Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

425results about How to "Strong tear resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Laminated material without metal foil for blocking package

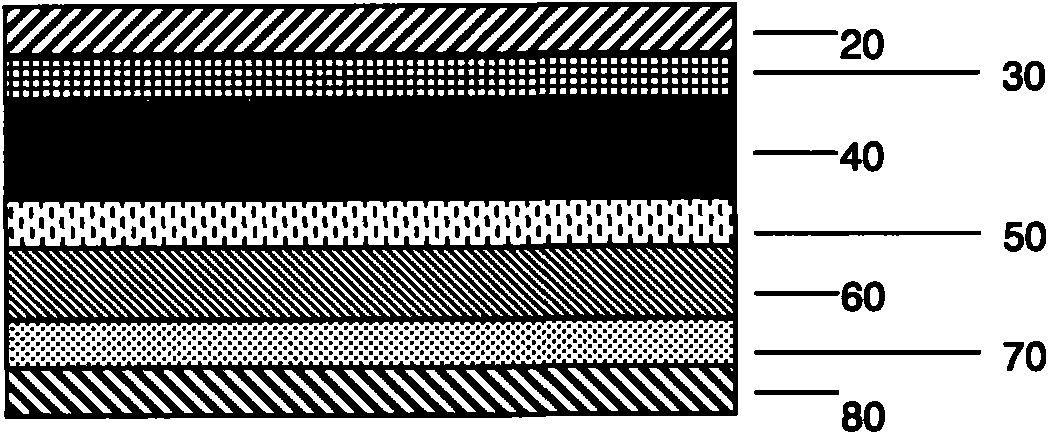

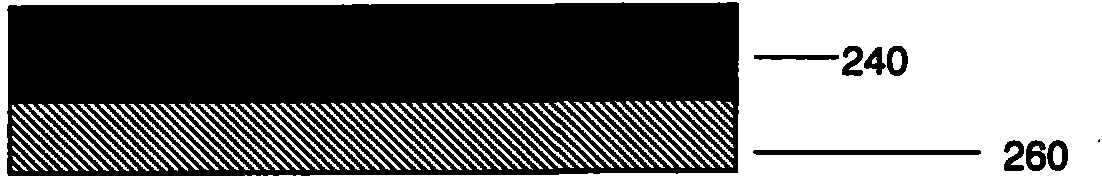

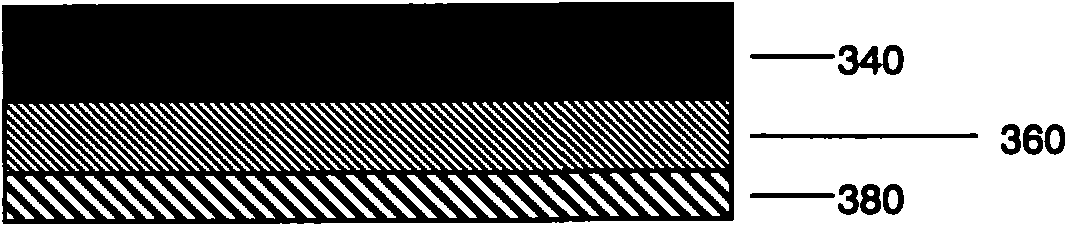

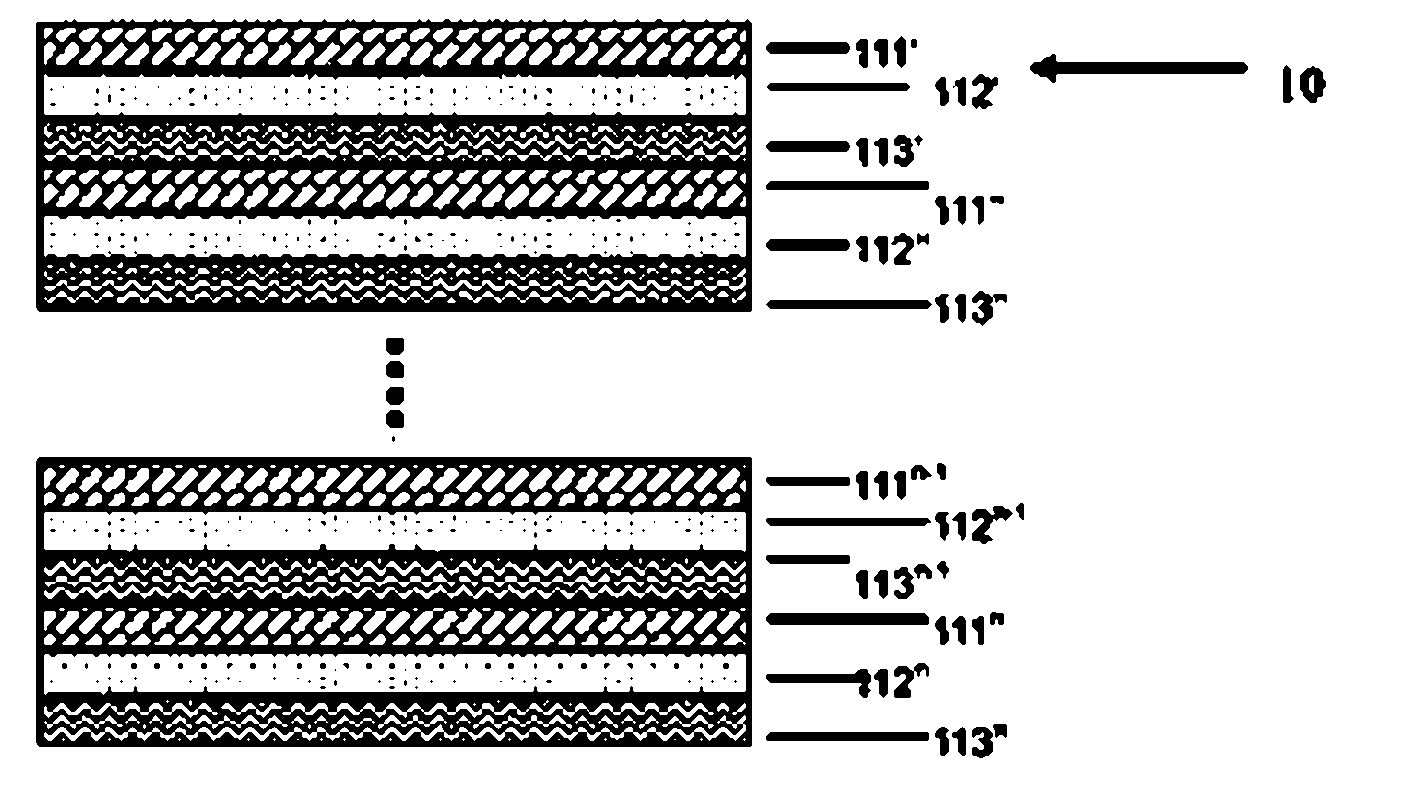

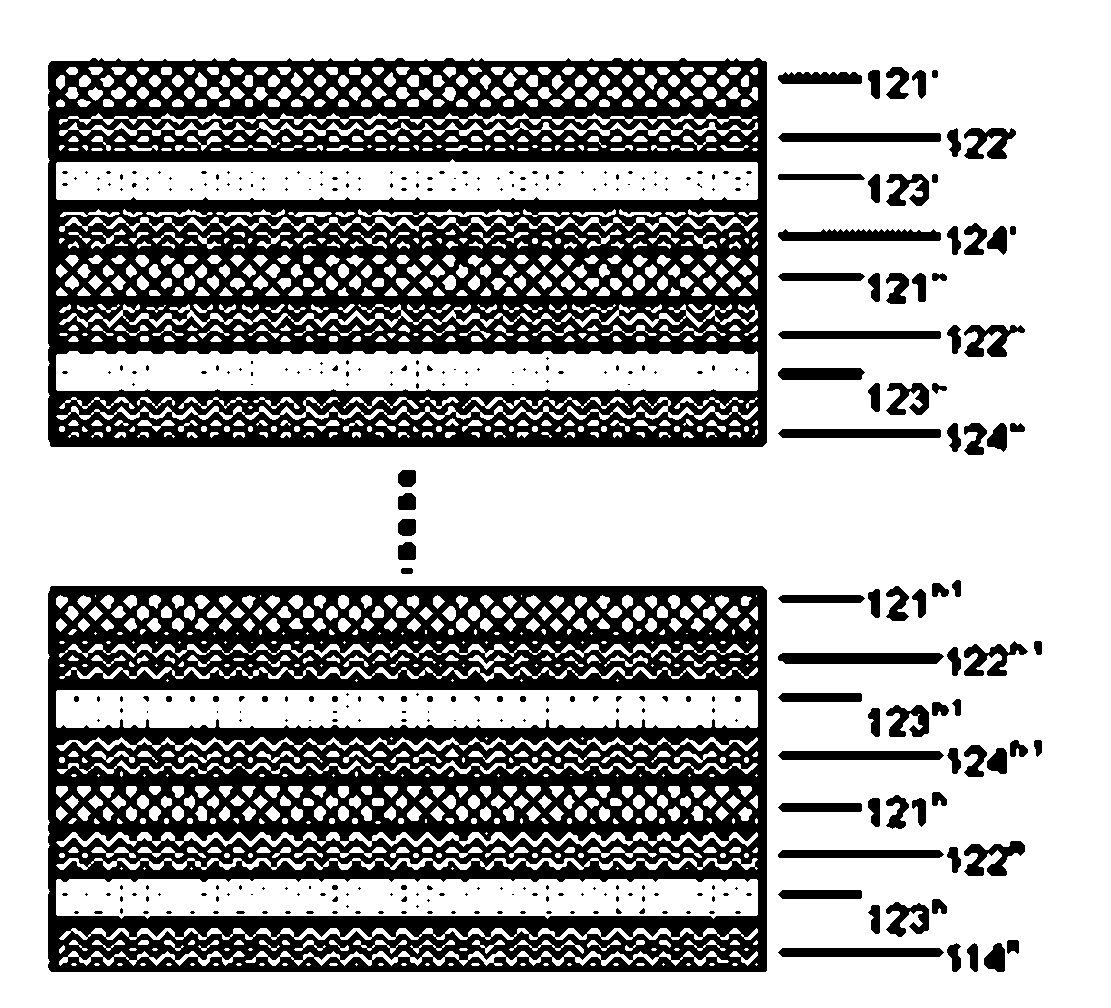

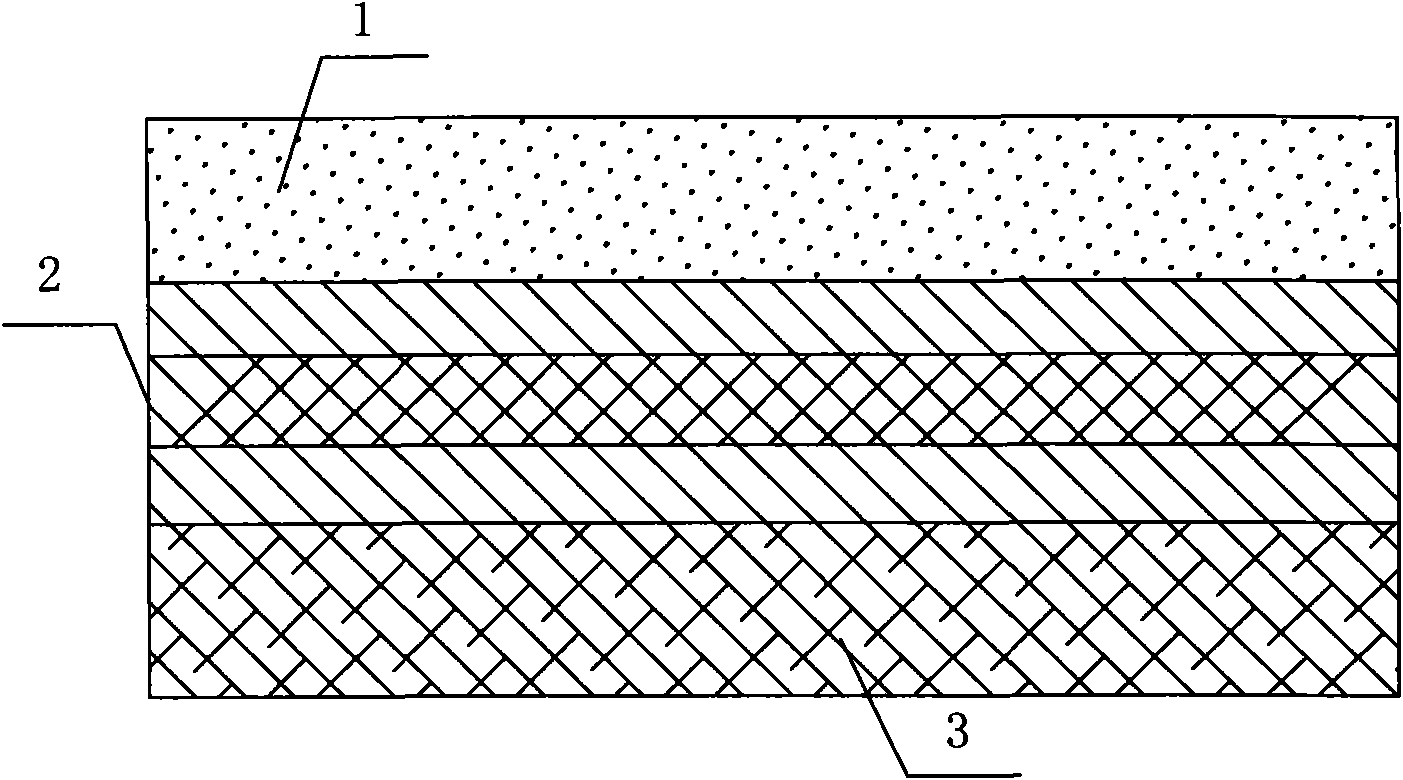

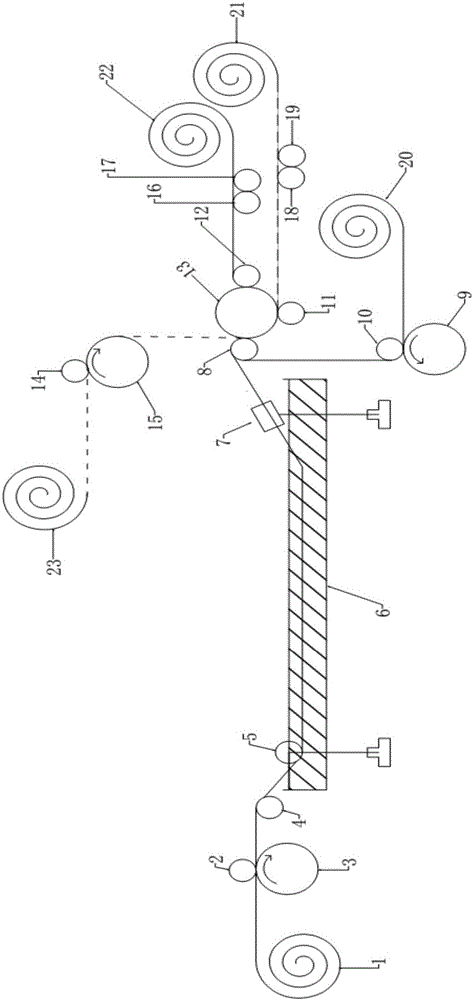

The invention discloses a laminated material without metal foil for a blocking package. The material at least comprises a substrate layer assembly and a composite blocking layer assembly, wherein the substrate layer assembly and the composite blocking layer assembly are laminated together; the substrate layer assembly has the effect of supporting; and the composite blocking layer assembly comprises at least one composite blocking layer which is prepared through a partition-laminated confluence layer multiplication and coextrusion method and comprises a plurality of repeated units. The material is characterized in that each repeated unit at least comprises three polymer constitutes, and each polymer constitute can form an individual layer or more than one individual layer; and only one of the polymer constitutes is a blocking polymer constitute which can block gas.

Owner:厦门天策材料科技有限公司

Barrier-property lapped polymer film packaging material

ActiveCN102001486AReduce dosageOne less contains at least dosageFlexible coversWrappersPolymer thin filmsEngineering

The invention discloses a barrier-property lapped polymer film packaging material comprising at least one layer-multiplied and coextruded lapped barrier compound layer. Each barrier compound layer comprises a plurality of repeating units which comprise at least two individual layers; each individual layer corresponds to one of two different polymers; at least one repeating unit of the lapped barrier compound layer at least comprises three individual layers; each of the individual layers corresponds to one of three different polymers; and at least one of the at least three polymers forms at least one barrier-property polymer part which can separate gas.

