Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

272results about How to "Excellent and stable performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

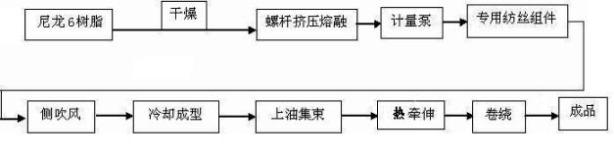

Denier/superfine denier nylon master granule, preoriented yarn (POY) and draw textured yarn (DTY) stretch yarn and preparation method thereof

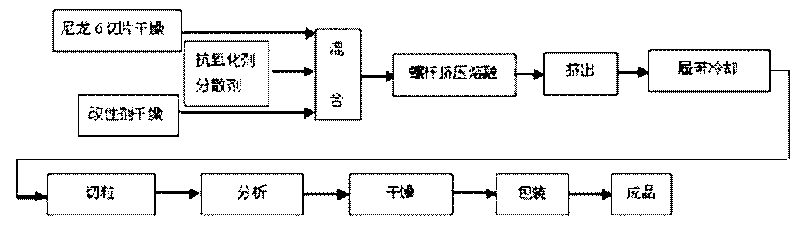

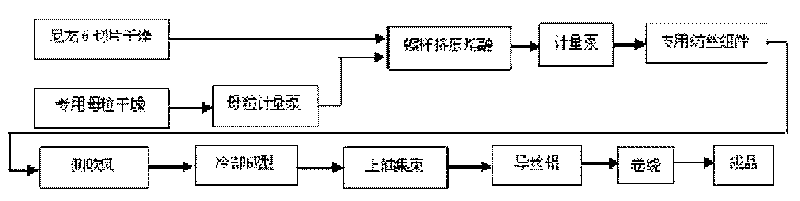

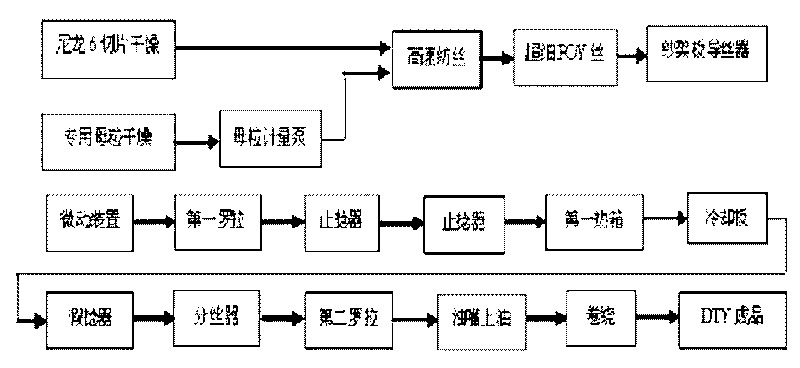

ActiveCN101724265AHigh tensile strengthImprove mixing performanceMelt spinning methodsMonocomponent polyamides artificial filamentYarnEngineering

The invention belongs to the field of spinning materials. Firstly, the invention provides a fine denier / superfine denier nylon master granule prepared by proportionally adding a modifying agent, an antioxidant and a dispersant to nylon 6 sliced sheets according to the proportion, melting, mixing and extruding, and the modifying agent is a metallic salt which can take effect on nylon base; The fine denier / superfine denier nylon master granule and the nylon 6 sliced sheets are proportionally mixed, melted and spun, and the fine denier / superfine denier nylon POY is prepared by cooling, oiling, bundling and coiling; and the POY is textured to obtain the DTY. The invention provides the fine denier / superfine denier nylon POY of which the filament size is 0.3-0.8dtex, the filament size of the DTY is 0.25-0.70dtex, which fills the vacancy that the fine denier / superfine denier nylon POY and the DTY are produced by the conventional yarn-spinning process at home and abroad.

Owner:HANGZHOU NORMAL UNIVERSITY

Preparation method of low-oxygen molybdenum alloy and application thereof

InactiveCN102041402AReduce oxygen contentOxygen content less impurityX-ray tube electrodesForging/hammering/pressing machinesMass ratioAlloy

The invention provides a preparation method of a low-oxygen molybdenum alloy. The method comprises the following steps: 1) selecting raw materials: uniformly mixing industrial molybdenum powder with Fisher particle size of 3-100 mum, powder containing strengthening elements with Fisher particle size of 3-10 mum, and carbon simple substance powder with Fisher particle size of 0.1-3 mum at certain mass ratio; 2) forming the raw materials: performing static pressing or mould pressing treatment on the mixed raw materials under pressure of 100-300 MPa to obtain formed blank; and 3) sintering the raw materials: sintering the formed blank in vacuum, hydrogen or inert gas environment at the high temperature of between 1,800 and 2,300 DEG C for 5-15 h to obtain the low-oxygen molybdenum alloy. Through the invention, the problem of high oxygen content of the molybdenum alloy prepared by powder metallurgy is solved. The low-oxygen molybdenum alloy prepared by the method can be used for preparing an X-ray tube rotating anode target, a composite target-based target, a high-temperature crucible, a hot-forging die and a high-temperature ceramic gasket.

Owner:XIAN GEMEI METAL MATERIAL

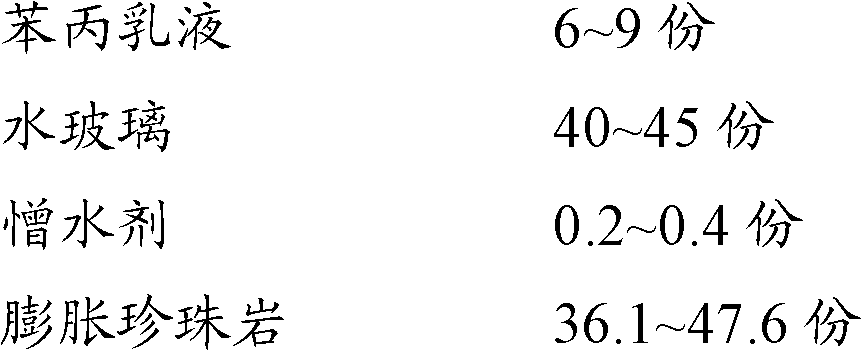

Modified expanded perlite insulation board and preparation method thereof

InactiveCN102584166AImprove insulation effectImprove mechanical propertiesEmulsionThermal insulation

The invention provides a modified expanded perlite insulation board and a preparation method thereof. The insulation board is prepared from 6-9 parts of distilled water, 0.2-0.5 part of mildew preventive, 6-9 parts of styrene-acrylic emulsion, 40-45 parts of water glass, 0.2-0.4 part of hydrophobic agent and 36.1-46.7 parts of expanded perlite. The preparation method comprises the following steps of: (1) mixing and stirring evenly the 6-9 parts of distilled water, the 0.2-0.5 part of mildew preventive and the 6-9 parts of styrene-acrylic emulsion; (2) under the condition of stirring, adding the 40-45 parts of water glass to a mixture obtained in step (1) slowly and mixing and stirring evenly; (3) adding the 0.2-0.4 part of organosilicon hydrophobic agent and the 36.1-46.7 parts of expanded perlite to a mixture obtained in step (2), mixing and stirring evenly and pressing the obtained mixture into plates; and (4) drying and cooling the plates obtained in the step (3) and then packaging and putting the plates in a storage. By adopting the method, the modified expanded perlite insulation board with good thermal insulation performance, water-proof performance, mechanical property and fire-retardant performance can be prepared.

Owner:深圳市嘉达节能环保科技有限公司

Steel plate for ship structure and manufacture method thereof

InactiveCN102212750AReasonable chemical composition designSimple production process controlSteel platesSheet steel

The invention discloses a steel plate for a ship structure and a manufacture method thereof. The steel plate for the ship structure comprises the following chemical components in percentage by weight: 0.10%-0.16% of C, 0.20%-0.45% of Si, 1.25%-1.55% of Mn, less than or equal to 0.015% of P, less than or equal to 0.005% of S, 0.020%-0.050% of Nb, 0.010%-0.020% of Ti, 0.030%-0.070% of V, 0.20%-0.40% of Ni, 0.015%-0.050% of Als, and the balance of Fe and unavoidable impurities, wherein Als is aluminum soluble in acid. According to the invention, the steel plate can be used for ships or offshore oil platforms; the steel plate is simple in component design and good and steady in performance and also has a good welding performance; and simultaneously, a preparation process is simple and is easy to operate.

Owner:LAIWU IRON & STEEL GRP

A kind of manufacturing method of thin-walled, ultra-long nickel-copper alloy pipe

The invention discloses a method for manufacturing thin-wall and ultra-long nickel-copper alloy pipes. The method comprises the following steps of: 1, smelting nickel and copper serving as raw materials in a vacuum induction furnace to prepare nickel-copper alloy ingots; 2, drawing and forging the nickel-copper alloy ingots into bar billets, and machining the bar billets into light bars; 3, rolling the light bars into pipe billets by adopting a cone mill, and removing scales on the surfaces of the pipe billets; 4, performing cold rolling machining; 5, sequentially cogging the cold rolled pipebillets, and performing crystallization and annealing treatment and boring treatment to obtain pipes; 6, continuously rolling the pipes, and performing annealing treatment and acid washing to obtain finished pipes; and 7, straightening the finished pipes, and thus obtaining the thin-wall and ultra-long nickel-copper alloy pipes with diameter-thickness ratio of 50 to 70 and length of over 15,000 millimeters. The finished nickel-copper alloy pipes machined with high deformation and cold-rolled by a continuous rolling production process have high tensile strength and yield strength and meet the plasticity requirement.

Owner:WESTERN TITANIUM TECH

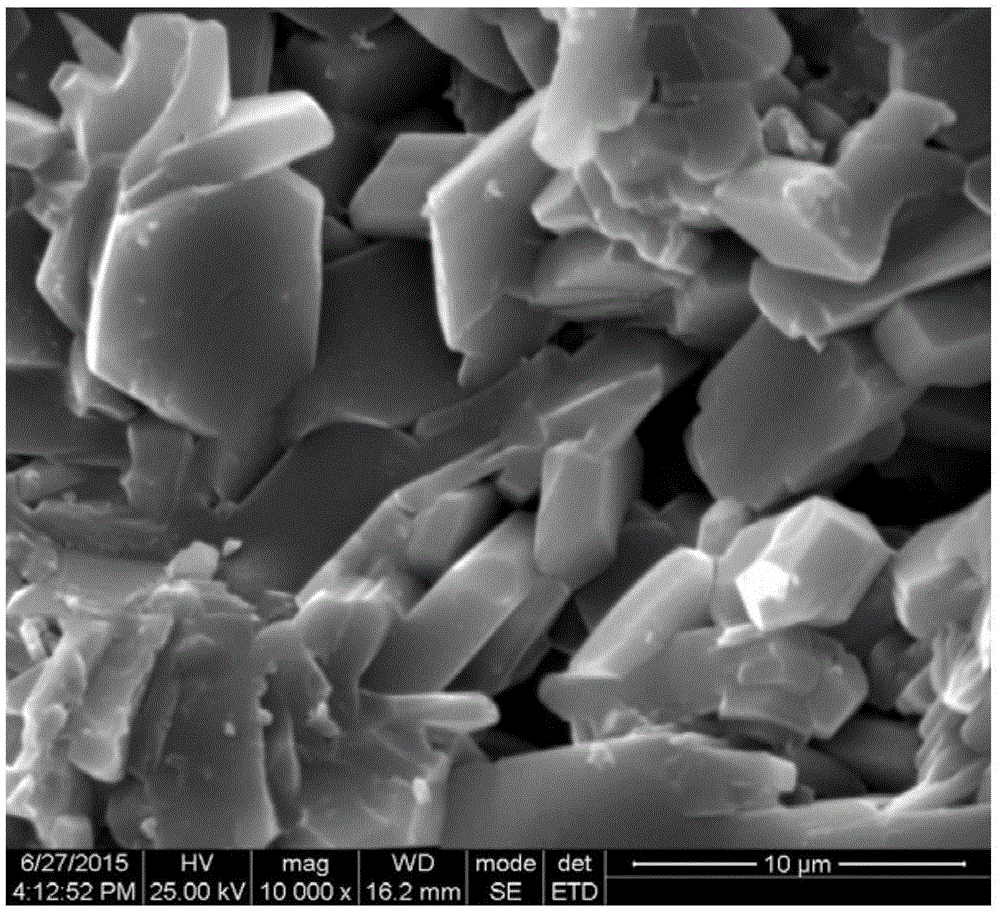

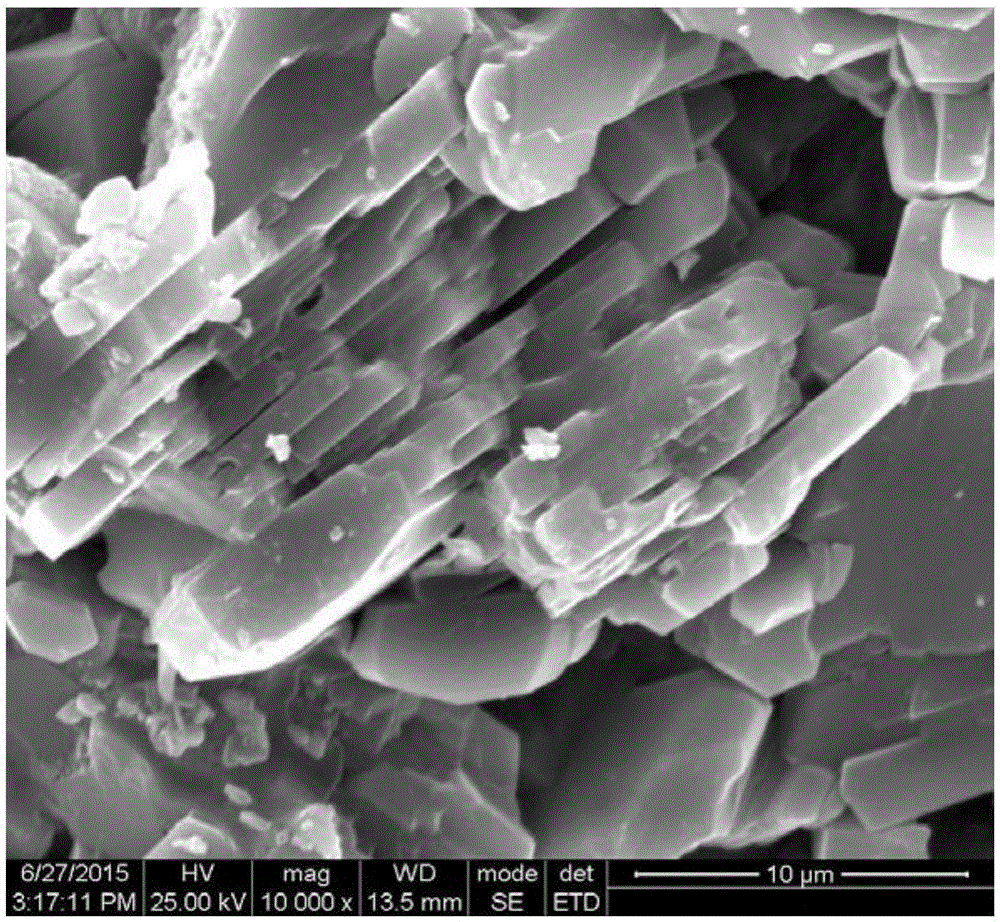

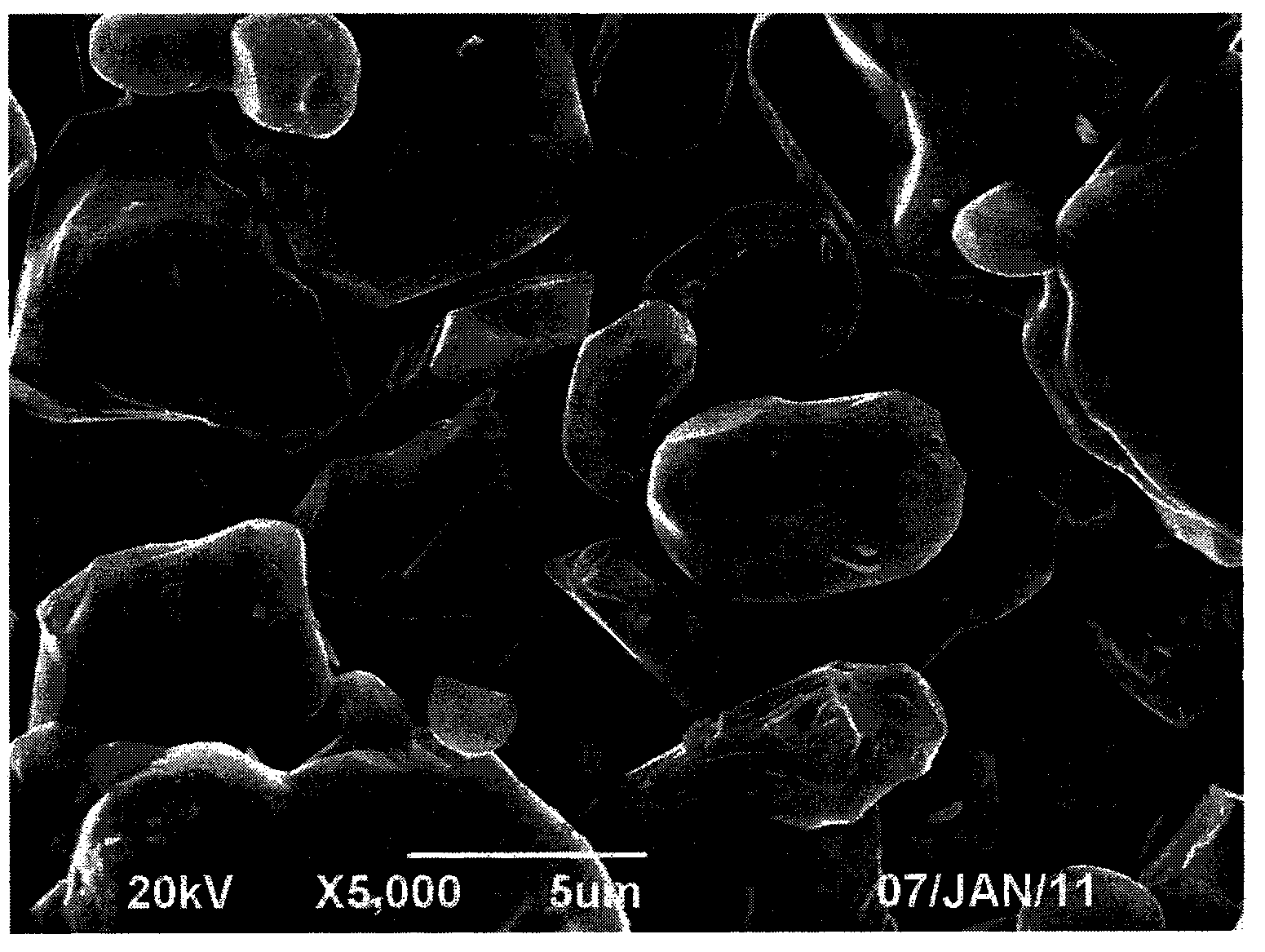

Ultrafine grain metal ceramics and preparation method thereof

The invention discloses ultrafine grain metal ceramics and a preparation method thereof and particularly relates to ultrafine grain Ti(C,N)-based metal ceramics and a preparation method thereof. The ultrafine grain metal ceramics comprises the following components of, by mass, 40%-85% of matrix phase, 5%-25% of reinforced phase, 8%-30% of binding phase, and the balance adding phase. The matrix phase is Ti(C,N). The adding phase is the second kind of carbide and is composed of one or more compounds in carbide, nitride, carbonitride and carbonitride solid solution of the fourth, fifth and sixthtransition metal elements of the periodic table. The reinforced phase comprises nano TiC particles and nano TiC whiskers. The mass ratio of the nano TiC particles and the nano TiC whiskers is 0.1-10:1. According to the ultrafine grain metal ceramics and the preparation method thereof, the component design is reasonable, the preparation process is simple, and the obtained product is excellent in performance, and large-scale industrialized application is convenient.

