Calcium hexaluminate and preparation method thereof

A technology of calcium hexaaluminate and aluminate cement, which is applied in the field of refractory materials, can solve the problems of the negative impact of the use of calcium hexaaluminate, the impact on the high temperature performance of castables, and the complexity of the process, achieving low cost, excellent product performance and Stable and simple process effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

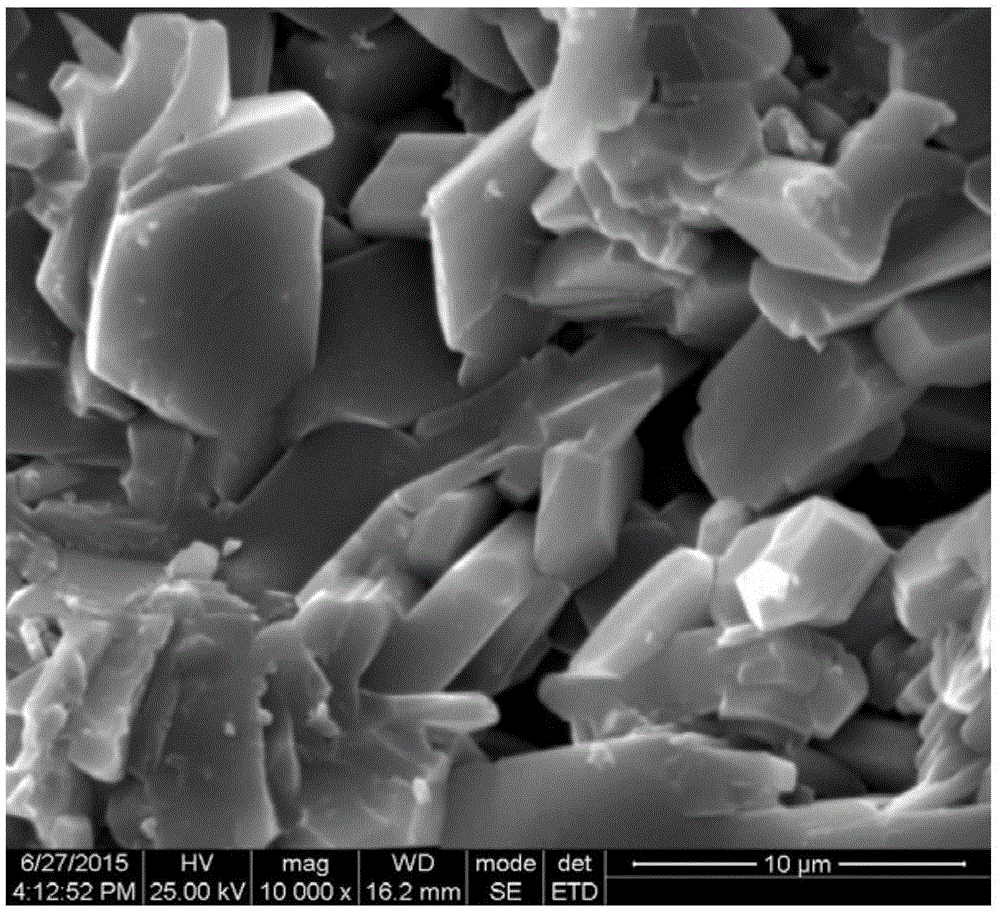

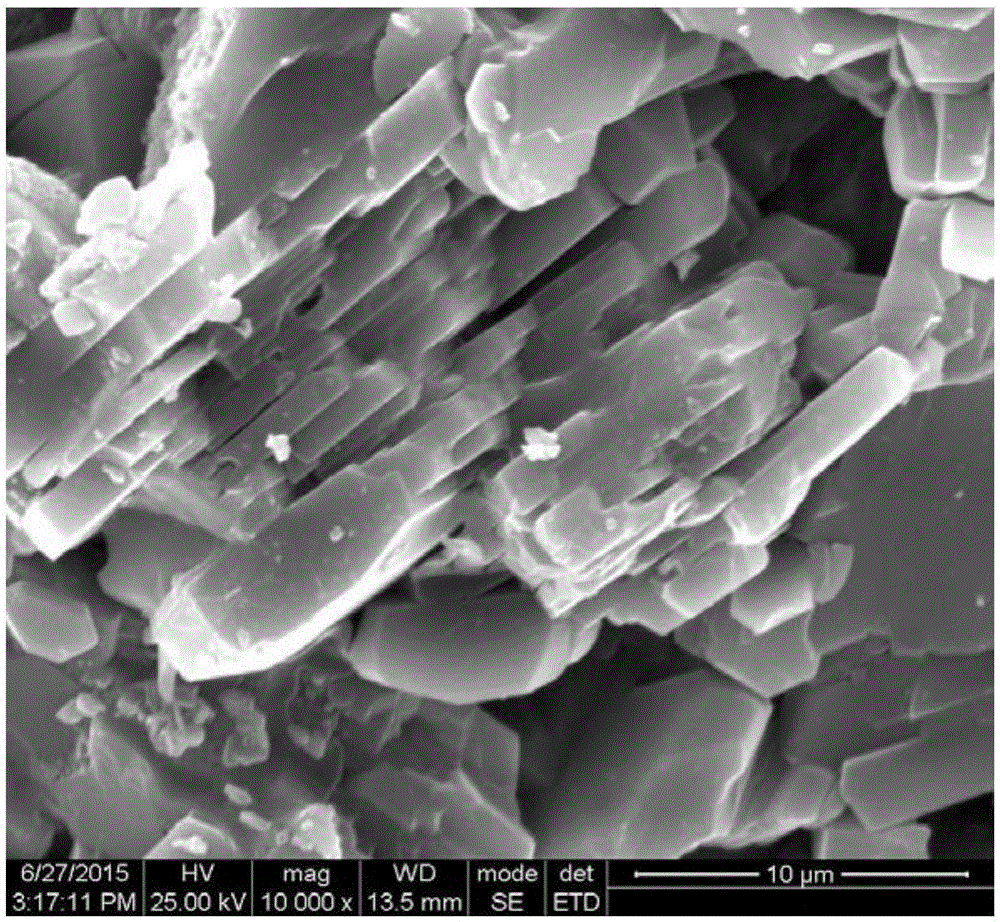

Image

Examples

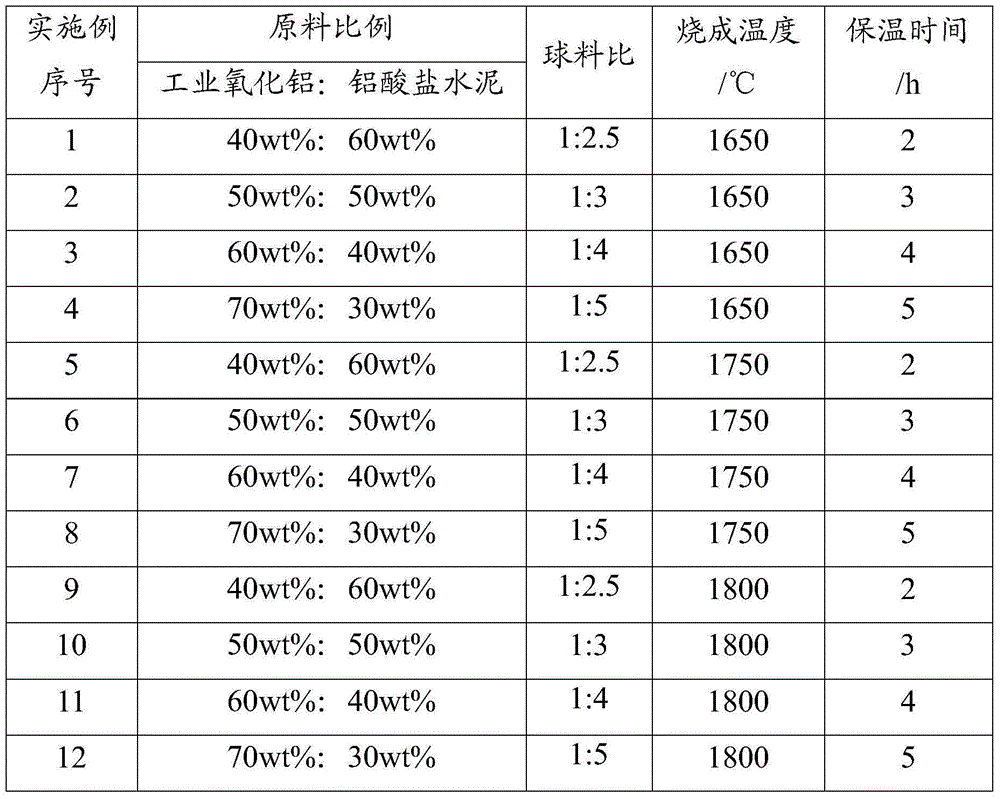

Embodiment 1~12

[0031] The preparation method of calcium hexaaluminate comprises the following steps:

[0032] (1) According to the ratio shown in Table 1, industrial alumina powder and aluminate cement are uniformly mixed in a ball mill to obtain mixed powder;

[0033] The particle size of industrial alumina powder meets: D 50 ≤20μm, D 90 ≤45μm.

[0034] CaO content in aluminate cement ≥ 20wt%, Al 2 o 3 Content≤80wt%, specific surface area≥300m 2 / kg.

[0035] (2) Continuously apply water to the mixed powder in the ball forming tray to obtain cue balls, and then continuously apply water to the cue ball and mixed powder in the ball forming barrel to obtain green balls.

[0036] (3) Dry the raw balls in a drying bin at 250°C, and then burn them at a corresponding firing temperature to obtain semi-finished products of calcium hexaaluminate;

[0037] (4) After the semi-finished product of calcium hexaaluminate is crushed and screened by a crusher, the finished product of calcium hexaalumi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| crystal size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com