Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

392 results about "Platinum crucible" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Iron alloy fusing sample preparation method for X-ray fluorescence spectrum analysis

InactiveCN101832891AReduce sample preparation timeAnalytical results are reliableMaterial analysis using wave/particle radiationPreparing sample for investigationX-rayFerrosilicon

The invention relates to an iron alloy fusing sample preparation method for X-ray fluorescence spectrum analysis, belonging to the technical field of materialization detection and aiming to solve the problem that fusing a film production alloy sample can erode a platinum crucible. The method comprises the steps of building up wall of the platinum crucible, preparing an oxidizing agent, pre-oxidizing an iron alloy sample and fusing and preparing sample from the iron alloy sample. The invention provides the fusing sample preparation method suitable for various iron alloys such as ferromanganese, silicomanganese, calcium silicon, ferrosilicon, ferromolybdenum, ferrotitanium, cymrite, ferrochrome, ferrocolumbium, ferrovanadium, silicon silicomanganese and the like. By adopting the method, a glass fusing piece can be manufactured without eroding the valuable platinum crucible, the sample can be completely oxidized in the sample preparation process, the sample preparation time is short, the prepared glass fusing piece is uniform and perfect, and the mineral effect and the granularity effect can be completely eliminated. The invention has safe and reliable method, simple and convenient operation and good repeatability, is suitable for various iron alloy samples and widens the application range of the fluorescence analysis.

Owner:HBIS COMPANY LIMITED HANDAN BRANCH COMPANY

Sealing glass frit

InactiveUS20050277541A1Reduce decreaseSolid electrolyte fuel cellsSealing/support meansFritRoom temperature

A sealing glass frit which is capable of stably joining metal members or ceramic members at temperatures thereof not higher than 1000° C., and at the same time stably maintaining the joined state of the members at temperatures ranging from room temperature to 700 or 800° C. A raw material in an amount of MG 300 g is prepared such that it has a composition of 40 to 70 mol % of SiO2, 5 to 20 mol % of Al2O3, 4 to 20 mol % of Na2O, 4 to 20 mol % of K2O, 5 to 20 mol % of ZnO, and 0.5 to 5 mol % of ZrO2, and the total content of Na2O and K2O is not lower than 12 mol %. The raw material is melted in a platinum crucible at 1550° C. for 8 hours, cast in a mold of stainless steel, held at 650° C. for 2 hours, and then cooled to room temperature at 5° C. / minute. The cooled raw material is pulverized in a mortar to obtain powder having a particle diameter 10 to 20 μm as a sealing glass frit.

Owner:NIPPON SHEET GLASS CO LTD

Environment-friendly electrode silver slurry of zinc oxide varistor suitable for two soldering technologies and preparation method of electrode silver slurry

ActiveCN104934103AGuaranteed normal transmissionReduce interface contact resistanceNon-conductive material with dispersed conductive materialCable/conductor manufactureSlurryResistor

The invention discloses an environment-friendly electrode silver slurry of zinc oxide varistor suitable for two soldering technologies and a preparation method of the electrode silver slurry. The silver slurry is composed of 60-80% silver powder, 1-5% of metal oxide, 2-5% of leadless glass powder and 10-37% of organic carriers by weight. The preparation method comprises the steps that the leadless glass powder is prepared by that raw materials are mixed well, placed in a platinum crucible and melt, and the melt material is removed and dried to obtain the leadless glass powder; the organic carriers are prepared by adding an organic solvent into a stainless steel container, adding organic resin, carrying out heating, and carrying out cooling and adding a surfactant after the resin is completely dissolved; and the silver slurry is prepared by mixing the silver powder, the metal oxide, the leadless glass powder and the organic carriers, and stirring and grinding the mixture in a vacuum manner. The preparation method is simple and suitable for both the reflow soldering and immersed soldering technologies, the solderability and the soldering resistance are high, the silver slurry can be used to prepare common type as well as lightning protection type varistor, the adhesion force, the conductivity and the electrical performance are high, and the performance completely reach the using requirements.

Owner:GUIYAN DETECTION TECH YUNNAN CO LTD

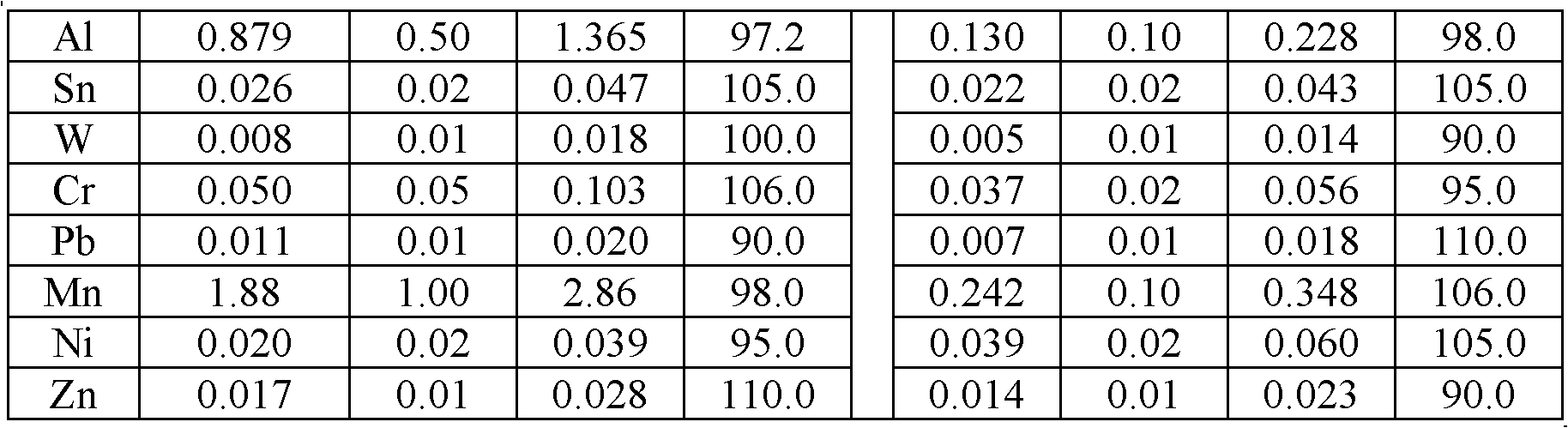

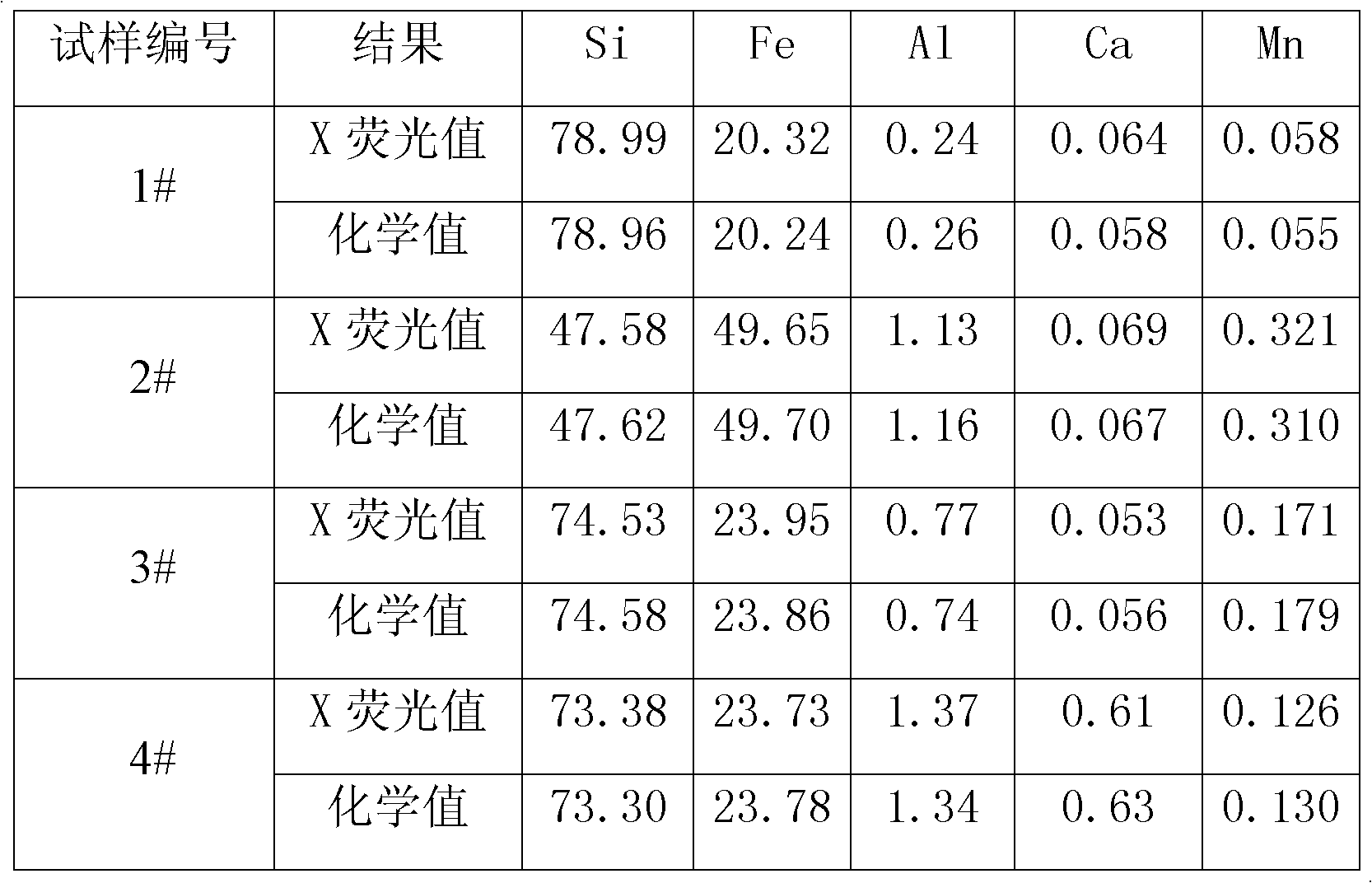

X-ray fluorescence spectroscopy analysis fusion sample preparation method of aluminum, manganese, calcium and iron alloy

InactiveCN102607934AEliminate sources of errorImprove analytical accuracyMaterial analysis using wave/particle radiationPreparing sample for investigationFluorescenceManganese

The invention discloses an X-ray fluorescence spectroscopy analysis fusion sample preparation method of an aluminum, manganese, calcium and iron alloy, which comprises the steps of: firstly, coating a uniform protection wall layer in a platinum crucible by using lithium tetraborate, then placing an aluminum, manganese, calcium and iron sample, an oxidizing agent, a lithium borate solvent and a releasing agent into the platinum crucible in which the protection wall is coated, uniformly mixing, and then pre-oxidizing the aluminum, manganese, calcium and iron sample; and finally, melting the pre-oxidized aluminum, manganese, calcium and iron sample, and cooling to obtain an aluminum, manganese, calcium and iron sample glass fuse piece, wherein the aluminum, manganese, calcium and iron sample is a detection sample or calibration sample of the aluminum, manganese, calcium and iron alloy, and the sample glass fuse piece is a detection sample glass fuse piece or calibration sample glass fuse piece of the aluminum, manganese, calcium and iron alloy. On the premise of no corrosion to the valuable platinum crucible, the glass fuse piece can be prepared, and the prepared sample is excellent and uniform, thus the mineral effect and the grain size effect are completely eliminated.

Owner:HBIS COMPANY LIMITED HANDAN BRANCH COMPANY

Digestion method of metallurgical materials and detection method

ActiveCN102564834ARetain complete digestionEnsure complete digestionPreparing sample for investigationRoom temperatureSolvent

The invention discloses a digestion method of metallurgical materials. The digestion method comprises the steps of: putting the metallurgical materials into a container, adding hydrochloric acid or nitric acid into the container, reacting under the heating condition, filtering a reaction solution after reaction is finished, collecting filtrate and cleaning residues; putting the cleaned residues in a platinum crucible, and heating to 250-600 DEG C for ashing treatment; after complete ashing of the residues, cooling to room temperature, then adding an alkali metal salt solvent, stirring uniformly, heating the mixture stirred uniformly to be 700-1050 DEG C, melting for 10-30 min, cooling, then adding 5-10ml concentrated hydrochloric acid or concentrated nitric acid, boiling, leaching, and obtaining a solution for melting the residues; and combining the filtrate with the solution for melting the residues and obtaining a digested solution. The digestion method is wide in application field, is simple in requirements on experiment instruments, and can be effectively applied in a laboratory equipped with various instruments.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

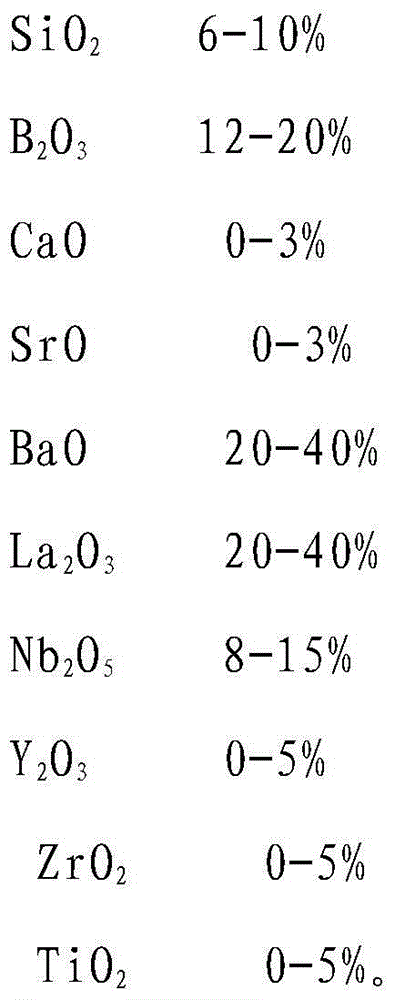

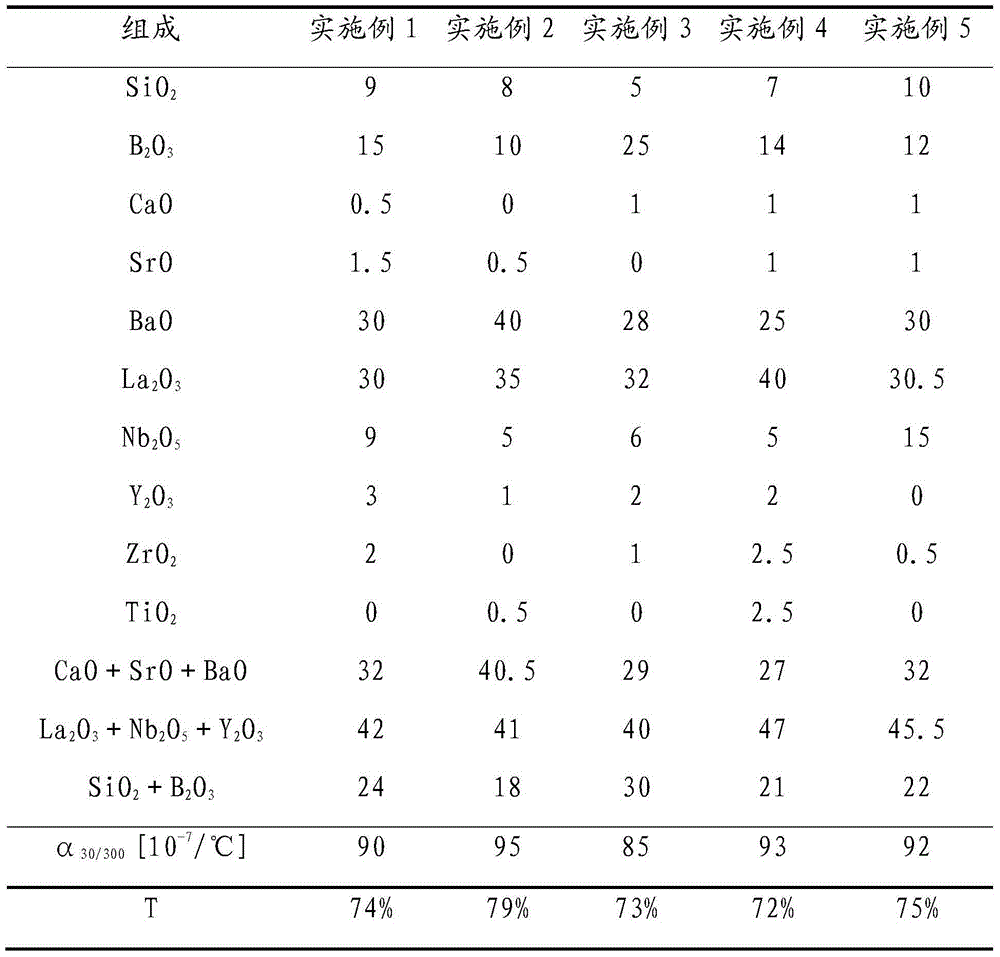

High-refractive-index ultraviolet-transparent glass and manufacturing method thereof

ActiveCN104402218AHigh refractive indexExcellent acid resistance and chemical stabilityFiberRefractive index

The invention discloses high-refractive-index ultraviolet-transparent glass and a manufacturing method thereof. The high-refractive-index ultraviolet-transparent glass comprises following components, by weight, 5-15% of SiO2, 10-25% of B2O3, 0-5% of CaO, 0-5% of SrO, 10-50% of BaO, 10-50% of La2O3, 5-15% of Nb2O5, 0-5% of Y2O3, 0-5% of ZrO2 and 0-5% of TiO2. The invention also provides the manufacturing method of the high-refractive-index ultraviolet-transparent glass. The method includes following steps: placing quartz sand, boronic acid or boron anhydrous, calcium carbonate, strontium carbonate, barium carbonate, lanthanum oxide, niobium pentoxide, yttria, zirconium oxide and titanium dioxide according to requirement in a formula into a pure-platinum crucible with addition of a reduction agent, melting the materials at 1400-1600 DEG C for 6-10 hours with stirring for 2-3 times during the melting process, and casting the molten glass into a specified specification. The invention also discloses an application of the high-refractive-index ultraviolet-transparent glass in an ultraviolet-transparent optical fiber plate. The high-refractive-index ultraviolet-transparent glass is high in refractive index and transmittance and is good in chemical stability.