Owner:湖南金锐美新材料有限公司

Polyamide reverse osmose membrane and production thereof

ActiveCN1817422AExcellent and stable performanceWide variety of sourcesSemi-permeable membranesLiquid layerReverse osmosis

A reverse-osmosis polyamide member is prepared through providing the aqueous solution of lentine and 2.4-diamino phenylsulfonic acid, immersing the porous carrier in it to have a liquid layer on it, and single-surface contacting with the organic solution of isophthalic dichlorid and symphenyl triformyl chloride for interface polymerizing reaction. Said reverse osmosis membrane can be used to treat the saline for removing either impurity (SO4 ions) or NaCl in different condition, having high selectivity.

Owner:凯膜特种分离技术(上海)有限公司

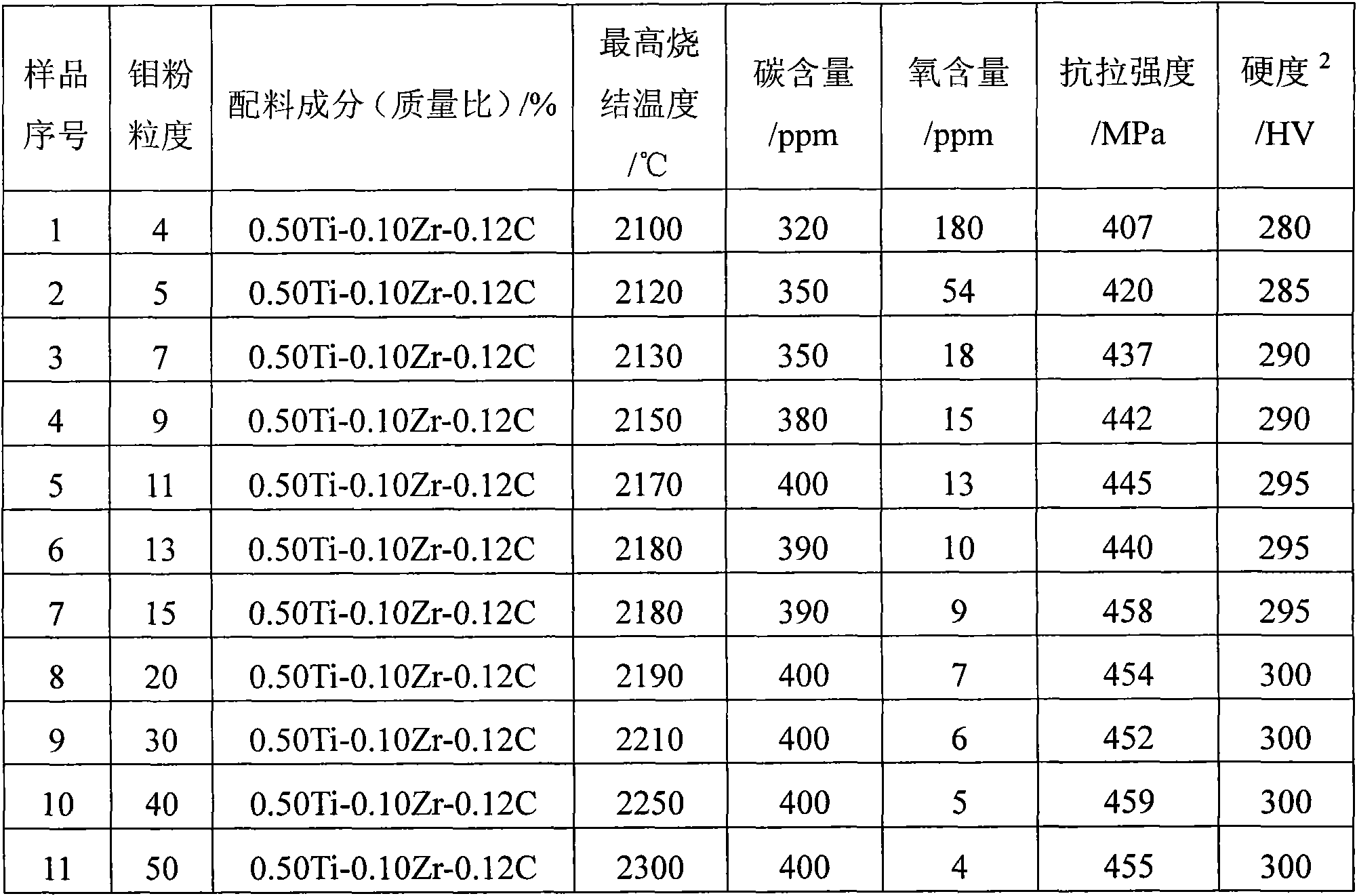

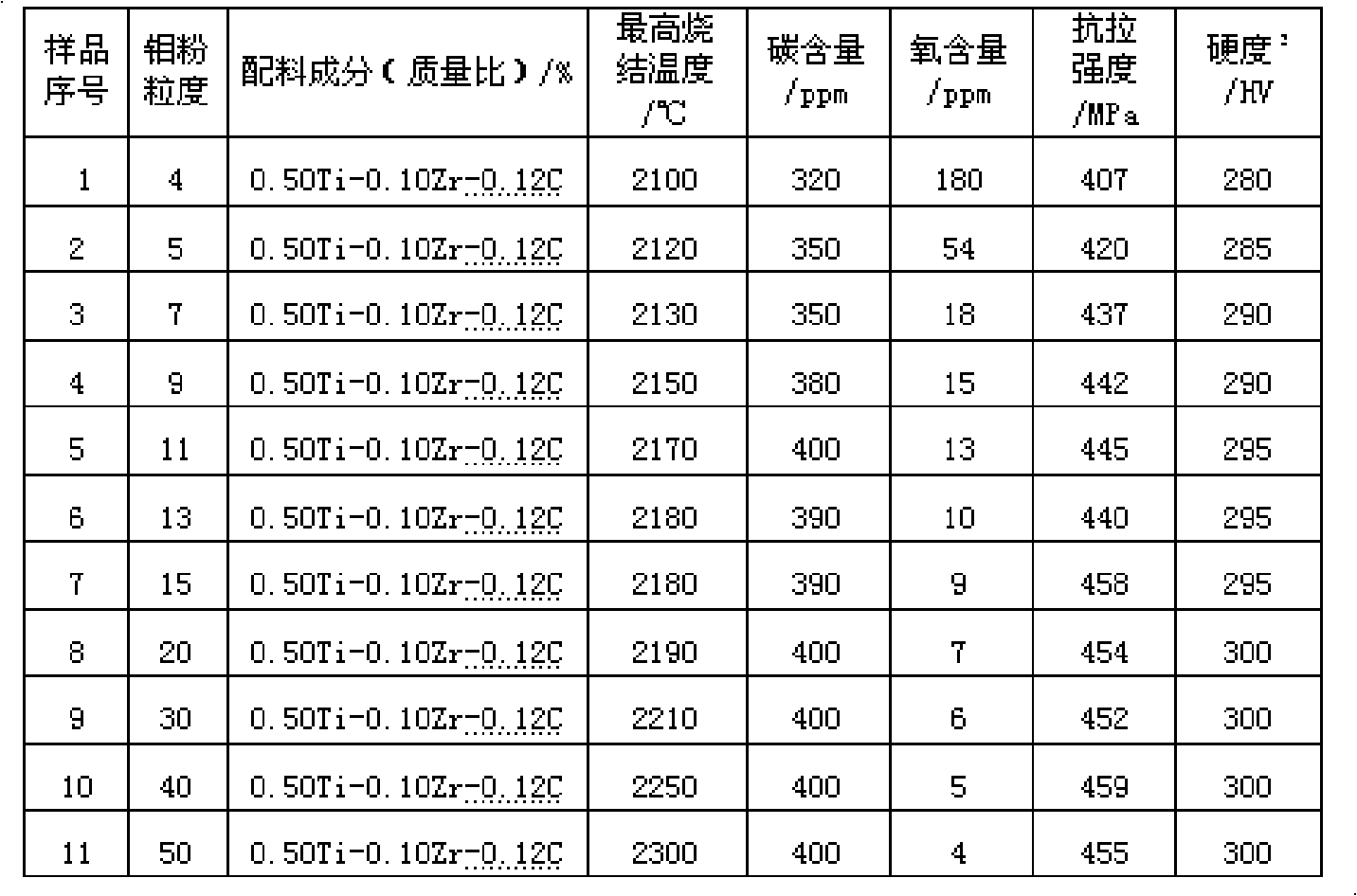

Method for preparing low-oxygen titanium-zirconium-molybdenum (TZM) alloy and application

ActiveCN102041404AReduce oxygen contentOxygen content less impurityX-ray tube electrodesForging/hammering/pressing machinesTitanium zirconiumAlloy

The invention provides a method for preparing a low-oxygen titanium-zirconium-molybdenum (TZM) alloy, which comprises the following steps of: 1) selecting raw materials, namely, uniformly mixing industrial molybdenum powder with the Fisher particle size of 4 to 50 mu m, powder containing titanium and zirconium and with the Fisher particle size of 3 to 10 mu m, and simple substance carbon powder with the Fisher particle size of 0.1 to 3 mu m according to a certain mass ratio; 2) shaping the raw materials, namely, treating the mixed raw materials under the pressure of 100 to 300 Mpa to obtain a shaped blank; and 3) sintering the raw materials, namely, sintering the shaped blank in the environment of vacuum, hydrogen or inert gas at the temperature of 1,800 to 2,300 DEG C for 5 to 15h to obtain the low-oxygen TZM alloy. The method solves the problem of high oxygen content of the TZM alloy prepared by a powder metallurgy method. The low-oxygen TZM alloy prepared by the method can be used for the preparation of a rotating anode of an X-ray tube, a composite target substrate, a high-temperature crucible, a hot-forging die and a high-temperature ceramic pad.

Owner:XIAN GEMEI METAL MATERIAL

Polyamide reverse osmose membrane and production thereof

InactiveCN1817423AExcellent and stable performanceWide variety of sourcesSemi-permeable membranesLiquid layerReverse osmosis

A reverse-osmosis polyamide member is prepared through providing the aqueous solution of lentine and piperazine, immersing the porous carrier in it to have a liquid layer on it, and single-surface contacting with the organic solution of symphenyl triformyl chloride for interface polymerizing reaction. Said reverse osmosis membrane can be used to treat the saline for removing either impurity (SO4 ions) or NaCl in different condition, having high selectivity.

Owner:凯膜过滤技术(上海)有限公司

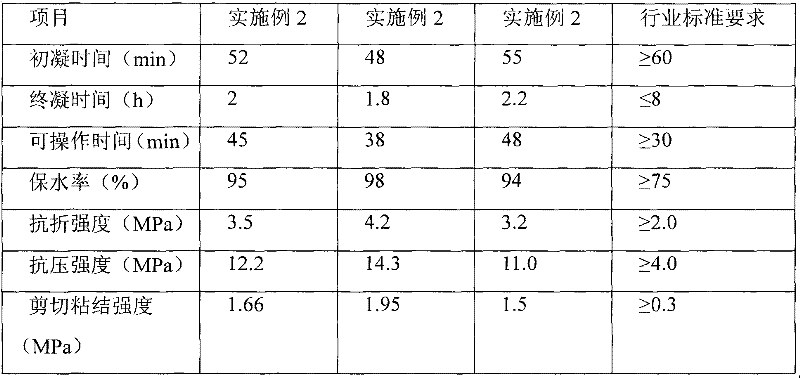

Ground floor plastering gypsum

The invention discloses a preparation method of a ground floor plastering gypsum, which is improvement of the ground floor plastering gypsum. The ground floor plastering gypsum is prepared mainly by the following ingredients according to weight percentage: 30-50% of desulfurization building gypsum, 50-70% of fine sand, 0.01-0.04% of binder, 0.015-0.05% of water retaining agent and 0.01-0.05% of retarder. The ground floor plastering gypsum is strong in cohesive force, good in water resistance and low in cost, and does not crack, thus being an ideal choice for replacing traditional plastering materials.

Owner:INNER MONGOLIA UNIV OF SCI & TECH

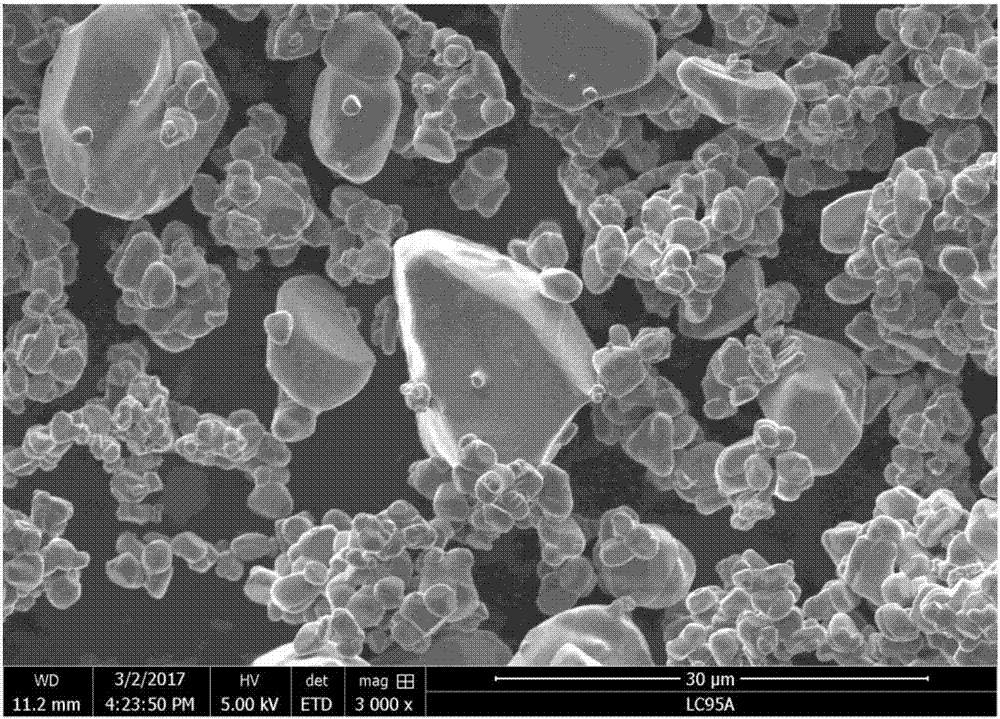

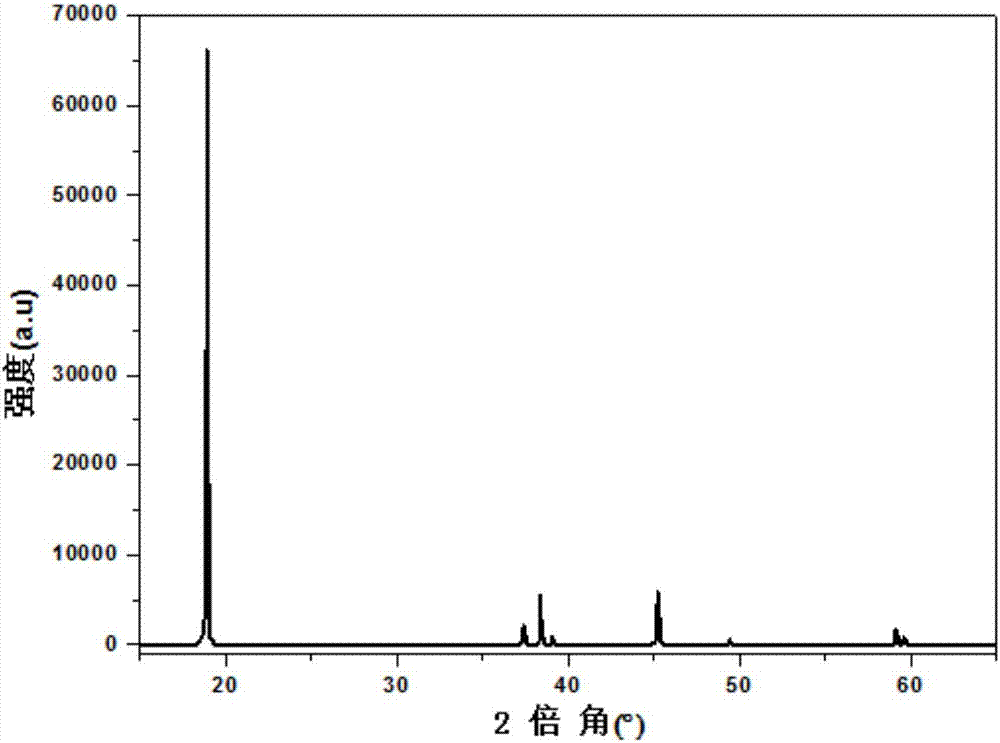

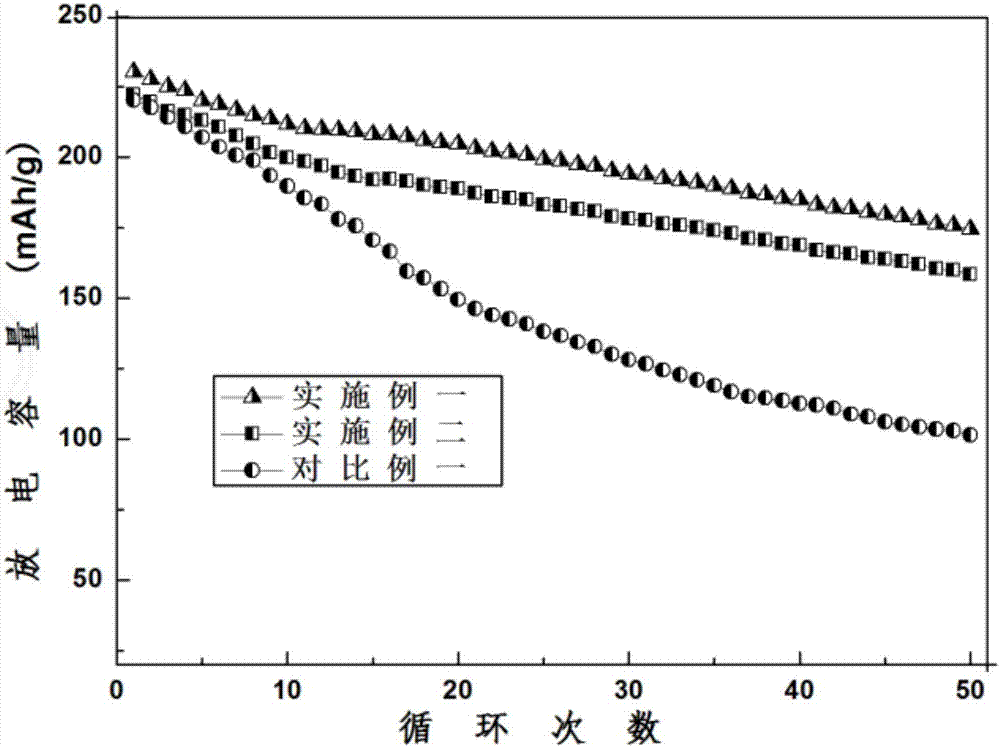

High voltage type lithium cobalt oxide and preparation method thereof

ActiveCN106986393AHigh specific capacityImprove cycle performanceCell electrodesSecondary cellsLithiumBall mill

