Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

50 results about "Bismuth germanate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Bismuth germanium oxide or bismuth germanate is an inorganic chemical compound of bismuth, germanium and oxygen. Most commonly the term refers to the compound with chemical formula Bi₄Ge₃O₁₂ (BGO), with the cubic evlitine crystal structure, used as a scintillator. (The term may also refer to a different compound with formula Bi₁₂GeO₂₀, an electro-optical material with sillenite structure, and Bi₂Ge₃O₉.)

Nanocomposite scintillator, detector, and method

InactiveUS20080093557A1Material analysis by optical meansLuminescent compositionsSodium iodideTungstate

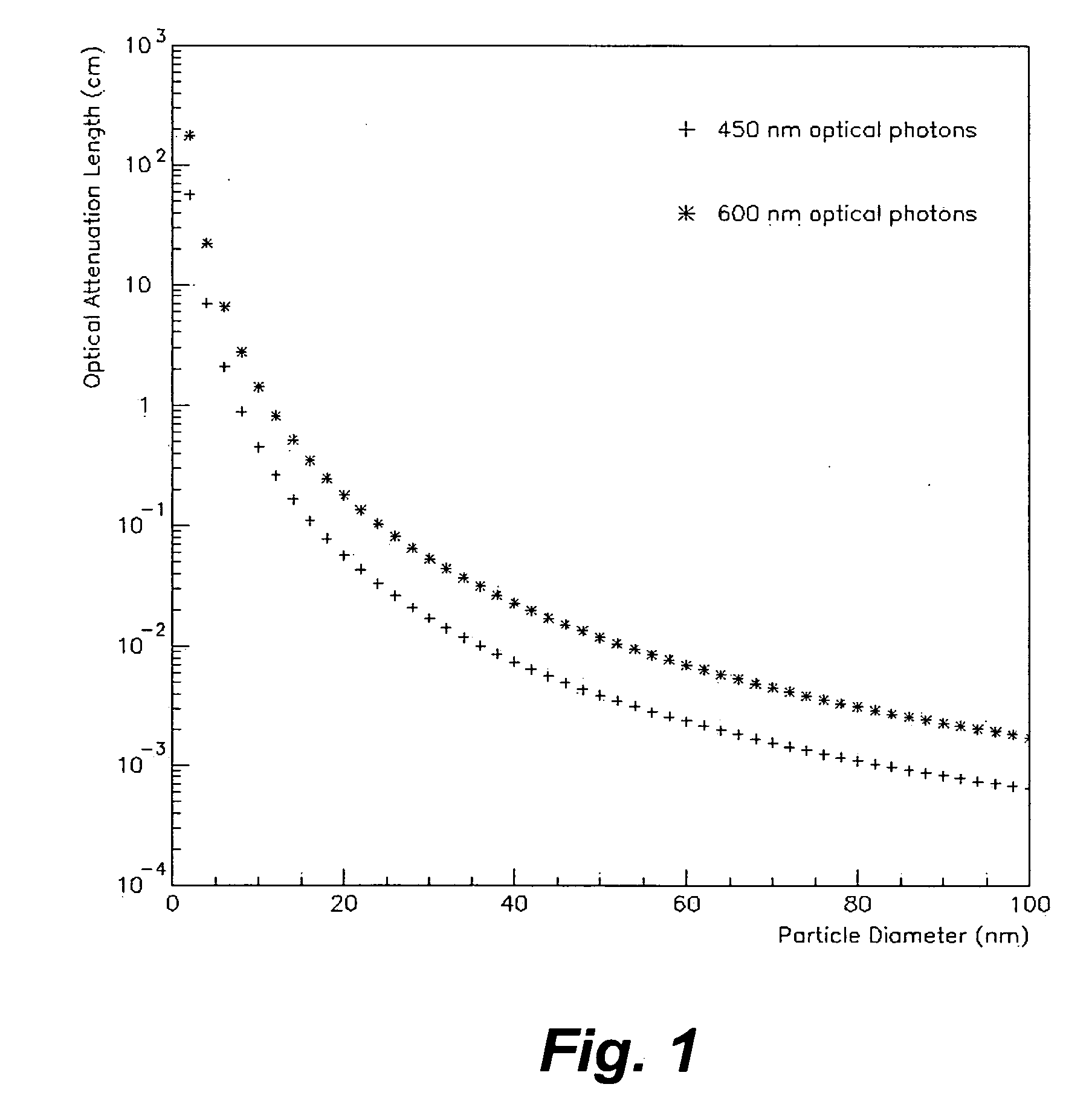

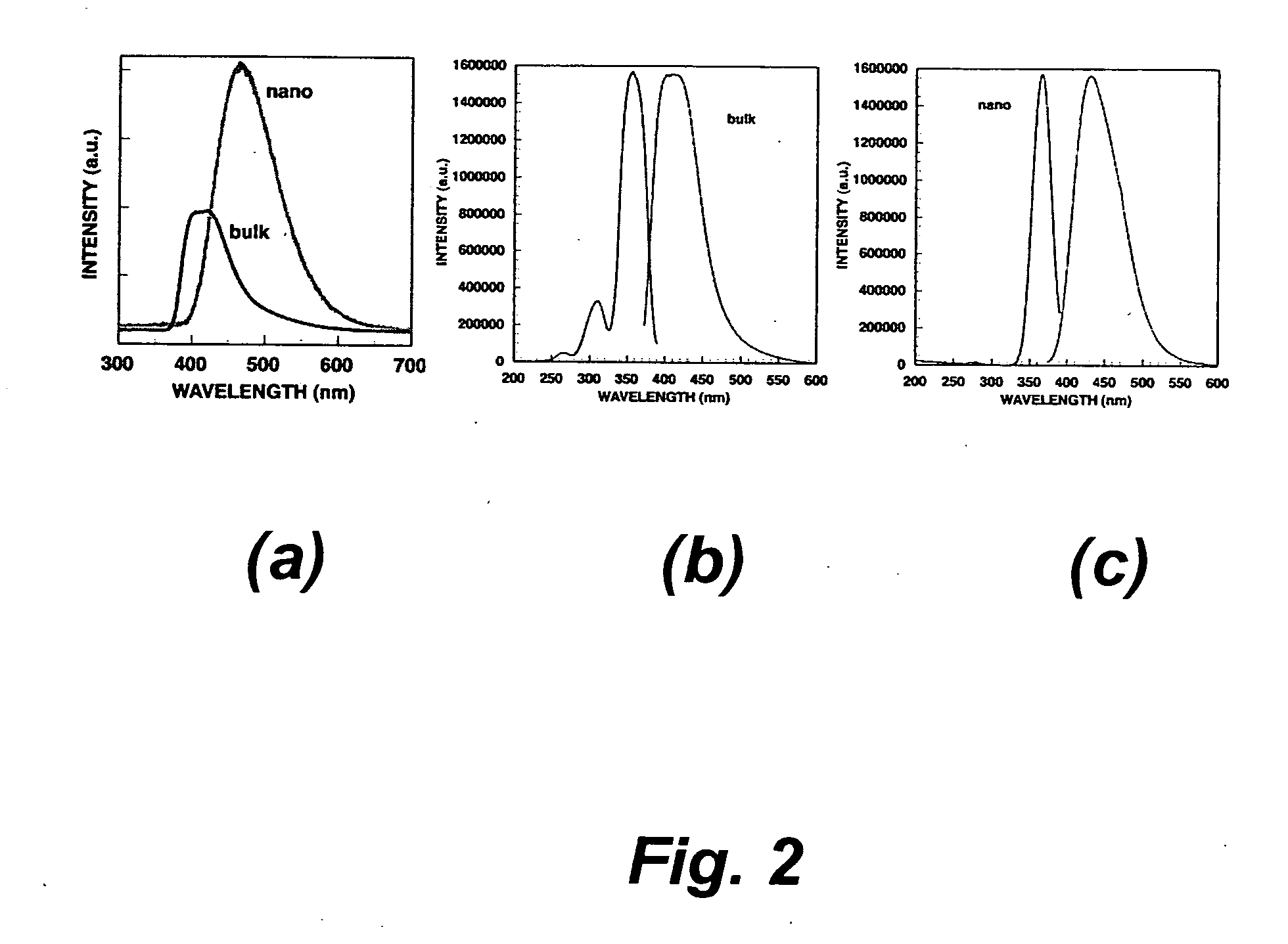

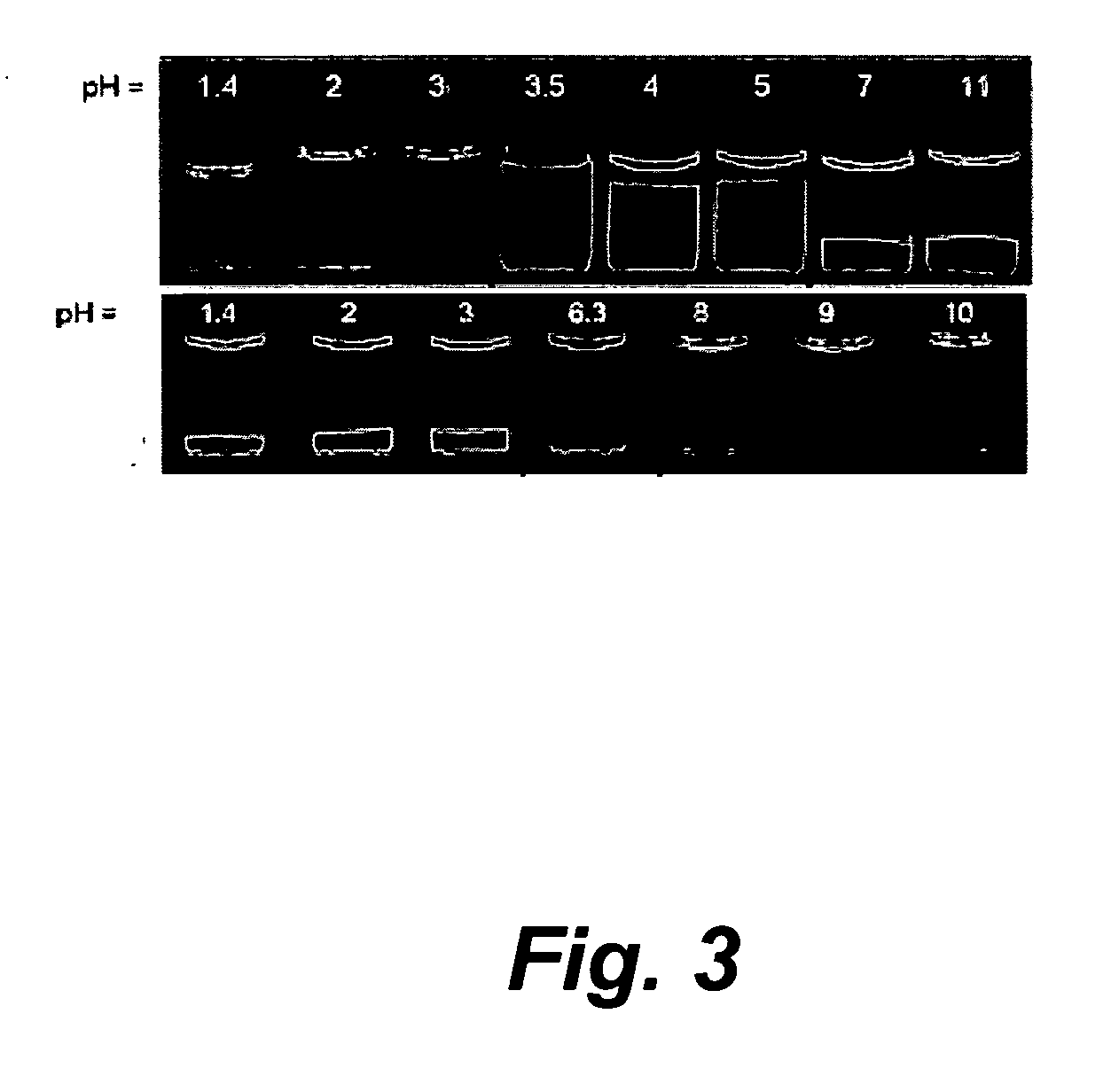

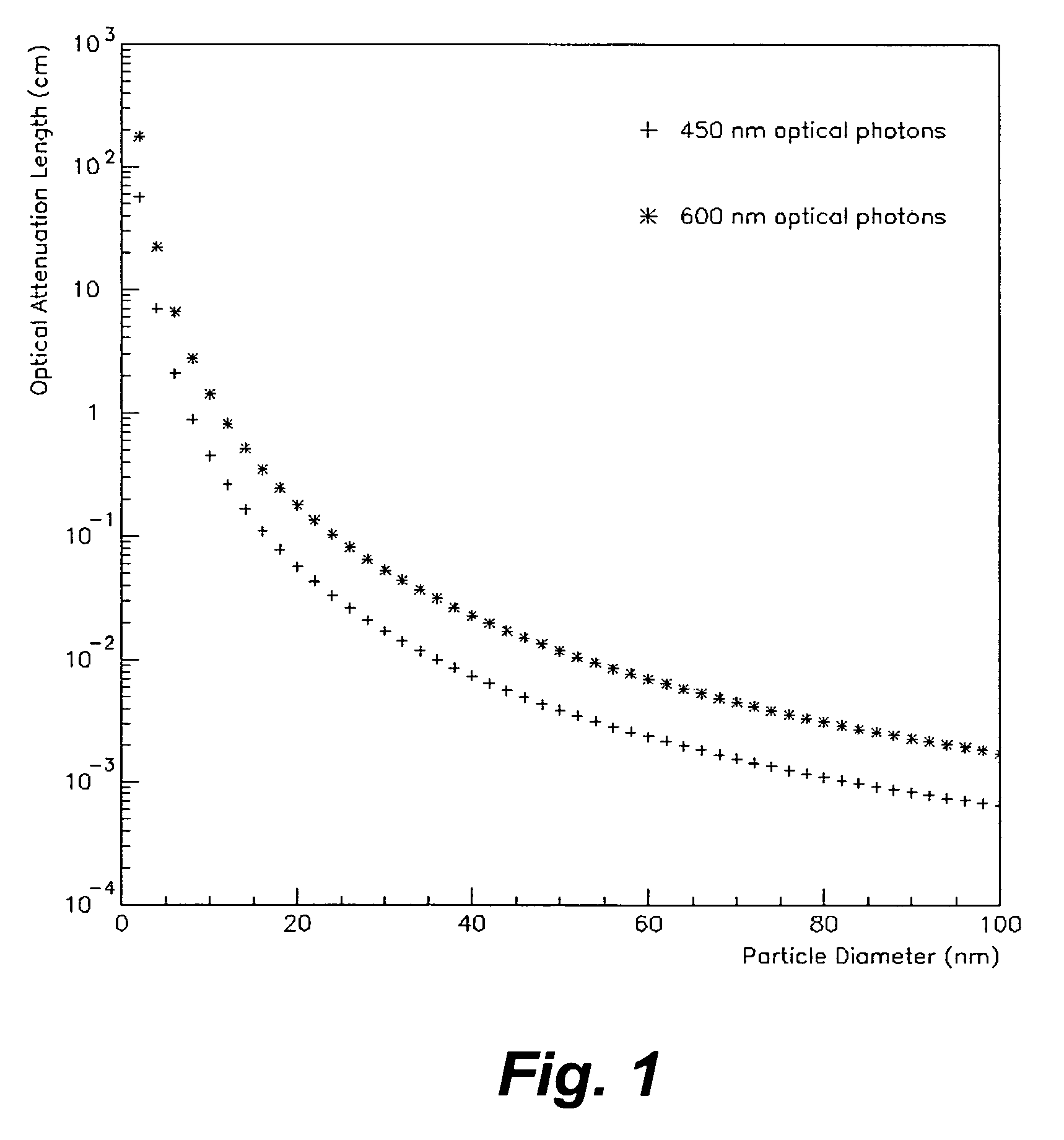

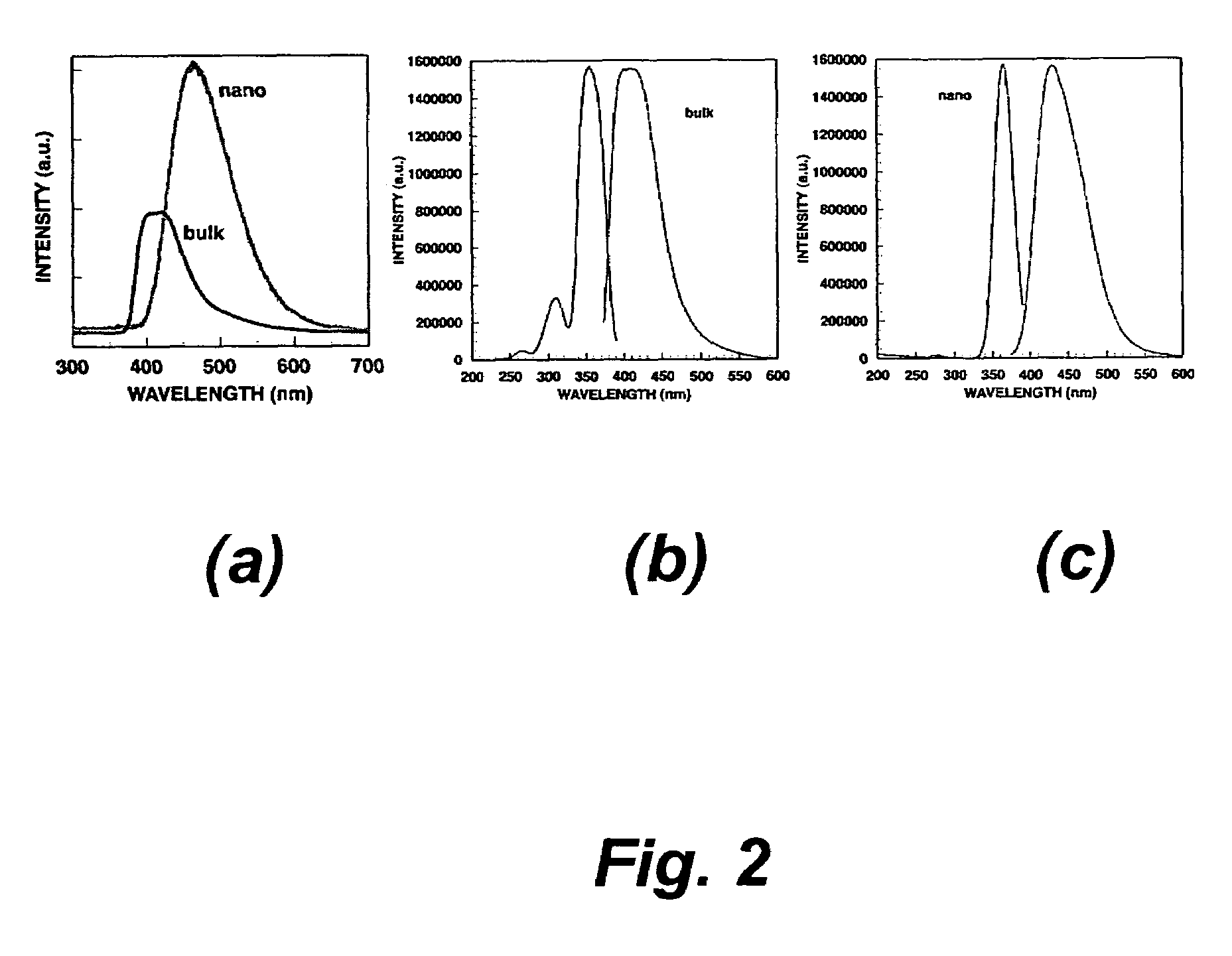

A compact includes a mixture of a solid binder and at least one nanopowder phosphor chosen from yttrium oxide, yttrium tantalate, barium fluoride, cesium fluoride, bismuth germanate, zinc gallate, calcium magnesium pyrosilicate, calcium molybdate, calcium chlorovanadate, barium titanium pyrophosphate, a metal tungstate, a cerium doped nanophosphor, a bismuth doped