparation and application thereof

ActiveCN106475134AGood dispersionImprove stabilityMolecular sieve catalystsOrganic compound preparationMolecular sieveDivalent metal

The invention discloses a core shell catalyst by taking hydrotalcite as a shell and a molecular sieve as a core as well as a preparation and an application thereof. According to the invention, divalent metal source and aluminum species in a core-shell molecular sieve are used for forming a hydrotalcite compound on the surface of the molecular sieve, and the core-shell structure molecular sieve by taking the molecular sieve as the core and the petal hydrotalcite as the shell is formed; after the molecular sieve is reduced, the nano-grade metal-modified molecular sieve catalyst having uniform size, high dispersibility, excellent heat stability and high universality is obtained, and can be used for a catalytic reaction for hydrogenation synthesis of m-dinitrobenzene to obtain m-phenylenediamine. compared with the prior art, the preparation process is simple, the metal atom utilization rate is high, applied metal source is almost completely reacted, no loss is generated, cost is reduced, and pollution on environment is reduced, industrial production is easy, and a series of different metal-modified molecular sieve catalysts can be prepared according to the modifiable character of the composition elements of the hydrotalcite and diversity of a topological structure of the molecular sieve.

Owner:EAST CHINA NORMAL UNIV

Preparation method of phase change energy storage paraffin microcapsule with multiple layers of capsule shells

ActiveCN105233770AHigh mechanical strengthGood application effectProductsReagentsParaffin waxPolyamide

The invention discloses a preparation method of a phase change energy storage paraffin microcapsule with multiple layers of capsule shells. The method comprises the following steps: 1, mixing a trimesoyl chloride active monomer with phase change paraffin, heating to form an oil phase liquid, adding the oil phase liquid to an aqueous emulsifier solution having a same temperature with the oil phase liquid, and adding an aqueous solution of an m-phenylenediamine cross-linking agent while stirring to prepare an oil-in-water emulsion; 2, continuously stirring the above paraffin microcapsule emulsion in a heat insulation state, adjusting the pH value of the paraffin microcapsule emulsion to be greater than 8.0 in the stirring process, centrifuging after the stirring ends, and washing with water; and 3, adding the above paraffin microcapsule with the inner layer capsule shell of polyamide to a trihydroxymethyl aminomethane-HCl buffer solution containing 4-(2-aminoethyl)-1,2-resorcinol, dipping while continuously stirring at room temperature, separating, washing with water, and drying. The energy storage paraffin microcapsule can prevent leakage of capsule core paraffin in the phase change process, has good endophilicity with water, and is in favor of transferring heat.

Owner:GUANGXI RES INST OF CHEM IND CO LTD

Anti-pollution reverse osmosis membrane and preparation method thereof

ActiveCN102921315AEasy to manufactureEasy to industrializeSemi-permeable membranesPolyvinyl alcoholDesalination

The invention discloses an anti-pollution reverse osmosis membrane and a preparation method thereof. The anti-pollution reverse osmosis membrane comprises a non-woven fabric, a polysulfone supporting layer, a polyamide desalination layer containing polyvinyl alcohol (PVA) molecules and a PVA cross-linking coating. According to the anti-pollution reverse osmosis membrane, the PVA molecules are introduced into the polyamide desalination layer, part of hydroxyl on the PVA molecules, amino of m-phenylenediamine and acyl chloride perssad are reacted to form the polyamide desalination layer, and the rest hydroxyl and hydroxyl which is later coated on the PVA molecules jointly participate in the reaction for generating the PVA cross-linking coating so that the polyamide desalination layer and the PVA cross-linking coating are combined together through chemical bonds, and adhesion of the PVA cross-linking coating is improved. The reverse osmosis membrane has the advantages of being anti-pollution, high in flux, high in desalinization ratio and easy to prepare.

Owner:BEIJING ORIGIN WATER FILM TECH

Method for online preparing high-throughput composite reverse osmosis membrane

ActiveCN103657430AReduce crosslink densityIncrease water fluxSemi-permeable membranesWater/sewage treatment bu osmosis/dialysisUltrafiltrationReverse osmosis