The invention provides a high voltage type lithium cobalt oxide with a high specific capacity and a cycle performance and a preparation method thereof. The preparation method of the high voltage type lithium cobalt oxide is characterized by comprising the following steps of: S1, selecting cobalt oxide A containing a doping element M, and ball-milling and mixing, sintering and crushing the cobalt oxide A with a lithium source and a source compound of a doping element N to obtain a lithium cobalt oxide material C1; S2, selecting cobalt oxide A' containing a doping element M', and ball-milling and mixing, sintering and crushing the cobalt oxide A' with a lithium source and a source compound of a doping element N' to obtain a lithium cobalt oxide material C2; and S3, proportioning and mixing the two lithium cobalt oxide materials C1 and C2 in a weight ratio of 5: 5 to 9: 1, and adding a secondary surface doping element Z to ball-mill and mix, and then roasting and crushing the mixture to obtain the high voltage type lithium cobalt oxide.

Owner:GEM JIANGSU COBALT IND CO LTD

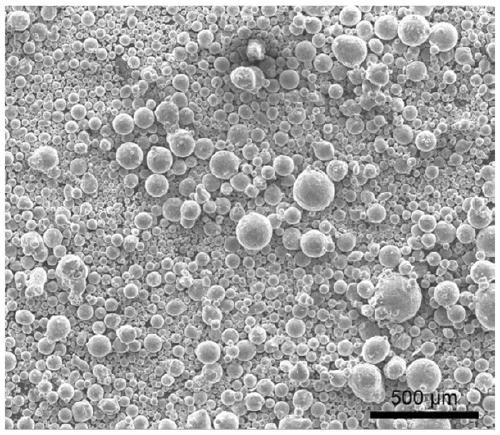

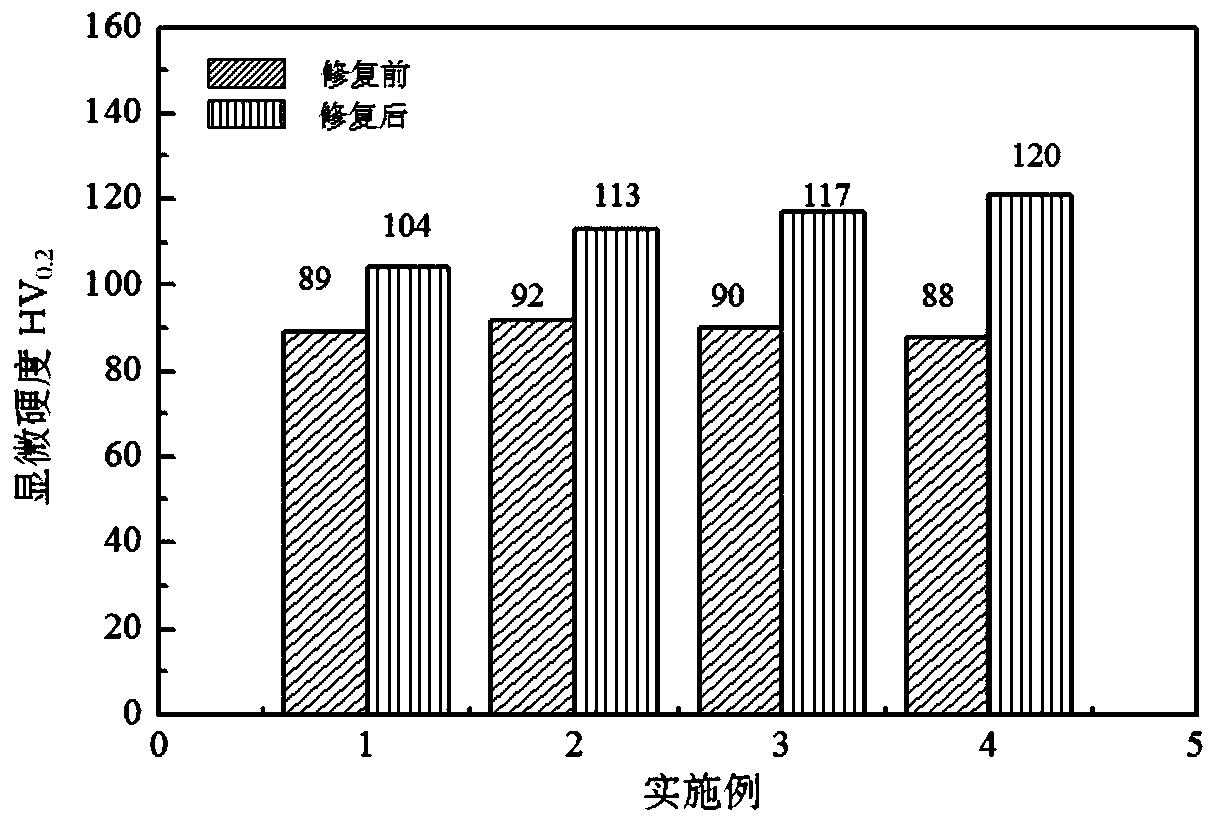

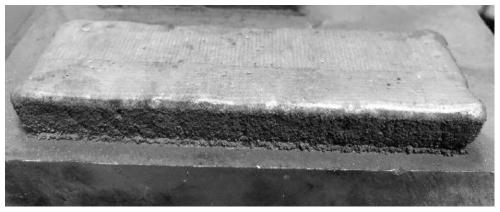

Aluminum alloy powder for laser coaxial powder feeding additive manufacturing and application of aluminum alloy powder in repairing 5-series aluminum alloy

ActiveCN111593238AEliminate anisotropyIncrease contentAdditive manufacturing apparatusMetallic material coating processesSi elementAluminium alloy

The invention discloses aluminum alloy powder for laser coaxial powder feeding additive manufacturing and application of the aluminum alloy powder in repairing 5-series aluminum alloy. The aluminum alloy powder is composed of the following components in percentage by mass: 0.4-1.5 wt% of Si, 0.5-5.0 wt% of Mg, 0.15-0.8 wt% of Cu, 0.05-0.9 wt% of Mn, 0.15-0.7 wt% of Zn, 0.01-1.0 wt% of Cr, 0.2-1.2wt% of Ti, 0.1-2.0 wt% of Fe, 0.2-2.1 wt% of Zr, 0.2-2.1 wt% of Sc, 0.15-0.65 wt% of Ni, 0.2-2.5 wt% of TiB2, 0.1-0.9 wt% of Ce, and the balance of Al. The beneficial elements including Zn, Cr, Ti, Fe, Ni, TiB2 and Ce are added on the basis of the 5-series aluminum alloy, second phases such as a long-range ordered phase and a twin crystal phase are formed to form synergistic reinforcement of the elements, so that the anisotropy of the material is eliminated, meanwhile, the content of Si element is increased, then a eutectic structure is formed in the later period of laser cladding solidification, and the eutectic structure is used for supplementing hot crack pores caused by rapid solidification.

Owner:CENT SOUTH UNIV +1

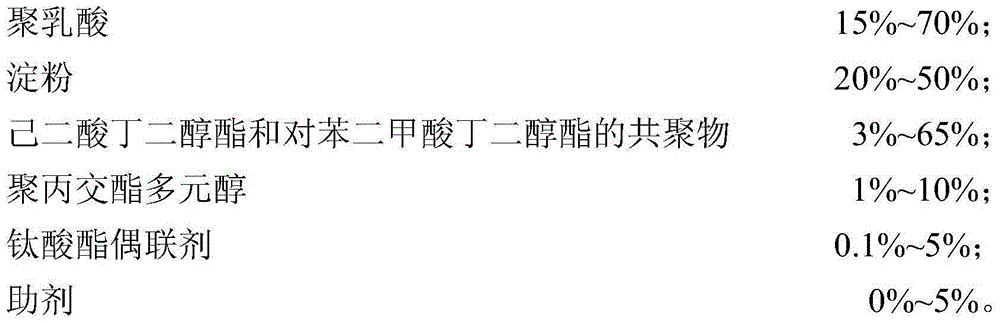

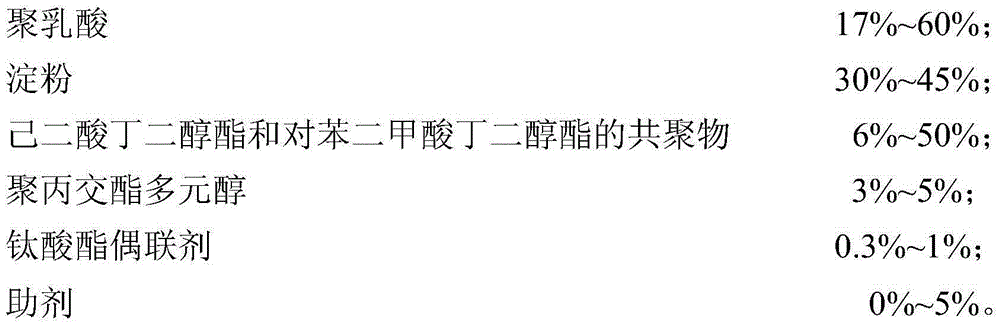

Fully-biodegradable material as well as preparation method and application thereof

The invention discloses a fully-biodegradable material as well as a preparation method and application thereof. The fully-biodegradable material is prepared from the following raw materials in percentage by weight: 15%-70% of polylactic acid, 20%-50% of starch, 3%-65% of a copolymer of butanediol adipate and butanediol terephthalate, 1%-10% of polylactide polyol, 0.1%-5% of a titanate coupling agent and 0-5% of an aid. The fully-biodegradable material has excellent mechanical property, can be biologically degraded and is relatively low in cost. The preparation method can be easily implemented by virtue of existing high-speed mixing equipment and double-screw extruders. The fully-biodegradable material has excellent and stable performance, can be biologically degraded, is relatively low in cost and is applicable to the fields of plastic packaging materials, agricultural plastic mulching films, disposable tableware and the like.

Owner:ECOTA ENVIRONMENTAL TECH

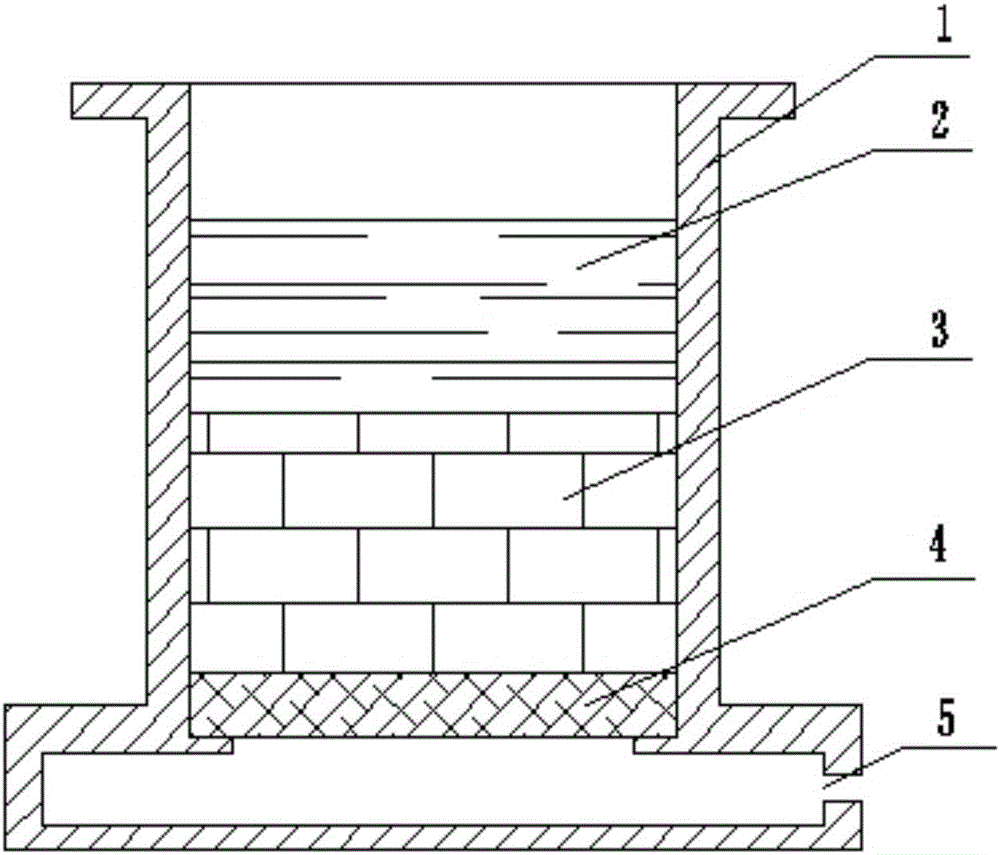

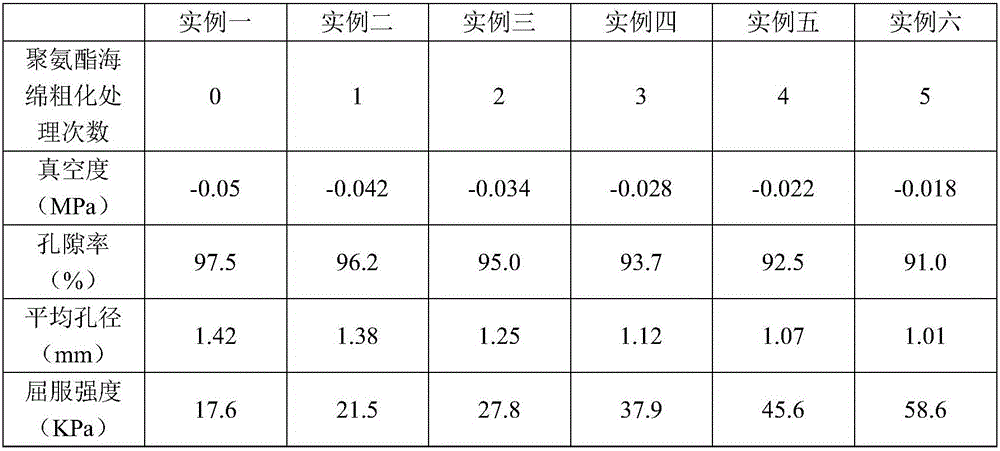

Method for preparing open pore foamed aluminum through investment casting

InactiveCN106623782AExcellent and stable performanceOptimizing pouring temperatureFoundry mouldsFoundry coresPorosityMolten state

The invention discloses a method for preparing open pore foamed aluminum, and the open pore foamed aluminum with a specific porosity is obtained through investment casting. The method comprises the steps of preparation of a polymeric sponge fired mold, preparation of a plaster model, injection molding of molten-state aluminum liquid and forming of the open pore foamed aluminum. The expected porosity, aperture and yield strength of the open pore foamed aluminum are controlled and obtained by controlling the frequency of roughening treatment of polymeric sponge. According to the main technical indexes and parameters of the obtained full open pore foamed aluminum, the porosity is larger than 91%, the aperture range is from 0.42 mm to 1.5 mm, and the maximum yield strength can reach 58.6 KPa. The properties of the open pore foamed aluminum are better and more stable by further selectively optimizing the aluminum liquid pouring temperature, plaster model preheating temperature and the vacuum degree.

Owner:LIAONING RONGDA NEW MATERIALS TECH CO LTD

Oil-based liquid-state fracturing fluid thickening agent, and preparation method thereof

ActiveCN103911136ADoes not affect outputDoes not affect structureDrilling compositionLiquid stateFracturing fluid

The invention discloses an oil-based liquid-state fracturing fluid thickening agent, and preparation method thereof. Density of the oil-based liquid-state fracturing fluid thickening agent ranges from 0.9 to 1.2g / cm<3>; gelling time is 20s or less; and viscosity of 1.2% of the oil-based liquid-state fracturing fluid thickening agent after dissolving is 30mPa.s or more. The invention also discloses a preparation method of the oil-based liquid-state fracturing fluid thickening agent.

