Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

832 results about "Barium hydroxide" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Barium hydroxide is a chemical compound with the chemical formula Ba(OH)₂(H₂O)ₓ. The monohydrate (x =1), known as baryta or baryta-water, is one of the principal compounds of barium. This white granular monohydrate is the usual commercial form.

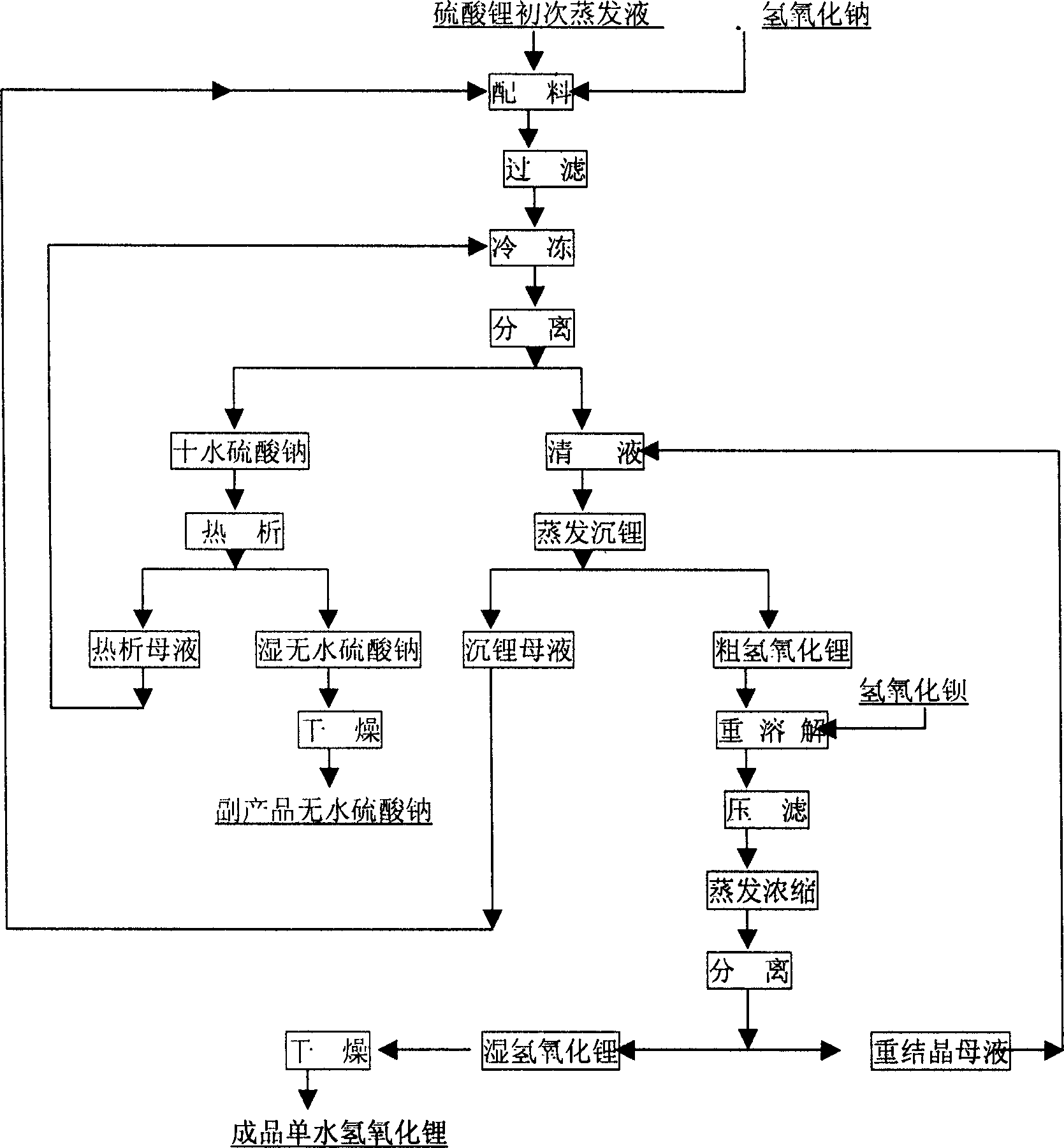

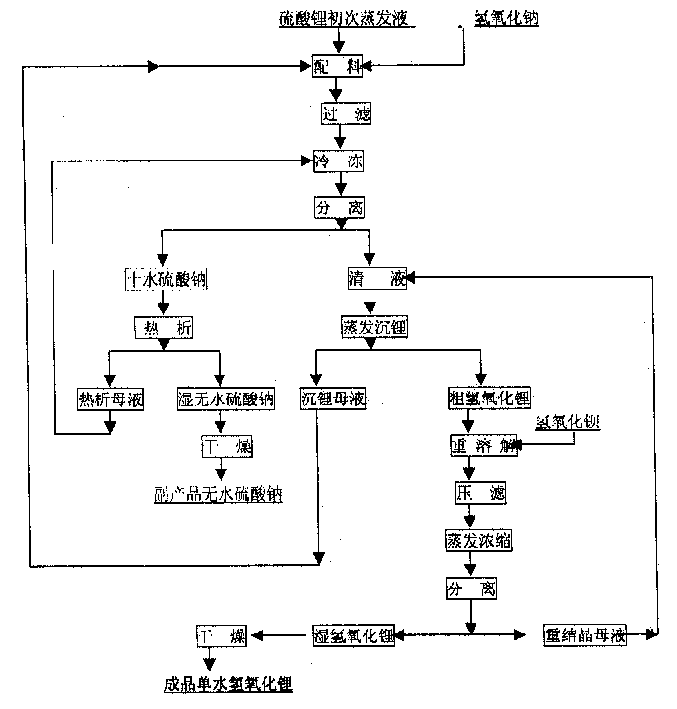

Production process of lithium hydroxide monohydrate

InactiveCN1486931AShort process routeHigh yieldSulfate/bisulfate preparationLithium oxides/hydroxidesSolubilityStrontium hydroxide octahydrate

In the production process of lithium hydroxide monohydrate, lithium sulfate solution and caustic soda are made to produce metathetic reaction to form mixture solution of sodium sulfate and lithium hydroxide, and sodium sulfate and lithium hydroxide monohydrate are then separated by means of the obvious difference in low temperature solubility. The production process includes the following steps: adding sodium hydroxide into lithium sulfate solution obtained through serial production steps to obtain mixture solution of sodium sulfate and lithium hydroxide; cooling to minus 10 deg.c to 5 deg.c for the crystallization and separation of sodium sulfate; heating to concentrate the separated clear liquid; crystallization and separation to obtain coarse lithium hydroxide monohydrate product; water dissolving coarse lithium hydroxide monohydrate, adding barium hydroxide to form insoluble barium sulfate, filtering, concentrating filtrate, crystallizing to separate wet lithium hydroxide monohydrate; and drying.

Owner:JIANGSU RONGHUI GENERAL LITHIUM IND CO LTD

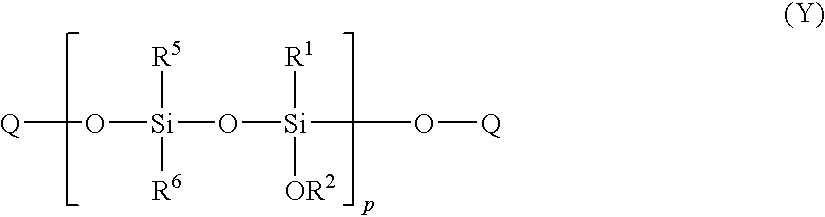

Process for producing polysiloxanes and use of the same

A process for the preparation of an organosilicon condensate which comprises reacting together a silicon containing compound having at least one silanol group and a silicon containing compound having at least one —OR group or at least one silanol group (or a compound having both groups) in the presence of strontium oxide, barium oxide, strontium hydroxide or barium hydroxide and optionally a solvent such as water, methanol, ethanol, 1-propanol, 2-propanol, 1-butanol and 2-butanol, acetone or toluene.

Owner:ZETTA RES & DEV LLC RPO SERIES

Novel method for producing lithium carbonate and lithium hydroxide

InactiveCN102115101ASimple production processLow costLithium oxides/hydroxidesLithium carbonates/bicarbonatesLithium sulphateCalcium hydroxide

The invention relates to a novel method for producing lithium carbonate and lithium hydroxide, which belongs to the technical field of production of lithium salts. The method comprises the following steps of: baking spodumene concentrate; preparing a lithium sulfate solution; preparing lithium carbonate mother liquor; and preparing lithium hydroxide, wherein the lithium hydroxide can also be obtained by adding barium hydroxide into the lithium carbonate mother liquor. The method has the advantages that: lime is added into a lithium carbonate sinker mother liquor to produce the lithium hydroxide by causticizing and transforming, and the production of lithium carbonate is combined with the production of the lithium hydroxide, so that a process flow is simplified, investment and production costs are lowered, a production process is more flexible to regulate and control, and the quality of a lithium carbonate product is more stable. By adopting the method, the mother liquor of lithium carbonate is easier to treat, impurities in the lithium hydroxide mother liquor are easy to treat, and the product quality is not influenced.

Owner:屈俊鸿

White carbon black rubber reinforcer and preparation method thereof

The invention relates to white carbon black rubber reinforcer and a preparation method thereof, and relates to rubber reinforcers. The white carbon black rubber reinforcer is white carbon black powder. By weight percent, nanoparticles in the white carbon black powder account for more than 80% of the total white carbon black powder. The preparation method includes: adding sodium silicate solution into a reactor, adding surfactant and silane coupling agent, heating, preheating carbon dioxide by a preheater, and adding the preheated carbon dioxide in the reactor for reaction to obtain reaction liquid; relieving the reactor to normal pressure, transferring the reaction liquid in the reactor to an ageing tank, and allowing for ageing to obtain aged slurry; rinsing and filtering the aged slurry, subjecting the aged slurry to solid-liquid separation to obtain filter cakes, washing the filer cakes, adding water to make slurry, adding sulfuric acid solution for acidification to keep pH of the acidified slurry at 3-7, continuing to filter and rinse until detected filtrate of saturated barium hydroxide solution has no precipitation, making the rinsed filter cakes into slurry, and drying the slurry to obtain the white carbon black rubber reinforcer.

Owner:XIAMEN UNIV

Internally-doped capillary crystalline waterproof material and preparation method thereof

InactiveCN105731859AImprove waterproof and anti-seepage performanceLow costCalcium hydroxideActive component

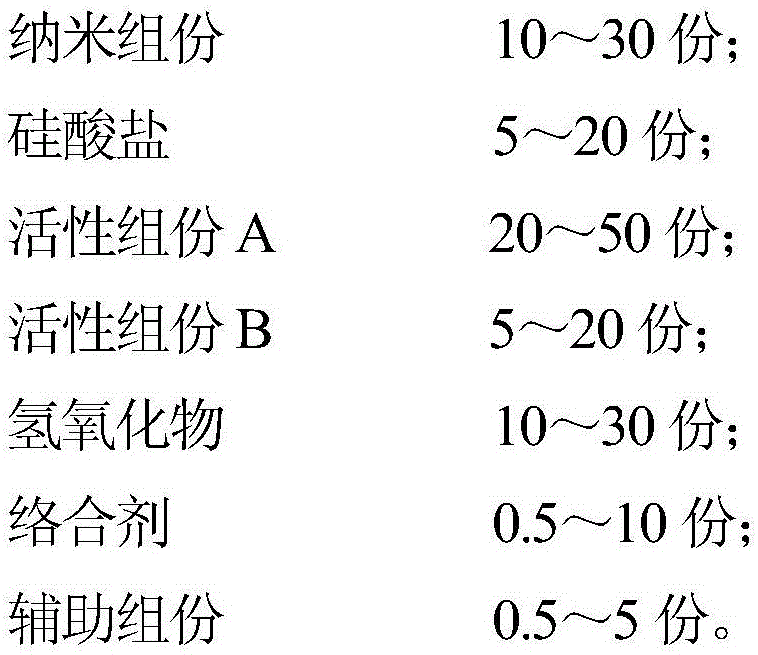

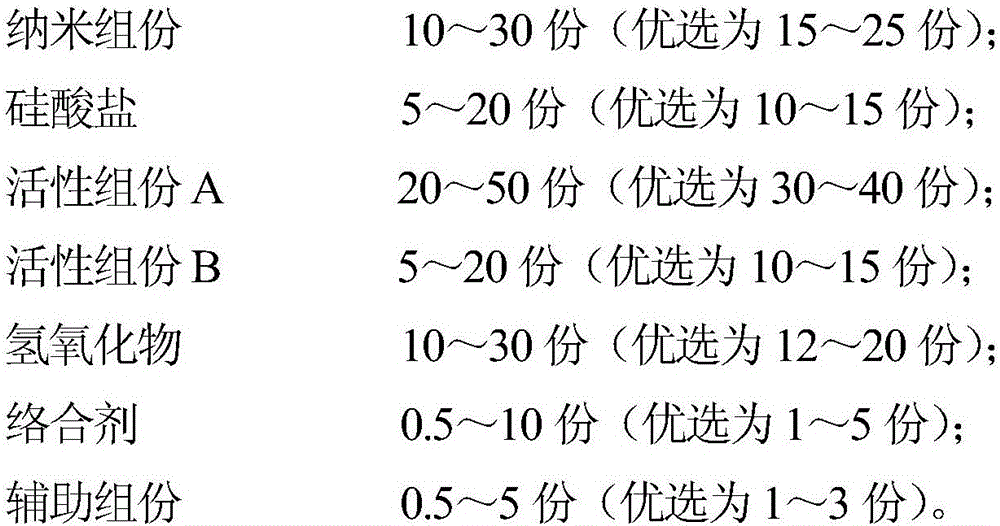

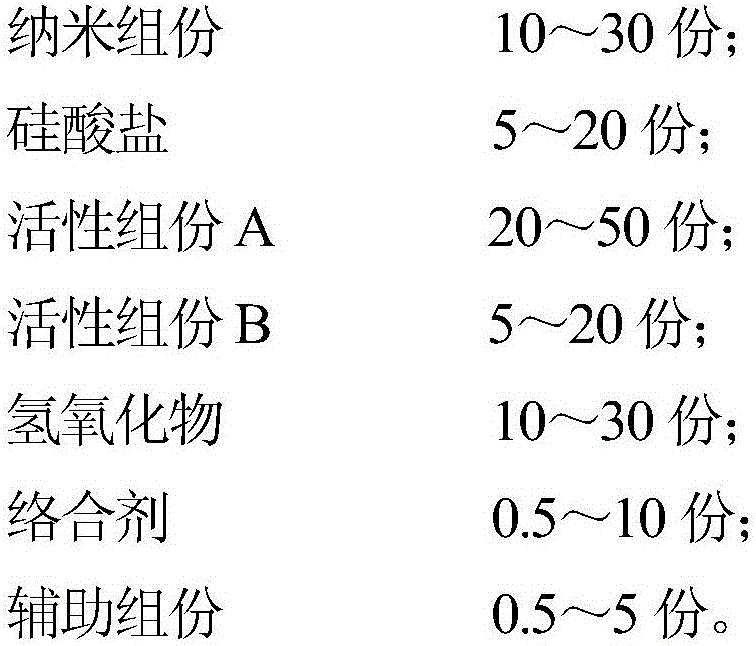

The invention relates to the field of cement concrete waterproof materials, in particular to a built-in osmotic crystal waterproof material and a preparation method thereof. The composition and mass parts of each component of the intermixed osmotic crystalline waterproof material are: 10-30 parts of nanometer component; 0.5-10 parts of complexing agent; 5-20 parts of silicate; 20-50 parts of active component A; 5-20 parts of active component B; 10-30 parts of calcium hydroxide / magnesium hydroxide / barium hydroxide; 0.5-5 parts of auxiliary components. First, mix the complexing agent and auxiliary components thoroughly; add calcium hydroxide / magnesium hydroxide / barium hydroxide to the above mixture, and stir well, then add active component A, active component B, silicate in sequence Components, nanomaterial components, and evenly mixed, weighed, packaged. The built-in permeable crystalline waterproof material of the invention can significantly improve the anti-permeability of the cement concrete structure, and can also improve the volume stability of the cement concrete structure and the like.

