Bismuth germanate nanometer powder preparation method

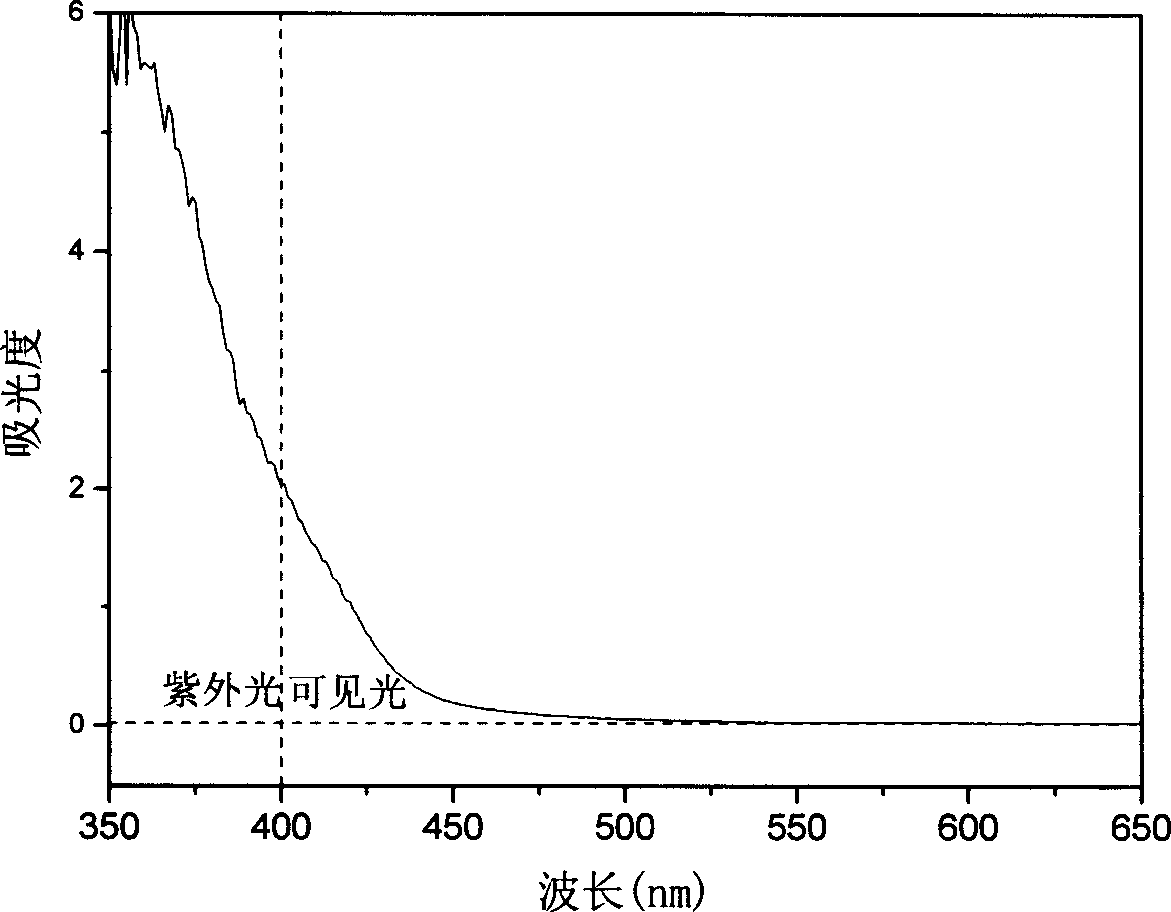

A nano-powder, bismuth germanate technology, applied in chemical instruments and methods, bismuth compounds, inorganic chemistry, etc., can solve the problems of difficulty in obtaining nano-powder, long time required for ball milling, low production efficiency, etc. The effect of uneven sintering mixing, widening the light response range, and low equipment requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

