Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

274 results about "Magnesium calcium" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Magnesium is needed to metabolize calcium, so it must be present in your body in adequate amounts. Given this mutually dependent relationship, it is key to have an appropriate ratio of both minerals for them to be effective. If your calcium intake is high, your magnesium intake needs to be adjusted proportionately.

Stable sodium-free or low-sodium aqueous solution of agreeable saltiness taste

A stable sodium-free aqueous seasoning solution of agreeable salty taste, adapted as a substitute for common salt in cooked and uncooked foodstuffs, containing purified water, an organic acid, a potassium salt, a calcium salt, and a magnesium salt. The mineral solution provides a dietary supplementation of magnesium, calcium, and potassium—indispensable minerals of a diet—to which colorants, natural essences and artificial essences (singly or in combination), and low concentrations of sodium chloride may be added.

Owner:REV

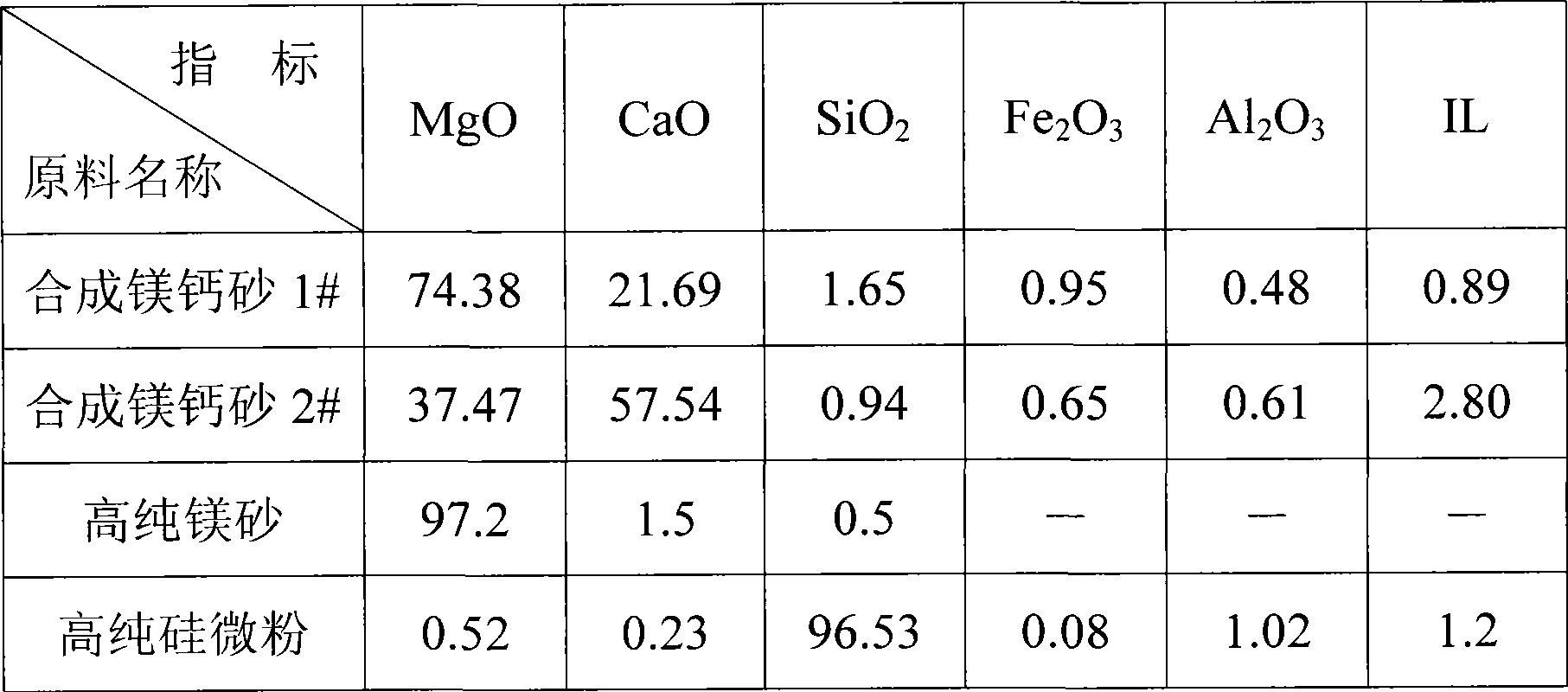

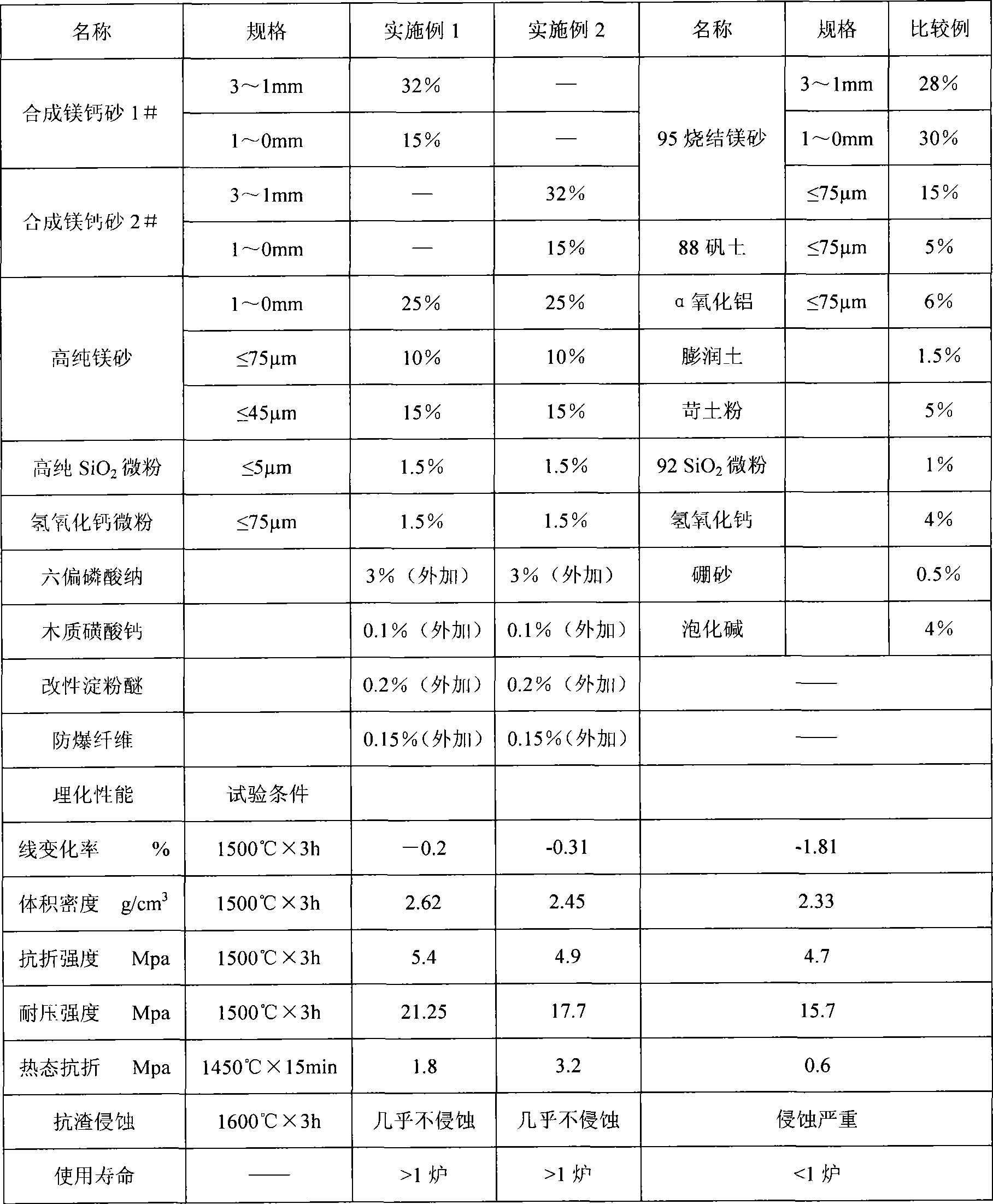

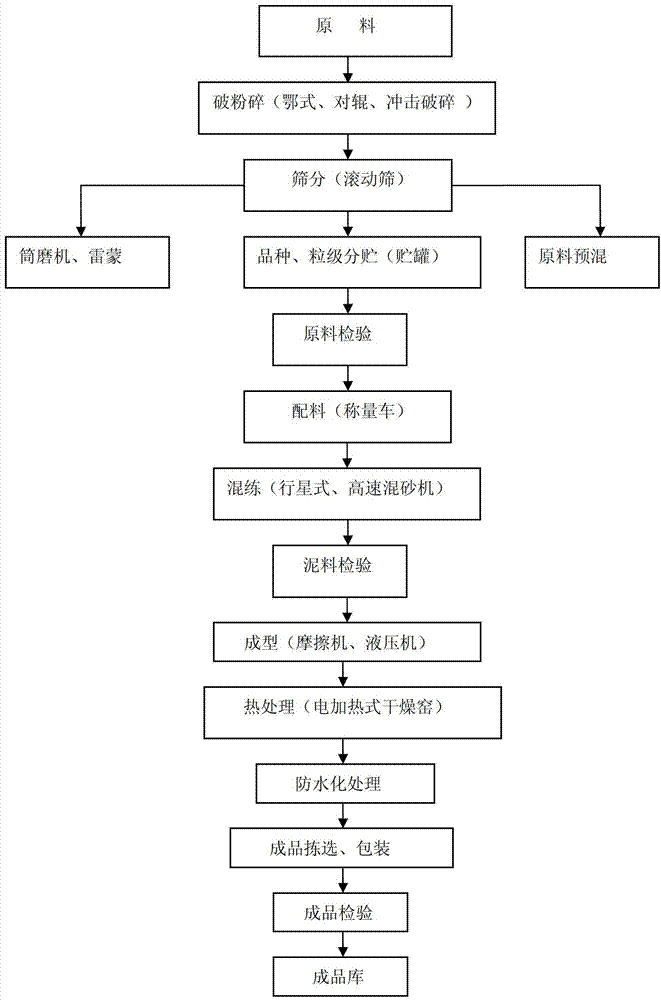

Magnesium calcium RH varnished tube hot spray repair material for smelting silicon steel and formulating method thereof

The invention relates to a calcium magnesium RH dip pipe hot spray repair material used for high-performance smelting silicon steel and a preparation method, and is characterized in that the invention adopts high-purity magnesium gravel and synthesis magnesium calcium as main components; more than one of organic addition agents of woodiness calcium sulphonate, modified starch ether, and the like are used in composite mode to substitute low-melting harmful plasticizers of soft clay, water glass, and the like used by conventional spray repair material to realize good spray repair adhesiveness and good high-temperature performance of the spray repair material. The invention uses two ultra fine powder of ultra fine MgO micro powder, SiO2 micro powder and calcium hydroxide micro powder in composite mode to act slushing enhancement effect, further improves adhesiveness and agglutinating property of the material, and enhances high temperature strength of the material. Provided spray repair material has high hot strength, good high-residue erosion resistance performance and good molten steel erosion resistance performance; spraying and repairing a dip pipe can make the service life be more than one furnace when a RH device smelts low sulphur special silicon steel, thus satisfying the requirements of the smelting of the special silicon steel.