Owner:SHENYANG JIANZHU UNIVERSITY

Barium metaphosphorate production process

InactiveCN1800000ASimple production processLow costPhosphorus compoundsManufacturing technologyPhosphate

The invention discloses a manufacturing technology of barium metaphosphate, which comprises the following steps: putting barium hydroxide in the container; adding the deionized water and active carbon to stir and heat with 1.05-1.10 specific gravity until the barium hydroxide is dissolved completely; stewing; filtering; obtaining fine barium hydroxide with iron, bronze, nickel, manganese and cobalt less than 0.0003 percent; putting the barium hydroxide in another container to stir and add high-quality phosphate; adjusting the pH value at 9-11 to obtain the deposition of barium hydrophosphate; adding the deionized water to dilute; obtaining the mixing paste of barium hydrophosphate; drying and condensing into barium metaphosphate by centrifugal spray. The technology is easy to adjust and control, whose production impurity content is low and recovery rate is high.

Owner:SHANXI SUPERNEW METAL MATERIAL

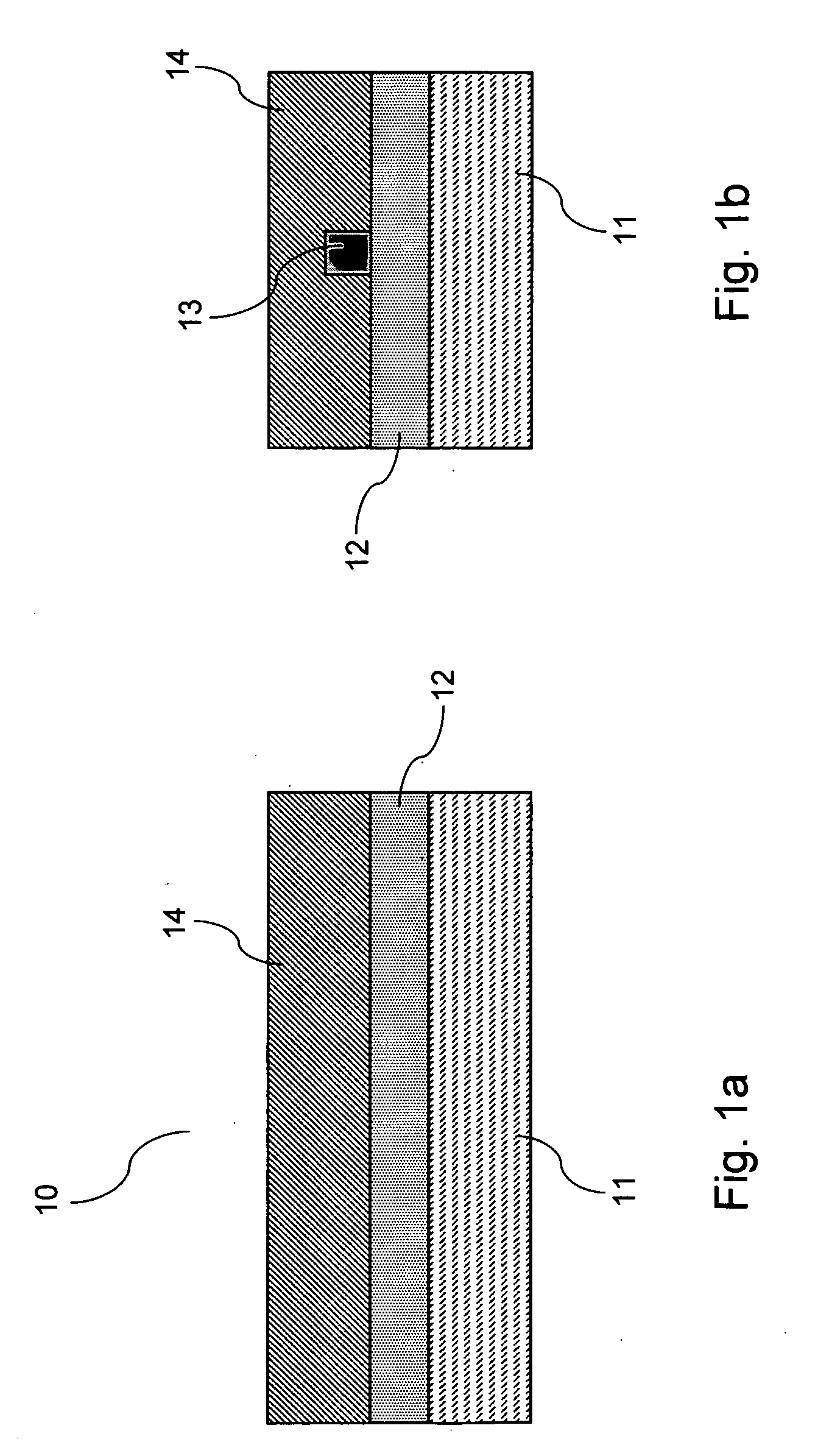

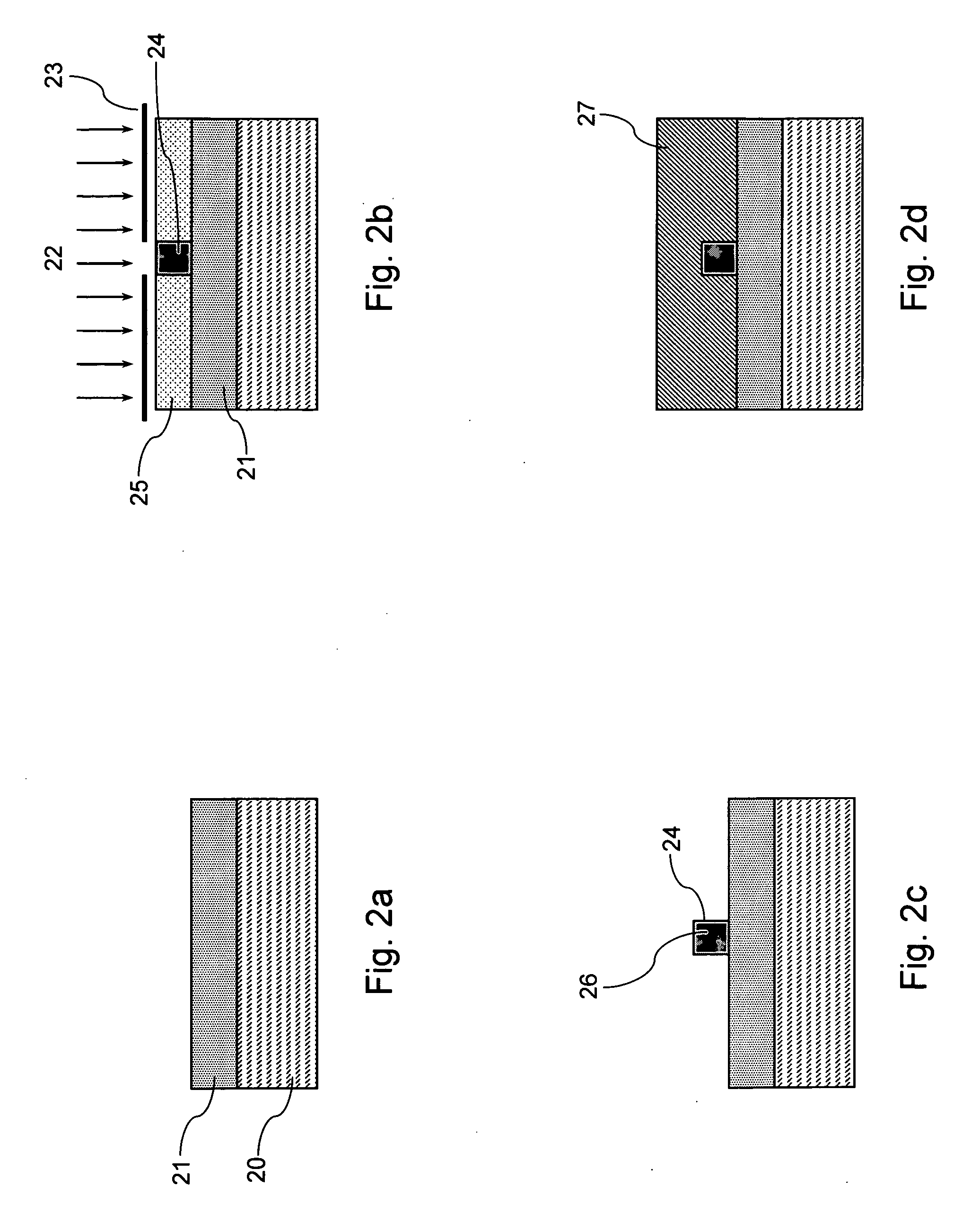

Method for producing polycrystal ingot

InactiveCN101696514AIncrease profitImprove efficiencyPolycrystalline material growthBy pulling from meltBarium saltShielding gas

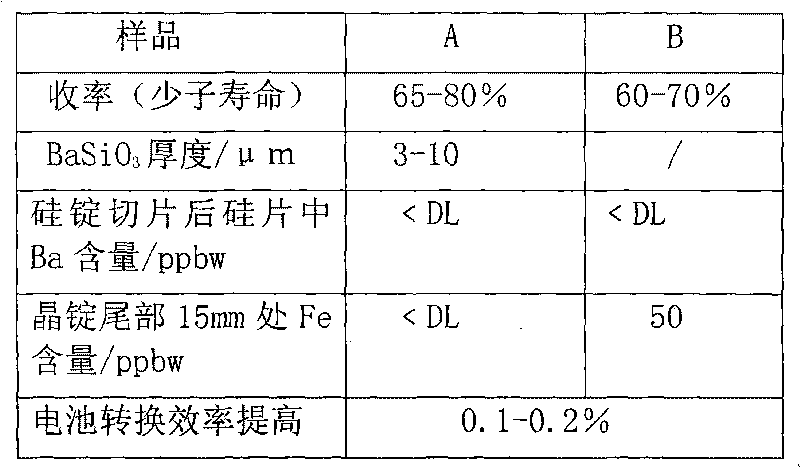

The invention relates to a method for producing a polycrystal ingot, which comprises the following steps: preparing a solution of barium hydroxide or a barium salt serving as a coating solution; preheating a quartz ceramics crucible; uniformly coating the coating solution of the solution of the barium hydroxide or the barium salt on the inner surface of the preheated quartz ceramics crucible; baking the quartz ceramics crucible; spraying silicon nitride on the inner surface of the quartz ceramics crucible after baking and rotating the quartz ceramics crucible; filling a silicon material into the quartz ceramics crucible; putting the quartz ceramics crucible into a polycrystal furnace; vacuumizing the polycrystal furnace and adding a protective gas to the polycrystal furnace; heating the silicon material to smelt the silicon material; gradually crystallizing the melted silicon material from the bottom to the top by directional solidification; at last performing high temperature annealing to form the polycrystal ingot used for making a battery through slicing; slicing a crystal ingot into silicon slices; making the silicon slices into battery plates by making herbs into wool, diffusing, etching edges, PECVD filming, screen painting and sintering; and testing and grading the battery plates. The coating in the crucible prevents impurities in the crucible from diffusing to the silicon material, and improves the lifetime of minority carrier close to the crucible, the utilization rate of the crystal ingot and the battery conversion efficiency.

