Internally-doped capillary crystalline waterproof material and preparation method thereof

A technology of osmotic crystalline waterproofing and water reducing agent, which is applied in the field of cement concrete waterproofing materials, which can solve the problems of high cost and short service life, and achieve the effects of low cost, reduced cost and improved overall impermeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

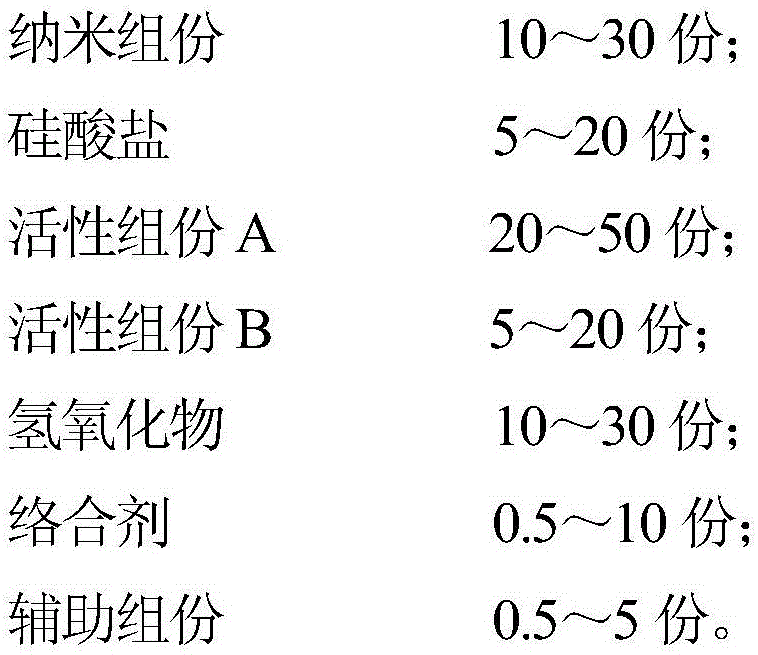

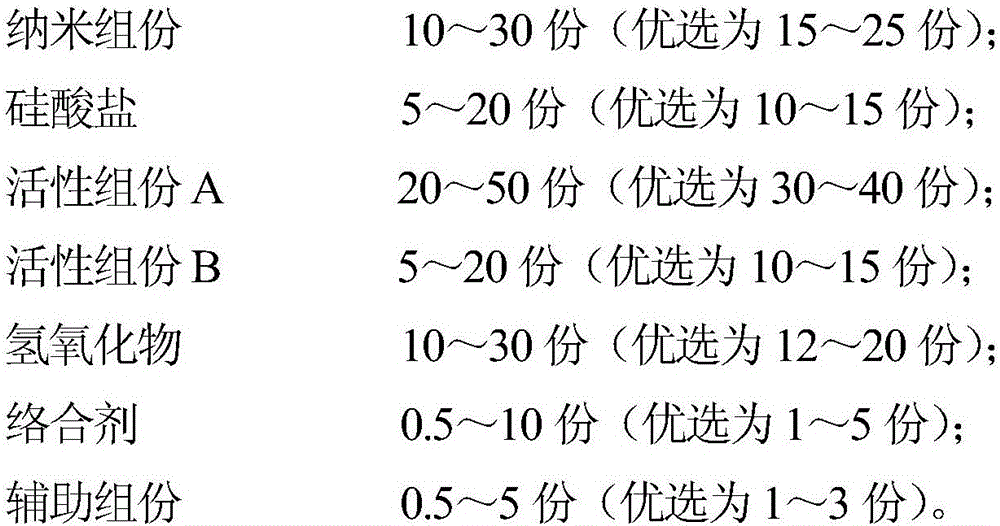

Method used

Image

Examples

Embodiment 1

[0033] In parts by weight, fully mix 1 part of tetrasodium aminotrimethylene phosphonate with 1 part of polycarboxylate water reducer powder, then add 5 parts of magnesium hydroxide and 10 parts of calcium hydroxide to the above-mentioned In the mixture, and stir evenly, finally add 35 parts of fly ash, 10 parts of ferrous sulfate heptahydrate, 3 parts of potassium sulfate, 20 parts of nano-calcium carbonate (particle size 50nm), and 15 parts of calcium silicate , and mix uniformly to obtain the osmotic intermixing type osmotic crystalline waterproof material of the present invention.

[0034] The technical indicators of this embodiment are as follows: 8% internal mixing, the 28-day compressive strength ratio of cement concrete is 108%, the 28-day anti-seepage pressure ratio is 285%, and the 56-day secondary anti-seepage pressure ratio is 235%.

Embodiment 2

[0036] In parts by weight, fully mix 5 parts of sodium hexametaphosphate and 1.5 parts of polyvinyl alcohol (rheological agent), then add 15 parts of calcium hydroxide to the above mixture, and stir evenly, and finally mix 35.5 15 parts of ground slag powder, 6 parts of sodium thiosulfate pentahydrate, 22 parts of superfine silica fume (50 μm in particle size), and 15 parts of sodium silicate were added in sequence and mixed evenly to obtain the permeable internal mixing type of the present invention. Penetrates crystalline waterproof material.

[0037] The technical indicators of this embodiment are as follows: 10% internal mixing, the 28-day compressive strength ratio of cement concrete is 122%, the 28-day anti-seepage pressure ratio is 298%, and the 56-day secondary anti-seepage pressure ratio is 223%.

Embodiment 3

[0039] In parts by weight, 2 parts of sodium diethylenetriamine pentamethylene phosphonate, 1 part of tartaric acid, 0.5 parts of water repellent, 1.5 parts of polycarboxylate superplasticizer powder are fully mixed, and then 2 parts of Add 35 parts of fly ash, 5 parts of metakaolin, 8 parts of potassium aluminum sulfate dodecahydrate, 15 parts of nano-silica powder and 18 parts of sodium silicate are added in sequence and mixed uniformly to obtain the osmotic internal doping type osmotic crystalline waterproof material of the present invention.

[0040] The technical indicators of this embodiment are as follows: 6% is added internally, the 28-day compressive strength ratio of cement concrete is 102%, the 28-day impermeability pressure ratio is 256%, and the 56-day secondary impermeability pressure ratio is 203%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com