Owner:上海彭浦特种耐火材料厂有限公司

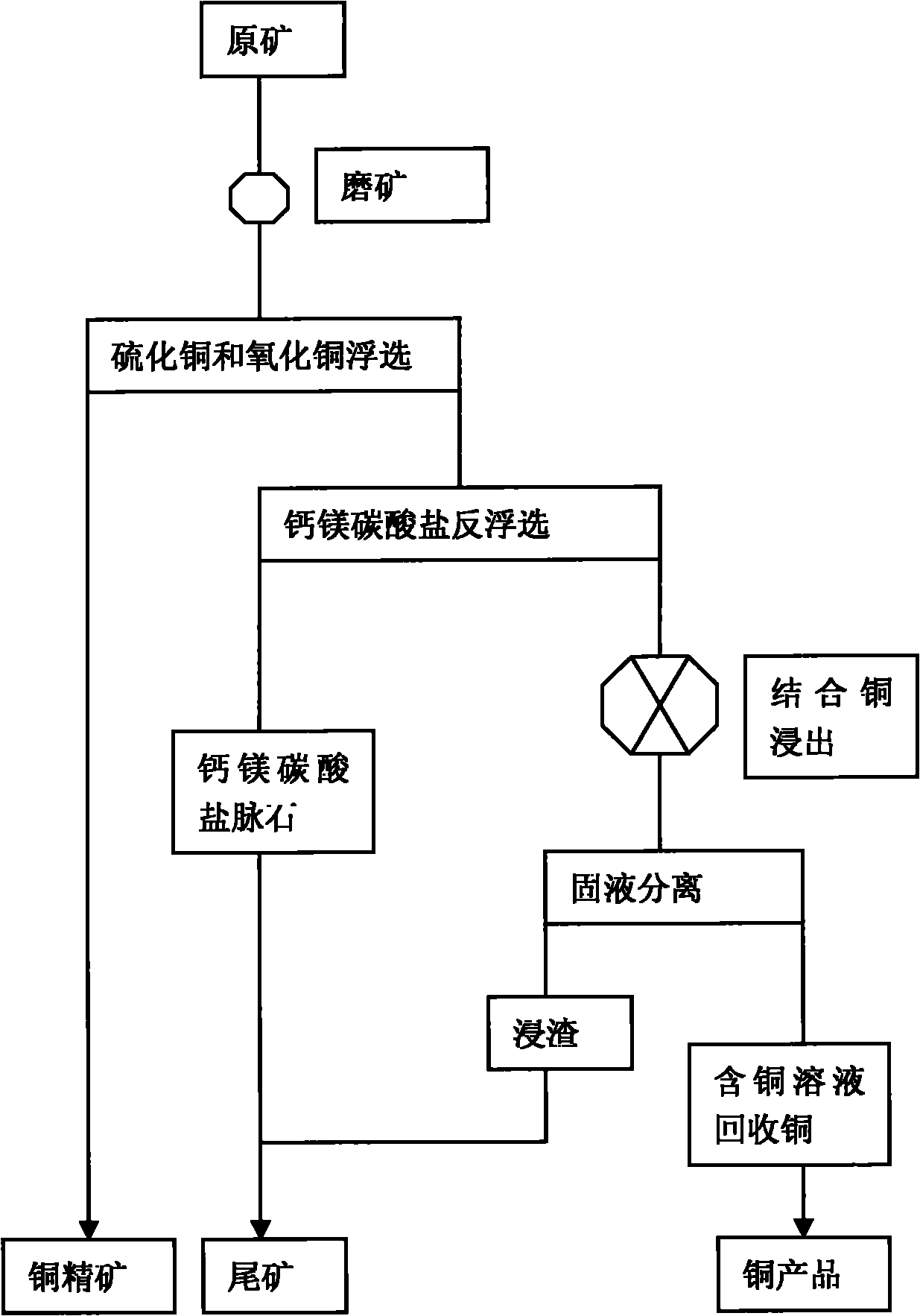

Flotation and metallurgy method of high-bonding-ratio carbonate gangue-type oxygen-sulfur mixed copper ore

ActiveCN101831559AAvoid lostReduce consumptionFlotationProcess efficiency improvementCopper oxideOxygen

The invention relates to a flotation and metallurgy method of high-bonding-ratio carbonate gangue-type oxygen-sulfur mixed copper ore. The flotation and metallurgy method comprises the following steps of: firstly, recovering copper sulfide minerals and free copper oxide minerals in the high-bonding-ratio oxygen-sulfur mixed copper ore with high calcium-magnesium carbonate gangue mineral content by flotation; carrying out reverse flotation on calcium-magnesium carbonate ore in tailings obtained after floatation with fatty acid to obtain middlings containing combined copper and less calcium-magnesium carbonate minerals; then, adding sulphuric acid and stirring to leach out combined copper; and processing a copper-contained solution obtained after solid-liquid separation to obtain a copper product by a metallurgy method. The method combines the flotation and the metallurgy for complementary advantages, efficiently recovers and utilizes high-bonding-ratio carbonate gangue-type oxygen-sulfur mixed copper ore resources incapable of being processed at present, lessens the emission of castoff, such as carbon dioxide, magnesium calcium sulfate, and the like and has favorable economic benefits and environmental benefits.

Owner:YUNNAN TIEFENG MINING CHEM NEW TECH CO LTD

Magnesium-calcium-carbon refractory material

The invention relates to a magnesium-calcium-carbon refractor material, in particular to a refractory material for smelting, which belongs to the technical field of refractory materials for smelting. The magnesium-calcium-carbon refractor material contains 1-25 parts of carbon, 0.2-6 parts of a magnesium-zirconium alloy, 60-96 parts of a mixture of dolomite sand, magnesium-calcium sand and magnesium sand, and 2-5 parts of a carbon-containing bonding agent, wherein the magnesium-zirconium alloy contains 3-35 percent of a zirconium element and the balance of magnesium and a small quantity of impurities. The magnesium-calcium-carbon refractor material provided by the invention can be taken as a refractory material for smelting, and has the advantages of oxidation resistance, high temperature resistance, slag permeation resistance, thermal shock resistance and easiness in producing.