Owner:TRINA SOLAR CO LTD

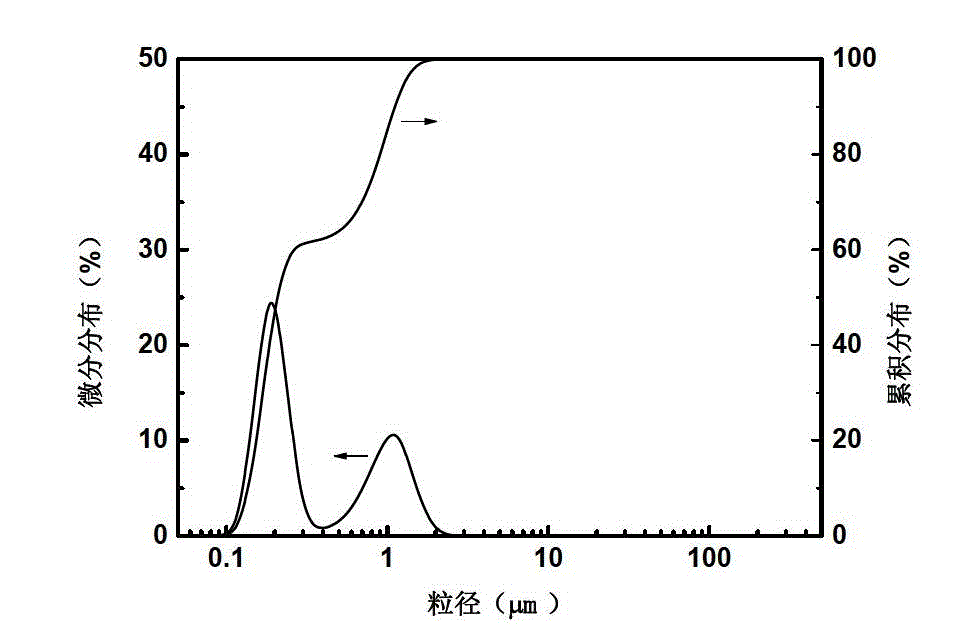

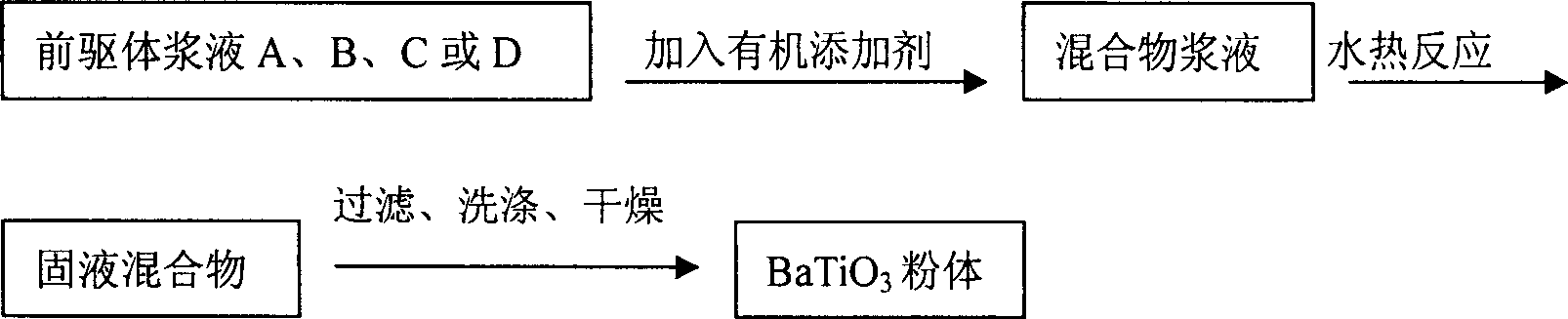

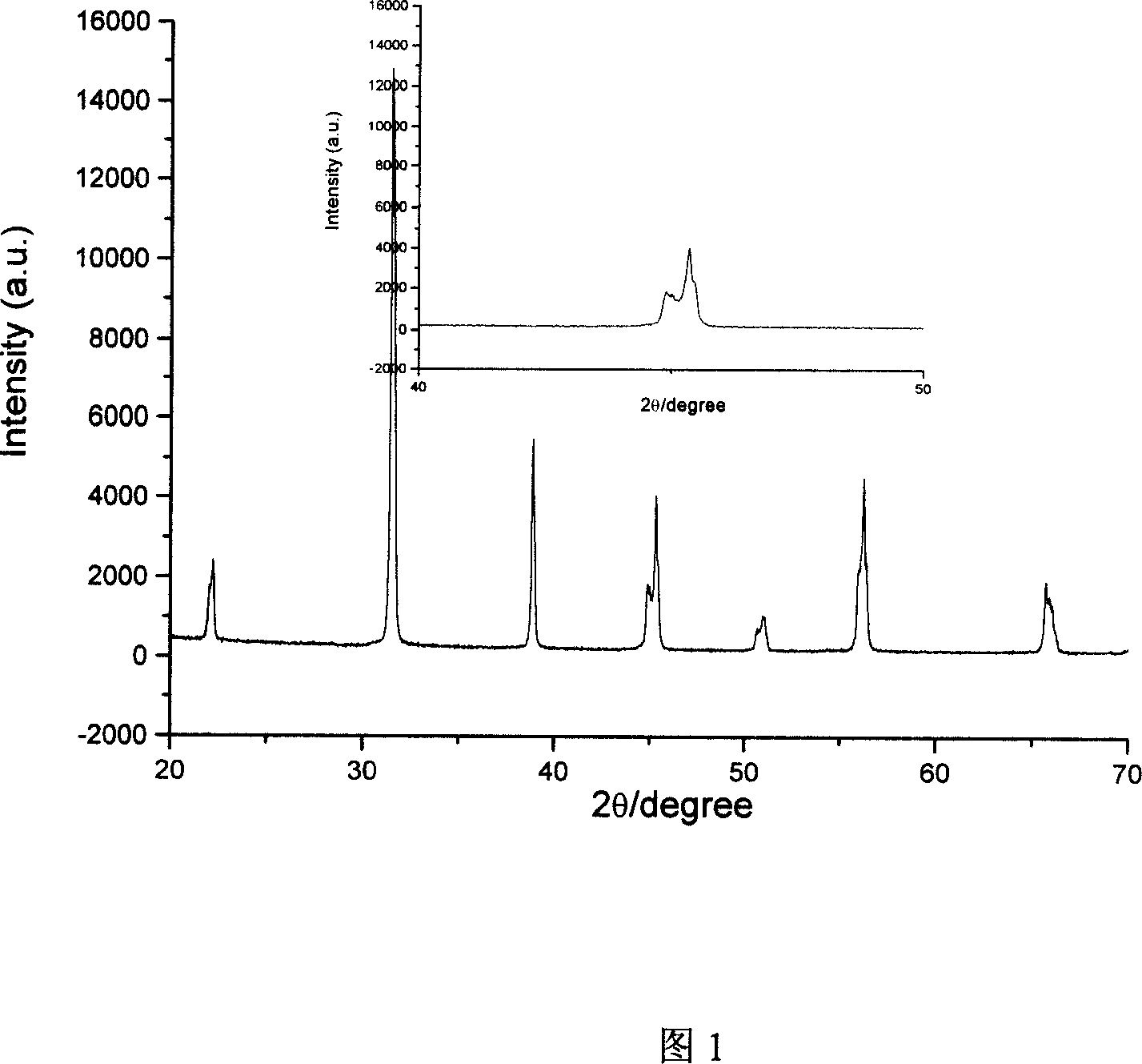

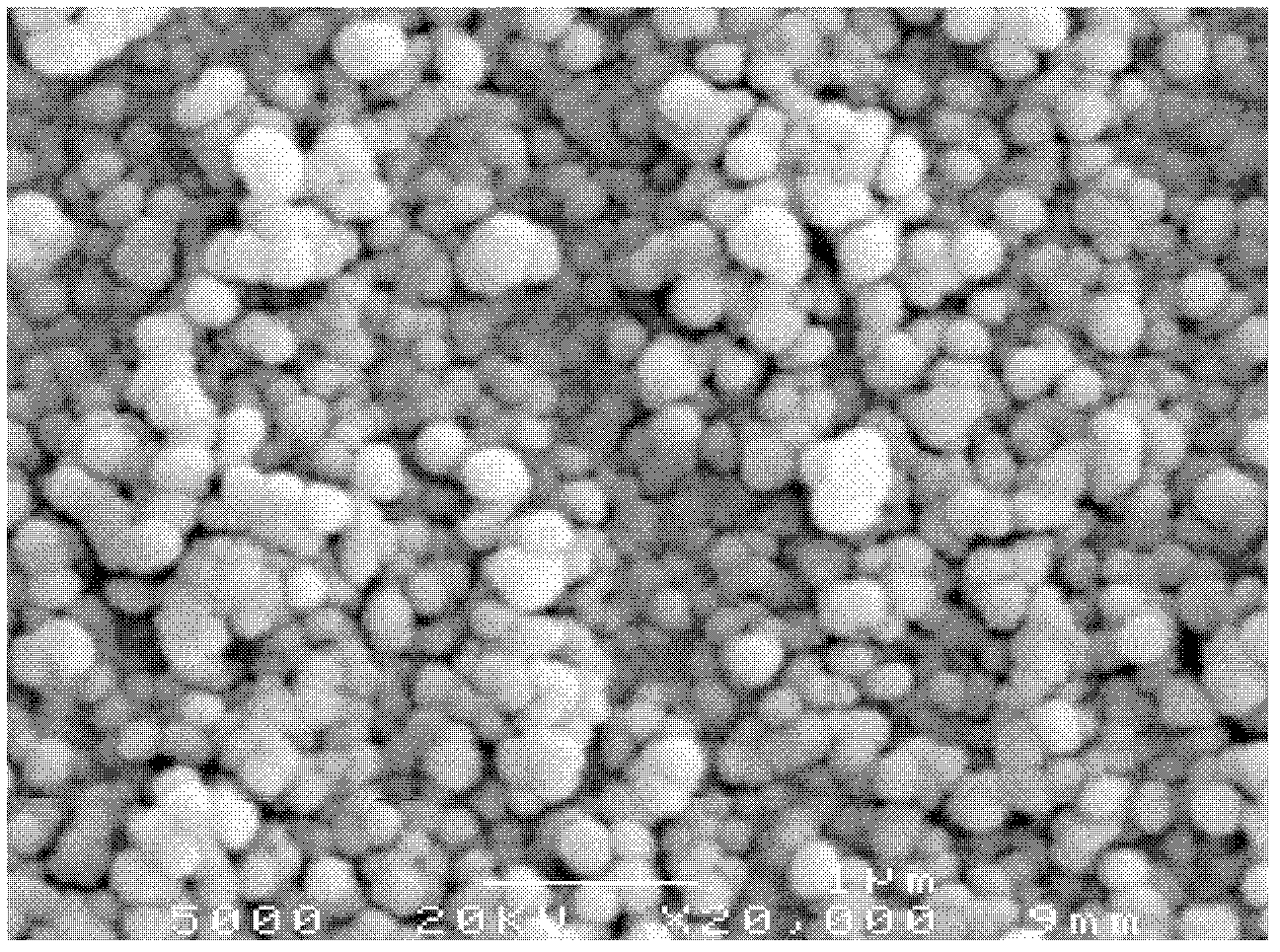

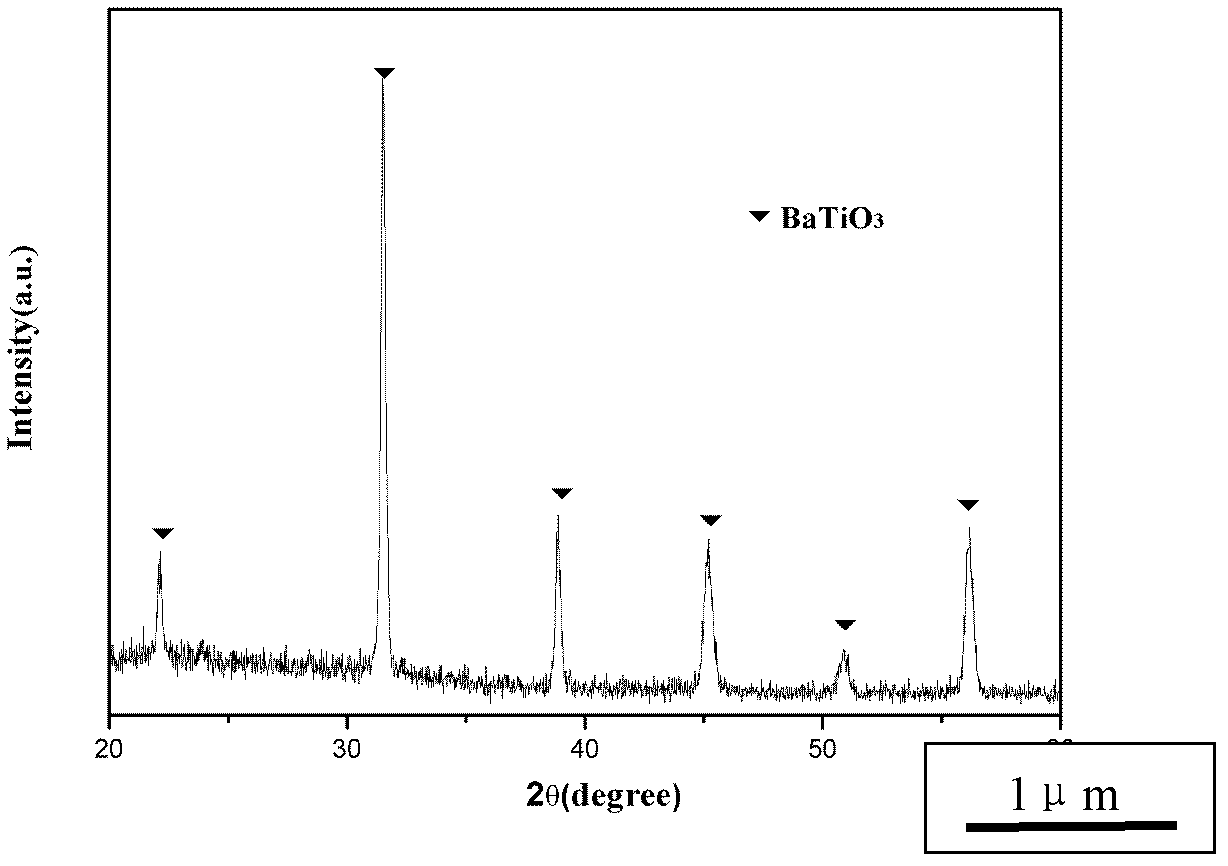

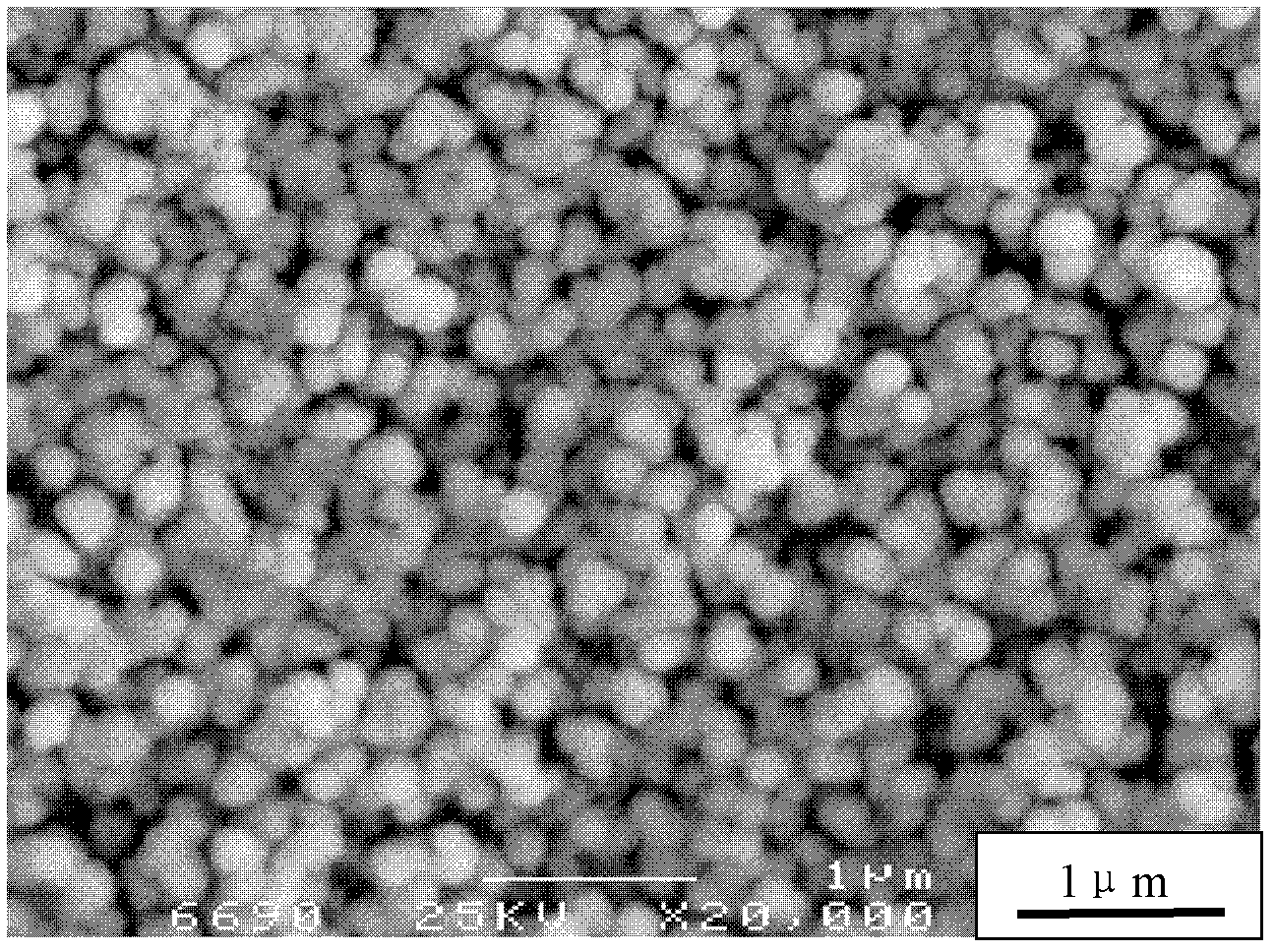

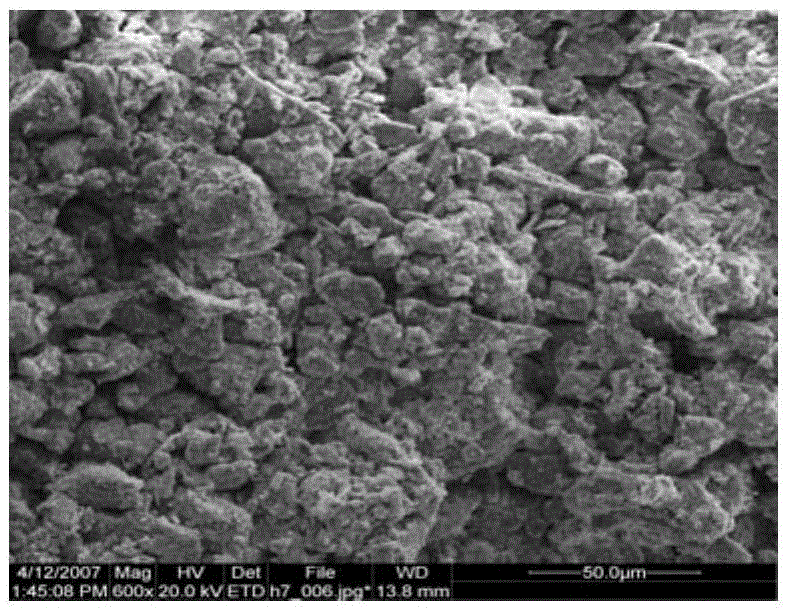

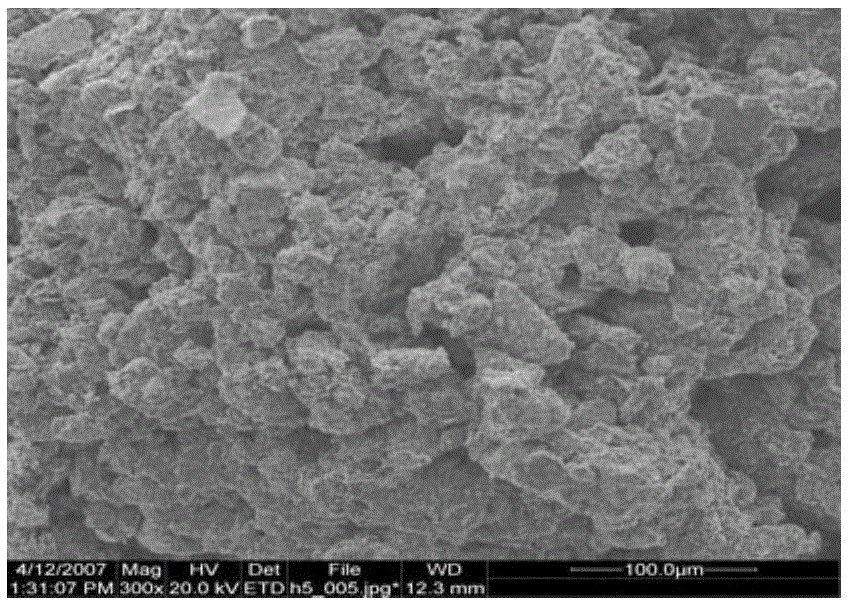

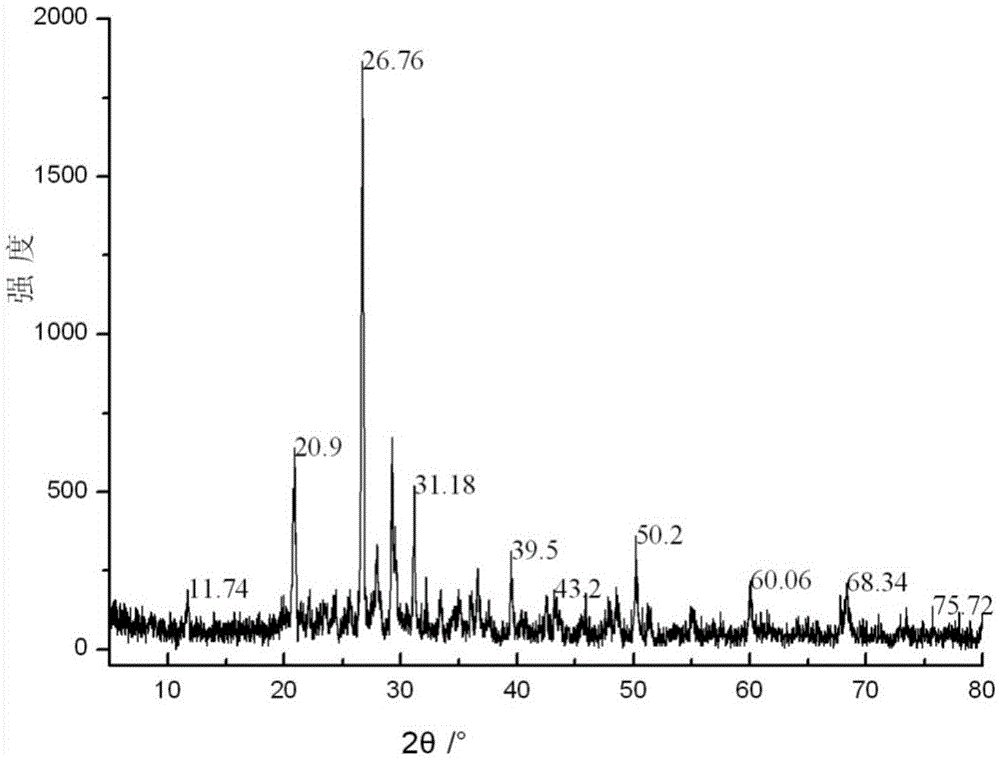

Preparation method of barium titanate powder body

InactiveCN1400168ANarrow particle distributionGood dispersionCalcium/strontium/barium carbonatesTitanium compoundsTitanium tetrafluorideBarium titanate

The preparation method of barium titanate (BaTiO3) includes the following steps: using titanium tetrafluoride and barium chloride or barium hydroxide as main raw material to prepare precursor body slurry liquor, then adding organic additive according to a certain ratio, placing them into reaction still to make hydrothermal reaction so as to obtain the invented product BaTiO3 powder body whose grain size is 20-200 nm. Said invented advantage lies in that it utilizes the regulation of class of organic additive and reaction condition to can regulate grain size distribution of product and make its product possess good grain uniformity, high sintering activity, high material property and chemical activity, and said method is easy to implement large-scale industrial production.

Owner:SHANDONG UNIV

Method for preparing uniform dispersion square phase barium titanate nanocrystal

InactiveCN101045554ANanostructure manufactureTitanium compoundsBarium titanateHydrothermal synthesis

A process for preparing the uniformly dispersed square barium sodium titanate nanocrystals by hydrothermal synthesis method includes using inorganic alkali or the combination of organ alkali and inorganic alkali to regulate the pH value of reaction system, respectively preparing the homogeneous solutions of the reactant precursors (TiO2 or tetrabutyl titanate and barium hydroxide) at 80-100 deg.C, and two-stage hydrothermal reaction in high-pressure reactor at 100-200 deg.C while crystallizing.

Owner:胜利油田华鑫石油材料有限公司

Coal-saving devulcanized coke cleaning clean synergistic agent and preparation technique thereof

InactiveCN101348743ALower ignition pointImprove oxidation effectSolid fuelsStrontium carbonateFerrosilicon

The invention relates to a process for preparing a clean synergist for saving coal, desulfurization and cleaning coke. Active calcium oxide and magnesium hydrate are mixed and added with sodium carbonate, ferrosilicon powders, manganese dioxide, strontium carbonate and barium hydroxide in turn and finally added with active carbon and evenly mixed to prepare the clean synergist which comprises the following compositions in percentage by weight: 20 to 30 percent of the active calcium oxide, 9 to 12 percent of the magnesium hydrate, 12 to 20 percent of the sodium carbonate, 8 to 10 percent of active carbon, 12 to 15 percent of the ferrosilicon powders, 8 to 12 percent of the manganese dioxide, 3 to 5 percent of the strontium carbonate and 5 to 7 percent of the barium hydroxide. on the premise of unchanging the prior coal burning process and equipment of various boilers and the prior smoke exhaust process and equipment, the clean synergist of the process is only needed to add according to the physicochemical index of coal used by customers, thereby achieving the functions of saving the coal, the desulfurization and cleaning the coke.

Owner:陈宏谋 +1

Solar water heater phase change heat storage material and its preparing method

InactiveCN1821340AHigh thermal efficiencyReduce volumeSolar heat devicesHeat-exchange elementsSolar waterZinc Acetate Dihydrate

The present invention discloses a kind of phase change heat storing material for solar water heater and its preparation process. The phase change heat storing material consists of sodium acetate trihydrate 80-90 wt%, barium hydroxide octahydrate 1-10 wt%, sodium borate decahydrate 1-5 wt%, zinc acetate 1-5 wt%, sodium dodecyl benzene sulfonate 1-5 wt% and gelatin 1-5 wt%. During the preparation, the mixture of the above said materials are heated to smelt completely to form the eutectic mixture, which is mounted inside solar water heater. The phase change heat storing material for solar water heater has phase change temperature fitting the operation temperature of solar water heater, high phase change latent heat, no overcooling and phase separation, no toxicity, no corrosion, stable performance and high repeatability, and is especially suitable for use in solar water heater.

Owner:NANJING UNIV

High-efficiency super-smooth chemical mechanical polishing method for lithium niobate crystal

InactiveCN103978406AReduce flatnessImprove removal efficiencyLapping machinesLapping toolsNonlinear optical crystalOXALIC ACID DIHYDRATE