nanophosphor, a lead doped nanophosphor, a thallium doped sodium iodide, a doped cesium iodide, a rare earth doped pyrosilicate, or a lanthanide halide. The compact can be used in a radiation detector for detecting ionizing radiation.

Owner:RGT UNIV OF CALIFORNIA

Nanocomposite scintillator, detector, and method

A compact includes a mixture of a solid binder and at least one nanopowder phosphor chosen from yttrium oxide, yttrium tantalate, barium fluoride, cesium fluoride, bismuth germanate, zinc gallate, calcium magnesium pyrosilicate, calcium molybdate, calcium chlorovanadate, barium titanium pyrophosphate, a metal tungstate, a cerium doped nanophosphor, a bismuth doped nanophosphor, a lead doped nanophosphor, a thallium doped sodium iodide, a doped cesium iodide, a rare earth doped pyrosilicate, or a lanthanide halide. The compact can be used in a radiation detector for detecting ionizing radiation.

Owner:RGT UNIV OF CALIFORNIA

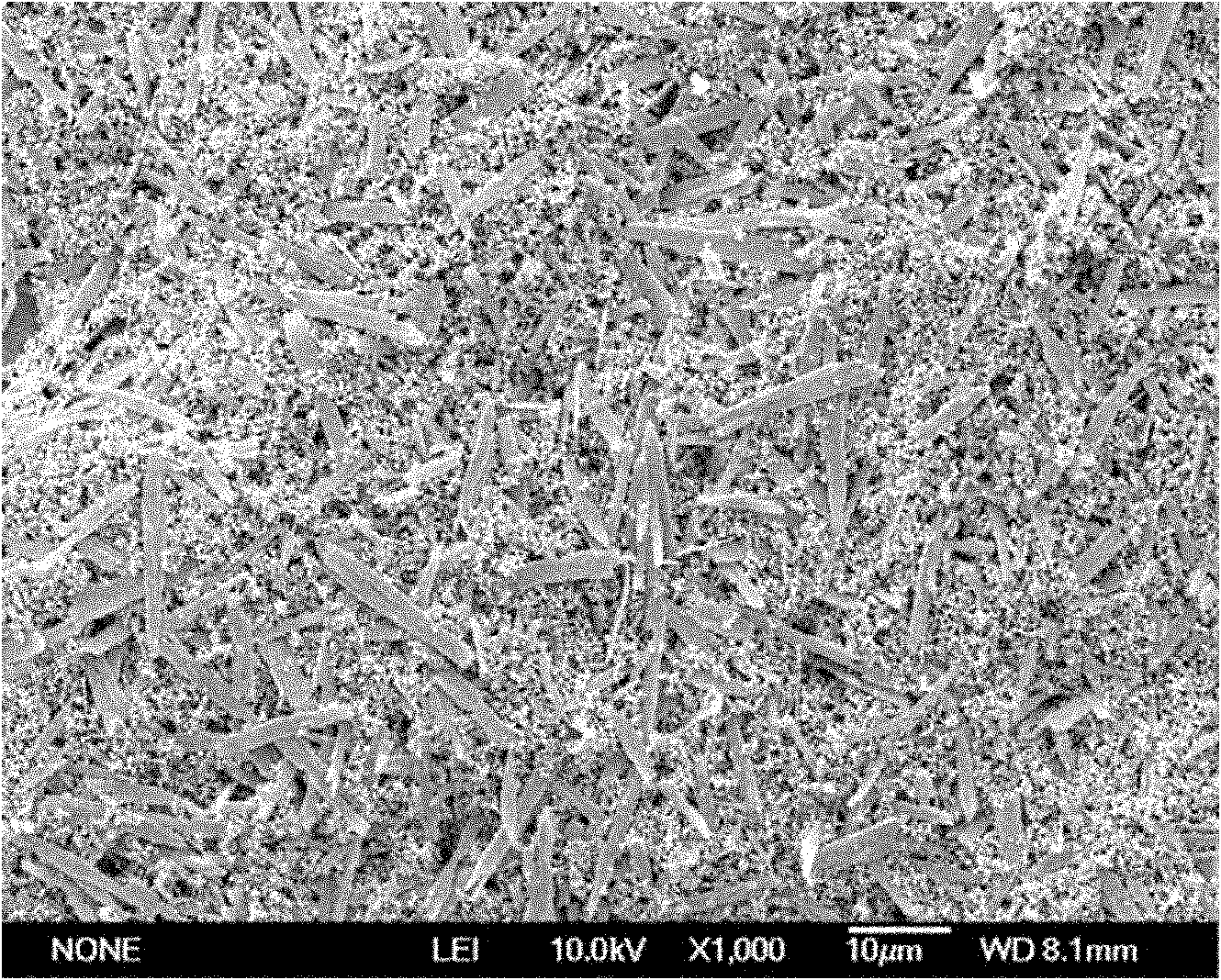

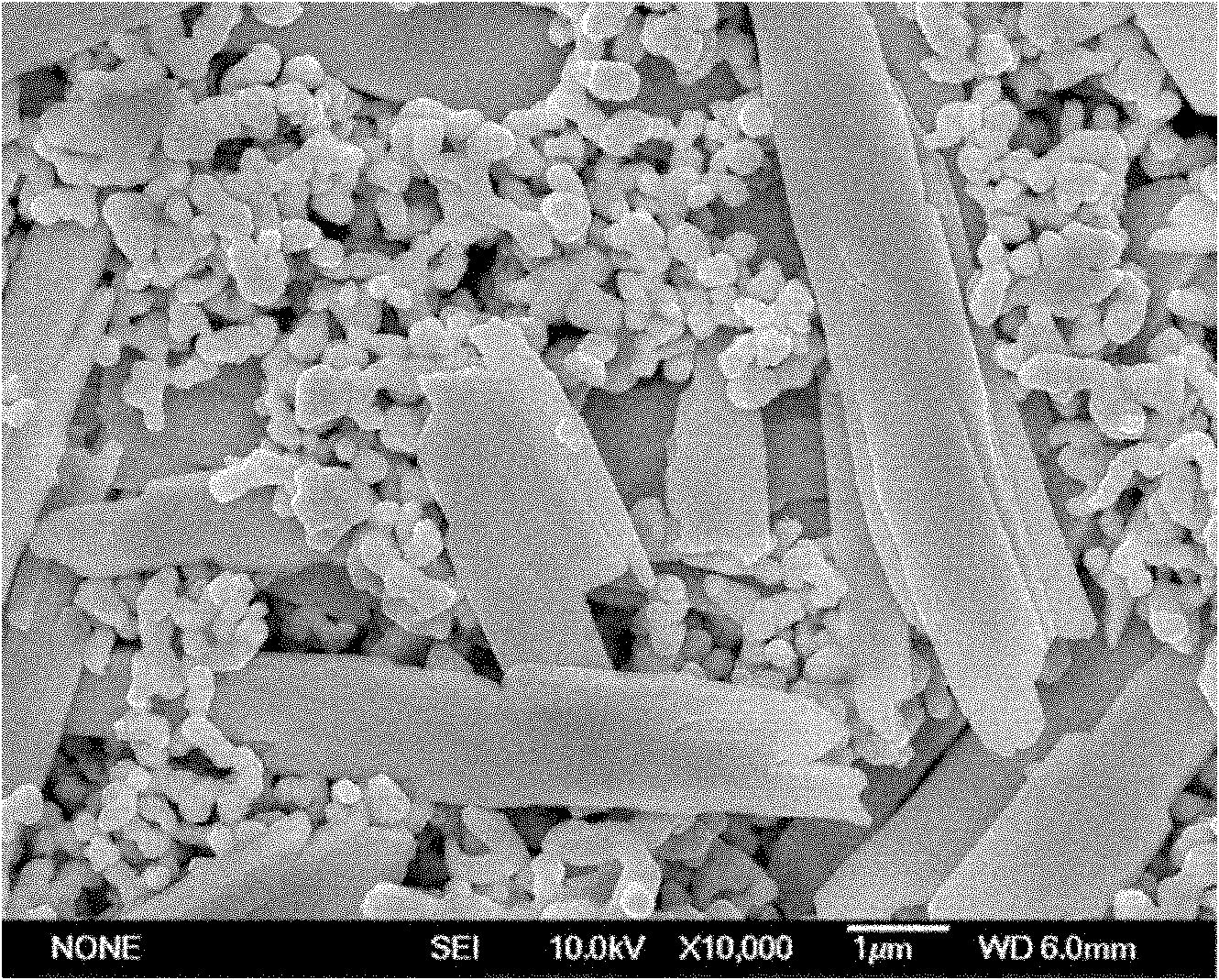

Bismuth germanate nanometer powder preparation method

InactiveCN1807261AExpand the photoresponse rangeOvercoming the characteristics of uneven mixing in sinteringBismuth compoundsMetal/metal-oxides/metal-hydroxide catalystsOrganic solventBiological activation