Owner:北京爱普聚合科技有限公司

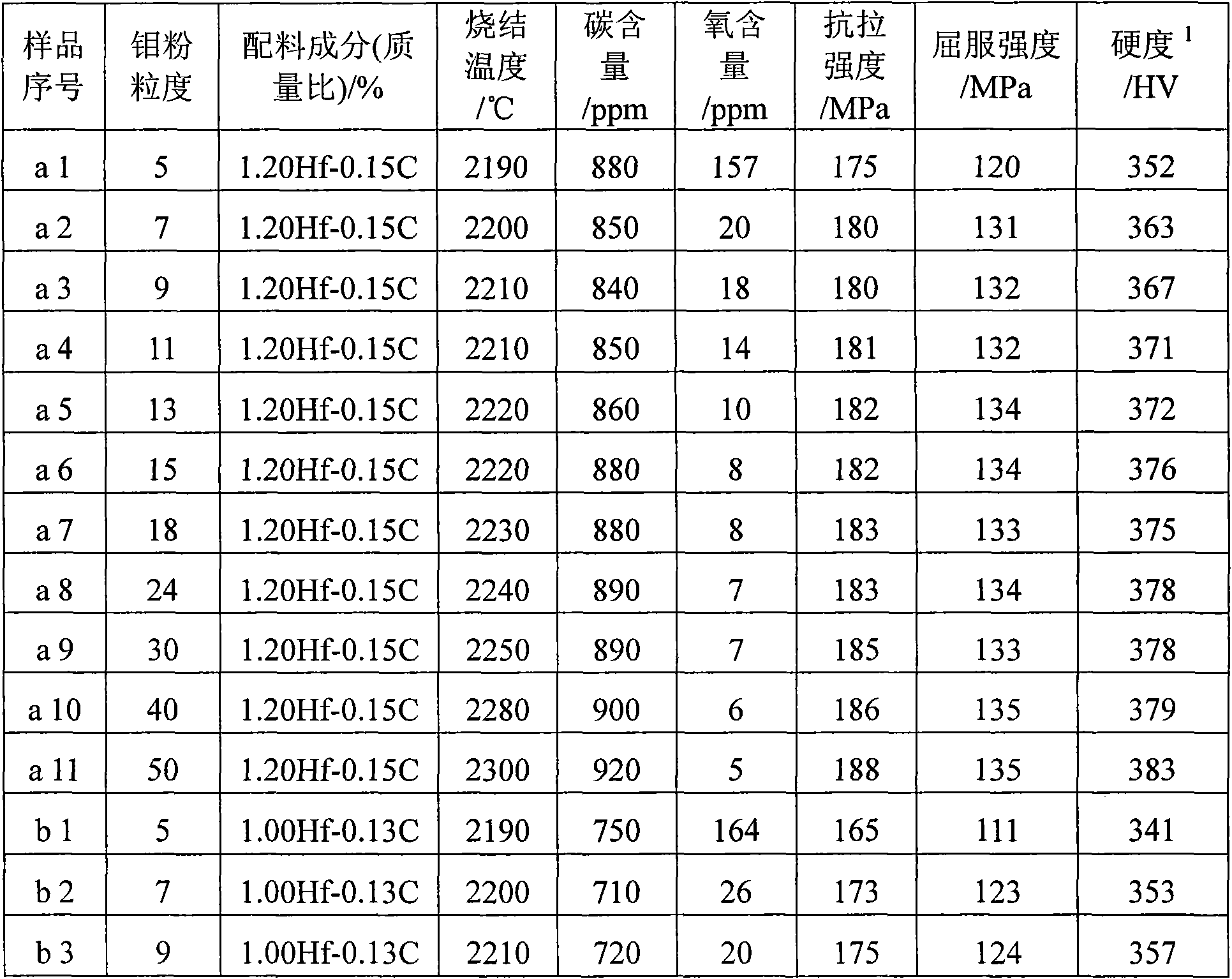

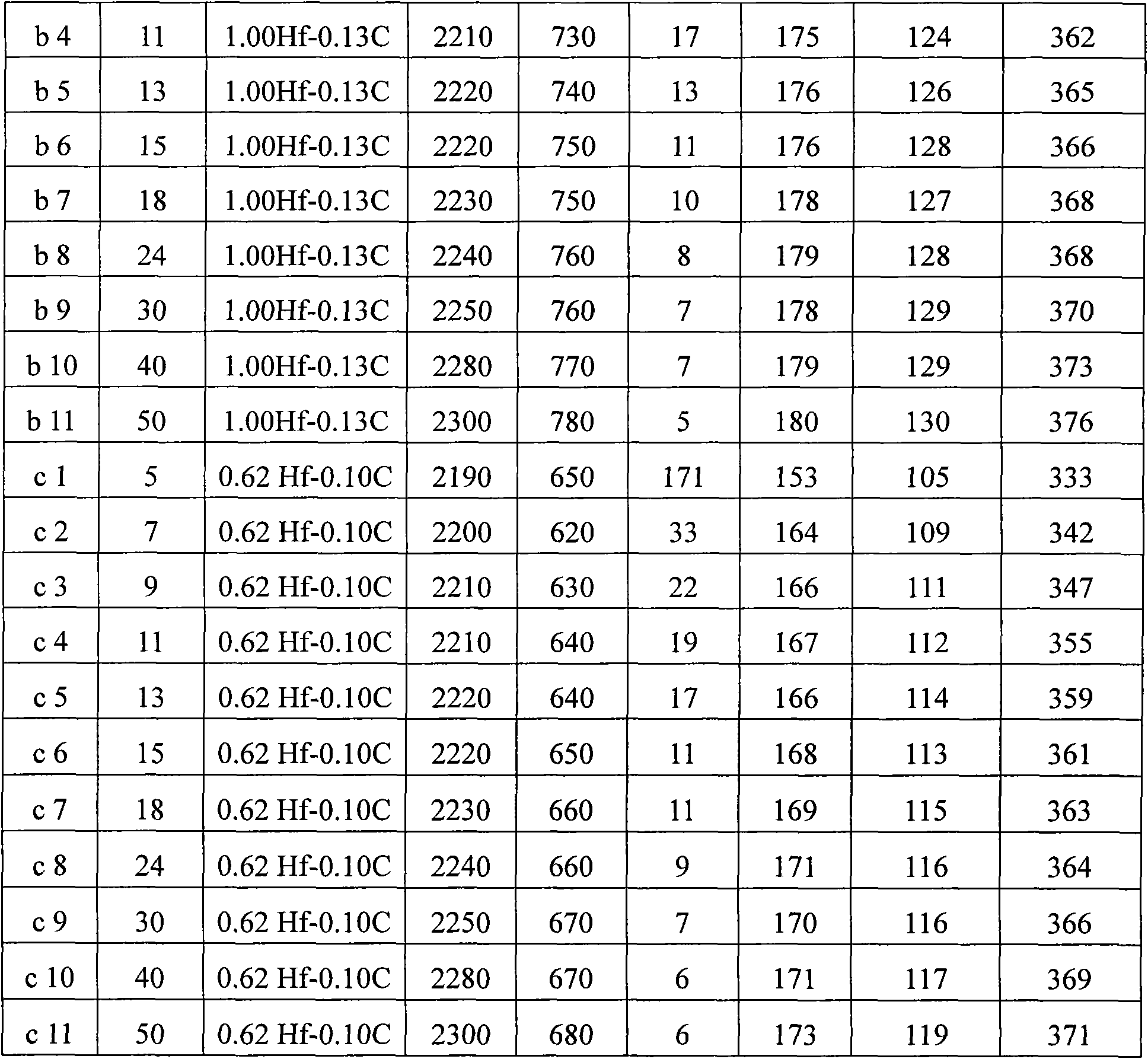

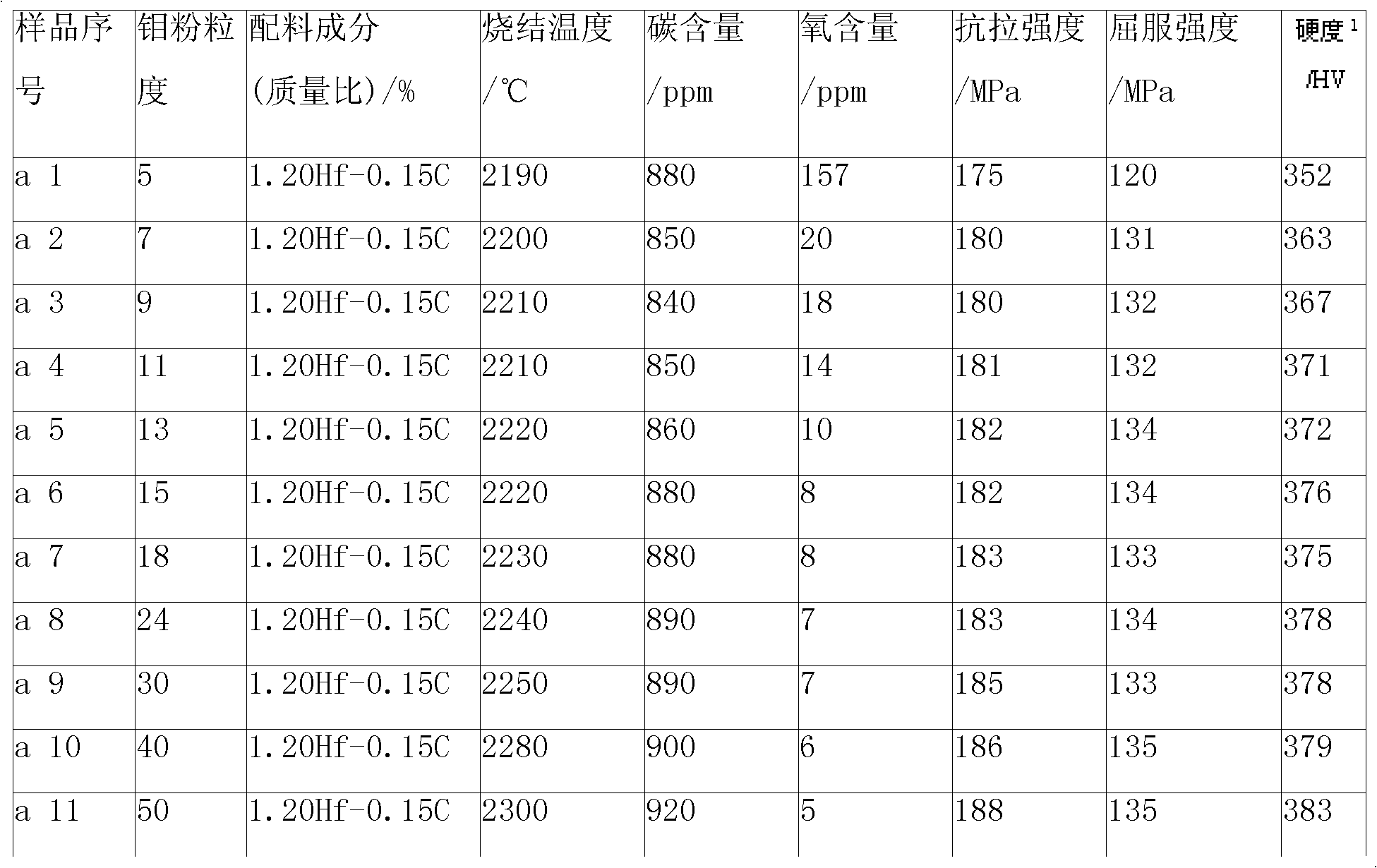

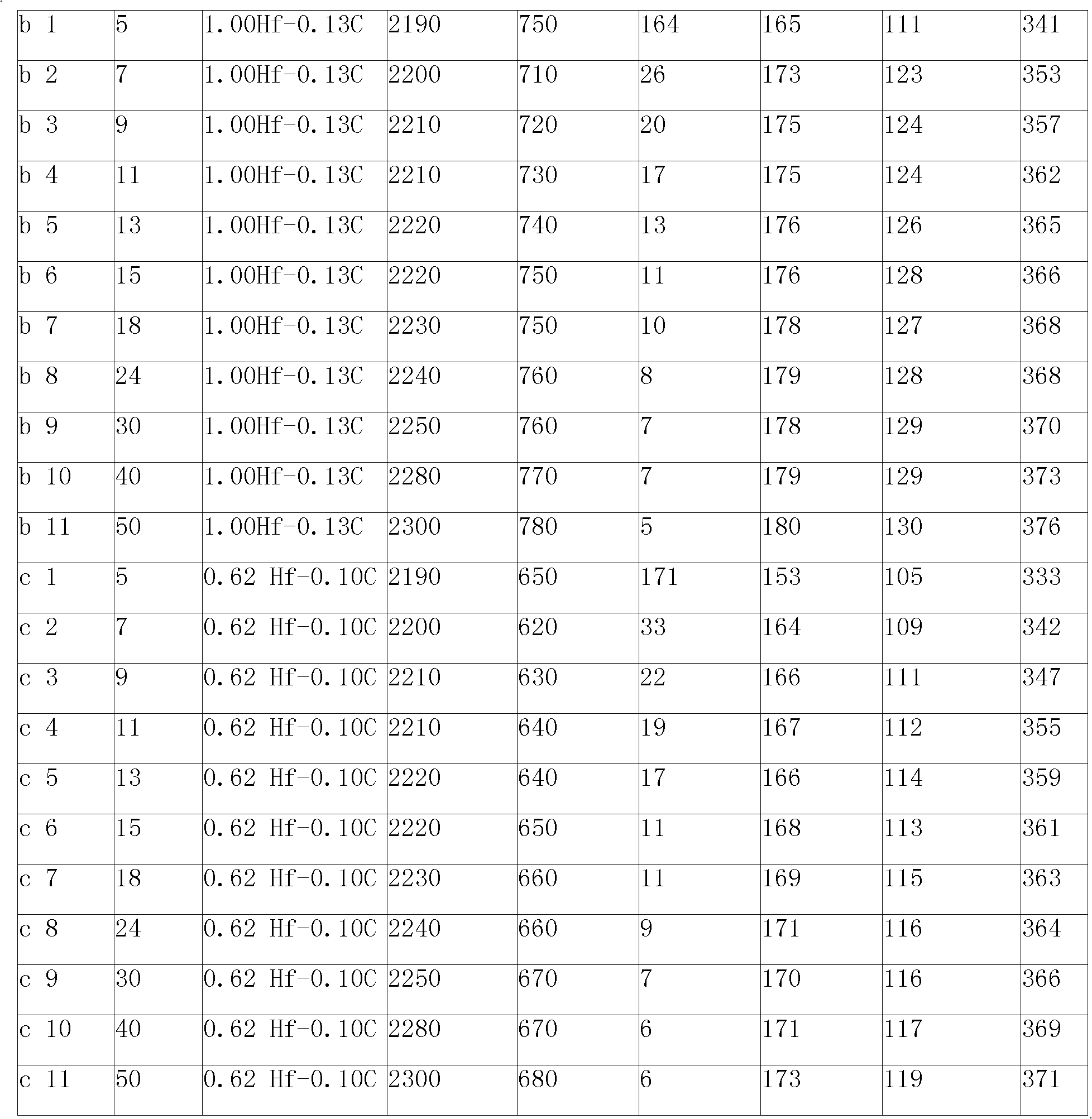

Preparation method of low-oxygen MHC alloy and application of low-oxygen MHC alloy

InactiveCN102041403AReduce oxygen contentOxygen content less impurityX-ray tube electrodesForging/hammering/pressing machinesHydrogenMass ratio

The invention provides a preparation method of a low-oxygen MHC alloy. The method comprises the following steps of: 1) selecting raw materials, namely uniformly mixing industrial molybdenum powder of which the Fisher particle size is 4 mu m to 50 mu m, hafnium-containing power of which the Fisher particle size is 3 mu m to 10 mu m and elementary carbon of which the Fisher particle size is 0.1 mu m to 3 mu m in a certain mass ratio; 2) molding the raw materials, namely treating the mixed raw materials under the pressure of 100 and 300MPa to obtain a molded blank; and 3) sintering the raw materials, namely sintering the molded blank in an environment of vacuum, hydrogen or inert gas and at the temperature of between 1,800 and 2,300 DEG C for 5 to 15 hours to obtain the low-oxygen MHC alloy. By the method, the problem that the MHC alloy prepared by a powder metallurgy method contains high oxygen is solved. The low-oxygen MHC alloy prepared by the method can be applied to the preparation of X-ray tube rotating anode targets, composite target base targets, high-temperature crucibles, hot-forged dies and high-temperature ceramic pads.