The invention discloses a high-efficiency super-smooth chemical mechanical polishing method for a lithium niobate crystal and belongs to the technical field of ultraprecision machining of nonlinear optical crystals. The high-efficiency super-smooth chemical mechanical polishing method is characterized in that a sample is a lithium niobate crystal; the lithium niobate crystal is processed by adopting a method of combining grinding of bonded abrasives, polishing of a retaining ring hard polishing pad and chemical mechanical polishing of a retaining ring soft polishing pad, wherein the hard polishing pad is a synthetic leather or polyurethane polishing pad; the soft polishing pad is non-woven fabric or fuzzy polishing pad; a pH value of a chemical mechanical polishing solution is 10.2-10.6; the chemical mechanical polishing solution contains four kinds of cerium oxide, silicon oxide, potassium hydroxide, sodium hydroxide, barium hydroxide, potassium permanganate, hydrogen peroxide, citric acid, acetic acid and oxalic acid; the grinding time of the bonded abrasives is 15-25 minutes; the polishing time of the hard polishing pad is 50-70 minutes; the chemical mechanical polishing time is 3-6 minutes; the removal rate of materials for chemical mechanical polishing is 420-460nm / min; the planeness of the polished lithium niobate is 3.8-5.5[mu]m; the surface roughness Ra of the polished lithium niobate is 0.35-0.5nm and the PV value of the polished lithium niobate is 3.8-6nm. The high-efficiency super-smooth chemical mechanical polishing method disclosed by the invention has the beneficial effect that a high-efficiency super-smooth polishing method of a nonlinear optical crystal is realized.

Owner:DALIAN UNIV OF TECH

Method for producing phenolic resin by utilizing paraformaldehyde

The invention relates to a method for producing phenolic resin by utilizing paraformaldehyde, which comprises the following steps of: 1. preparing raw materials in the following proportion by weight: 350-400 phenol, 176-224 paraformaldehyde, 1.5-2 sodium hydroxide, 10-15 barium hydroxide, 14-20 urea and 80-150 water; 2. adding the phenol, the sodium hydroxide and the barium hydroxide into a reaction kettle for heating; adding 1 / 8 of paraformaldehyde and controlling the temperature in the kettle; and adding again every 15-25 minutes and adding totally seven time; 3. preserving heat for 60-80 minutes and then heating to the temperature of 95-110 DEG C for high temperature reaction for 30-50 minutes; and 4. when an opacifying point reaches 52-57 DEG C, adding the urea and the water and discharging when the temperature in the kettle is decreased to 50 DEG C to obtain a finished product. The method overcomes the problems of inconvenient liquid formaldehyde transportation, large energy consumption, environmental pollution and the like troubling enterprise development for a long time, and is beneficial to the development of the trade.

Owner:湖南中野高科技特种材料有限公司

A method for recovering and preparing a lithium-manganese-iron phosphate positive-electrode material covered with carbon from waste lithium iron phosphate batteries

InactiveCN108923090AHigh recovery rateHigh purityCell electrodesNanotechnologyLithium iron phosphateFiltration

The invention provides a method of recovery and reutilization of waste lithium iron phosphate batteries. The method includes (1) separating positive electrode material mixture from the waste lithium iron phosphate batteries; (2) fully dissolving the positive electrode material mixture with sulfuric acid, performing filtration to obtain a first filtrate, adding ammonia water into the filtrate understirring until the pH value of the system is 1.0-1.9, stirring the mixture, and performing filtration to obtain a second filtrate and iron phosphate precipitate; (3) adding barium hydroxide or bariumnitrate into the second filtrate and performing filtration to obtain a third filtrate; (4) adding the third filtrate, the iron phosphate precipitate, a manganese source, a phosphorus source and a carbon source according to the element ratio of a product to be prepared that is lithium-manganese-iron phosphate LiFe<1-x>Mn<x>PO4 to obtain a solution mixture; and (5) subjecting the solution mixture to ball milling, drying and crushing, pre-sintering a product at a first temperature in an inert atmosphere, and sintering the product at a second temperature to obtain the lithium-manganese-iron phosphate positive-electrode material covered with carbon. Through the method, all elements in the waste lithium iron phosphate batteries are recovered and reutilized.

Owner:SHENZHEN DYNANONIC

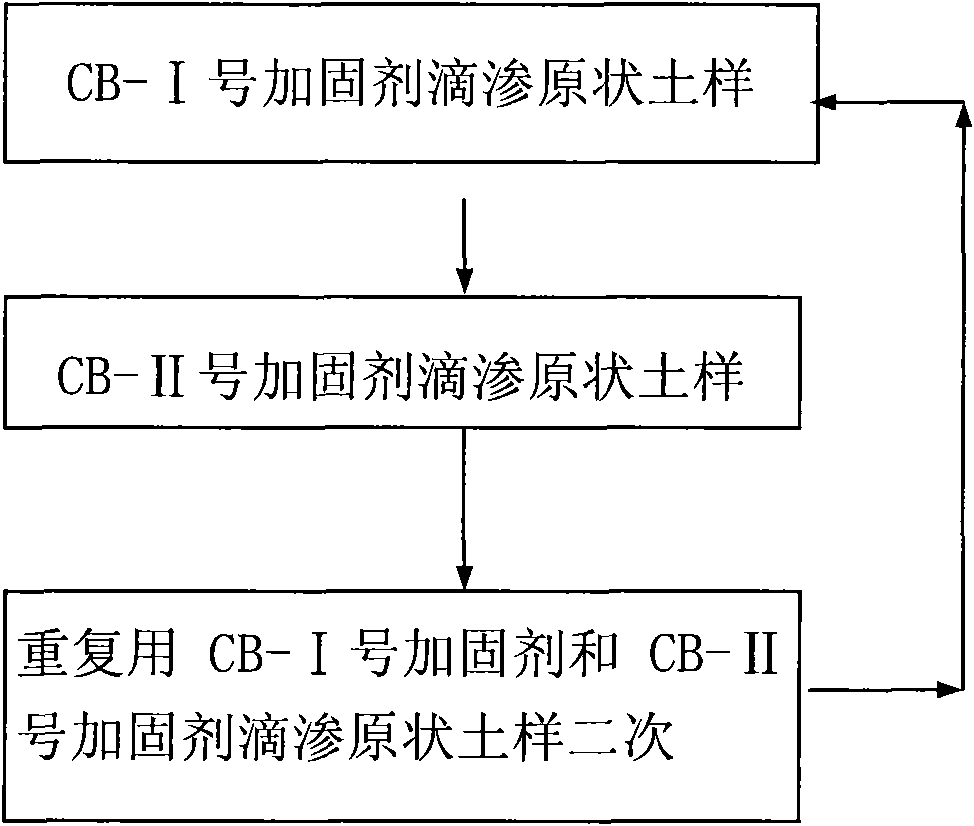

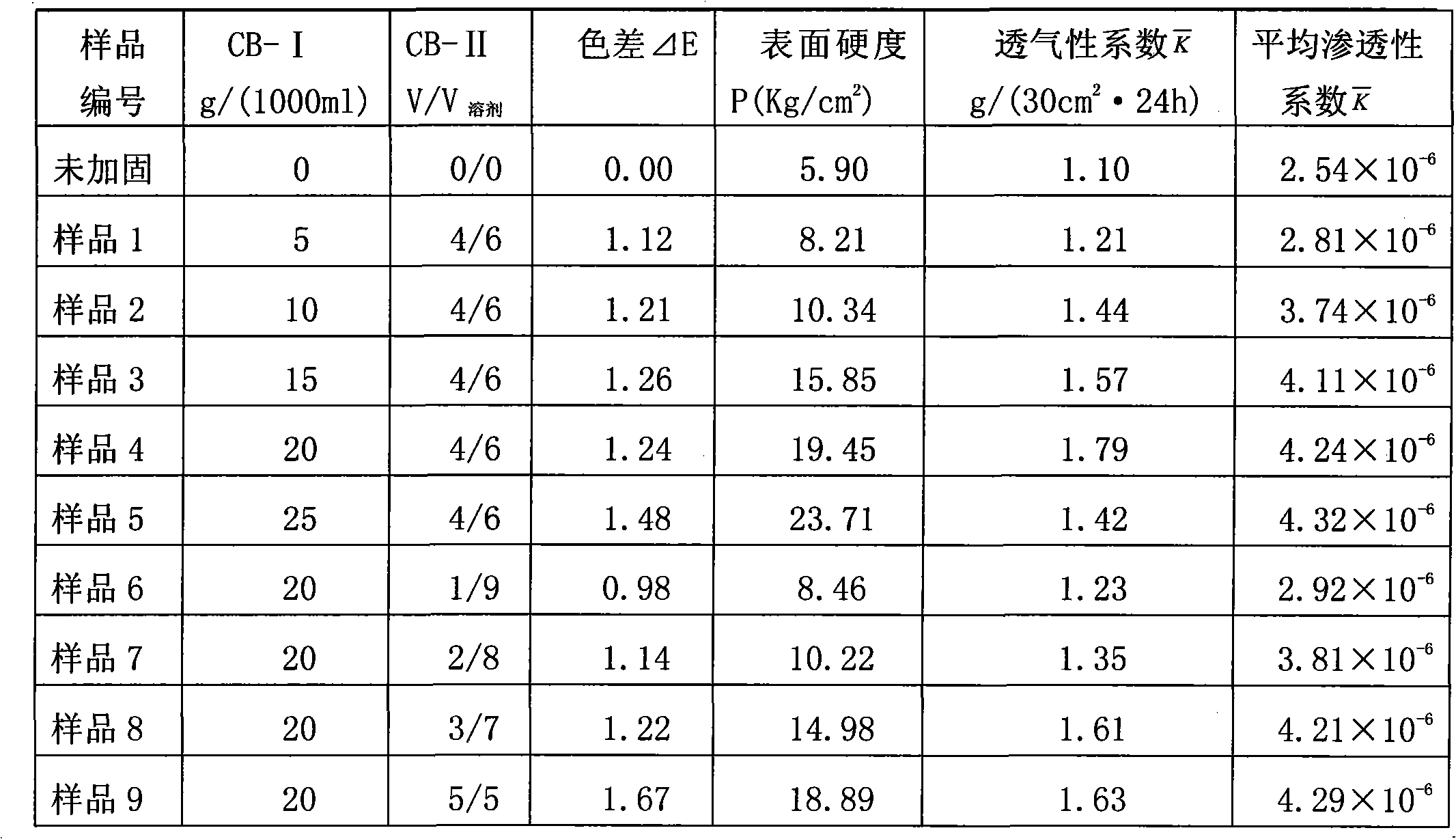

Loess relic efflorescence-proof reinforcing agent and preparation and reinforcing method thereof