Owner:CHINA BUILDING MATERIALS ACAD

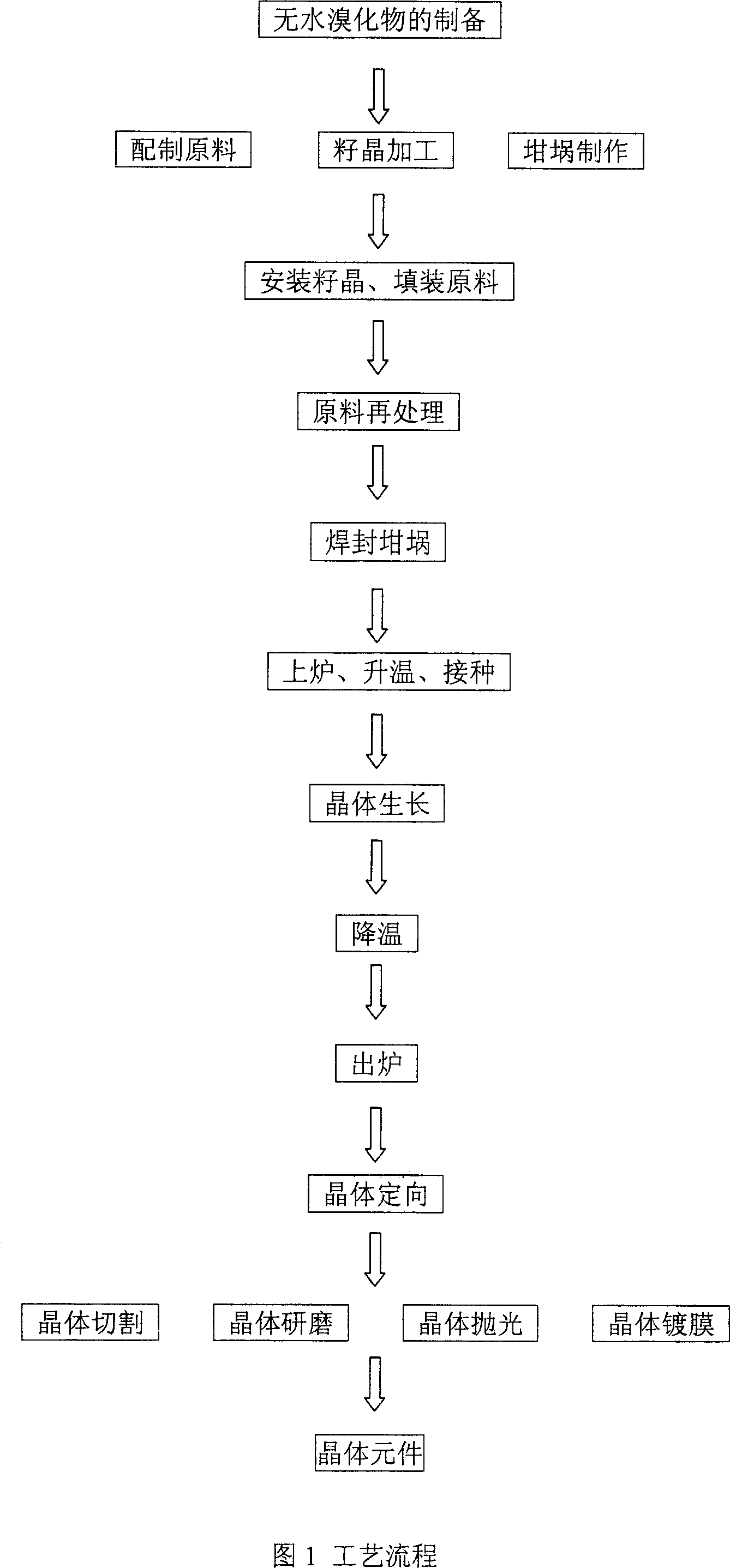

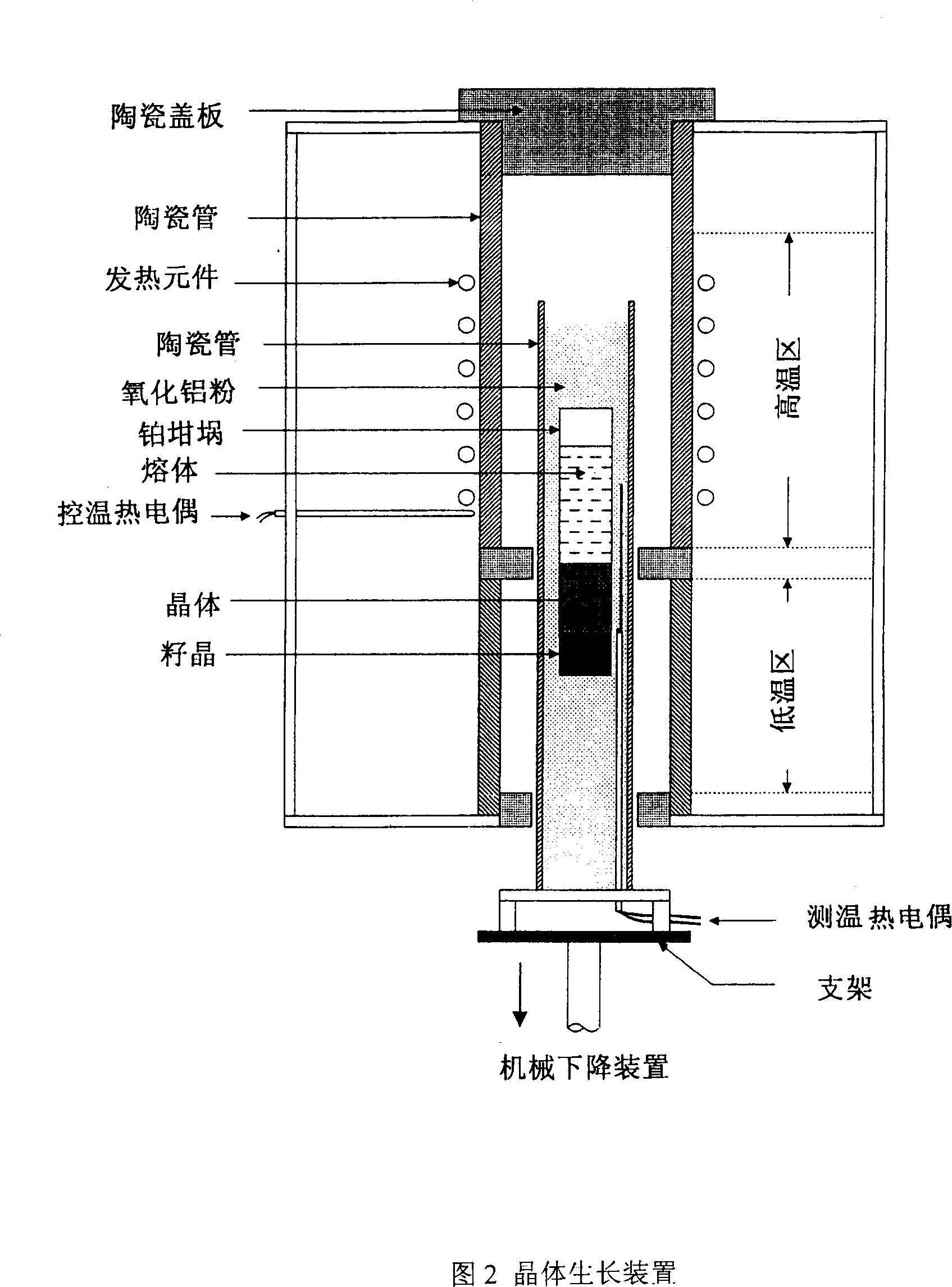

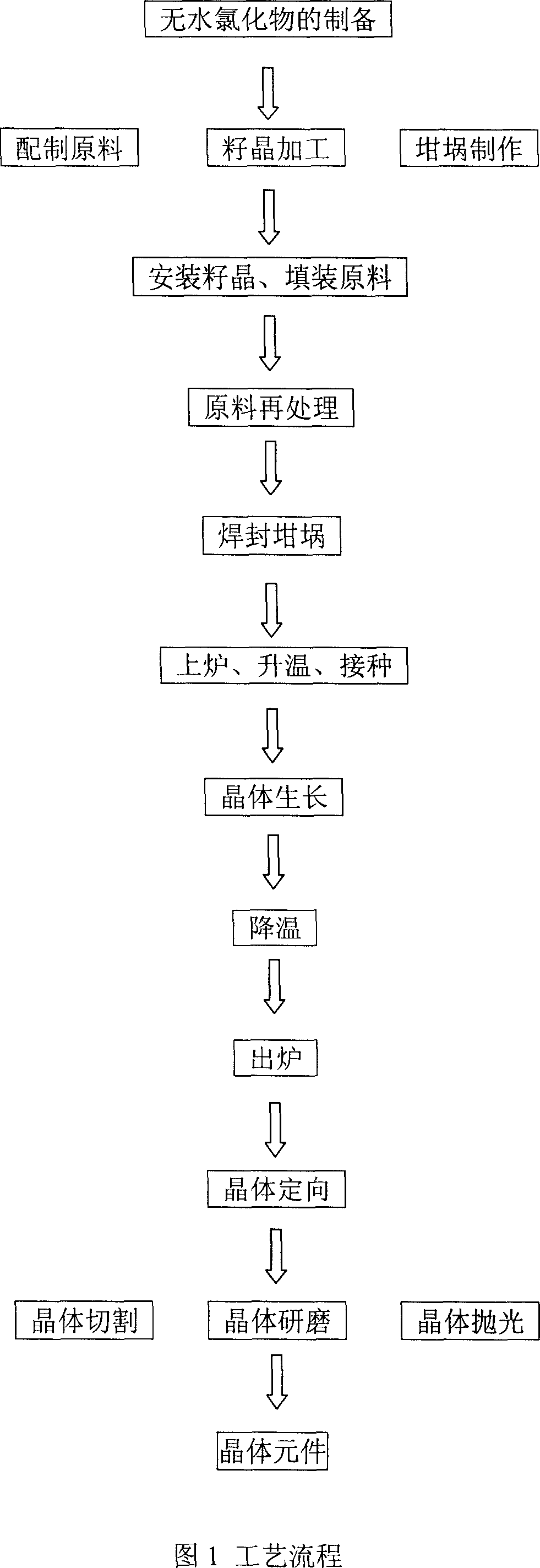

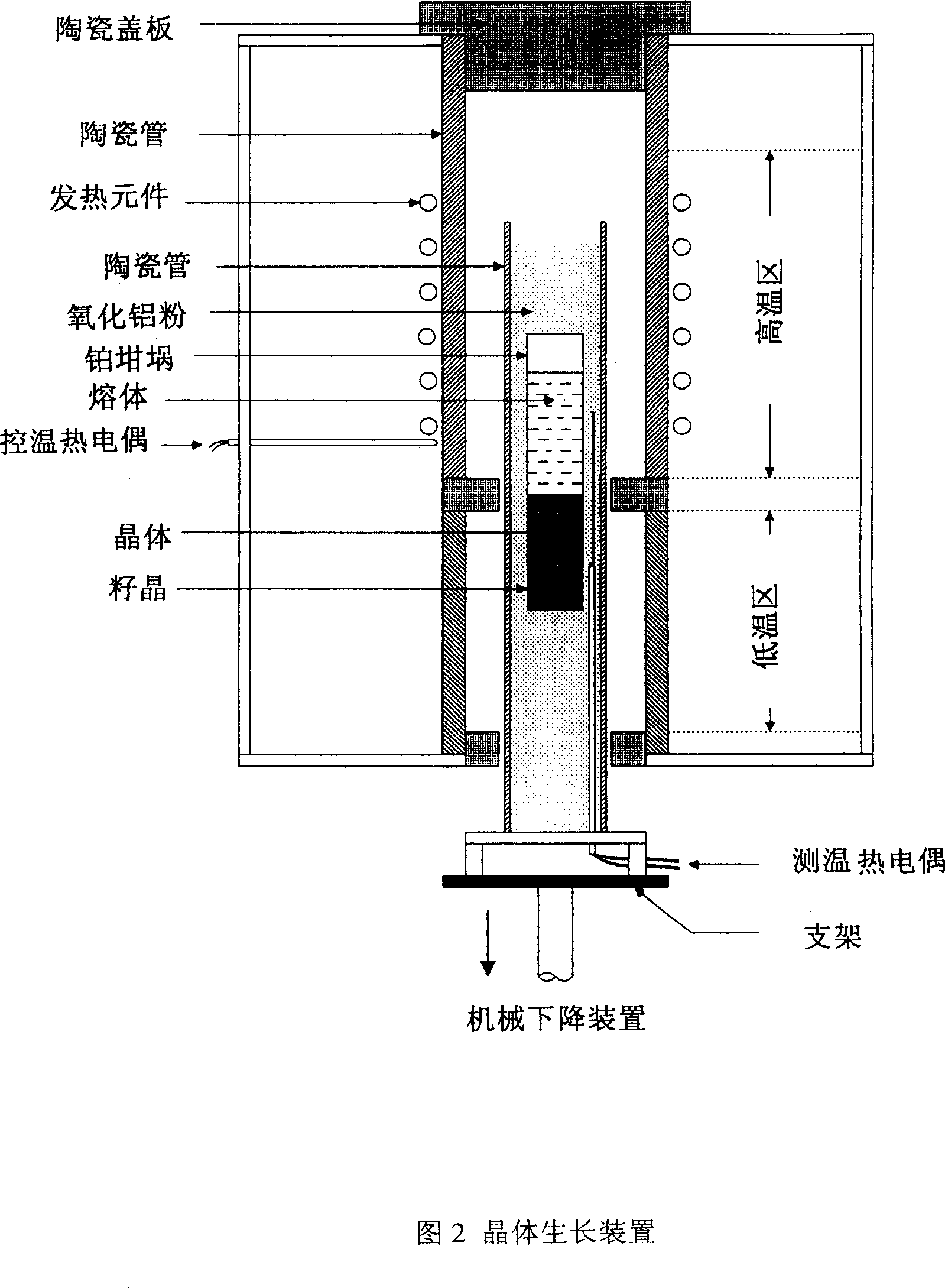

Novel glittering crystal LaBr3Ce3+ crucible-lowering method growth process

InactiveCN101070607ASolve deliquescencePolycrystalline material growthFrom frozen solutionsFurnace temperatureSingle crystal

The present invention discloses a growth craft of crucible descent method of neotype scintillating crystal LaBr3:Ce3+, which belongs to the domain of crystal growth. Take LaBr3.7H2O and CeBr3.7H2O as the initial raw material, and prepare anhydrous bromide LaBr3 and CeBr3 through the processing of halogenation roasting anhydration. Prepare LaBr3:Ce3+ batch according to suitable CeBr3 doping density, and mix into few active carbon powders as the deoxidizer. Fill crystallons and raw materials using special platinum crucible, and put crucible into crystal growth stove after solder seal it. Control furnace temperature between 850 Deg C and 900 Deg C. Adjust the position of crucible to make welding raw materials and crystallons, and it will form the solid liquid interface whose temperature gradient is between 20 Deg C / centimeter and 50 Deg C / centimeter. Carry on the crucible decline crystal growth at the speed of 0.3-3millimeter / hour, and it can be grown high quality and integrity LaBr3:Ce3+ single crystal. The craft has solved the key technology problems of anhydrous raw material preparation, melt mass oxidation and volatilization and so on, and LaBr3:Ce3+ single crystal can be mass grown in the condition of non-vacuum airtight crucible.