Owner:厦门天策材料科技有限公司

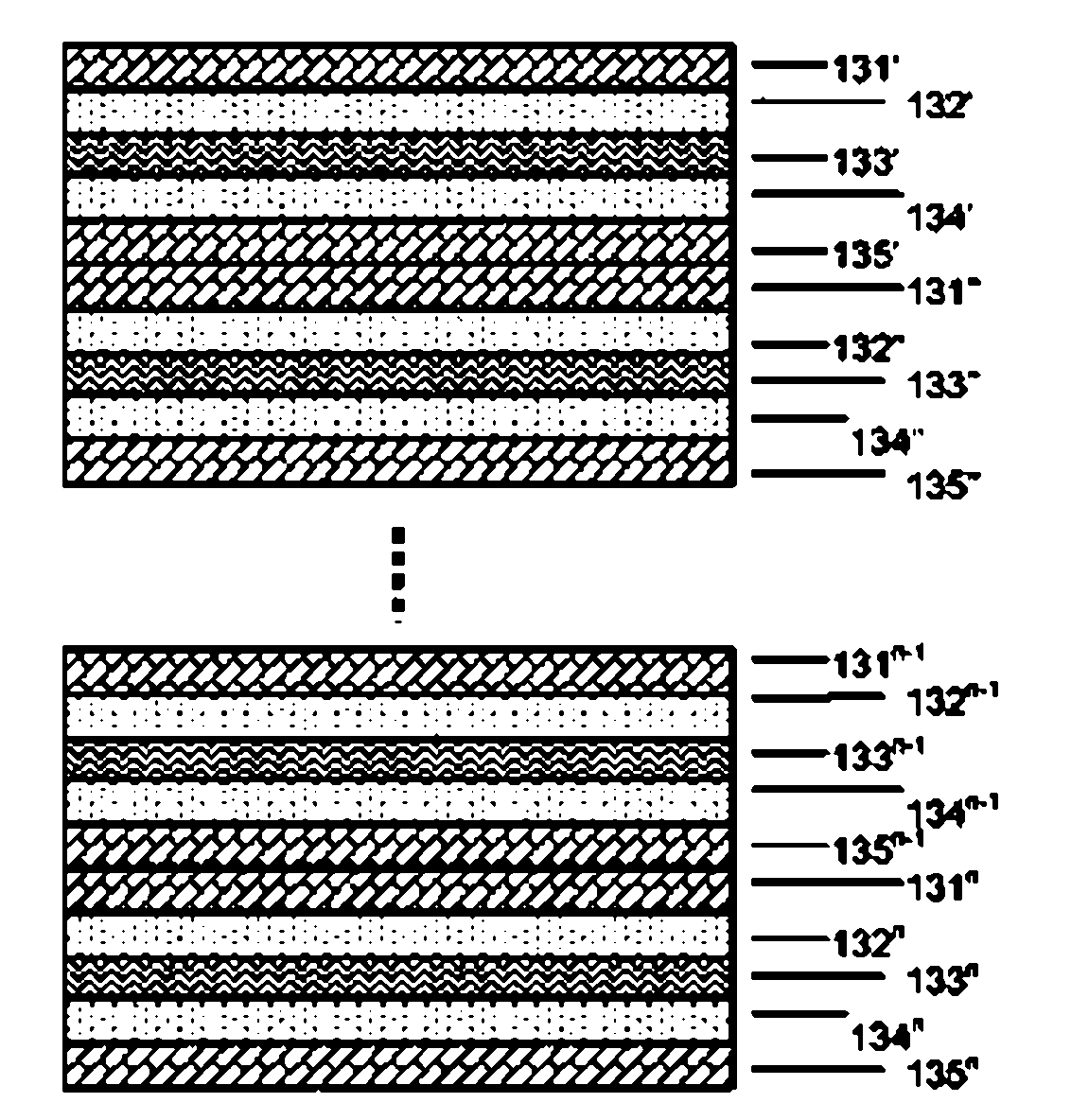

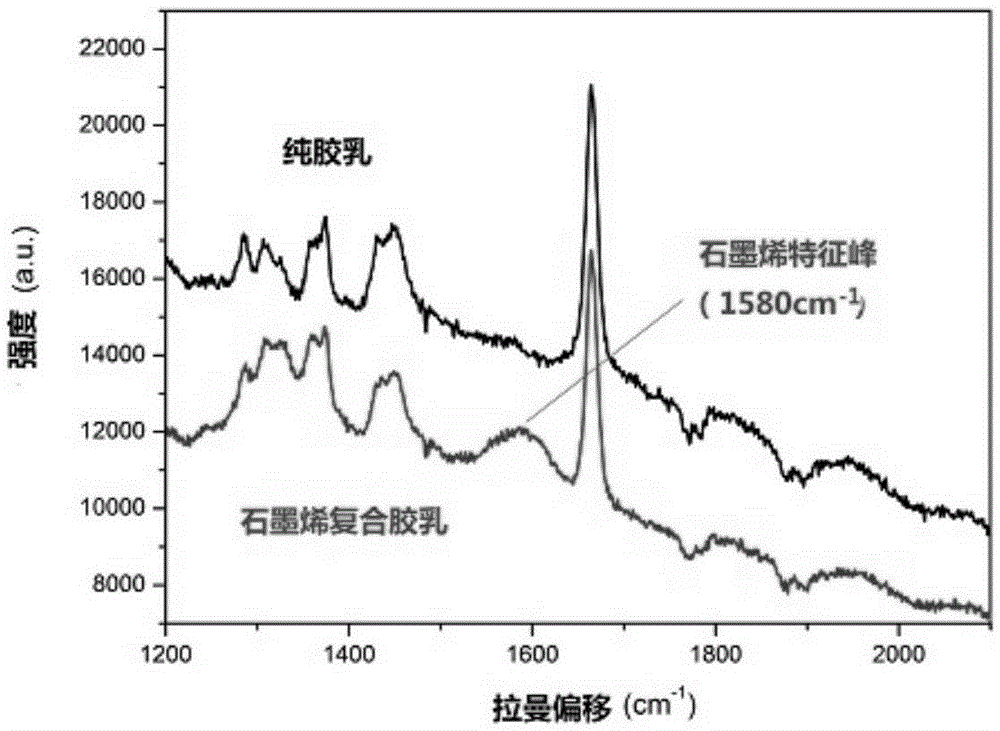

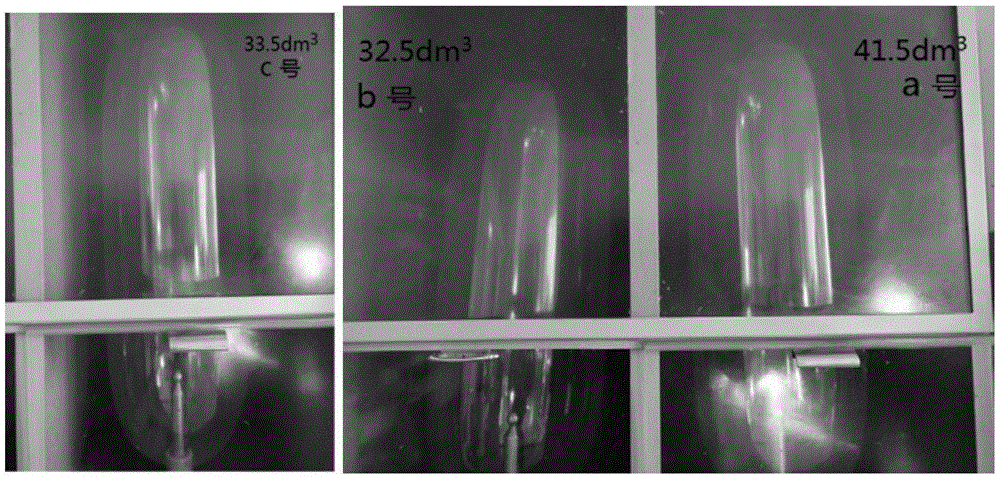

Method for preparing high-strength and high-isolation condoms from modified graphene/latex composite material

InactiveCN105237828AHigh strengthHigh barrier condomsMale contraceptivesCoatingsMedical equipmentVulcanization

The invention relates to the fields of composite materials and medical equipment, in particular to a method for preparing high-strength and high-isolation condoms by utilizing a modified graphene / latex composite material. The method comprises the following steps: preparing modified graphene into a stable dispersion liquid, then carrying out direct recombination after latex compounding and prevulcanization curing period, or vulcanization recombination is finished at the same time in the period, and finally a compound rubber emulsion is finally obtained. After the curing of the compound rubber, the condom product is prepared by adopting a mold impregnating method. Compared with existing products, the grapheme compounded condom prepared by the invention has the advantages that the permeance of small-size viruses can be effectively blocked and the performance indexes such as tear resistance, blasting volume and ultimate elongation under same thickness are obviously improved. The method disclosed by the invention has the advantages of scientific principle, obvious characteristics, non-toxicity, innocuity, stable performance, high matching degree with prior art for condom production and the like.

Owner:LIAONING LANJING TECH CO LTD

Electronic device housing and manufacturing method therefor

ActiveCN102781187AStrong tear resistanceHigh tensile strengthAntenna supports/mountingsCasings/cabinets/drawers detailsEngineeringSilica gel

The invention discloses an electronic device housing and a manufacturing method for the electronic device housing. The manufacturing method comprises the following steps: forming a metal antenna on the surface of an active plastic layer of the electronic device housing by an LDS (Laser Direct Structuring) technology; spraying a layer of bottom coating agent on the surface of the active plastic layer and the surface of the metal antenna; moulding a layer of liquid silica gel on the surface of the active plastic layer sprayed with the bottom coating agent and the surface of the metal antenna in an injection way, drying the liquid social gel to form a silica gel protective layer. According to the electronic device housing and the manufacturing method for the electronic device housing, the silica gel protective layer is moulded on the surface of the electronic device housing in an injection way by liquid silica gel, and can be suitable for various different using environments for the electronic device housing, can be manufactured to be very soft or relatively hard, and has high anti-tearing and anti-stretching strength; simultaneously, the product is diversified in colour, smudginess-resistant, chemical-resistant, and soft and smooth in hand feeling.