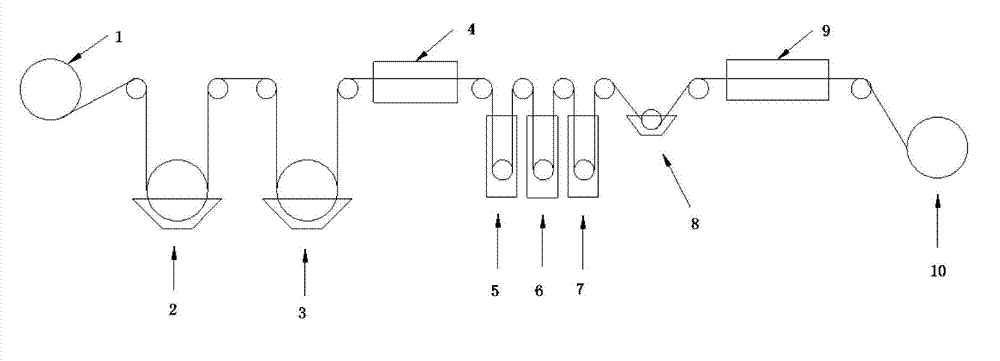

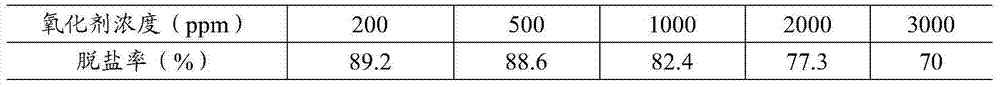

The invention discloses a method for online preparing a high-throughput composite reverse osmosis membrane. The method comprises the following steps of using a membrane coating machine to enable an ultrafiltration base membrane to pass through m-phenylenediamine aqueous solution, normal hexane solution of trimesoyl chloride, an oven, a purge tank, an oxidation tank, a reduction cell, a glycerite tank and a protective liquid tank; drying in the oven to obtain the high-throughput composite reverse osmosis membrane. The method has the characteristics that the process is simple, the water flux of the membrane is high, dry films of the high-throughput composite reverse osmosis membrane can be directly produced, membrane components can be wound conveniently, large-scale production can be realized, the process is stable, and the like. The high-throughput composite reverse osmosis membrane can be applied in the field of household water purification, municipal administration tap water is utilized to supply pressure without an additional booster pump, the cost is greatly reduced, and the energy is saved.

Owner:BEIJING ORIGIN WATER FILM TECH

High-flux and reverse-osmosis composite membrane from eurelon

InactiveCN1778457AImprove hydrophilicityImprove performanceSemi-permeable membranesPolysulfone membraneReverse osmosis

A high-flux composite reverse osmosis polyamide member features that on a supporting polysulfone membrane, there is a functional aromatic polyamide layer which is prepared from aromatic polyamine (the mixture of lentine and 5-sulfonyl lentine) and aromatic polyacyl chloride chosen from sym-phenyltrimethyl acyl chloride, 5-isocyanate-isophthalic chloride, meta-phenyldimethyl acyl chlorid, and their mixture.