Owner:NINGBO UNIV +1

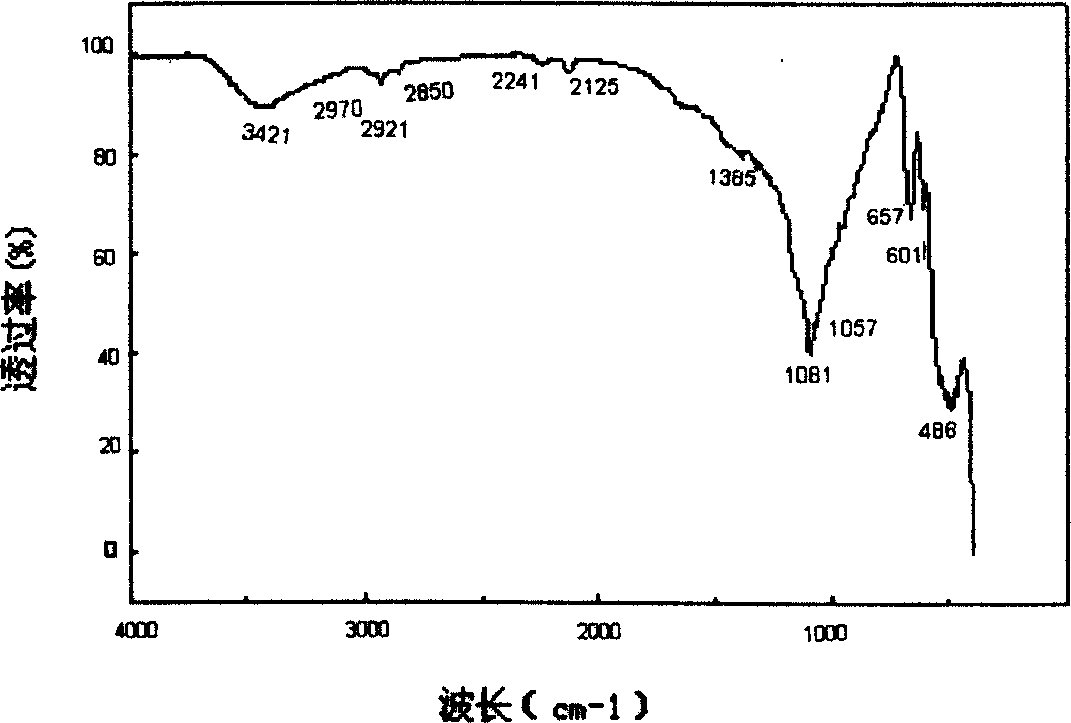

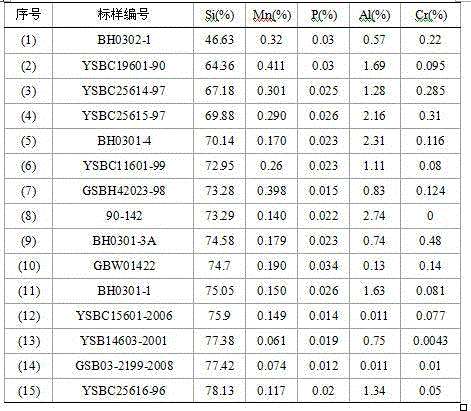

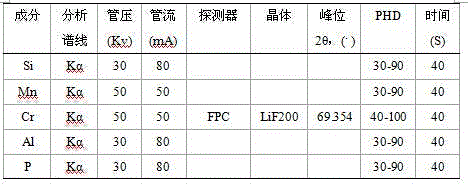

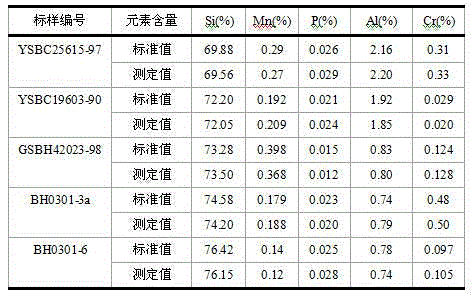

Method for analyzing ferrosilicon alloy components for X-ray fluorescence spectrum analysis

InactiveCN102156142AShort preparation timeEvenly distributedMaterial analysis using wave/particle radiationPreparing sample for investigationTest sampleX-ray

The invention discloses a method for analyzing ferrosilicon alloy components for X-ray fluorescence spectrum analysis. A method for preparing a sample comprises the following steps of: selecting a proper oxidant; adding a flux into a platinum crucible, putting the platinum crucible in a high temperature furnace, and melting the flux at high temperature to manufacture a wall built-up flux crucible with the basement of flux; mixing a ferrosilicon alloy test sample, the flux and the oxidant, pouring the mixture into the flux crucible, and covering a certain amount of mixed flux; and putting the flux crucible filled with the ferrosilicon alloy test sample, the flux, the oxidant and the mixed flux into the high temperature furnace, preliminarily oxidizing at low temperature, shifting into a high temperature zone, and melting at high temperature to prepare the ferrosilicon alloy test sample glass sample for the X-ray fluorescence spectrum analysis. In the technical scheme, elements are uniformly distributed in the prepared glass sample, and the glass sample has no particle effect and can be preserved for a long time; moreover, the operation method is simple and safe, the preparation time of the sample is short, and primary and secondary quantity elements in the ferrosilicon alloy are rapidly and accurately measured.

Owner:MAANSHAN IRON & STEEL CO LTD

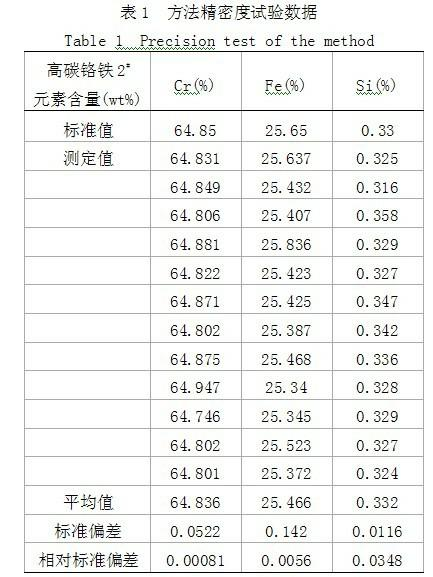

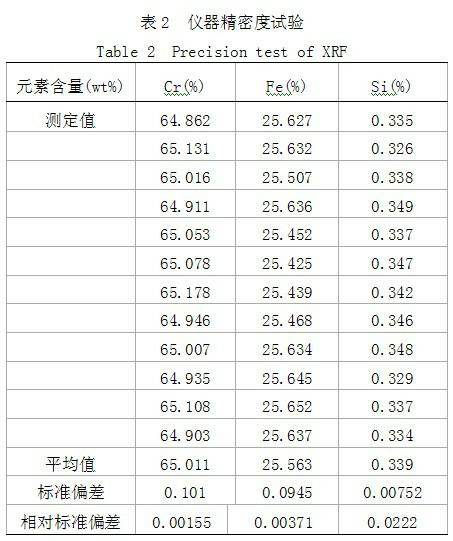

Sample preparation method by fusing medium-carbon ferrochrome and high-carbon ferrochrome

InactiveCN102426122AAvoid corrosionAnalytical data is reliableMaterial analysis using wave/particle radiationPreparing sample for investigationMolten stateShape change

The invention discloses a sample preparation method by fusing medium-carbon ferrochrome and high-carbon ferrochrome, which comprises the following steps of: (1) suspending wall: fusing lithium tetraborate in a platinum crucible, and rotating the platinum crucible, so that the fused lithium tetraborate is evenly suspended at the side wall and the bottom of the surface in the crucible, and a fusion agent crucible is formed; (2) previously oxidizing: mixing oxidizing agent with a standard sample or a sample to be tested of the medium-carbon ferrochrome or the high-carbon ferrochrome, and oxidizing in the fusion agent crucible which is cooled to be room temperature; (3) fusing: fusing the previously-oxidized standard sample or the sample to be tested; and (4) preparing a sample glass piece: cooling the fused standard sample or the sample to be tested to be room temperature, and forming the glass piece of the standard sample or the sample to be tested by the fused sample. Therefore, the influence of line spectrum peak shift or spectrum peak shape change and the like to an analysis result caused by the inconsistent absorption and enhancement effect, the mineral effect, the surface effect, the granularity and the analysis element chemical valence among ferrochrome alloy elements can be effectively eliminated.

Owner:HBIS COMPANY LIMITED HANDAN BRANCH COMPANY

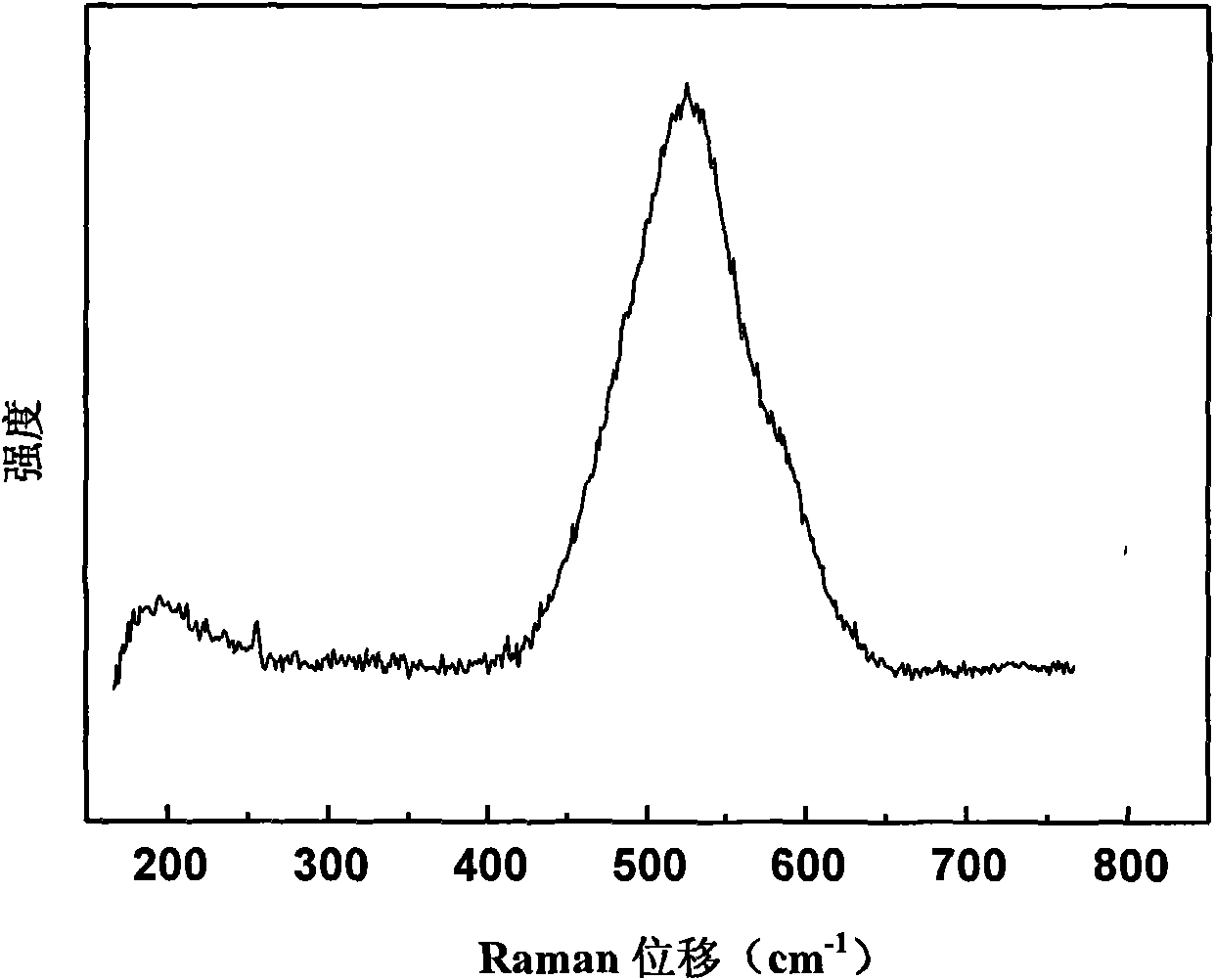

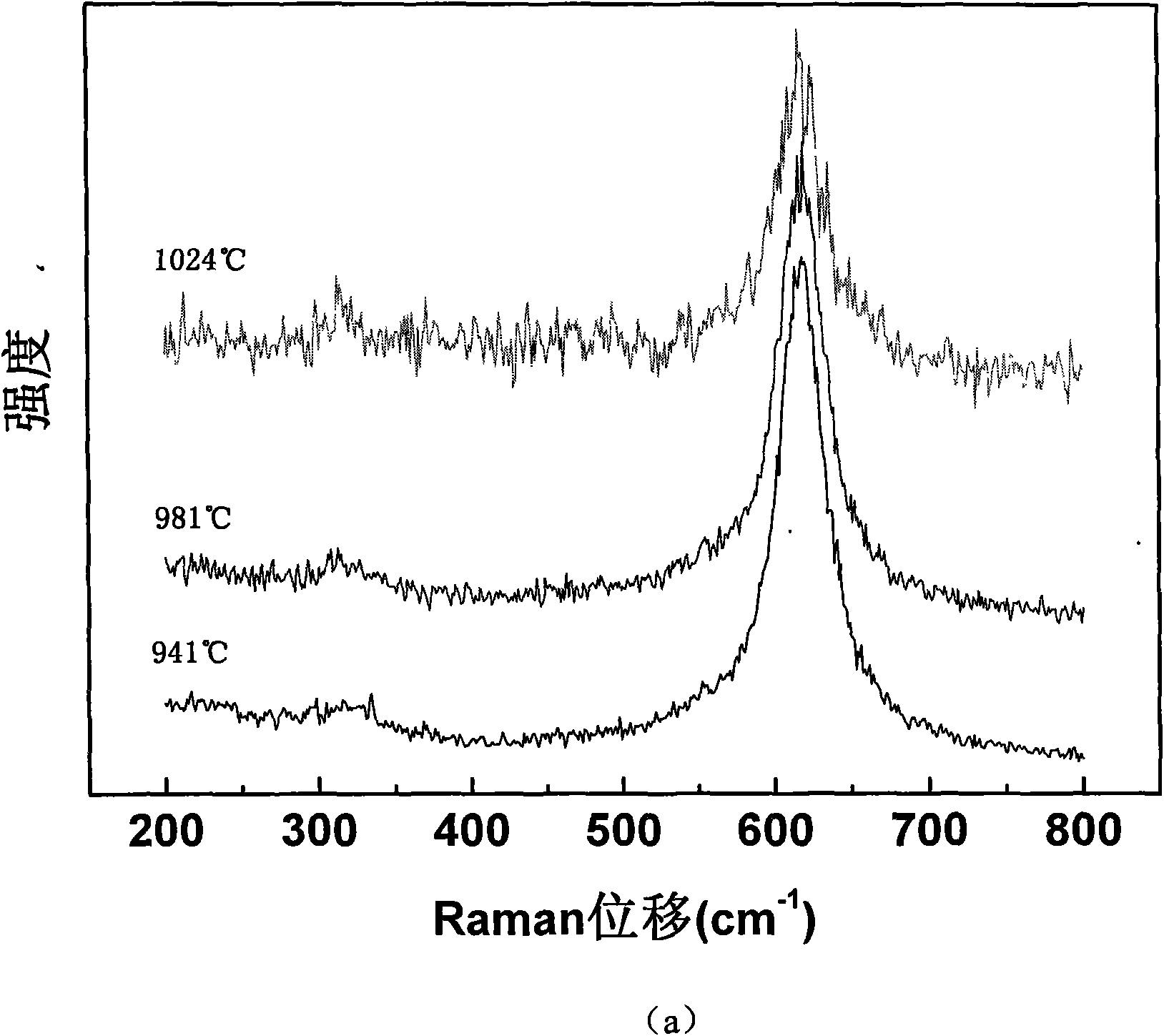

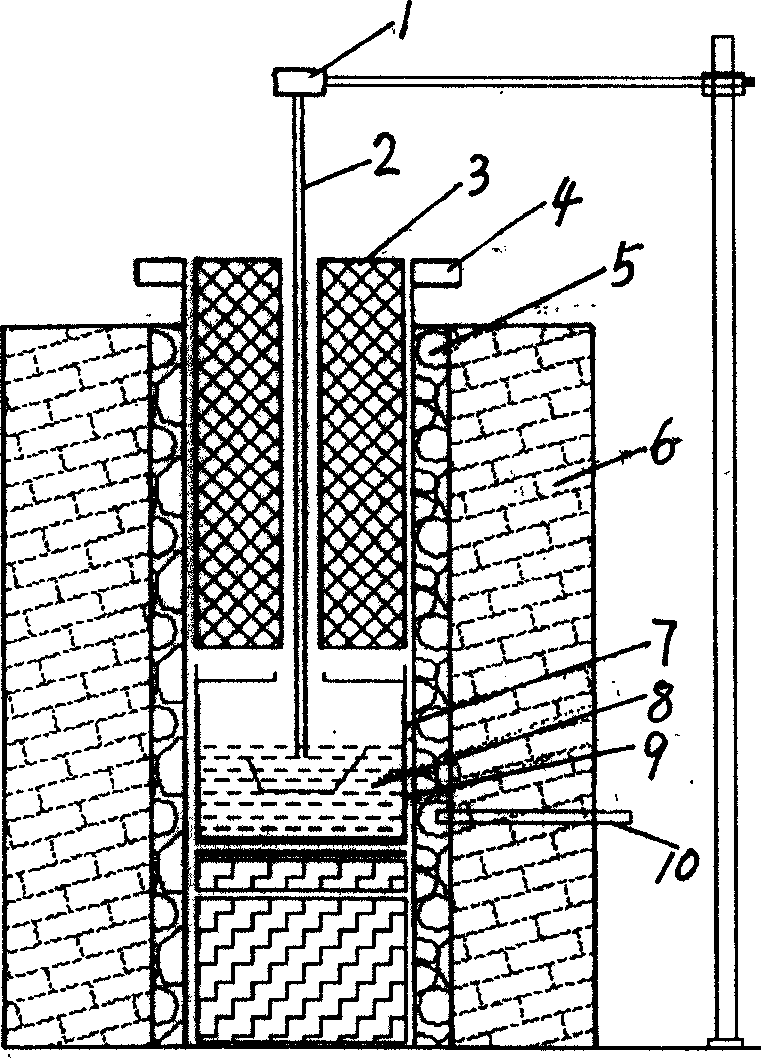

Sealed sample cell for Raman spectrum measurement of high-temperature volatile molten salt and use method thereof