Owner:XIAN GEMEI METAL MATERIAL

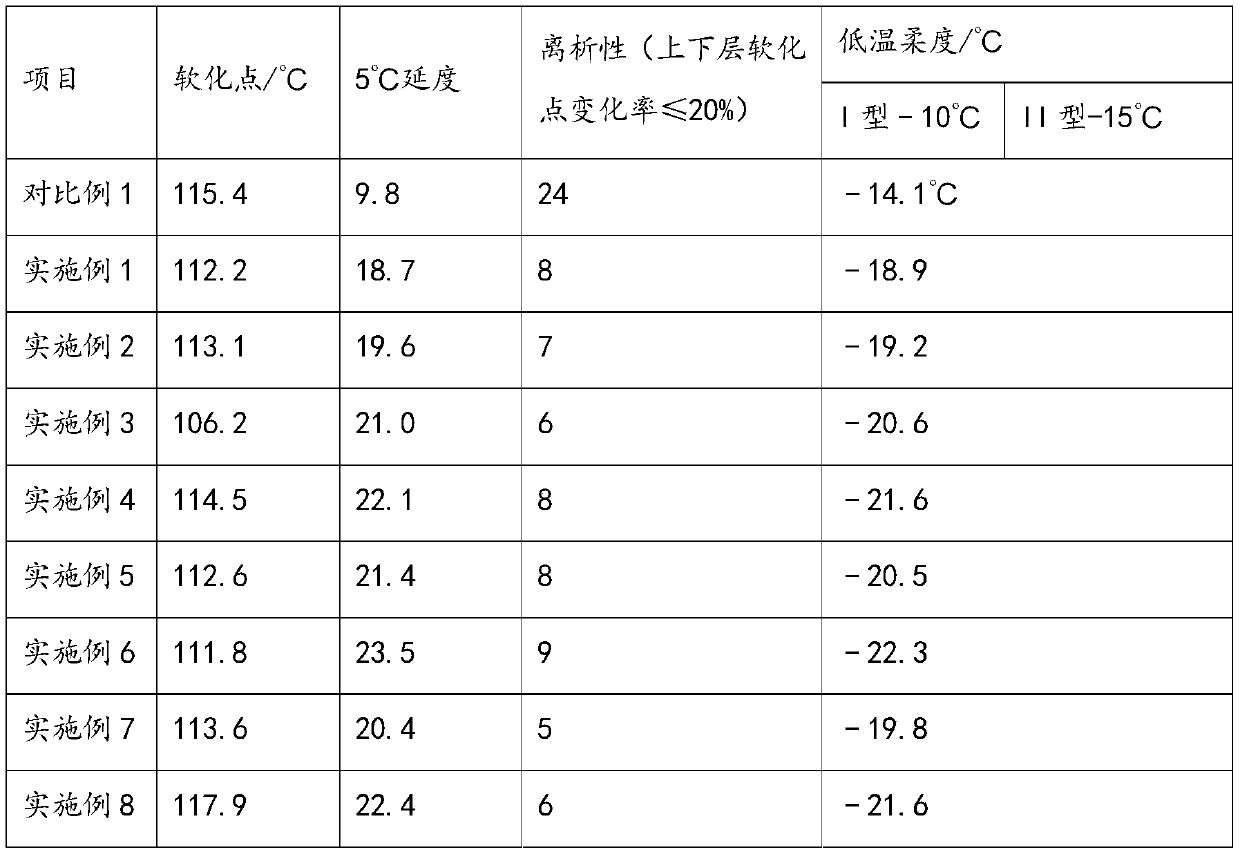

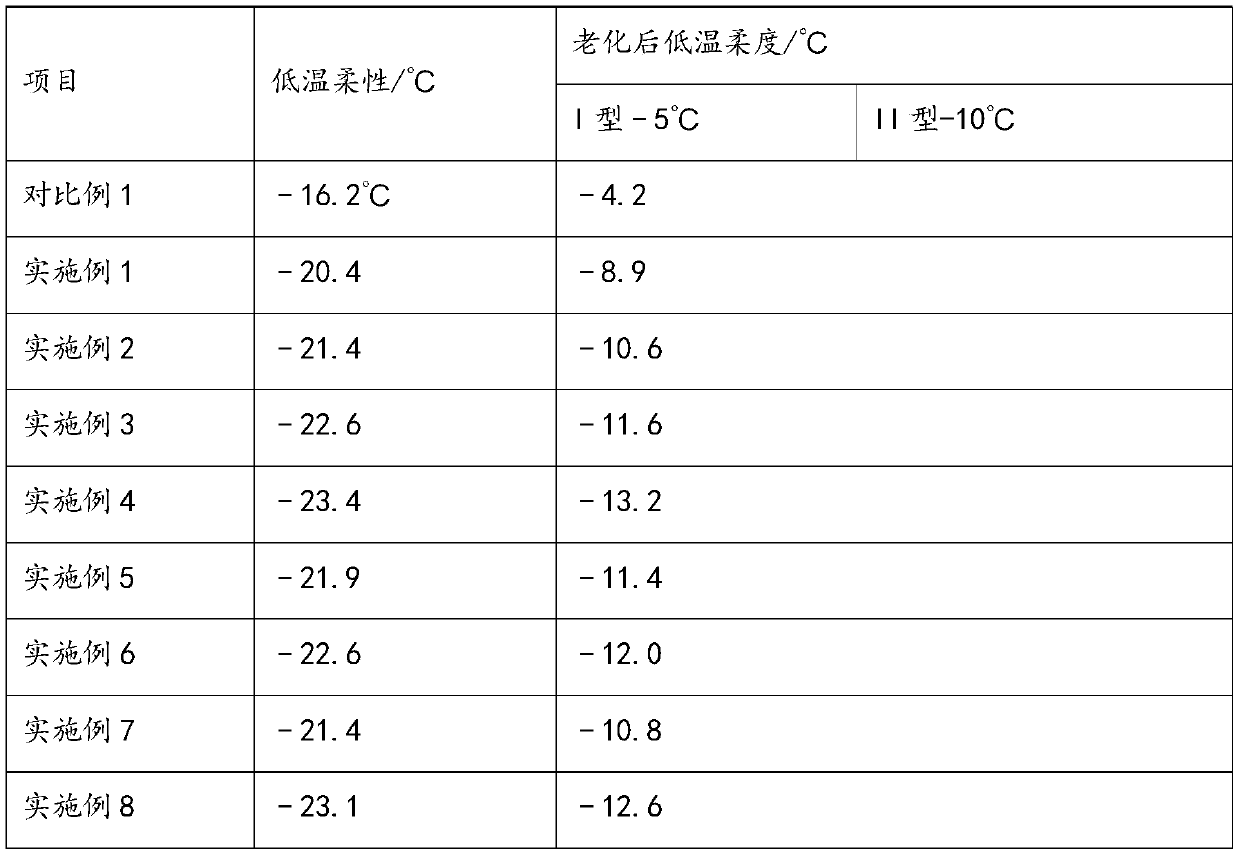

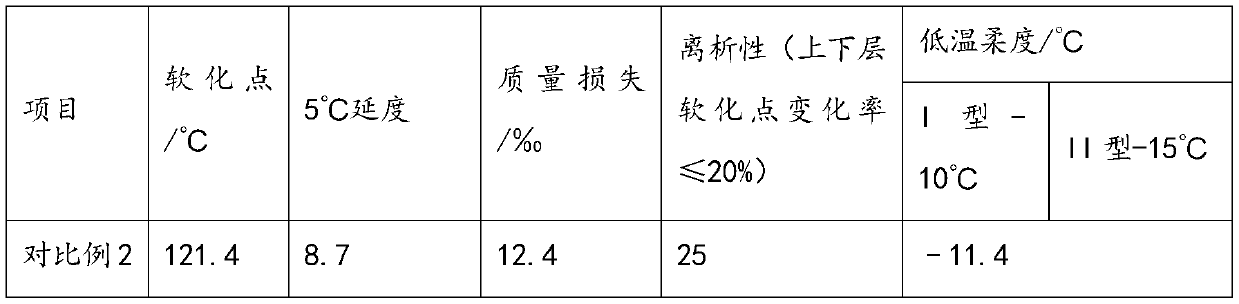

Efficient and environment-friendly rubber-powder-modified asphalt waterproof coiled material and preparing method

InactiveCN110042670AFast swelling rateGood compatibilitySynthetic resin layered productsConstructions elementsEnvironmental resistanceBituminous waterproofing

The invention relates to an efficient and environment-friendly rubber-powder-modified asphalt waterproof coiled material and a preparing method. The preparing method comprises the steps of mixing anduniformly stirring 34-54 parts of matrix asphalt and 1.5-15 parts of softening oil, increasing the temperature to 150-170 DEG C, starting to add 10-15 parts of waste rubber powder and 0.01-0.03 part of an activating agent, increasing the temperature, maintaining the temperature at 170-180 DEG C, conducting development for 60-80 minutes at the rotation speed of 20-200 r / min, afterwards, adding 4-15parts of waste rubber powder, conducting stirring development for 10-20 minutes, conducting cutting and grinding once through a colloid mill, adding 15-30 parts of a filler, and then conducting stirring development for 30-60 minutes to obtain a modified asphalt coating material; conducting coating and cladding technologies on the prepared modified asphalt coating material, and then conducting cooling rolling to prepare the rubber-powder-modified asphalt waterproof coiled material. According to the efficient and environment-friendly rubber-powder-modified asphalt waterproof coiled material andthe preparing method, by adding the activating agent, all technology parameters of the batching period are greatly adjusted, the technology time can be shortened, the technology temperature and stirring speed can be lowered, and the prepared product also has better performance indexes, has excellent storage stability and application performance, and is an efficient, energy-saving and environment-friendly product.

Owner:YUZHONGQING WATERPROOF MATERIALS CO LTD

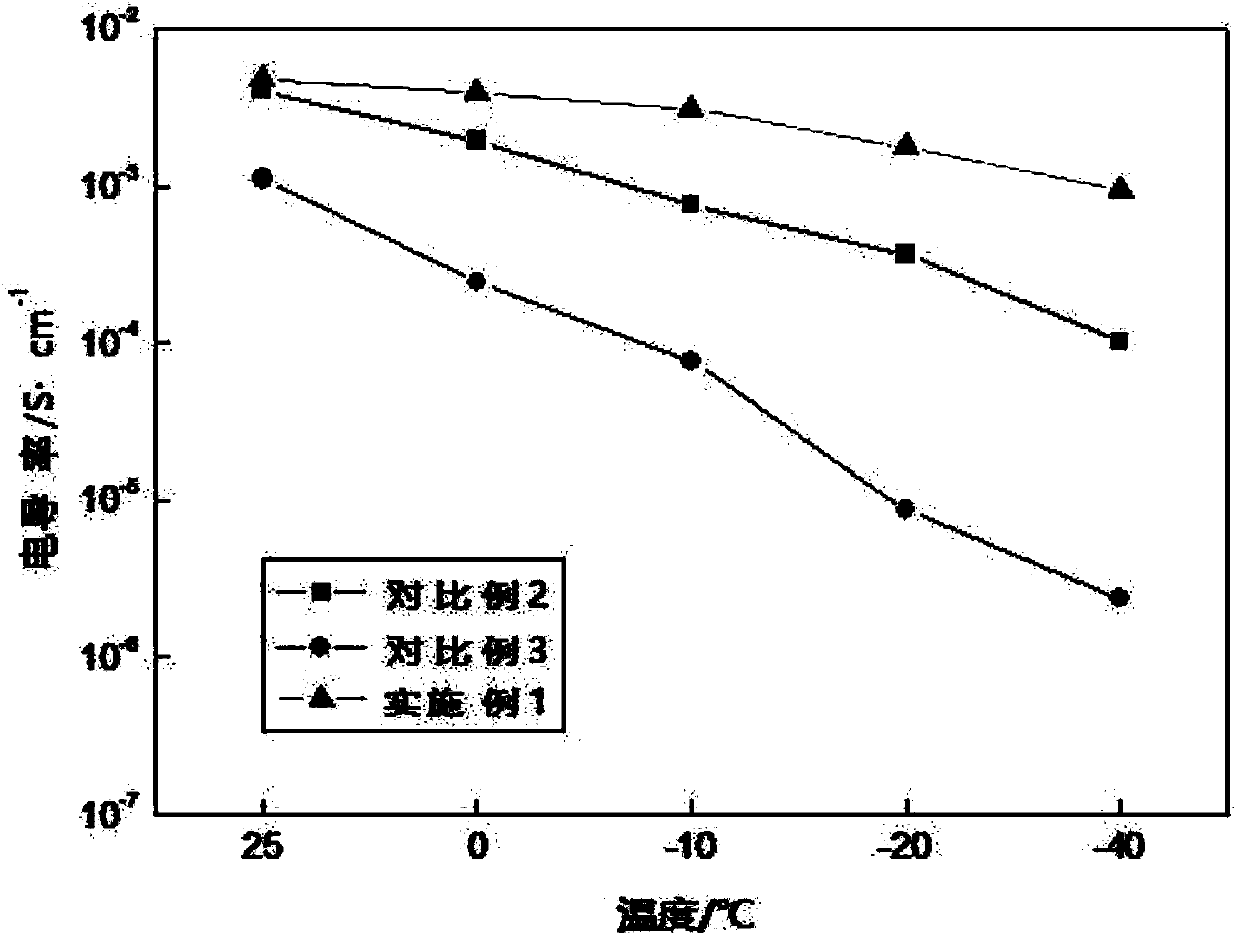

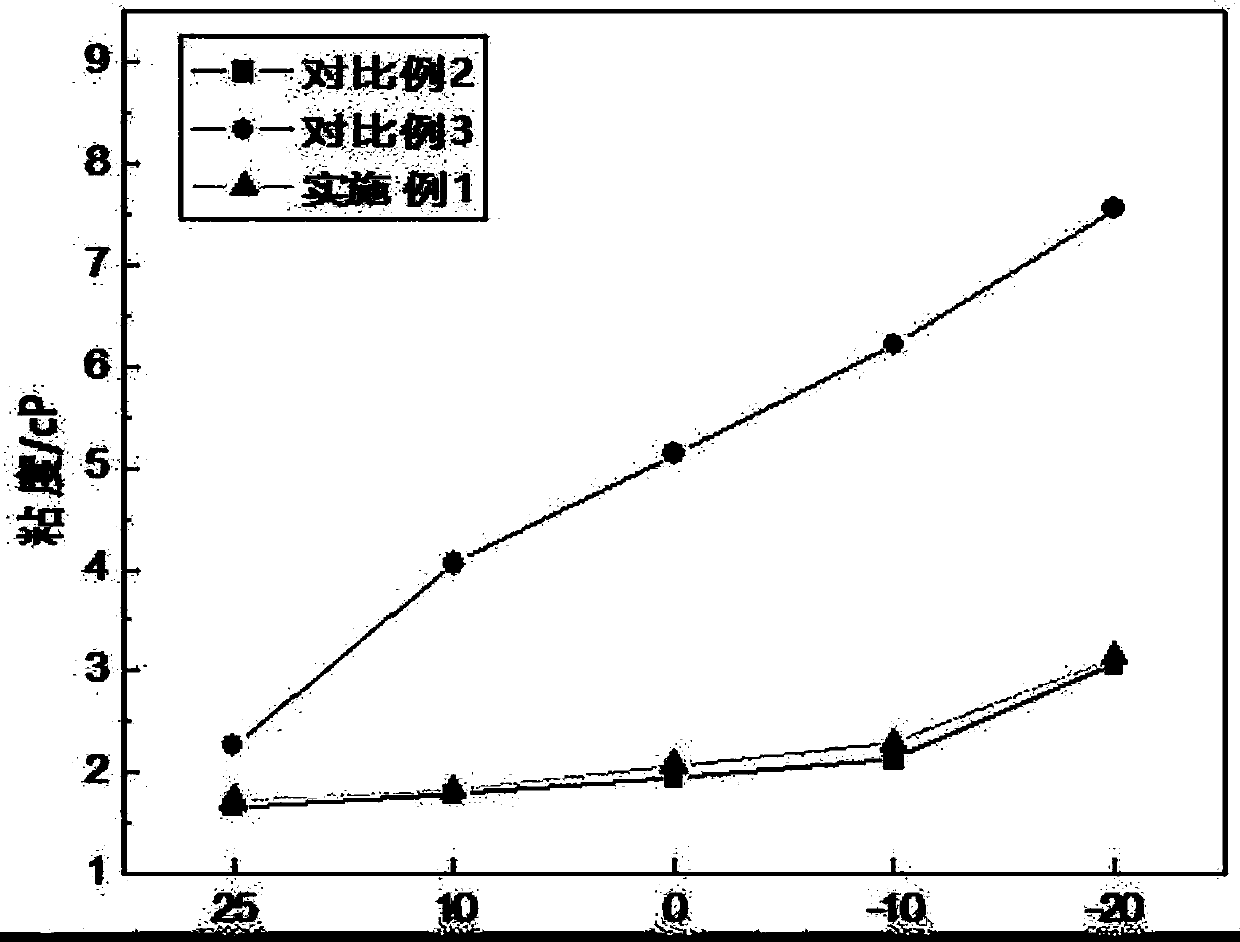

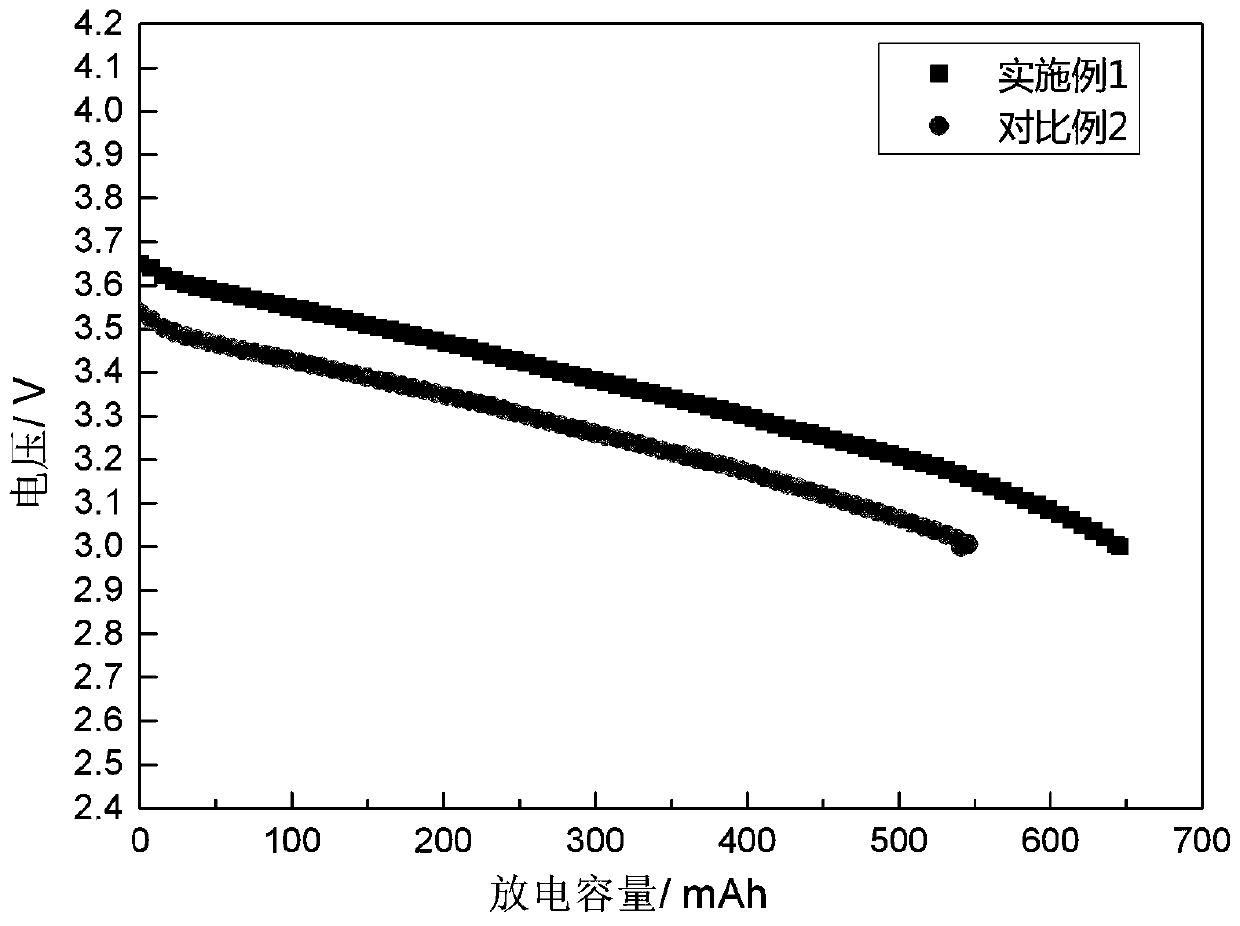

Electrolyte for improving low temperature performance of lithium ion battery and lithium ion battery comprising same

ActiveCN109860709APrevent the decomposition processImproved reversible capacity performanceSecondary cellsLithium electrodeNitrogen

The invention discloses an electrolyte for improving the low temperature performance of a lithium ion battery and a lithium ion battery comprising the same. The electrolyte comprises conductive lithium salt, a non-aqueous organic solvent, and additives, wherein the additives include a conventional negative electrode film forming additive, an additive with the structure of Formula I, and an anhydride-type compound additive with the structure of Formula II. According to the battery electrolyte provided by the invention, under synergistic effects among the additive with the structure of Formula I, the anhydride-type compound additive with the structure of Formula II, a nitrogen-containing lithium salt type additive and the conventional negative electrode film forming additive, the electrolytethus has excellent film forming performance on the electrode surface, the cycle performance and the rate performance of the lithium ion battery in a low temperature condition can be effectively improved, and the high temperature cycle performance and the storage performance of the battery are little affected.