Owner:LOVEPAC CONVERTING BEIJING +1

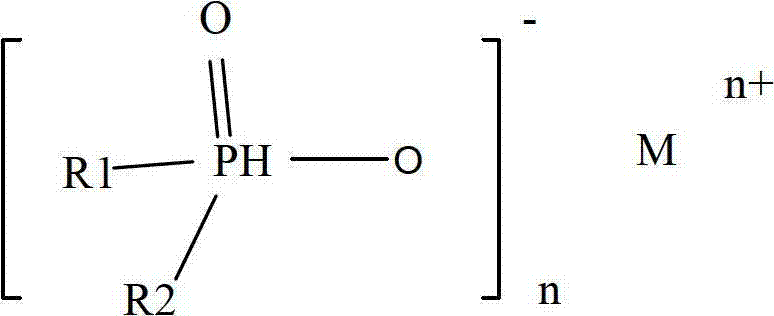

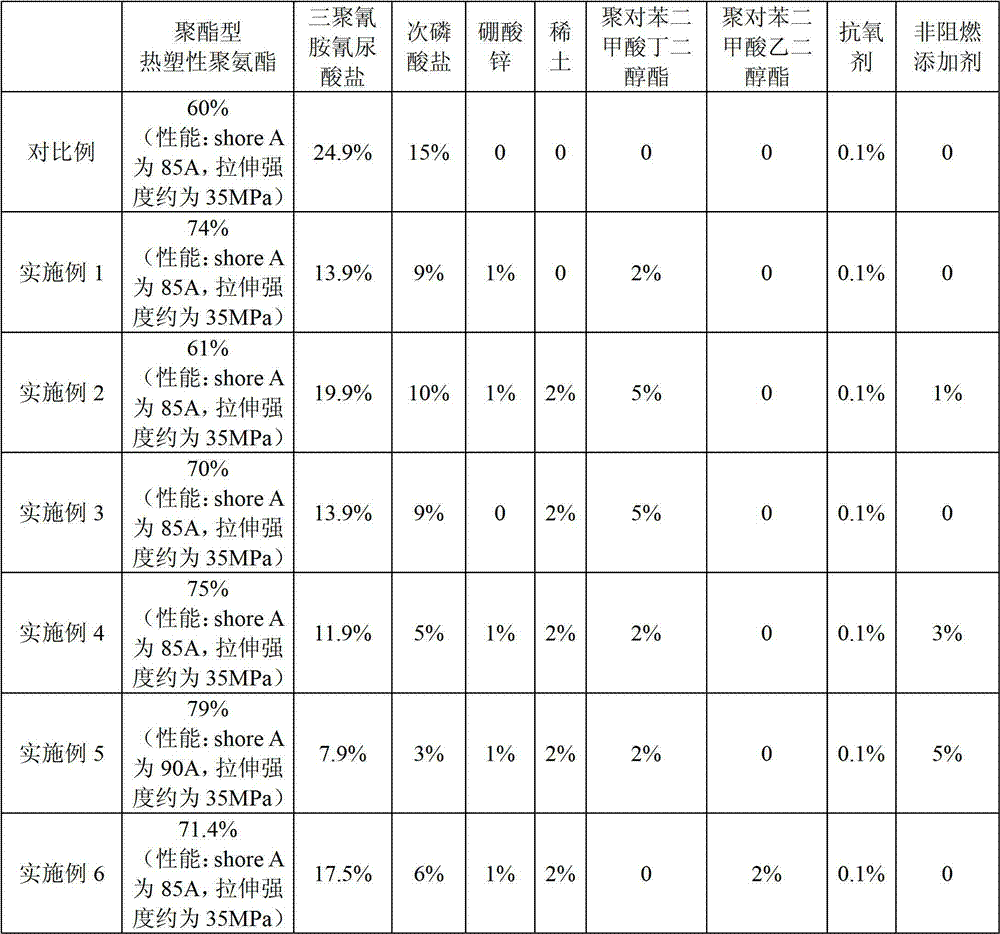

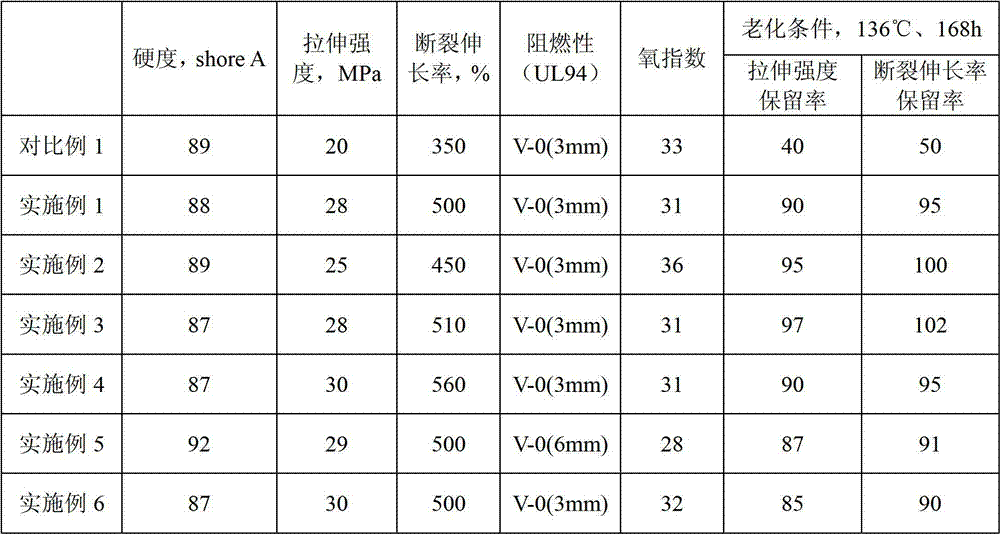

Inflaming retarding thermoplastic polyurethane elastic body

The invention discloses an inflaming retarding thermoplastic polyurethane elastic body which comprises the following components by weight percentage of: 60-80% of polyester thermoplastic polyurethane, 10-30% of halogen-free fire retardant, 1-10% of inflaming retarding synergist, 1-10% of chain extender, 0.1-2% of antioxidant and less than 5% of non-inflaming-retarding additive. According to the inflaming retarding thermoplastic polyurethane elastic body disclosed by the invention, the good inflaming retarding performance can be achieved and relatively good mechanical performances of previous high tensile strength, cracking elongation at break and the like of a TPU (Thermoplastic Polyurethane) raw material; the inflaming retarding thermoplastic polyurethane elastic body has the advantages of good wear resistance, tearing resistance, hydrolysis resistance and anti-ageing performance; and the inflaming retarding thermoplastic polyurethane elastic body does not contain halogens and heavy metal and particularly does not contain lead, cadmium, mercury, hexavalent chromium heavy metal, as well as poly-brominated diphenyl ether and poly-brominated biphenyls, so that the European Union RoH2.0 instruction requirements are met.

Owner:NINGBO QINGHU ELASTOMER SCI & TECH

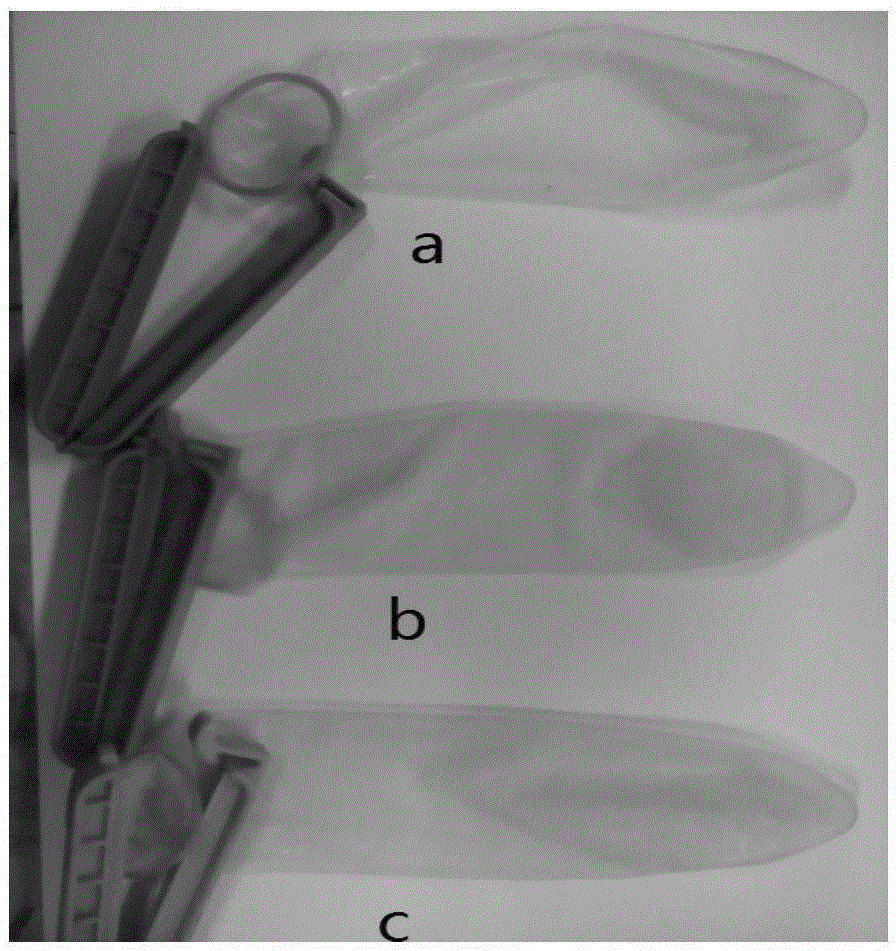

Preparing method for high-strength high-isolation condom comprising modified graphene/latex interlayer

InactiveCN105237829ATransmission probability reduction and suppressionImprove comfortCoatingsHigh isolationHigh intensity

The invention relates to the field of composite materials and medical instruments, in particular to a preparing method for a high-strength high-isolation condom comprising a modified graphene / latex interlayer. The preparing method includes the steps that stable dispersion liquid prepared by modified graphene, latex liquid and common auxiliaries are mixed evenly to prepare compound latex liquid; a three-time impregnation process is adopted for forming, conventional latex liquid is used for impregnation in first-time and third-time impregnation, and the modified graphene / latex compound latex liquid is used as impregnation liquid in second-time impregnation to obtain the condom which is provided with conventional latex films on the innermost surface and the outermost surface and a modified graphene / latex compound material film interlayer in the middle to be of a sandwich structure finally. The prepared composite grapheme condom has the characteristic of blocking penetration of small-size viruses. Tear resistance and other indexes are obviously improved, and the blasting volume and the ultimate elongation rate are obviously increased on the premise of the same size. The high-strength high-isolation condom has the advantages of being scientific in principle, poisonless, harmless, stable in performance and capable of being matched with the current condem production process easily, and characteristics are remarkable.