Owner:江苏苏嘉集团新材料有限公司

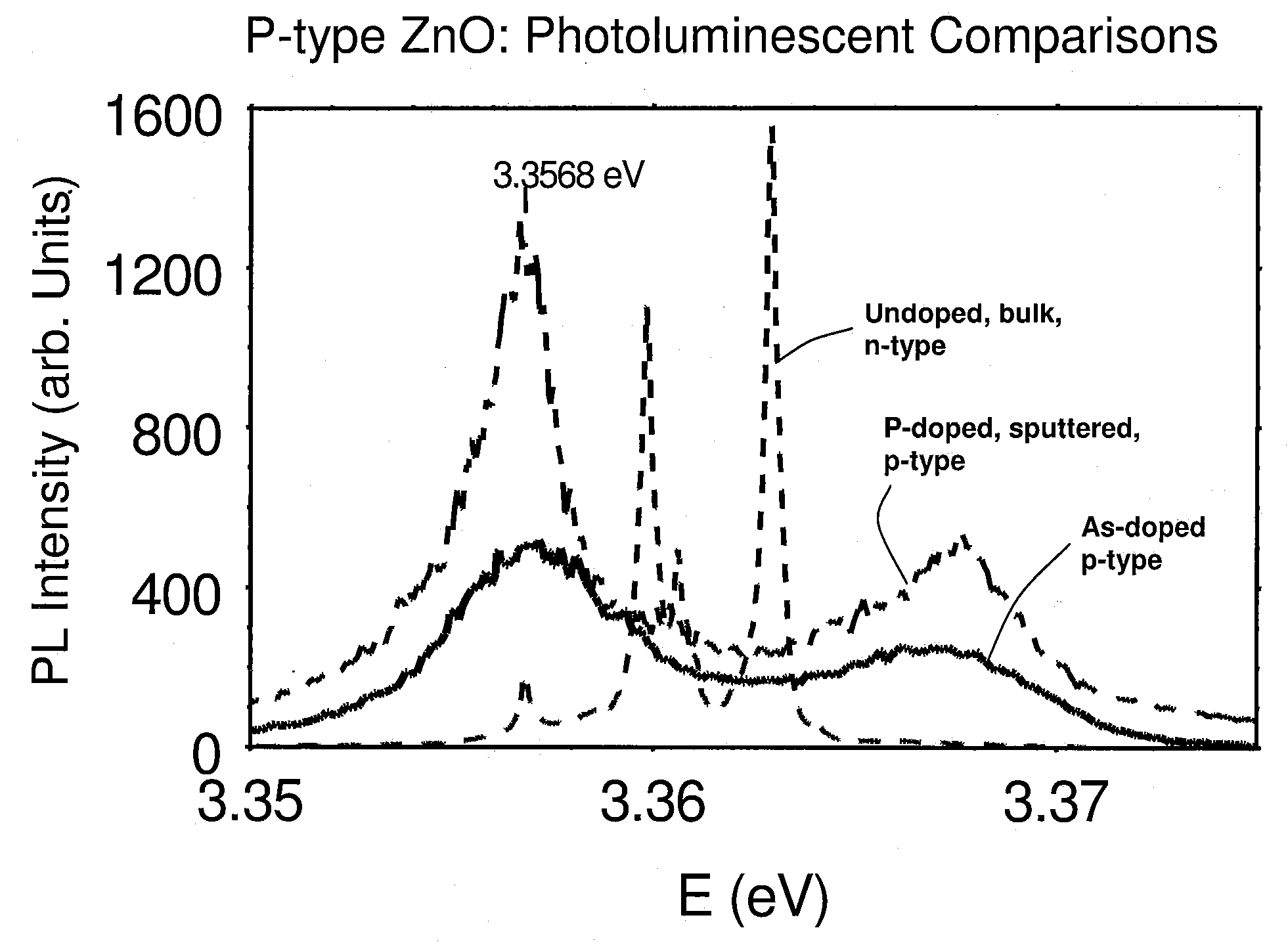

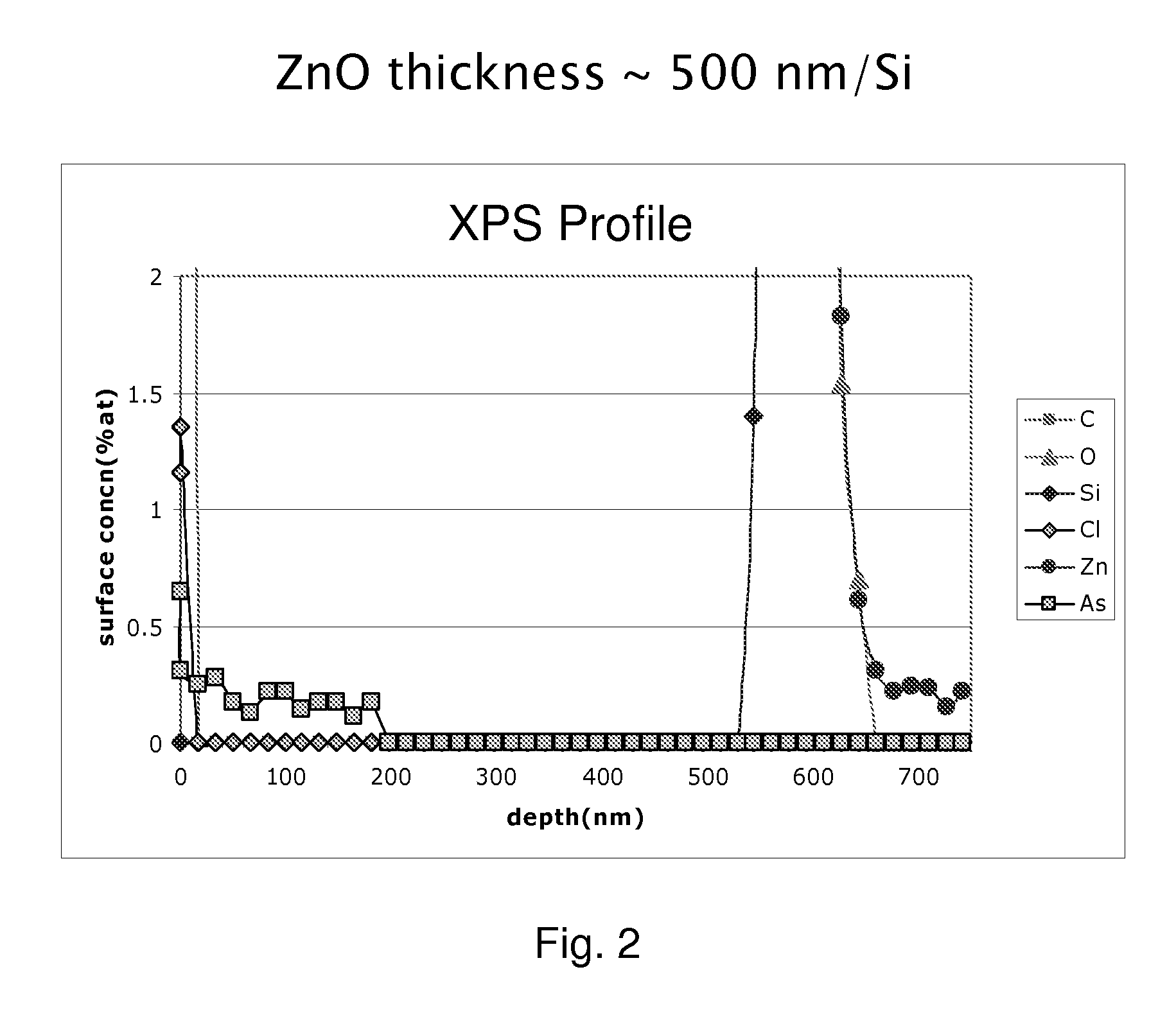

P-type group II-VI semiconductor compounds

InactiveUS7161173B2Diminish desired electronic propertyInhibit single crystal formationPolycrystalline material growthSemiconductor/solid-state device manufacturingAlkaline earth metalSemiconductor materials

A persistent p-type group II-VI semiconductor material is disclosed. The group II-VI semiconductor includes atoms of group II elements, atoms of group VI elements, and one or more p-type dopants. The p-type dopant concentration is sufficient to render the group II-VI semiconductor material in a single crystal form. The semiconductor resistivity is less than about 0.5 ohm·cm, and the carrier mobility is greater than about 0.1 cm2 / V·s. Group II elements include zinc, cadmium, the alkaline earth metals such as beryllium, magnesium calcium, strontium, and barium, and mixtures thereof. Group VI elements include oxygen, sulfur, selenium, tellurium, and mixtures thereof. P-type dopants include, but are not limited to, nitrogen, phosphorus, arsenic, antimony, bismuth, copper, chalcogenides of the foregoing, and mixtures thereof.

Owner:ZENO MATERIALS LLC

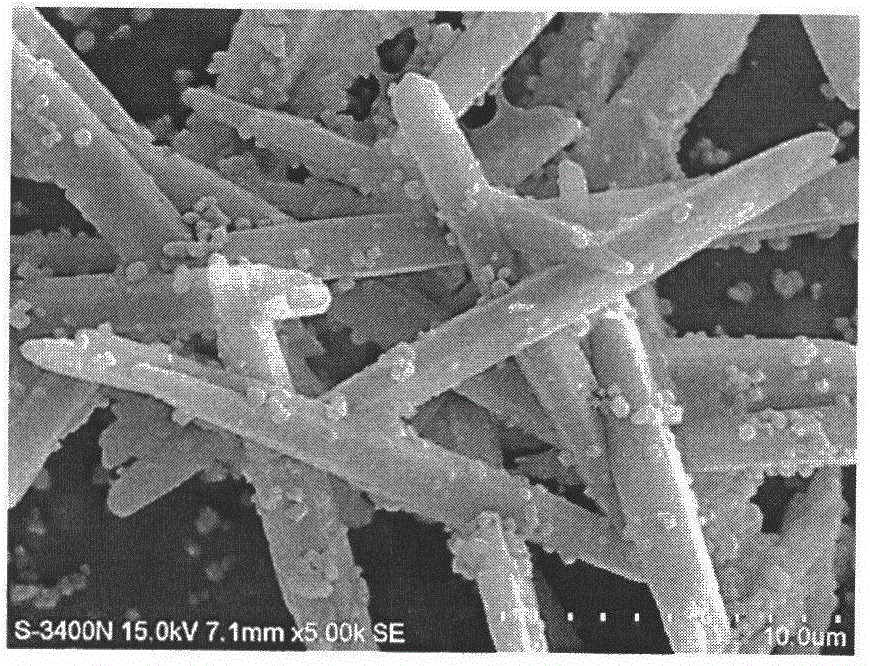

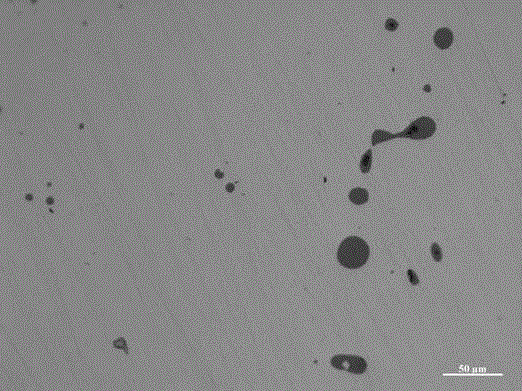

Preparation method for aragonite calcium carbonate whisker with high length-diameter ratio

InactiveCN104790024AEasy to operateLow magnesium to calcium ratioPolycrystalline material growthFrom normal temperature solutionsFiltrationCarbonization

The invention relates to a preparation method for an aragonite calcium carbonate whisker with a high length-diameter ratio. The preparation method comprises the following specific implementation steps: adding a 1.0-8.2 wt% prepared Ca(OH)2 suspension liquid into a carbonation reactor, adding MgCl2 in the aqueous solution form into the reactor, controlling the magnesium-calcium ratio R to be 0.6-2.0 and the carbonization temperature to be 30-85 DEG C, under the action of stirring, mixing CO2 with the flow rate of (5-120)m<3> / (h.m<3> suspension liquid)and N2, introducing the mixture of the CO2 and N2 to a gas distributor at the bottom of the carbonation reactor, and tracking the whole process of carbonation reactor by adopting a digital display pH meter; performing suction filtration and washing on the slurry generated after the carbonization is completed, drying for 5 hours at the temperature of 80 DEG C, and crushing, so as to obtain a calcium carbonate whisker sample. Compared with the existing method for preparing the aragonite calcium carbonate whisker through a carbonation method, the preparation method provided by the invention has the advantages that the calcium carbonate whisker with the high length-diameter ratio is synthesized by adopting the one-step method, the multistage growth is avoided, and the operation is simpler; the co-heating reaction balance phase of magnesium chloride and calcium hydroxide is avoided, the magnesium-calcium ratio in the reaction slurry is low, and the synthesis efficiency is higher.