InactiveCN101629899AImprove signal-to-noise ratioHigh measurement accuracyRaman scatteringAdditive ingredientHearth

The invention provides a sealed sample cell for Raman spectrum measurement of high-temperature volatile molten salt and a use method thereof. The sample cell comprises a platinum crucible, a crucible cover, a hearth, a hearth cover and heating platinum wires. The use method is characterized by adopting high-temperature alumina cement to seal the gap between the crucible cover and the mouth of the platinum crucible after feeding samples to be analyzed into the platinum crucible; during measurement, providing current for the heating platinum wires to heat the samples to be analyzed to the measurement temperature, adopting a thermocouple to measure the temperature of the platinum crucible; using the sample cell by matching an upper laser inlet type micros laser Raman spectrometer. The sealed sample cell of the invention can be used for Raman spectrum analysis of the high-temperature volatile molten salt such as cryolite and NaF-AlF3 molten salt with different mol ratios. The use method of the invention can avoid the ingredients of the molten salt to be measured from being affected by escape of the volatile substances, thus improving the measurement precision of the Raman spectrum.

Owner:NORTHEASTERN UNIV

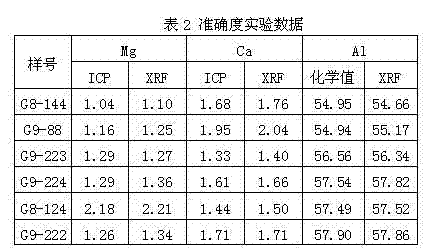

Melted sampling method for aluminum magnesium calcium iron alloy for X-ray fluorescence spectrum analysis

InactiveCN102331364AAccelerationAccuracyMaterial analysis using wave/particle radiationPreparing sample for investigationGranularityLithium carbonate

The invention discloses a melted sampling method for aluminum magnesium calcium iron alloy for X-ray fluorescence spectrum analysis. The melted sampling method is characterized by comprising the following steps of: hanging a layer of uniform lithium tetraborate protective wall in a platinum crucible; putting an aluminum magnesium calcium iron sample, lithium carbonate and potassium iodide into the platinum crucible in which the protective wall is hung, mixing uniformly, and covering a layer of lithium tetraborate; pre-oxidizing the aluminum magnesium calcium iron sample; and melting the oxidized aluminum magnesium calcium iron sample, and cooling to obtain a glass fuse piece of the aluminum magnesium calcium iron alloy. By the method, the sampling time is short, the manufactured glass fuse piece is uniform and perfect, and the specification of a mineral effect and a granularity effect can be eliminated completely. The glass fuse piece can be used for the X-ray fluorescence spectrum analysis, the obtained analytic result is accurate and reliable, and the requirements of modern enterprises on quick and accurate detection of analytic data are met. The method is safe, reliable, easy to operate and high in repeatability, and the application range of an X-ray fluorescence spectrum method is broadened.

Owner:HBIS COMPANY LIMITED HANDAN BRANCH COMPANY

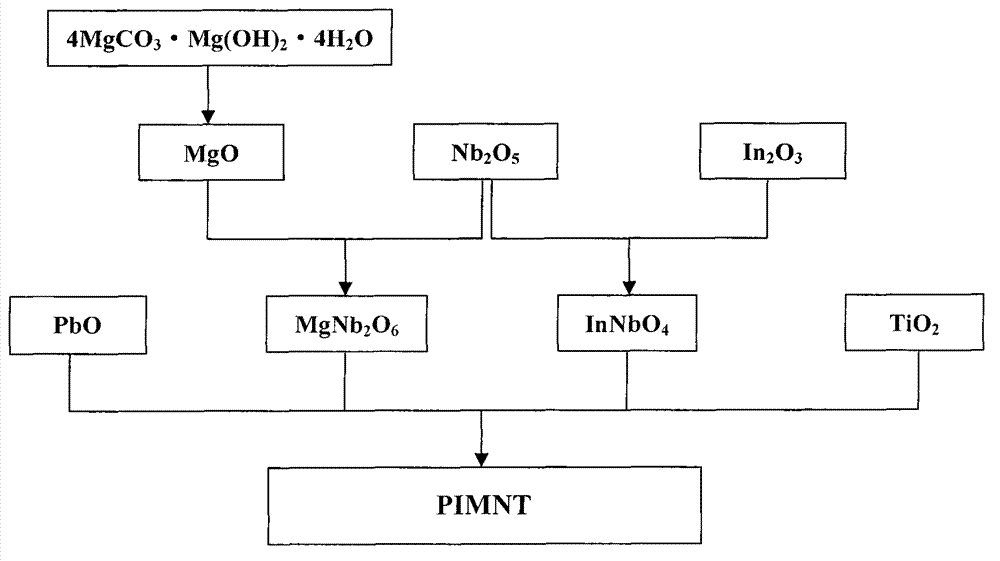

Novel growth technology of relaxation ferroelectric monocrystal PIMNT (Lead Magnesium/Indium Niobate-Lead Titanate)

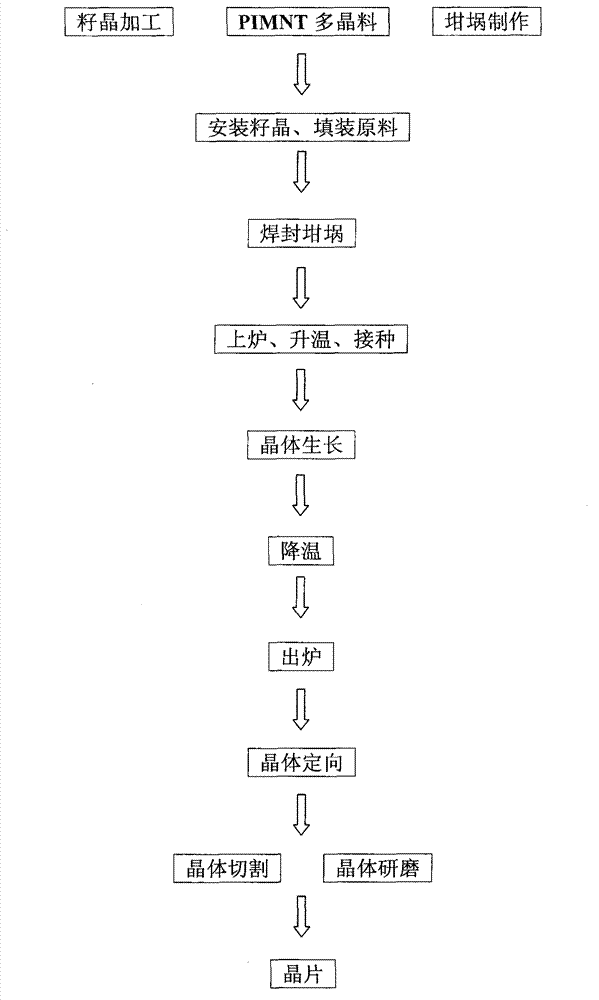

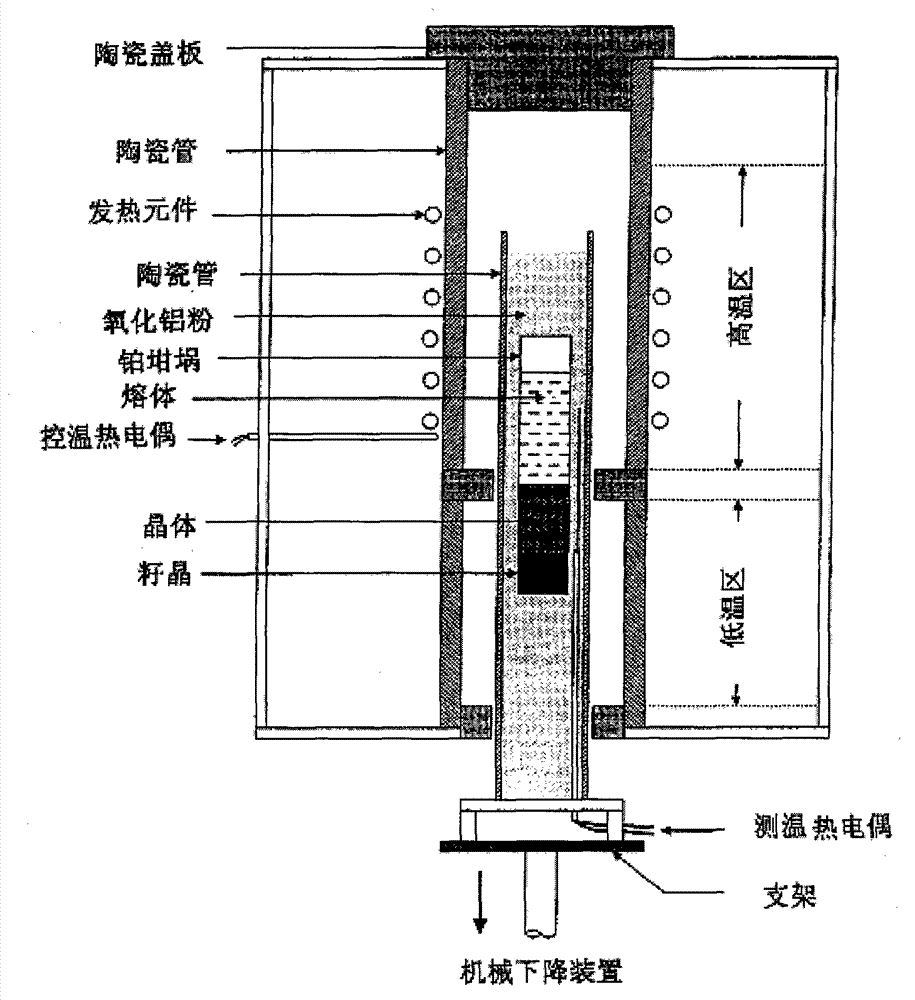

InactiveCN102925959APrevent melt leakageReduce thermal stressPolycrystalline material growthFrom frozen solutionsIndiumSynthesis methods

The invention discloses a novel growth technology of relaxation ferroelectric mono-crystal PIMNT by using a Bridgman-Stockbarger method, belonging to the technical field of mono-crystal growth. The novel growth technology of the relaxation ferroelectric mono-crystal PIMNT comprises the steps of: regarding high-purity PbO, Nb2O5, In2O3, TiO2 and 4MgCO3.Mg(OH)2.4H2O as initial raw materials to prepare a PIMNT polycrystal material through a precursor step-by-step synthesis method, wherein the chemical constitution is xPb(In1 / 2Nb1 / 2)O3-yPb(Mg1 / 2Nb2 / 3)O3-(1-x-y)PbTiO3, where x=0.24-0.26, and y=0.43-0.45; selecting high-quality seed crystal in a [110], [111] or [001] crystallographic direction; adopting a single-layer or double-layer seamless platinum crucible to contain the seed crystal and a material ingot; putting the crucible after being sealed in a mono-crystal growth furnace; controlling the temperature of the furnace at 1350-1400 DEG C; adjusting the position of the crucible to enable the material ingot to be welded with the top part of the seed crystal so as to form a steady solid-liquid interface with a temperature gradient of 20-50 DEG C; and growing the mono-crystal at a dropping speed of the crucible of less than 1 mm / h to obtain a high-quality and large-size PIMNT mono-crystal. The novel growth technology of the relaxation ferroelectric mono-crystal PIMNT, disclosed by the invention, has the advantages of overcoming a leakage phenomenon of a high-temperature lead-rich melt, avoiding volatilization of components of the melt, and particularly lead oxide steam, efficiently solving a poly-crystallized growth problem of a solid solution with composition complexity, and being suitable for growing high-quality and large-size PIMNT mono-crystals in batches.

Owner:NINGBO UNIV

Method for measuring phosphorous content by adopting bismuth phosphomolybdate blue-sulfuric acid photometry

InactiveCN101788494ASolve the problem of drift instabilityAbsorbance unchangedMaterial analysis by observing effect on chemical indicatorPreparing sample for investigationIronstoneAdditive ingredient

The invention relates to a measurement method of the phosphorous content in an iron ore, in particular to a method for measuring the phosphorous content by adopting a bismuth phosphomolybdate blue-sulfuric acid photometry. The method comprises the following steps of: weighing 0.25g of sample and putting into a platinum crucible containing about 2g of mixed fusing agent, putting in a muffle furnace with the temperature of 100 DEG C, fusing for 10min and taking out; cleaning the exterior of the platinum crucible, then putting the platinum crucible into a beaker containing about 80ml of hot water, adding 320ml of concentrated HNO on an electric furnace, heating at low temperature and dissolving, leaching the crucible out, taking the beaker out, cooling, then transferring into a 250ml volumetric flask, diluting to a scale and shaking up for later use; sucking 25ml of mother solution of a fusing sample in the platinum crucible, putting into a 50ml volumetric flask, adding 2.5ml of bismuth nitrate solution, 5ml of ammonium molybdate solution, 3ml of 8mol / L sulfuric acid solution and 5ml of ascorbic acid solution (prepared when needed), shaking up, carrying out color comparison at 750nm wavelength, measuring an absorbance value, and carrying out result conversion by using a guide sample with similar ingredients. The invention effectively solves the problem of instable absorbance value in a method for measuring the phosphorous content by adopting a traditional molybdenum blue spectrophotometry and ensures that the absorbance remains unchanged within two hours.