Owner:LIAONING LANJING TECH CO LTD

Fully-degradable compound non-woven for cleaning and manufacturing process thereof

ActiveCN106313747AStrong tear resistanceStrong oil and water absorptionLamination ancillary operationsLaminationPolymer scienceAdhesive

A fully-degradable compound nonwoven for cleaning and the manufacturing process thereof consists of a spunbond nonwoven layer and a composite fiber layer; the spunbond nonwoven layer is a degradable spunbond nonwoven layer; the composite fiber layer is a reticular fiber layer formed through wet-laying, and the spunbond nonwoven layer and composite fiber layer are spunlaced into one. Structure and manufacturing process of the invention are simple. The degradable spunbond nonwoven layer and composite fiber layer are spunlaced together; after oven drying and hot rolling, the compound is processed to a nonwoven product with preset patterns on the surface without dropping scraps, wherein the degradable spunbond nonwoven layer can make the product have stronger intensity. The adhesive, Tencel or cotton fiber in the composite fiber layer can be intermeshed during spunlace; in the meanwhile, fiber pulp will also be planted in between the two layers, thereby consolidating the two layers to a net and making the product have strong oil and water absorptivity as well as strong tear resistance.

Owner:DALIAN RUIGUANG NONWOVEN GROUP

Bacterial cellulose composite dressing

ActiveCN103480028AHigh mechanical strengthStrong tear resistanceBiochemical fibre treatmentMicroorganism based processesWound dressingAntibiotic Y

The invention relates to a bacterial cellulose composite dressing, which is prepared by soaking a composite material composed of bacterial cellulose and non-woven fabrics or woven fabrics in an antibiotics-containing water solution. The bacterial cellulose composite dressing is prepared by following steps: choosing bacterial strains capable of secreting bacterial cellulose to made into a seed mash, then evenly dropwise adding the seed mash on non-woven fabrics or woven fabrics, which have been subjected to a sterilization treatment, adding a small amount of fermentation culture medium for cultivation of 12 to 48 hours, then adding fermentation culture medium, cultivating for 3 to 6d, taking out the fermentation products, and finally subjecting the fermentation products to a purifying treatment so as to obtain the bacterial cellulose composite non-woven fabrics or woven fabrics. The preparation method has the advantages of simple technology, and convenient operation, and is capable of preparing bacterial cellulose wound dressings with various functions according to the needs.

Owner:钟春燕

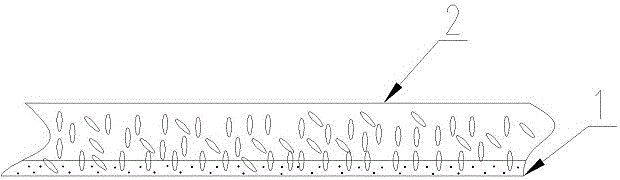

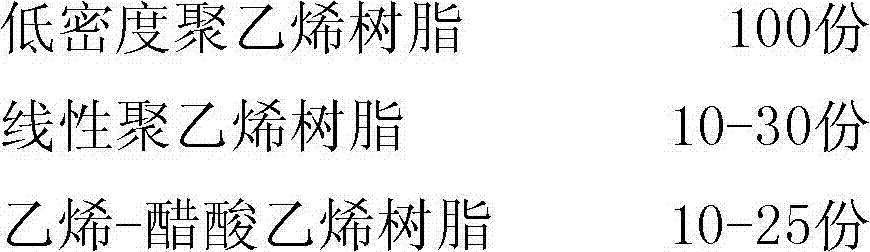

Anti-mildew modified atmosphere packaging film for fruits and vegetables and preparation method for mildew-proof modified atmosphere packaging film

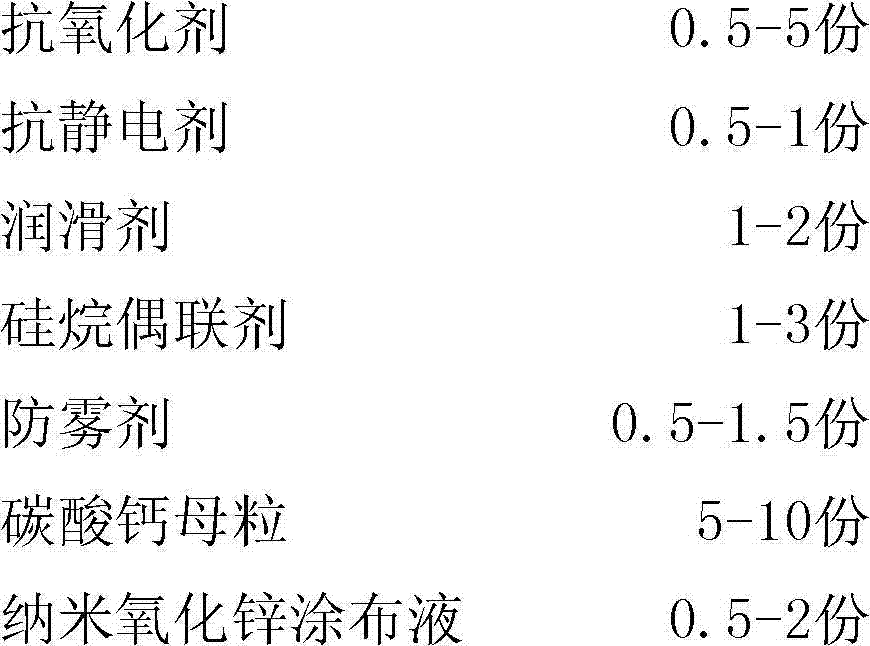

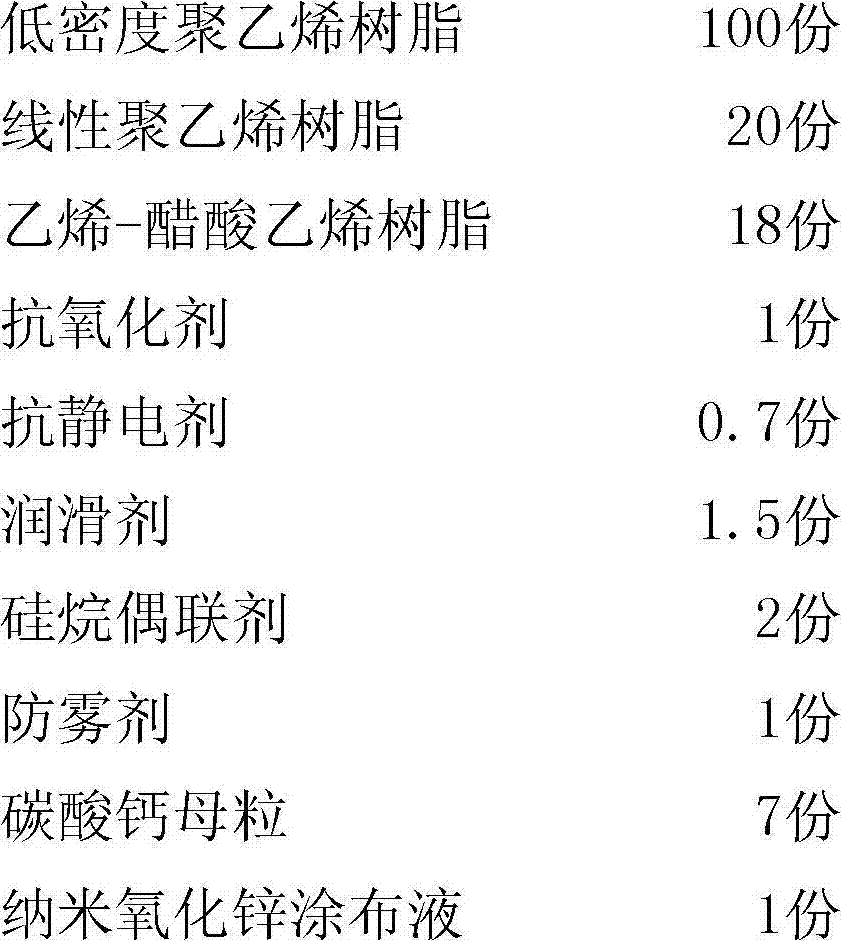

ActiveCN102886950AFixed uniformGood permeabilityFruit and vegetables preservationSynthetic resin layered productsChemistryAntioxidant

The invention discloses an anti-mildew modified atmosphere packaging film, which is prepared from the following components in parts by weight: 100 parts of low density polyethylene resin, 10 to 30 parts of linear polyethylene resin, 10 to 25 parts of ethylene-vinyl acetate resin, 0.5 to 5 parts of antioxidant, 0.5 to 1 part of antistatic agent, 1 to 2 parts of lubricant, 1 to 3 parts of silane coupling agent, 0.5 to 1.5 parts of anti-fogging agent, 5 to 10 parts of calcium carbonate master batch and 0.5 to 2 parts of nano zinc oxide coating solution. The invention also discloses a preparation method for the packaging film. The packaging film prepared by the method has an anti-oxidation function, an anti-fog function, an antibacterial function, an anti-mildew function and a fruit and vegetable respiration adjustment function, the refreshing time of fruits and vegetables can be prolonged, and the quality of the fruits and the vegetables can be improved.