ActiveCN101935531AImprove reinforcementLow costOther chemical processesOrganic fertilisersOxalatePolymer science

The invention relates to a loess relic efflorescence-proof reinforcing agent and a preparation and reinforcing method thereof. The method comprises the following steps: dissolving 5-25g of oxalate and 1-15ml of CB-I reinforcing agent prepared from phosphoric acid in every 1000ml of ethanol, and dissolving 15-150g of CB-II reingorcing agent prepared from barium hydroxide in every 2500ml of carbinol; and utilizing a dual reinforcing method of carrying out microprecipitation and adsorption on the losess relic by the CB-I reingorcing agent and the CB-II reingorcing agent, and utilizing a three-step dripping mode to achieve the reinforcing effect. By adopting the technical scheme of the invention, a loess relic efflorescence-proof reinforcing material and the reinforcing method which are suitable for dry, semi-dry and humid environment conditions of a semihumid area are obtained. The chemical raw materials of the invention are technical pure, and has the advantages of low cost, simple manufacturing process and reinforcing method, and easy operation, thereby having good market development prospect. After being processed by the loess relic efflorescence-proof reinforcing material of the invention according to the reinforcing method, the loess relic shows excellent reinforced effect.

Owner:SHAANXI NORMAL UNIV

Preparation method for monodisperse barium titanate nanopowder

InactiveCN102502798AAvoid generatingHigh purityNanotechnologyTitanium compoundsHydration reactionBarium titanate

The invention discloses a preparation method for monodisperse barium titanate nanopowder combining with sol-gel method and hydrothermal method, comprising the following steps of: preparing original solution and dripping solution from absolute ethyl alcohol, tetrabutyl titanate, nitric acid and deionized water; mixing the dripping solution with the original solution to obtain TiO2 sol; pouring the TiO2 sol in the liner of a polytetrafluoroethylene high-pressure reactor, adding barium octahydrate precursor solution of different concentrations and then stirring; placing the liner in the step 3 in a stainless steel high-pressure reactor, sealing and then placing in a high-temperature oven to perform hydrothermal reaction; finishing the reaction and cooling, then opening the reactor, filtering and washing the reactants to be neutral by using the deionized water and the absolute ethyl alcohol, and then drying the reactants in the oven , so as to obtain the monodisperse barium titanate nanopowder. The preparation method for monodisperse barium titanate nanopowder disclosed by the invention combines with the advantages of sol-gel method and hydrothermal method for preparing powder, so that the synthesised barium titanate nanoparticles have the advantages of being high in purity, controllable in particle size, complete in crystal particle development etc; and the preparation method for monodisperse barium titanate nanopowder is simple in equipment, practicable in operation and convenient for industrialized batch production.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

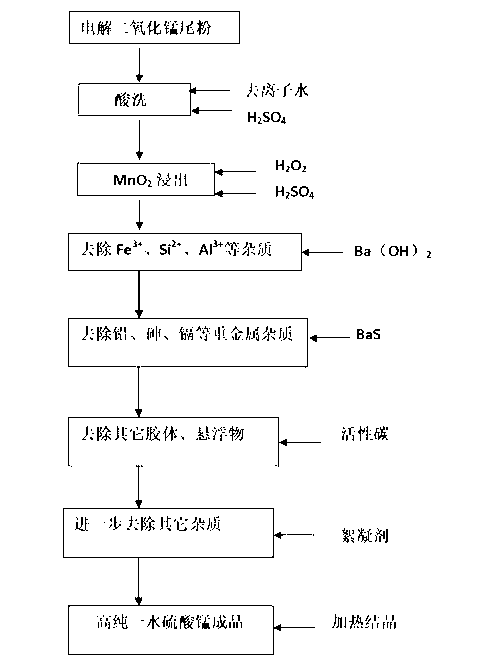

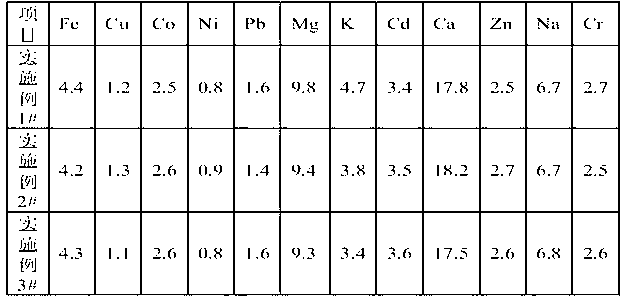

Method for high-purity manganese sulfate monohydrate

InactiveCN103342390ALess impuritiesQuality improvementManganese sulfatesElectrolysisChemical products

The invention relates to the preparation field of chemical products and particularly relates to a method for high-purity manganese sulfate monohydrate. The method specifically comprises the following steps of: taking tail powder of electrolytic manganese dioxide as a raw material, carrying out water washing and acid washing, then carrying out leaching and reducing on MnO2 by taking hydrogen peroxide as a reducing agent, adding barium hydroxide solution, removing Fe<3+>, Si<2+> and Al<3+>, adding barium sulfide solution into the obtained solution, heating the solution to 60-80 DEG C after uniform stirring, carrying out solid-liquid separation, and removing heavy metal elements such as Pb; adding activated carbon in the solution, carrying out stirring and solid-liquid separation at 60-80 DEG C, adding polyacrylamide as a flocculant into the solution after being subjected to activated carbon separation, standing for 24-36 hours after uniform stirring, and carrying out the solid-liquid separation; and carrying out high-temperature crystallization on the obtained solution so as to obtain a manganese sulfate monohydrate product. According to the method, the tail powder produced during the production of the electrolytic manganese dioxide is adequately utilized, the high-purity manganese sulfate monohydrate is produced at a relatively low cost, and then manganese sulfate for ternary materials applied to lithium battery industries is further obtained.

Owner:GUANGXI NANNING SHENGRUI METALLURGICAL & CHEM TECH

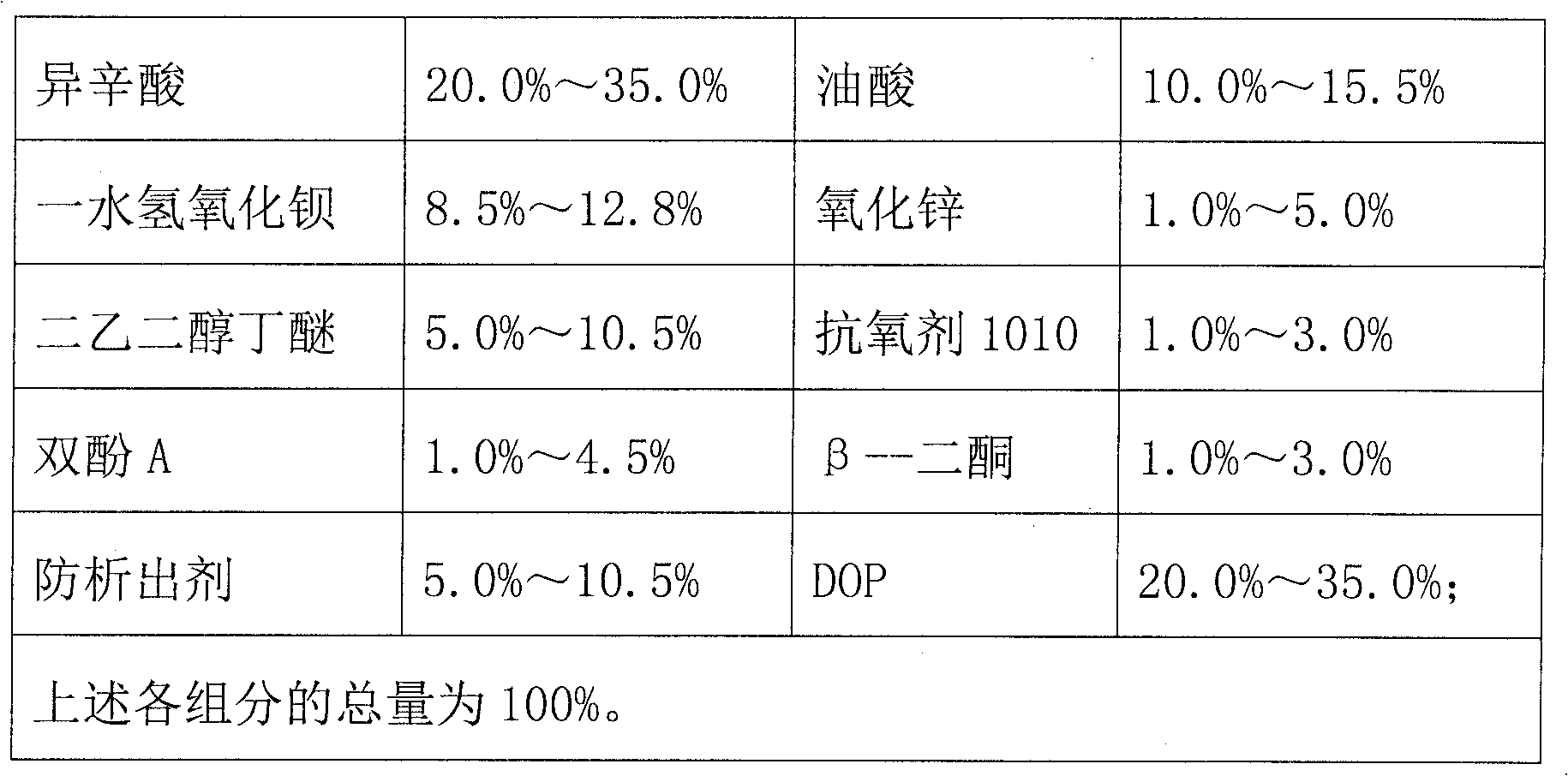

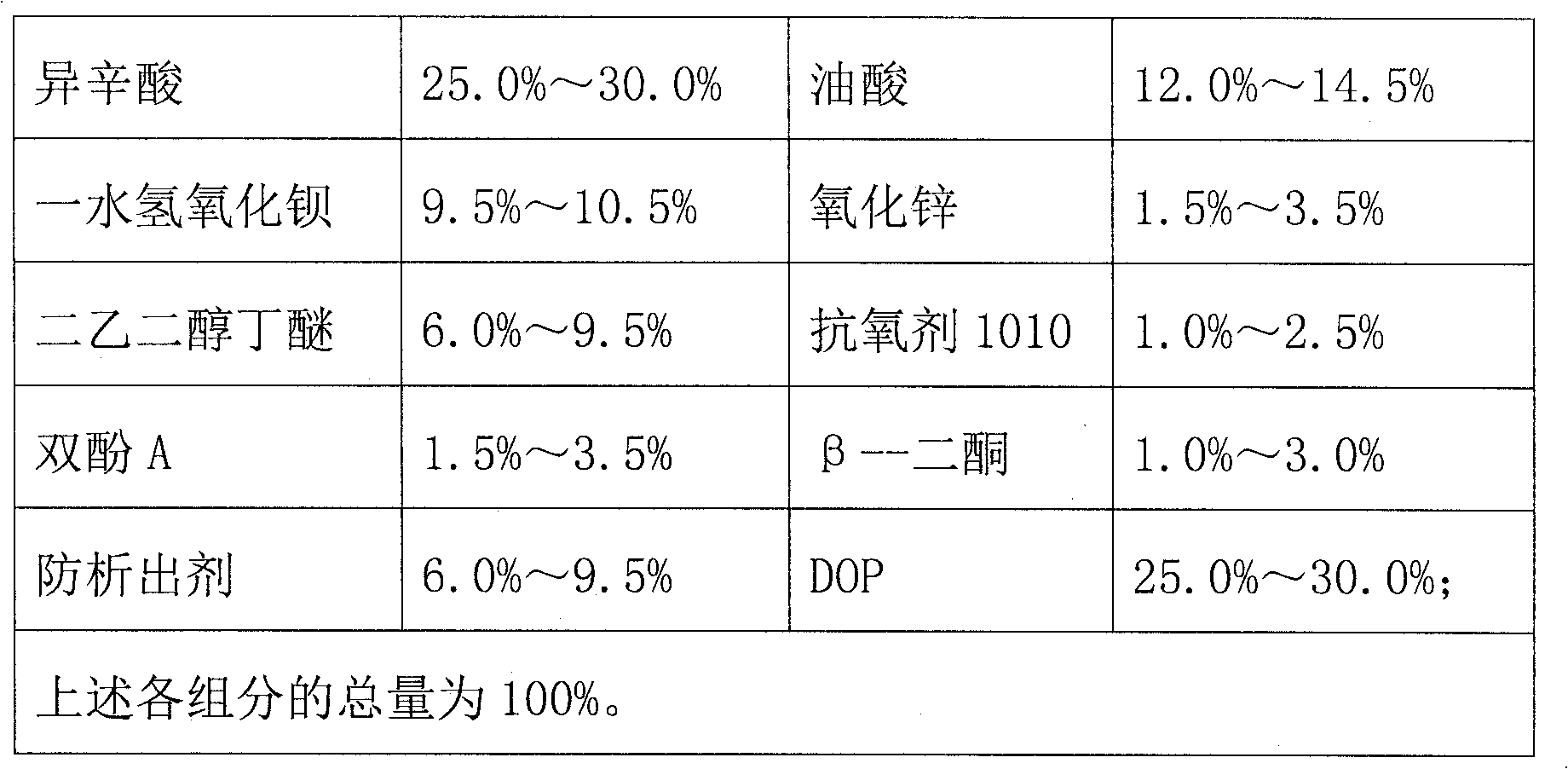

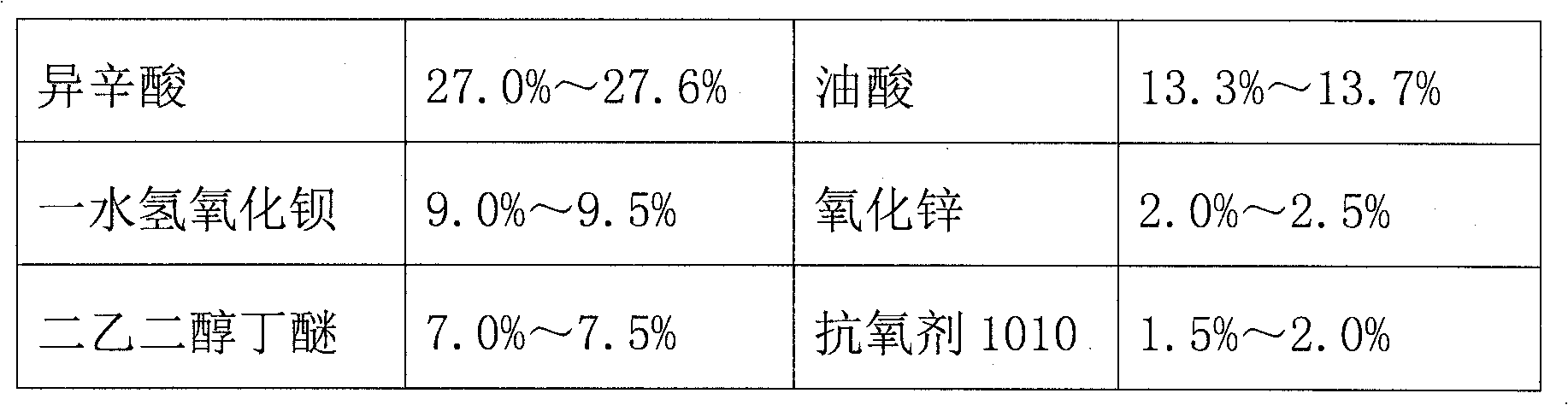

Barium-zinc liquid stabilizer, preparation method and application thereof

InactiveCN101775153AGood compatibilityReduce the effect of "zinc burn"Synthesis methodsOleic Acid Triglyceride

