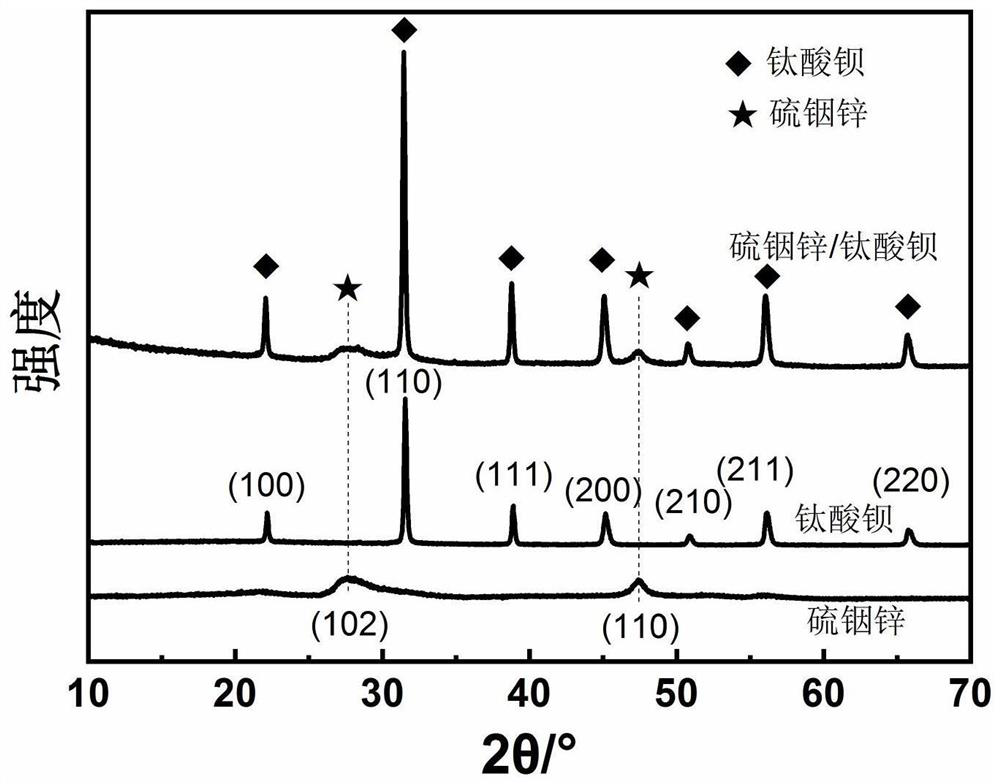

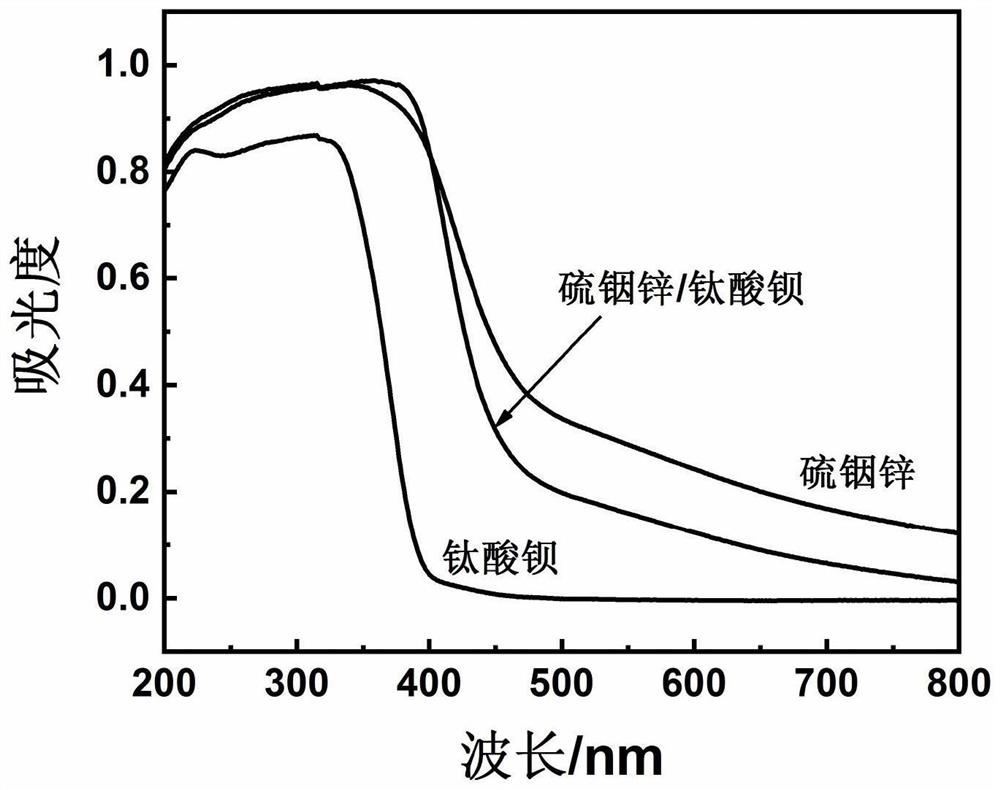

A kind of preparation method of sulfur indium zinc/barium titanate composite photocatalyst

A technology of indium-zinc sulfide and composite light, which is applied in catalyst activation/preparation, physical/chemical process catalysts, chemical instruments and methods, etc. Recombination probability, low cost, and the effect of extending the photoresponse range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