Owner:TIANJIN JIEDONG FRESH PRESERVATION TECH PRODIVITY PROMOTION CENT

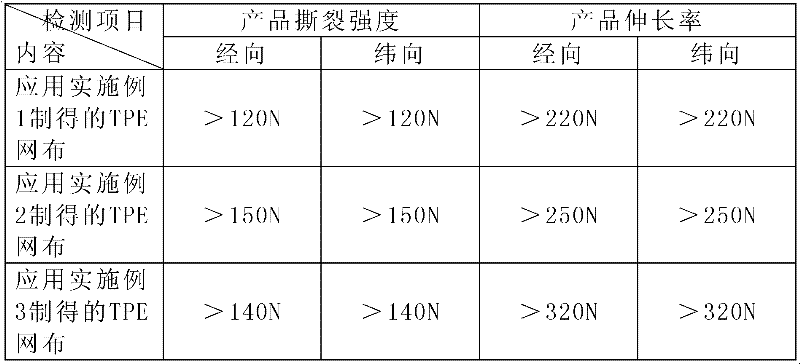

TPE (Thermoplastic Elastomer) yarns for weaving TPE mesh

ActiveCN102230248AStrong mechanical propertiesIncrease elasticityFibre typesYarnTextile technologyLinear low-density polyethylene

The invention relates to TPE (Thermoplastic Elastomer) yarns for weaving a TPE mesh, belonging to the weaving technical field. The TPE yarns are compound yarns; core bodies of the TPE yarns are terylene filament yarns, and are coated with TPE compound materials on the surfaces; and the TPE compound materials are characteirzed by comprising the following components in percentage by weight: 35-45% of TPE materials, 8-18% of HDPE (High-Density Polyethylene), 20-30% of LLDPE (Linear low-Density Polyethylene), 5-15% of PE (Polyethylene) master adhesive and 8-18% of PE adhesive. The TPE yarns have stronger mechanical performance and better environmental friendliness; and the TPE mesh produced from the TPE yarns provided by the invention have the advantages of strong tear resistance and high tensile rate.

Owner:TAIZHOU DONGHAI PLASTIC PRODS MFG

Room-temperature cured flexible epoxy adhesive and preparation method thereof

ActiveCN106281160AQuick responseImprove early strengthNon-macromolecular adhesive additivesEpoxy resin adhesivesRoom temperatureReactive diluent

The invention relates to a room-temperature cured flexible epoxy adhesive and a preparation method thereof. The room-temperature cured flexible epoxy adhesive is characterized by being prepared from a component A epoxy resin and a component B epoxy curing agent; in a utilization process, the component A epoxy resin and the component B epoxy curing agent are selected at the weight ratio of the component A epoxy resin to the component B epoxy curing agent of (1.15 to 1.20) to 1; after the component A epoxy resin and the component B epoxy curing agent are sufficiently mixed, the room-temperature cured flexible epoxy adhesive is obtained, wherein the component A epoxy resin is prepared from the following components in parts by weight: 100.5 to 115 parts of epoxy resin, 0.5 to 20 parts of a reactive diluent and 0.5 to 20 parts of an epoxy accelerant; the component B epoxy curing agent is prepared from the following components in parts by weight: 5 to 15 parts of an alicyclic amines curing agent, 28 to 100 parts of a polyether amines curing agent, 10 to 80 parts of a curing accelerant and 0.5 to 2 parts of a bonding accelerant. The adhesive prepared by the method can be cured at room temperature, is high in bonding strength and good in low-temperature flexibility, and can be used for elastic bonding.

Owner:武汉拓路特铺技术工程有限公司

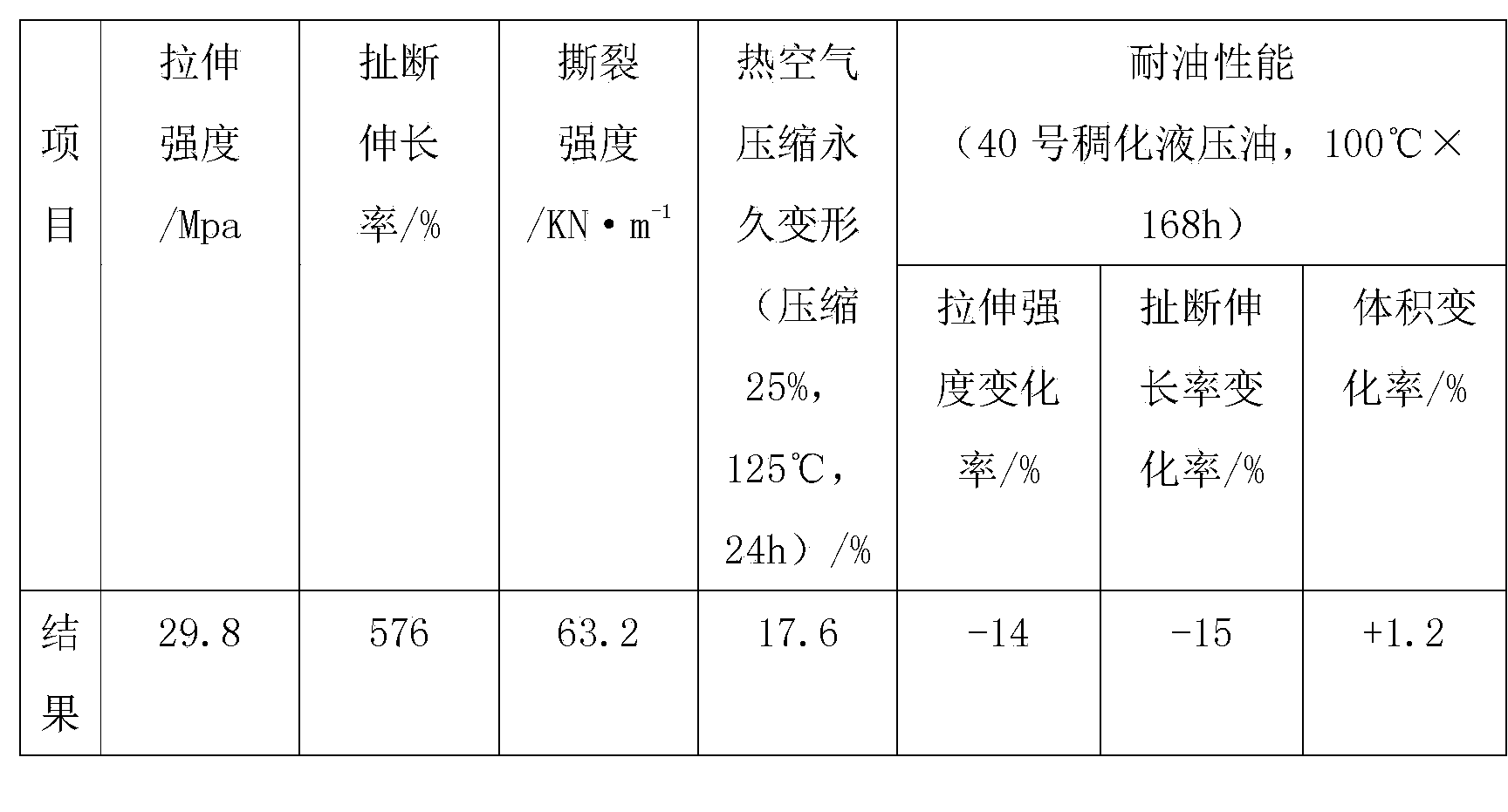

High-strength tear-resistant rubber sealing gasket and preparation method thereof

The invention discloses a high-strength tear-resistant rubber sealing gasket and a preparation method thereof. The high-strength tear-resistant rubber sealing gasket is prepared from raw materials, namely chlorosulfonated polyethylene rubber, silicon rubber, bisphenol A type polycarbonate, cashew nut shell oil modified phenolic resin, hexamethylenetetramine, dicumyl peroxide, spray carbon black, modified nano ceramics, silicon-magnesium-calcium crystal whiskers, nanometer wollastonite, zinc methacrylate, magnesium oxide, stearic acid, vinyl silicone oil, chlorinated paraffin 4-7, triethyl citrate and the like. According to the high-strength tear-resistant rubber sealing gasket and the preparation method thereof disclosed by the invention, the organic composite modification is carried out by adopting multiple nano ceramic powder, namely nanometer aluminum nitride, nanometer titanium carbide and nanometer zirconium boride, so that the compatibility of the nano ceramic powder and rubber can be enhanced; the modified nano ceramic powder, the silicon-magnesium-calcium crystal whiskers, the nanometer wollastonite and the like are filled in a modified rubber material together to prepare the sealing gasket, so that the mechanical strength, impact resistance and especially tear resistance of the sealing gasket can be remarkably improved; the heat resistance, abrasion resistance and the like of the rubber can also be improved.

Owner:WUHU YINHONG HYDRAULIC COMPONENTS

Knife-scrapping coating tent cloth and preparation process thereof

ActiveCN103317805AWaterproofAntifoulingNon-macromolecular adhesive additivesSynthetic resin layered productsUltravioletPolyvinyl chloride

The invention discloses knife-scrapping coating tent cloth. The knife-scrapping coating tent cloth sequentially comprises a basic cloth layer, an adhesion layer, a shading layer and a surface layer from inside to outside, wherein the adhesion layer is prepared from polyvinyl chloride paste resins, plasticizers, stabilizers, inorganic flame retardant and mould inhibitors; the shading layer is prepared from polyvinyl chloride of which the k value is 80, plasticizers, stabilizers, inorganic flame retardant, carbon black pigment color pastes, ultraviolet absorbent and mould inhibitors; the surface layer is prepared from polyvinyl chloride of which the k value is 85, plasticizers, acrylic ester, inorganic flame retardant and methylbenzene. The knife-scrapping coating tent cloth has the excellent performances of waterproofing, antifouling, inflame retardance, anti-aging and the like, is high in tearing resistant performance and extremely high in peeling strength, and has high self-cleaning and excellent uvioresistant functions. The knife-scrapping coating tent cloth is high in product performance and long in service life, and the requirement of clients is met.