Owner:迁安市津唐球墨铸管有限公司

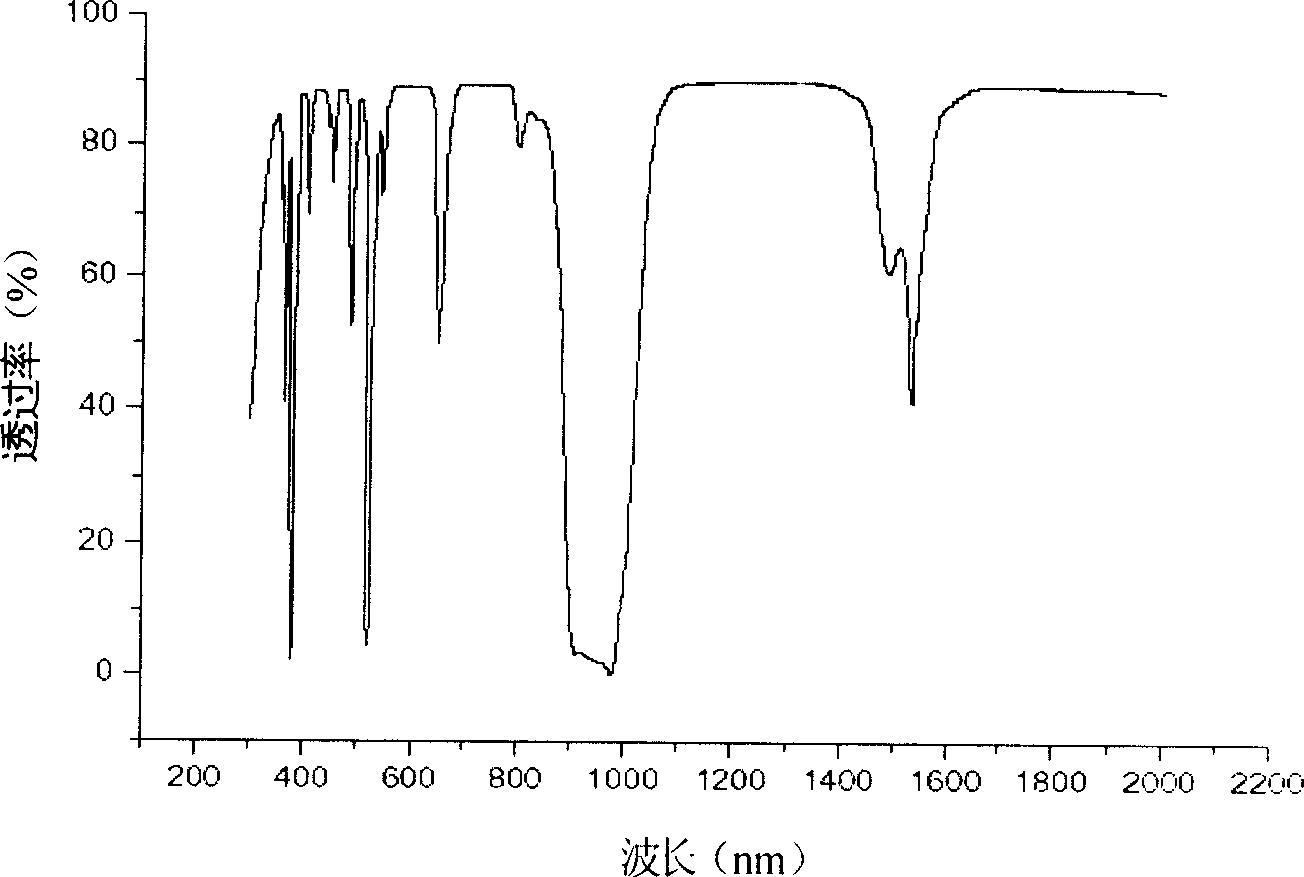

Light amplified erbium Ytterbium codoped multi-component oxide glass and method for manufacturing same

InactiveCN1634785AMeet the needs of rapid expansion of transmission capacityGood chemical stabilityOptical light guidesNon-linear opticsFiberOptoelectronics

Owner:XI'AN INST OF OPTICS & FINE MECHANICS - CHINESE ACAD OF SCI

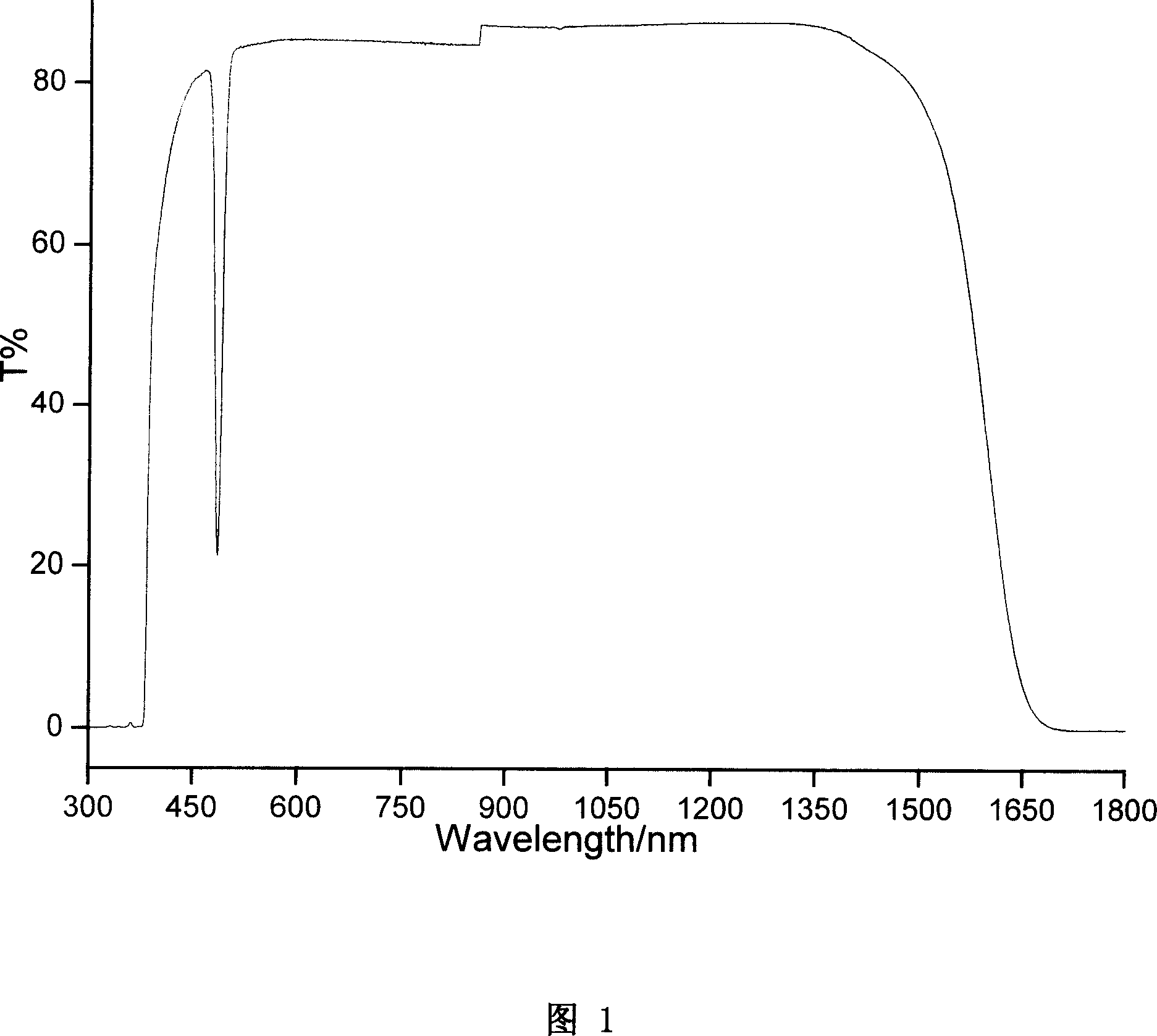

3 mu m luminous rare earth ion doped fluorophosphates laser glass and preparation method thereof