Owner:GUANGXI UNIV +1

High-quality H13 rear earth mold steel and production method thereof

The invention relates to high-quality H13 rear earth mold steel and a production method thereof, and belongs to the technical field of mold steel making. The high-quality H13 rear earth mold steel provided by the invention comprises the following ingredients based on weight percent: 0.37-0.42% of C, 0.80-1.20% of SiO, 0.20-0.50% of Mn, 5.00-5.50% of Cr, 1.20-1.75% of Mo, 0.80-1.20% of V, not greater than 0.025% of P, not greater than 0.005% of S, 0.001-0.010% of rear earth element, and the balance of Fe. The production method of the mold steel provided by the invention comprises the following steps of electric furnace smelting, ladle furnace LF refining, VD furnace vacuum degassing, rear earth-magnesium-calcium composite line feeding, argon-protected pouring, forging, annealing and thermal treatment. The mold steel provided by the invention has the following great advantages of high purity, high tissue uniformity, high mechanical property and isotropy, effectively improves the service life of a mold, and reduces production cost.

Owner:INNER MONGOLIA NORTH HEAVY INDS GROUP

Method for vermicular cast iron by using mixed vermiculizer

The invention relates to a method for vermicular cast iron by using a mixed vermiculizer, which comprises the following steps: 1) proportioning; 2) preparing the mixed vermiculizer; 3) vermiculizing; 4) carrying out secondary inoculation; 5) carrying out test sprue and quick metallographic examination; 6) removing slag for coverage; and 7) casting. The molten iron sulfur content detection determines that when a vermiculizer formed by mixing a rare-earth magnesium-calcium vermiculizer and a low-silicon magnesium conglomeration nodulizer in different ratios is used for vermiculization, after carrying out primary inoculation with a silicon-barium inoculator and secondary inoculation with a 75 iron-silicon alloy, the vermicular percentage of the prepared vermicular cast iron is greater than or equal to 85%, the pearlite content in the base is greater than or equal to 50%, the tensile strength sigma b is greater than or equal to 420Mpa, the hardness is HB175-210, and the elongation percentage delta is greater than or equal to 1.5%.

Owner:丹阳市锦雄机械制造有限公司

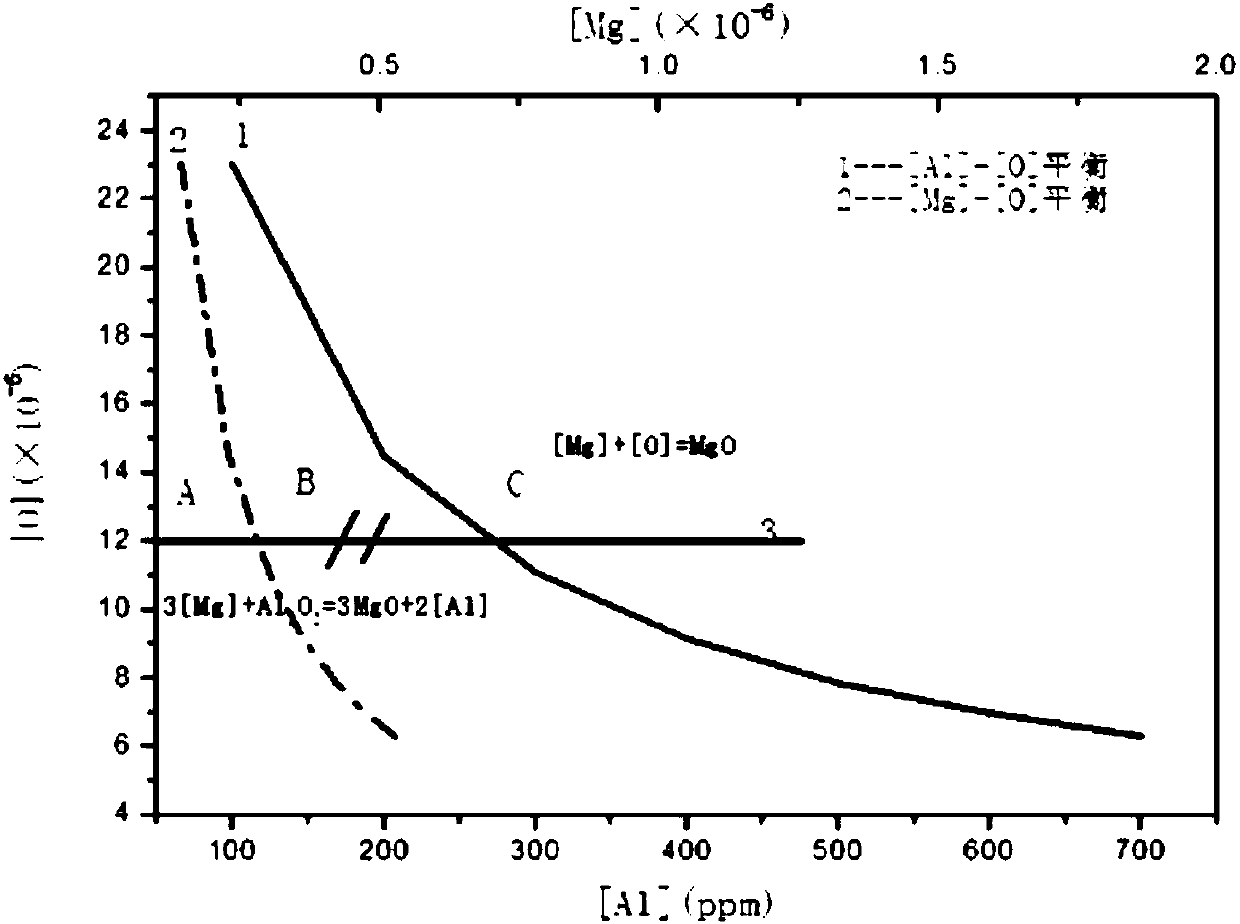

Smelting method for modifying sulfide inclusions in non-quenched and tempered steel or pinion steel

The invention discloses a smelting method for modifying sulfide inclusions in non-quenched and tempered steel or pinion steel. A modification process is mainly realized by the following step: feedinga silicon-magnesium-calcium composite core-spun yarn into refined molten steel, or respectively feeding a silicon-magnesium core-spun yarn and a silicon-calcium core-spun yarn into the refined moltensteel, so that the content of magnesium in the steel is 4-25ppm, and the content of calcium in the steel is 5-25ppm. According to the method, by optimizing the contents of oxygen, sulfur, manganese, calcium, magnesium and aluminum in the steel in a refining process, the sulfide inclusions in the non-quenched and tempered steel and the pinion steel are modified effectively, so that the form, size and distribution of sulfide are controlled, the inclusions in the non-quenched and tempered steel and the pinion steel are transformed into 'internal hard oxide particle and external covered sulfide' composite inclusions, and the quality of special steel is enhanced.

Owner:SHANGHAI UNIV

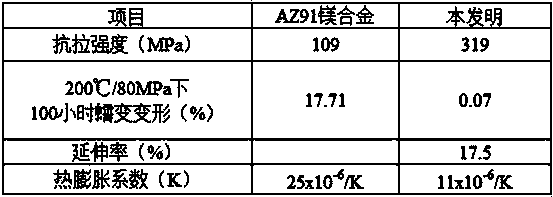

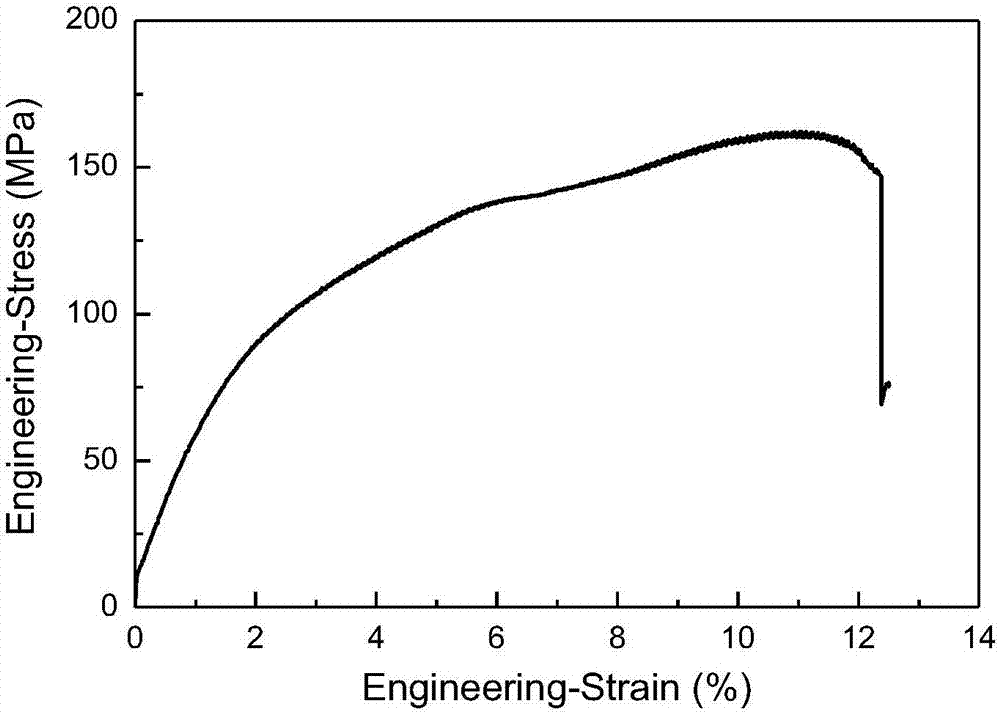

Multielement-reinforced heat-resistant magnesium alloy and manufacturing method thereof