Owner:GUANGDONG UPAL DISPLAY TECH CO LTD

PVC wrapping film

The invention discloses a PVC wrapping film which comprises the following raw materials in parts by weight: 80-120 parts of PVC resin, 10-20 parts of a plasticizer, 4-6 parts of butadiene-acrylonitrile rubber P83 powder, 1.5-2.5 parts of oleamide, 4-6 parts of a tribasic and dibasic heat stabilizer, 2-3 parts of CPE, 1-1.5 parts of ACR and 0.5-1.5 parts of stearic acid. The PVC wrapping film has the beneficial effects that (1) the film has high flexibility, damage difficulty, high bursting force resistance, impact resistance, tear resistance and high tension and can replace case packing; (2) a shrinkage ratio is large, articles can be tightly coated after thermal shrinkage, and if the film is made into a through bag of which two ends are open to be subjected to thermal shrinkage, the articles can be lifted at the two opening ends, the weight of 15KG can be borne, and the articles are convenient to carry; (3) the transparency is excellent, the light transmittance is 80 percent, products can be displayed and can be promoted invisibly, and a delivery error during the cargo movement link is reduced; (4) the film is moisture-proof, waterproof and dustproof, a packaging effect can be achieved, attractive appearance of the products can be realized, and the products are protected; (5) the PVC wrapping film is non-toxic, tasteless and pollution-free and belongs to an environment-friendly packaging material.

Owner:郭良来

Composite sound-proof formed foaming automobile carpet and preparation method thereof

ActiveCN101574938AStrong composite fastnessGood formabilityVehicle arrangementsSynthetic resin layered productsPolyesterFiber

The invention discloses a composite sound-proof formed foaming automobile carpet and a preparation method thereof. The carpet is made of three layers of materials, namely a fabric layer, a middle multi-layer co-extrusion film layer and a bottom material layer, wherein the fabric layer is made of polyester fiber; the middle multi-layer co-extrusion film layer is made of PE / PE / AD / NYLON / AD / PE / PE multi-layer co-extrusion films; and the bottom material layer is made of polyester fiber. The sound-proof formed foaming automobile carpet provided by the invention has good sound insulation effect, can effectively prevent PU foaming breakdown, and has no toxic odor such as formaldehyde and the like and no penetrating odor; the fabric of the carpet has elegant color and the loop appearance can be adjusted; and the composite sound-proof formed foaming automobile carpet is an environment-friendly carpet with high sound insulation performance. The method for preparing the composite sound-proof formed foaming automobile carpet provided by the invention has simple process, high efficiency, strong operability, high qualification rate of finished products, and can be suitable for mass production.

Owner:江苏中联地毯有限公司

Compatible blend, its preparation and use

The present invention discloses a kind of compatible mixture and it's preparing method and application. Thermosplasticity Polyurethane (TPU) is obtained from reaction of macromolecule glycol, diethylene glycol isocyanogens and short chain glycol. It has soft and hard chain segment, turning out with excellent flexibility and thermoplastic, and has two kinds of vitrification transforming temperature respectively corresponding to hard and soft phase, but it has a high price. The flexibility and wearable performance of copolymer of octane-ethene (POE) is rather bad, and the price is low. The invention creatively mixes both the two kinds of elastomer materials to produce new-style thermosplasticity elastomer, and to obtain new-style material with advantages of two kinds of materials. The compatible mixture of the invention has such advantages as hard, wearable, anticorrosive, anti-aging, low pollution, good processing performance and good using performance.

Owner:SUN YAT SEN UNIV

Degradable non-woven fabric glue dipping composite preparation technology and materials thereof

InactiveCN105015140AExcellent tear resistanceImprove barrier effectLamination ancillary operationsSynthetic resin layered productsWoven fabricColloidal Solution

The invention discloses a production technology of a composite material prepared from degradable PVA non-woven fabric. According to the production technology, the PVA non-woven fabric and a PVA colloidal solution serve as raw materials. At least one face of the PVA non-woven fabric is soaked into the PVA colloidal solution, and the mass fraction of PVA in the colloidal solution is controlled to be 10-30%. When the non-woven fabric enters and passes a metal disk box at a certain speed, one side or two sides of the PVA non-woven fabric can be dipped with colloidal sol in the metal disk box, when the PVA non-woven fabric moves to a scraper, the redundant PVA colloidal solution is scraped away through the scraper, and the PVA non-woven fabric dipped face and the PVA non-woven fabric are composited through grinding, drying and cooling operation. The prepared composite material has very good obstructing performance on liquid and solid and good permeability to gas and is resistant to abrasion and tearing. The composite material can serve as raw materials of disposable medical treatment and public health protective articles.

Owner:青岛天和清原科技有限公司

Self-supporting bag and composite film thereof

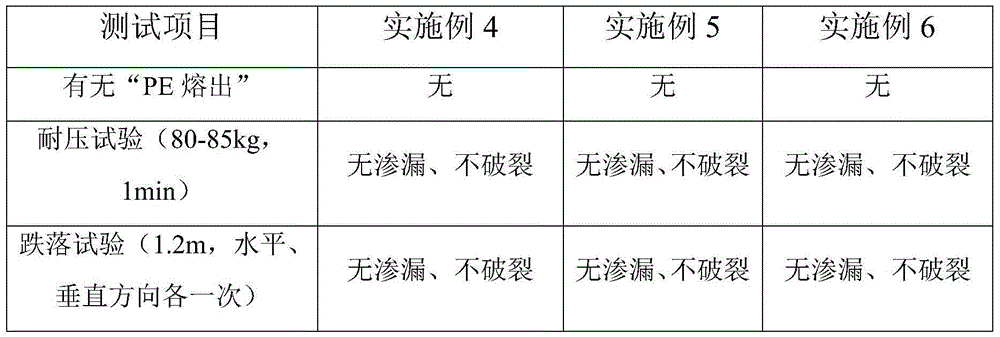

ActiveCN104924712AGood heat sealingGuaranteed leak-proof effectSynthetic resin layered productsLaminationLow-density polyethyleneLinear low-density polyethylene

The invention discloses a polyethylene film. The polyethylene film comprises a composite layer, a middle layer and a heat sealing layer which are sequentially overlapped. The composite layer comprises 60-70wt% of metallocene polyethylene and 30-40wt% of low-density polyethylene; the middle layer comprises 30-35wt% of high-density polyethylene, 30-35wt% of linear low-density polyethylene and 30-35wt% of low-density polyethylene; the heat sealing layer comprises 33-35% of low-density polyethylene, 63-65% of reinforcing polyethylene resin, 0.5-0.8wt% of slipping agent and 1.3-2.0wt% of anti-blocking agent. A melting point of the composite layer is higher than that of the middle layer, and the melting point of the middle layer is higher than that of the heat sealing layer. The invention further provides a composite film and a self-supporting bag which are prepared through the polyethylene film. By the adoption of the PE film, PE melting of the heat sealing portion can be effectively avoided, the heat sealing performance of the PE film is greatly improved, and the polyethylene film has excellent adaptation, pressure resistance and falling resistance and meets the requirement of actual production.

Owner:河北永新包装有限公司

Aroma increase fish luring type fish net

InactiveCN103757734AImprove tensile propertiesStrong tear resistanceMonocomponent polyolefin artificial filamentArtifical filament manufactureSodium PyrithionePolyamide

The present invention discloses an aroma increase fish luring type fish net, which comprises the following raw materials by weight: 91-100 parts of ultrahigh molecular weight polyethylene, 6-7 parts of polyamide wax micro-powder, 1-2 parts of epoxydized linseed oil, 1-2 parts of zinc pyrithione, 2-3 parts of mannitol, 0.1-0.2 part of sodium polyacrylate, and 3-4 parts of a modified plasticizer. The aroma increase fish luring type fish net has a certain aroma so as to increase the fishing amount to a certain extent and increase the fishing income, and has characteristics of strong tensile resistance, strong tear resistance, a certain weather resistance and long service life.

Owner:CHAOHU ASIANEPS FISHING NET MFG

Medical gloves and manufacturing method thereof

The invention relates to the technical field of hand protection articles, in particular to medical gloves and a manufacturing method thereof. The gloves are made from the following raw materials in percentage by mass: 36 percent of EVA, 20 percent of LLDPE, 43 percent of LDPE and 1 percent of an opening agent. The gloves contain no protein, thereby effectively avoiding skin allergy caused by powder; the surfaces of the gloves can be provided with textures, thereby preventing an implement from falling off when the gloves are used; the gloves can be worn on the left and right hands randomly; thegloves are flexibly, conveniently and disposably used and can effectively prevent various infections; the gloves have a high tensile strength, thereby avoiding being torn when worn; the gloves have high shock resistance and tear resistance; the inner surfaces of the gloves are smooth so that the gloves are conveniently worn; and the gloves have the advantages of low production cost, good performances, accessibility and relatively great market competitiveness. The gloves are applicable to medical treatment, medicament, health protection, hairdressing, beautifying and food processing, and otheroperation industries.

