A kind of preparation method of black titanium dioxide nano film

A black titanium dioxide, nano-film technology, applied in chemical instruments and methods, catalyst activation/preparation, metal/metal oxide/metal hydroxide catalysts, etc. , unfavorable chemical reactions and other problems, to achieve the effect of expanding the light response range, application environment friendly, and promoting catalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

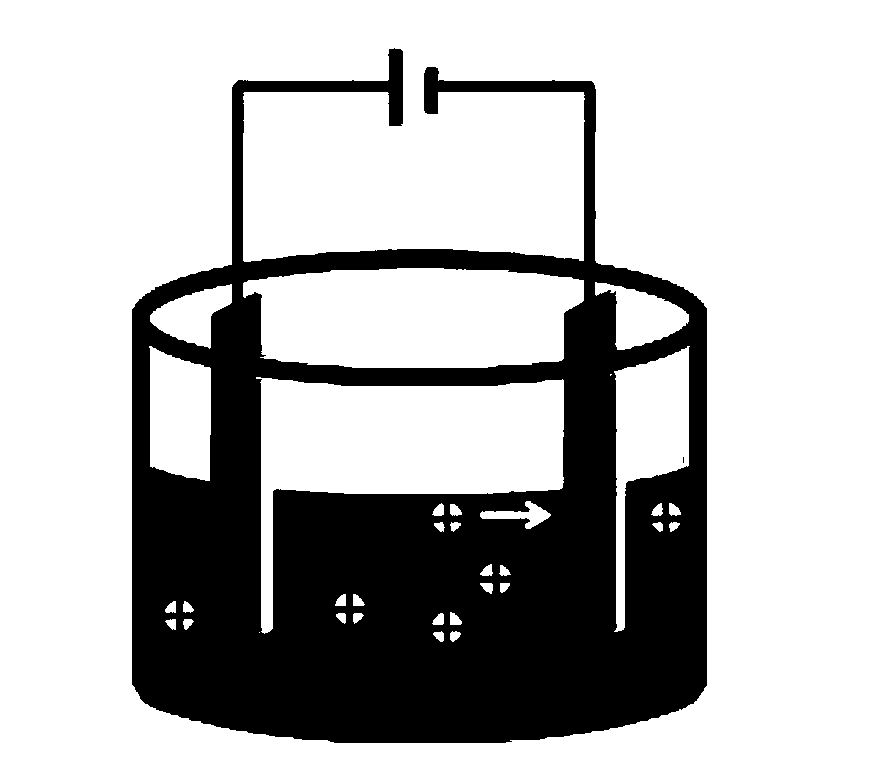

[0017] The technological process of the black titanium dioxide nano-film preparation method that this embodiment involves comprises three steps of the preparation of nano-particles, the preparation of nano-film and the thickness control of nano-film:

[0018] (1), preparation of nanoparticles: 5mL mass percentage concentration is 95% titanium tetraisopropoxide dissolved in 95mL mass percentage concentration is 99.7% isopropanol, then add 10mg mass percentage concentration is 98% nickel nitrate , stirred until the nickel nitrate was dissolved to form a mixed solution, and then added dropwise the mixed solution to 900 mL of water with a pH of 1.5 and a temperature of 2°C adjusted with nitric acid and continued to stir for 24 hours to obtain a transparent colloidal solution. The colloidal solution was placed at 40 The rotary evaporator at ℃ continued for 12 hours to remove isopropanol, and the colloid solution after removing isopropanol was placed in a high-speed centrifuge with a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com