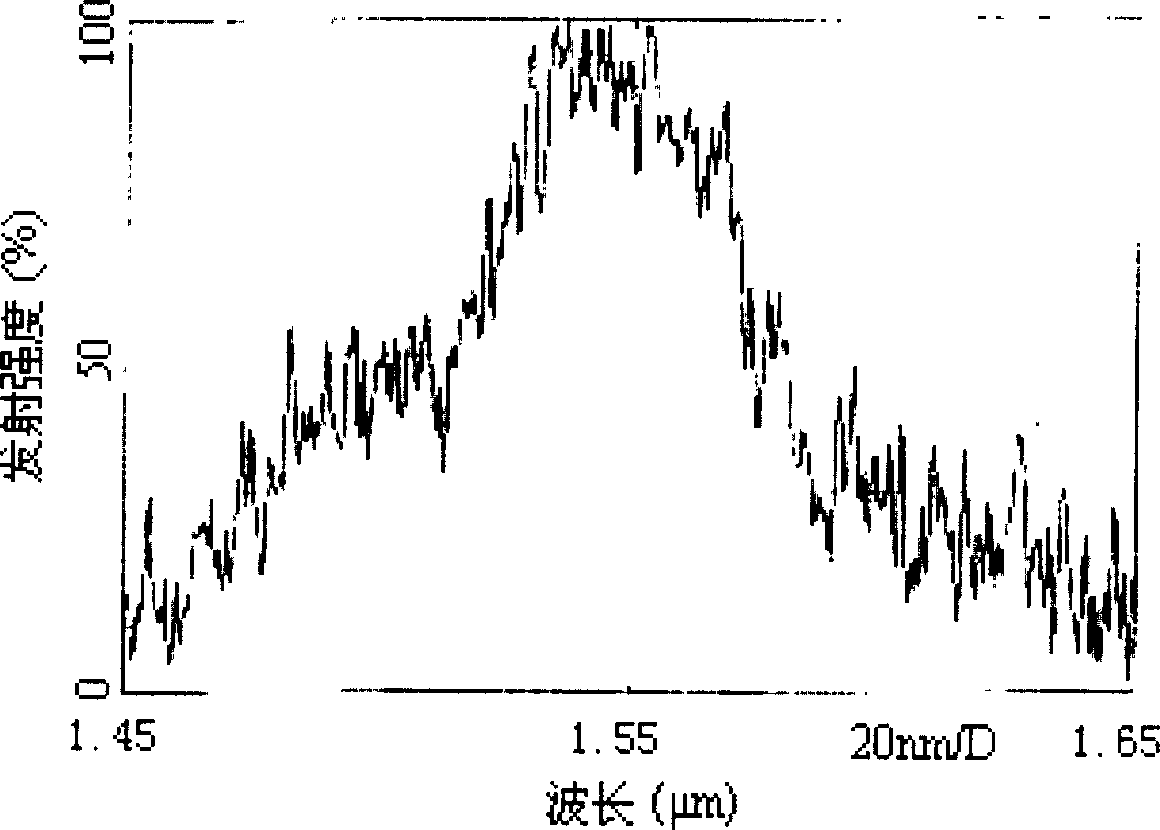

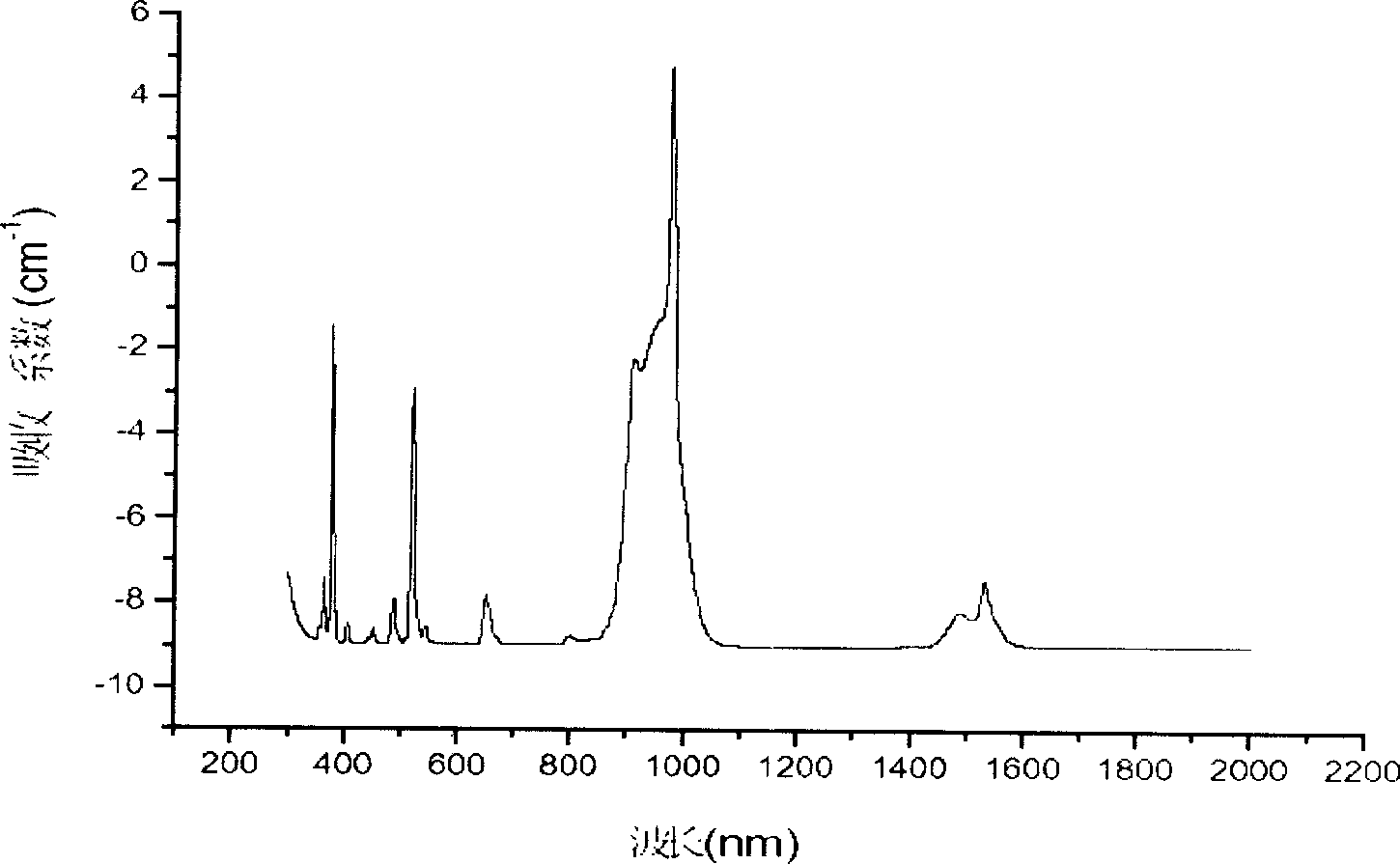

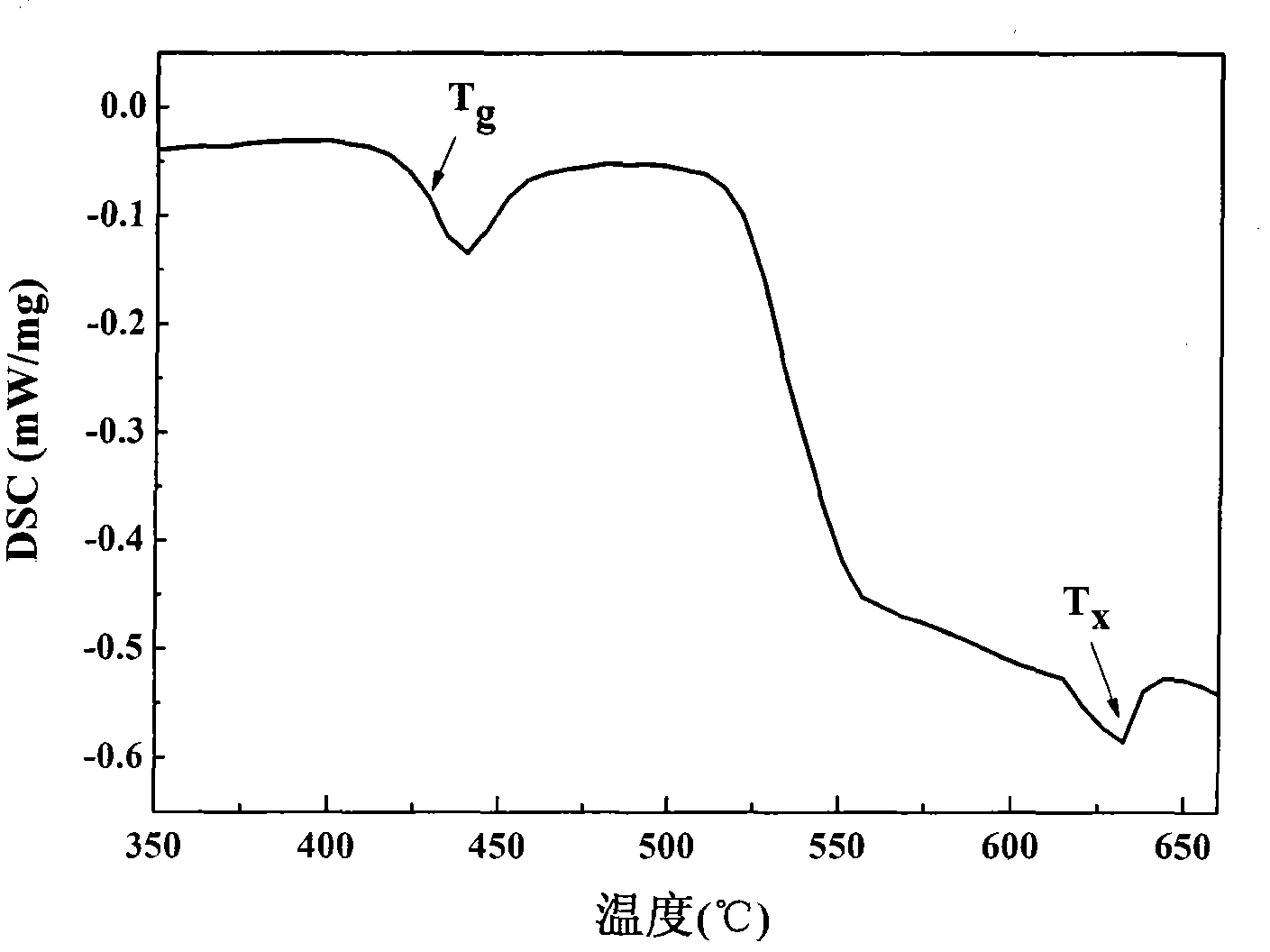

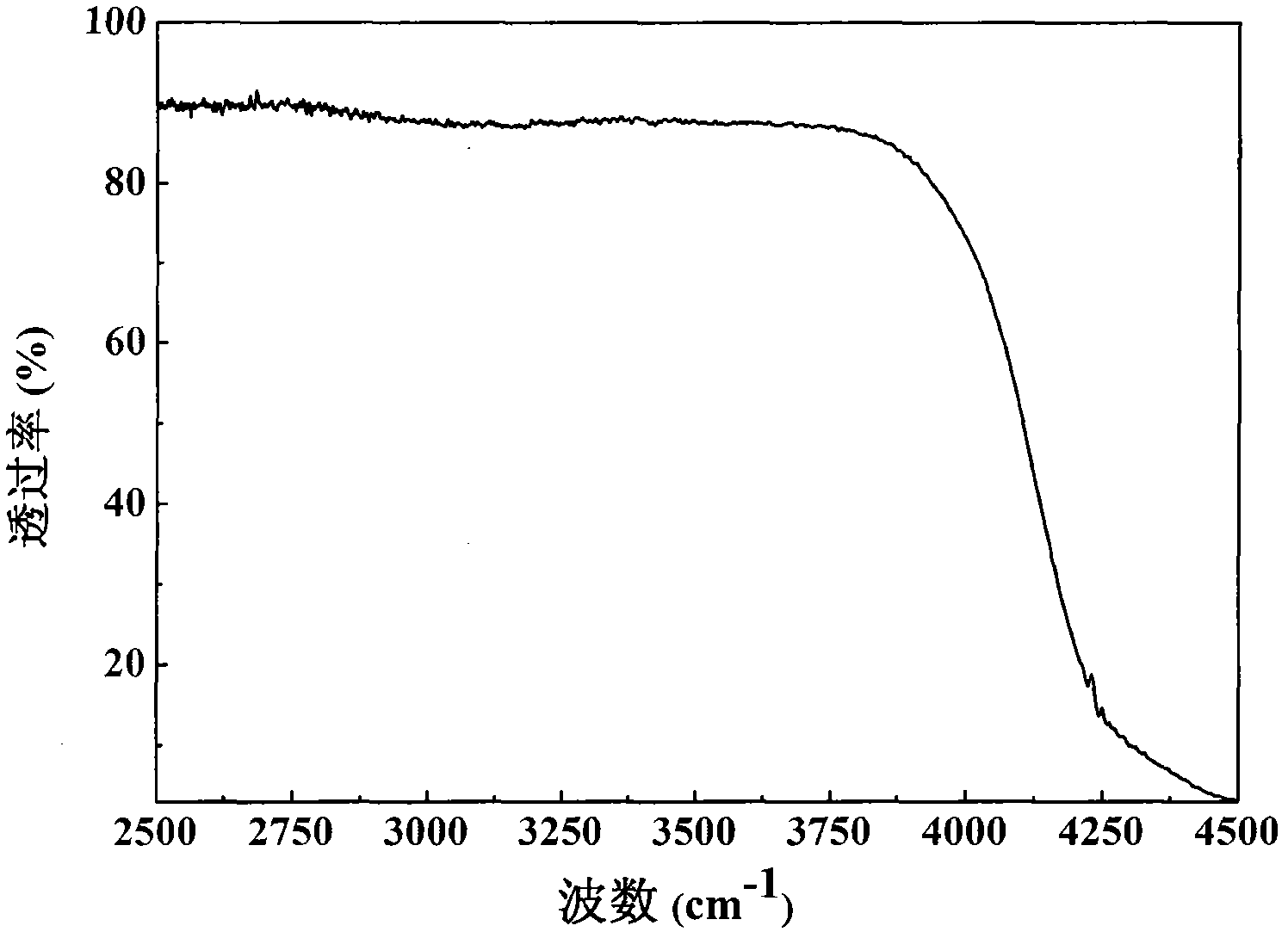

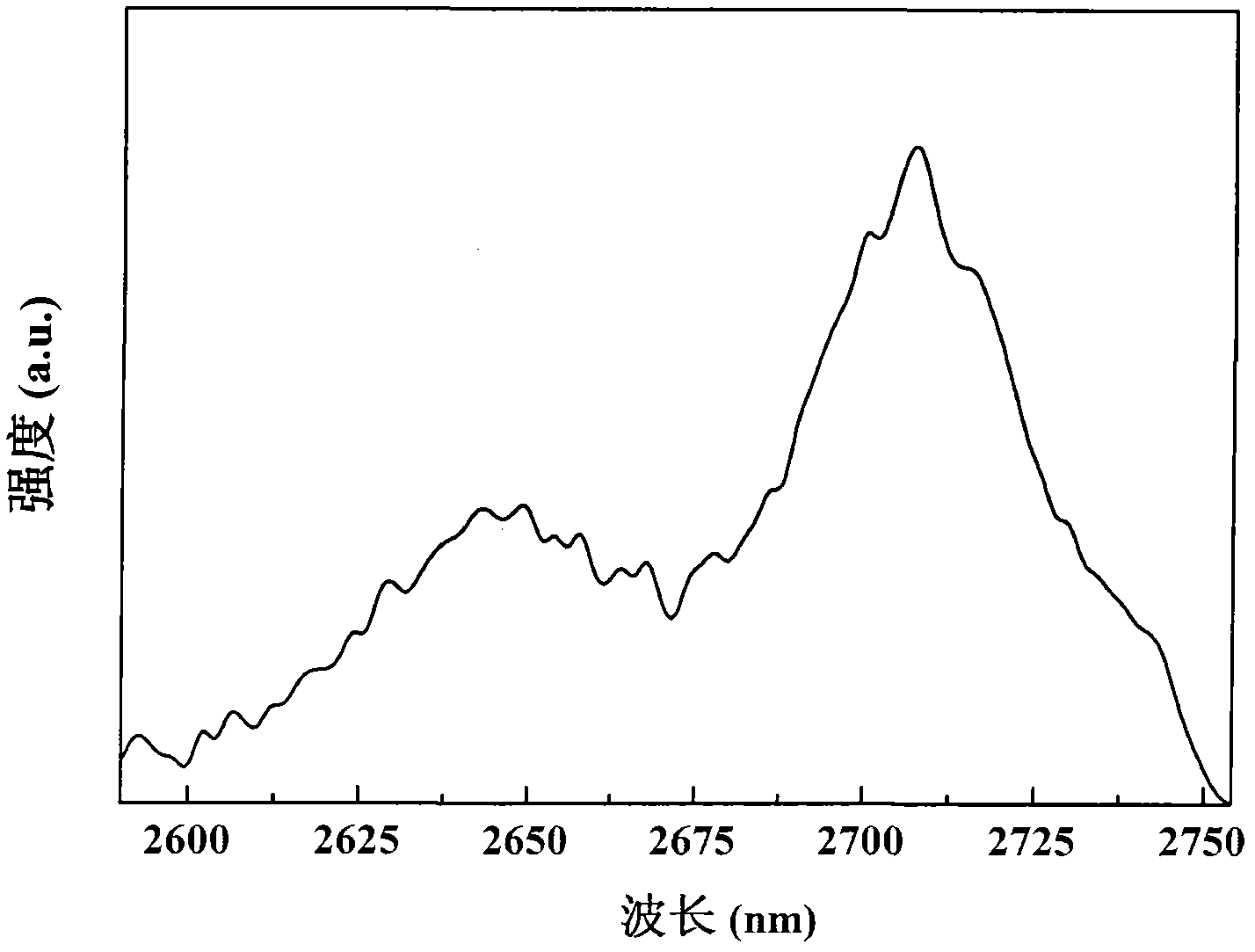

InactiveCN102211872ANo devitrificationHigh infrared transmittanceRare-earth elementStability parameter

The invention relates to 3 mu m luminous rare earth ion doped fluorophosphates laser glass and a preparation method thereof. The glass comprises the following components by molar percent: 15-20% of Al(PO3)3, 13-17% of MgF2, 5-25% of CaF2, 5-25% of SrF2, 17-22% of BaF2, 18-22% of NaF and 3-5% of RF3 (R can be rare-earth elements such as Er, Pr, Tm, Ho, or Nd). The glass is prepared by using a platinum crucible and a silicon carbide rod electric furnace fusion method. The glass in the invention is transparent, has no crystallization, has high infrared transmissivity at the vicinity of 3 mu m wave band, good physical and chemical properties and stability parameter delta T of more than or equal to 150 DEG C and can obtain strong 3 mu m fluorescence under the pumping of a laser diode with a wavelength of 980 nm, and the method is suitable for preparation and application of 3 mu m luminous rare earth ion doped special glass and optical fiber materials.

Owner:SHANGHAI INST OF OPTICS & FINE MECHANICS CHINESE ACAD OF SCI

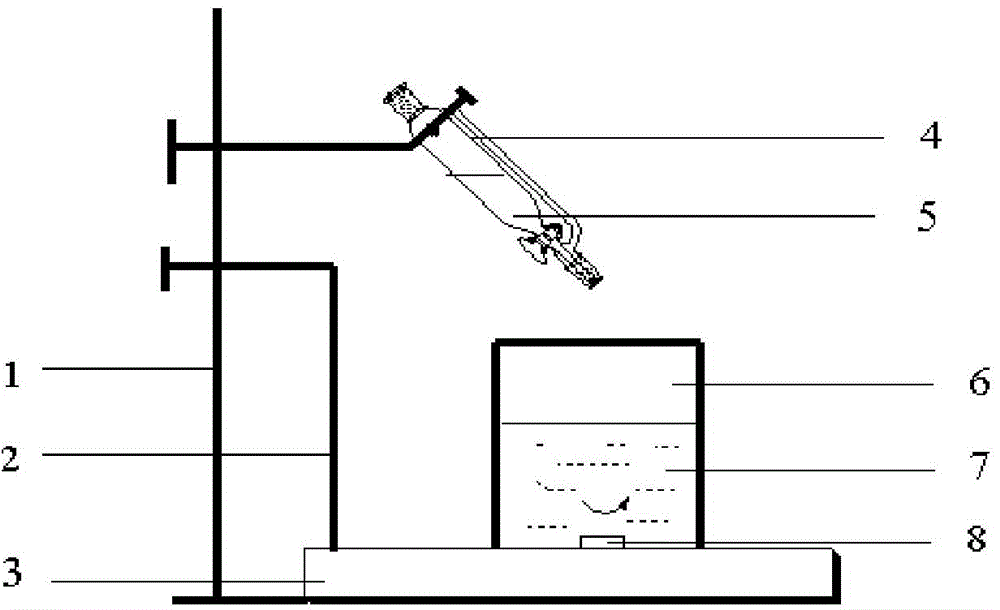

Growth method for fluxing medium of boron phosphate single crystal

InactiveCN101435109ALarge UV cut-off wavelengthShort UV cut-off wavelengthPolycrystalline material growthFrom melt solutionsRoom temperatureLength wave

The invention relates to a growth method of a fluxing agent of boron phosphate monocrystal, which comprises the steps of: 1) proportionally mixing a boron phosphate compound and the fluxing agent, putting the mixture into platinum crucible, and heating till completely fusing in a crystal growing furnace; and then cooling to the temperature being 2 to 15 DEG C above a saturation temperature, thus obtaining a high temperature melt containing boron phosphate and the fluxing agent; and 2) putting seed crystal loaded on a seed rod into the high temperature melt, keeping constant temperature for 10 to 180 minutes, reducing the temperature to saturation temperature, and rotating the seed rod at the speed of 10 to 50 revolution / minute; and reducing the temperature at the speed of 0.1 to 2 DEG C / day, lifting the crystal from the liquid surface after the crystal grows up, and cooling to room temperature at the speed of 20 to 50 DEG C / hour to obtain the boron phosphate monocrystal. The fluxing agent used by the method can reduce the viscosity of the high temperature melt, is beneficial to melt mass transportation in the process of crystal growth, avoids the formation of inclusions in the crystal, and can stably grow the transparent boron phosphate monocrystal which has cm-level size, short ultraviolet cutoff wavelength and good mechanical processing performance, is not easy to crack, does not absorb moisture, and is easy to be stored.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