The invention relates to PVC heat stabilizer, in particular to heat stabilizer applied to decoration of PVC materials, a preparation method and application thereof. The barium-zinc liquid stabilizer is prepared from the following components in percentage by weight:, 20.0 to 35.0 percent of sodium iso-octoate, 10.0 to 15.5 percent of oleic acid, 8.5 to 12.8 percent of barium monohydrate, 1.0 to 5.0 percent of zinc oxide, 5.0 to 10.5 percent of diethylene glycolmonobutylether, 1.0 to 3.0 percent of antioxidant 1010, 1.0 to 4.5 percent of bisphenol A, 1.0 to 3.0 percent of beta-diketone, 5.0 to 10.5 percent of anti-separation agent, and 20.0 to 35.0 percent of DOP, wherein the total amount of components is 100 percent. The invention solves the problem that products have foreign smell based on raw materials, simplifies the production process by a one-step synthesis method, has more convenient operation, and has the effects that: firstly, the stabilizer saves energy consumption and reducing pollution; secondly, the stabilizer has high value advantage compared with international products with the same function and has better competitive force; and thirdly, the stabilizer belongs to green and environment-friendly product, and has strong vitality.

Owner:德清县东来化学有限公司

Gas-solid composite powder base fire-extinguishing agent and preparation method thereof

InactiveCN101417166AAvoid resurgenceHas natural moisture resistanceFire extinguisherGas solidCalcium hydroxide

The invention discloses a gas-solid composite ultra-fine powder-based extinguishing agent and a preparation method thereof, which are characterized in that according to the mass percentage in the system, 73-89 percent of ultra-fine zeolite, with the average particle size below 10 microns is arranged in a pressure withstanding vessel for vacuum-pumping; subsequently, 5.0-20.0 percent of 2-bromine-3, 3, 3-trifluoropropene liquid is injected into the vessel, stands for 12-24 hours at the temperature of 35-50 DEG C and cooled to room temperature; subsequently, 0.5-2.0 percent of barium hydroxide and 2.5-5.0 percent of talcum powder are added into the vessel and all powders are uniformly mixed; the obtained gas-solid composite ultra-fine powder-based distinguishing agent has high distinguishing efficiency, low corrosion and good anti-afterburning; the raw material is cheap and easy to be obtained; the preparation process is simple; the gas-solid composite ultra-fine powder-based distinguishing agent not only can be used as a distinguishing agent but also can be used as an additive to various commercial powder extinguishing agents, and is applicable to various fire extinguishers for fighting various fires such as solid fire, combustible gas fire, liquid fire and the like.

Owner:UNIV OF SCI & TECH OF CHINA

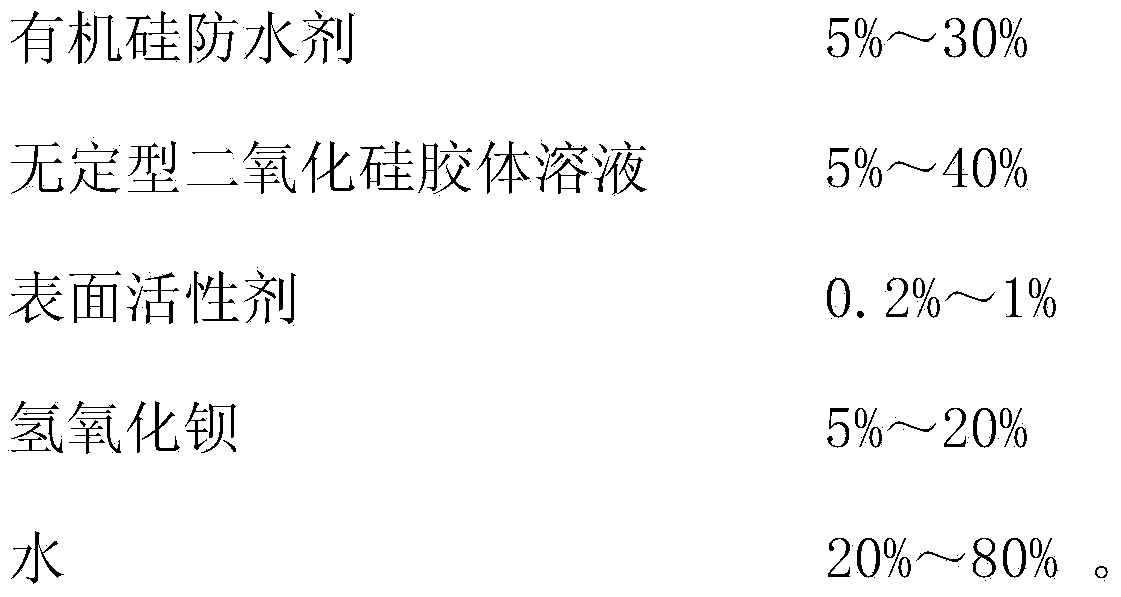

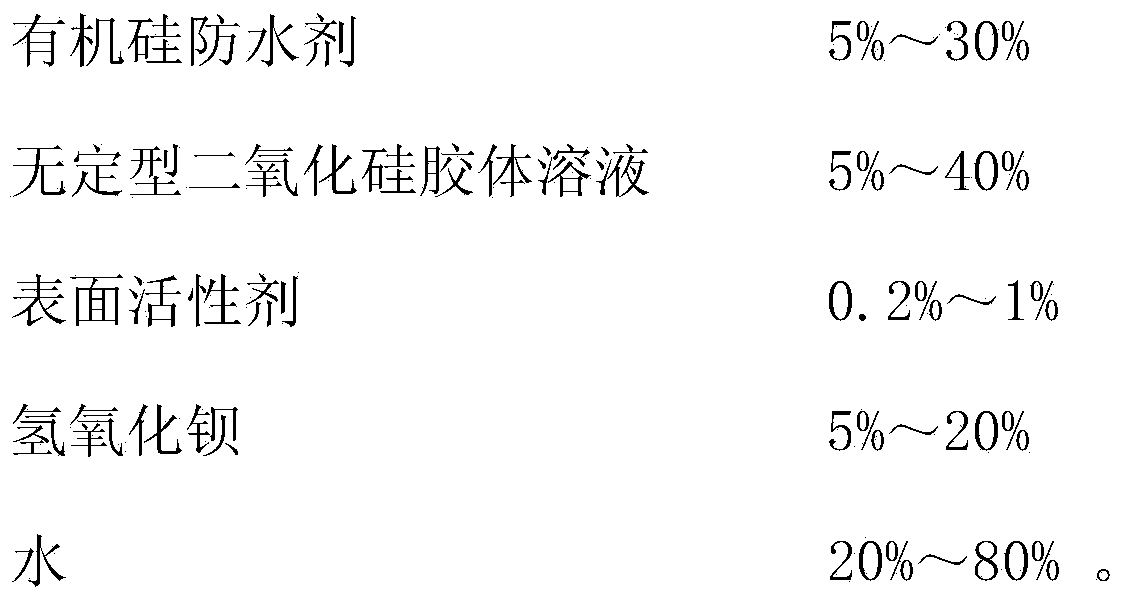

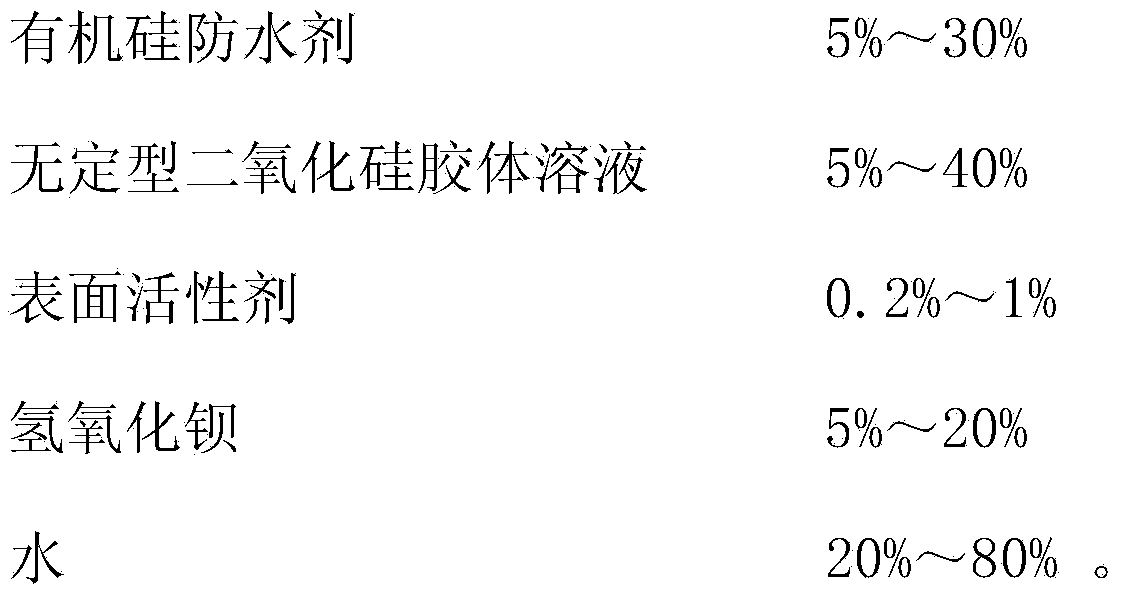

Capillary crystalline waterproofing agent and preparation method thereof

The invention relates to the technical field of concrete protective agents for buildings and in particular discloses a capillary crystalline waterproofing agent and a preparation method of the capillary crystalline waterproofing agent. The capillary crystalline waterproofing agent consists of an organic silicon waterproofing agent, an amorphous silicon dioxide colloidal solution, a surfactant, barium hydroxide and water. The preparation method comprises the following steps: sequentially adding the water, organic silicon waterproofing agent, the amorphous silicon dioxide colloidal solution, the surfactant and the barium hydroxide into a reaction kettle, heating to a reaction temperature, stirring, reducing the temperature to room temperature, filtering to remove impurities, and obtaining the capillary crystalline waterproofing agent. The capillary crystalline waterproofing agent is an organic and inorganic combination, is colorless transparent liquid, has the characteristics of high infiltration capacity, high hydrophobicity, low water absorption rate, environment friendliness and harmlessness and can penetrate into concrete pores to form lots of insoluble crystals to block the concrete pores, the intrusion of sulfate to the concrete can be reduced, and a waterproof protective effect is achieved.

Owner:北京宇阳泽丽防水材料有限责任公司

Anti-corrosion building concrete

InactiveCN103332898AGood anti-corrosion and anti-erosion propertiesEvenly dispersedChemical reactionSilanes

The invention relates to anti-corrosion building concrete. The anti-corrosion building concrete comprises cement and an admixture, and further comprises a preservative and a dispersing agent, wherein the preservative mainly comprises aluminum silicate and barium hydroxide; the dispersing agent is mainly silica fume; the preservative is 10%-15% of the total weight of the concrete; the dispersing agent is 10%-15% of the total weight of the concrete. The anti-corrosion building concrete disclosed by the invention has good anti-corrosion anti-erosion performances; the dispersing agent which is composed of methyl cellulose and silica fume can be used for uniformly dispersing the preservative, so that the anti-corrosion effect of the preservative can be brought into player better; isobutyl triethoxy silane is penetrated into the concrete to generate chemical reaction with air exposed in an acid or alkali environment as well as water molecules in a substrate, so that a water-repellent treatment layer is formed, and therefore, the water is restrained from entering the substrate.

