Rare earth doped bismuth germanate single crystal optical fiber and cladding method

A technology of rare earth doping and bismuth germanate, which is applied in the direction of cladding optical fiber, single crystal growth, single crystal growth, etc., can solve the problems such as the inapplicability of quartz, and achieve the effect of high power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] A preparation of rare earth ion doped silicate optical fiber and its cladding method, the rare earth ion is selected as Yb 3+ , specifically prepared by the following method:

[0037] (1) Ingredients: Yb 2 o 3 、 Bi 2 o 3 、GeO 2 Be raw material, introduce raw material by 0.5:2:3 mole composition ratio, and put into agate mortar and grind 50min, thereby raw material is mixed;

[0038] (2) Pressing material: Press the prepared raw materials into rods under the water pressure of 60MPa;

[0039] (3) Burning material: put the material rod into the muffle furnace, the heating rate is 80°C / h, the constant temperature is 700°C, the constant temperature time is 20h, the cooling rate is 60-120°C / h, and it is lowered to room temperature.

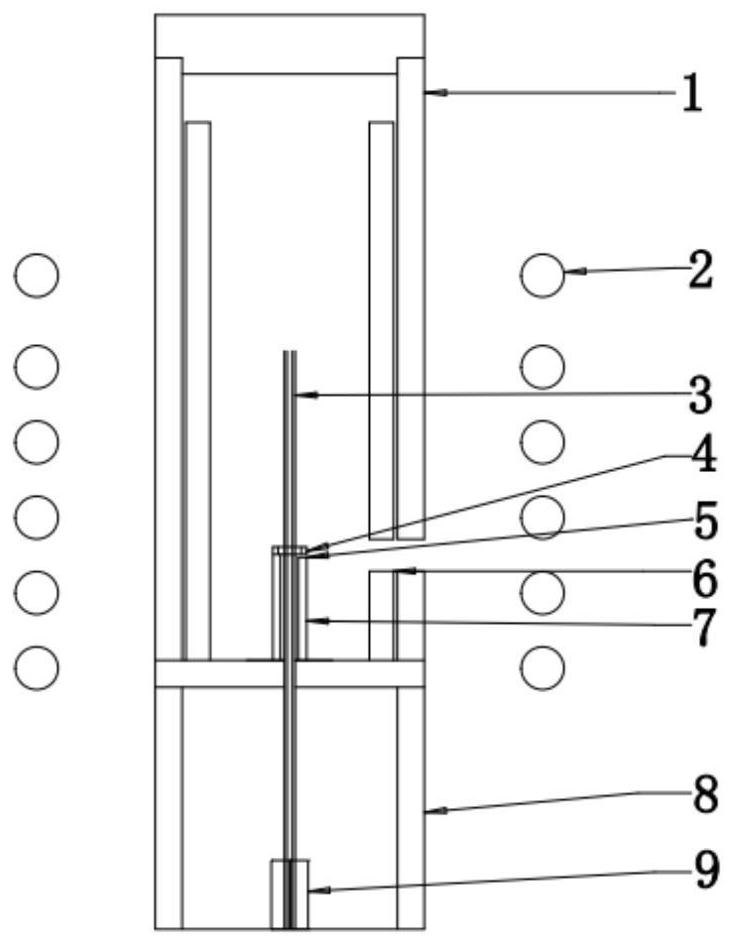

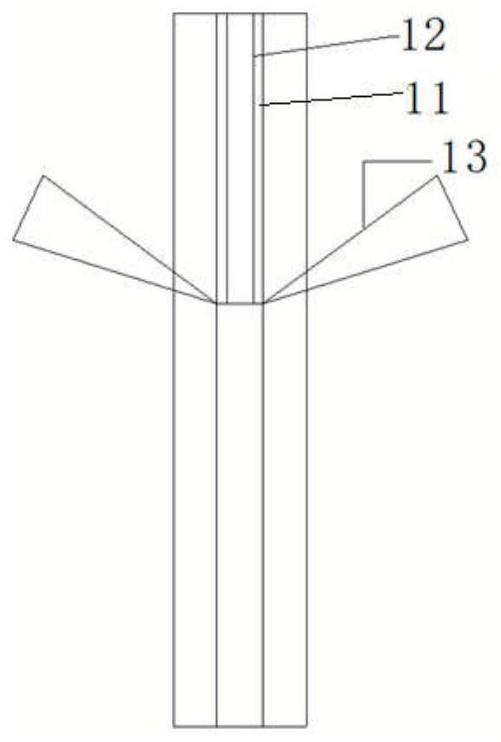

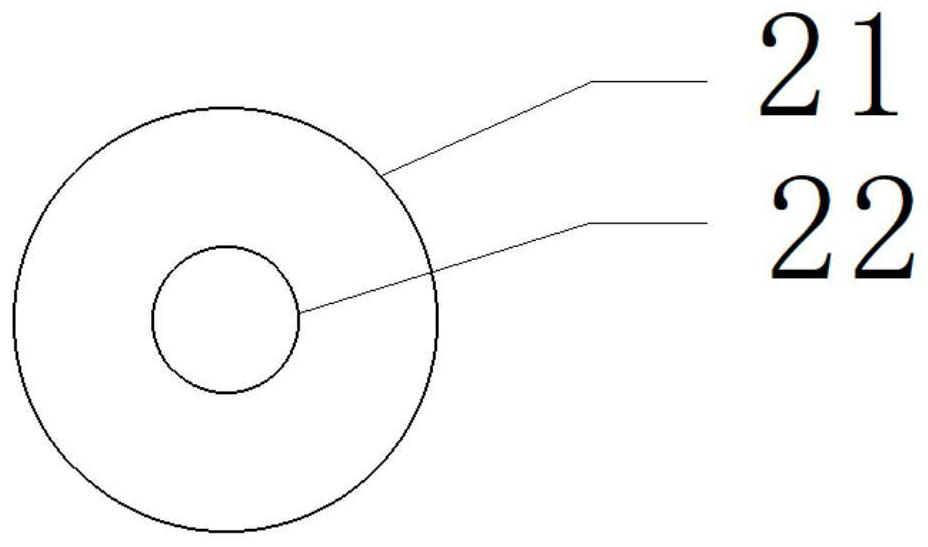

[0040] (4) Growing fiber core: a silicate optical fiber doped with rare earth ions with a diameter of 1 mm is prepared by the micro-draw method or the laser heating susceptor method. Among them, the pulling speed of the micro pull-down met...

Embodiment 2

[0046] A preparation of rare earth ion doped silicate optical fiber and its cladding method, the rare earth ion is selected as Yb 3+ , specifically prepared by the following method:

[0047] (1) Ingredients: Yb 2 o 3 、 Bi 2 o 3 、GeO 2 Be raw material, introduce raw material by 0.65:2:3 mole composition ratio, and put into agate mortar and grind 60min, thereby raw material is mixed;

[0048] (2) Pressing material: Press the prepared raw materials into rods under the water pressure of 75MPa;

[0049] (3) Burning material: put the material rod into the muffle furnace, the heating rate is 120°C / h, the constant temperature is 800°C, the constant temperature time is 25h, the cooling rate is 60-120°C / h, and it is lowered to room temperature.

[0050] (4) Growing fiber core: a silicate optical fiber doped with rare earth ions with a diameter of 2 mm was prepared by the micro-draw method or the laser heating susceptor method. Among them, the pulling speed of the micro pull-down ...

Embodiment 3

[0056] A kind of preparation and cladding method of rare earth ion doped silicate optical fiber, select rare earth ion as Tm 3+ , specifically prepared by the following method:

[0057] (1) Ingredients: Tm 2 o 3 、 Bi 2 o 3 、GeO 2 Be raw material as raw material, introduce raw material by 0.003:2:3 mole composition ratio, and put into agate mortar and grind 40min, thereby raw material is mixed;

[0058] (2) Pressing material: Press the prepared raw materials into rods under the water pressure of 48MPa;

[0059] (3) Burning material: Put the material rod into the muffle furnace. The heating rate is 150°C / h, the constant temperature is 650°C (constant temperature time 30h), the cooling rate is 60-120°C / h, down to room temperature.

[0060] (4) Growing fiber core: prepare a rare earth ion-doped silicate optical fiber with a diameter of 1.5 mm by micro-draw method or laser heating susceptor method. Among them, the pulling speed of the micro pull-down method is: 0.3-0.5mm / mi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com