Owner:HANGZHOU WATER TREATMENT TECH DEV CENT

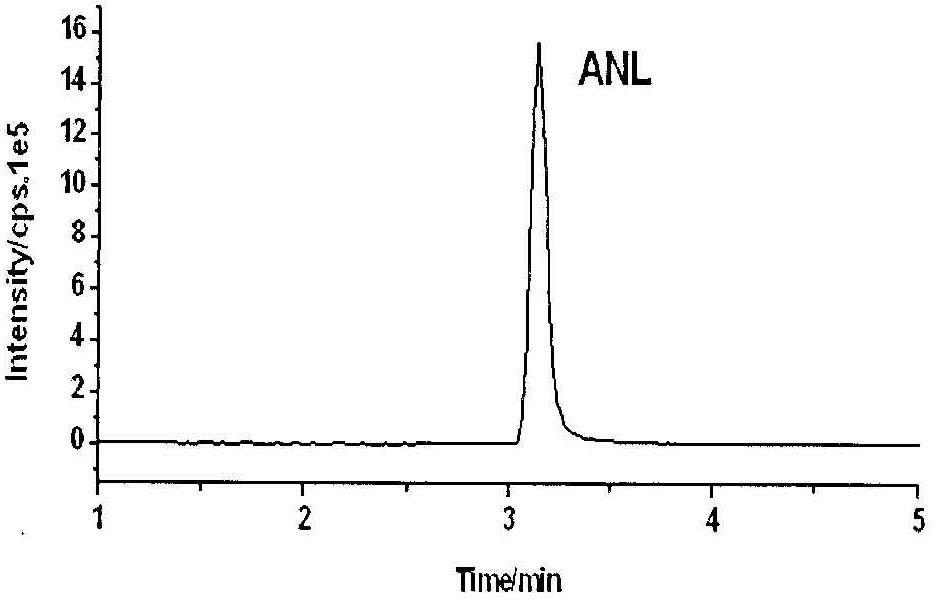

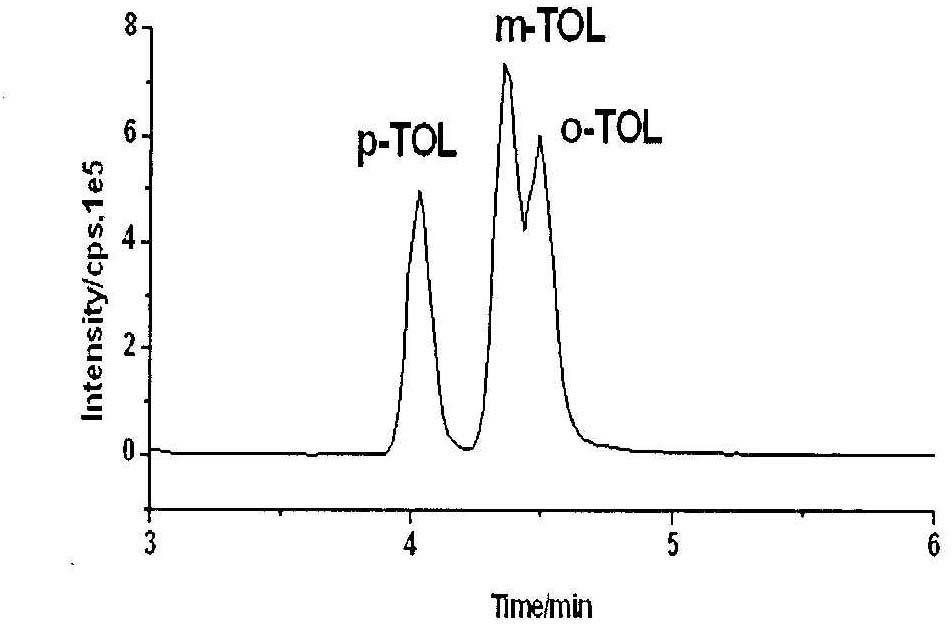

Method for detecting 10 types of aromatic amines compounds in cigarette mainstream smoke by liquid chromatography-tandem mass spectrometry

ActiveCN102608232ASimplified processing stepsSaving volume and smoking experiment timeComponent separationToluidineAniline

A method for detecting 10 types of aromatic amines compounds (including aniline, ortho toluidine, m-toluidine, p-aminotoluene, m-phenylenediamine, m-methoxyaniline, 1- naphthylamine, 2- naphthylamine, 3- aminobphenyl and 4- aminobphenyl) in cigarette mainstream smoke by liquid chromatography-tandem mass spectrometry is characterized in that a Cambridge filter and an absorbing bottle containing 5%of HC1 solution respectively gather the aromatic amines compounds in a particle phase matter and a gas phase matter of mainstream smoke, after the 5%HCI solution is used for extracting the aromatic amines compounds on the filter, the aromatic amines compounds are purified by an HLB (hydrophile-lipophile balance) solid-phase extraction column, and a liquid chromatography-tandem mass spectrometry instrument is used for determining the 10 types of aromatic amines in the mainstream smoke in cigarettes. Compared with an existing GC-MS (gas chromatography-mass spectrometer) analysis method for detecting aromatic amines in mainstream smoke of cigarettes, the method does not need derivatization reaction or liquid-liquid extraction operation, greatly simplifies pretreatment steps of samples, improves analysis efficiency, and can more comprehensively detect harmful aromatic amines compounds in mainstream smoke of cigarettes.

