Modified expanded perlite insulation board and preparation method thereof

A technology of expanded perlite and thermal insulation board, which is applied in the field of thermal insulation materials, can solve the problems of poor impact resistance and compressive strength, and high moisture absorption, and achieve the effects of good fire resistance, good thermal insulation performance, and excellent mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

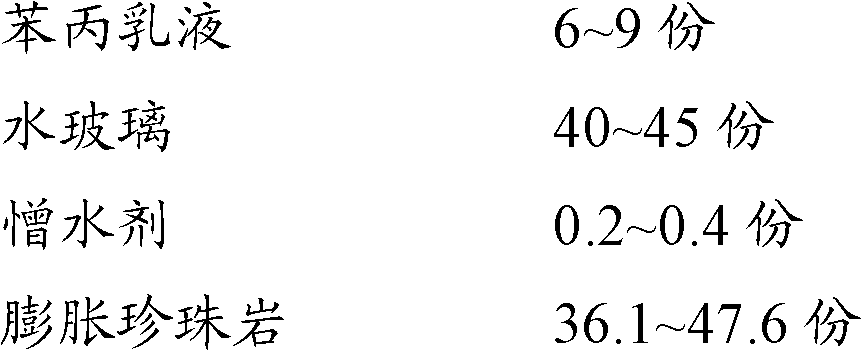

Method used

Image

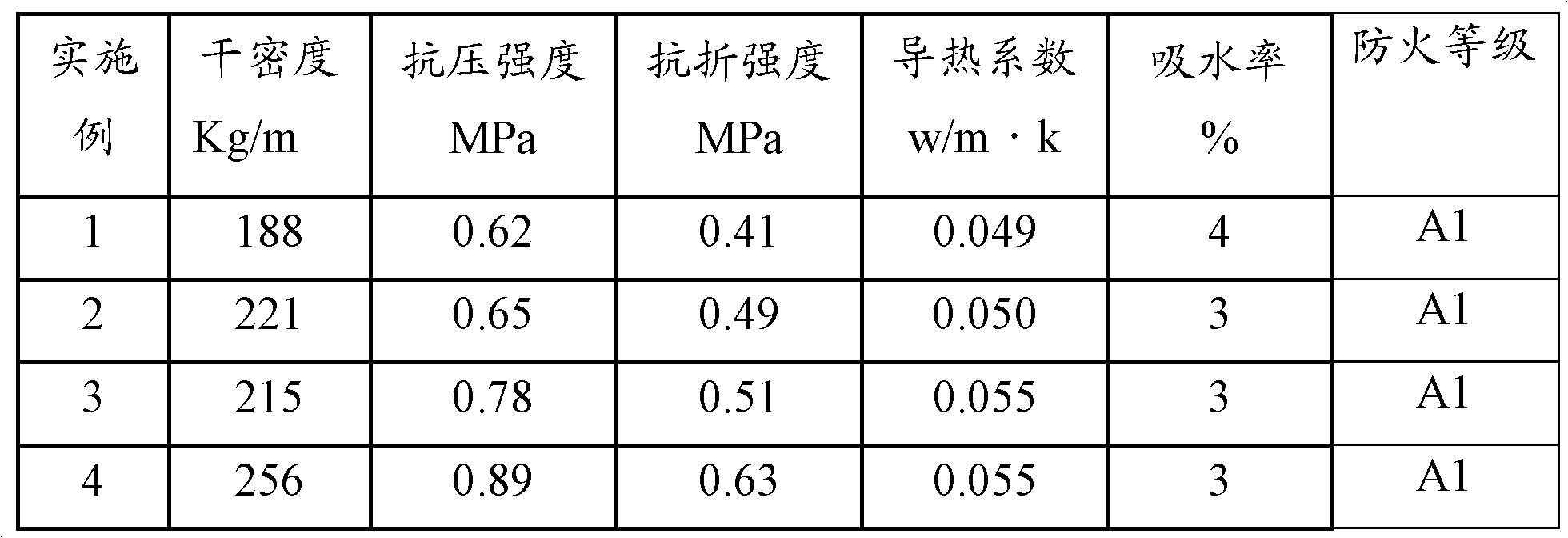

Examples

Embodiment 1

[0027] (1) Add 6 parts of distilled water, 0.2 parts of antifungal agent and 6 parts of styrene-acrylic emulsion (Germany BASF-px7035xap) to the disperser, and stir at 400 rpm for 5 minutes;

[0028] (2) Slowly add 40 parts of water glass (modulus is 3, Baume concentration °Bé is 40) to the disperser at 400rpm, stir for 10min and place in the mortar mixer;

[0029] (3) Add 0.2 parts of silicone water repellent (Germany Wacker-BS1001) and 47.6 parts of expanded perlite (bulk density 735-784N / m 3 , the thermal conductivity at room temperature is 0.03-0.04w / m k), mixed and stirred at 200rmp for 20 minutes, poured into a fixed mold and leveled, and then pressed into a plate with a hydraulic press at a pressure ratio of 2;

[0030] (4) The plates were baked in a constant temperature oven at 120° C. for 1 hour, and then packaged and put into storage after cooling.

Embodiment 2

[0032] (1) Add 9 parts of distilled water, 0.5 parts of antifungal agent and 9 parts of styrene-acrylic emulsion (Germany BASF-px7035xap) to the disperser, and stir at 400 rpm for 5 minutes;

[0033] (2) Slowly add 45 parts of water glass (modulus is 3, Baume degree Bé is 40) to the disperser at a rotating speed of 400rpm, stir for 10min and place in a mortar mixer;

[0034] (3) Add 0.4 parts of silicone water repellent (German Wacker-BS1001) and 36.1 parts of expanded perlite (bulk density 735-784N / m 3 , the thermal conductivity at room temperature is 0.03-0.04w / m k), mixed and stirred at 200rmp for 20 minutes, poured into a fixed mold and leveled, and then pressed into a plate with a hydraulic press at a pressure ratio of 2;

[0035] (4) Bake the plates in a constant temperature oven at 140°C for 1.5 hours, and pack them into storage after cooling.

Embodiment 3

[0037] (1) Add 6 parts of distilled water, 0.2 parts of antifungal agent and 6 parts of styrene-acrylic emulsion (Germany BASF-px7035xap) to the disperser, and stir at 400 rpm for 5 minutes;

[0038](2) Slowly add 40 parts of water glass (modulus is 3, Baume degree Bé is 40) to the disperser at a rotating speed of 400rpm, stir for 10min and place in a mortar mixer;

[0039] (3) Add 0.2 parts of silicone water repellent (Germany Wacker-BS1001) and 47.6 parts of expanded perlite (bulk density 735-784N / m 3 , the thermal conductivity at room temperature is 0.03~0.04w / m k), mixed and stirred at 200rmp for 20min, poured into a fixed mold and leveled, and then pressed into a plate with a hydraulic press at a pressure ratio of 2.2;

[0040] (4) Bake the plates in a constant temperature oven at 120°C for 1 hour, and pack them into storage after cooling.

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com