A kind of photocatalyst varnish with high-efficiency formaldehyde removal indoor

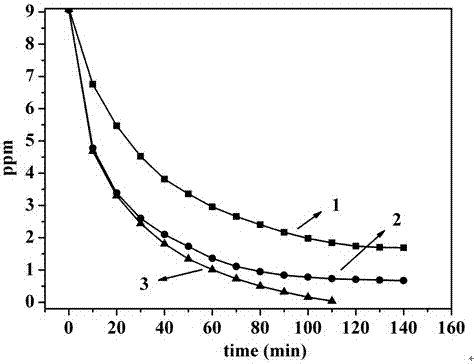

A technology of photocatalyst and varnish, applied in coating, organic compound/hydride/coordination complex catalyst, organic chemistry, etc., can solve the problems of no use value, insufficient natural light, low proportion of ultraviolet light, etc., and achieve formaldehyde degradation High efficiency, large contact surface and easy adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

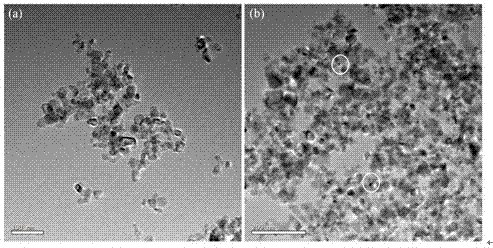

Method used

Image

Examples

Embodiment 1

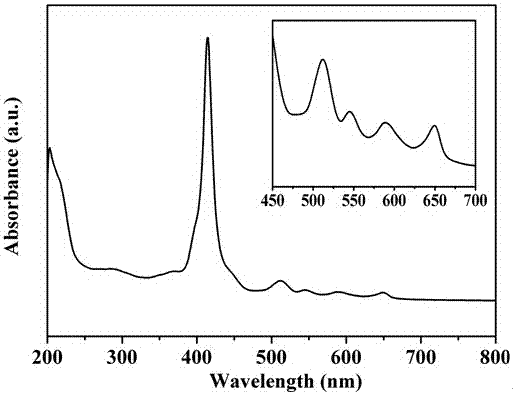

[0048] Embodiment 1, the first, the synthesis of four (p-mercaptophenyl) porphyrins;

[0049] (1) Synthesis of tetraphenylporphyrin: Add 0.101 mol of benzaldehyde and 250 mL of propionic acid into a round-bottomed flask, sonicate until uniform, and heat to reflux at 145 °C; add 0.101 mol of pyrrole into a 30 mL Propionic acid, add dropwise to the above solution, 20-30 min dropwise, reflux for 1 h; Rotary steam, remove about 100 mL propionic acid, add 100 mL ethanol to the bottle, place at 0°C for 12 h, suction filter, column Chromatographic separation collects tetraphenylporphyrin.

[0050] (2) Synthesis of tetrakis(p-sulfonylchloridephenyl)porphyrin: put 10 mL of chlorosulfonic acid in a round bottom flask, add 0.5 g of tetraphenylporphyrin, stir at 0°C for 5 hours, and rotate at 500r / min dropwise into a beaker containing 137 grams of ice, neutralize pH=7 with NaOH solution, remove water by rotary evaporation, dissolve the solid with absolute ethanol, filter with suction, sp...

Embodiment 2

[0057] Example 2, the synthetic method of tetrakis (p-mercaptophenyl) porphyrin is the same as that of Example 1 for preparing TiO2-Ag-mercapto porphyrin photocatalyst; accurately measure 70 mL of absolute ethanol and place it in a 500 mL beaker , at a stirring speed of 2000r / min, 30 mL of tetraethyl orthosilicate was added, and the pH value of the solution was adjusted to 2 with hydrochloric acid. After stirring for 10 min, 18 mL of distilled water was added, and the stirring was continued for 30 min to obtain silica sol.

[0058] Prepare indoor high-efficiency formaldehyde-removing photocatalyst varnish as follows: (1) Take 150 grams of distilled water, 1.4 grams of ink dispersion aid, TiO 2 -8 grams of Ag-mercaptoporphyrin photocatalyst, 40 grams of silica sol, 0.3 grams of 35% acetic acid solution; (2) Put distilled water in a high-speed disperser, and add 1.4 grams of ink wetting and dispersing agent at a stirring speed of 3000r / min , stir and disperse for 15min; adjust t...

Embodiment 3

[0059] Embodiment 3, the synthetic method of tetrakis (p-mercaptophenyl) porphyrin and preparation TiO 2 The method of -Ag-mercaptoporphyrin photocatalyst is the same as embodiment 1; Accurately measure 70 mL of dehydrated alcohol and place it in a 500 mL beaker, add 20 mL of orthosilicate ethyl ester at a stirring speed of 2000r / min, The pH value of the solution was adjusted to 1.1 with hydrochloric acid, after stirring for 10 min, 15 mL of distilled water was added, and the stirring was continued for 30 min to obtain silica sol.

[0060] Prepare indoor high-efficiency formaldehyde-removing photocatalyst varnish as follows: (1) Take 180 grams of distilled water, 2 grams of ink dispersion aids, TiO 2 - 10 grams of Ag-mercaptoporphyrin photocatalyst, 50 grams of silica sol, 0.48 grams of 35% acetic acid solution; (2) Put distilled water in a high-speed disperser, and add 2 grams of ink wetting and dispersing agent at a stirring speed of 4000r / min , stir and disperse for 18min;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com