A method for recovering and preparing a lithium-manganese-iron phosphate positive-electrode material covered with carbon from waste lithium iron phosphate batteries

A lithium iron phosphate battery and lithium manganese iron phosphate technology, which is applied in the field of comprehensive utilization of waste resources, can solve problems such as high cost, poor battery performance, and complicated processing, and achieve low cost, environmental friendliness, and high energy density.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

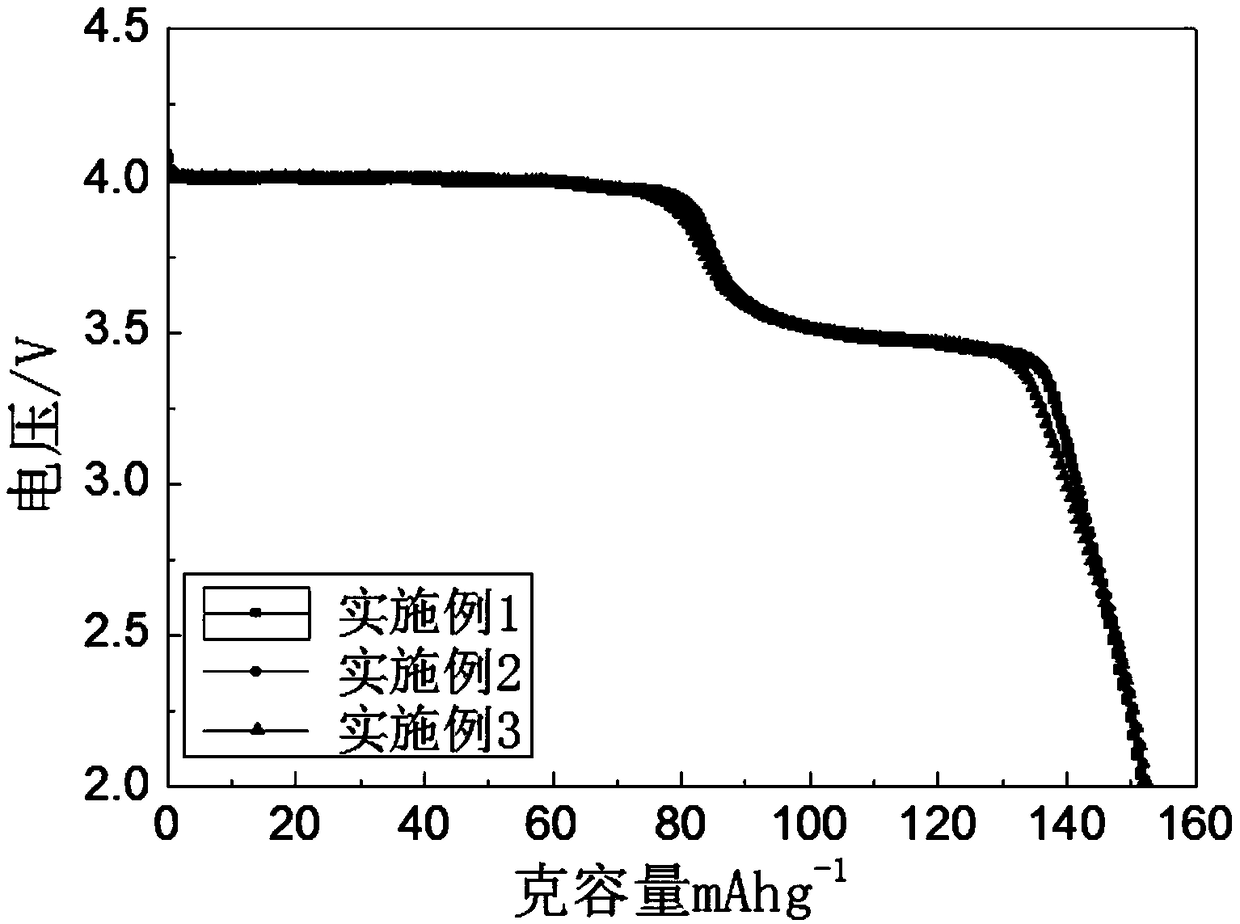

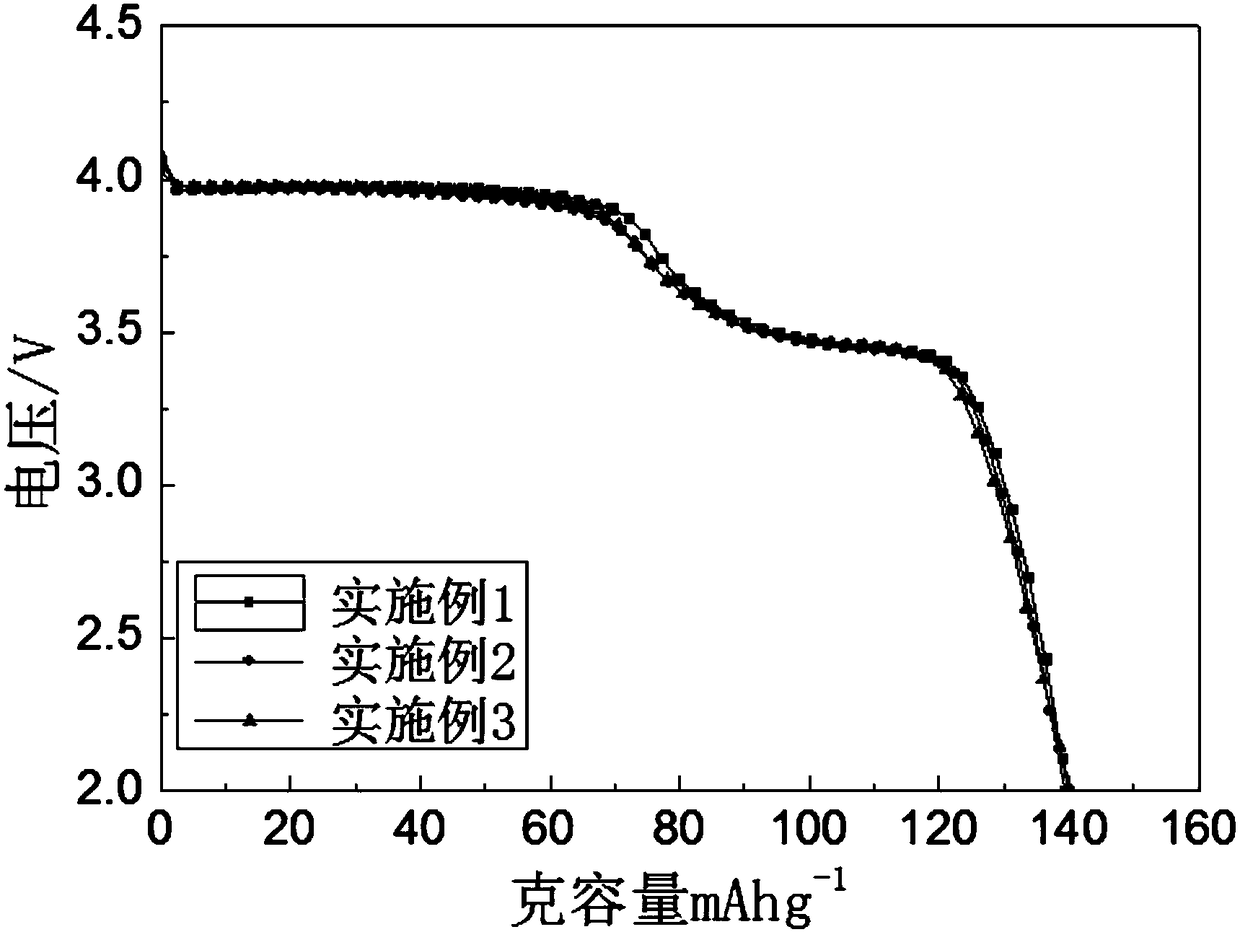

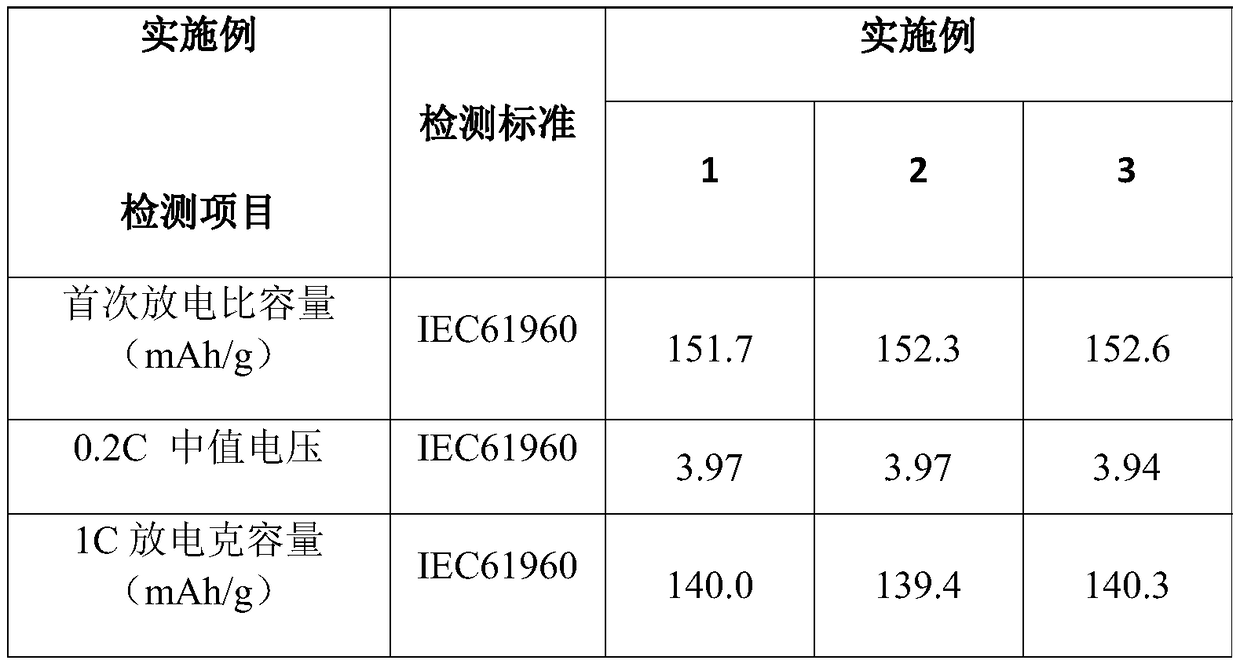

Embodiment 1

[0043] A method for reclaiming and preparing carbon-coated lithium manganese iron phosphate cathode materials from waste lithium iron phosphate batteries, comprising the following steps:

[0044] S11. After discharging the residual power of the waste lithium iron phosphate battery, disassemble the battery, separate the positive electrode sheet, wash and dry the positive electrode sheet;

[0045] S12. Calcining the dried positive electrode sheet in an oxygen atmosphere at 500° C. for 1 hour to carbonize the binder, and separating the calcined positive electrode mixture from the current collector aluminum foil to obtain lithium iron phosphate powder and Positive electrode mixture of conductive carbon;