Owner:ZHENGZHOU TOBACCO RES INST OF CNTC

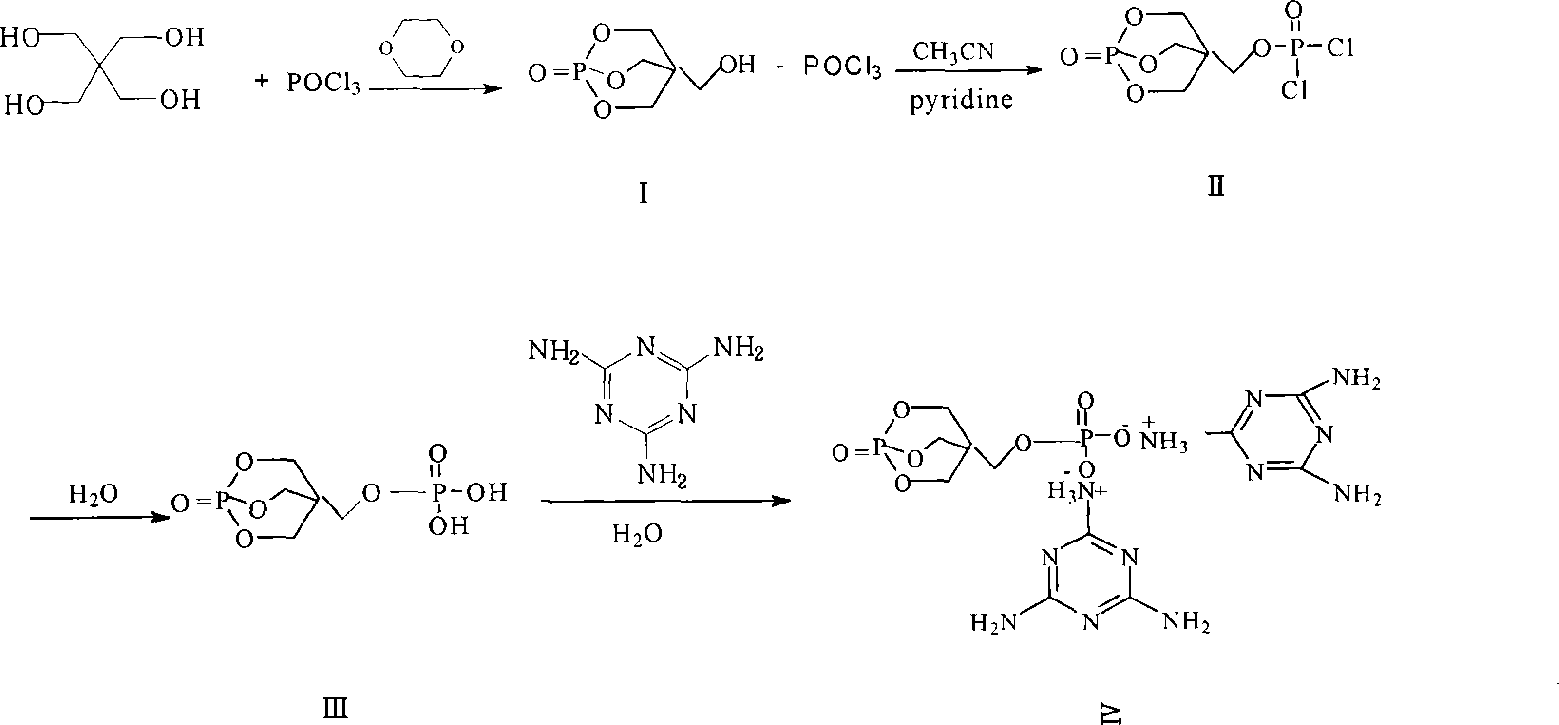

Nano composite material of flame retardant epoxy resin made from salt of phosphate bi melamine

This invention discloses a method for preparing flame-retardant epoxy resin nanocomposite. The method comprises: (1) mixing Na-montmorillonite, organic solvent aqueous solution and silane coupling agent into a reactor, heating to 40-100 deg.C, and reacting for 2-22 h to obtain organic montmorillonite; (2) utilizing 1-oxy-4-hydroxymethyl-2,6,7-trioxy-1-phosphabicyclo[2.2.2]octane, POCl3 and melamine as the raw materials to prepare (1-oxo-4-methylene-2,6,7-trioxy-1-phosphabicyclo[2.2.2]octane)phosphate dimelamine salt flame retardant; (3) adding organic montmorillonite and flame retardant into a mixture of epoxy resin and curing agent m-phenylenediamine, and curing at 80-160 deg.C for 6-12 h to obtain flame-retardant epoxy resin / organic montmorillonite nanocomposite. In the flame-retardant epoxy resin / organic montmorillonite nanocomposite, the flame retardant and organic montmorillonite have good synergistic effect. The flame-retardant epoxy resin nanocomposite has such advantages as low addition amount, good thermal and mechanical properties, and high flame retardancy.

Owner:EAST CHINA UNIV OF SCI & TECH

Waterborne anticorrosive coating and preparation method

InactiveCN105176313AReduce surface tensionIncrease wettabilityAnti-corrosive paintsEpoxy resin coatingsMeth-Sodium phosphates

The invention discloses a waterborne anticorrosive coating. The waterborne anticorrosive coating comprises the following components: waterborne epoxy resin emulsion, a pigment filler, a film forming assistant, a leveling agent, a defoaming agent, a thickening agent, a dispersing agent, water and a curing agent, wherein the pigment filler is mixture of iron oxide red and zinc phosphate which are mixed according to a mass ratio of 1:1; the film forming assistant is glycol; the leveling agent is polyacrylic acid or hydroxymethyl cellulose; the defoaming agent is tributyl phosphate; the thickening agent is hydroxymethyl cellulose; the dispersing agent is sodium hexametaphosphate; the curing agent is one of diethylenetriamine, m-phenylenediamine, modified phenolic amine and diamino diphenyl sulfone (DDS). The invention further discloses a preparation method of the waterborne anticorrosive coating, the coating has good anticorrosive performance, the preparation method is simple and feasible and the cost is low.

