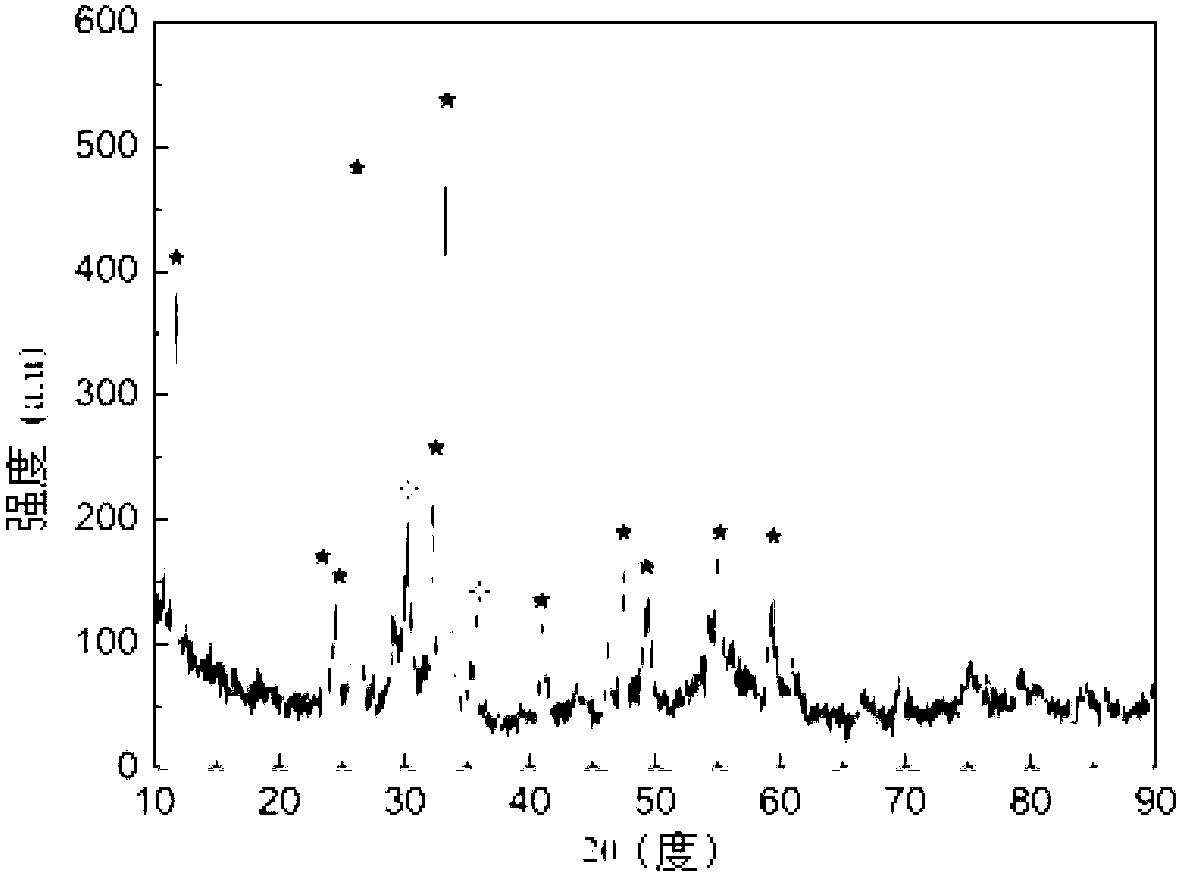

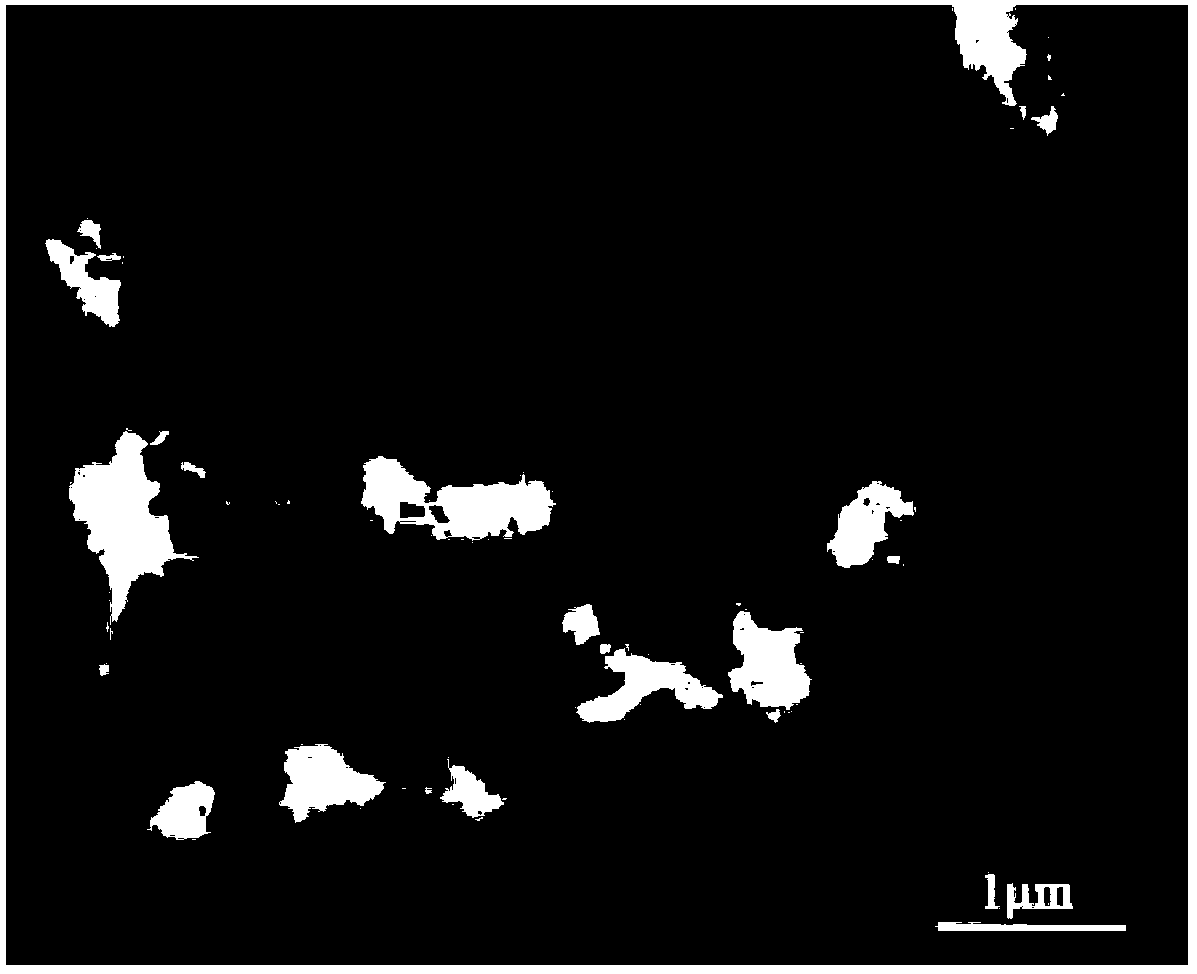

Preparation method of Fe2O3/BiOCl nano-composite powder

A nanocomposite powder, fe2o3 technology, applied in the direction of nanotechnology, nanotechnology, chemical instruments and methods, etc., can solve the problems of inconspicuous pearlescent effect, and achieve the effect of good pearlescent effect, low cost and simple synthesis process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0015] Specific implementation mode one: Fe in this implementation mode 2 o 3 The preparation method of / BiOCl nanocomposite powder is carried out according to the following steps:

[0016] 1. Dissolving bismuth nitrate in nitric acid, stirring evenly, adding water to dilute to obtain bismuth nitrate solution, the concentration of bismuth nitrate in the bismuth nitrate solution is 0.0001-0.02mol / L, and the concentration of nitric acid is 0.02-10mol / L;

[0017] 2. Prepare an ammonia solution with a concentration of 0.001-2mol / L;

[0018] 3. Add the ammonia water and the bismuth nitrate solution dropwise into the water container while stirring, and control the pH value of the system to be 7-10 during the dropwise addition to obtain the bismuth hydroxide colloid;

[0019] 4. Dissolving ferric chloride into water to obtain a ferric chloride solution with a concentration of 0.005 to 0.02mol / L;

[0020] 5. Polyethylene glycol is dissolved in water to obtain an aqueous solution of...

specific Embodiment approach 2

[0023] Embodiment 2: This embodiment differs from Embodiment 1 in that the concentration of bismuth nitrate in the bismuth nitrate solution in step 1 is 0.001-0.015 mol / L, and the concentration of nitric acid is 0.2-8 mol / L. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0024] Embodiment 3: This embodiment differs from Embodiment 1 or Embodiment 2 in that the concentration of bismuth nitrate in the bismuth nitrate solution in step 1 is 0.008 mol / L, and the concentration of nitric acid is 0.9 mol / L. Others are different from the first or second specific embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com