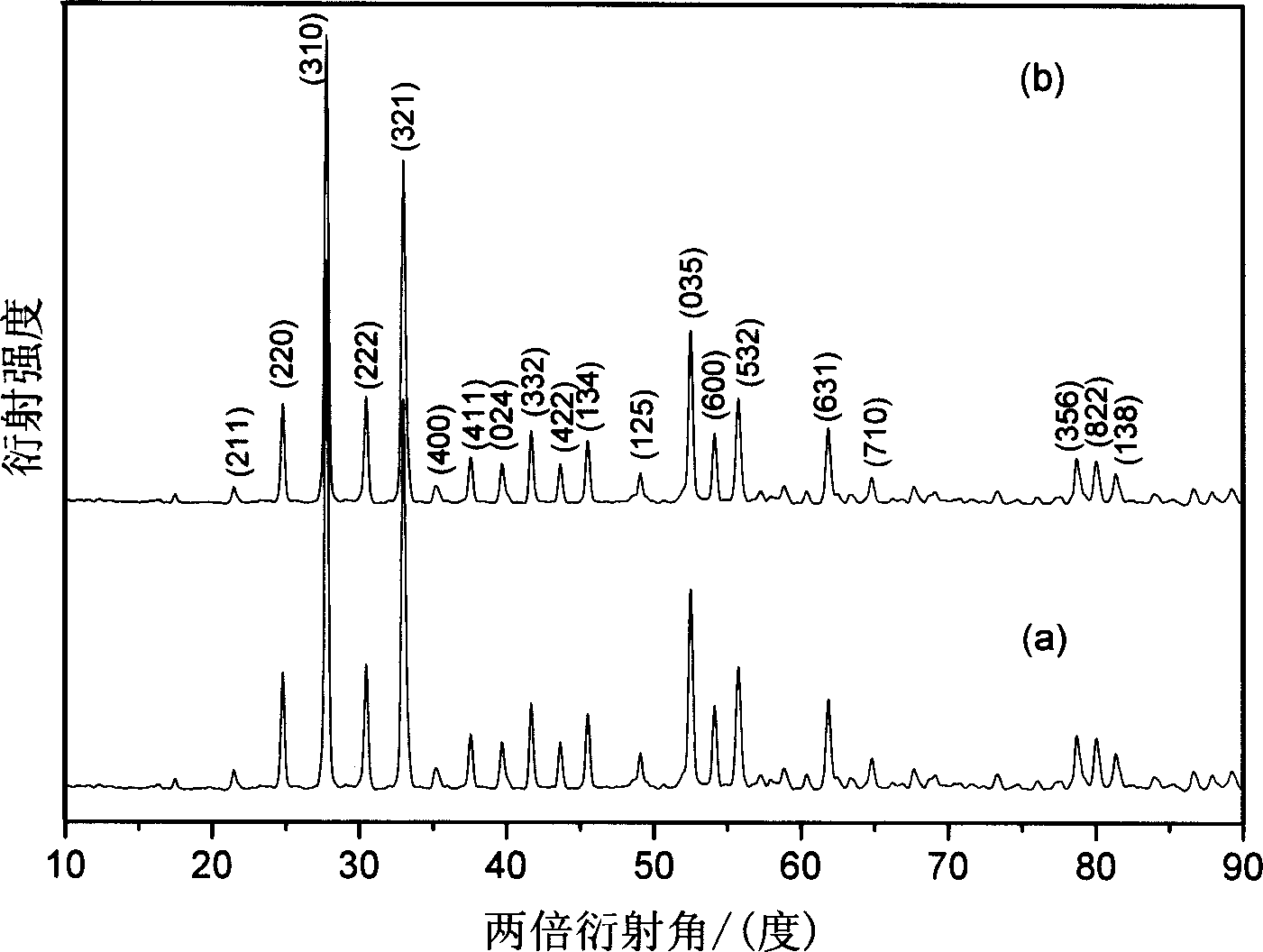

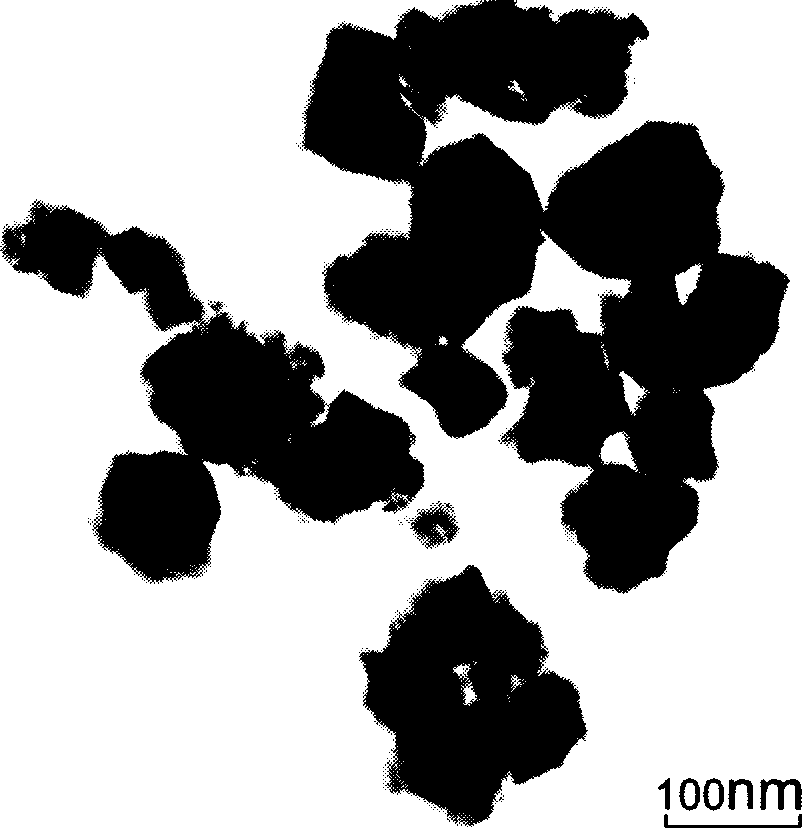

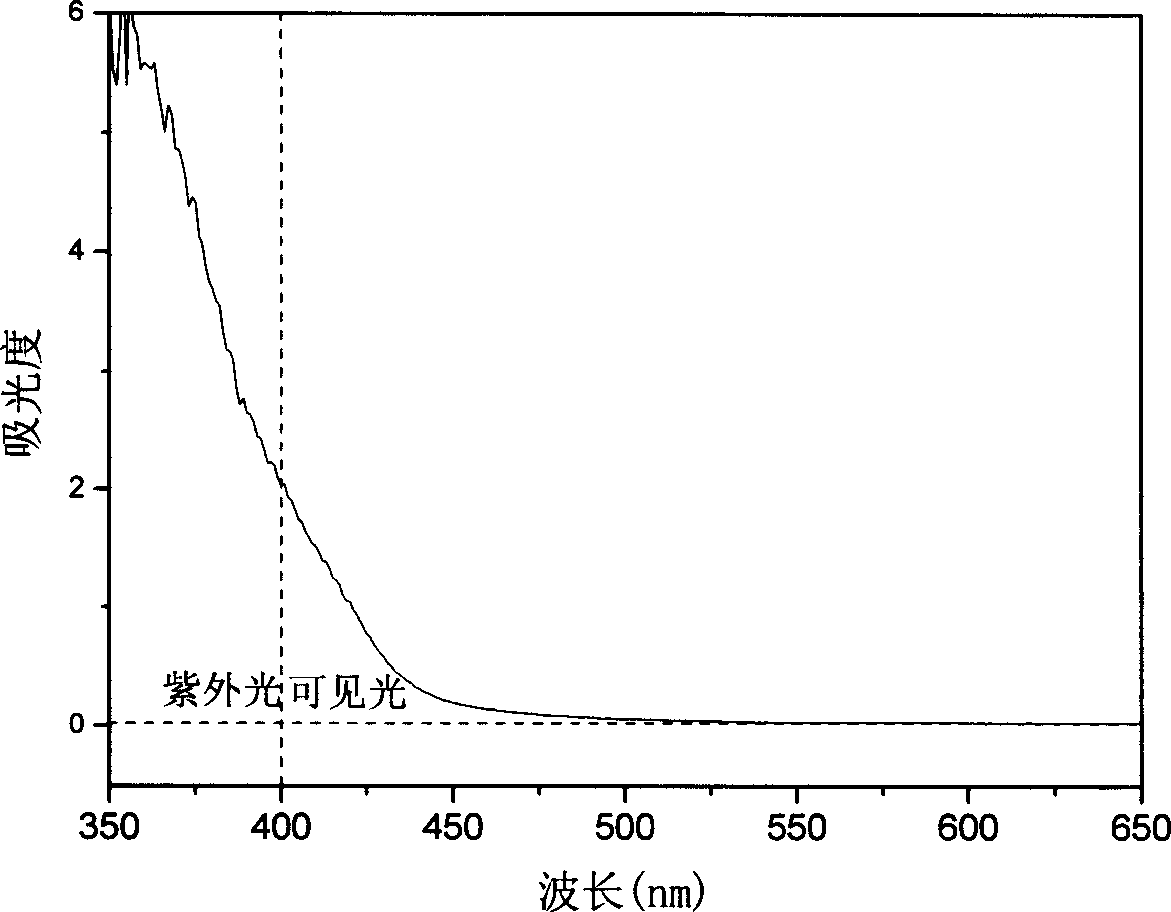

The invention relates to a preparation method for nano bismuth germanate powder, which comprises: dissolving the bismuth salt into organic solvent with concentration as 0. 5~5M / L; adding Ge-contained compound by mole ratio to bismuth as 1: 12 into the solution; stirring and forming even sol; evaporating on normal or negative pressure to the sol to obtain the dried precursor powder; finally, sintering the powder on aerobic environment to obtain the final product. This invention needs low temperature and short time to prepare the Bi12GeO20 powder with high-efficient photocatalysis activation.

Owner:SHANGHAI JIAO TONG UNIV

Bismuth silicate-germanate mixed crystal and preparation method thereof

InactiveCN102011187AImprove flicker performanceReduce manufacturing costPolycrystalline material growthFrom frozen solutionsCruciblePhysical chemistry

The invention discloses a bismuth silicate-germanate mixed crystal and a preparation method thereof, belonging to the single crystal field. The molecular formula of the bismuth silicate-germanate mixed crystal is Bi4Si3-xGexO12. The preparation method comprises the following steps: using high-purity Bi2O3, SiO2 and GeO2 as raw materials to fully grind, presinter and obtain a polycrystalline material; and placing seed crystal at the bottom of a crucible in advance, placing the synthesized polycrystalline material in the crucible, and transferring the crucible to a crystal growing furnace while controlling the temperature to 1050-1150 DEG C, the temperature gradient of the solid-liquid interface to 20-50 DEG C / cm and the growth velocity to 0.2-0.5mm / h. The raw material components of the bismuth silicate-germanate mixed crystal provided by the invention are adjustable and are distributed evenly; the mixed crystal has the scintillation property of bismuth silicate and the scintillation property of bismuth germanate, the mixed crystal has large size; the preparation method adopts stable temperature field and simple processing equipment; and multicrystal can grow at the same time, the growth efficiency of the mixed crystal is high, the production cost is low and the mixed crystal is suitable for industrial production.

Owner:SHANGHAI INST OF TECH

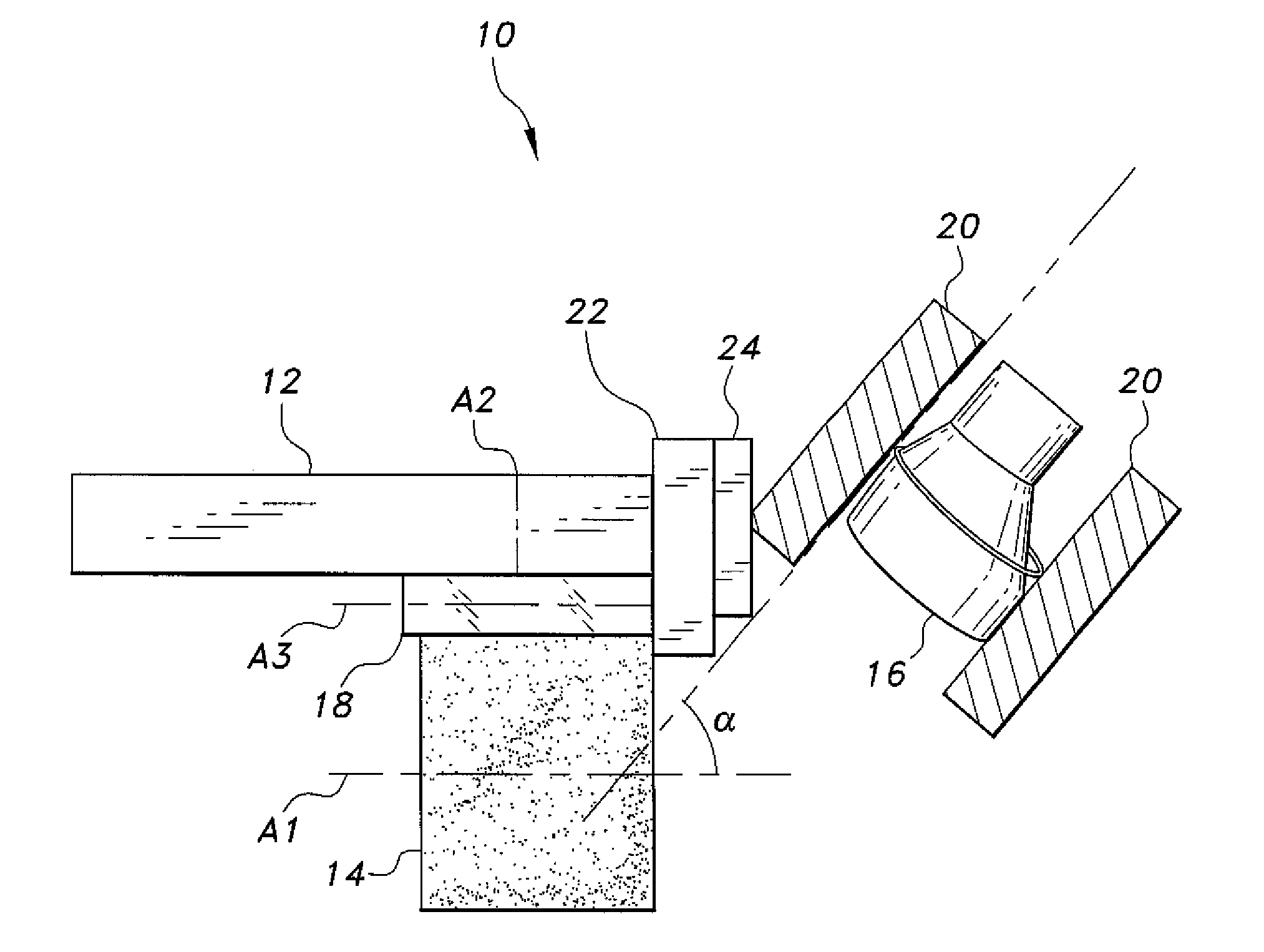

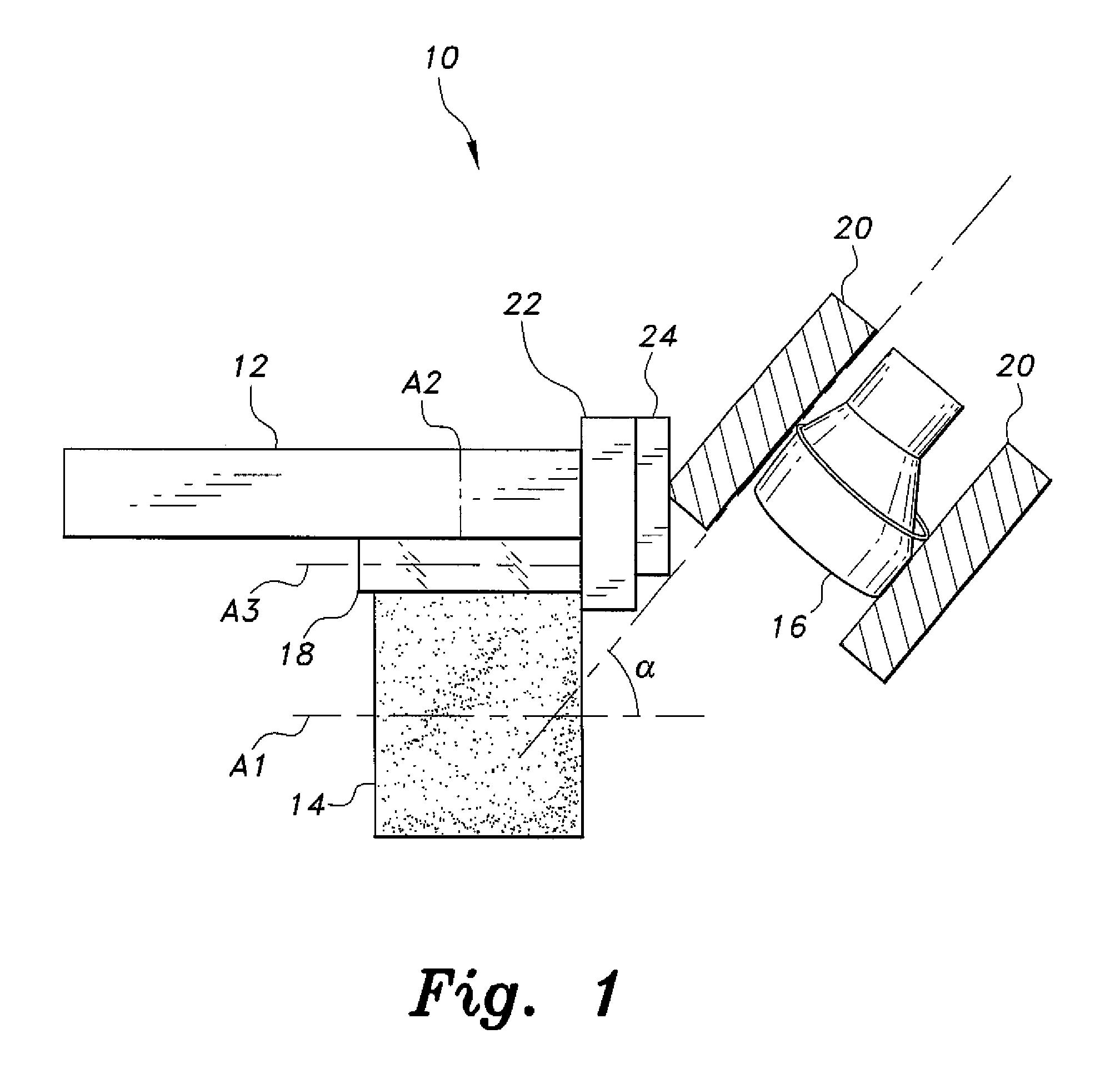

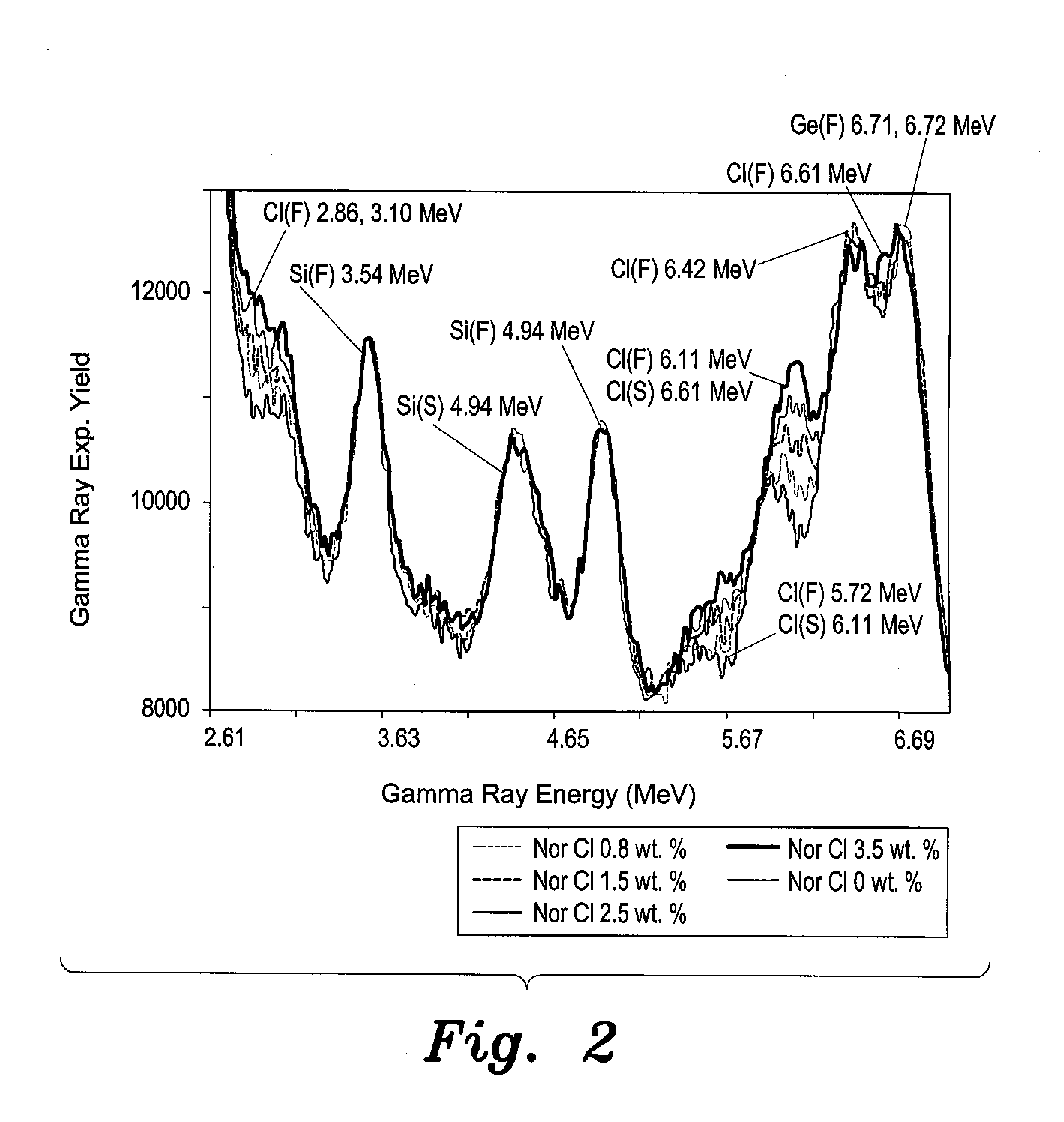

System and method for measuring chlorine concentration in fly ash cement concret

InactiveUS20140346366A1Readily apparentMaterial analysis using wave/particle radiationMaterial analysis by optical meansAxis of symmetryBismuth germanate

The system for measuring chlorine concentration in fly ash cement concrete utilizes a portable neutron generator and a gamma-ray detector for performing prompt gamma neutron activation analysis of chlorine concentration in a fly ash cement concrete specimen. The system includes a portable neutron generator for generating a pulsed neutron beam having a neutron energy of approximately 2.5 MeV and a gamma-ray detector, such as a bismuth germanate (BGO) gamma-ray detector. A moderator having opposed first and second faces is further provided. The first face is positioned adjacent a target plane of the portable neutron generator, and the second face is adapted for positioning adjacent the fly ash cement concrete specimen. A detection axis of the gamma-ray detector is angled at approximately 45° with respect to an axis of symmetry of the fly ash cement concrete specimen.