Owner:ENG EQUIP CO LTD SUZHOU SAI SIDE

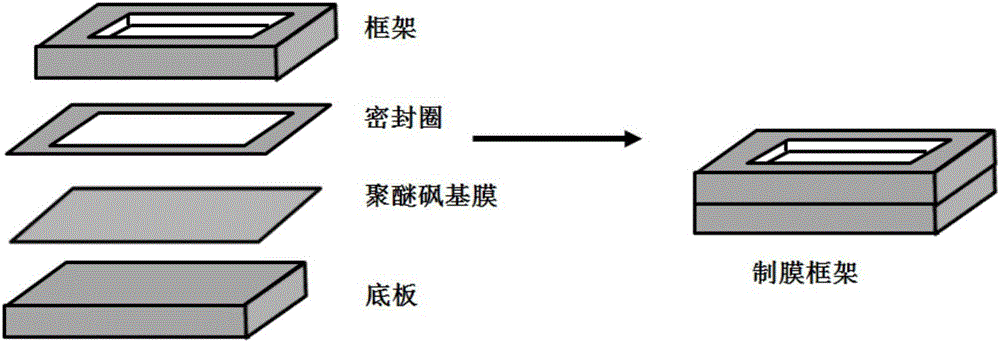

Preparation method of polyethersulfone-based composite positive permeable membrane

InactiveCN105771703AHigh porosityImprove hydrophilicitySemi-permeable membranesMembranesPorosityPolyethylene glycol

The invention discloses a preparation method of a polyethersulfone-based positive permeable membrane, and relates to the field of membrane separation. The method comprises the following steps: dissolving polyethersulfone and polyethylene glycol in a solvent; coating membrane casting fluid on a low-temperature glass plate; leaving the membrane casting fluid to stand on the glass plate, and enabling the membrane casting fluid to generate thermally induced phase separation; finally immersing the glass plate into water, and enabling the solvent to be removed. The prepared base membrane is prepared into a polyamide separating layer by an interfacial polymerization method, the base membrane is sequentially immersed into an m-phenylene diamine-aqueous solution of which the percentage by weight is 1.0-4.0wt% and a trimesoyl chloride-hexane solution of which the percentage by weight is 0.05-0.2wt%, and finally heat treatment is performed at 60 DEG C for 300 s so that the polyethersulfone-based composite positive permeable membrane is obtained. The polyethersulfone-based composite positive permeable membrane prepared by the method disclosed by the invention has high hydrophilicity and porosity, and besides, a fault surface adopts a perforated finger shaped structure. Tests on properties of the composite membrane indicate that the composite membrane prepared by the method disclosed by the invention has a high permeation flux and a high interception rate.

Owner:BEIJING UNIV OF TECH

Preparation method of composite reverse osmosis membrane

InactiveCN102886207AAchieve modificationHigh mechanical strengthSemi-permeable membranesReverse osmosisUltrasonic dispersion

The invention discloses a preparation method of a composite reverse osmosis membrane, and particularly relates to a preparation method of an organic acylating chlorination nanometer titania modified aramid composite reverse osmosis membrane. The preparation method comprises the following steps of: preparing organic phase solution of trimesoyl chloride; then adding acylating chlorination modified nanometer titania into the organic phase solution to prepare uniform suspension liquid; soaking backup polysulfone supporting membrane in m-phenylenediamine (MPD) aqueous solution with the mass concentration of 0.5% to 3%, wherein the aqueous solution contains sodium dodecyl sulfate (SDS); then rolling through a rubber roller to remove excessive solution; after drying the solution, contacting the dried solution with the organic phase solution that is subjected to ultrasonic dispersion just now for 10 to 120 seconds; and finally, drying the solution in vacuum to obtain the product. The preparation method of the composite reverse osmosis membrane disclosed by the invention has the advantages that a stable structure is formed in the reaction, therefore, the mechanical strength of the reverse osmosis membrane can be improved, and meanwhile, the flux of pure water of the membrane can be improved by virtue of nano particles while an original high salt removing rate is maintained. The preparation method is simple and is easy to implement.

Owner:HANGZHOU WATER TREATMENT TECH DEV CENT

Polyamide reverse osmose membrane and production thereof

InactiveCN1817423AExcellent and stable performanceWide variety of sourcesSemi-permeable membranesLiquid layerReverse osmosis

A reverse-osmosis polyamide member is prepared through providing the aqueous solution of lentine and piperazine, immersing the porous carrier in it to have a liquid layer on it, and single-surface contacting with the organic solution of symphenyl triformyl chloride for interface polymerizing reaction. Said reverse osmosis membrane can be used to treat the saline for removing either impurity (SO4 ions) or NaCl in different condition, having high selectivity.