The invention discloses a multielement-reinforced heat-resistant magnesium alloy and a manufacturing method thereof. The multielement-reinforced heat-resistant magnesium alloy is prepared from the following raw materials in parts by weight: 1000 parts of magnesium, 65-85 parts of aluminum, 5-8 parts of zinc, 10-30 parts of yttrium, 1.5-5 parts of manganese, 5-15 parts of neodymium, 3-4 parts of cerium, 1-4 parts of calcium, 0.4-1 part of strontium, 0.1-0.5 part of silicon, 3-6 parts of silver and 10-40 parts of boron carbide. The manufacturing method comprises the following steps: carrying out acid washing, drying and preoxidation on the boron carbide, preheating the materials, smelting the magnesium and aluminum while introducing protective gas, adding an aluminum-manganese alloy and a pure zinc ingot to carry out alloying, adding an aluminum-silver alloy, a magnesium-silicon alloy, a magnesium-yttrium alloy, a magnesium-cerium alloy, a magnesium-neodymium alloy, a magnesium-calcium alloy and a magnesium-strontium alloy, smelting, adding the boron carbide particles for reinforcement, carrying out gas refinement on the melt by using argon, carrying out extrusion casting, and finally, carrying out solid solution aging treatment to obtain the heat-resistant magnesium alloy finished product. The magnesium alloy has excellent comprehensive properties under high-temperature conditions.

Owner:YANGZHOU FENG MING METAL PROD

Biodegradable zinc (or zinc alloy) and porous biphase calcium phosphate composite material and preparation method thereof

ActiveCN102727937AGood biocompatibilitySolve the degradation rateProsthesisPorosityBiphasic calcium phosphate

The present invention provides a biodegradable zinc (or zinc alloy) and porous biphase calcium phosphate composite material and a preparation method thereof. The composite material comprises porous biphase calcium phosphate and zinc or a zinc alloy, wherein the zinc or the zinc alloy is arranged in the porous biphase calcium phosphate through suction casting, the porosity of the porous biphase calcium phosphate is 60-95%, the HA content is 10-70%, the beta-TCP content is 30-90%, and the zinc or the zinc alloy is zinc, a zinc-magnesium alloy, a zinc-yttrium alloy, a zinc-calcium alloy, a zinc-magnesium-manganese alloy, a zinc-magnesium-calcium alloy or a zinc-magnesium-yttrium alloy. The composite material is non-porous at the initial stage, and has good mechanical stability and good mechanical strength; after the composite material is implanted a certain time, the composite material is degraded, and the portion which is degraded slowly maintains the mutually-penetrated porous structure so as to prompt the bone to grow in the structure; and the composite material is gradually degraded along with the gradual growth of the bone in the structure, and the composite material is completely degraded when the bone is healed, such that the good coordination of the biodegradability of the composite material and the osteoinductive is provided.

Owner:JIANGYIN BIODEGRADE MEDICAL TECH CO LTD

Calcium-magnesium hydrogen producing agent

InactiveCN102783691AOut-of-the-boxStrong reducing agentCosmetic preparationsToilet preparationsWrinkle skinSkin elasticity

The invention discloses a calcium-magnesium hydrogen producing agent, of which the main component is a hydrogen producing agent. The hydrogen producing agent is selected from one or various combination of calcium hydride, magnesium hydride, calcium hydroxide magnesium, magnesium-magnesium hydride, calcium-calcium hydride, magnesium-calcium hydride, calcium-magnesium hydride, calcium-magnesium-magnesium hydride, calcium-magnesium-calcium hydride, calcium-magnesium-magnesium hydride-calcium hydride, coral calcium hydroxide magnesium, Na MgH3, and Mg2FeH6. the calcium-magnesium hydrogen producing agent can be added into water, beverage or wine as an additive, or can be coated on the surface of skin or taken as soaking liquid to remove internal or surface active oxygen. The calcium-magnesium hydrogen producing agent has a remarkable prompting effect for recovering various oxidized damages, relieving discomfort caused by drinking, diluting stain and wrinkle of the skin, recovering skin elasticity, and delaying senescence.

Owner:李志林

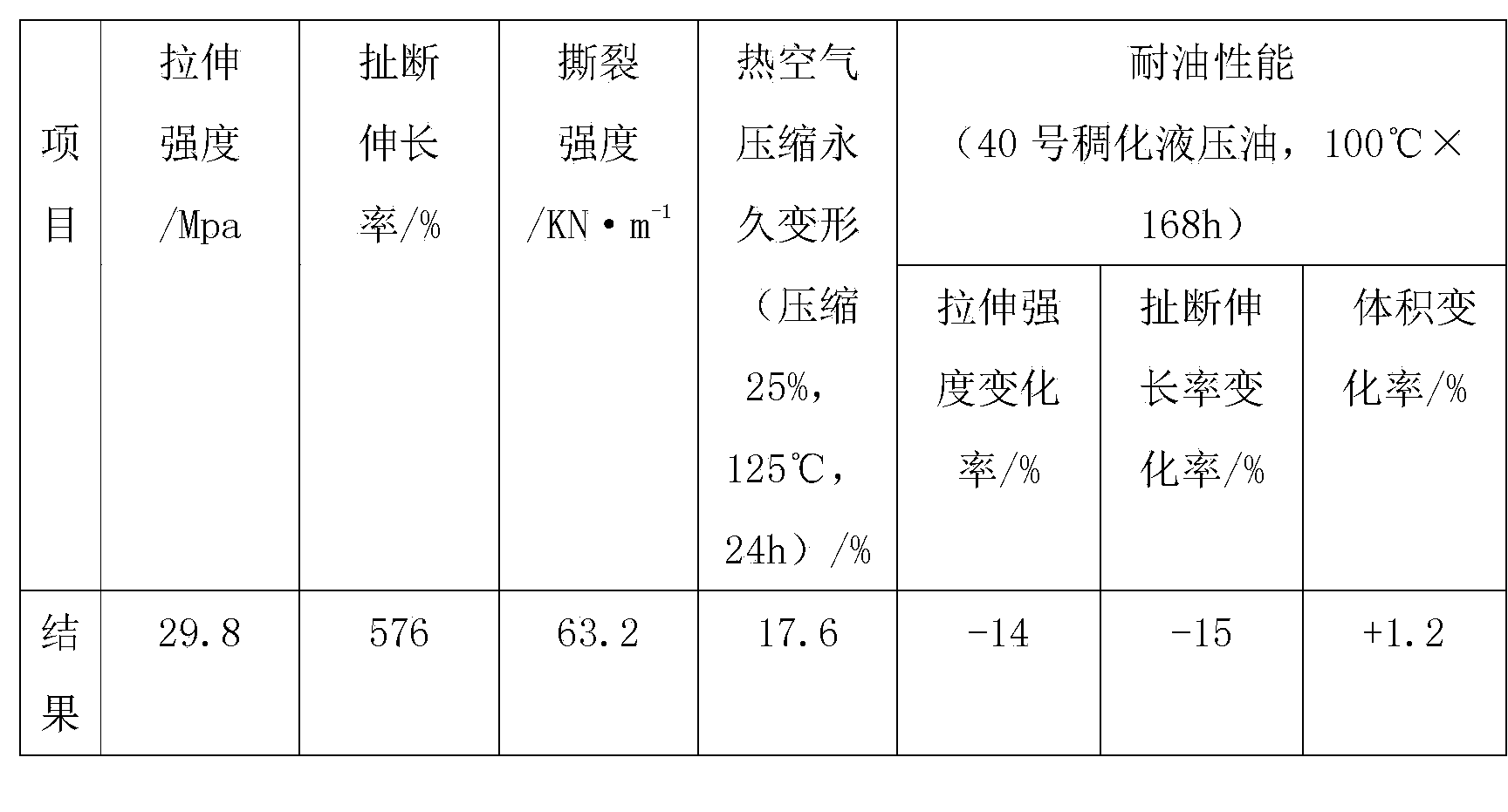

High-strength tear-resistant rubber sealing gasket and preparation method thereof

The invention discloses a high-strength tear-resistant rubber sealing gasket and a preparation method thereof. The high-strength tear-resistant rubber sealing gasket is prepared from raw materials, namely chlorosulfonated polyethylene rubber, silicon rubber, bisphenol A type polycarbonate, cashew nut shell oil modified phenolic resin, hexamethylenetetramine, dicumyl peroxide, spray carbon black, modified nano ceramics, silicon-magnesium-calcium crystal whiskers, nanometer wollastonite, zinc methacrylate, magnesium oxide, stearic acid, vinyl silicone oil, chlorinated paraffin 4-7, triethyl citrate and the like. According to the high-strength tear-resistant rubber sealing gasket and the preparation method thereof disclosed by the invention, the organic composite modification is carried out by adopting multiple nano ceramic powder, namely nanometer aluminum nitride, nanometer titanium carbide and nanometer zirconium boride, so that the compatibility of the nano ceramic powder and rubber can be enhanced; the modified nano ceramic powder, the silicon-magnesium-calcium crystal whiskers, the nanometer wollastonite and the like are filled in a modified rubber material together to prepare the sealing gasket, so that the mechanical strength, impact resistance and especially tear resistance of the sealing gasket can be remarkably improved; the heat resistance, abrasion resistance and the like of the rubber can also be improved.