Owner:SHANSHAN ADVANCED MATERIALS QUZHOU CO LTD

Formula and preparation method of novel green environment-friendly flexible soft-paste porcelain decorative tile

The invention relates to the field of resource utilization and environment protection, and specifically relates to a formula and a preparation method for preparing a green environment-friendly flexible soft-paste porcelain decorative tile with a waste produced in a ceramic production process. The invention especially relates to a method for preparing the green environment-friendly flexible soft-paste porcelain decorative tile with a polishing waste produced during a ceramic polishing production process. The formula comprises, by mass, 50-120 parts of acrylic emulsion, 0.5-5 parts of an antifoaming agent, 0.1-3 parts of a wetting agent, 1-10 parts of a film-forming aid, 40-100 parts of the polishing waste, 70-130 parts of natural colored sand, and 5-15 parts of water. The solid content of the acrylic emulsion is 40-60%. With the formula and the preparation method provided by the invention, the production cost of soft-paste porcelain can be substantially reduced; the pollution problem of ceramic polishing waste can be solved, such that waste is turned valuable; no calcination is needed during the entire production cost; wastewater and waste material discharge amounts are low; and the processing method is simple.

Owner:LIAONING SILICATE RES INST

Patterned photovoltaic backplate and preparation method thereof

InactiveCN109796806ASimple processSimple production equipmentInksOther printing apparatusEpoxyPolyolefin

The invention discloses a patterned photovoltaic backplate and a preparation method thereof. The process is simple and convenient, production equipment is simple and low in cost, and the performance is stable and excellent. The patterned photovoltaic backplate comprises a base layer and a patterned ink layer, wherein the ink layer is formed by ink printed on the surface of the base layer, and theink is prepared from, by weight, 120-800 parts of fluororesin, 10-500 parts of modified resin, 100-500 parts of pigments and fillers, 5-300 parts of a diluent, 5-85 parts of a curing agent and 5-15 parts of an aid. The modified resin is a combination of one or more of polyhydroxy alkyd resin, polyhydroxy polyester resin, polyhydroxy acrylic resin, polyhydroxy polyolefin resin, polyhydroxy polycarbonate resin and epoxy resin.

Owner:SUZHOU FIRST PV MATERIAL CO LTD

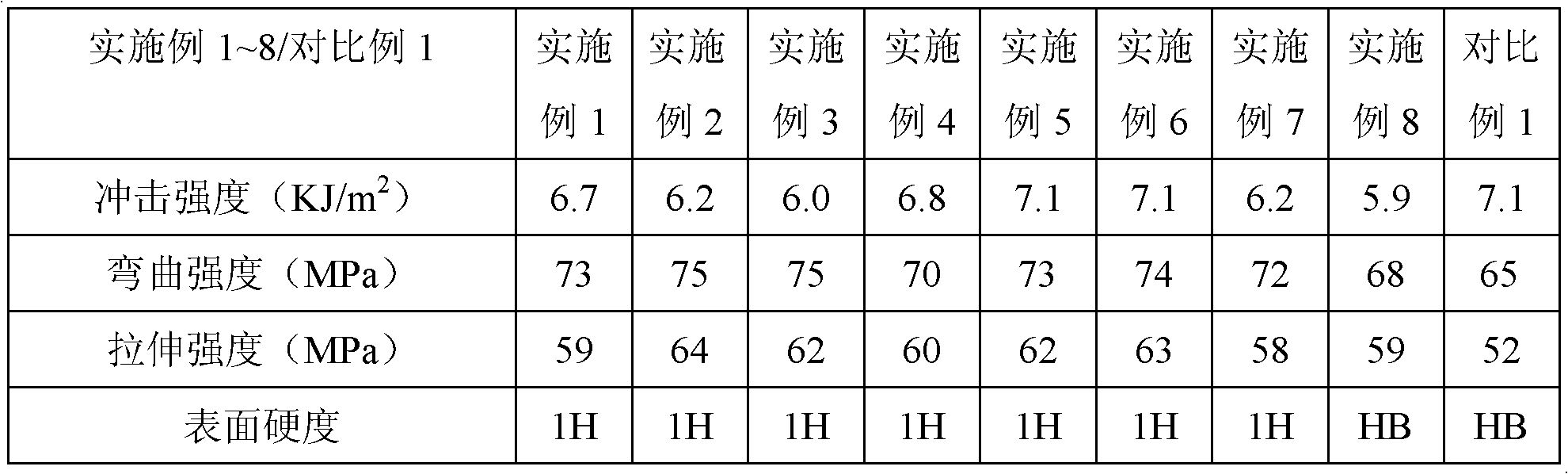

ABS / attapulgite composite material and preparation method thereof

The invention discloses an ABS / attapulgite composite material, comprising the following materials, by weight: 49%-70% of ABS, 15%-35% of attapulgite, 3%-20% of compatilizer and 0%-1% of ubricant. Attapulgite is a natural mineral, which belongs to the rod-like structure, and is beneficial to improving the smoothness of surface of the ABS / attapulgite composite material, and the compatibilizer improves compatibility of the ABS and the attapulgite, so as to endow the ABS / attapulgite composite material of the invention with advantages of high hardness, good bending strength; therefore, the composite material shows excellent mechanical properties. The invention also discloses a preparation method of the ABS / attapulgite composite material. The method is simple and easy to operate, can uniformly harmonize the attapulgite and the ABS through simple steps and prepare the ABS / attapulgite composite material with excellent performances.

Owner:宁波康德新材料有限公司

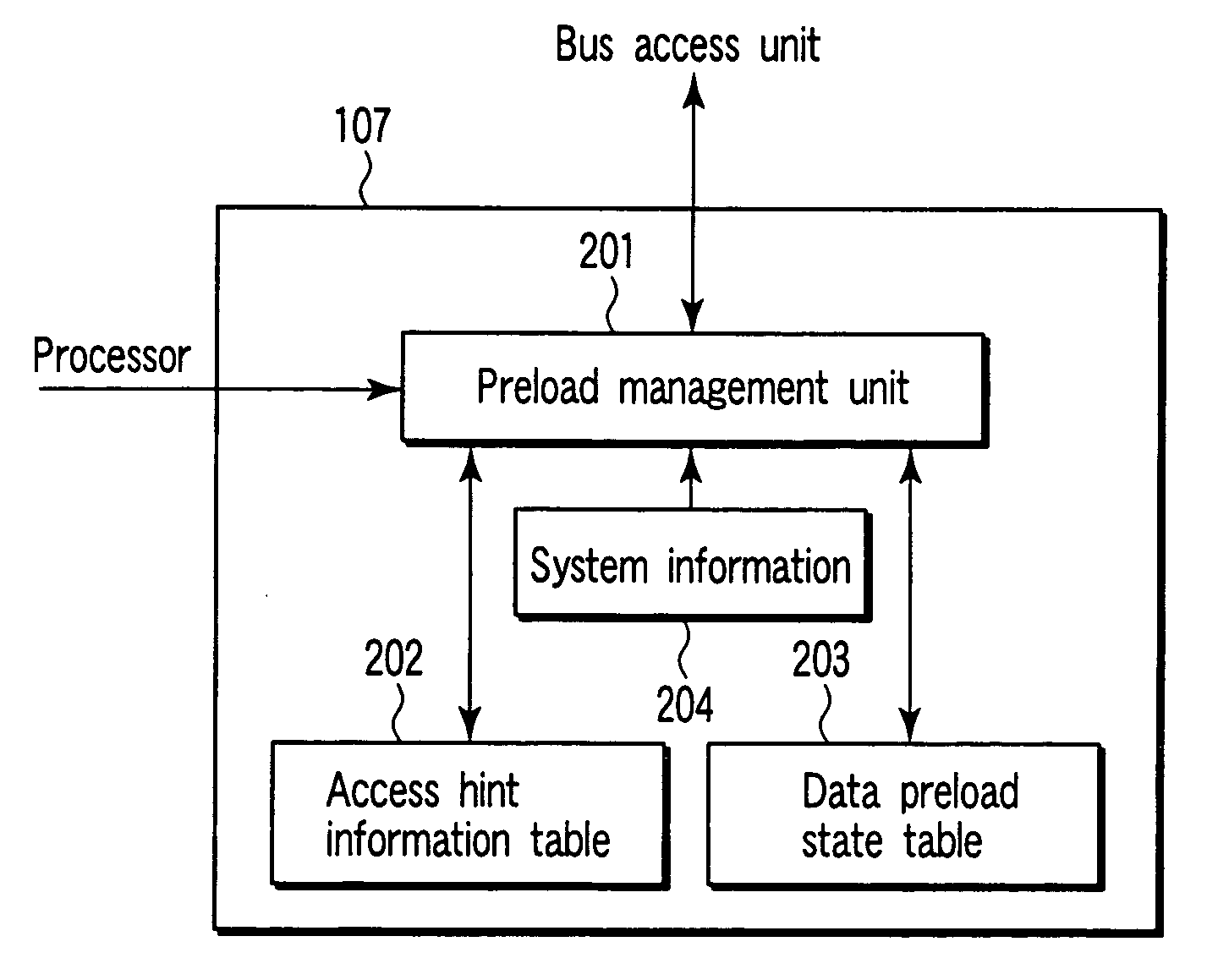

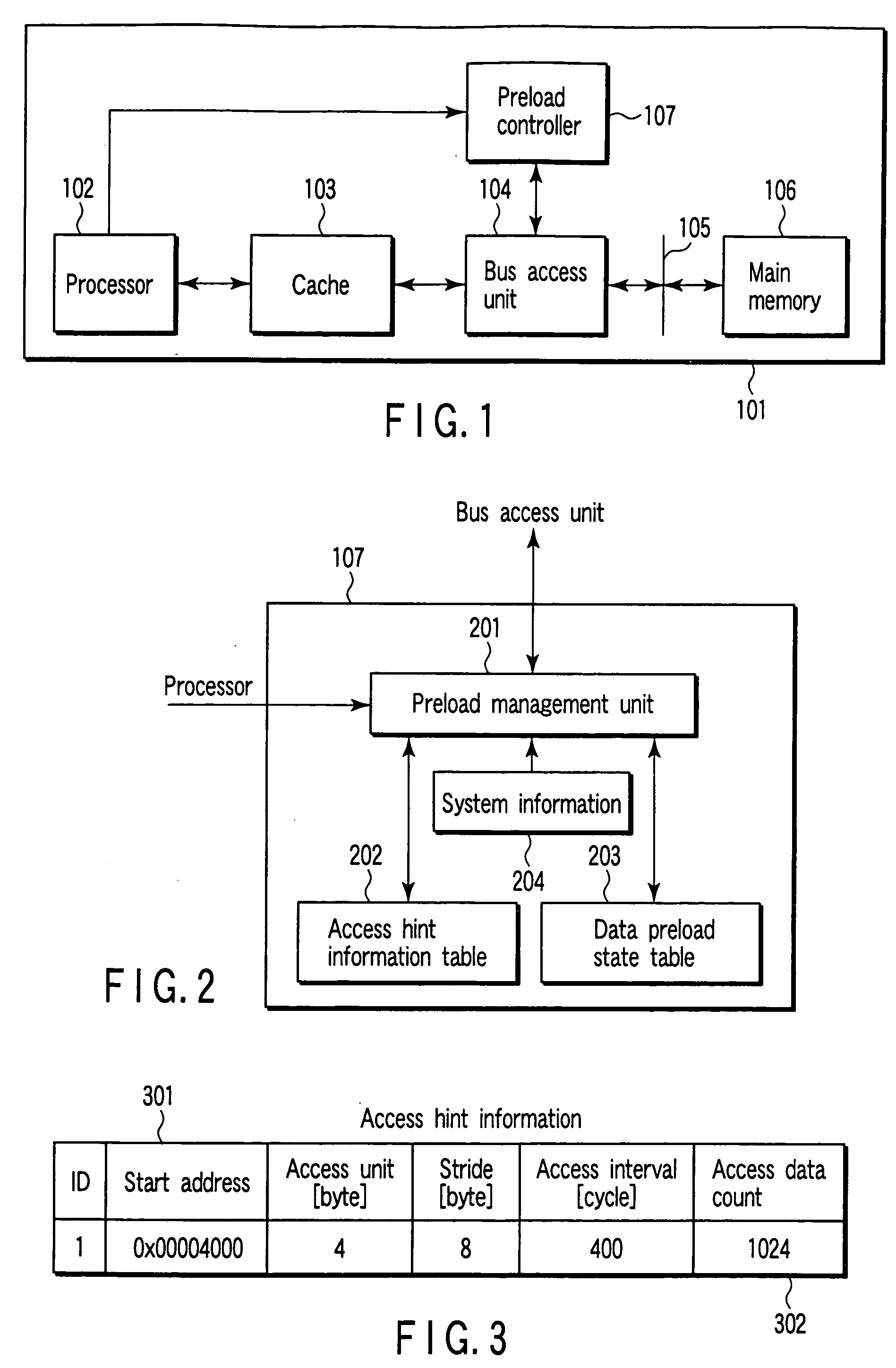

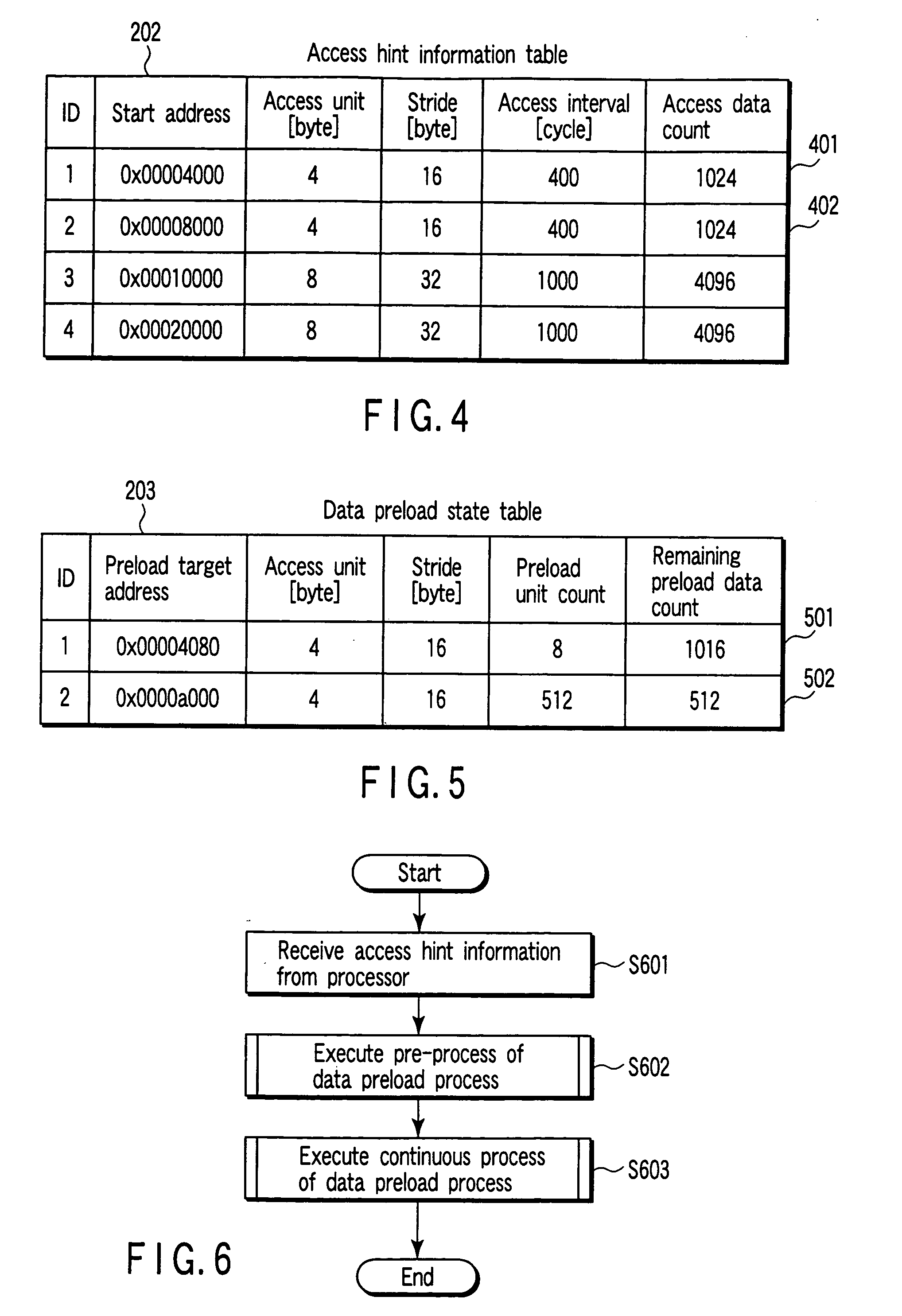

Preload controller, preload control method for controlling preload of data by processor to temporary memory, and program

InactiveUS20060004966A1Improve effectivenessExcellent and stable performanceDigital computer detailsMemory systemsInformation accessDelayed time

A preload controller for controlling a bus access device that reads out data from a main memory via a bus and transfers the readout data to a temporary memory, including a first acquiring device to acquire access hint information which represents a data access interval to the main memory, a second acquiring device to acquire system information which represents a transfer delay time in transfer of data via the bus by the bus access device, a determining device to determine a preload unit count based on the data access interval represented by the access hint information and the transfer delay time represented by the system information, and a management device to instruct the bus access device to read out data for the preload unit count from the main memory and to transfer the readout data to the temporary memory ahead of a data access of the data.

Owner:KK TOSHIBA

Aqueous film-forming foam extinguishing agent based on short fluorocarbon chains

ActiveCN105854216ARaw materials are easy to getReduce manufacturing costFire extinguisherHydrophilic polymersOrganic solvent

The invention provides an aqueous film-forming foam extinguishing agent based on short fluorocarbon chains. The aqueous film-forming foam extinguishing agent is composed of fluorocarbon surface active agents, hydrocarbon surface active agents, hydrophilic polymers, organic solvents, water and the like. The fluorocarbon surface active agents are anion-cation fluorine surface active agent composites based on the short fluorocarbon chains. The mole ratio of anion fluorocarbon surface active agents to cation fluorocarbon surface active agents is 5:1-1:5. The aqueous film-forming foam extinguishing agent is low in production cost, simple in preparation method, environmentally friendly, and high in extinguishing speed.