Owner:凯膜过滤技术(上海)有限公司

Preparation method of low-voltage positive charge hollow fiber nanofiltration membrane

InactiveCN105498547AIncrease water fluxStrong anti-pollutionMembranesSemi-permeable membranesCarbon nanotubeOil phase

The invention relates to a preparation method of a low-voltage positive charge hollow fiber nanofiltration membrane and belongs to the technical field of membrane preparation. The preparation method comprises the following steps: firstly pretreating by immersing a hollow fiber ultrafilter membrane into distilled water; then successively adding carbon nanotube, m-phenylenediamine, a surfactant, an acid binding agent and a pH regulator into deionized water to prepare a water-phase solution with pH of 8-12; adding trimesoyl chloride into an organic solvent, mixing and dissolving to obtain an oil-phase solution; and finally carrying out a reaction by letting the hollow fiber membrane be contacted with the water-phase A solution, carrying out a reaction by letting the hollow fiber membrane be contacted with the oil-phase solution, drying and preserving so as to obtain the low-voltage positive charge hollow fiber nanofiltration membrane. The prepared nanofiltration membrane has advantages of high water flux, high separation efficiency of divalent saline ions and above, strong anti-pollution ability, long service life and the like.

Owner:RES CENT FOR ECO ENVIRONMENTAL SCI THE CHINESE ACAD OF SCI

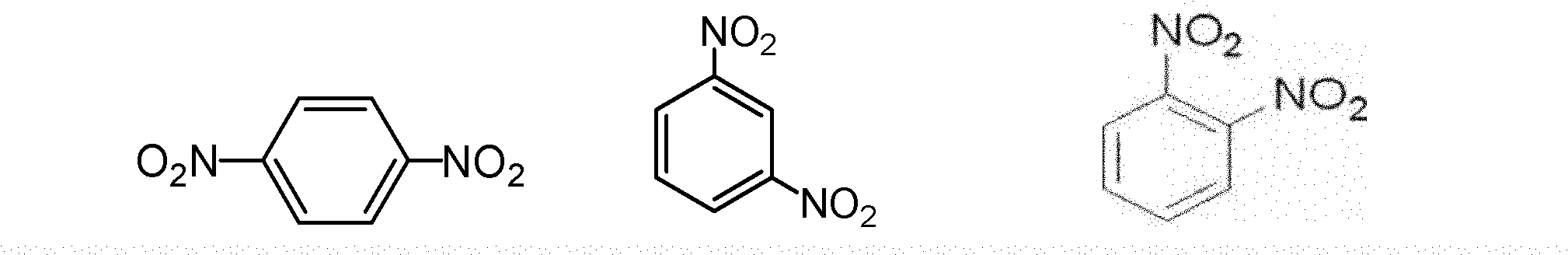

Method for producing phenylene diamine by performing hydrogenation reduction on mixed dinitrobenzene with palladium catalyst

ActiveCN102070464AReduce consumptionImprove product qualityOrganic compound preparationAmino compound preparationHigh energyPalladium catalyst

The invention belongs to a method for producing phenylene diamine, in particular to the method for producing the phenylene diamine by performing hydrogenation reduction on mixed dinitrobenzene with palladium catalyst. The prior art which produces the phenylene diamine by performing the hydrogenation reduction by adopting a Raney nickel or carrier nickel catalyst has the disadvantages of high energy consumption, low raw material conversion rate, and poor product quality. The method comprises the following steps of: adding 100 weight parts of dinitrobenzene, 100 to 200 weight parts of alcohols solvents and 0.5 to 1 weight part of the palladium catalyst into a reaction kettle, wherein the temperature in the reaction kettle is between 40 and 60 DEG C and the pressure is between 0.25 and 0.60 MPa; performing hydrogenation for 30 to 120 minutes; conveying a reaction product to a filter; dealcoholizing in a dealcoholization tower for recovering to obtain phenylene diamine solution; and obtaining m-phenylenediamine, o-phenylenediamine and p-phenylenediamine products by dewatering, rectifying and separating. The method has the advantages of improving product quality, reducing raw material consumption and reducing production cost.