Owner:KING FAHD UNIVERSITY OF PETROLEUM AND MINERALS

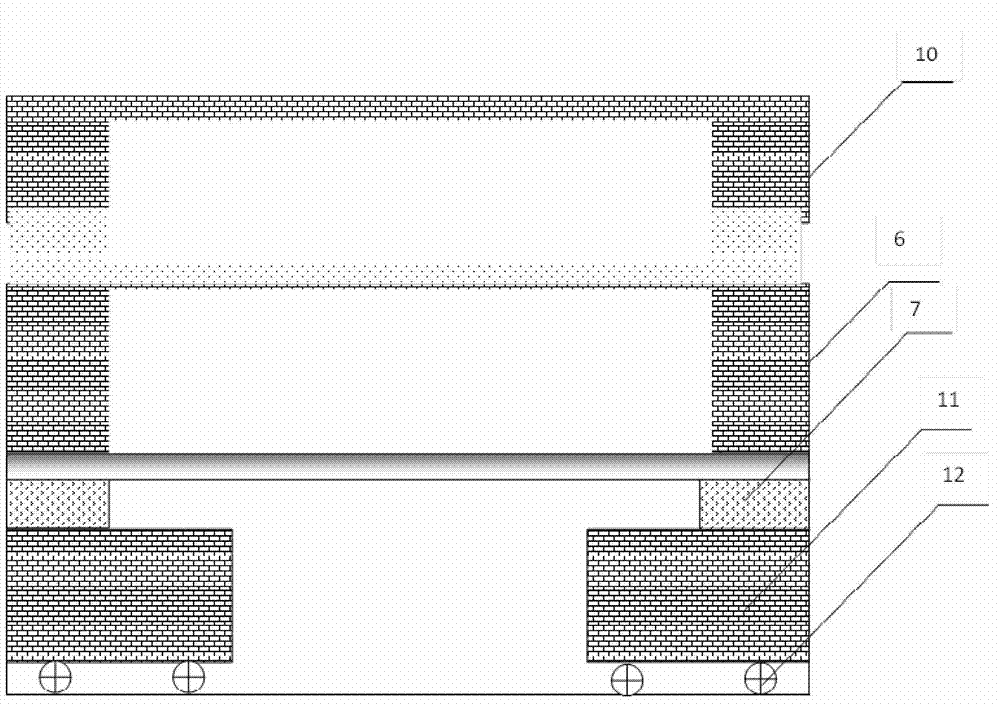

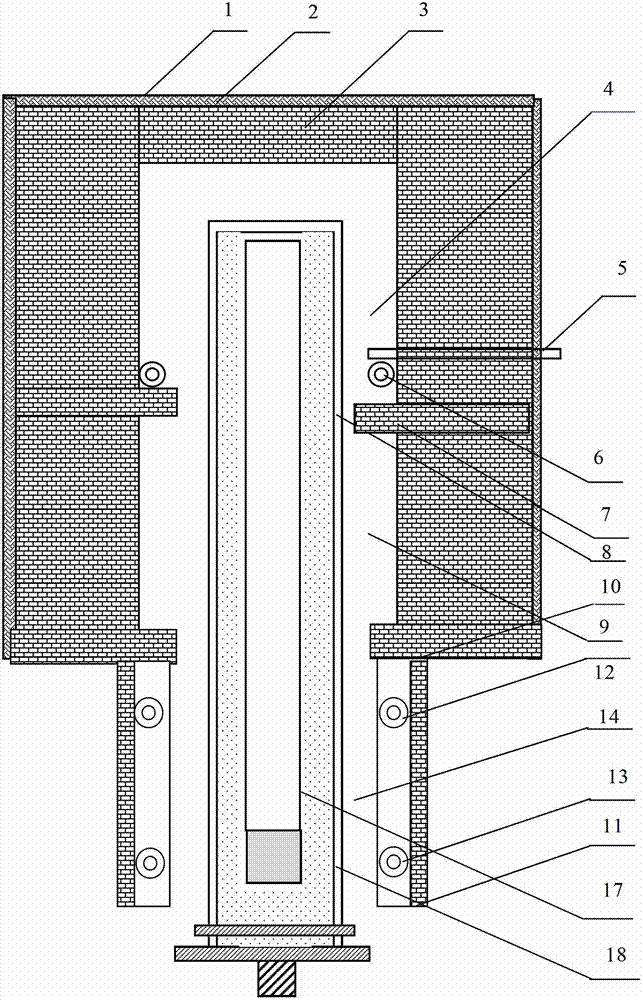

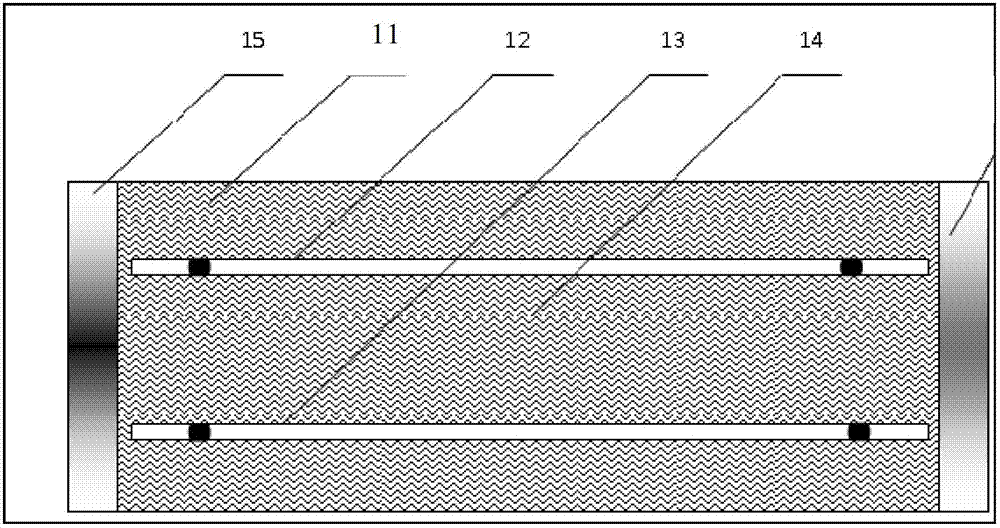

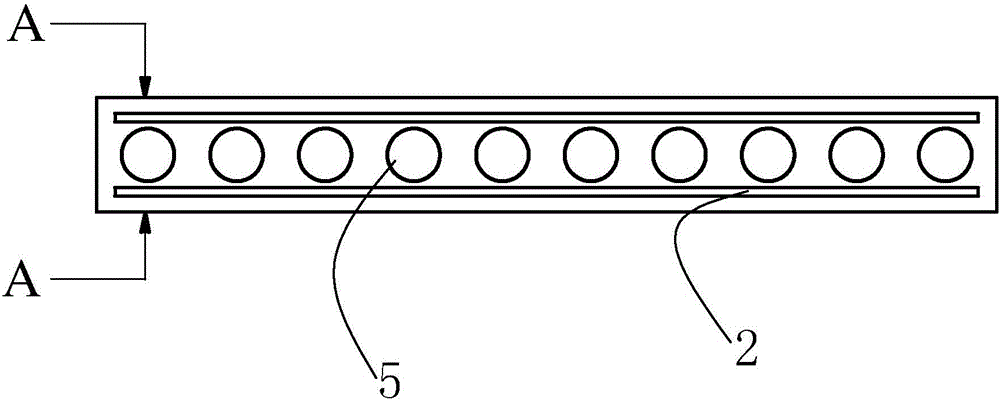

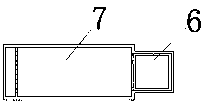

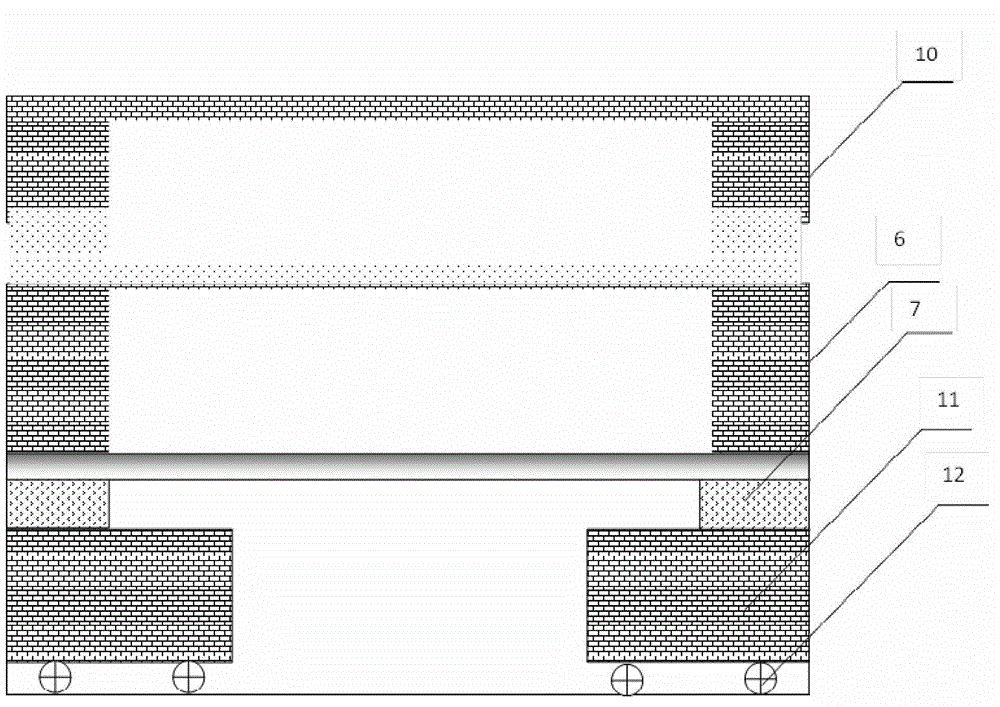

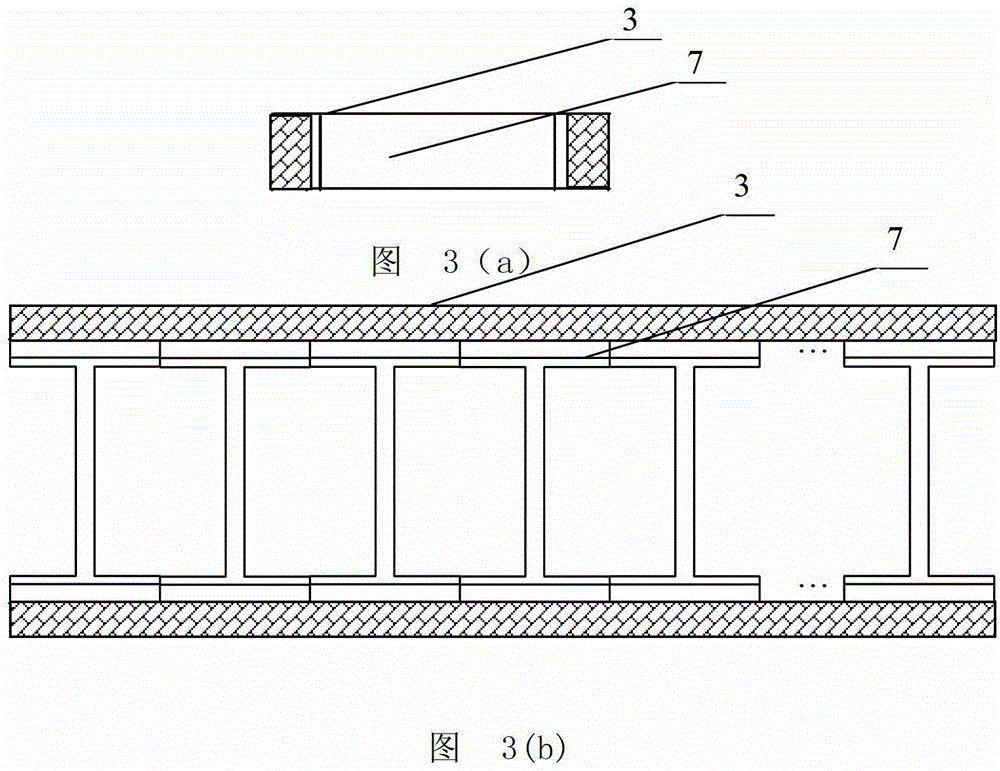

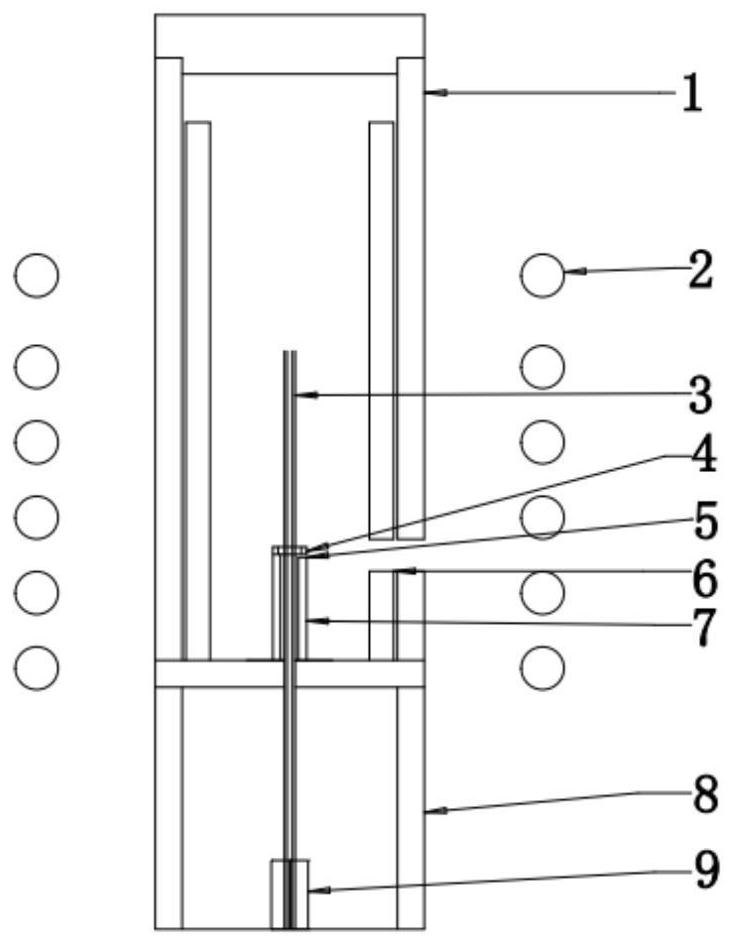

Growing device and method for growing wide plate-shaped bismuth germanate crystal according to descent method

ActiveCN102828230AShorten the growth cycleMeet growthPolycrystalline material growthFrom frozen solutionsBrickScintillation crystals

The invention provides a growing device and method for growing a wide plate-shaped bismuth germanate crystal according to a descent method. According to the method provided by the invention, a wide plate-shaped and high-quality bismuth germanate inorganic scintillation crystal is prepared according to the steps of: changing the shape of an upper separating brick 7 in the growing device and flexibly adjusting the horizontal width of the growing device and the height of a high-temperature area; designing a platinum crucible and an aluminum oxide leading crucible in huge size; utilizing a long crystal as a seed crystal to horizontally inoculate; and adjusting the uniform horizontal temperature field and the suitable longitudinal temperature gradient.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

Ladle castable

The invention relates to ladle castable, particularly to castable for ladle linings or working layers. In order to solve the technical problems, hte invention provides the ladle castable used at the direct lining where a ladle is in direct contact with molten steel; the ladle castable comprises the following components in percentage by weight: 8-20% of sintered microporous aluminum spinel of 12-8mm, 11-15% of sintered microporous aluminum spinel of 8-5mm, 12-15% of sintered microporous aluminum spinel of 5-3mm, 10-15% of sintered microporous aluminum spinel of 3-1mm, 30-35% of sintered microporous aluminum spinel smaller than or equal to 1mm, 0-15% of modified magnesia-calcium clinker smaller than or equal to 1mm, 1% of chromium carbide powder, 3-5% of compound gel powder, 1% of hydrated alumina micropowder, 1% of nacrite powder, 0.5% of bismuth germanate powder, 3-5% of modified pure calcium aluminate cement, 0.1% of C7H10N2O2S, 0.1% of C2H14Na2O6S2, and 0.05% of 4-morpholineethanesulfonic acid. Through the adoption of the ladle castable disclosed by the invention, the reacting degree of the material of the ladle lining and slags can be lowered; the high-temperature performance and the slag corrosion resistance of slag-resistance ladle products are improved; the thermal shock resistance of ladles is greatly improved; the service life of whole casting ladles is effectively prolonged, and compared with conventional ladles of the same type, the service life of ladles using the castable disclosed by the invention is prolonged by 30% and more.