Owner:WUHU YINHONG HYDRAULIC COMPONENTS

Magnesium-calcium-zirconium slag non-sticking spraying coating

The invention relates to magnesia-calcium-zirconium non-stick slag spray paint, which effectively solves the problems of high energy consumption and environmental pollution during the use of the paint. The invention is calculated by weight percentage: dolomite 20-80%, zircon sand 2 -10%, corundum powder 5-15%, silicon micropowder 2-10%, bentonite 2-5%, soft clay 5-15%, phosphate 2-6%, calcium lignosulfonate 0.1-1%, boric acid 0.2-2%, the total amount is 100%. The test in the steel-making converter shows that the spray coating of the present invention has good fluidity, can complete the gunning operation within three minutes, can effectively isolate the slag and is easy to clean up the slag, reducing the work Time, the main raw material used in the present invention is non-burning dolomite, which is not hydrated, has a wide range of raw material sources, is convenient to obtain, and because it does not burn raw materials, it saves a lot of energy, which is beneficial to reduce costs and save energy consumption.

Owner:郑州荣达工矿集团有限公司

Preparation method of compacted graphite cast iron

The invention discloses a preparation method of compacted graphite cast iron, which is characterized by comprising the following steps of: (1) raw material selection; (2) pretreatment; (3) rare earth-magnesium-calcium vermicularizing alloy preparation; (4) vermicularizing treatment; (5) stokehole sample test and rapid metallographic test; (6) slag covering; (7) late inoculation; and (8) pouring. In the method, the sulfur content of molten iron can be controlled between 0.03% and 0.04% after the molten iron is pretreated; and after being subjected to vermicularizing treatment by using rare earth-magnesium-calcium vermicularizing alloy and late inoculation treatment by using 75 ferrosilicon alloy, the prepared compacted graphite cast iron has the vermicular graphite rate of more than or equal to 85%, the tensile strength sigmab of more than or equal to 420 Mpa, the hardness HB of 175-210 and the elongation delta of more than or equal to 1.5%, and the pearlite content in a matrix of the compacted graphite cast iron is more than or equal to 50%.

Owner:丹阳市锦雄机械制造有限公司

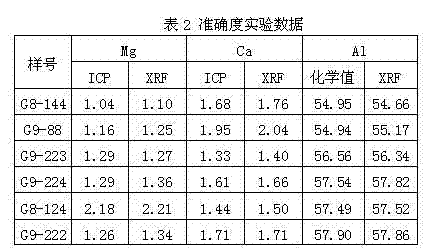

Melted sampling method for aluminum magnesium calcium iron alloy for X-ray fluorescence spectrum analysis

InactiveCN102331364AAccelerationAccuracyMaterial analysis using wave/particle radiationPreparing sample for investigationGranularityLithium carbonate

The invention discloses a melted sampling method for aluminum magnesium calcium iron alloy for X-ray fluorescence spectrum analysis. The melted sampling method is characterized by comprising the following steps of: hanging a layer of uniform lithium tetraborate protective wall in a platinum crucible; putting an aluminum magnesium calcium iron sample, lithium carbonate and potassium iodide into the platinum crucible in which the protective wall is hung, mixing uniformly, and covering a layer of lithium tetraborate; pre-oxidizing the aluminum magnesium calcium iron sample; and melting the oxidized aluminum magnesium calcium iron sample, and cooling to obtain a glass fuse piece of the aluminum magnesium calcium iron alloy. By the method, the sampling time is short, the manufactured glass fuse piece is uniform and perfect, and the specification of a mineral effect and a granularity effect can be eliminated completely. The glass fuse piece can be used for the X-ray fluorescence spectrum analysis, the obtained analytic result is accurate and reliable, and the requirements of modern enterprises on quick and accurate detection of analytic data are met. The method is safe, reliable, easy to operate and high in repeatability, and the application range of an X-ray fluorescence spectrum method is broadened.

Owner:HBIS COMPANY LIMITED HANDAN BRANCH COMPANY

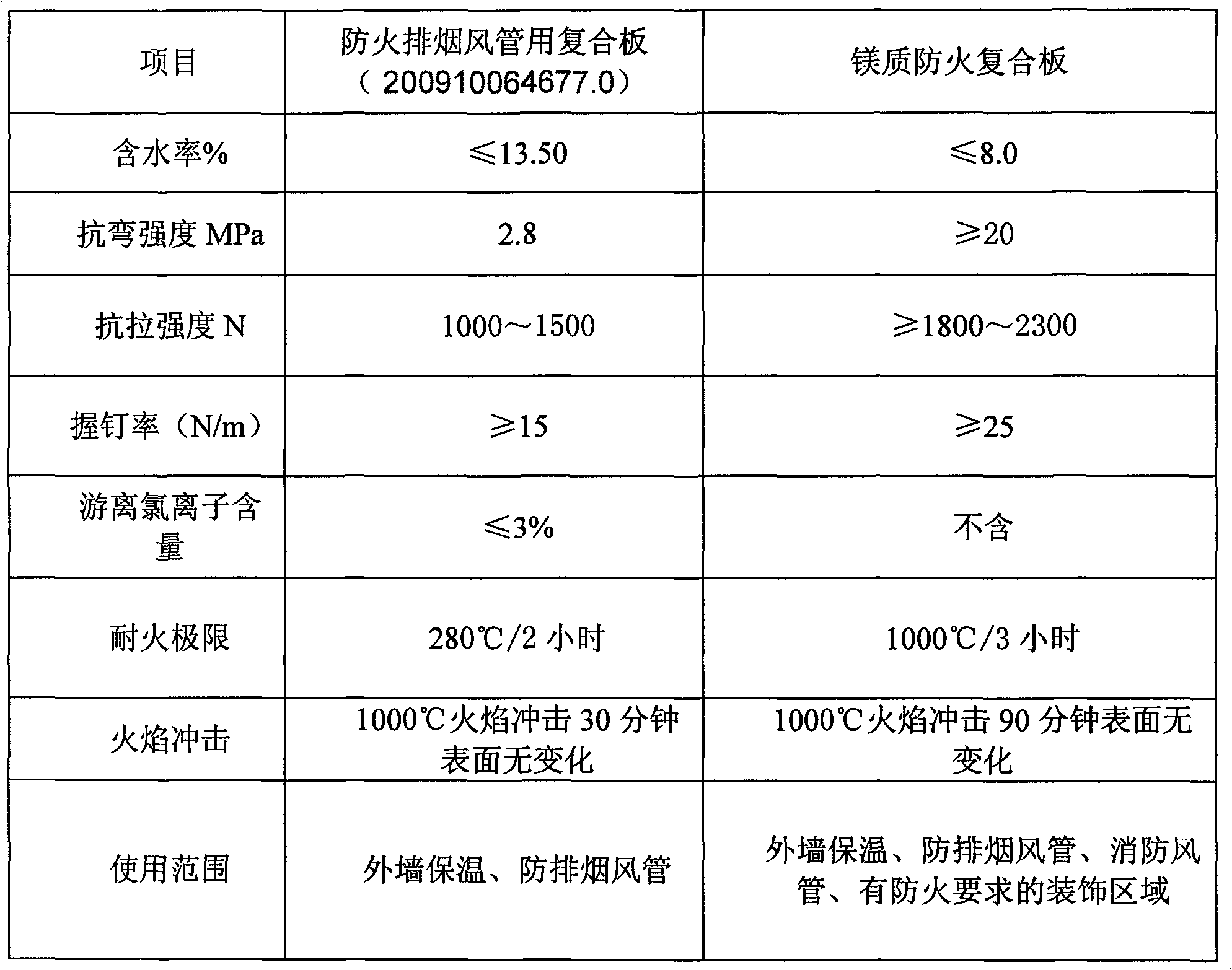

Fire-proof magnesium composite board

ActiveCN103510671ANot brokenNo deformationCovering/liningsCeramic shaping apparatusCalcium silicateSodium Bentonite

The invention belongs to the field of new materials for fire control, and relates to a novel fire-proof composite board. According to the fire-proof composite board, a high-strength magnesium calcium silicate jelling inorganic material is used as an upper plane material and a lower plane material, a magnesium calcium silicate structure composite layer is taken as a core layer, and aluminum sulfate fiber grid glass fibers or non-inflammable non-woven fabrics or plant fibers are taken as reinforcing materials, are laid outside the core layer and are formed in a hot-pressing and composite mode. The high-strength magnesium calcium silicate jelling inorganic material comprises, by weight, 20%-25% of magnesium sulfate, 15%-20% of calcium silicate, 3%-5% of wollastonite fibers, 30%-40% of magnesium oxide, 3%-5% of plant fibers, 3%-5% of aluminum sulfate fibers, 3%-5% of modifying agents, 3%-5% of bentonite, 3%-5% of foaming agents, 1%-3% of phosphoric acid and the balance water. The magnesium composite board can bear a high temperature of 1000 DEG C, the fire-proof performance reaches the A1 level, the material cannot crack or deform, the strength is high, the composite board is sound-proof and thermal-insulating, the service life of the composite board can reach more than 30 years, the composite board can be nailed and planed and is convenient to use, the defects that a traditional fire-proof board is flammable and prone to halogenide, efflorescence and deformation are thoroughly overcome, and the composite board is suitable for decoration fire-proof boards, fire-proof smoke exhaust air pipe and the like.

Owner:HANGZHOU KECHUANG AIR HOSE CO LTD

A kind of high-calcium-magnesium-calcium brick and its preparation method

The invention discloses a high-calcium magnesium-calcium brick and a preparation method thereof. The main raw materials and components thereof are: 9-16% of 5-7mm magnesia-calcium sand, 9-16% of 3-5mm magnesia-calcium sand, 1-3mm magnesia-calcium sand 9-16%, 0.5-1mm magnesia-calcium sand 13-32%, magnesia-calcium sand ≤0.5mm 5-25%, binder 2-5%, made of fused zirconia and electric Additives 1-5% mixed with molten lime. The preparation method is as follows: according to the above-mentioned raw materials, carry out formula combination, batching, kneading, molding, firing, dipping in wax, and then carry out vacuum aluminum foil packaging. The inventive product not only has high hydration resistance, but also has high slag erosion resistance due to its high purity, and is also superior to other similar products in terms of thermal shock stability. At the same time, because the brick contains more than 40% free CaO, it has excellent performance of cleaning molten steel, and is especially suitable for producing high-cleanness steel such as stainless steel.