Owner:上海鸿源鑫创材料科技有限公司 +1

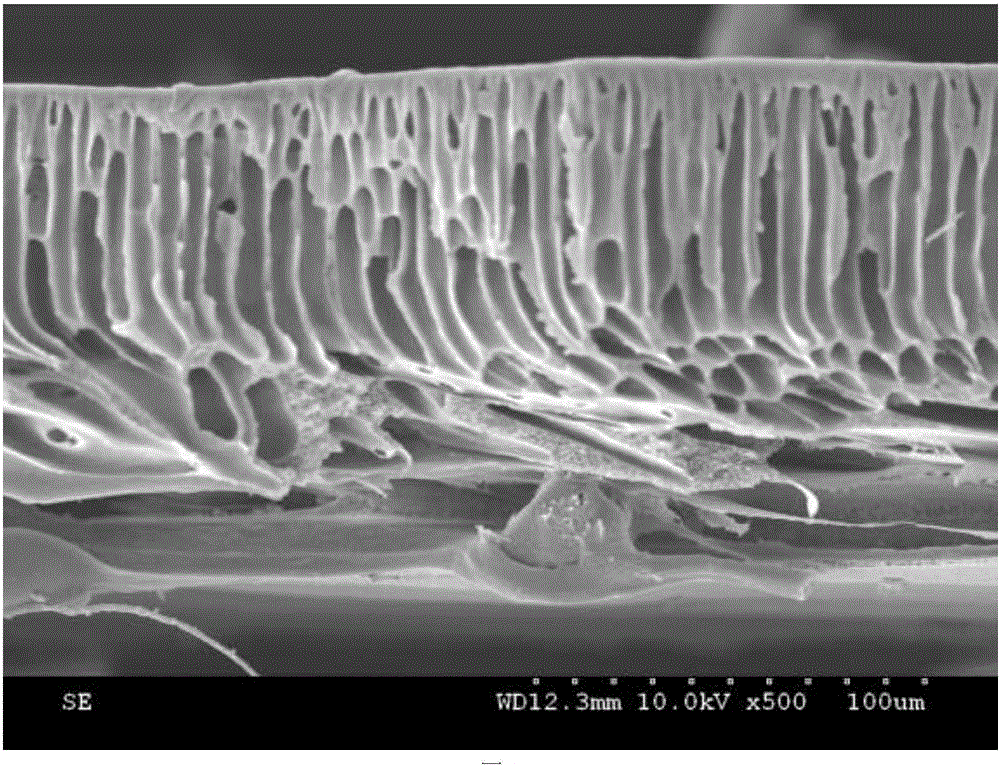

A preparation method of poly(m-phenylene isophthalamide) hollow fiber nanofiltration membrane

The invention relates to a preparation method of poly(m-phenylene isophthalamide) hollow fiber nanofiltration membrane. Poly(m-phenylene isophthalamide) is adopted as raw material, sufficiently mixed with organic solvent and additive, to obtain homogeneous spinning stock solution, the spinning stock solution is prepared into the hollow fiber nanofiltration membrane by use of immersion precipitation phase inversion method. In the spinning stock solution, the content of the poly(m-phenylene isophthalamide) is of 10%-25%, the content of the organic solvent is of 50%-70%, and the content of the additive is of 8%-25%. The prepared hollow fiber nanofiltration membrane has the outside diameter of 0.8-2.5mm, the inside diameter of 0.5-2.0mm, the pore size distributed in 2-30 nm, the tensile strength up to 8-15 MPa, and the breaking elongation in the range of 90%-160%. At 25 DEG C., under the operating pressure of 0.5 MPa, in the membrane treatment experimental study with 500 mg / L Na2SO4 water solution as study system, the water flux is up to 32-85 L / m2.h, and the interception rate for Na2SO4 is up to 50%-95%. The process is easy to operate, the film-forming process is simple, and the membrane has excellent mechanical property, high water flux, and wide application prospects.

Owner:RES CENT FOR ECO ENVIRONMENTAL SCI THE CHINESE ACAD OF SCI

High-flux high-interception-rate positive charge composite nanofiltration membrane and preparing method of high-flux high-interception-rate positive charge composite nanofiltration membrane

ActiveCN105013333AAvoid pollutionImprove throughputSemi-permeable membranesPolyetherimideOrganic solvent

The invention discloses a high-flux high-interception-rate positive charge composite nanofiltration membrane and a preparing method of the high-flux high-interception-rate positive charge composite nanofiltration membrane. The preparing method comprises the following steps that (1) polyetherimide is dissolved into organic solvents to be prepared into a polyetherimide solution; stirring and still standing defoaming are carried out; a casting membrane solution is prepared; the casting membrane solution is scratched on the smooth surface of a non-woven fabric; the materials are put into the air, and is put into an ethylenediamine water solution to be soaked; the materials are taken out and are flushed by deionized water; an interlinked base membrane is obtained after the drying in the air; one side, with the scratched casting membrane solution, of the non-woven fabric is called as the surface A; (2) m-phenylenediamine and positive charge materials are put into water to be prepared into a water solution; (3) the surface A of the interlinked base membrane is soaked into the water solution prepared in the second step, is taken out and dried; then, the surface A is soaked into the n-hexane solution of the trimesoyl chloride, and is taken out and dried to obtain the high-flux high-interception-rate positive charge composite nanofiltration membrane. The high-flux high-interception-rate positive charge composite nanofiltration membrane has the advantages of high flux and higher interception rate. The production time is short, and the process is simple.