Owner:CIVIL AVIATION FLIGHT UNIV OF CHINA +1

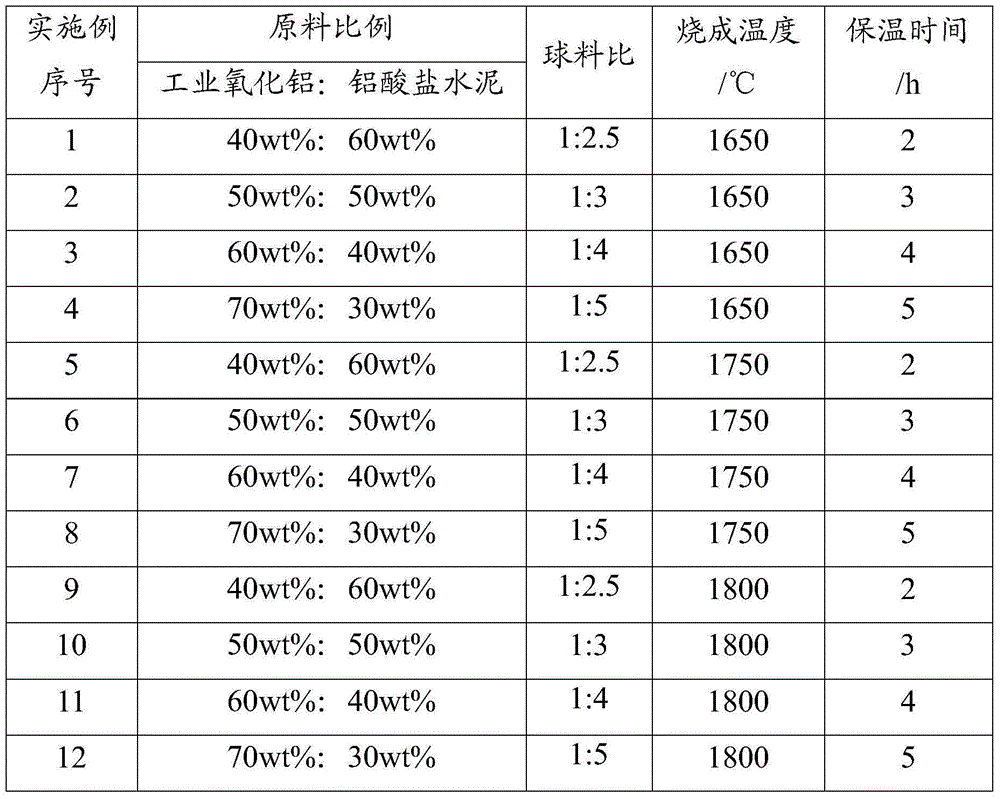

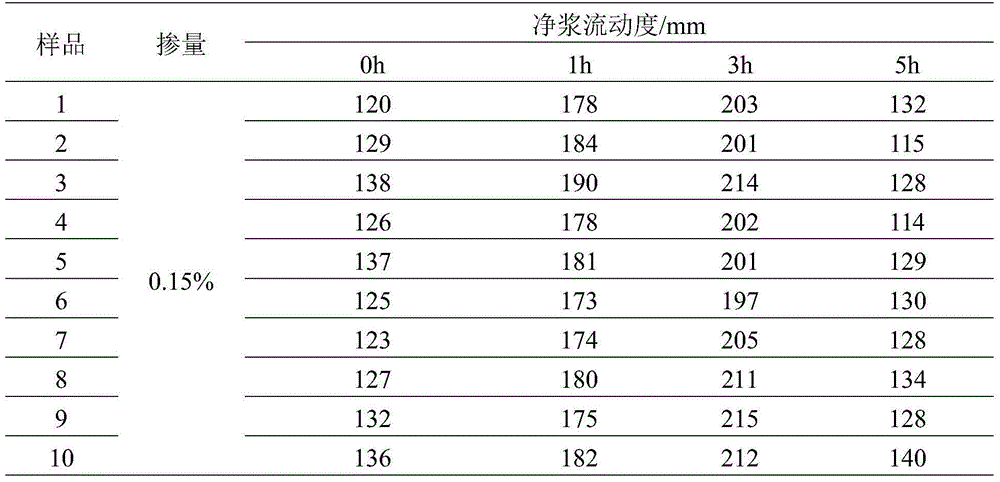

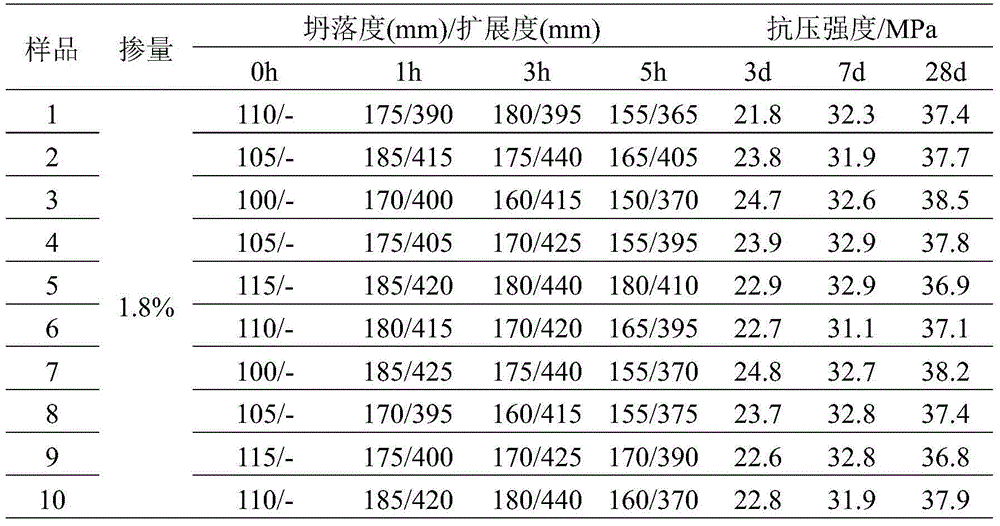

Calcium hexaluminate and preparation method thereof

InactiveCN105036167ALower sintering temperatureIncrease productivityAlkaline-earth metal aluminates/aluminium-oxide/aluminium-hydroxide preparationRefractoryVolume density

The invention discloses a preparation method of calcium hexaluminate. The method includes the following steps that firstly, 40-80 wt% of industrial aluminum oxide powder and 20-60 wt% of aluminate cement are evenly mixed, mixed powder is obtained, the mixed powder is subjected to secondary balling fabrication processing, and green balls are obtained; secondly, after the green balls are dried, the green balls are sintered for 1-5 hours at the temperature of 1650-1800 DEG C, and then the calcium hexaluminate is obtained through smashing and screening. The preparation method of the calcium hexaluminate has the advantages that the technology is simple, cost is low, the production cycle is short, and large-scale industrial production can be achieved. The prepared calcium hexaluminate is high in purity and stable in performance. After the calcium hexaluminate is added into an amorphous fire-resistant material product, the volume density of a fire-resistant material can be effectively reduced, and accordingly the fire-resistant material has the advantages of being good in high-temperature volume stability, heat-preserving and heat-isolation performance, alkali resistance and the like.

Owner:浙江自立新材料股份有限公司

Preparation method of slump-retaining polycarboxylic acid type water-reducer

The invention discloses a preparation method of a slump-retaining polycarboxylic acid type water-reducer. The preparation method comprises the following steps: 1) a hydroxyl-containing unsaturated monomer, an amine unsaturated monomer, an initiator, a reducing agent and a chain transfer agent are subjected to an oxidation-reduction free radical polymerization reaction to obtain a copolymerization product containing an amino group; 2) excessive sodium hydride is added into methoxypolyethylene glycol to react, epoxy chloropropane is added after the reaction, and desalination is carried out after stirring and reacting so as to obtain epoxy methoxy polyethylene glycol; 3) the copolymerization product containing an amino group is added into the epoxy methoxy polyethylene glycol to react, and pH value is adjusted by alkaline neutralization after the reaction so as to prepare the slump-retaining polycarboxylic acid type water-reducer. According to the method, product performance is adjusted by controlling molecular structure / molecular weight of the copolymerization product containing an amino group and molecular weight of methoxy polyethylene glycol. Reaction is fast and efficiency is high. In addition, no organic solvent is used; the water-reducer is nontoxic and pollution-free; and operation is simple. The prepared polycarboxylic acid type water-reducer is a slump-retaining polycarboxylic acid type water-reducer, has stable product performance and especially has a good slump-retaining effect on a mud sandy stone material.

Owner:JIANGSU CHINA RAILWAY ARIT NEW MATEIRALS CO LTD

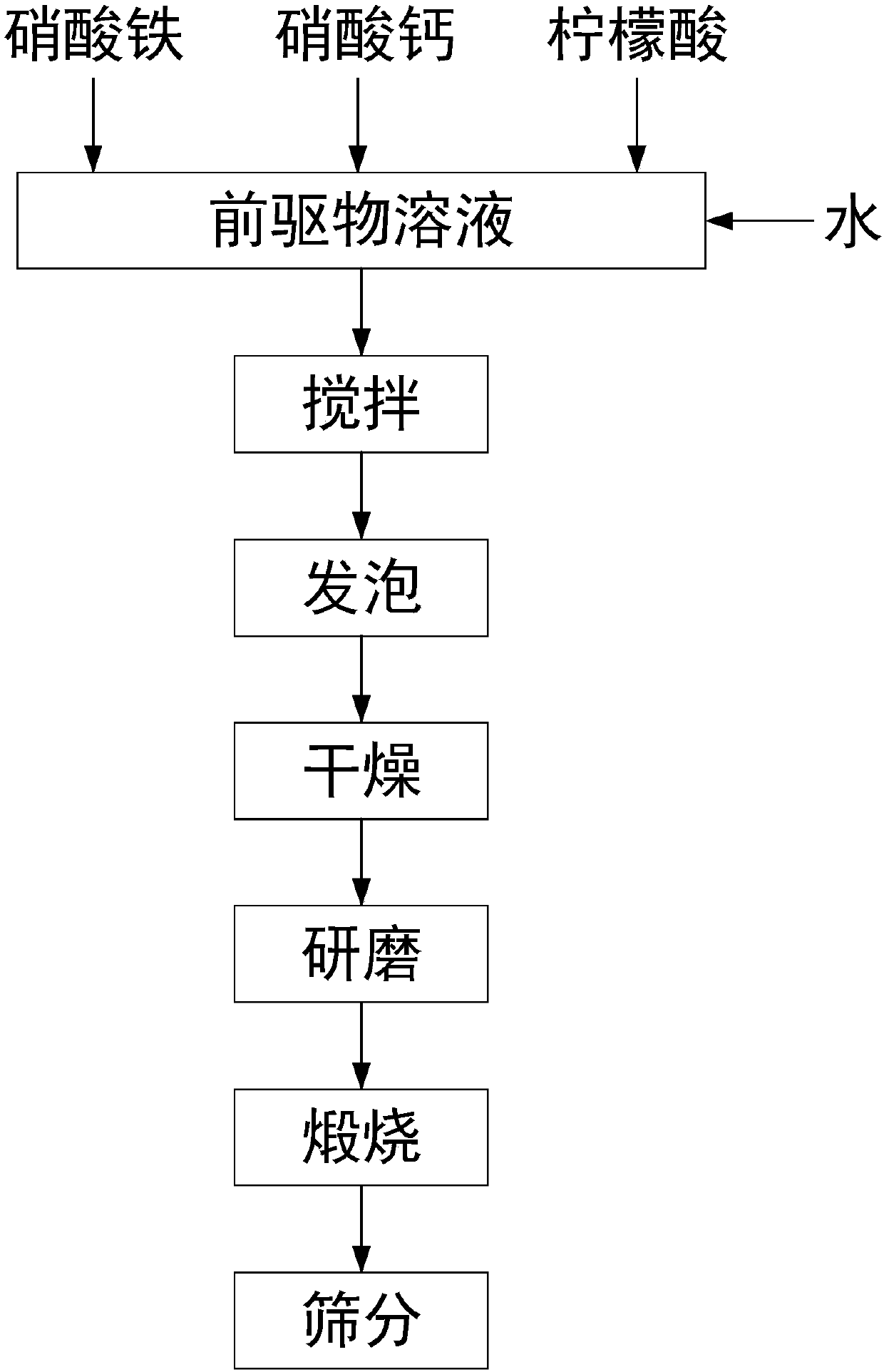

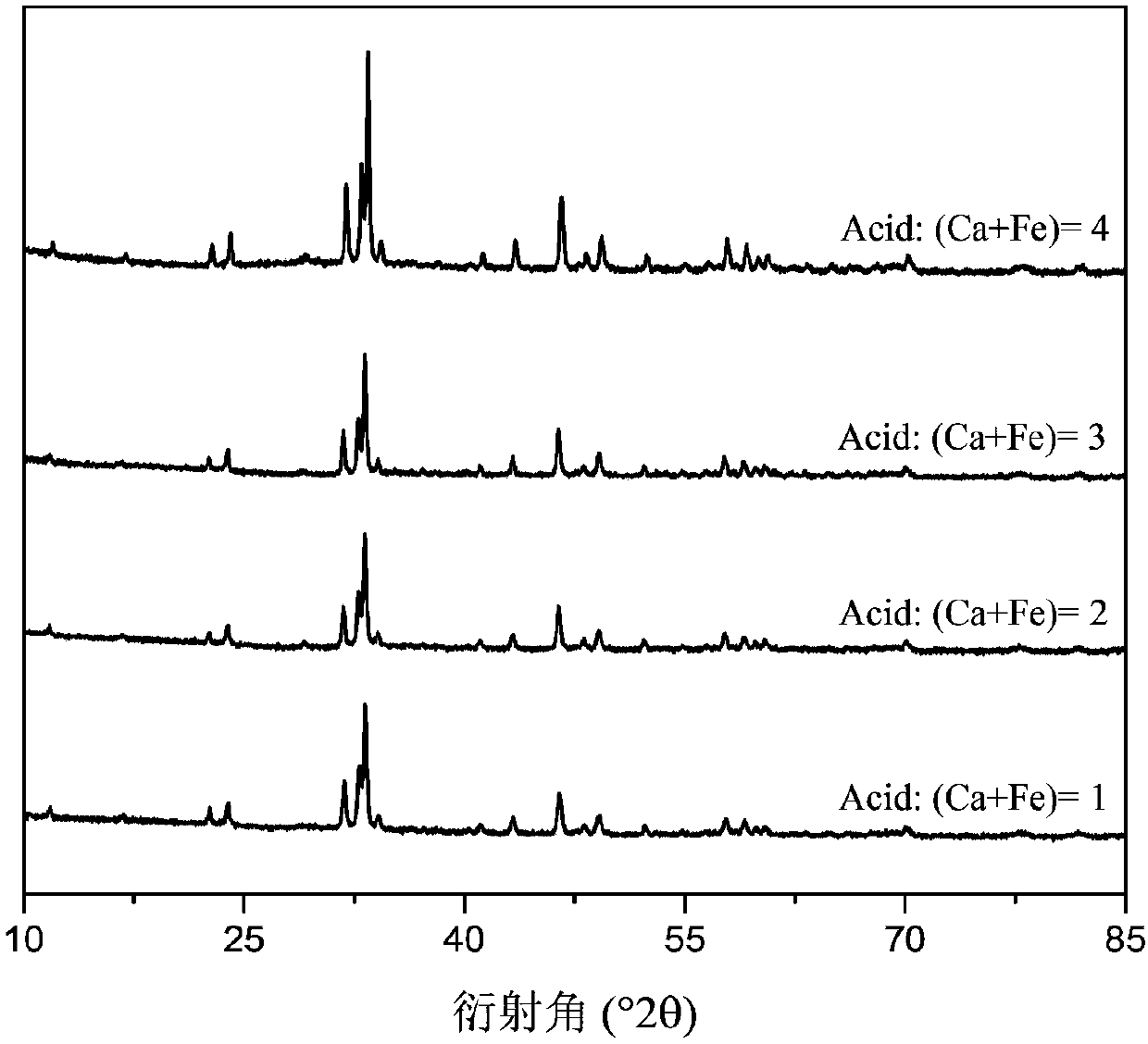

Preparation method of calcium-iron type Ca2Fe2O5 catalyst

InactiveCN107857301AGood dispersionLarge specific surface areaIron compoundsMetal/metal-oxides/metal-hydroxide catalystsCombustionFoaming agent

The invention discloses a preparation method of a calcium-iron type Ca2Fe2O5 catalyst. The method adopts ferric nitrate, calcium nitrate and citric acid as precursors which are added with a certain amount of water to prepare a solution, and the solution is stirred at 40 DEG C for 30 minutes to be evenly dispersed, wherein the citric acid is added as a foaming agent for foaming at 180 DEG C for 12h, an obtained foaming substance is ground, sieved, and then calcined at 650 DEG C in a muffle furnace for 4h to finally obtain a high-purity Ca2Fe2O5 catalyst. The Ca2Fe2O5 catalyst prepared by the method has a large specific surface area and a stable framework structure, can keep extremely strong stability after being oxidized and reduced by an oxidant and a reducing agent for a plurality of times, and can be used in the fields of chemical chain combustion, chemical chain hydrogen production, photocatalysis and the like.

Owner:SOUTHEAST UNIV

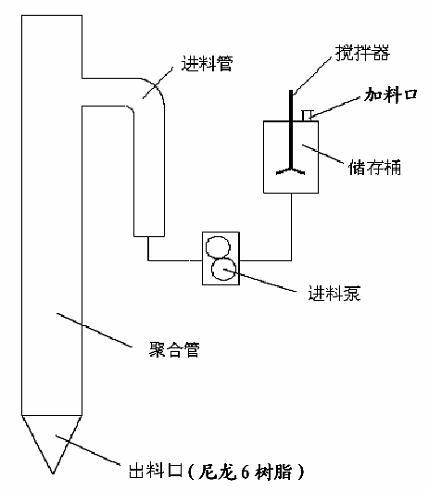

Nylon-6 resin, nylon-6 fiber and preparation method thereof

InactiveCN102161755AHigh tensile strengthSlow crystallization rateMelt spinning methodsArtifical filament manufacturePolymer scienceCaprolactam

The invention relates to the field of spinning materials, and firstly provides a nylon-6 resin which is prepared by the polymerization reaction of a caprolactam monomer and fixed melt of compounds of metals in the second main group, wherein based on the total weight of the caprolactam monomer, the weight of the compounds of metals in the second main group is 0.01-1.0%. The invention also provides a nylon-6 fiber which is prepared from the nylon-6 resin by melt spinning. By using the nylon-6 resin and the preparation method provided by the invention, the fine-denier or superfine-denier nylon-6 fiber with a fineness of about 0.10-1.0dtex can be obtained. Both the strength and the breaking elongation of the fiber conform to post-weaving requirements. Besides, the invention fills up the gap that the fine-denier / superfine-denier nylon-6 filament can not be produced by the conventional high-speed spinning method home and abroad, and increases the technological content and added value of the nylon-6 fiber product.

