High-strength tear-resistant rubber sealing gasket and preparation method thereof

A rubber gasket and tear-resistant technology, applied in the field of gaskets and their preparation, can solve the problems of mechanical strength, tear-resistant service life and equipment use requirements, and achieve outstanding tear-resistant performance and good corrosion resistance. Excellent sealing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

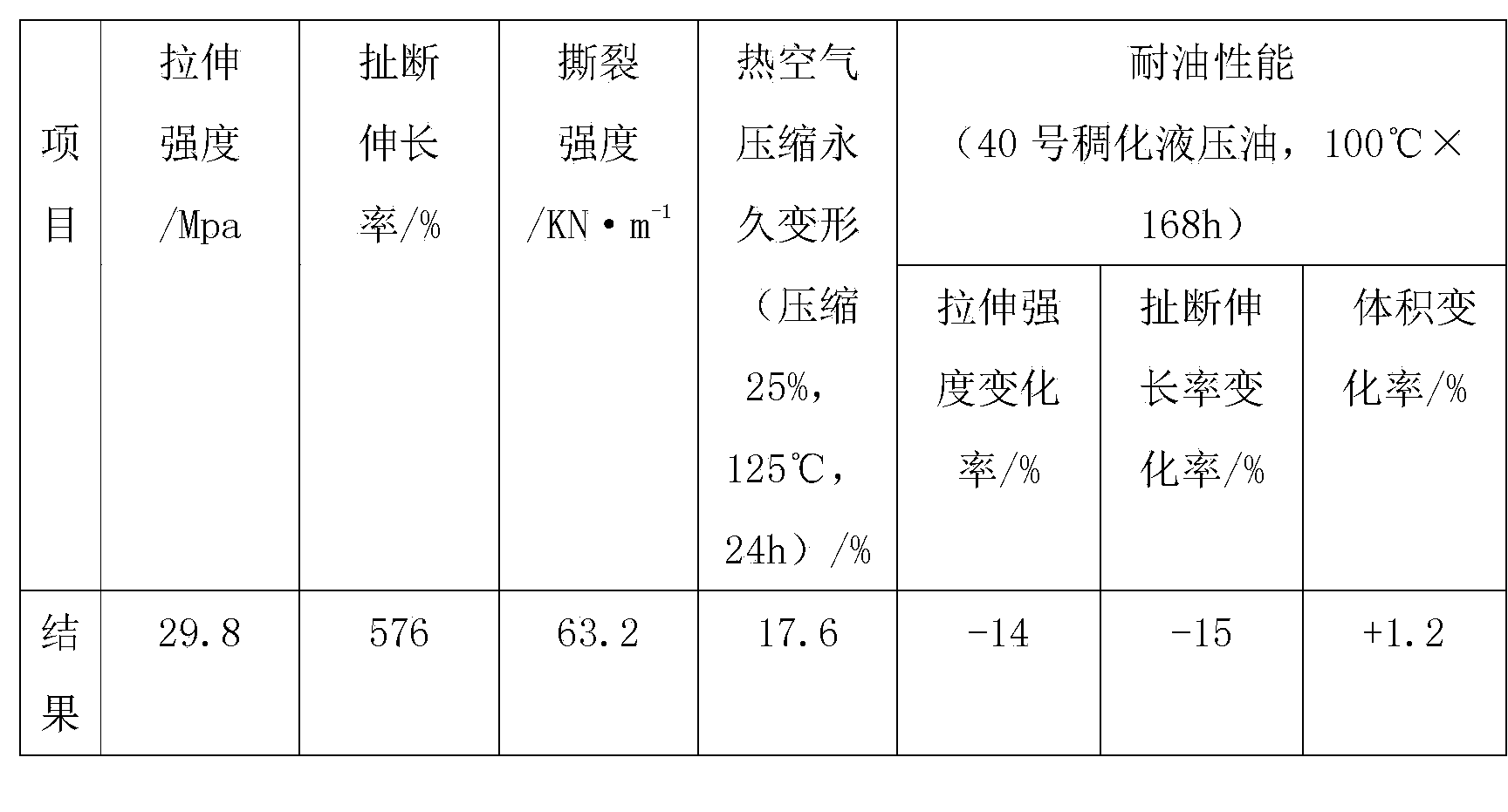

Examples

Embodiment Construction

[0014] A high-strength tear-resistant rubber gasket made of the following raw materials by weight (kg): chlorosulfonated polyethylene rubber (TS-830) 50, silicone rubber (SP-352) 25, bisphenol A polycarbonate Ester 15, cashew nut shell oil modified phenolic resin 10, hexamethylenetetramine 1.5, dicumyl peroxide 2, spray carbon black 18, modified nano ceramics 12, silicon magnesium calcium whisker 8, nano wollastonite 6. Zinc methacrylate 2, magnesium oxide 1.5, stearic acid 2, vinyl silicone oil 4, chlorinated paraffin 6, triethyl citrate 7, vulcanizing agent TRA 2, calcium stearate 1, zinc stearate 2 , accelerator TT 2, accelerator NA-22 1, anti-aging agent NBC 3, anti-aging agent RD 1.

[0015] The preparation method of described modified wollastonite is as follows:

[0016] a. Take the dried wollastonite and crush it to less than 15 μm, put it into a dispersion kettle, add deionized water three times the amount of wollastonite, and then add 2.5% sodium polyacrylate, 1.5% t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com