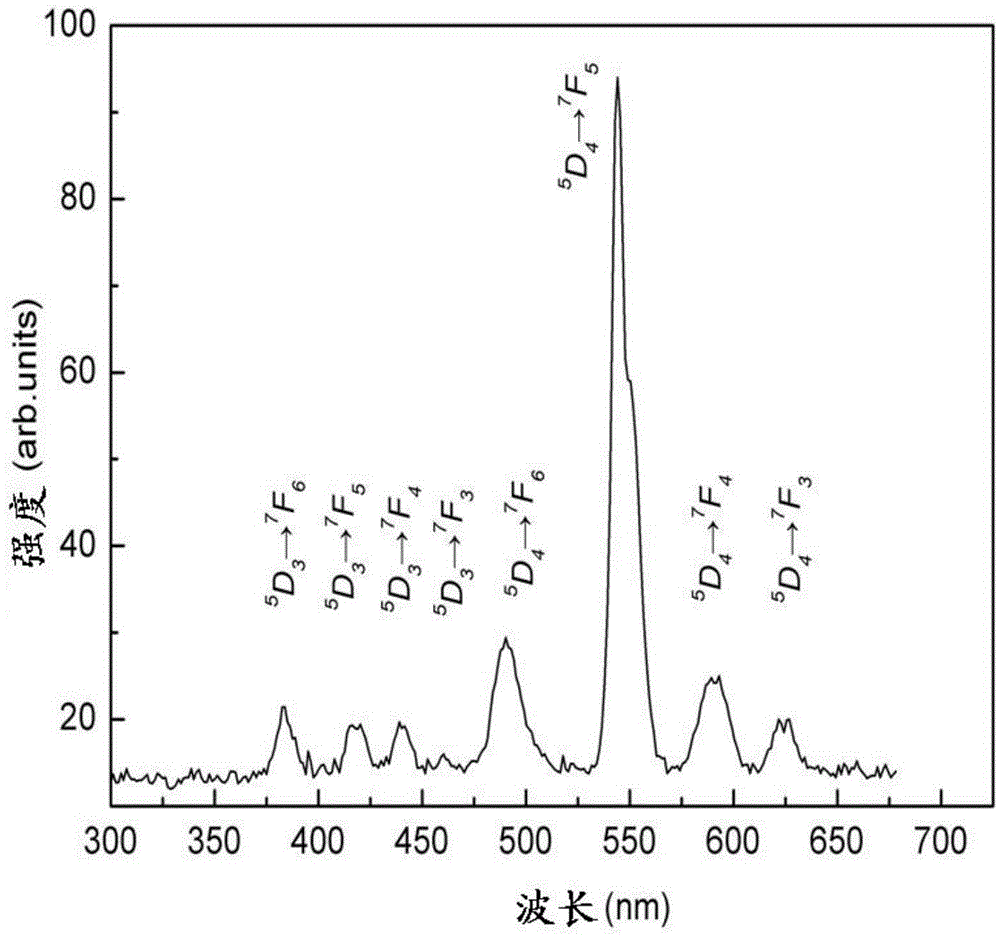

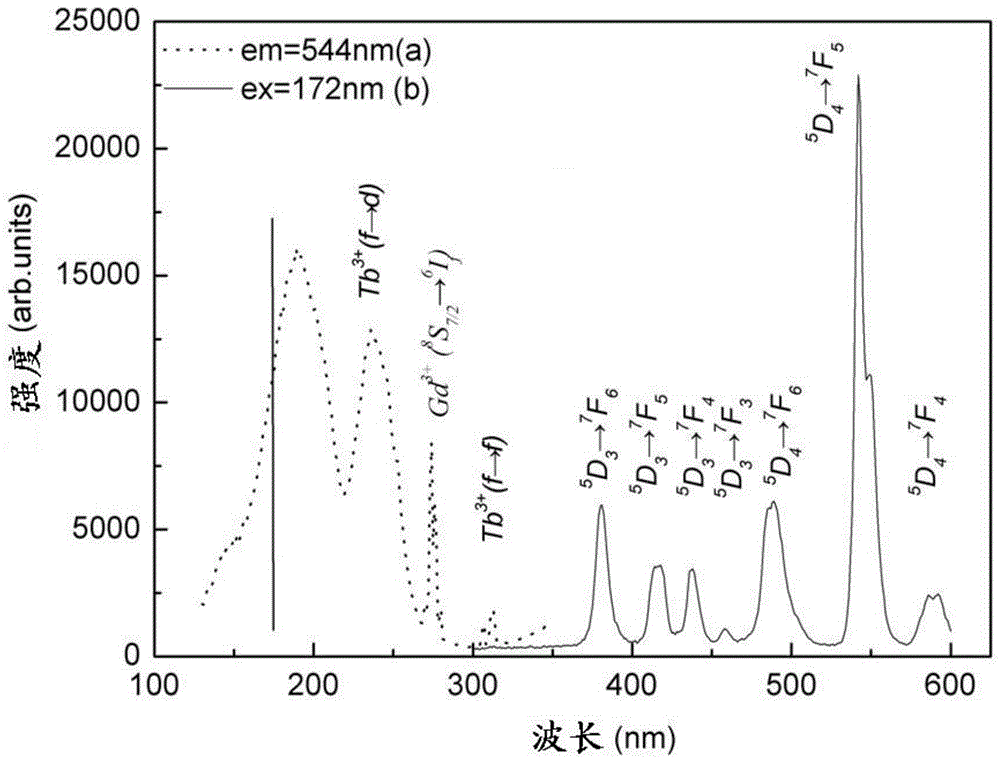

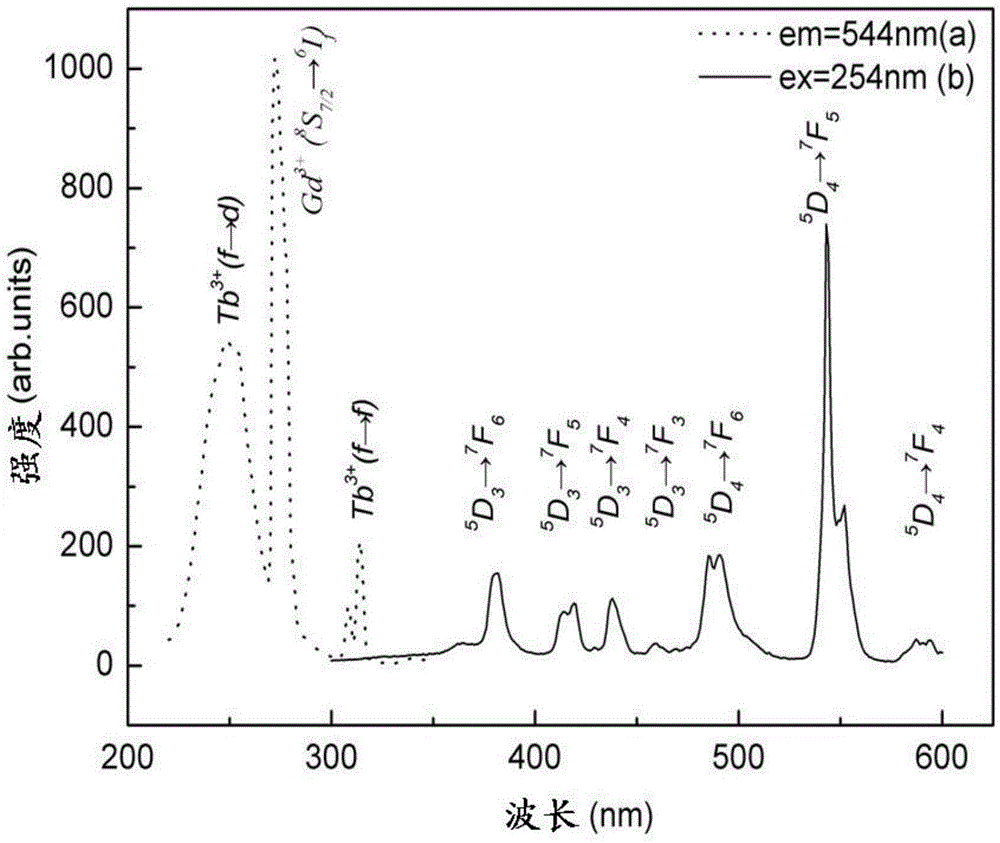

Borophosphate fluorescent powder capable of emitting green fluorescence as well as preparation method and application of borophosphate fluorescent powder

ActiveCN104449723AEasy to dopeLuminous GuaranteeLuminescent compositionsRare-earth elementFluorescence

The invention relates to borophosphate fluorescent powder capable of emitting green fluorescence as well as a preparation method and application of the borophosphate fluorescent powder. The chemical constitution general formula of the borophosphate fluorescent powder is (Ln1-xTbx)7O6(BO3)(PO4)2, wherein Ln represents rare earth elements, and x is more than or equal to 0.01 and less than or equal to 0.1. The preparation method of the borophosphate fluorescent powder capable of emitting green fluorescence comprises the following steps: (a) adding ground NH4H2PO4, H3BO3, Ln2O3 and Tb4O7 into a covered alumina crucible, and heating to react at 300-500 DEG C for 6-12 hours, so as to obtain a head product; (b) pressing the ground head product into a wafer with the diameter of 1cm-5cm, and adding the wafer into a covered platinum crucible; and (c) putting the platinum crucible in a heating furnace containing carbon powder, calcining at 1000-1500 DEG C for 12-30 hours, and naturally cooling to obtain the borophosphate fluorescent powder. By virtue of magnetic dipole transition of electrons on a terbium ion outer layer from <5>D4 to <7>F5, the borophosphate fluorescent powder is capable of emitting green fluorescence. The preparation method of the borophosphate fluorescent powder capable of emitting green fluorescence has the beneficial effects that utilized equipment is simple and safe to operate, conditions are easy to control, and the quality of a prepared product is reliable.

Owner:英特美光电(苏州)有限公司

Flux method for growth of gallium phosphate crystal

InactiveCN1763264AImprove piezoelectric performanceElimination contentPolycrystalline material growthFrom melt solutionsLithium carbonateSeed crystal

The present invention is fluxing agent growth process of gallium phosphate crystal. Through using lithium carbonate and molybdenum oxide as flux, gallium oxide and ammonium dihydrogen phosphate as main material, mixing ammonium dihydrogen phosphate, gallium oxide, lithium carbonate and molybdenum oxide in the weight ratio of 1 to 1.23 to 1.12 to 6.57, setting the mixture in platinum crucible, heating to melt inside growth furnace and cooling to the temperature of 10-20 deg.c over the solution saturation point to obtain the mixed melt of gallium phosphate and the flux, introducing seed crystal into the growth furnace, lowering the temperature to 1-2 deg.c over the solution saturation point when the seed crystal begins to melt and rotating the seed crystal in 30 rpm for 24 hr, gallium phosphate crystal is grown. After lowering the temperature, the crystal is taken out of the solution. The process can eliminate water from the crystal and raise the piezoelectric performance of the crystal.

Owner:SHANDONG UNIV

Method for measuring content of alloy elements in ferrosilicon and silicon-aluminum-barium-calcium by X-ray fluorescent spectrometry

InactiveCN104569018AImprove thermal conductivityImprove accuracyMaterial analysis using wave/particle radiationFerrosiliconSodium carbonate anhydrous

The invention discloses a method for measuring the content of alloy elements in ferrosilicon and silicon-aluminum-barium-calcium by X-ray fluorescent spectrometry, belongs to the technical field of physicochemical detection, and aims to solve the technical problem of corrosion of a platinum crucible during a sample melting manufacturing process. According to the technical scheme, the method comprises four steps: (1) oxidizing and melting a sample; (2) melting and manufacturing a sample piece; (3) drawing a working curve; (4) measuring the content of the alloy elements in the sample, wherein a sample oxidizing and melting container is a ceramic crucible which is filled with graphite carbon powder being higher than or equal to 99.85 percent in purity; a mixed flux is formed by mixing potassium nitrate, boracic acid and anhydrous sodium carbonate in the weight ratio of 1:2:3. According to the method, the possibility of the corrosion of the platinum crucible during the sample melting process is eliminated thoroughly by selecting the oxidizing container and the mixed flux; the problem about accurately analyzing and measuring the content of the alloy elements in the ferrosilicon and the silicon-aluminum-barium-calcium by the X-ray fluorescent spectrometry is solved by controlling an oxidizing agent, the melting temperature and the time and optimizing the weight the weighed sample and various reagents; therefore, the method has a good popularization prospect.

Owner:HBIS COMPANY LIMITED HANDAN BRANCH COMPANY

Bridgman-stockbarge process for growing scintillation crystal LaCl3:Ce3+

InactiveCN1932087ASolve deliquescencePolycrystalline material growthFrom frozen solutionsScintillation crystalsChloride

The present invention is Bridgman-Stockbarge process of growing scintillation crystal LaCl3:Ce3+, and belongs to the field of monocrystal growing technology. The initial material LaCl3 .7H2O and CeCl3 .7H2O are first prepared into anhydrous chlorides LaCl3 and CeCl3 through chlorination, roasting and dewatering; and compounded material LaCl3:Ce3+ with proper CeCl3 doping concentration and small amount of active carbon powder blended as deoxidizer is then prepared. After filling the seed crystal and material are set inside platinum crucible and the crucible is sealed up, the crucible is set in crystal growing furnace at 920-980 deg.c for soldering the material to the seed crystal and forming solid-liquid interface of temperature gradient of 20-50 deg.c / cm, and the crucible is then fallen at the speed of 0.3-3 mm / hr to grow excellent LaCl3:Ce3+ monocrystal. The process is suitable for mass production of LaCl3:Ce3+ monocrystal.

Owner:NINGBO UNIV +1

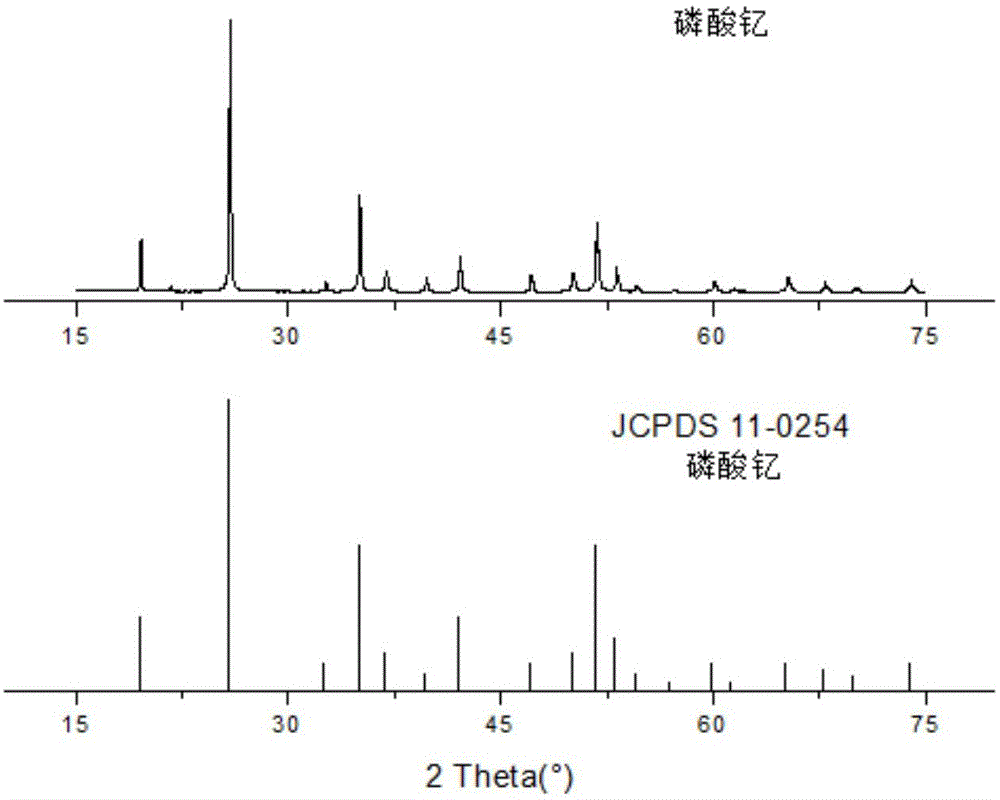

Preparation method of yttrium phosphate nano material

InactiveCN103553014AChemically stableHigh purityMaterial nanotechnologyPhosphorus compoundsHydrogen phosphatePhosphate

The invention belongs to the technical field of synthesis of functional materials and relates to a preparation method of an yttrium phosphate nano material. The method comprises the following steps: firstly, dissolving yttrium oxide in nitric acid and reacting to generate yttrium nitrate liquor; then, dissolving diammonium hydrogen phosphate particles in secondary distilled water to obtain diammonium hydrogen phosphate liquor; then, diluting the yttrium nitrate liquor and heating to almost boiling, and slowly dropwise adding the diammonium hydrogen phosphate liquor and continuously stirring to obtain a white turbid liquid; centrifuging the obtained white turbid liquid, pouring a supernatant liquid out, and washing the centrifuged precipitate with water and then centrifuging again; repeating the above processes till the pH of the centrifuged supernatant liquid is equal to 7, and washing to obtain purified precipitate; and then, drying the purified precipitate in a vacuum drying box, placing in a platinum crucible, and roasting in a chamber electric furnace to obtain the yttrium phosphate nano material. The preparation of the yttrium phosphate nano material is simple in preparation process, mild in reaction condition, low in energy consumption, low in cost, easy to operate and environment-friendly, and the prepared yttrium phosphate nano material is high in purity.

Owner:QINGDAO UNIV

Formula of a glass ceramic material and preparation method

The formulation and methods of glass-ceramic Substrate materials, which consisted essentially of the micro-powder SiO2 and the BSG materials containing four kinds of oxides:60-85wt úÑ SiO 2 ,15-35wt úÑ B 2 O 3 , 0.1-2.5wt úÑ K 2 O ú¼ 0.1-2.5wt%Na 2 O ,where the BSG materials occupied 55-90 wt% and SiO 2 occupied 10-45wt%.According to formulation, after the chemically pure SiO 2 , B 2 O 3 , K 2 O, Na 2 O were ball-milled, desiccated and mixed in the platinum crucible, the mixture was heat-preserved and stirred at a temperature between about 1300 and 1550 deg.C , which made its crystallochemical reaction sufficiently. After pouring the melt-out glass in crucible into the water to quench, offspring of transparent broken glass which had been hydroball-milled is gained as the glass dust to synthesize the BSG materials. In terms of formulation the BSG material and the chemically pure SiO 2 were ball-milled, blended and shaped granule finally. When reaction was carried out in a constant-temperature at 850-900 deg.C, the glass-ceramic Substrate materials were prepared as the above-indicated aspect of the invention. The capability index of the glass-ceramic substrate materials was: the dielectric constant ªŠ < 4(1 MHz), the dielectric losses tan ª€íœ 0.001 (1MHz), the insulation resistivity ªÐ í¦ 10 13 ª© cm, holdoff voltage Intensity E í¦ 5í‡10 7 V / m, the bending resistance intensity í¦ 200 Mpa, the thermal expansion coefficient alphaíÍ 3.6 í‡ s 10 -6 / deg.C, the thermal conductivity k íÍ 1 W / m*K. The prepared glass-ceramic Substrate materials can meet the request of the medium / low temperature co-fired industrialization with many layers wirings and the microelectronics assembling techniques of modern integrated circuit techniques.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

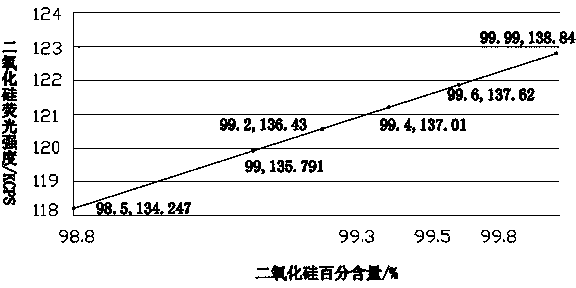

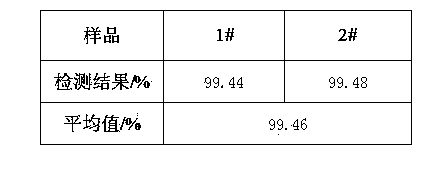

Method for efficiently and accurately detecting content of silicon dioxide in quartz sand

InactiveCN104280367AImprove detection efficiencyIncrease credibilityPreparing sample for investigationFluorescence/phosphorescenceLithiumPhysical chemistry

The invention discloses a method for efficiently and accurately detecting the content of silicon dioxide in quartz sand. The method comprises the following steps: melting with analytically pure lithium tetraborate serving as a solvent at a high temperature in a platinum crucible to manufacture a sample wafer, namely a to-be-detected sample, required by a luminoscope, with analytically pure lithium tetraborate as a solvent before detection, adding 4N-level quartz sand to melt series standard samples, establishing a standard working curve, and finally, detecting and analyzing the to-be-detected sample according to the working curve to obtain the content of silicon dioxide. The standard samples and the to-be-detected sample are manufactured by melting through analytically pure lithium tetraborate, detection is performed by the luminoscope with the characteristics such as stable and rapid detection, and the weighed sample is large in amount and can generally reach 0.6-1.0g, which is 3-5 times the weight (0.2g) of a sample in a traditional alkali fusion detection method, so that the relative deviation during detection is much small. Moreover, analytically pure lithium tetraborate serves as the solvent, so that the melted sample is uniform and stable, and the detection result is real and reliable; and elements of analytically pure lithium tetraborate are light elements, matrix interference is almost avoided, and the reliability of the detection result obtained by the method provided by the invention is higher than that of the detection result obtained by the traditional method.

