Device and method for preparing silica by taking sodium silicate as raw material

A technology of silica and water glass, applied in the direction of silica, silica, etc., can solve the problem of further improvement, long reaction time, particle size, product pore volume, pore size, specific surface area and dispersion performance cannot reach high Performance products and other issues, to achieve the effect of high pore volume, large specific surface area, and easy access

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

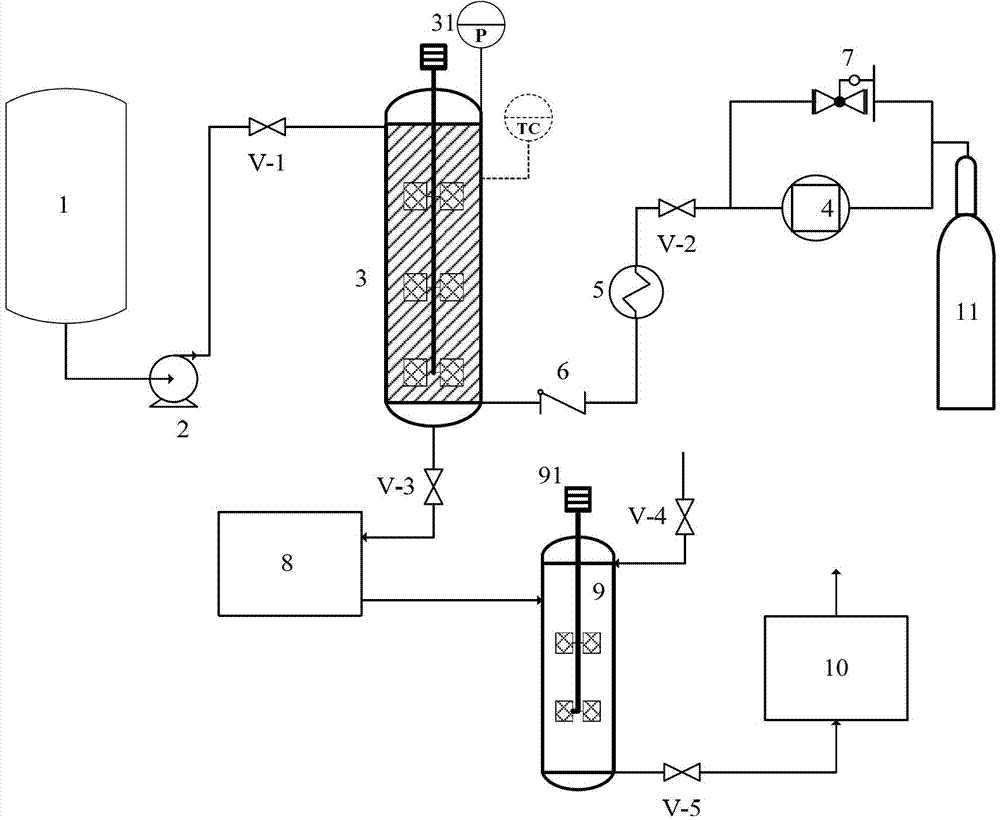

Method used

Image

Examples

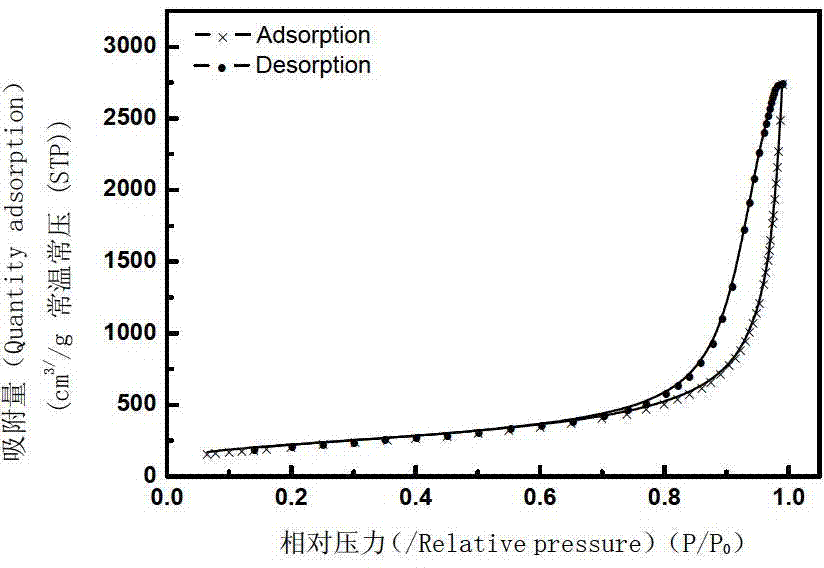

Embodiment 1

[0041] Drugs: sodium silicate nonahydrate (Sinopharm Chemical Reagent Co., Ltd., AR), absolute ethanol (Sinopharm Chemical Reagent Co., Ltd., AR), carbon dioxide (Xiamen Xinhongli Industrial Co., Ltd., purity >98%).