Owner:HANGZHOU NORMAL UNIVERSITY

Acrylonitrile butadiene styrene (ABS)/ nerchinskite composite material and preparation method thereof

The invention discloses an acrylonitrile butadiene styrene (ABS) / nerchinskite composite material, which is prepared from 49 to 70 weight percent of ABS copolymer, 15 to 35 weight percent of nerchinskite, 3 to 20 weight percent of compatilizer and 0 to 1 weight percent of lubricating agent. The mechanical properties such as hardness and toughness of the composite material are improved by adding the nerchinskite, the compatilizer and the like into the ABS. The invention also discloses a preparation method for the ABS / nerchinskite composite material. The method comprises the following steps of: fully mixing the ABS copolymer, the nerchinskite, the compatilizer and the selectively added lubricating agent uniformly through mixing equipment to obtain a mixed material; and adding the mixed material into a double-screw extruder, performing melt blending, melt extrusion and granulation, and thus obtaining the ABS / nerchinskite composite material. The material has excellent and stable performance, facilitates industrialized production, and has good economic benefits and broad application prospect.

Owner:宁波康德新材料有限公司

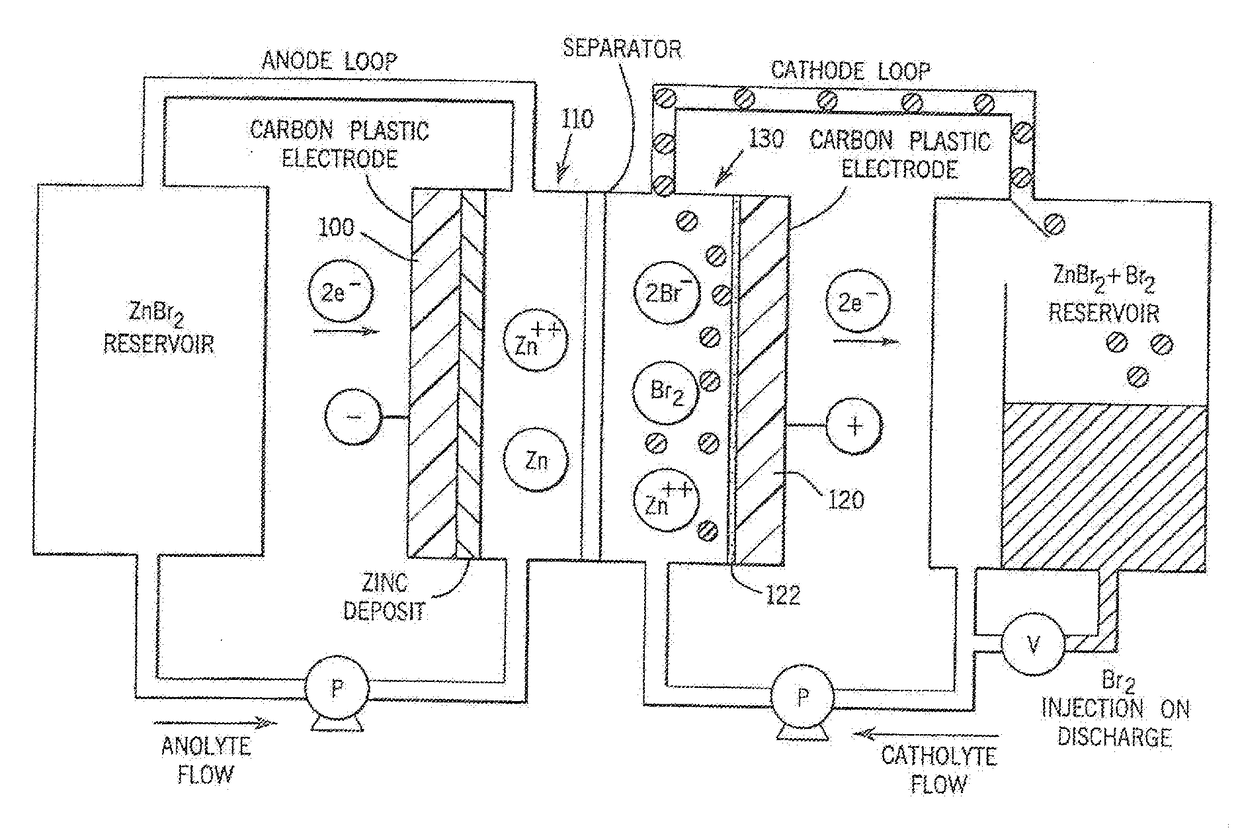

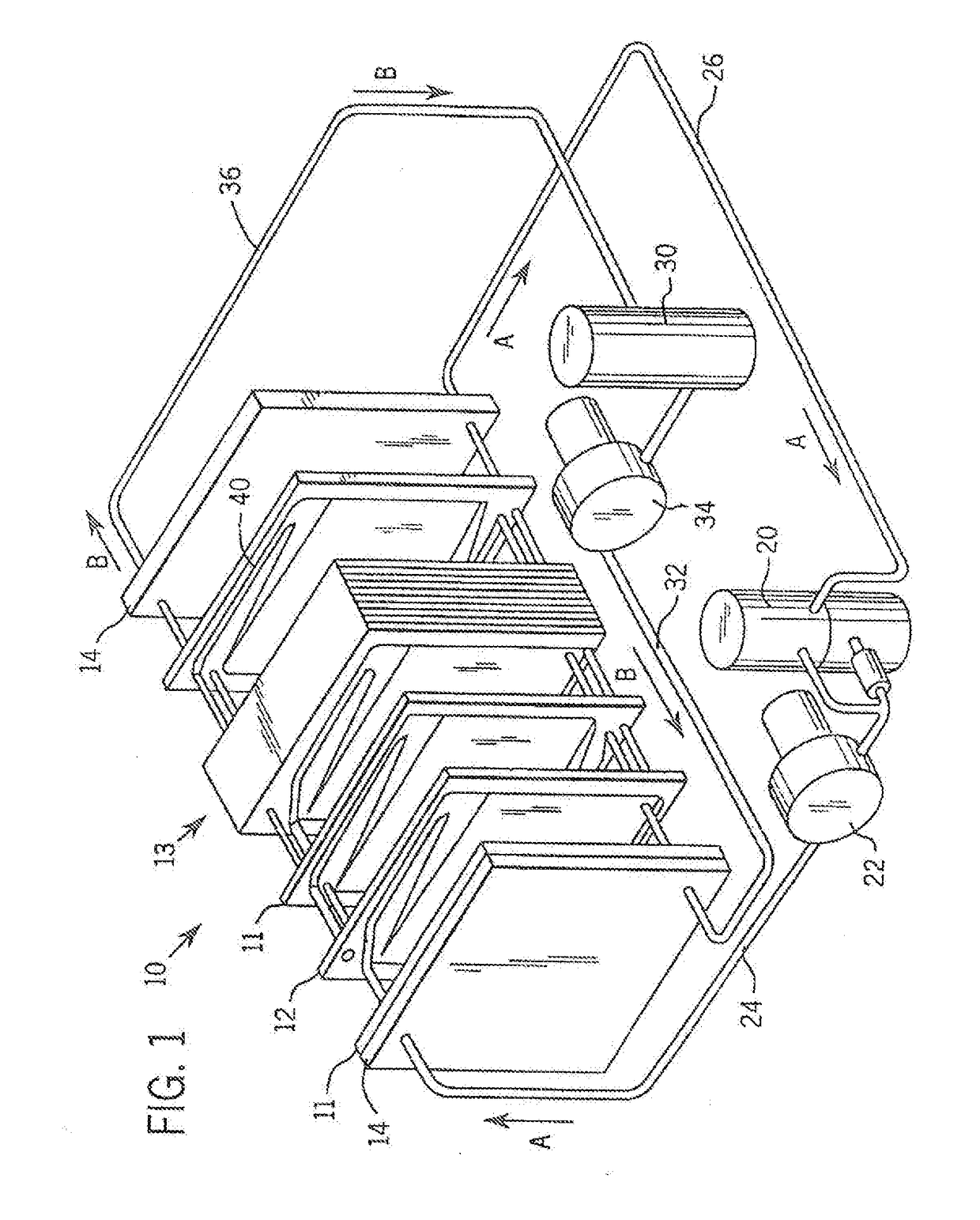

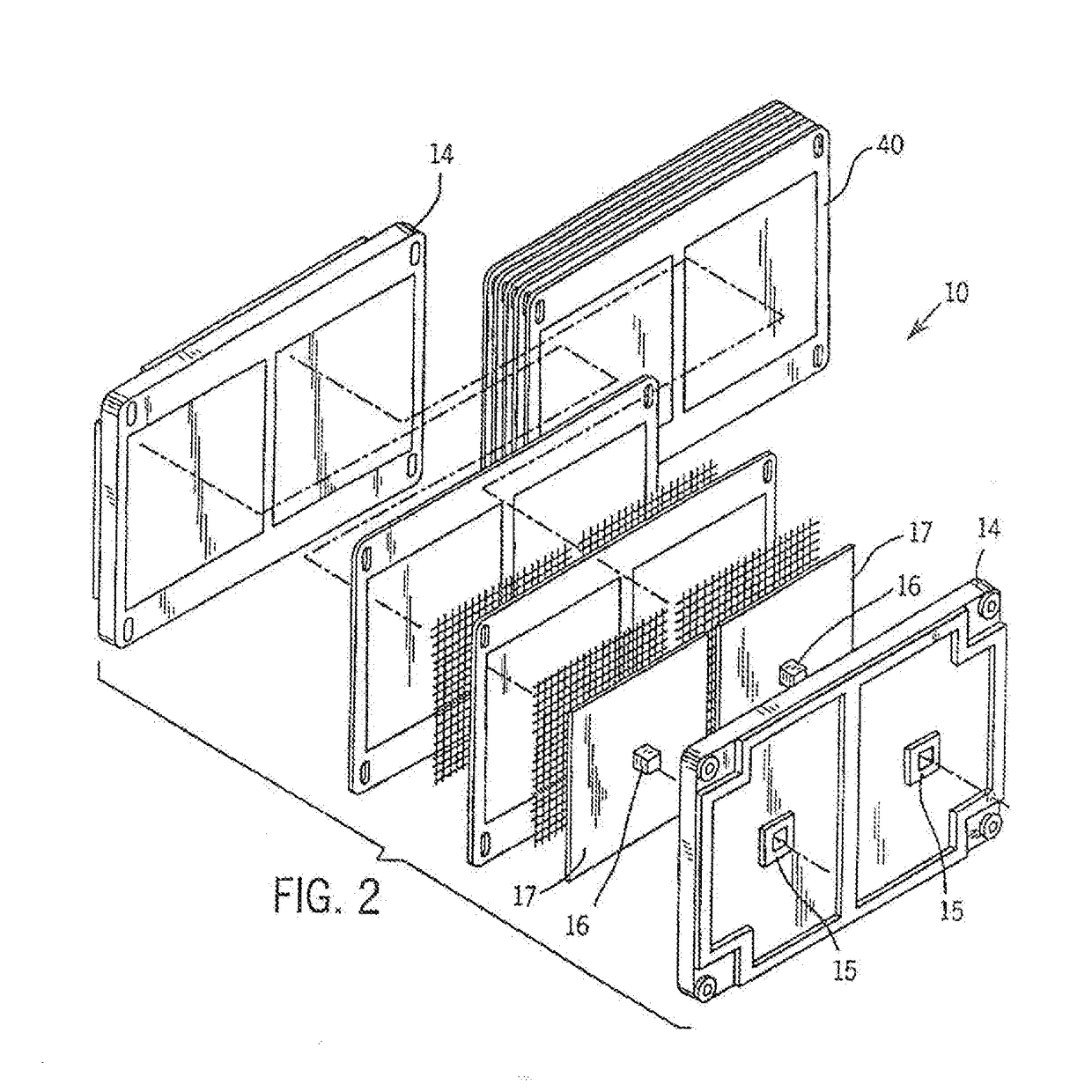

Electrolyte System For Rechargeable Flow Battery

InactiveUS20170214077A1Improve stabilityManufacturing EaseRegenerative fuel cellsAqueous electrolyte fuel cellsHalogenElectrical battery

An electrolyte system is provided for a rechargeable electrode zinc-halogen flow battery that utilizes a highly similar or identical electrolyte positioned on both sides of an ion-conducting membrane. The electrolyte system containing zinc salts, electrolyte conductivity enhancer, and an appropriate amount of bromine complexing agent achieves significant improvements on battery energy efficiency, self-discharge rate, and electrolyte level cycle stability over the prior art electrolyte systems.

Owner:FAITH TECH INC

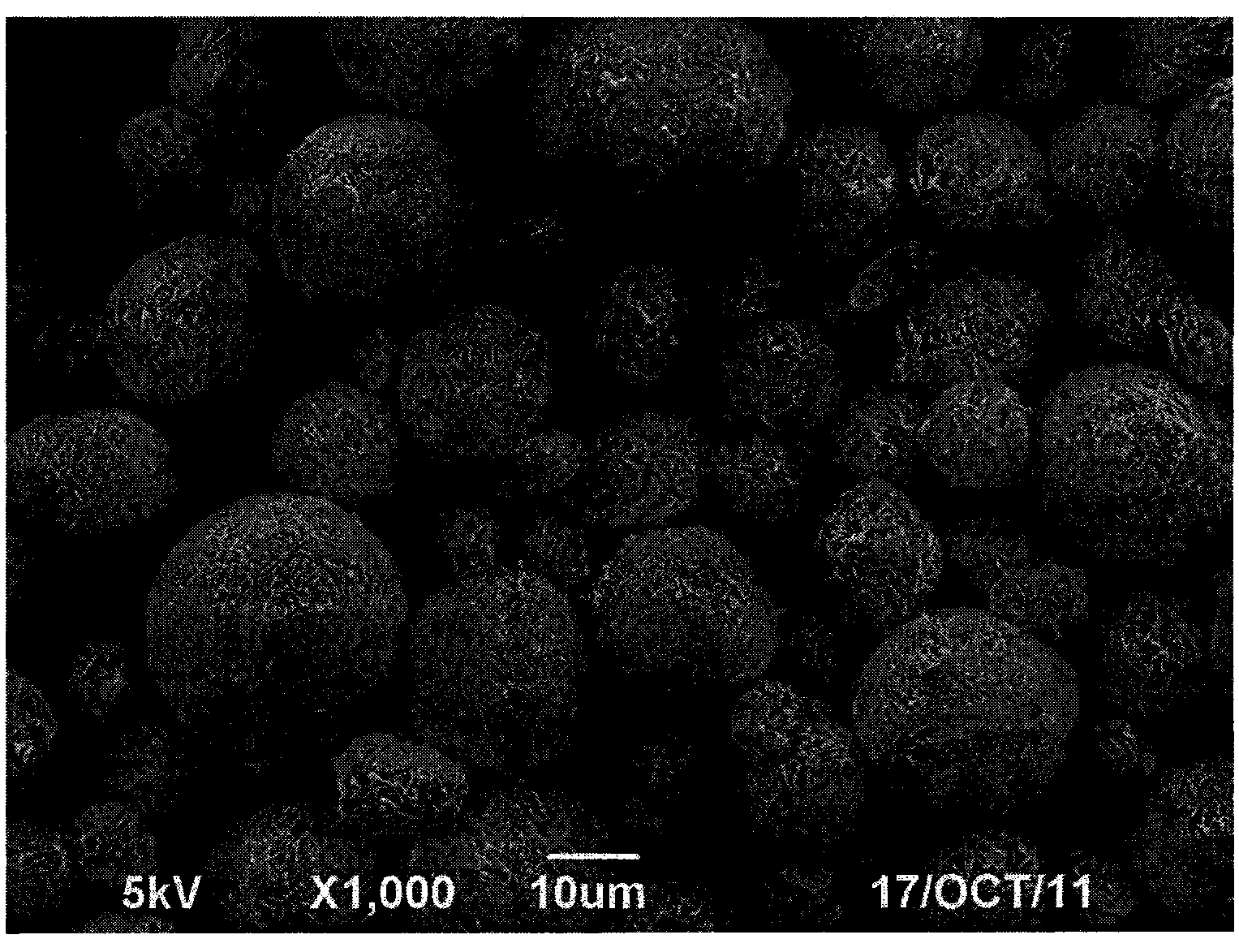

Preparation technology for spherical lithium cobalt oxide doped with Ti, Mg and Al

InactiveCN102583585BSimple processReaction is easy to controlCell electrodesCobalt carbonatesAlkalinityCobalt(II,III) oxide

The invention relates to the field of lithium ion battery materials and particularly relates to a preparation technology for spherical lithium cobalt oxide doped with Ti, Mg and Al. According to the preparation technology, pure water serves as base solution under the conditions that temperature ranges from 40 DEG C to 80 DEG C and a stirring speed is controlled to 60-180 r / min, ammonium bicarbonate is added into the base solution to adjust the alkalinity of the base solution to range from 5 to 30, cobalt-salt mixed solution and ammonium bicarbonate solution are continuously pumped into the base solution in parallel flow and are subjected to sedimentation reaction under the temperature of 40-80 DEG C, the solid content and the alkalinity of slurry in a reaction system are controlled, reaction feed liquid flows out continuously from an overflow gate at the upper part of a reaction kettle to enter into an ageing kettle and then is washed by a washing press and dried by a vacuum drier, spherical cobalt carbonate is subjected to primary calcination to obtain cobaltosic oxide, and the cobaltosic oxide and a lithium source are subjected to secondary calcination to obtain the spherical lithium cobalt oxide doped with Ti, Mg and Al. According to the invention, the process is simple, the reaction is easy to control, the production cost is low, the product application range is wide, and thus, the method is relatively large in production value; and the spherical lithium cobalt oxide is stable in performance and better in overcharging prevention performance.

Owner:ANHUI ALAND NEW ENERGY MATERIALS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com