Owner:镇江崟鑫新型建材科技有限公司

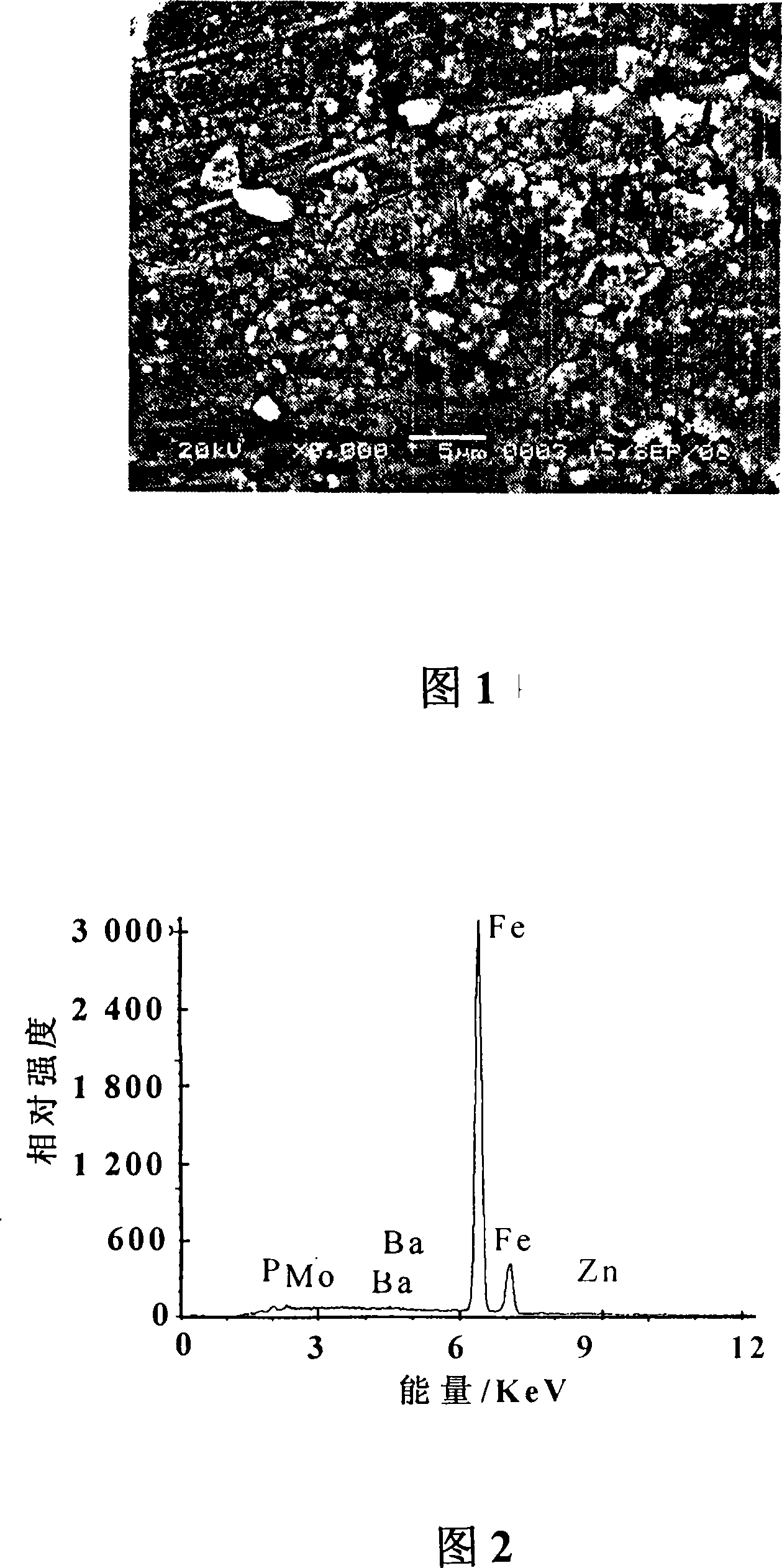

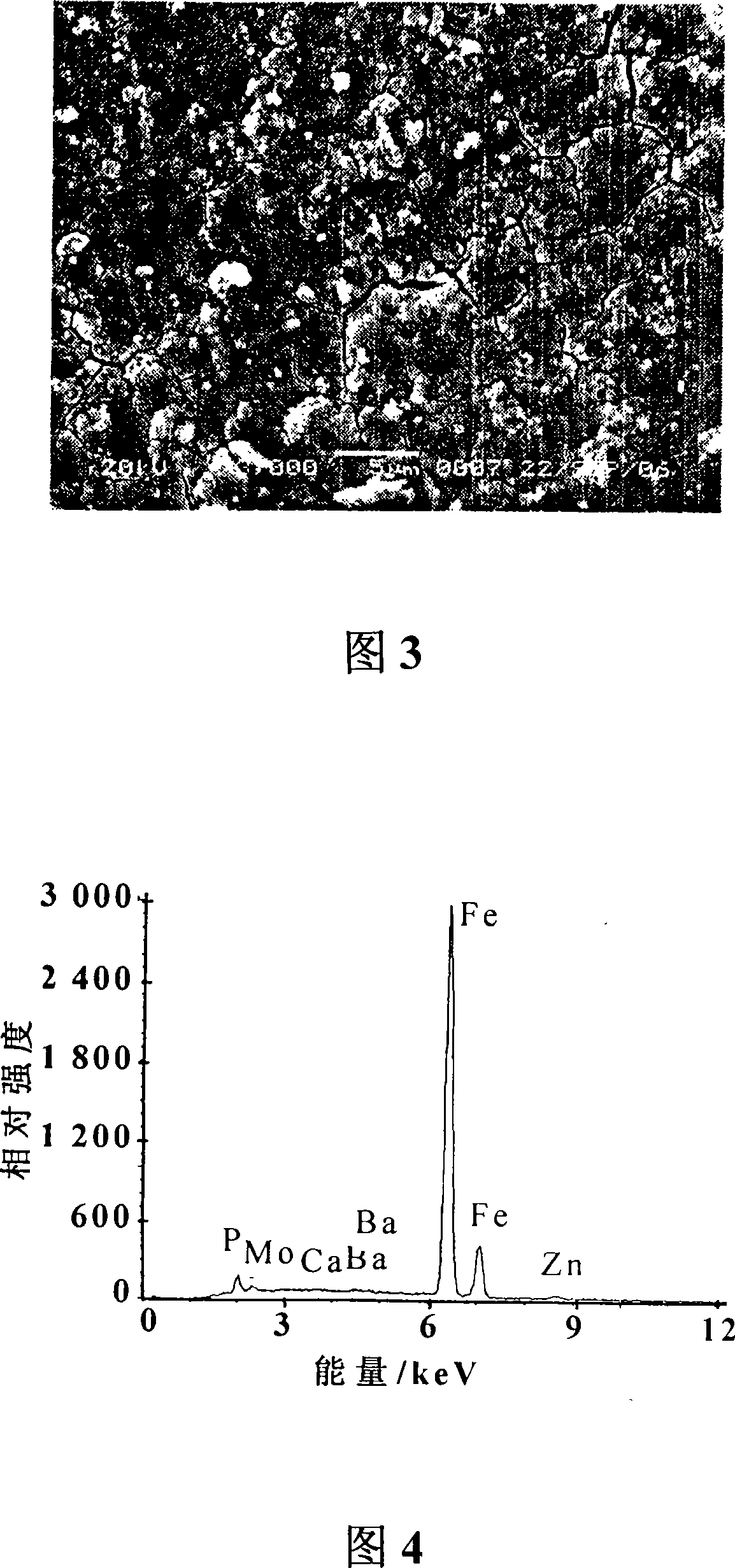

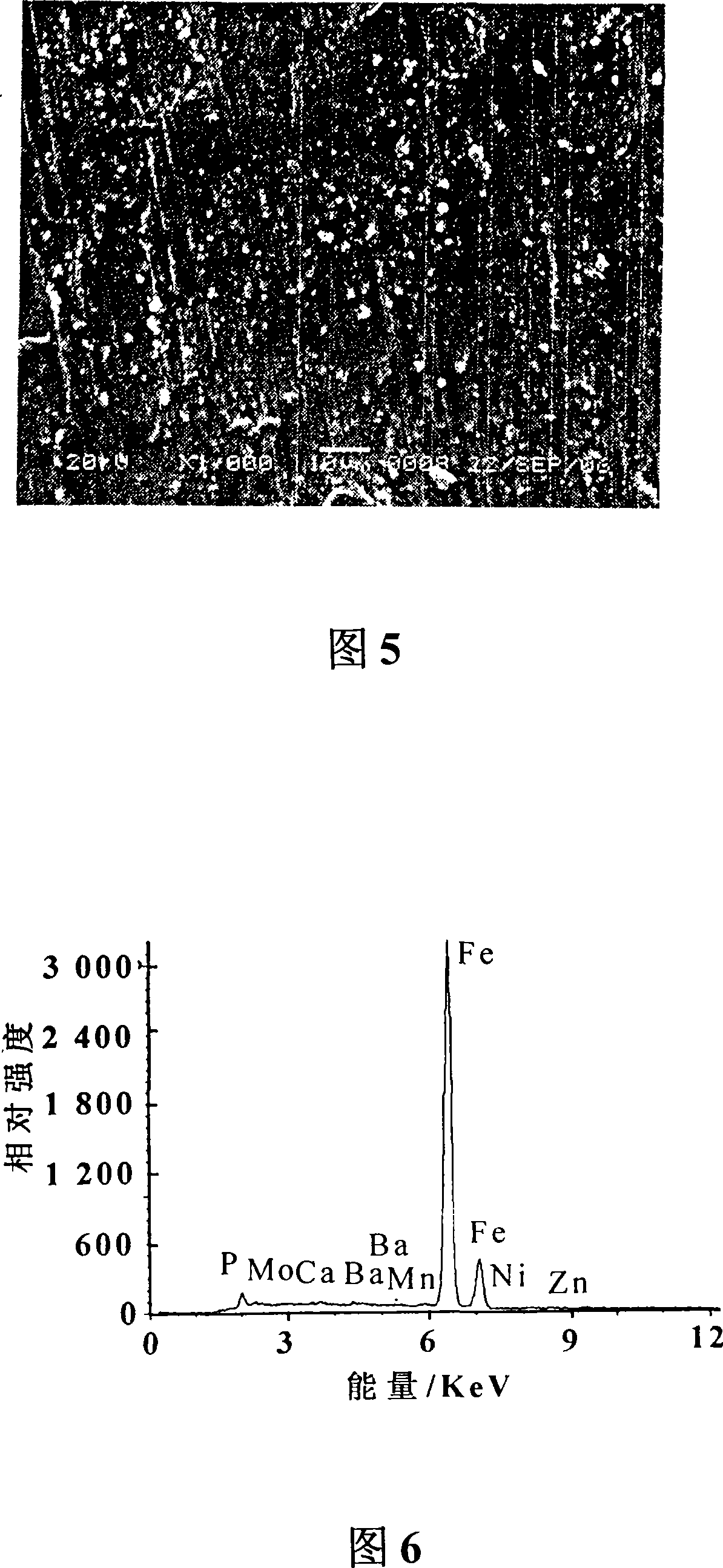

Normal temperature barium salt modified phosphorizing liquid capable of avoiding water wash after phosphorized

InactiveCN101109081AQuality improvementImprove corrosion resistanceMetallic material coating processesEpoxyBarium nitrate

The invention relates to a phosphating washing-free phosphating solution modified with barium salt at ambient temperature. The phosphating solution comprises a phosphoric acid, a nitric acid, and Zn2+, Ca2+, Mn2+, Ni2 plus salt thereof, ammonium molybdate,ammonium tungstate, phytate, H2O2 and barium nitrate or barium hydroxide. The pH value ranges from 1.6 to 4.2. The invention can be phosphated under soak, rinse, brush or the combined way thereof at 3 DEG C.to 45 DEG C.. The phosphating solution is stable and capable of automatically precipating and removing the SO42- inside the phosphating solution and therefore eliminating the influence of SO42- on quality; the phosphorizating membrane is continues, uniform and compact, the membrane weight is between 0.5g is multiplied by m and 3.0g is multiplied by m minus 2 and the iron-red epoxy primer is sprayed and the adhesion thereof can be 1 grade.

Owner:余取民 +3

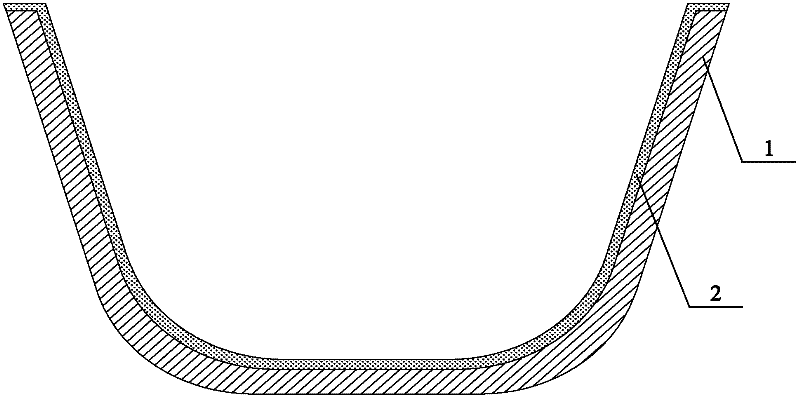

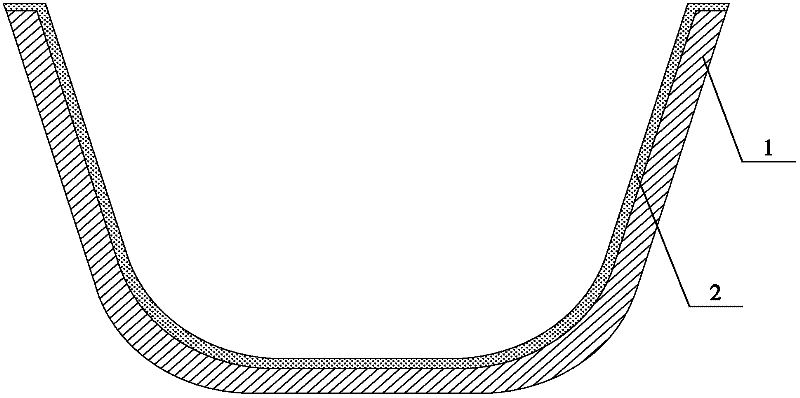

Preparation method of quartz crucible coating

InactiveCN102260902APlay a protective effectExtended service lifeBy pulling from meltCoatingsMetasilicateBarium hydroxide

The invention provides a method for preparing a quartz crucible coating. The method comprises the following steps of: (a) preparing a barium hydroxide solution, wherein the weight ratio of barium hydroxide to water in the barium hydroxide solution is 1:(46-52); and (b) heating a quartz crucible till the temperature is above 200 DEG C, uniformly spraying the barium hydroxide solution on the inner wall and the upper opening of the quartz crucible, and forming a barium hydroxide coating on the inner wall and the upper opening of the quartz crucible after spraying. According to the method, the barium hydroxide formed on the surface of the crucible is reacted with carbon dioxide in air to form barium carbonate; when the quartz crucible is heated on a mono-crystal furnace, the barium carbonate is decomposed into barium oxide; the barium oxide is reacted with the quartz crucible to form barium metasilicate; a barium metasilicate layer can be used for protecting the quartz crucible; mono-crystal silicon can be prevented from reacting with the quartz crucible in a high-temperature drawing process; the service life and the long crystal yield of the quartz crucible are improved; furthermore,the intensity of the quartz crucible can also be increased; and the high-temperature softening phenomenon is reduced.

Owner:JIANGSU JINGDING ELECTRONICS MATERIAL

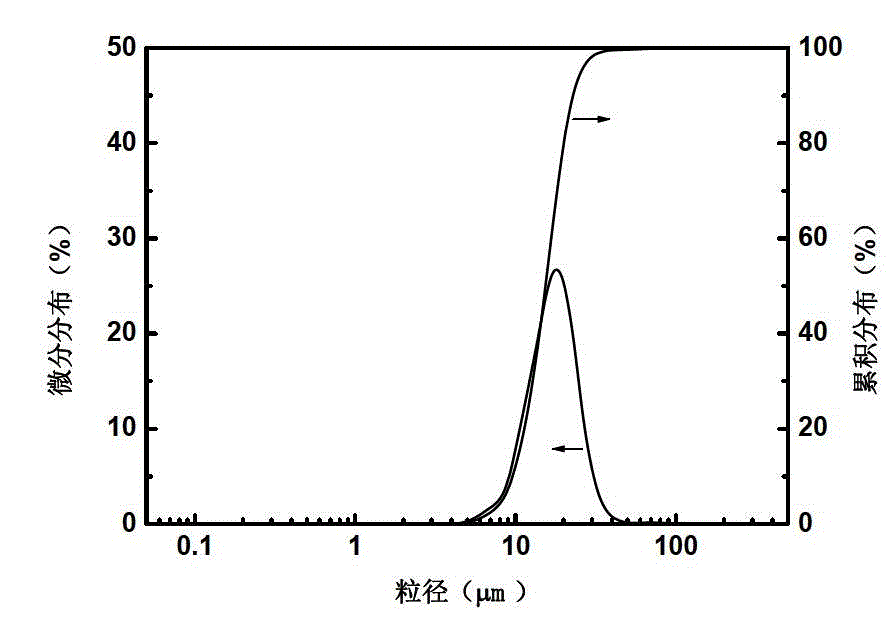

Preparation of nano barium titanate powder

InactiveCN101348938APromote crystallizationImprove purityPolycrystalline material growthFrom normal temperature solutionsBarium titanateFiltration

The invention relates to a preparation method for nano barium titanate powder. The method comprises the following steps: nano titanium dioxide (TiO2), tetrabutyl titanate (TiC16H36O4) and barium hydroxide (Ba(OH)2.8H2O) are takes as raw materials, and ammonia water is taken as a precipitating agent; moreover, an appropriate surface-active agent or organic solvent is selected to adjust reaction medium so as to carry out reaction at a temperature between 150 and 300 DEG C for 4 to 24 hours with the filling degree of between 60 and 90 percent and the Ba to Ti molar ratio of between 1.1 and 3.0; and finally, after the reactants are cooled down to room temperature, filtration, washing and drying are carried out so as to prepare the nano barium titanate powder. The technique can simplify technical steps, and has easily controlled technical parameters; moreover, the prepared powder has the characteristics of complete crystallization, controllable grain diameter range of between 50 and 90nm, narrow granule distribution range, high purity, excellent dispersivity, high sintering activity, and the like; because the adopted raw materials do not contain common ions such as Cl-, K+ and N+, the preparation method can simplify washing process and increase the purity of the powder, thereby reducing the adverse influence on material properties caused by impurity ions and ensuring the quality of high-end products.

Owner:UNIV OF JINAN

Hydrogen production composition and preparation method thereof, and method for preparing hydrogen

The invention discloses a hydrogen production composition and a preparation method thereof, and a method for preparing hydrogen. The hydrogen production composition is formed by mixing a metal powder body, an activating agent and an additive, wherein the metal powder body is a mixture of one or more than two of aluminum powder, magnesium powder and zinc powder; the activating agent is a mixture of one or more than two of sodium chloride, potassium chloride and sodium fluoride; and the additive is a mixture of one or more of calcium hydroxide, barium hydroxide and calcium chloride. In the hydrogen production method, the hydrogen production quantity, the hydrogen production speed and / or the hydrogen production time are controlled by changing a composition proportion of the hydrogen production composition and / or changing a proportion of the hydrogen production composition to water. The hydrogen production composition is convenient to use and preserve, low in cost, and nontoxic and harmless; and on-site hydrogen supply and enduring hydrogen supply in which the hydrogen production quantity and the hydrogen production speed can be controlled can be realized.