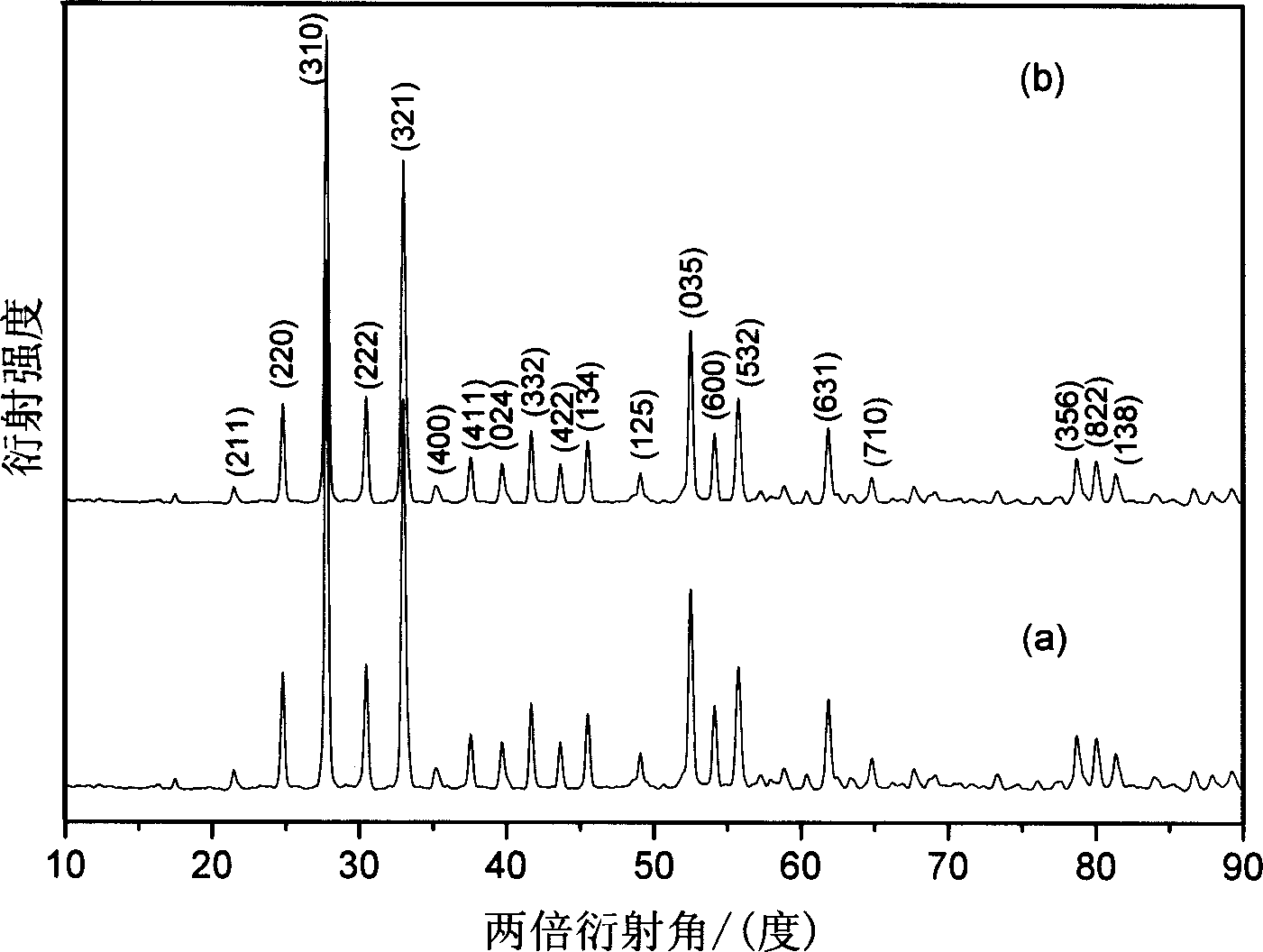

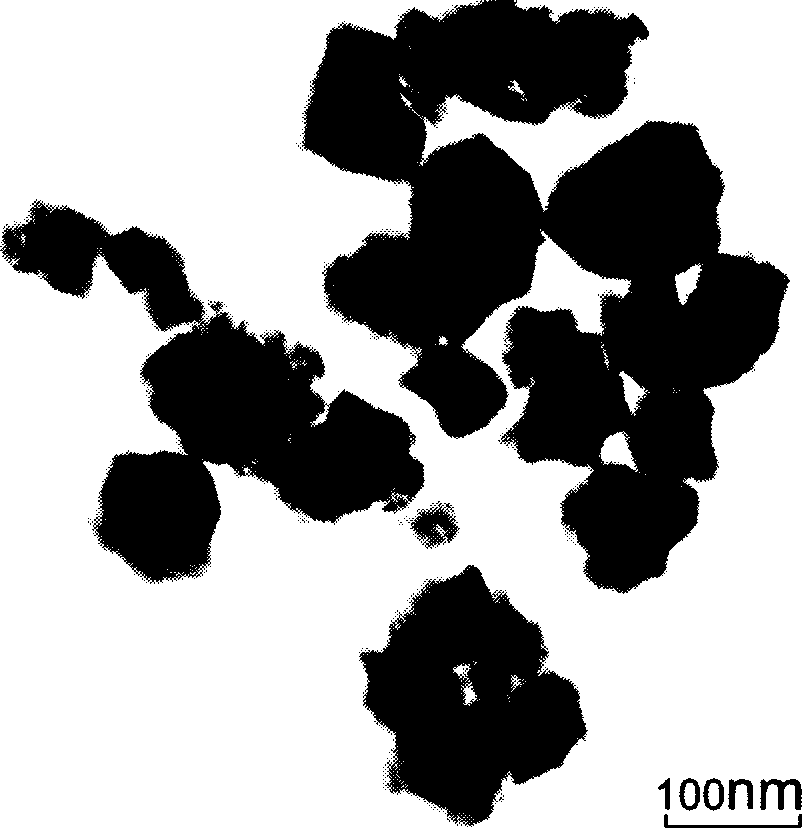

[0030] 0.12mol bismuth nitrate pentahydrate (Bi(NO 3 ) 3 ·5H 2 O) dissolved in 180ml glacial acetic acid (CH 3 COOH), then dropwise added 0.01mol tetraethoxygermanium ((C 2 h 5 O) 4 Ge), while adding 60ml ethylene glycol dimethyl ether (CH 3 OCH 2 CH 2 OH) as a co-solvent to adjust the viscosity of the solution, fully stirred to form a uniform sol. The aforementioned sol was evaporated and dried at 150° C. to obtain a precursor powder. The resulting precursor powder was sintered at 650 °C under normal pressure for 0.8 hours to obtain Bi 12 GeO 20 Nano powder.

Embodiment 2

[0032] 0.12mol bismuth nitrate (Bi(NO 3 ) 3 ) dissolved in 30ml of anhydrous acetone (CH 3 COCH 3 ), and then dropwise added 0.01mol tetramethoxygermanium ((CH 2 O) 4 Ge), while adding 15ml diethylene glycol dimethyl ether (CH 3 OCH 2 CH 2 ) 2 O was used as a co-solvent to adjust the viscosity of the solution, and it was fully stirred to form a uniform sol. The aforementioned sol was evaporated and dried at 350° C. to obtain a precursor powder. The resulting precursor powder was sintered at 750 °C under normal pressure for 0.5 hours to obtain Bi 12 GeO 20 Nano powder.

Embodiment 3

[0034] 0.12mol bismuth acetate (Bi(CH 3 COO) 3 ) dissolved in 100ml absolute ethanol (CH 3 CH 2 OH), and then add 0.01mol germanium nitrate (Ge(NO 3 ) 4 ), and stirred thoroughly to form a homogeneous sol. The aforementioned sol was evaporated and dried at 100° C. to obtain a precursor powder. The resulting precursor powder was sintered at 450 °C under normal pressure for 4 hours to obtain Bi 12 GeO 20 Nano powder.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com