Bismuth germanate monocrystal growing method

A growth method and bismuth germanate technology, applied in the directions of single crystal growth, crystal growth, single crystal growth, etc., can solve the problems of difficulty in further improving crystal quality, slow and uneven component diffusion, uneven temperature distribution, etc. Improve the resistance to radiation damage, facilitate the diffusion of components, and improve the effect of radial symmetry

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

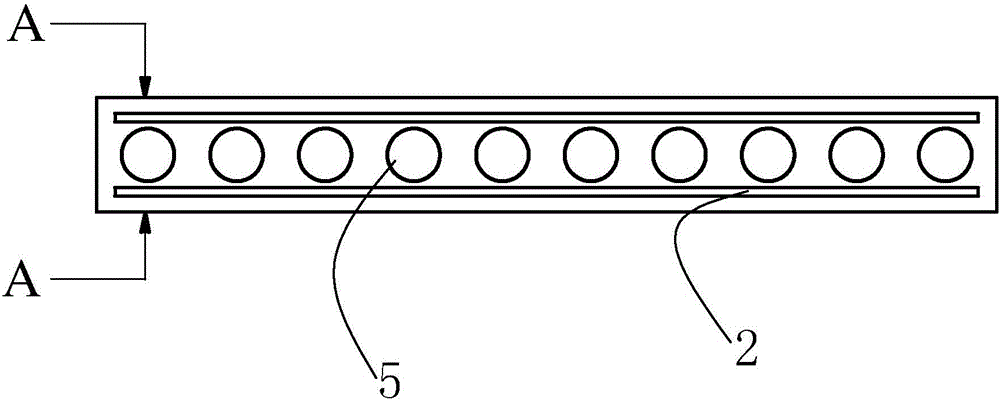

Image

Examples

Embodiment 1

[0036]1) Mix bismuth oxide with a purity of 5N and germanium oxide powder with a purity of 5N according to the stoichiometric ratio (ie, molar ratio) of 2:3 and mix them evenly. After high-temperature compounding, they are rapidly cooled to obtain block bismuth germanate polycrystalline After crushing it through a 50-mesh sieve, weigh four parts of the sieve with a mass of 11kg, and press it into four cylindrical bismuth germanate cakes under the conditions of 180°C and 150MPa. The diameter is slightly smaller than 76.2mm.

[0037] 2) Put the seed crystals of the [001] orientation into the bottoms of four platinum crucibles 4 with a diameter of 76.2 mm, and then put the above-mentioned pressed bismuth germanate cakes into the four platinum crucibles with seed crystals respectively In 4, the bismuth germanate cake is placed on the seed crystal, the platinum crucible 4 is sealed, and placed in four crucible guide tubes 34 respectively, silicon oxide powder is filled between the ...

Embodiment 2

[0043] 1) Mix bismuth oxide with a purity of 6N and germanium oxide powder with a purity of 6N according to the stoichiometric ratio (ie, molar ratio) of 2:3 and mix them evenly. After high-temperature compounding, they are rapidly cooled to obtain block bismuth germanate polycrystalline After crushing it through a 100-mesh sieve, weigh two portions of 15.5kg undersize, and press it into two cylindrical bismuth germanate cakes under the conditions of 25°C and 350MPa. The cake diameter was slightly less than 101.6 mm.

[0044] 2) Put the seed crystals of the [110] orientation into the bottoms of two platinum crucibles 4 with a diameter of 101.6 mm, and then put the pressed bismuth germanate cake into the above two platinum crucibles with seed crystals respectively In 4, the bismuth germanate cake is placed on the top of the seed crystal, the platinum crucible 4 is sealed, and placed in two crucible guide tubes 34 respectively, zirconia powder is filled between the platinum cruc...

Embodiment 3

[0050] 1) Mix bismuth oxide with a purity of 5N and germanium oxide powder with a purity of 6N according to the stoichiometric ratio (ie, molar ratio) of 2:3 and mix them evenly. After high-temperature compounding, they are rapidly cooled to obtain block bismuth germanate polycrystalline After crushing it through an 80-mesh sieve, weigh ten portions of 7.5kg undersieve, and press it into ten cylindrical bismuth germanate cakes under the conditions of 50°C and 350MPa. The cake diameter is slightly less than 60mm.

[0051] 2) Put the seed crystals of the [001] orientation into the bottoms of 10 platinum crucibles 4 with a diameter of 60 mm, and then put the above-mentioned compressed bismuth germanate cakes into the above 10 platinum crucibles 4 with seed crystals respectively In the process, the bismuth germanate cake is placed on the seed crystal, the platinum crucible 4 is sealed, and placed in ten crucible guide tubes 34 respectively, and alumina powder is filled between the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com