Owner:TUNGHSU GRP

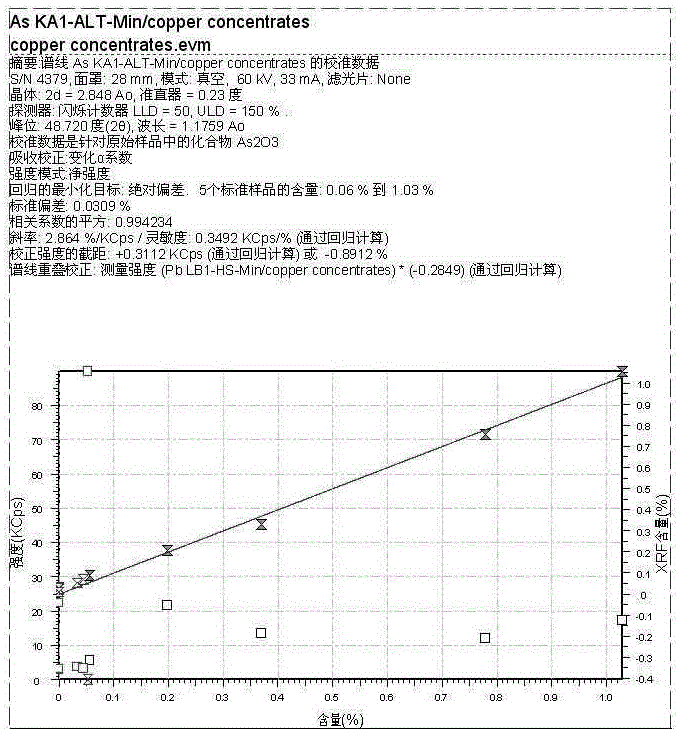

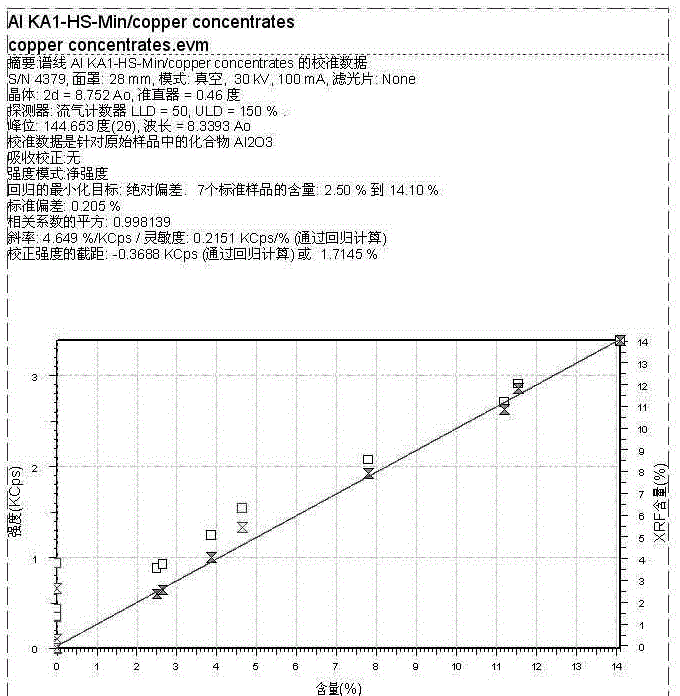

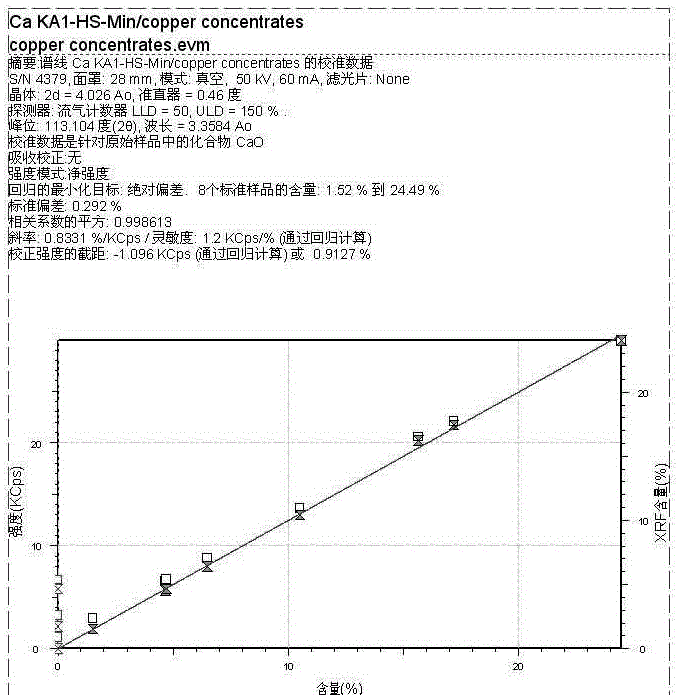

Melting flaking method of copper concentrate for X-ray fluorescent spectrometry

InactiveCN105806865ARetention stabilityWon't be lostMaterial analysis using wave/particle radiationPreparing sample for investigationLithium metaborateFluorescence

The invention discloses a melting flaking method of copper concentrate for X-ray fluorescent spectrometry. A lithium tetraborate and lithium metaborate mixed solvent serves as a base in a platinum crucible, sodium carbonate, silica, lithium nitrate and a copper concentrate sample are weighed, put into the platinum crucible in sequence and stirred evenly, the mixture is covered with a lithium tetraborate and lithium metaborate mixed solvent, put into a 600 DEG C muffle furnace, taken out after 15 min and then melted with a sample smelting furnace at 800 DEG C, a releasing agent is added and fully shaken evenly, the mixture is poured into a mould, cooled and then taken out, and sample flakes are obtained. By means of the method, it is guaranteed that sulfur in copper concentrate can remain in the sample flakes stably rather than be lost due to high temperature in the preparation process. The method is suitable for determination of the content of copper, sulfur, lead, zinc, manganese, arsenic, iron, silicon, aluminum, magnesium, calcium and other elements in copper concentrate.

Owner:NANTONG ENTRY EXIT INSPECTION & QUARANTINE BUREAU OF THE PEOPLES REPUBLIC OF CHINA

Method for simultaneously determining content of phosphorus, magnesium, iron, aluminum, silicon, calcium, titanium, manganese and strontium in phosphorite by adopting ICP-AES

InactiveCN106290318ANo distractionNo apparent interferencePreparing sample for investigationAnalysis by thermal excitationLithium metaborateLithium bromide

The invention relates to the technical field of analysis test, and in particular relates to a method for simultaneously determining content of phosphorus, magnesium, iron, aluminum, silicon, calcium, titanium, manganese and strontium in phosphorite by adopting inductively coupled plasma atomic emission spectrometry (ICP-AES). Specifically, lithium metaborate is a non-oxidant solvent with a high melt point, has high decomposition capacity for a majority of test samples, and can effectively decompose rocks and minerals difficult to dissolve. The method comprises the following steps: placing a phosphorite test sample into a platinum crucible, adding the lithium metaborate solvent and a lithium bromide releasing agent, melting and decomposing the phosphorite sample by using a high-frequency sample melting machine, pouring in a polytetrafluoroethylene beaker with 10 percent nitric acid at a high temperature by virtue of a magnetic stirrer, after the primary sample melting acidification sizing, performing matrix matching by adopting a national grade-I phosphorite, establishing a standard curve by adopting a Yttrium internal standard method, and determining the content of phosphorus pentoxide, magnesium oxide, iron oxide, aluminum oxide, silicon dioxide, calcium oxide, titanium oxide, manganese oxide and strontium oxide in the phosphorite by adopting the ICP-AES. The method has the advantages of rapidness, convenience and accuracy, and is particularly suitable for batch determining the phosphorite samples.

Owner:YUNNAN PHOSPHATE CHEM GROUP CORP

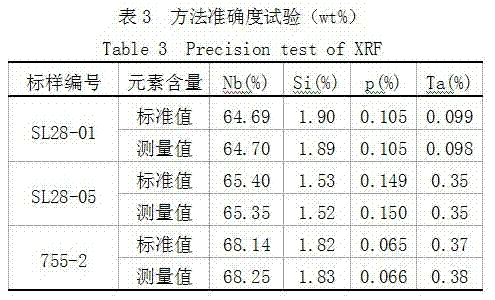

Method for measuring element content in ferrocolumbium alloy by X-fluorescence

InactiveCN102359973AImprove oxidation effectFast analysisMaterial analysis using wave/particle radiationAlloyBarium peroxide

The invention discloses a method for measuring an element content in a ferrocolumbium alloy by X-fluorescence. The method comprises the following steps of: (1) hanging on a wall; (2) oxidizing; (3) smelting; (4) measuring fluorescence intensity and drawing a calibration curve; and (5) preparing a glass sample sheet to be sampled, measuring the spectral line intensity of columbium, thallium, silicon and phosphorus in the glass sample sheet to be sampled, and determining the percentage content of the columbium, thallium, silicon and phosphorus in a ferroniobium sample to be tested according to the calibration curve of the step (4). The ferroniobium glass sheet is successfully prepared by hanging lithium tetraborate on the wall and selecting barium peroxide as an oxidant for high-temperature fusion under the condition of no corrosion damage to a platinum crucible and provides a proper sample for measuring by using an X-fluorescence method. After an oxidization process of raising temperature gradually is adopted in particular, a very good oxidization effect can be achieved. The method can effectively improve the analysis speed of the element content in ferroniobium and the accuracy of analysis data and has the characteristics of simple operation and practicability.

Owner:HBIS COMPANY LIMITED HANDAN BRANCH COMPANY

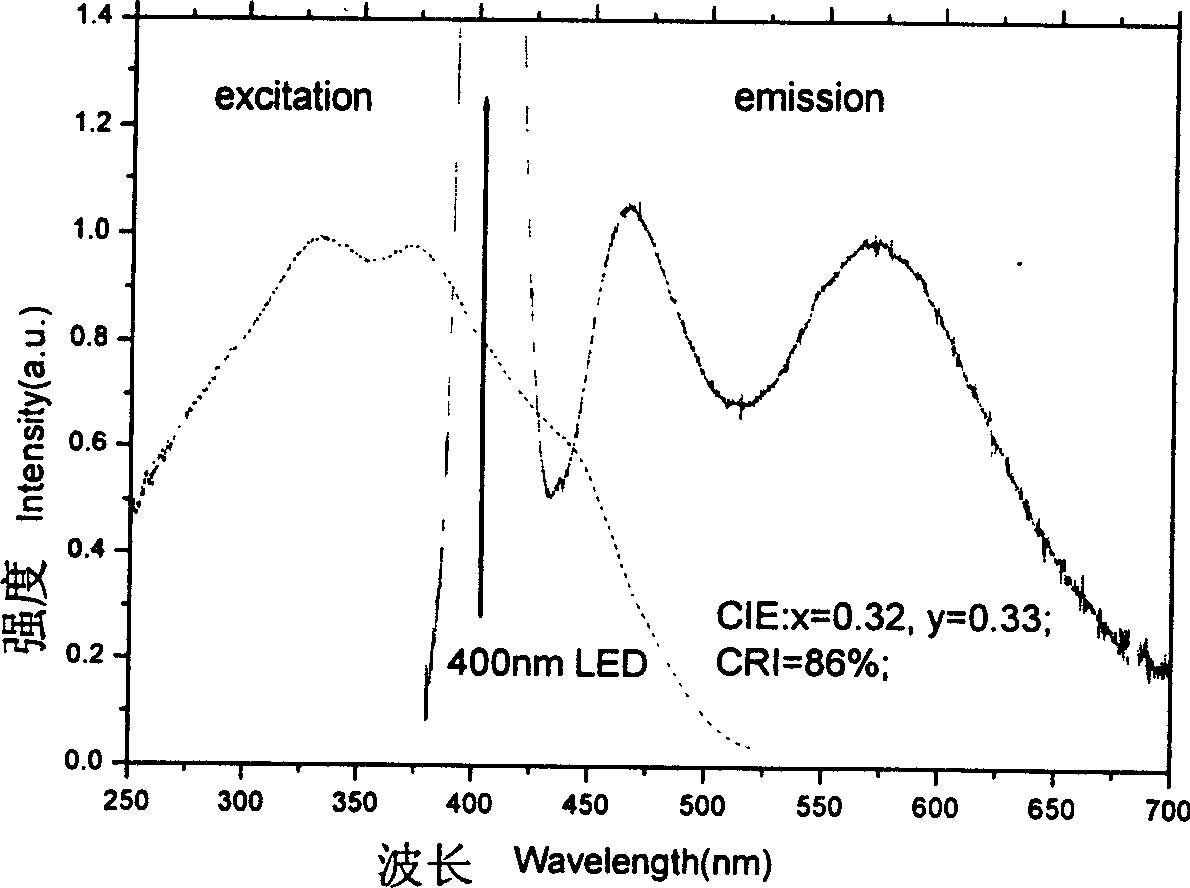

Single-phase whitelight fluorescent powder for ultraviolet light excitation

InactiveCN1850940AEnergy efficient lightingLuminescent compositionsUltraviolet lightsLight-emitting diode

The invention relates to a singleness phase white light fluorescent dye suitable for ultraviolet light and the manufacture method. It includes the following steps: grinding the raw material, putting into high purity corundum crucible or platinum crucible, putting into high-temperature furnace; under the condition of 1100-1400 degree centigrade and carbon or hydrogen deoxidization, heating 3-5 hours to gain the whit light fluorescent dye. The invention could be used in the new generation white light LED and the current fluorescent lamp.

Owner:CHANGCHUN INST OF OPTICS FINE MECHANICS & PHYSICS CHINESE ACAD OF SCI

Magnetic rotation glass and its preparation technology

InactiveCN100999384ALower melting temperatureVerdet constant is highGlass furnace apparatusMagnetic rotationCerium

This invention relates to a magnetic optical rotation glass, its components to molar percentage are: Tb2O3: 15 ~35 shares; B2O3 + SiO2: 40 ~ 80; Al2O3: 0 ~ 15; ZnO:0 ~ 30; ZrO2:0 ~ 6; AlF3 + MgF2+CaF2: 0 ~12; TiO2:0 ~ 10; InF3:0.5 ~ 7. First mix the raw materials according to composition; Preheat electric furnace to 1200 to 1300 deg C, add the mixed materials in the platinum crucible, when to 1350 to 1410 deg mix glass liquid for 3~ 5h; Reduce temperature to 1250 to 1350 deg C, pour glass liquid into the mold, precisely annealing in the annealing furnace. This invention use one time melting way, solve the problem of high temperature of glass clarification and leveling in the background technology, Rumsfeld constant is higher than the international common terbium magneto-optical glass, much higher than the magneto-optical glass containing cerium.

Owner:XI'AN INST OF OPTICS & FINE MECHANICS - CHINESE ACAD OF SCI

Method for growing rare-earth ferrite magneto-optical crystal

InactiveCN101545133ALow growth temperatureEffective control of volatilizationPolycrystalline material growthFrom frozen solutionsRare-earth elementSingle crystal

The invention relates to a method for growing a rare-earth ferrite magneto-optical material RFeO3 crystal (R is Y, Gd, Tm, Nd, Sm, Eu, Ho, Yb and other rare-earth elements), which belongs to the field of monocrystalline growth. The method comprises the following steps: evenly mixing an initial firing material formed by R2O3 and Fe2O3 with a composite fluxing agent of PbO, PbF2 and B2O3; placing the mixture in a platinum crucible to be sealed by air; placing the crucible in a reducing furnace to heat and melt the raw materials; and realizing growth of the rare-earth magneto-optical crystal of different chemical compositions by controlling the temperature of the furnace, regulating air flow amount or water flow amount of the bottom of the crucible, and optimizing the gradient of solid-liquid interface temperature, the growth speed and other parameters. The method reduces the growth temperature of the crystal trough the fluxing agent, and causes local supercooling and quick nucleating by introducing air or water to the bottom of the crucible, thereby growing the RFeO3 monocrystal with large dimension. Meanwhile, the method has simple equipment, one furnace more products and low cost, and is favorable for realizing batch production of the crystal and the like.

Owner:SHANGHAI INST OF TECH

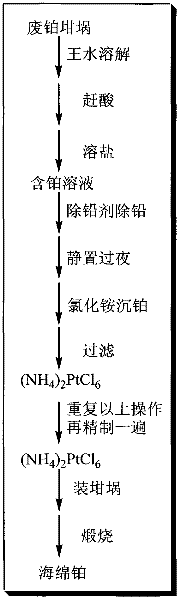

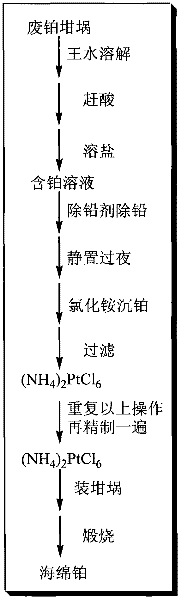

Method for recycling platinum from waste platinum crucibles

The invention relates to a method for recycling platinum from waste platinum crucibles. The method comprises 5 steps that: waste platinum crucibles are dissolved by using aqua regia; lead is removed by using a lead removing agent; platinum is precipitated by using ammonium chloride; platinum is refined; and platinum is calcined. According to the invention, waste platinum crucibles containing impurities such as lead, niobium, silicon and sodium are recycled as a platinum raw material; the raw material is dissolved by using aqua regia; concentrated sulfuric acid or water-soluble sulfate is added to the material, such that lead is pre-removed, and the frequency of repeated platinum precipitation by using ammonium chloride is reduced. Therefore, a platinum refining period is shortened, an agent dosage is reduced, a purification cost is reduced, and the purity of platinum sponge can be improved.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com