[0046] S13. Dissolve the above positive electrode mixture with 98% concentrated sulfuric acid and filter to obtain the first filtrate with pH=0.4, add ammonia water to the first filtrate, stir while adding ammonia water until the pH reaches 1.0, continue stirring for a period of ...

Embodiment 2

[0052] A method for reclaiming and preparing carbon-coated lithium manganese iron phosphate cathode materials from waste lithium iron phosphate batteries, comprising the following steps:

[0053] S21. After discharging the residual power of the waste lithium iron phosphate battery, disassemble the battery, separate the positive electrode sheet, wash and dry the positive electrode sheet;

[0054] S22. Calcining the dried positive electrode sheet in an oxygen atmosphere at 900° C. for 4 hours to carbonize the binder, and separating the calcined positive electrode mixture from the current collector aluminum foil to obtain lithium iron phosphate powder and Positive electrode mixture of conductive carbon;

[0055] S23. Dissolve the above positive electrode mixture with 98% concentrated sulfuric acid and filter to obtain the first filtrate with pH = 0.8, add ammonia water to the first filtrate, stir while adding ammonia water until the pH reaches 1.5, continue stirring for a period ...

Embodiment 3

[0061] A method for reclaiming and preparing carbon-coated lithium manganese iron phosphate cathode materials from waste lithium iron phosphate batteries, comprising the following steps:

[0062] S31. After discharging the residual power of the waste lithium iron phosphate battery, disassemble the battery, separate the positive electrode sheet, wash and dry the positive electrode sheet;

[0063] S32. Calcining the dried positive electrode sheet in an oxygen atmosphere at 700° C. for 5 hours to carbonize the binder, and separating the calcined positive electrode mixture from the current collector aluminum foil to obtain lithium iron phosphate powder and Positive electrode mixture of conductive carbon;

[0064] S33. Dissolve the positive electrode mixture with 98% concentrated sulfuric acid and filter to obtain the first filtrate with pH=0.6, add ammonia water to the first filtrate, stir while adding ammonia water, until the pH reaches 1.9, continue stirring for a period of time...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com