Owner:PERFECT WORLD CO LTD

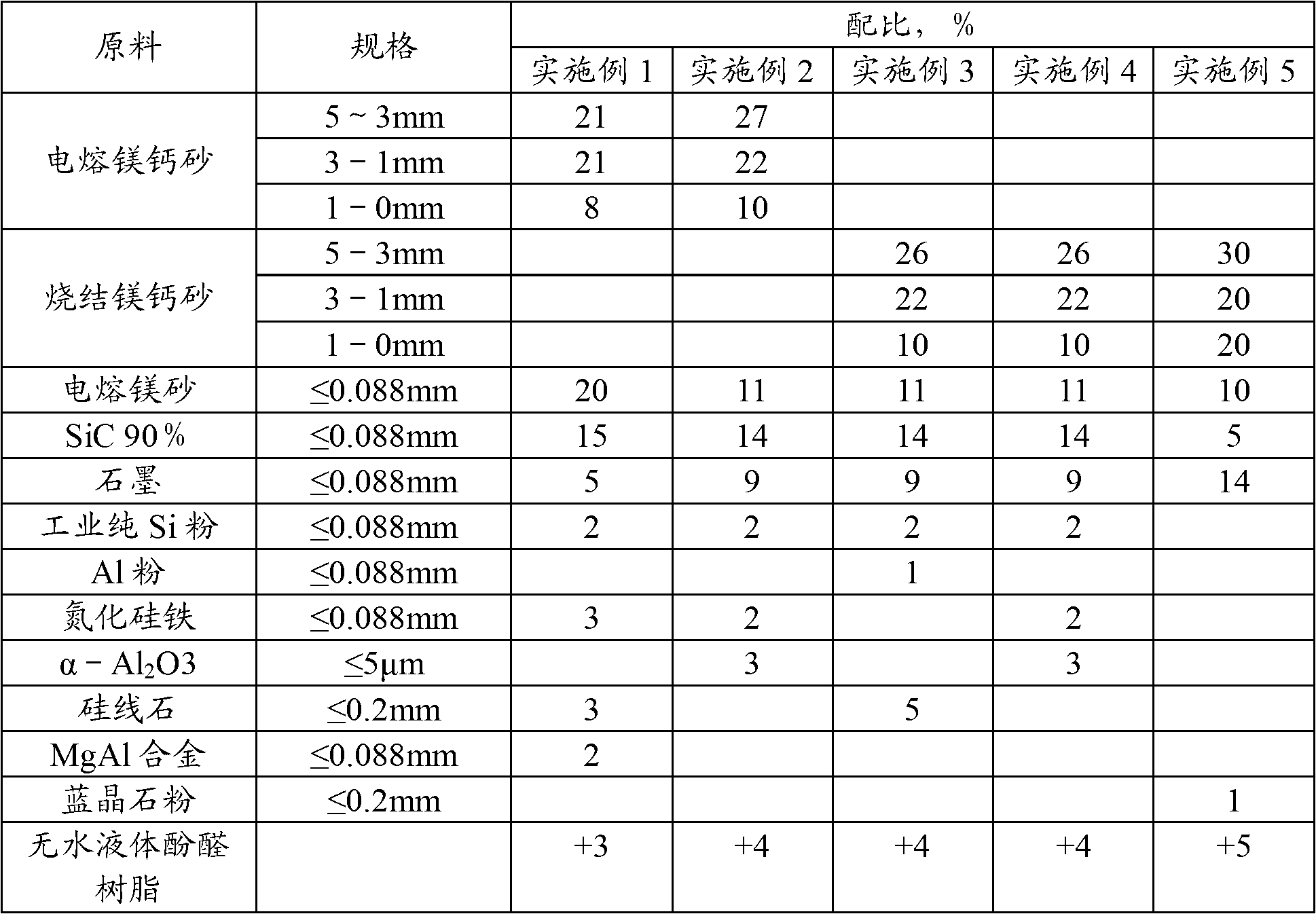

Preparation method and proportion of components of low-carbon magnesium-calcium carbon brick for manufacturing inner lining of steel-making refining furnace

The invention relates to a preparation method and proportion of components of a low-carbon magnesium-calcium carbon brick for manufacturing an inner lining of a steel-making refining furnace. In the invention, electro-fused or sintered magnesium-calcium powder, magnesia micro-powder, nano-carbon block, graphite, an antioxidant and a binding agent are mainly adopted as main components for proportioning, the carbon content in the components is lower than 5%, and a finished product can be prepared by controlling the components of raw materials and the grain size, and carrying out mixing, molding and heat treatment. The product is conductive to smelting of low-carbon steel and can smelt high-quality pure steel and clean steel and overcome the problems of environmental pollution and shortage of resources caused by using magnesium-chromium bricks for the inner lining of the refining furnace.

Owner:ZHENGZHOU ANNEC IND

Low-porosity aluminum-magnesium-calcium rear earth based cellular Al alloy foam and preparation thereof

The invention discloses a low porosity rate Al-Mg-Ca-rare-earth-based closed-cell foamed aluminum alloy and a preparation method which are a foamed aluminum alloy with good corrosion-resistant performance, high strength, high finished product rate, simple method and low cost and a preparation method. The foamed aluminum alloy takes calcium carbonate as a foaming agent, the porosity rate is between 40 and 75 percent, wherein, the manganese accounts for 1 to 11 percent (mass percentage) of the alloy, the calcium accounts for 0.5 to 5 percent (mass percentage) of the alloy, the rare earth accounts for 0.10 to 1.2 percent (mass percentage) of the alloy. The preparation method is that: the pure aluminum is heated up for melting, the melting body is added with the manganese equivalent to 1 to 11 percent of the mass of the alloy, the calcium equivalent to 0.5 to 5 percent of the mass of the alloy and the rare earth equivalent to 0.10 to 1.2 percent of the mass of the alloy, and kept for 10 to 30 minutes; the temperature of the melting body is ensured between 650 and 690 DEG C, the melting body is stirred for 2 to 12minutes with the speed of between 300 and 600rpm; the calcium carbonate equivalent to 0.5 to 5 percent of the mass of the pure aluminum is added into the melting body to stir so as to make the aluminum alloy melting body to be foamed, the low porosity rate Al-Mg-Ca-rare-earth-based closed-cell foamed aluminum alloy is obtained after cooling.

Owner:SOUTHEAST UNIV

Light-weight, heat-insulating and environment-friendly composite wall building material

InactiveCN105801063AImprove flexural strengthHigh compressive strengthCeramicwareLow-density polyethyleneCellulose

The invention discloses a light-weight, heat-insulating and environment-friendly composite wall building material.The building coating is prepared from cellulose, carbon fiber particles, rubber particles, plant particles, low-density polyethylene resin, organosilicon-modified epoxy resin, calcium carbonate, magnesium oxide, magnesium silicate, magnesium calcium carbonate, calcium borate, nanosized silica, light-weight ceramic, EVA redispersable rubber powder and the like.The building wall coating has the advantages of being high in breaking strength and compressive strength, has the effects of heat preservation and sound insulation, is low in heat conductivity coefficient and good in energy-saving effect, and has the good waterproof effect.The obtained wall material is portable, low in cost, free of pollution and environmentally friendly, energy consumption and the production cost are greatly reduced, and the material can be widely applied to building construction.

Owner:韩旭霞

P-type group ii-vi semiconductor compounds

InactiveUS20070102709A1Polycrystalline material growthSemiconductor/solid-state device manufacturingSemiconductor materialsAlkaline earth metal

A persistent p-type group II-VI semiconductor material is disclosed. The group II-VI semiconductor includes atoms of group II elements, atoms of group VI elements, and one or more p-type dopants. The p-type dopant concentration is sufficient to render the group II-VI semiconductor material in a single crystal form. The semiconductor resistivity is less than about 0.5 ohm·cm, and the carrier mobility is greater than about 0.1 cm2 / V·s. Group II elements include zinc, cadmium, the alkaline earth metals such as beryllium, magnesium calcium, strontium, and barium, and mixtures thereof. Group VI elements include oxygen, sulfur, selenium, tellurium, and mixtures thereof. P-type dopants include, but are not limited to, nitrogen, phosphorus, arsenic, antimony, chalcogenides of the foregoing, and mixtures thereof.

Owner:ZENO MATERIALS LLC

Magnesium-calcium pyrophyte pressed-fibre board and method of manufacturing the same

InactiveCN101172825AObvious beneficial effectGood effectSolid waste managementWeather resistancePlant fibre

Owner:谢涛

Magnesium-calcium-titanium-carbon brick and preparation method thereof

InactiveCN102765951AImprove thermal shock resistanceSolve the shortcomings of the large change rate of the reburning lineCalcium in biologyHexamethylenetetramine

The invention relates to the field of fireproof materials, particularly to a magnesium-calcium-titanium-carbon brick and a preparation method of the brick. The brick is characterized in comprising the following raw materials based on weight: sintered dolomite sand, fused magnesite, graphite, asphalt powders, anhydrous resin, urotropine, an antioxidant and industrial titanium dioxide. Compared with the prior art, the magnesium-calcium-titanium-carbon brick has the following beneficial effects: (1) the brick can be widely applied to various external refining devices such as LF (ladle furnace), VAD (vacuum arc degassing) furnace, VOD (vacuum oxygen decarburization) furnace, AOD (argon oxygen decarburization) furnace, RH (recirculation degassing) furnace, GOR (gas oxidation refining) furnace, ASEA-DKF and K-OBM-S, thereby having wide application value; (2) the brick can resist against corrosion, endure peeling, and has good high-temperature vacuum stability, and the product is small in re-burning line change, good in thermal shock stability, and not limited by intermittent usage conditions; (3) the product has excellent hydration resistance; and (4) the brick does not contain water or need any external water, so that the magnesium-calcium fireproof material can be effectively protected from hydration, and the brick is especially fit for matching with the magnesium-calcium fire brick.

