Method for online preparing high-throughput composite reverse osmosis membrane

A reverse osmosis membrane, high-flux technology, applied in semi-permeable membrane separation, chemical instruments and methods, osmosis/dialysis water/sewage treatment, etc., can solve the problems of increasing storage and transportation costs, and achieve convenient rolling membrane elements , process stability, and the effect of reducing crosslinking density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Example 1: On-line preparation of high-flux composite reverse osmosis membrane

[0034] The implementation steps of this embodiment are as follows:

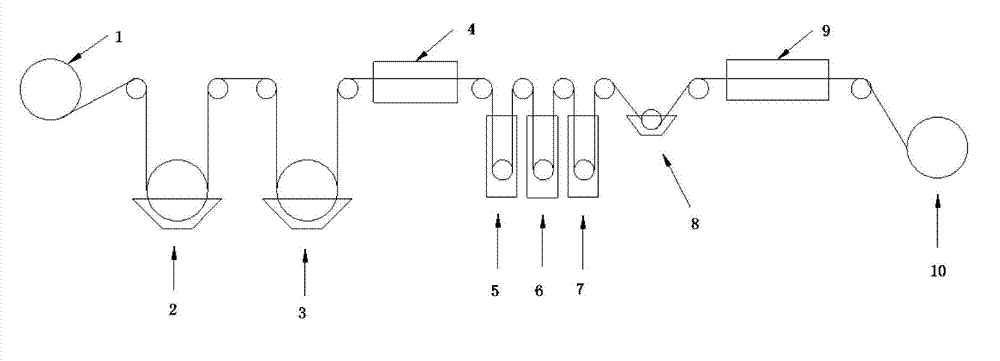

[0035] An ultrafiltration base membrane with a pore size of 0.005-0.01 μm, which is composed of non-woven fabric and polysulfone support layer, is installed on the attached figure 1 On the unwinding shaft of the film coating machine shown, start the active motor, and the leading cloth on the film coating machine starts to run at a speed of 2m / min. Under the traction of the leading cloth of the film coating machine, the ultrafiltration base film first passes through the The aqueous phase tank of 2.0g / L m-phenylenediamine (MPD) aqueous solution forms a layer of aqueous solution film on described ultrafiltration base membrane; Then

[0036] By the oil phase groove that the n-hexane solution of 1.0g / L trimesoyl chloride (TMC) is housed, m-phenylenediamine and trimesoyl chloride are interfacially polymerized at the oil-water i...

Embodiment 2

[0049] Embodiment 2: On-line preparation of high flux composite reverse osmosis membrane

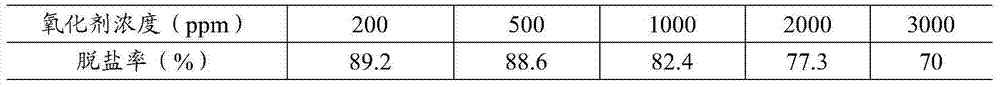

[0050] Carry out according to the same method described in Example 1, just add 200ppm, 500ppm, 1000ppm, 2000ppm and 3000ppm potassium permanganate solution by weight respectively in the oxidant tank, control the liquid level height and the film coating machine running speed, make ultrafiltration The time for the base film to pass through the oxidant tank is 1 minute. In this way, a high-flux polyamide composite reverse osmosis membrane is prepared. The properties of the prepared membrane were measured by the method described in the specification of this application, and the results are listed in Table 1.

[0051] Table 1: Performance of high flux composite reverse osmosis membrane in this example

[0052]

[0053]

[0054] From the results listed in Table 1, it can be seen that the flux is significantly improved when the membrane is treated with different concentrations of oxidan...

Embodiment 3

[0055] Embodiment 3: On-line preparation of high flux composite reverse osmosis membrane

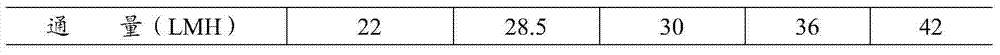

[0056] Carry out according to the same method described in embodiment 1, just add respectively by weight 200ppm, 300ppm, 400ppm, 500ppm polyvinyl alcohol solution in the protective solution tank. In this way, a high-flux polyamide composite reverse osmosis membrane is prepared. The properties of the prepared membrane were measured by the method described in the specification of this application, and the results are listed in Table 2.

[0057] Table 2: Performance of high flux composite reverse osmosis membrane in this example

[0058]

[0059] As can be seen from the results in Table 2, the use of different concentrations of PVA to coat the surface of the membrane can play a good protective role. The higher the PVA concentration, the higher the desalination rate of the high-flux composite reverse osmosis membrane. The more the flux is reduced, the performance of the high-flux compos...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| salt rejection rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com