Owner:TIANJIN UNIV

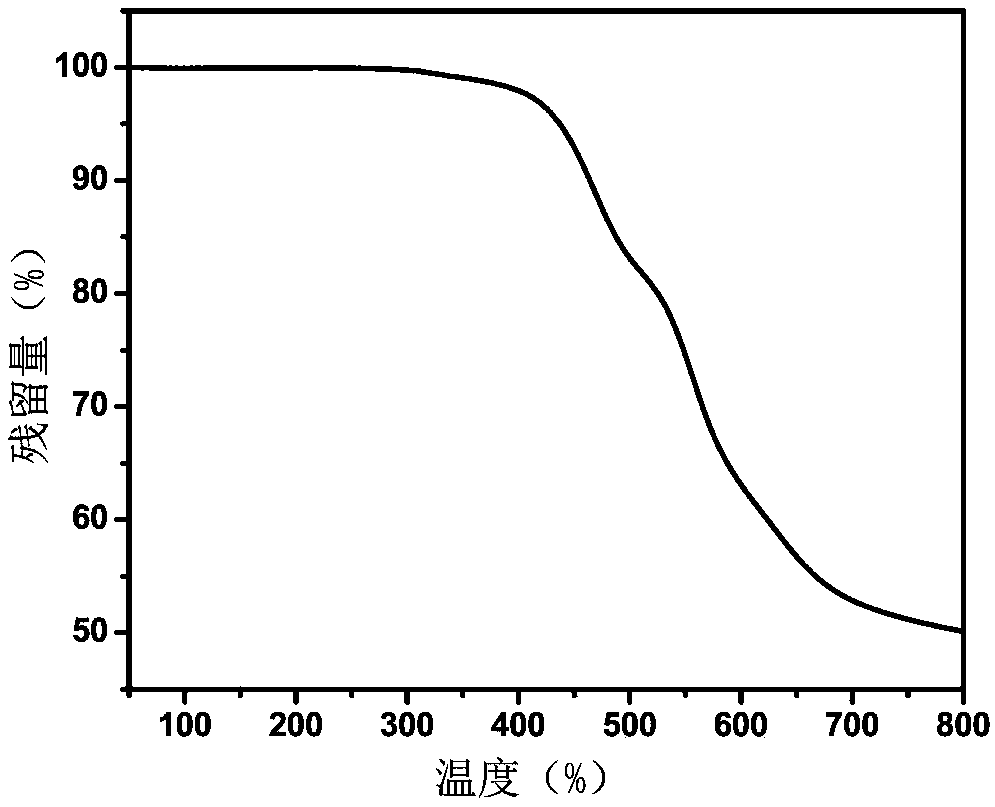

Polyimide resin containing furan ring and preparation method of polyimide resin

The invention relates to polyimide resin containing a furan ring and a preparation method of the polyimide resin. The polyimide resin containing the furan ring is obtained by reaction of 2,5-furan bis(formamide p-phenylenediamine) or 2,5-furan bis(formamide m-phenylenediamine) and dicarboxylic anhydride monomer, wherein the structural formula of the 2,5-furan bis(formamide m-phenylenediamine) is as shown in the description, and the structural formula of the 2,5-furan bis(formamide p-phenylenediamine) is as shown in the description; and the structural formula of the obtained polyimide resin containing the furan ring is as shown in the description, wherein X is a residue of the dicarboxylic anhydride monomer, and n is an integer greater than 0. The glass transition temperature of the obtained polyimide resin containing the furan ring is 250-400 DEG C, and the temperature is 420-500 DEG C under the condition of 5% of thermal degradation mass loss in a nitrogen gas environment; and the obtained polyimide resin containing the furan ring has higher usage temperature and thermal stability, has excellent mechanical properties and can be applied to many high and new technical fields of aerospace, space, micro-electronics, precision machinery and the like.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

Micro-reaction system and micro-reaction method for preparing para/meta-aramid

ActiveCN104667846AEfficient removalRemove suppressionChemical/physical/physico-chemical stationary reactorsChloridePyridine

The invention relates to a micro-reaction system and a micro-reaction method for preparing para / meta-aramid. The micro-reaction system is composed of a micro-reactor and a stirring kettle, wherein the micro-reactor is internally provided with a microstructure distribution plate or a micro-channel; and sieve pores or through grooves are formed in the microstructure distribution plate. The method comprises the steps of dissolving p / m-phenylenediamine into a calcium chloride solution, and adding pyridine to obtain a reaction solution A; dissolving isophthaloyl dichloride / paraphthaloyl chloride into the calcium chloride solution to obtain a reaction solution B; mixing the reaction solutions A and B in the micro-reactor, and triggering condensation polymerization reaction to obtain a reaction solution C; enabling the reaction solution C to enter the stirring kettle, and reacting under stirring to produce a product D; and washing the product D to obtain para / meta-aramid. The material mixing effect is enhanced through the micro-reactor, so that reaction heat can be rapidly removed, and the process stability is improved; and due to the further reaction in the stirring kettle, the polymerization degree is further increased, the pressure drop in the reaction process is reduced, and the safety is improved.

Owner:TSINGHUA UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com