Owner:营口青花耐火材料股份有限公司

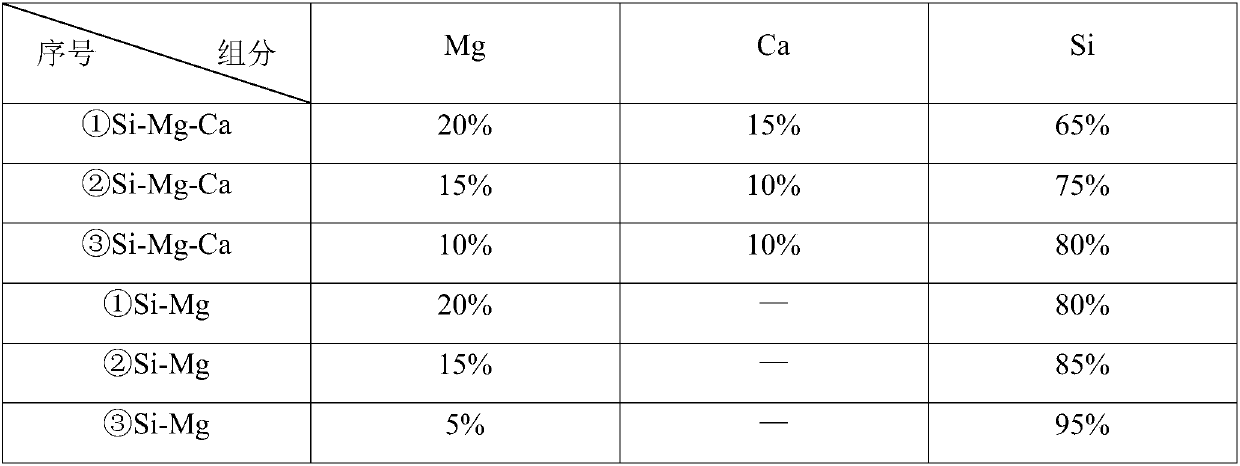

Magnesium-calcium alloy cored wire for ferrous metallurgy and preparation method of magnesium-calcium alloy cored wire

The invention discloses a magnesium-calcium alloy cored wire for ferrous metallurgy and a preparation method of the magnesium-calcium alloy cored wire. The magnesium-calcium alloy cored wire is composed of a core material and a sheath. The core material is composed of magnesium, calcium and silicon and is prepared from 6%-38% of Mg, 5%-30% of Ca and the balance silicon and inevitable impurity elements during raw material preparation; and preferably, the mass ratio of Mg to Ca is controlled to be between 5:3 and 7.5:3. For gear steel, free-cutting steel and non-quenched and tempered steel, the morphology of Al2O3 inclusion and MnS inclusion and the cleanliness of molten steel can be improved through Ca, and the morphology of the inclusion and the cleanliness of the molten steel can also be improved through Mg; the functions of inclusion denaturation and molten steel purification can be achieved at the same time through magnesium-calcium composite treatment; and the effective function of Ca can be remarkably improved through Mg, and the yield of Ca can be remarkably increased through Mg. The cored wire is fed during refining, and the functions of deoxidization, inclusion modification, molten steel purification and steel performance improving can be achieved.

Owner:SHANGHAI UNIV

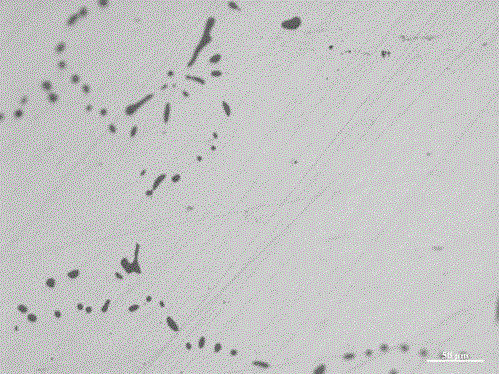

MgCa-SiC-C fireproof material and preparation method thereof

The invention discloses an MgCa-SiC-C fireproof material, belonging to the technical field of fireproof materials. The MgCa-SiC-C fireproof material comprises the following components by mass: 50-70% of electrically molten or sintered magnesium-calcium sand or magnesium-domolite sand granule, 10-20% of electrically molten or sintered magnesium sand fine powder, 5-17% of silicon carbonate, 5-15% of graphite, 1-10% of additive, and anhydrous resin bonder accounting for 3-5% of total mass percent of the electrically molten or sintered magnesium-calcium sand or magnesium-domolite sand granule, the electrically molten or sintered magnesium sand fine powder, the silicon carbonate, the graphite and the additive. The invention further discloses a preparation method of the MgCa-SiC-C fireproof material. The MgCa-SiC-C fireproof material can be applied to a high-temperature steel and iron metallurgy container, especially as an inner lining of a hot metal ladle for iron making, and can meet smelting requirements of the preprocessed hot metal ladle.

Owner:SHOUGANG CORPORATION

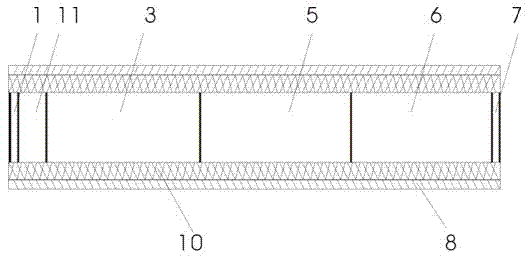

Lining structure of rotary kiln

The invention discloses a lining structure of a rotary kiln. The lining of the rotary kiln comprises a rear kiln mouth, a preheating zone, a decomposing zone, an upper side transitional zone, a firing zone, a lower side transitional zone and a front kiln mouth, wherein the rear kiln mouth is formed by compounding corundum hollow sphere light castable with mullite amorphous castable; the preheating zone is made of an alkali-resistant composite brick or a clay composite brick or a high-aluminum composite brick or alkali-resistant castable; the decomposing zone is made of a clay composite brick or a high-aluminum composite brick or a silicon mullite composite brick; the upper side transitional zone is made of a periclase spinel composite brick or a silicon mullite composite brick or a magnesium composite brick; the firing zone is made of a magnesium chromium composite brick or a periclase spinel composite brick or a magnesium calcium zirconium composite brick or a magnesium iron aluminum composite brick; the lower side transitional zone is made of a silicon mullite composite brick or a spinel composite brick or a magnesium composite brick; and the front kiln mouth is formed by compounding corundum hollow sphere light castable with steel fiber reinforced mullite amorphous castable. The lining is made of a heavy / light composite fireproof material with an energy-saving function, the rotary kiln is subjected to segmented construction according to the requirement, and the firing zone is made of a heavy / light composite brick particularly, so that the barrel wall temperature is greatly reduced, the service life of the rotary kiln is prolonged, and energy saving and consumption reducing effects are achieved.

Owner:ZHEJIANG UNIV

Manufacturing method of soluble alloy fracturing ball for oil and gas exploitation

The invention discloses a manufacturing method of a soluble alloy fracturing ball for oil and gas exploitation. The manufacturing method specifically comprises the steps of respectively weighing the following raw materials: 1 to 10% of zinc, 1 to 10% of magnesium-calcium intermediate alloy, 1 to 5% of nickel, 1 to 6% of copper, 1 to 3% of ferric chloride, 1 to 3% of magnesium-aluminum intermediate alloy, 0.5 to 4.5% of magnesium-neodymium intermediate alloy, 0.5 to 3.5% of manganese, 0.4 to 1.1% of zirconium compound and the balance of magnesium, wherein the sum of the mass fraction of the components is 100%; respectively preheating the raw materials; adding the preheated raw materials to a crucible, heating to 680 to 700 DEG C first, and then cooling the crucible to 670 to 700 DEG C; pouring to a die so as to prepare a casting rod; performing hot extrusion on the casting rod on a magnesium alloy extruder so as to obtain a blank; and machining the blank by adopting a machine tool, so that the soluble alloy fracturing ball for oil and gas exploitation is obtained. The problems of incapability of self dissolution and difficulty in flowback of a steel fracturing ball are solved.

Owner:XIAN UNIV OF TECH

A kind of preparation method of the catalyst that is used for acetone heterogeneous synthesis isophorone

ActiveCN102258994APH adjustmentExtend your lifeOrganic compound preparationCarbonyl compound preparationMagnesium saltGas phase

The invention relates to a method for preparing a catalyst used in synthesizing isophorone through an acetone multiphase method. The method provided by the invention comprises the following steps: weighing and dissolving a certain quantity of magnesium salt, calcium salt, aluminum salt and transition metal salt in distilled water to prepare a mixed salt solution; dropwise adding a precipitator-alkali solution to the mixed salt solution in the stirring course; and aging, filtering, washing, drying and roasting the precipitates to finally obtain the catalyst. Compared with the prior art, the method provided by the invention has the characteristics: (1) the preparation course of the catalyst is simple; (2) the price of the raw materials of the catalyst is low; and (3) the reaction is carriedout under gas phase conditions, and the catalyst is a magnesium-calcium-aluminum composite oxide modified by the transition metal. The catalyst provided by the invention has certain acid strength andalkali strength, thereby enabling the catalyst to have higher catalytic activity and stability. In the reaction for preparing the isophorone through acetone condensation, the conversion rate of acetone is about 34%, the selectivity of the isophorone reaches more than 90%, and the one-way running time is larger than 1000 hours.

Owner:NINGBO QIANYAN NEW MATERIAL TECH

Calcium-magnesium composite board

InactiveCN1939873ASolve the return of moistureSolve the problem of blooming frostSolid waste managementGlass fiberMetasilicate

A magnesium-calcium composite board consists of magnesium oxide, magnesium chloride, calcium metasilicate powder, vegetable fibre, glass fibre, gypsum powder, phosphoric acid, organic silicon and fatty acid. The process is carried out by mixing the raw materials proportionally and obtaining the final product. It is cheap, has better board strength and water-proof and fire-proof functions and can be used for building decorative materials.

Owner:遵义汉丰装饰材料有限责任公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com