Owner:徐州国隆电力配件铸造有限公司

Ce < 3 + >-doped silicate scintillation glass as well as preparation method and application thereof

PendingCN111499204AEasy to adjustImprove tissue uniformityMeasurement with scintillation detectorsGlass shaping apparatusFluorescenceEmission efficiency

The invention discloses Ce < 3 + > doped silicate scintillation glass as well as a preparation method and application thereof. The Ce < 3 + >-doped silicate scintillation glass comprises the followingcomponents: Li2O, MgO, Al2O3, SiO2 and Ce2O3, and the fluorescence emission efficiency of the Ce < 3 + >-doped silicate scintillation glass under the excitation of cathode rays is 4.65 times that ofbismuth germanate crystals. The main process of the preparation method is as follows: calcining precursor powder to generate a microcrystalline phase component in the precursor powder, melting, casting and annealing the powder to form amorphous glass, and carrying out crystallization heat treatment to precipitate the microcrystalline phase again and enhance the precipitation ratio, thereby greatlywidening the fluorescence emission spectrum of the scintillation glass and enhancing the fluorescence emission efficiency of the scintillation glass. The invention can be used for manufacturing a scintillation detector, and can also be used for thermal neutron detection when 6Li nuclide is introduced.

Owner:MATERIAL INST OF CHINA ACADEMY OF ENG PHYSICS

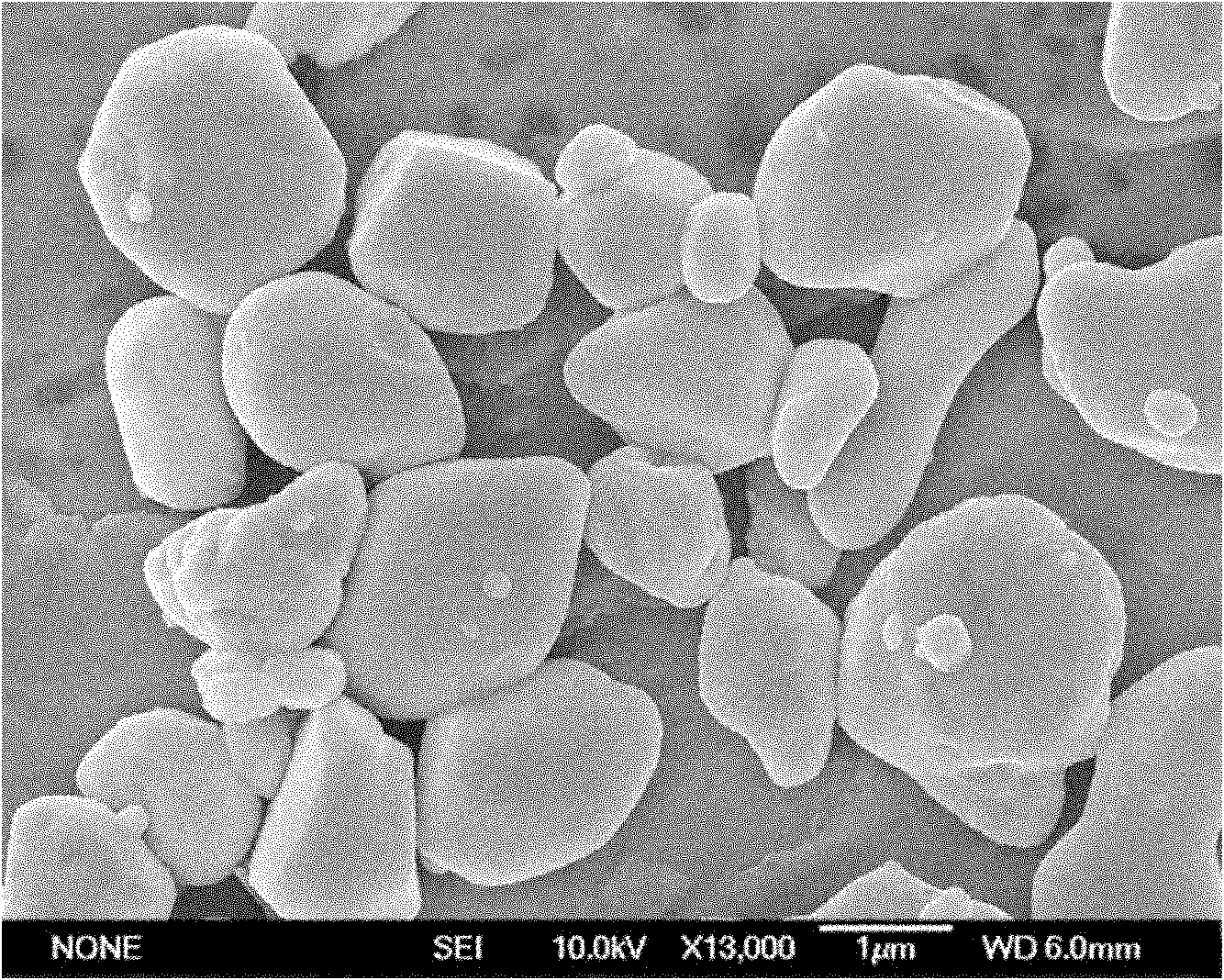

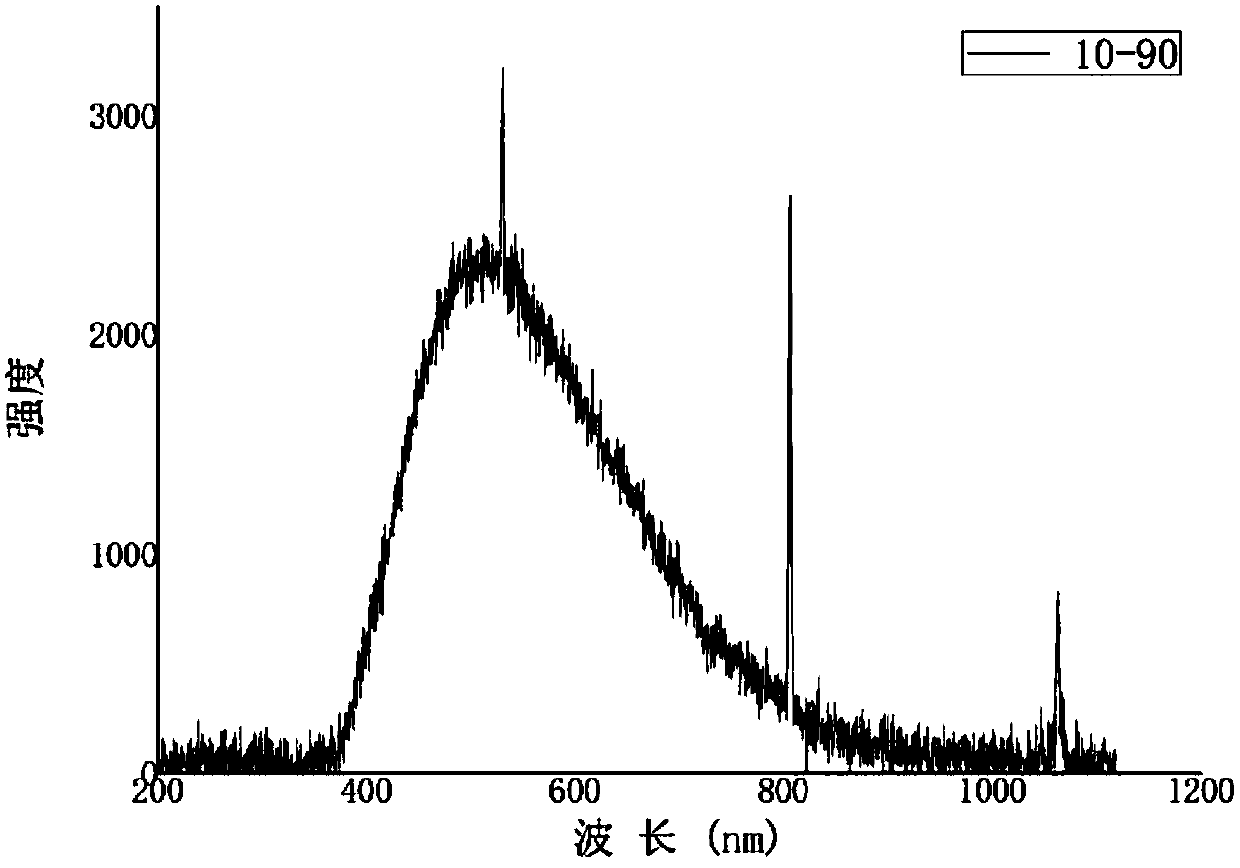

Preparation method of lead tungstate powder with high scintillation property

InactiveCN101973583AHigh luminous intensityImprove flicker performanceLuminescent compositionsTungsten compoundsChemical reactionTungstate

The invention discloses a preparation method of a lead tungstate powder with high scintillation property, comprising the following specific steps of: a) dropwise adding a water soluble lead salt solution into a water soluble tungstate solution with a pH value being not less than 7 at the uniform velocity so that the coprecipitation chemical reaction is conducted at 30-80 DEG C; b) filtering, washing and drying the obtained lead tungstate precipitation; and c) carrying out thermal treatment on the obtained lead tungstate crystal grains. By the invention, the luminescence peak of the lead tungstate powder body is within the blue light wave band of 450-500nm and belongs to fast luminescence component; the luminescence strength is high and is remarkably improved by about 15 times in comparison with the luminescence strength of the power obtained by grinding lead tungstate crystal grains which grow by a descending method, can reach the luminescence level of the power obtained by grinding of bismuth germanate crystal grains which grow by a descending method and has excellent scintillation property; in addition, the invention has the advantages of simple operation, short reaction time, low requirements on experimental equipment, high controllability and the like, and is suitable for large-scale production.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

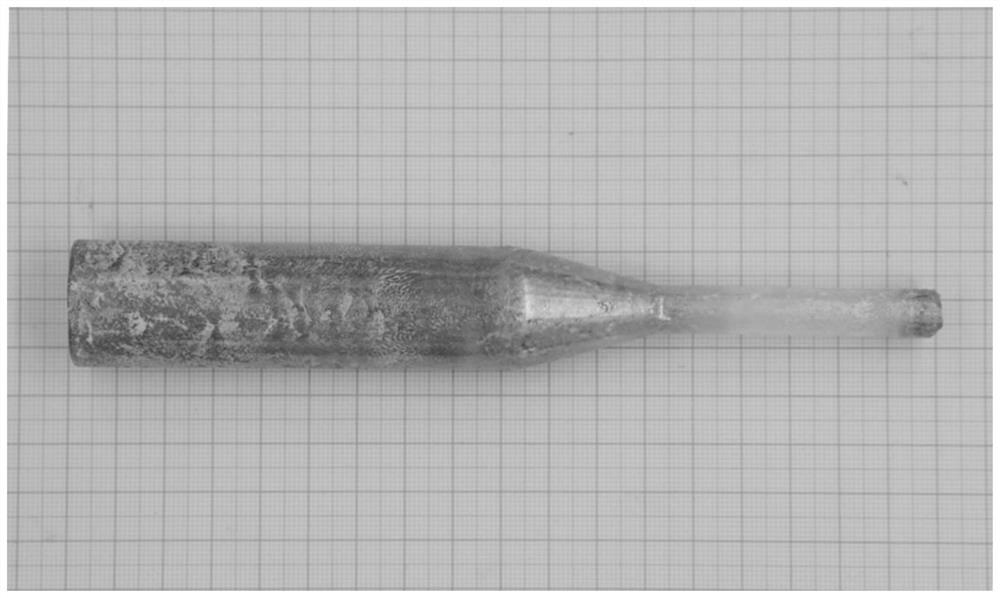

Device and method of growing 500-1000mm long bismuth germanate crystals by descent method

ActiveCN102787350AAvoid crackingPrevent proliferationPolycrystalline material growthFrom frozen solutionsScintillation crystalsEngineering

The invention provides a device and a method of growing 500-1000mm long bismuth germanate crystals by descent method. The device of growing bismuth germanate crystals includes a furnace structure system and an auxiliary heating system. According to the invention, by means of the furnace structure system and the auxiliary heating system, the temperature in the corresponding gradient region and auxiliary heating region of the crystal growth device is simultaneously controlled and regulated to insure that the whole growth device is provided with the best temperature field. According to the invention, the height of the high temperature region of the growth device and the height of the auxiliary heating system can be regulated by a ratio of 1:1 according to the length of the grown crystals, in addition, a long-size platinum crucible and alumina lead-down crucible are designed, a suitable temperature gradient and descent speed are obtained, and long-size and high-quality bismuth germanate scintillation crystals are prepared efficiently.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