Owner:SUN YAT SEN UNIV

Method of protecting archives with red-ink handwriting from spreading and sinking in during process of papering and repairing

ActiveCN102166916AWater permeableGood water permeabilityPaper/cardboardPaperhangingHandwritingPhosphoric acid

Provided is a method of protecting archives with red-ink handwriting from spreading and sinking in during process of papering and repairing. The method comprises the steps of uniformly mixing, by mass, 1 part of phospho-tungstic acid, 2.3 to 3.9 parts of phosphoric acid, 48.8 to 52.0 parts of acetone and 2.8 to 9.2 parts of tetraeththyl orthosiliate to prepare a first reinforcing agent and coating the agent on red-ink handwritings; preparing a second reinforcing agent with 1 part by mass of ethyl cellulose, 6.25 parts by mass of barium hydroxide and 40 parts by mass of methanol and coating the agent on the red-ink handwritings coated with the first reinforcing agent; and preparing a third reinforcing agent with, by mass, 1 part of ethyl cellulose banana oil solution and 0.03 to 0.17 part of polymethylmethacrylate banana oil solution, wherein mass percentage of the ethyl cellulose banana oil solution is 4% and mass percentage of the polymethylmethacrylate banana oil solution is 4%, and coating the third reinforcing agent on the red-ink handwritings coated with the second reinforcing agent. The method of protecting the red-ink handwritings enables improvement in tensile strength, folding strength and tearability of testing paper after dry heating aging, hydrothermal aging and ultraviolet aging tests. After the aging process, the handwritings which are reinforced by the reinforcing agents exhibit minor chromatic aberration. Pigments of the handwritings are not easy to fade and the handwritings can be durably kept.

Owner:SHAANXI NORMAL UNIV

Method for recycling vanadium from vanadium-containing electrolysis aluminum slag ash

InactiveCN103276218AAchieve recyclingMeet the enterprise product quality requirementsProcess efficiency improvementElectrolysisPhosphate

The invention relates to a method for recyclingvanadium from vanadium-containing aluminum slag ash. The method comprises the following steps: first, purifying the aluminum slag ash, removing or converting soluble salts and aluminum nitride which are contained in the aluminum slag ash; then mixing the purified aluminum slag ash and sodium carbonate uniformly in a certain ratio, calcining the mixture for 60min at 900DEG C to obtain a clinker, leaching the clinker in a hot water of 80 DEG C, firstly precipitating the vanadium in the clinker through use of a calcium oxide emulsion or a barium hydroxide solution; in a hot solution containing a moderate amount of the sodium carbonate and a small amount of sodium hydroxide, stirring a vanadium-precipitating slag enriched with the vanadium so as to transfer the vanadium into the solution while stirring, removing impurities consisting of silicon, aluminum and phosphate step by step through respective use of a 20% hydrochloric acid, magnesium chloride and ammonia liquor, further precipitating and enriching the vanadium in the solution to obtain ammonium metavanadate through use of ammonium chloride. The method has the advantages of good comprehensive utilization of the aluminum slag ash, an ideal effect on recycling of the vanadium in the vanadium-containing aluminum slag ash, environment friendliness, and certain economic efficiency.

Owner:周长祥

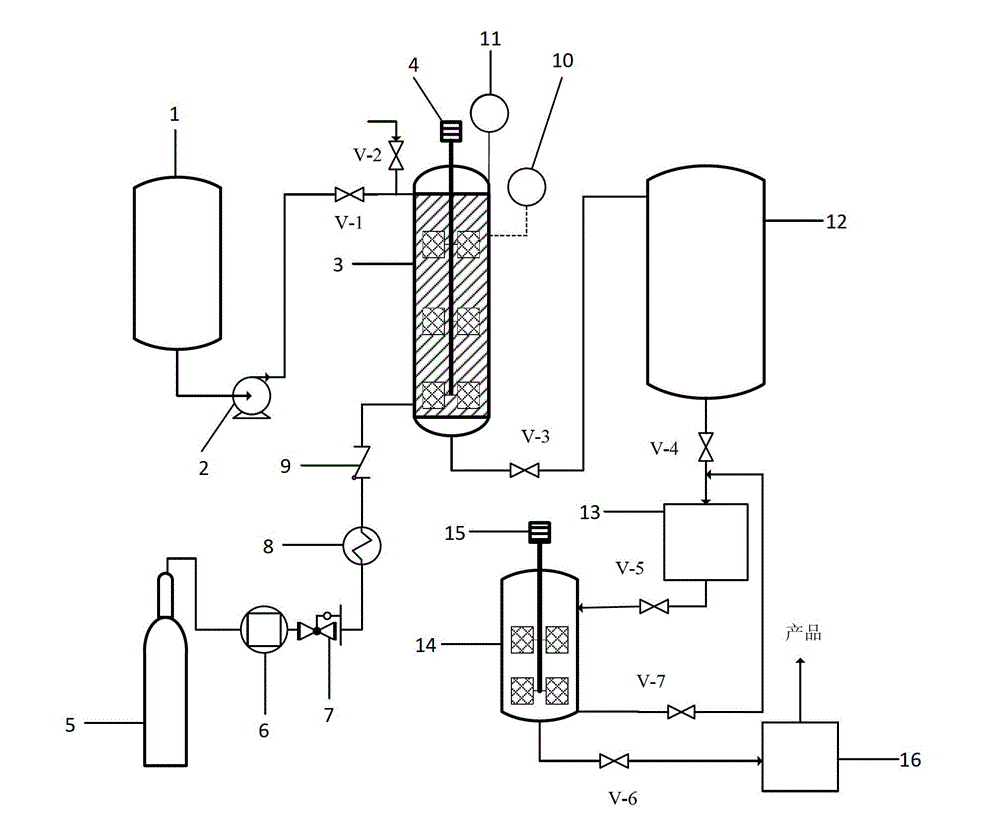

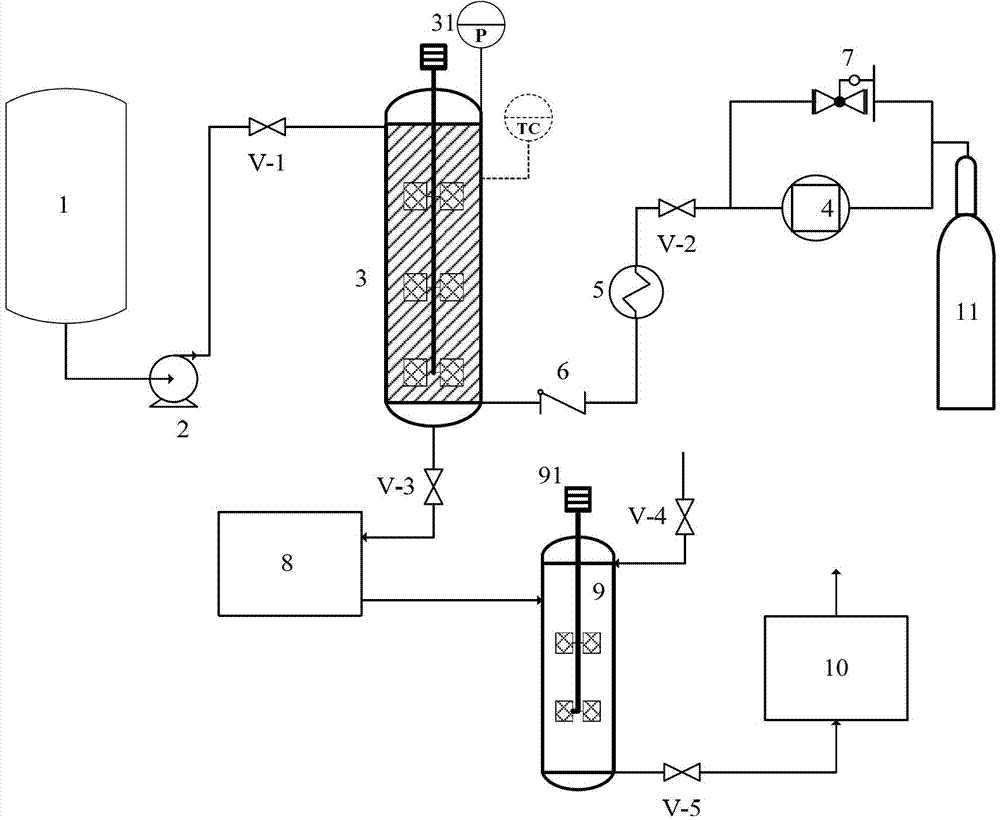

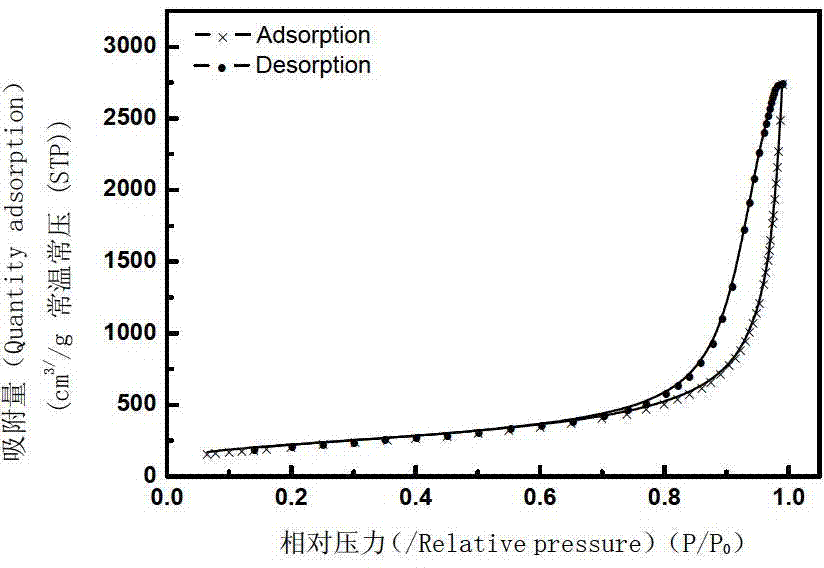

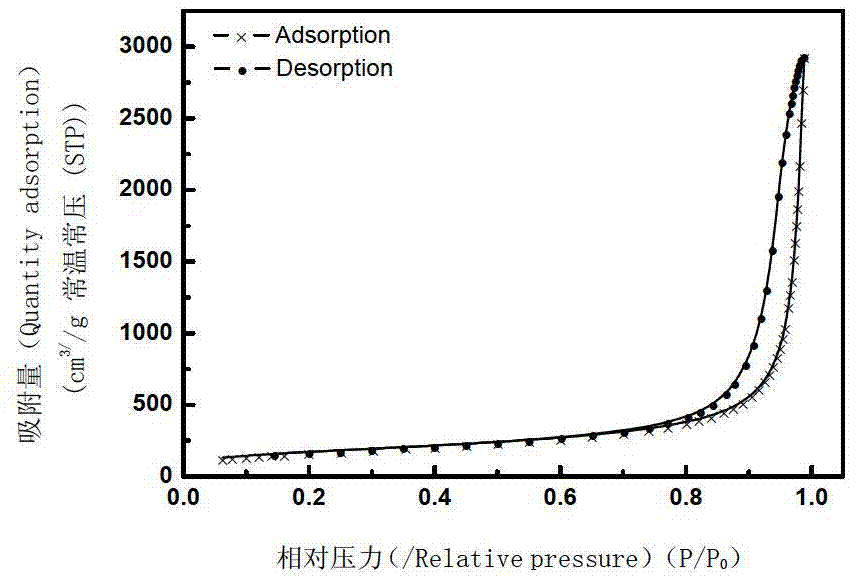

Device and method for preparing silica by taking sodium silicate as raw material

The invention discloses a device and a method for preparing silica by taking sodium silicate as a raw material, and relate to the preparation of silica. The device comprises a sodium silicate solution storage tank, a high-pressure carbonization reaction / aging kettle, a gas compressor, a heat exchanger, a check valve, a back pressure valve, a pumping, filtering and cleaning machine, a slurry preparation tank, a dryer, a carbon dioxide storage tank and a temperature control system. The method comprises the following steps: dissolving solid sodium silicate in water, filtering the obtained object, then adding water into the obtained product so as to obtain a sodium silicate solution, pumping the sodium silicate solution into the kettle, and feeding carbon dioxide into the kettle so as to obtain silica gel; controlling the temperature and carbon dioxide pressure in the kettle, carrying out aging and pore fixing on the obtained product and removing the pressure in the kettle so as to obtain saliferous silica slurry, then transferring the saliferous silica slurry to the pumping, filtering and cleaning machine to carry out solid-liquid separation, washing a filter cake by using water, detecting filter liquor by using a saturated barium hydroxide solution, stopping washing until no precipitation exists, and washing the filter cake by using anhydrous ethanol; and adding ethanol into the filter cake, and stirring the obtained product so as to prepare slurry, and then drying and crushing the obtained object so as to obtain silica. The process is simple, and a subtranslucent silica product with a high pore volume and a large specific surface area is obtained conveniently.

Owner:厦门点石新材料有限公司

Anti-crack and self-repairing concrete and preparation method thereof

The invention discloses anti-crack and self-repairing concrete and a preparation method thereof. The anti-crack and self-repairing concrete is prepared from the following components in parts by weight: 200-300 parts of cement, 100-180 parts of fly ash, 500-700 parts of crushed stone, 80-140 parts of water, 40-60 parts of hemihydrate gypsum, 50-100 parts of silicon powder, 20-40 parts of polypropylene fiber, 10-15 parts of a silane coupling agent, 60-80 parts of calcium oxide, 5-10 parts of a water reducing agent, 30-50 parts of ammonium chloride and 10-20 parts of barium hydroxide octahydrate;and the preparation method comprises the steps that concrete slurry is mixed, specifically, the cement, the fly ash, the crushed stone, the hemihydrate gypsum and the silica powder are mixed and stirred for 30-40 min, the water reducing agent and the water are added and stirred for 5-10 min, then the ammonium chloride and the barium hydroxide octahydrate are added and stirred for 40-60 min, thenthe polypropylene fiber and the silane coupling agent are added to be stirred for 20-30 min, and then the concrete slurry is obtained; and the calcium oxide is sealed and loaded into a fiberglass pipe, and then the fiberglass pipe loaded with the calcium oxide is mixed in the concrete slurry to obtain the anti-crack and self-repairing concrete. The anti-crack and self-repairing concrete and the preparation method thereof have the advantages that the prepared concrete is resistant to cracking, self-repairing of cracks is realized, and strength after repairing is high.

Owner:北京天地建设砼制品有限公司

Flaked and powdered mural reinforcing protective agent and preparation and reinforcing method thereof

ActiveCN105599534AReinforcementPlay the role of anti-weatheringPainting preservationAridPhosphoric acid

The invention provides a flaked and powdered mural reinforcing protective agent and a preparation and reinforcing method thereof. The agent is prepared from a reinforcing agent TB-1 prepared by dissolving 150-250 ml of ethyl orthosilicate in 1000 ml of ethyl alcohol, a reinforcing agent TB-2 prepared by dissolving 2-5 g of oxalic acid and 2-5 ml of phosphoric acid in each 1000 ml of ethyl alcohol, a reinforcing agent TB-3 prepared by 5-10 g of barium hydroxide and 2-3 g of poly(ethylene glycol) which are ground into the 100-200 nanometer scale through a ball mill in each 1000 ml of methyl alcohol, and a reinforcing agent TB-4 prepared by dissolving 3-5 g of disodium octoborate tetrahydrate in 100 ml of water according to the volume ratio of (2-5):(7-10):(7-10):(0.5-1.5). The coffin chamber flaked and powdered mural reinforcing material and the reinforcing method which are suitable for dry, semi-dry and humid environment conditions of arid regions, semi-arid regions and semi-humid regions are obtained.

Owner:SHAANXI NORMAL UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com