[0042] Weigh solid sodium silicate into a certain amount of deionized water, heat to promote dissolution, and after natural cooling, filter to remove insoluble impurities, prepare a water glass solution with a concentration of 0.25mol / L, and pump it into a liquid storage tank. Pour the water glass solution into the high-pressure carbonization reaction aging kettle, set the stirring speed at 300 rpm, and control the reaction temperature at 35±5°C. The carbon dioxide is pumped into the high-pressure carbonization reaction aging kettle with a compressor, the carbon dioxide is preheated at the heat exchanger, the carbon dioxide pressure is controlled at 4±0.5MPa, and the temperature and pressure are maintained for 60 minutes. Keep the reaction temperature unchanged, ...

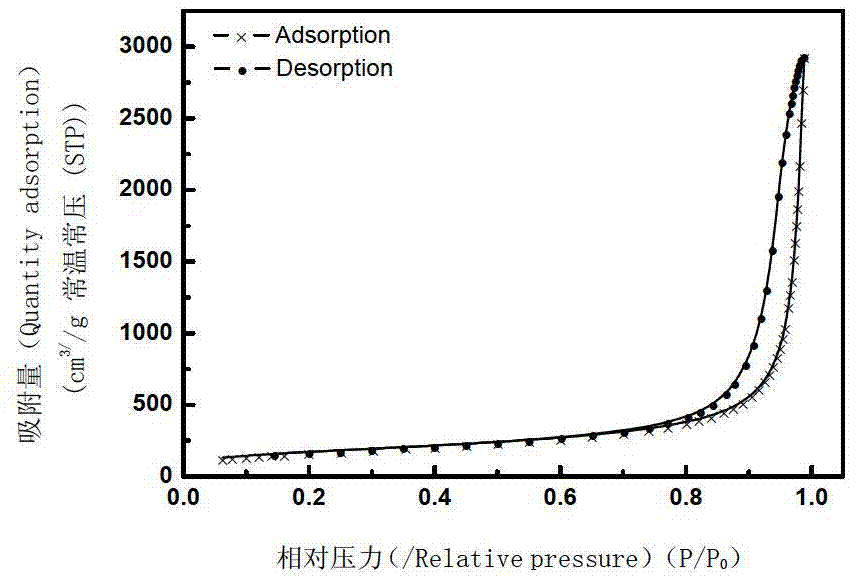

Embodiment 2

[0044] Drugs: sodium silicate nonahydrate (Sinopharm Chemical Reagent Co., Ltd., AR), absolute ethanol (Sinopharm Chemical Reagent Co., Ltd., AR), carbon dioxide (Xiamen Xinhongli Industrial Co., Ltd., purity >98%).

[0045] Weigh solid sodium silicate into a certain amount of deionized water, heat to promote dissolution, and after natural cooling, filter to remove insoluble impurities, prepare a water glass solution with a concentration of 0.25mol / L, and pump it into a liquid storage tank. Pour the water glass solution into the high-pressure carbonization reaction aging kettle, set the stirring speed at 300 rpm, and control the reaction temperature at 35±5°C. The carbon dioxide is pumped into the high-pressure carbonization reaction aging kettle with a compressor, the carbon dioxide is preheated at the heat exchanger, the carbon dioxide pressure is controlled at 4±0.5MPa, and the temperature and pressure are maintained for 60 minutes. Then, raise the temperature to 50°C, cont...

Embodiment 3

[0047] Drugs: sodium silicate nonahydrate (Sinopharm Chemical Reagent Co., Ltd., AR), absolute ethanol (Sinopharm Chemical Reagent Co., Ltd., AR), carbon dioxide (Xiamen Xinhongli Industrial Co., Ltd., purity >98%).

[0048] Weigh solid sodium silicate into a certain amount of deionized water, heat to promote dissolution, filter to remove insoluble impurities after natural cooling, prepare a water glass solution with a concentration of 0.5mol / L, and pump it into a liquid storage tank. Pour the water glass solution into the high-pressure carbonization reaction aging kettle, set the stirring speed at 300 rpm, and control the reaction temperature at 70±5°C. The carbon dioxide is pumped into the high-pressure carbonization reaction aging kettle with a compressor, the carbon dioxide is preheated at the heat exchanger, the carbon dioxide pressure is controlled at 10±0.5MPa, and the temperature and pressure are maintained for 60 minutes. Then, raise the temperature to 90°C, and conti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Pore volume | aaaaa | aaaaa |

| Pore volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com