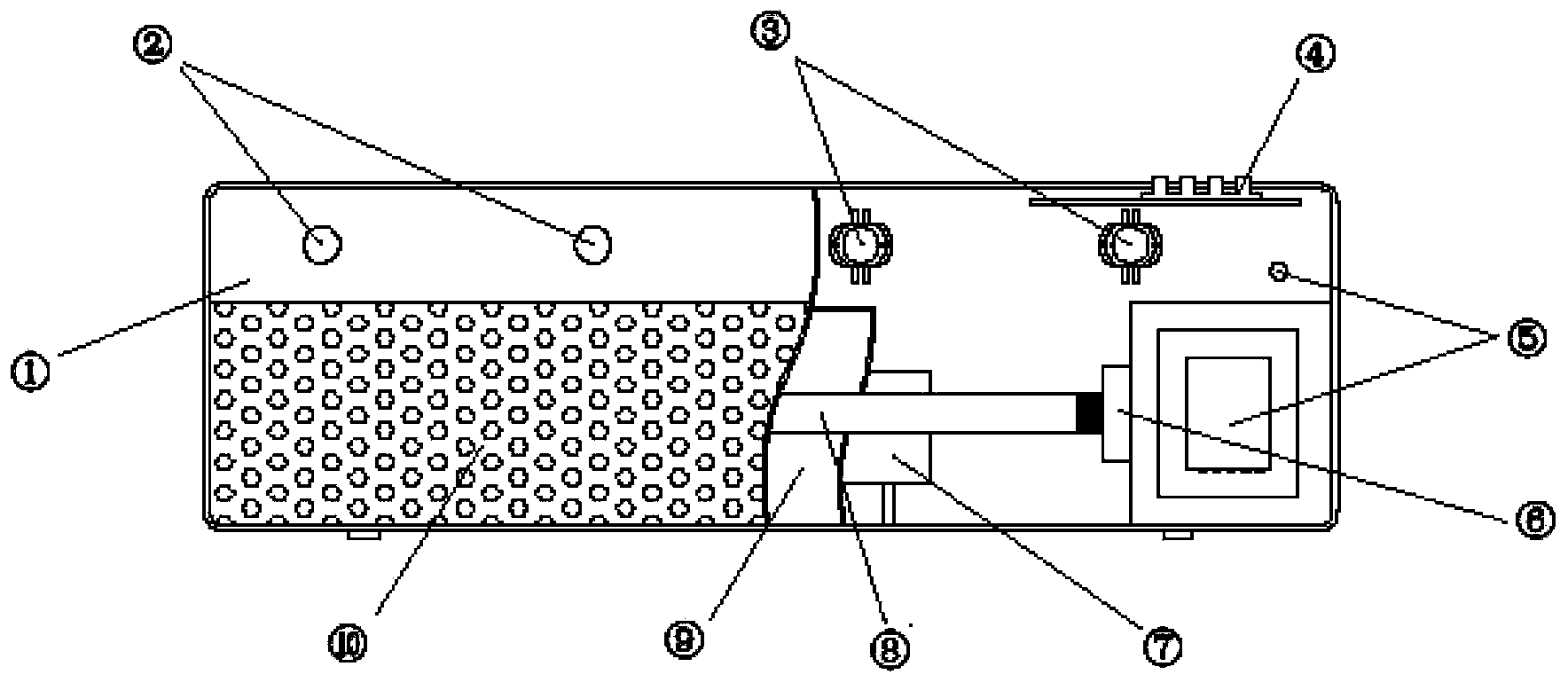

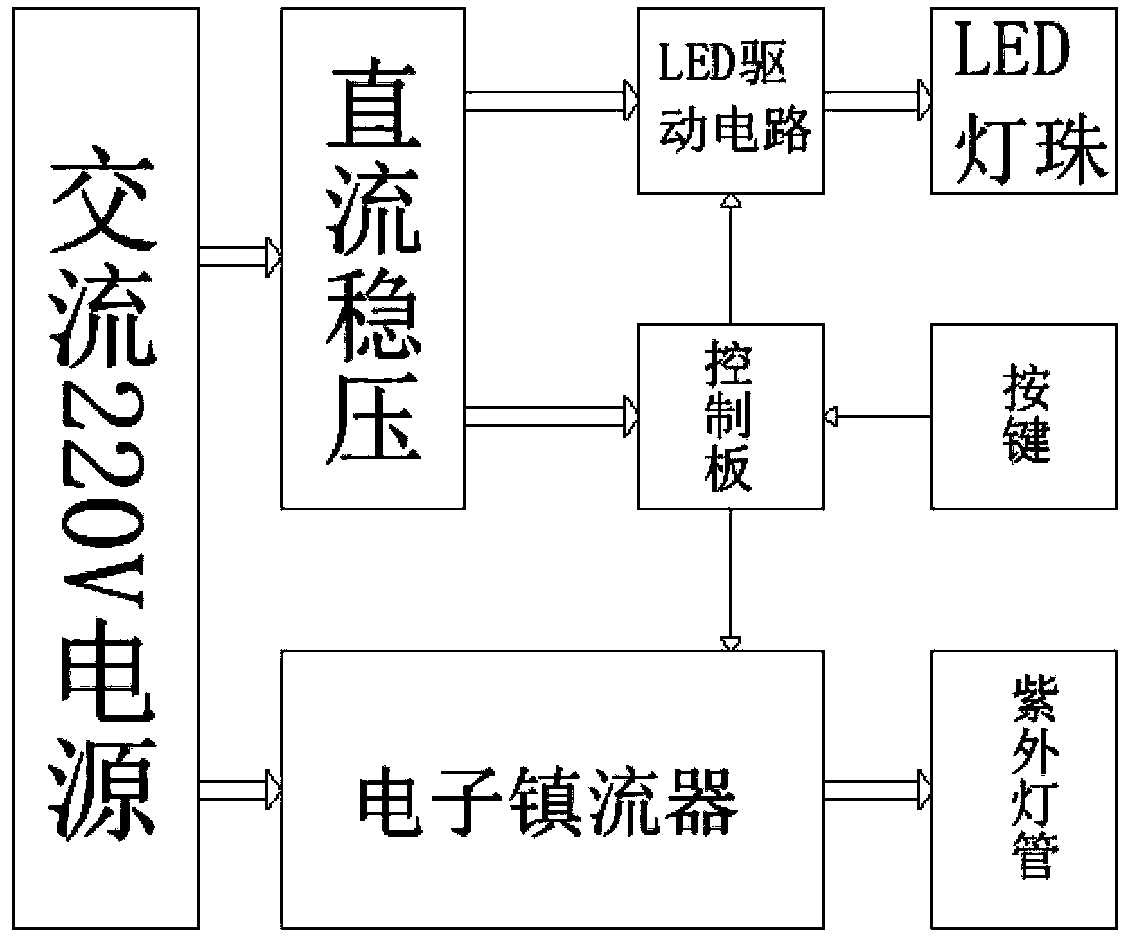

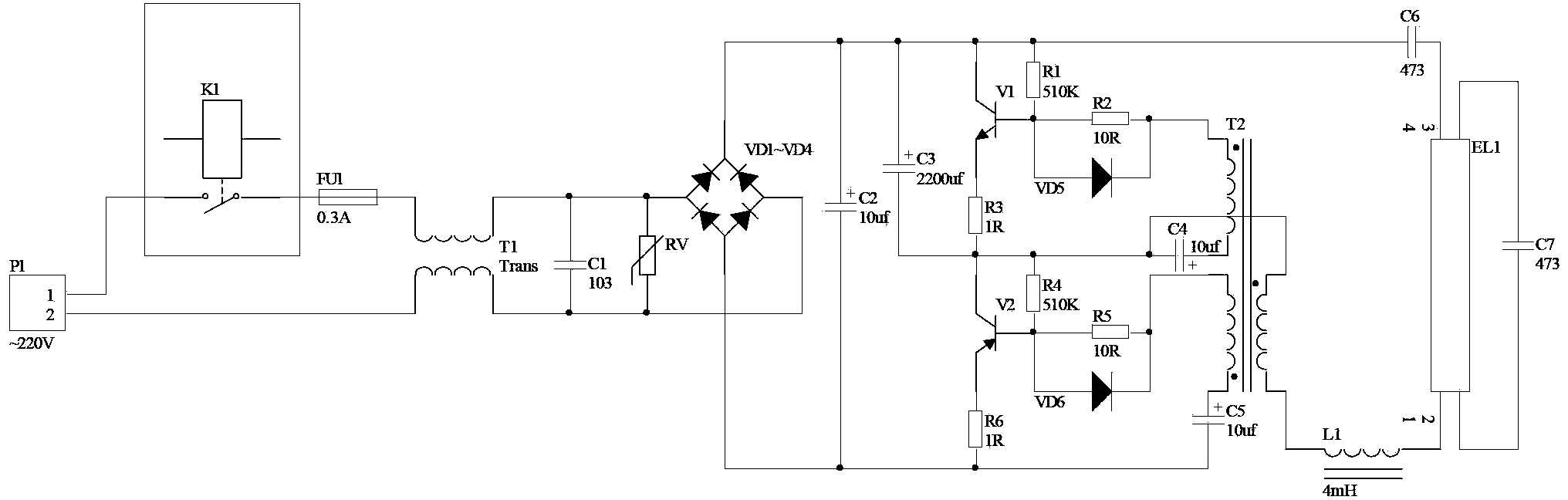

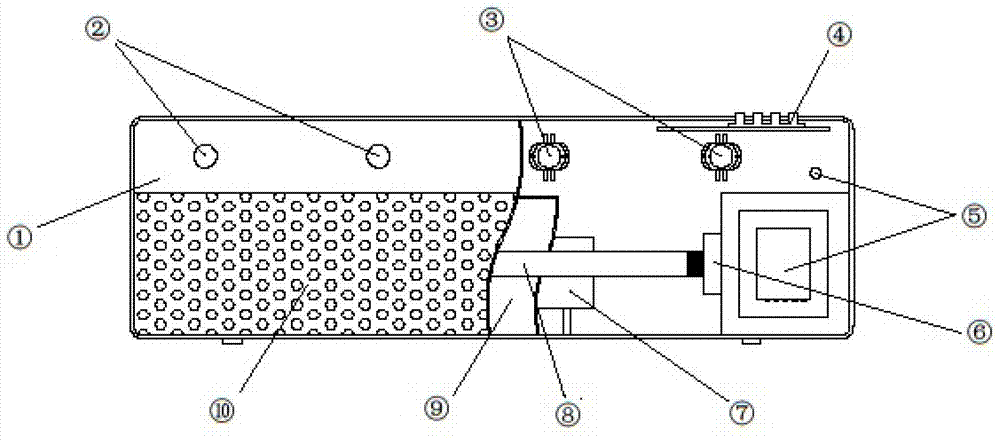

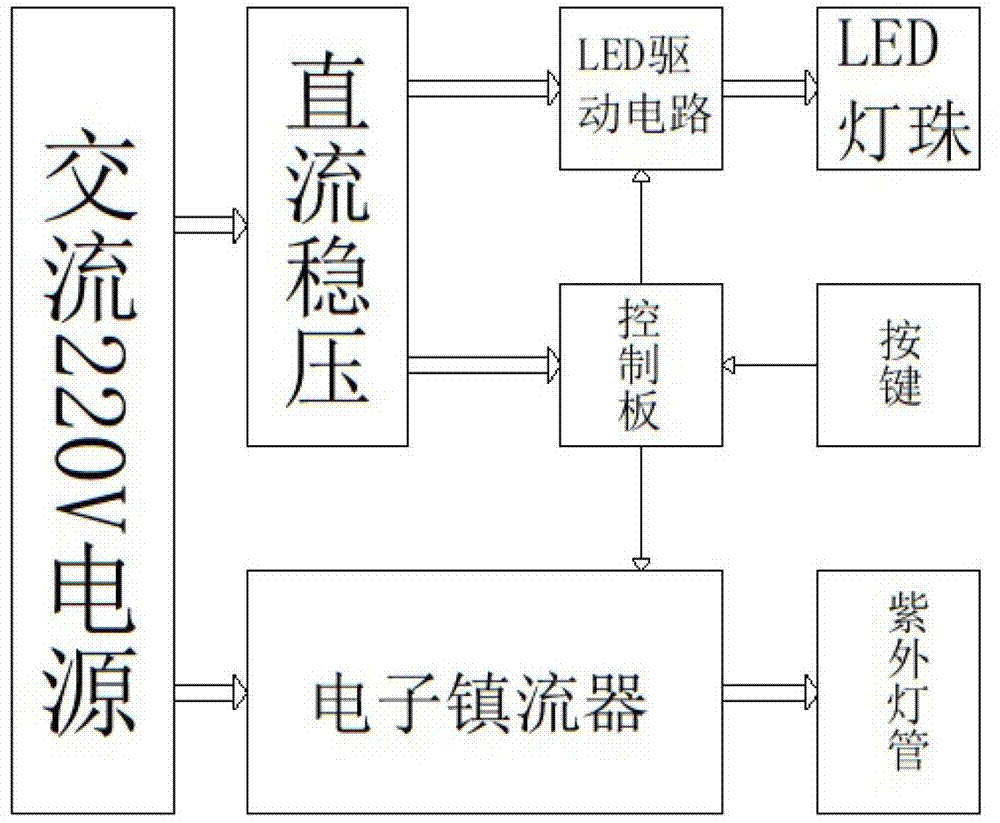

Artificial luminous health-care physiotherapy instrument capable of supplementing vitamin D and calcium

ActiveCN103394165APromote absorption and transformationHigh absorption rateLuminescent compositionsRadiation therapyDiseaseSesquioxide

The invention provides an artificial luminous health-care physiotherapy instrument capable of supplementing vitamin D and calcium. The artificial luminous health-care physiotherapy instrument comprises a red light generation unit, an ultraviolet lamp tube, a lamp shade, a display and a control circuit, wherein the ultraviolet lamp tube is made of violet ray glass; the fluorescent ultraviolet power which comprises the following components in percentage by weight: 23-27 percent of zinc sulfide, 18-22 percent of bismuth germanate, 14-18 percent of yttrium oxysulifde, 14-18 percent of magnesium silicate, 8-12 perecent of strontium wolframate, 4-8 percent of strontium aluminate, 3-5 percent of calcium pyrophosphate, 1.5-2.5 percent of butyl acetate and 0.5-1.5 percent of aluminium sesquioxide is absorbed on the inner wall of a lamp tube under electrostatic action. The health-care physiotherapy instrument can effectively supplement lost vitamin D and calcium in a human body so as to prevent and improve various diseases caused by the lack of vitamin D and calcium, and is good in efficacy of supplementing vitamin D and calcium, convenient and safe in use, and simple in structure.

Owner:赵同泉

Cleaning process of bismuth germanate wafer

InactiveCN103230894ALess corrosiveReduce processing costsCleaning using liquidsPropanoic acidKerosene

The invention relates to a cleaning process of a bismuth germanate wafer. The cleaning process comprises: a preliminary cleaning step of cleaning the bismuth germanate wafer by using secondary de-ionized water to remove massive pollutants with relatively weak surface adhesive power; a second cleaning step of cleaning the bismuth germanate wafer by using aviation kerosene to remove organic greasy dirt on a surface; a third cleaning step of cleaning the bismuth germanate wafer by using a CC14 solution to further remove the organic dirt on the surface of the bismuth germanate wafer; a fourth cleaning step of cleaning the bismuth germanate wafer by using a 15%-25% propionic acid and ultrapure de-ionized water mixed solution to remove inorganic dirt on the surface; and a drying step of blow-drying the bismuth germanate wafer.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

Method for manufacturing fibre containing bismuth germinate micro-nano powder

InactiveCN101498060AFree radical scavengingAdjust pHFilament forming substance formingMelt spinning methodsTin dioxideFiber

The invention relates to the filed of fiber manufacture, in particular to a fiber manufacture method of micro-nano powder comprising bismuth germinate. The invention uses polyester, polypropylene or nylon as base material which comprises 1 percent to 50 percent of multielement mixing ultra-fine powder by weight percentage, and the multielement mixing ultra-fine powder comprises the following ingredients by the following weight percentage: 1 percent to 49 percent of bismuth germinate micro powder, 1 percent to 49 percent of tin dioxide, 1 percent to 2 percent of trace elements beneficial to human bodies, such as calcium, kalium, iron, zinc, silver, and the like, and the granularity of the trace elements is from 0.3 micron to 0.5 micron. After being sliced, the base material is stirred with the multielement mixing ultra-fine powder, wherein the weight percentage of the mixed ultra-fine powder in the base material slices is 1 percent to 50 percent, then 1 percent to 5 percent of a polymer spinning aid is added, melted and fully stirred for 20 minutes at a melting temperature of 260 DEG C to 286 DEG C, and the mixture is sprayed, cooled, fixed, curled, pulled to form the fibers comprising the bismuth germinate.

Owner:TOPRET IND DESIGN(SHANGHAI) CO LTD

Glass micro-beads for noctilucence reflective cloth and preparation method thereof

The invention discloses glass micro-beads for noctilucence reflective cloth and a preparation method thereof. The glass micro-beads are prepared from the following raw materials in parts by weight: 27-34 parts of sillimanite, 36-52 parts of sandy pebble, 21-33 parts of adularia, 30-40 parts of barite, 15-25 parts of hydrated basic magnesium carbonate, 24-36 parts of china stone, 19-28 parts of tremolite, 7-14 parts of zinc sulfide, 5-10 parts of bismuth germanate, and 6-12 parts of an additive. The glass micro-beads have high refractive index and high brightness, have quite good reflective effect at night, are safe and reliable, besides have excellent weather resistance, corrosion resistance and durability, are durable in use, and can completely satisfy use requirements of the noctilucence reflective cloth.

Owner:BENGBU GAOHUA ELECTRONICS

Bismuth germanate monocrystal growing method

InactiveCN106757353AHighly programmedImprove growth qualityPolycrystalline material growthFrom frozen solutionsVertical gradientAdditive ingredient

The invention discloses a bismuth germanate monocrystal growing method, and belongs to the field of crystal growing. The bismuth germanate monocrystal is grown by a method of combining a rotatable multi-crucible technology and a vertical gradient solidification method. The method provided by the invention has the advantages that the radial symmetry of a crystal growing interface temperature field is improved; the growth quality of the bismuth germanate monocrystal is improved; meanwhile, the ingredient diffusion is facilitated; the uniform distribution of ingredients is promoted; the growth velocity of the bismuth germanate monocrystal is accelerated. The program control degree is high; the temperature accuracy is high; the fluctuation is small; the repeatability is high; the yield is high; the cost is low.

Owner:FIRST RARE MATERIALS CO LTD

Glass-ceramic containing a bismuth germanate crystal phase, and preparation method thereof

InactiveCN107698165AEasy to processImprove performanceLuminescent compositionsFull width at half maximumBismuth germanate

The present invention relates to a glass-ceramic containing a bismuth germanate crystal phase, and a preparation method thereof, wherein the microcrystalline phase of the glass-ceramic is bismuth germanate, and the preparation raw materials of the glass-ceramic comprise bismuth trioxide, germanium dioxide and bismuth hydroxide according to a molar ratio of 10-40:60-90:3-10. The specific preparation method comprises: (1) preparing raw materials according to a certain ratio, and grinding the raw materials; (2) mixing the grinded raw materials, and carrying out high temperature melting to preparea glass; and (3) annealing the prepared glass, and cooling to obtain the glass-ceramic containing the bismuth germanate crystal phase. According to the present invention, the scintillating glass-ceramic material has the light-emitting property similar to the crystal material with the full width at half maximum of about 200 nm, has good processability so as to be widely used in ray detection, further has advantages of excellent glass material performance, stable size, simple preparation process, designable performance and low production cost, and can be welded to metals.

Owner:TONGJI UNIV

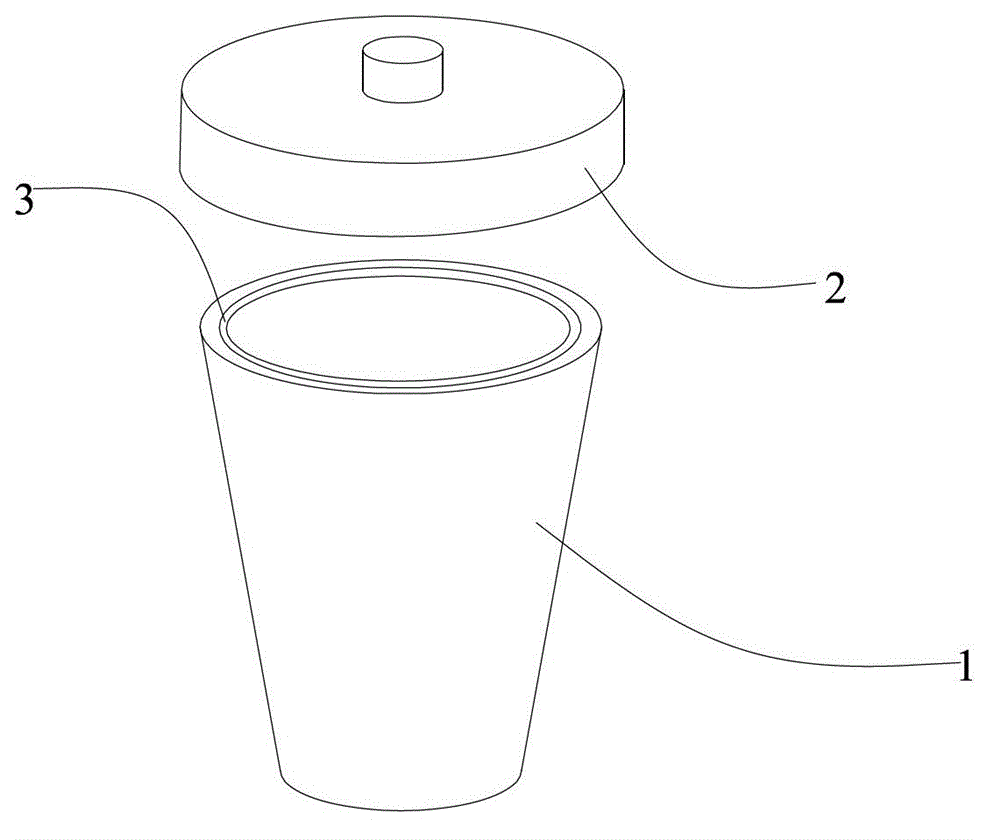

Composite crucible, preparation method thereof and method for bismuth germanate crystal growth using the crucible

InactiveCN103938266AReduce usageLow costPolycrystalline material growthFrom frozen solutionsPlatinumAdhesive

The present invention provides a composite crucible, a preparation method thereof and a method for bismuth germanate crystal growth using the crucible. The composite crucible includes a platinum film placed on the inner surface of a ceramic crucible. The bismuth germanate crystal growth method comprises: adding bismuth germanate polycrystalline material into the ceramic crucible seeded with bismuth germanate crystal seeds; then adding high temperature adhesive into the matching gap between the ceramic crucible and a ceramic cap and sealing; putting the crucible into a single-crystal furnace, heating the single-crystal furnace from room temperature to a first temperature above the melting point of bismuth germanate but below the melting point of platinum at a first temperature raising rate, and keeping the first temperature for a first period of time; moving down the composite crucible at a predefined downward movementrate so as to grow single crystals, meanwhile heating the single-crystal furnace from the first temperature at a second temperature raising rate lower than the first temperature raising rate to a second temperature below the melting point of platinum, keeping the second temperature for a second period of time in which the composite crucible is moving down at the predefined downward movement rate until the single crystals completely grow up; and blowing off and cooling down the furnace. The crucible and the methods reduce the use of platinum and costs.