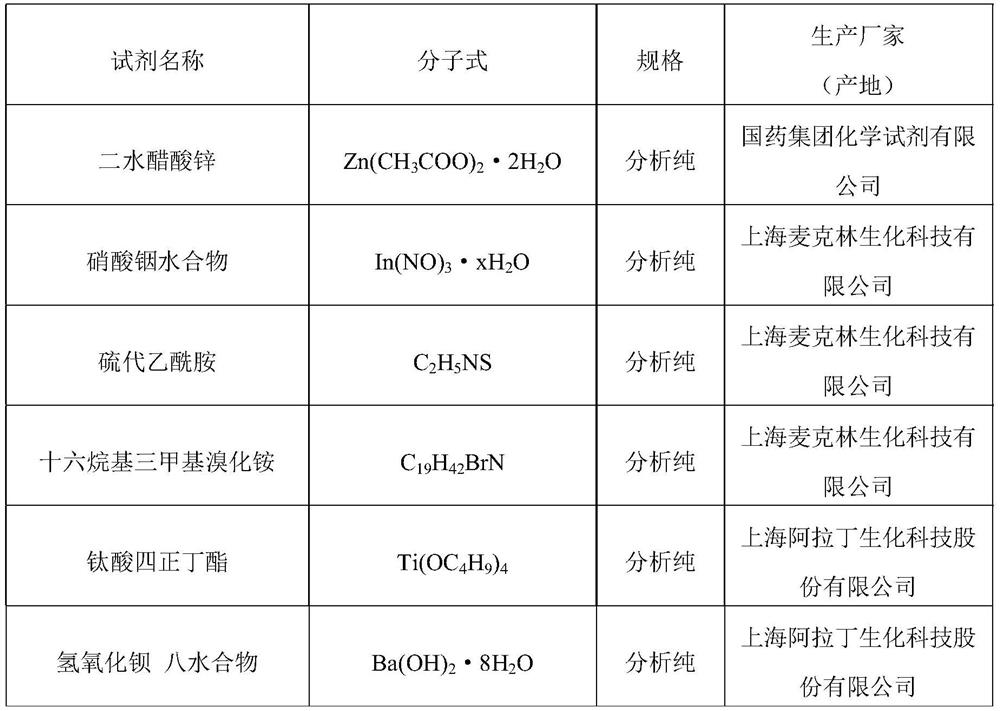

[0029] Weigh 2mmol of zinc acetate dihydrate, 4mmol of indium nitrate hydrate, and 16mmol of thioacetamide in a 100mL beaker, add 50mL of absolute ethanol, stir to dissolve, add 0.1g of cetyltrimethylammonium bromide, and continue to sonicate After stirring to form a transparent solution, transfer it to a 100mL polytetrafluoroethylene-lined hydrothermal kettle, add absolute ethanol to 80% of the total capacity, and after hydrothermal reaction at 180°C for 24 hours, the obtained solid is centrifuged, washed with water and alcohol 3 times each, after vacuum drying at 60°C for 24 hours to obtain sulfur indium zinc;

[0030] Weigh 2mL of tetra-n-butyl titanate and dissolve it in 15mL of absolute ethanol, add ammonia solution (V / V% is 50%) drop by drop until the hydrolysis is complete; add 2.78g of barium hydroxide and 50mL of water, and bathe in 90℃ water for 2h Until the barium hydroxide is completely dissolved; continue to add 0.2 g of the above-mentioned sulfur indium zinc, the...

Embodiment 2

[0039] Weigh 2mmol of zinc nitrate hydrate, 4mmol of indium trichloride hydrate and 12mmol of sodium sulfide in a 100mL beaker, add 50mL of absolute ethanol, stir to dissolve, add 0.1g of cetyltrimethylammonium bromide, continue to sonicate, After stirring to form a transparent solution, transfer it to a 100mL polytetrafluoroethylene-lined hydrothermal kettle, add absolute ethanol to 80% of the total capacity, and after hydrothermal reaction at 150°C for 16 hours, the obtained solid is centrifuged, washed with water and alcohol. 3 times, after vacuum drying at 60°C for 24 hours, sulfur indium zinc was obtained;

[0040] Weigh 2mL of tetraisopropyl titanate and dissolve it in 15mL of absolute ethanol, add ammonia solution (V / V% is 50%) drop by drop until the hydrolysis is complete; add 2.78g of barium hydroxide and 50mL of water, and bathe in water at 90°C for 1h Until the barium hydroxide is completely dissolved; continue to add 0.2 g of the above-mentioned sulfur indium zinc,...

Embodiment 3

[0044] Weigh 2mmol of zinc chloride, 4mmol of indium sulfate and 14mmol of thiourea into a 100mL beaker, add 50mL of absolute ethanol, stir to dissolve, add 0.1g of cetyltrimethylammonium bromide, continue ultrasonication and stirring to form a transparent solution Then transfer to a 100mL polytetrafluoroethylene-lined hydrothermal kettle, add absolute ethanol to 80% of the total capacity, and after hydrothermal reaction at 200°C for 8 hours, the obtained solid is centrifuged, washed with water and alcohol for 3 times, 60 After vacuum drying at ℃ for 24 hours, sulfur indium zinc was obtained;

[0045] Weigh 2mL of tetra-n-butyl titanate and dissolve it in 15mL of absolute ethanol, add ammonia solution (V / V% is 50%) drop by drop until the hydrolysis is complete; add 2.78g of barium hydroxide and 50mL of water, and bathe in 90℃ water for 2h Until the barium hydroxide is completely dissolved; continue to add 0.3 g of the above-mentioned sulfur indium zinc, then transfer to a poly...

PUM

| Property | Measurement | Unit |

|---|---|---|

| charge carrier lifetime | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com