Owner:FIRST RARE MATERIALS CO LTD

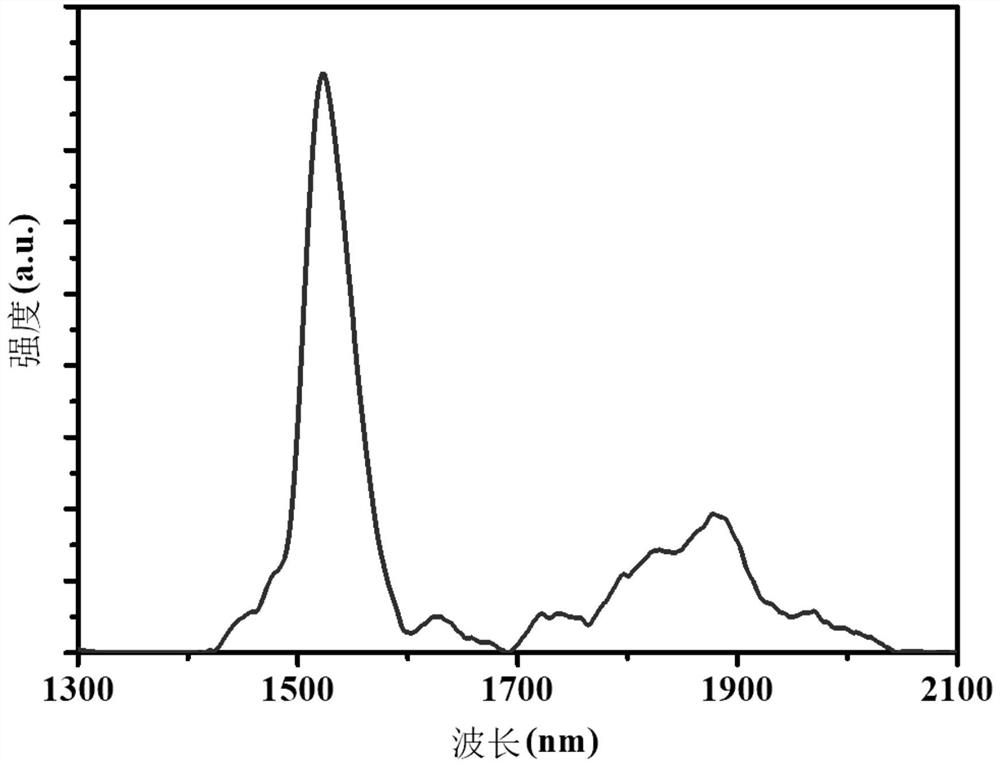

Thulium-doped BGSO human eye safety laser crystal and preparation method thereof

InactiveCN113699582APrevent volatilizationInhibition of segregationPolycrystalline material growthFrom frozen solutionsLuminescenceSeed crystal

The invention discloses a thulium-doped bismuth silicon germanate laser crystal and a preparation method thereof. The molecular formula of the material is (TmxBi1-x)4(GeySi1-y)3O12, the value range of x is 0.005-0.15, and the value range of y is 0.1-0.9. The method comprises the following steps: mixing the raw material powder in proportion, sintering, grinding, and sintering again to obtain a thulium-doped bismuth germanium silicate polycrystal material; putting a seed crystal into a seed trap part of the crucible and fixing the seed crystal, filling the thulium-doped bismuth germanate polycrystal material into the crucible and sealing the crucible, and moving the crucible into a down-leading pipe; placing the lead-down pipe in a crystal furnace, and after the polycrystal material in the crucible is completely melted, keeping the temperature for 2-4 hours; and descending the leading-down pipe at the speed of 0.2-0.5 mm / h, and carrying out crystal growth. The thulium-doped bismuth silicon germanate laser crystal prepared by the invention has high-intensity broadband luminescence in a range of 1.5-2.0 microns, can realize high-power laser output, and has a wide application prospect in the directions of laser ranging radars and space communication.

Owner:SHANGHAI INST OF TECH

Growth method of bismuth germanate single crystal

ActiveCN103695994ASimple growth processQuality improvementPolycrystalline material growthFrom frozen solutionsMolten stateSingle crystal

The invention discloses a growth method of bismuth germanate single crystal. The method comprises the following steps: with Bi2O3 and GeO2 as raw materials, carrying out combination reaction in a constant-temperature environment under ultrasonic vibration, so as to obtain a bismuth germanate polycrystal material with which is uniform in component and is in molten state; and preparing the bismuth germanate single crystal by adopting a bridgman crystal growth method. Growth of the bismuth germanate single crystal is realized at the crucible growth part in one step by an ultrasonic sensing technology. By adopting the method, the link of melting and synthetizing the polycrystal material by using a platinum crucible in the bismuth germanate single crystal growth process employing the traditional descending method is removed, the growth technology of the bismuth germanate single crystal is simplified, the production cycle is shortened, and the dosage of precious metal platinum is greatly reduced, so that the production cost is reduced. Meanwhile, intervention of external impurity elements in the production process also can be avoided by the growth method disclosed by the invention, and the quality of the bismuth germanate crystal is further improved.

Owner:安徽昱升光电科技有限公司

Eco-friendly antirust coating for exhaust equipment

InactiveCN105949940AGood dispersionImprove permeabilityAnti-corrosive paintsEpoxy resin coatingsEpoxyHexamethylenediamine

The invention discloses an eco-friendly antirust coating for exhaust equipment. The coating is made from the following raw materials: carbonyl iron powder, polyvinyl butyral, calcium tripolyphosphate, coal ash, aluminium powder, an epoxy resin E44, an epoxy resin E20, polyvinyl alcohol castor oil, butyl acetate, hexamethylenediamine, polyamide, styrene, azodiisobutyronitrile, polyaluminum ferric silicate, isobutene triethoxysilane, polymerized ferrophosphorous powder, phytic acid, ureidopropyltrimethoxysilane, bismuth germanate, an aluminate coupling agent and a proper amount of absolute ethanol. The coating is safe and free of toxicity, is high in adhesive force and good in rust resistance, wear resistance and impact resistance, and can keep excellent characteristics in the severe environment. Through use of the coating, the service life of a material is prolonged and the cost is reduced, and therefore the coating is worthy of popularization.

Owner:CHUZHOU VOCATIONAL & TECHN COLLEGE

Bismuth silicate-germanate mixed crystal and preparation method thereof

InactiveCN102011187BImprove flicker performanceReduce manufacturing costPolycrystalline material growthFrom frozen solutionsCruciblePhysical chemistry

The invention discloses a bismuth silicate-germanate mixed crystal and a preparation method thereof, belonging to the single crystal field. The molecular formula of the bismuth silicate-germanate mixed crystal is Bi4Si3-xGexO12. The preparation method comprises the following steps: using high-purity Bi2O3, SiO2 and GeO2 as raw materials to fully grind, presinter and obtain a polycrystalline material; and placing seed crystal at the bottom of a crucible in advance, placing the synthesized polycrystalline material in the crucible, and transferring the crucible to a crystal growing furnace whilecontrolling the temperature to 1050-1150 DEG C, the temperature gradient of the solid-liquid interface to 20-50 DEG C / cm and the growth velocity to 0.2-0.5mm / h. The raw material components of the bismuth silicate-germanate mixed crystal provided by the invention are adjustable and are distributed evenly; the mixed crystal has the scintillation property of bismuth silicate and the scintillation property of bismuth germanate, the mixed crystal has large size; the preparation method adopts stable temperature field and simple processing equipment; and multicrystal can grow at the same time, the growth efficiency of the mixed crystal is high, the production cost is low and the mixed crystal is suitable for industrial production.

Owner:SHANGHAI INST OF TECH

Gas-sensing ceramic material

The invention discloses a gas-sensing ceramic material which consists of the following raw materials in parts by weight: 30-37 parts of silicon carbide, 17-20 parts of silicon oxide, 10-17 parts of silicon dioxide, 2-6 parts of zinc oxide, 1-4 parts of tin oxide, 7-10 parts of iron oxide, 3-5 parts of vanadium pentoxide, 3-6 parts of zirconium oxide, 2-6 parts of nickel oxide, 0.5-2 parts of gallium arsenide, 0.1-0.7 part of indium phosphide and 0.1-0.5 part of bismuth germanate. According to the gas-sensing ceramic material disclosed by the invention has the advantages of component diversification, high sensitivity and functional diversification and is suitable for detecting multiple gases.

Owner:QINGDAO DAFANG WISDOM NETWORK TECH CO LTD

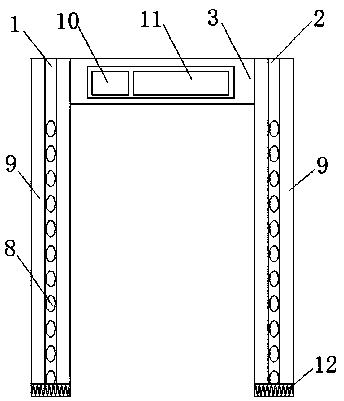

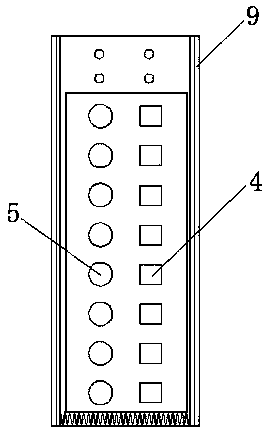

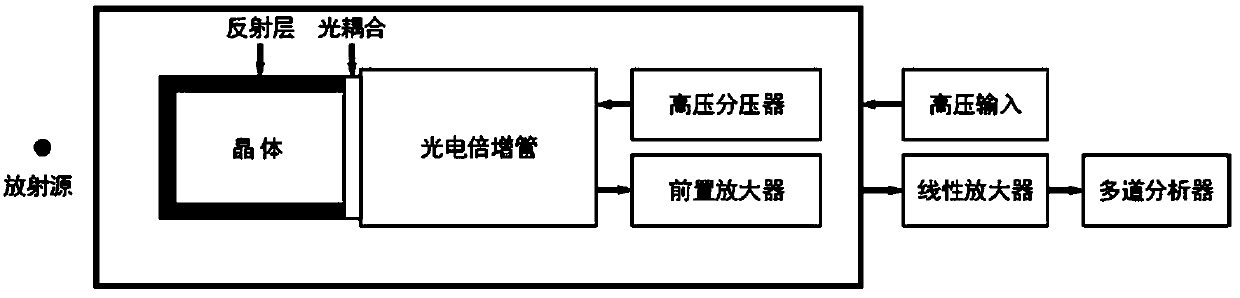

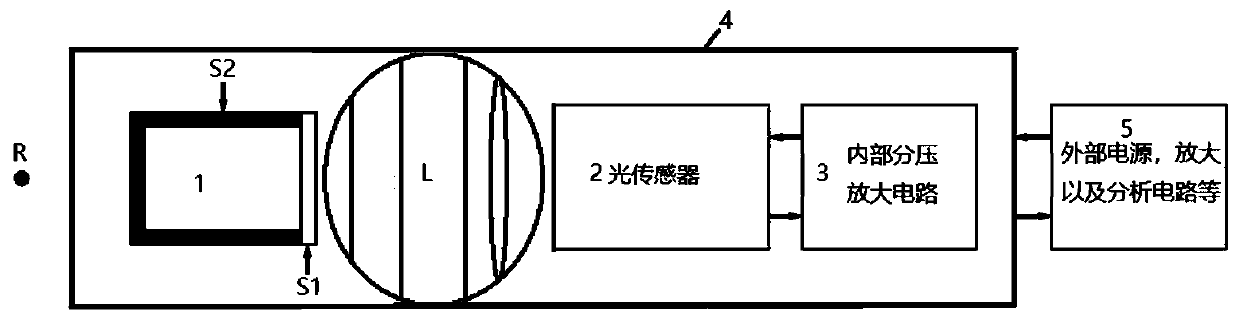

Nuclear radiation and metal dual-energy detection security-check door

PendingCN110231646AIncrease detection typesSimple structureX/gamma/cosmic radiation measurmentGeological measurementsNuclear radiationSilicon photomultiplier

The invention provides a nuclear radiation and metal dual-energy detection security-check door. The door comprises a left side door and a right side door which are vertically arranged in parallel andoppositely, a control box is mounted at the top of upper ends of the left side door and the right side door through bolts, the inside of the left side door and the right side door is provided with a sensing area from top to bottom, the sensing area comprises a metal detector and a nuclear radiation detector, the metal detector and the nuclear radiation detector both are connected on the control box; a detection head of the nuclear radiation detector is composed of a scintillation crystal and a silicon photomultiplier, a rear end face of the scintillation crystal is closely attached to a surface of the silicon photomultiplier, and the scintillation crystal is one of yttrium silicate and bismuth germanate. The nuclear radiation and metal dual-energy detection security-check door provided bythe invention is simple in structure and convenient to use, realizes a function of detecting metals and nuclear radiation at the same time by combination of the metal detector and the nuclear radiation detector, improves detection varieties of the security-check door, and has high sensitivity and adaptability.

Owner:无锡通透光电科技有限公司

Growth device and method for growing wide-plate bismuth germanate crystals by descending method

ActiveCN102828230BShorten the growth cycleMeet growthPolycrystalline material growthFrom frozen solutionsBrickScintillation crystals

The invention provides a growing device and method for growing a wide plate-shaped bismuth germanate crystal according to a descent method. According to the method provided by the invention, a wide plate-shaped and high-quality bismuth germanate inorganic scintillation crystal is prepared according to the steps of: changing the shape of an upper separating brick 7 in the growing device and flexibly adjusting the horizontal width of the growing device and the height of a high-temperature area; designing a platinum crucible and an aluminum oxide leading crucible in huge size; utilizing a long crystal as a seed crystal to horizontally inoculate; and adjusting the uniform horizontal temperature field and the suitable longitudinal temperature gradient.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

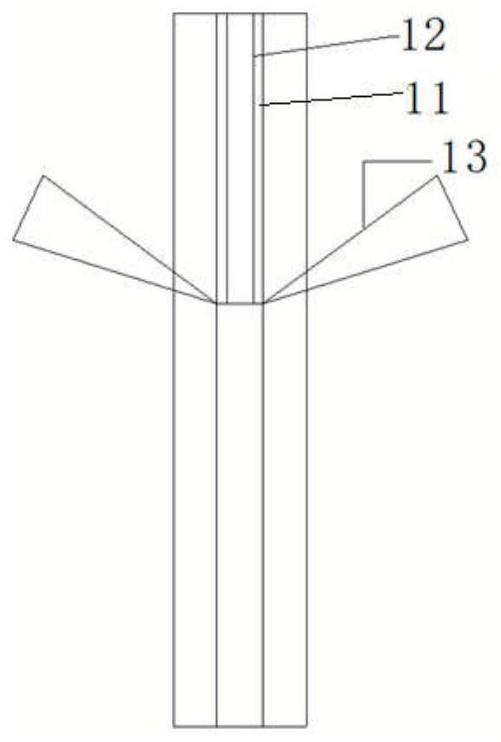

Rare earth doped bismuth germanate single crystal optical fiber and cladding method

ActiveCN112723751ALaser efficientIncrease powerGlass making apparatusPolycrystalline material growthFiberRare earth ions

The invention provides a rare earth doped bismuth germanate single crystal optical fiber, which comprises an outer cladding and an inner fiber core, the fiber core is of a Bi4Ge3O12 single crystal structure doped with rare earth ions with a certain concentration, the cladding is of a Bi4Ge3O12 structure, raw materials adopted for preparing the fiber core are rare earth ion oxide, Bi2O3 and GeO2, and the molar ratio of Bi2O3 to GeO2 is (1-2): (3-4). According to the invention, a two-layer structure is arranged and comprises an external cladding and an internal fiber core, the external cladding is a glass structure prepared from Bi4Ge3O12, the internal fiber core is a Bi4Ge3O12 single crystal structure doped with rare earth ions, and meanwhile, the invention also provides a preparation method of the optical fiber, and compared with the prior art, the laser output by the prepared optical fiber is more efficient and higher in power.

Owner:NANJING TONGLI CRYSTAL MATERIALS RES INST CO LTD

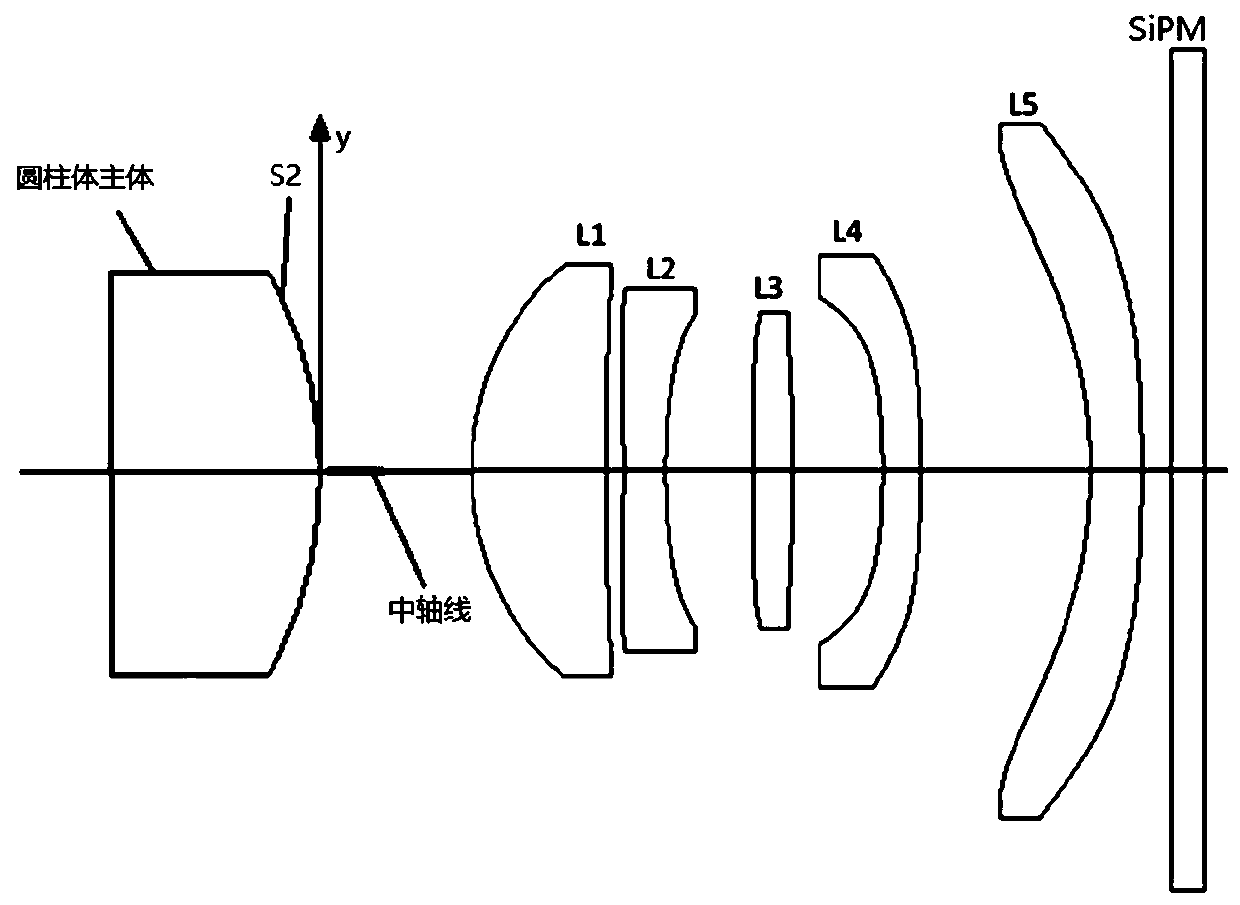

Bismuth germanate scintillation crystal radiation detector with exit surface matched with lens group

InactiveCN110737013AOvercoming selectivityOvercome the inherent pitfalls of optimizationX/gamma/cosmic radiation measurmentImage resolutionScintillation crystals

The invention relates to a scintillation crystal radiation detector with a special light emitting surface matched with a lens group. A matched wide-angle and large-depth-of-field lens group is constructed, so the collection efficiency of the optical sensor on the scintillation light is improved and the energy resolution is improved. The specific parameter design considers the matching with the emergent wave band of the scintillation crystal, so the incident light sensor for focusing and collecting the scintillation light can be increased, the energy resolution is improved, the shape of the light emitting surface of the scintillation crystal matched with the lens group is correspondingly designed, the measurement efficiency and the measurement precision are further improved, and the detection performance can be further improved especially when a high-performance detector is developed.

Owner:左慈斌

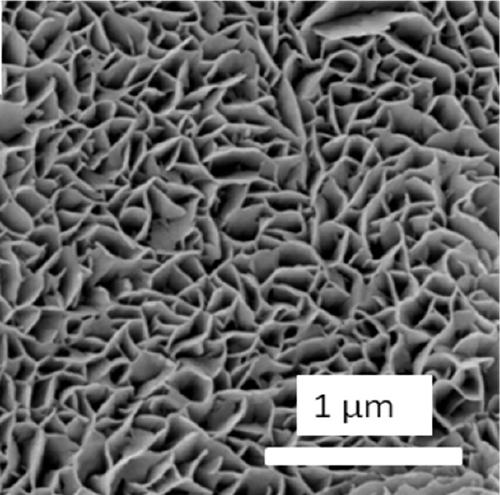

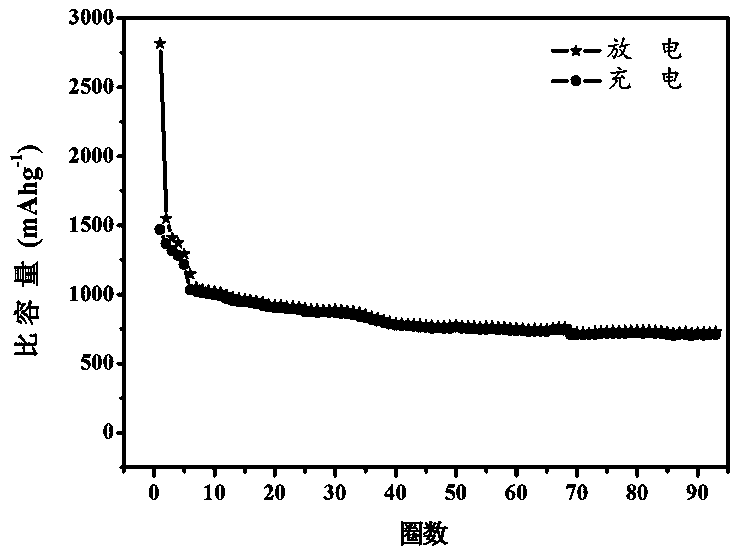

Bismuth germanate two-dimension nanosheet and preparing method thereof

ActiveCN109553132AHigh charge and discharge capacityPromote circulationCell electrodesSecondary cellsCharge dischargeSolvent

The invention discloses a bismuth germanate two-dimension nanosheet and a preparing method thereof. The bismuth germanate has a two-dimension nanosheet morphology structure, with the thickness of a sheet layer being 3-50 nm and the diameter of the sheet layer being 200-500 nm. The nanosheet is prepared from bismuth triiodide and germanium dioxide, by adopting ethylene glycol-water mixture liquid as a solvent, adopting foamed nickel as a substrate and by utilizing a solvothermal process. The mole ratio of the bismuth triiodide to the germanium dioxide is (0.3-2):1, the total amount of the addedbismuth triiodide and germanium dioxide is 1-4 mmol, the amount of the ethylene glycol is 5-25 mL, and the amount of the water is 5-25 mL. When the nanosheet is used for a lithium ion battery negative electrode material, the reversible capacity in the first cycle of the material under a current density of 100 mA / g can be 1200-1469 mAh / g, the capacity retention ratio after 100 cycles is 50-65%, and the electrode material has high charging-discharging capacity and shows good cyclic performance.

Owner:SHANGQIU NORMAL UNIVERSITY

Castable

The invention relates to castable, in particular to castable for ladle linings or working layers. In order to solve the technical problem, the castable is provided to be used for a direct lining, making contact with molten steel, of a steel ladle. The castable is prepared from, by weight, 8%-20% of sub-white corundum ranging from 12 mm to 8 mm, 11%-15% of sintered porous alumina spinel ranging from 8 mm to 5 mm, 12%-15% of sintered porous alumina spinel ranging from 5 mm to 3 mm, 10%-15% of sintered porous alumina spinel ranging from 3 mm to 1 mm, 30%-35% of sintered porous alumina spinel smaller than or equal to 1 mm, 0-5% of modified dead burned high-calcium magnesite smaller than or equal to 1 mm, 1% of tri-chromium dicarbide powder, 3%-5% of compound gel powder, 1% of hydrated alumina micro powder, 1% of nacrite powder, 0.5% of bismuth germanate powder, 3%-5% of modified pure calcium aluminate cement, 0.1% of C7H10N2O2S, 0.1% of C21H14Na2O6S2 and 0.05% of 2-morpholineethanesulfonic acid. According to the castable, the reaction degree of the steel ladle lining material and slag can be reduced, high-temperature performance and slag corrosion resistance of a ladle product with slag resistance are improved, thermal shock resistance of the ladle is greatly improved, the service life of an integrally poured ladle is effectively prolonged, and the service life is prolonged by 30% or above compared with ordinary same types of ladles.

Owner:张婷

An artificial light health care physiotherapy instrument capable of supplementing vitamin D and calcium

ActiveCN103394165BPromote absorption and transformationHigh absorption rateLuminescent compositionsRadiation therapySesquioxidePhysiology

The invention provides an artificial luminous health-care physiotherapy instrument capable of supplementing vitamin D and calcium. The artificial luminous health-care physiotherapy instrument comprises a red light generation unit, an ultraviolet lamp tube, a lamp shade, a display and a control circuit, wherein the ultraviolet lamp tube is made of violet ray glass; the fluorescent ultraviolet power which comprises the following components in percentage by weight: 23-27 percent of zinc sulfide, 18-22 percent of bismuth germanate, 14-18 percent of yttrium oxysulifde, 14-18 percent of magnesium silicate, 8-12 perecent of strontium wolframate, 4-8 percent of strontium aluminate, 3-5 percent of calcium pyrophosphate, 1.5-2.5 percent of butyl acetate and 0.5-1.5 percent of aluminium sesquioxide is absorbed on the inner wall of a lamp tube under electrostatic action. The health-care physiotherapy instrument can effectively supplement lost vitamin D and calcium in a human body so as to prevent and improve various diseases caused by the lack of vitamin D and calcium, and is good in efficacy of supplementing vitamin D and calcium, convenient and safe in use, and simple in structure.

Owner:赵同泉

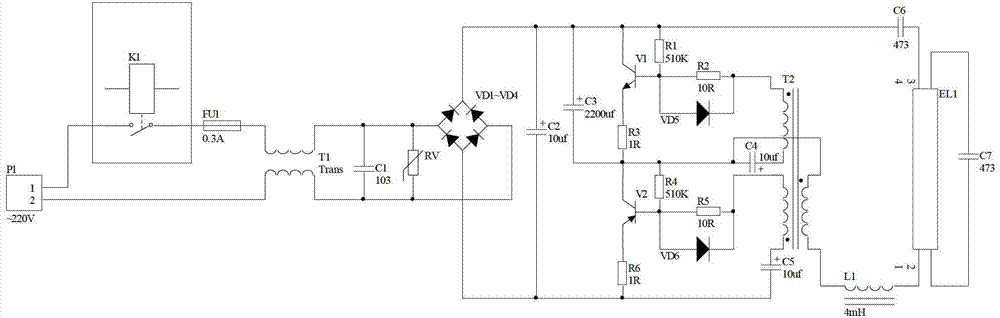

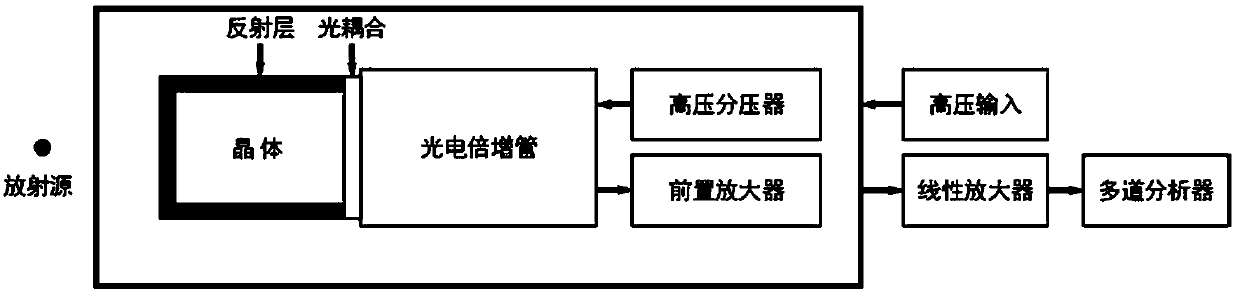

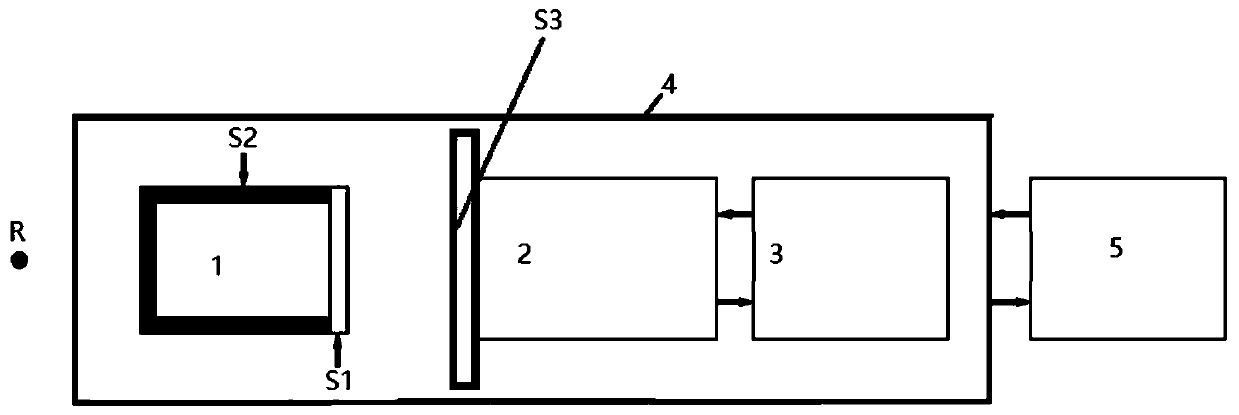

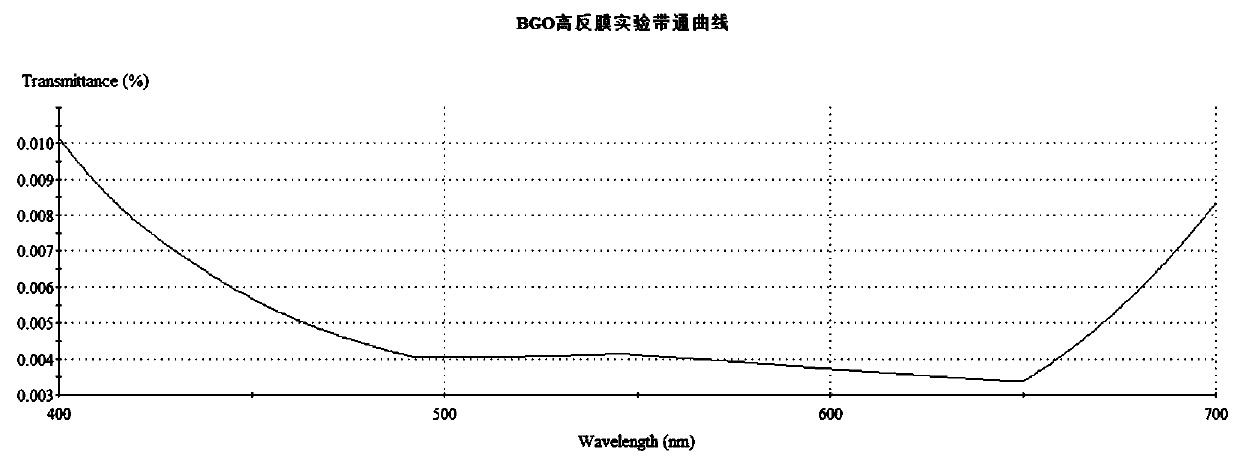

Bismuth germanate scintillating crystal radiation detector plated with high reflecting film and special light-out surface

InactiveCN110727014AImproved energy resolutionImprove light outputRadiation intensity measurementScintillation crystalsThin membrane

The invention relates to a scintillating crystal radiation detector plated with a high reflecting film and a special light-out surface. According to the detector, the conception of performing pertinent film design according to a main transmitting waveband of a scintillating crystal itself is adopted, and the difficulties that the data volume is excessively large and analysis is not easy in thin film research are overcome; an appropriate reflecting film material is obtained, the material has adhesive force as good as the crystal, and film layers are small in quantity and easy to realize; and special light-out surface design matched with a total-reflection film plating scheme is further provided, and measurement efficiency and measurement precision are improved accordingly.

Owner:刘佳莉

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com