Owner:卢锦辉

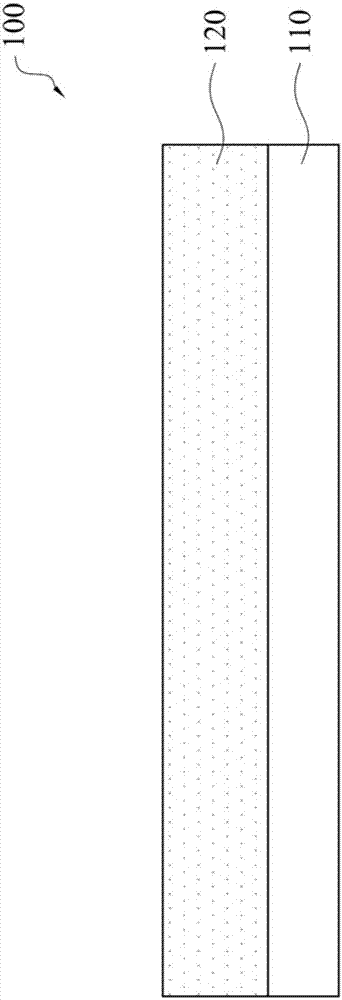

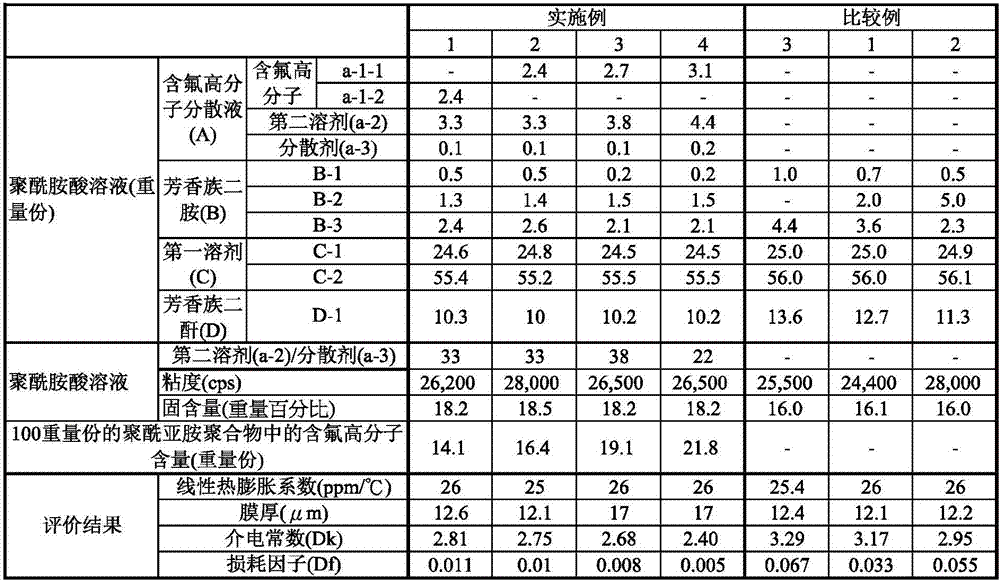

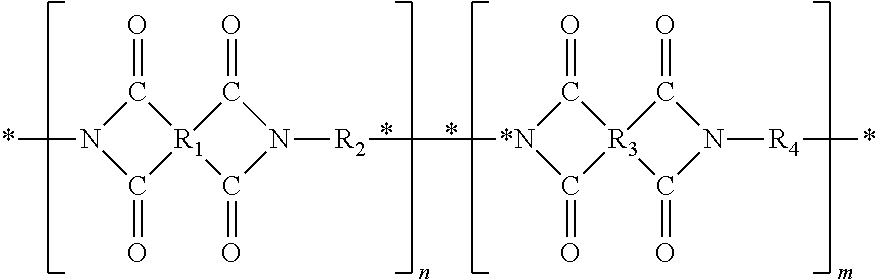

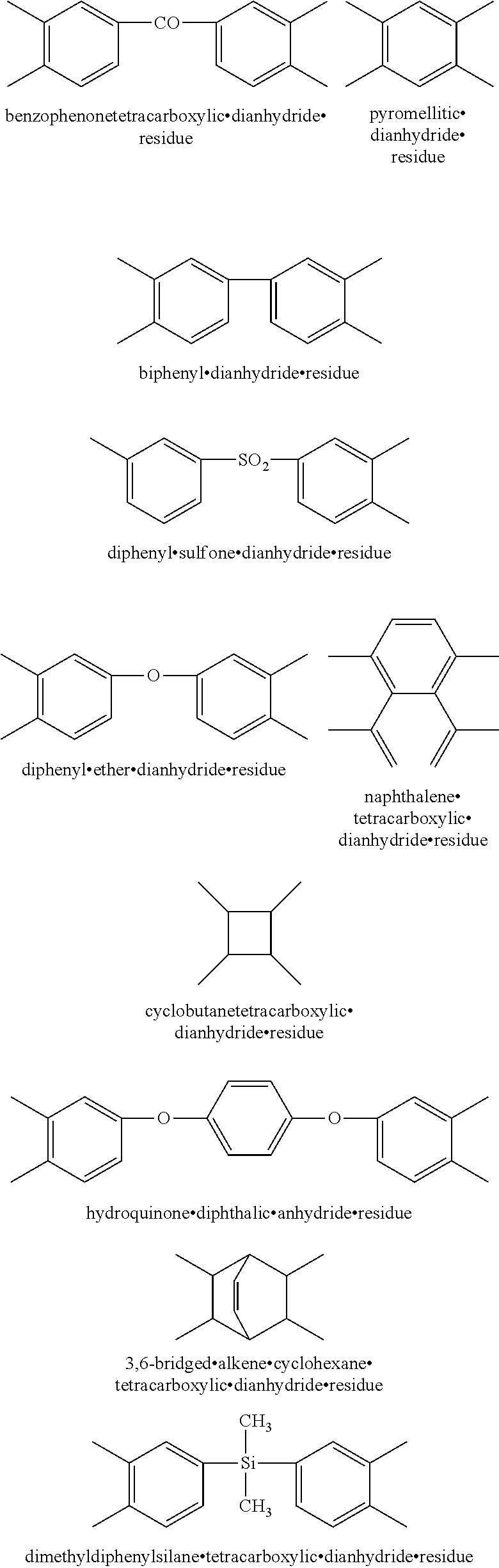

Manufacturing method of polyimide with low dielectric coefficient, polyimide film and application thereof

ActiveCN107286650AStrong tear resistanceImprove bending resistanceMetal layered productsPolyimide membraneChemistry

The invention provides a method, which comprises the following steps of providing fluorine-containing high molecular dispersion liquid (A) and aromatic diamine (B) dissolved in a first solvent (C), wherein the fluorine-containing high molecular dispersion liquid (A) contains fluorine-containing high molecular polymers (a-1), a second solvent (a-2) and dispersing agents (a-3); mixing the fluorine-containing high molecular dispersion liquid (A) and aromatic diamine (B) to form a first mixture; adding aromatic tetracarboxylic dianhydride (D) into the first mixture so as to form a polyamide acid solution; performing the solvent removal step and the heating step on the polyamide acid solution so as to prepare the polyimide. The prepared polyimide film has a low dielectric coefficient and a low loss factor.

Owner:THINFLEX CORP

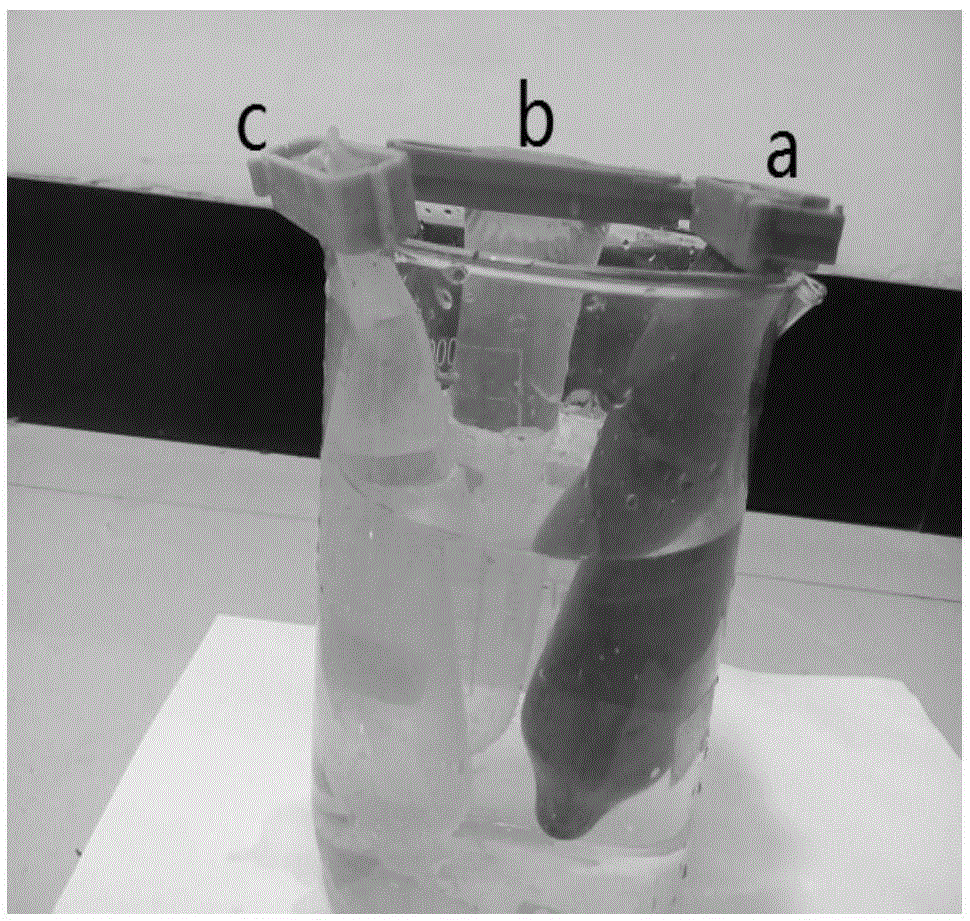

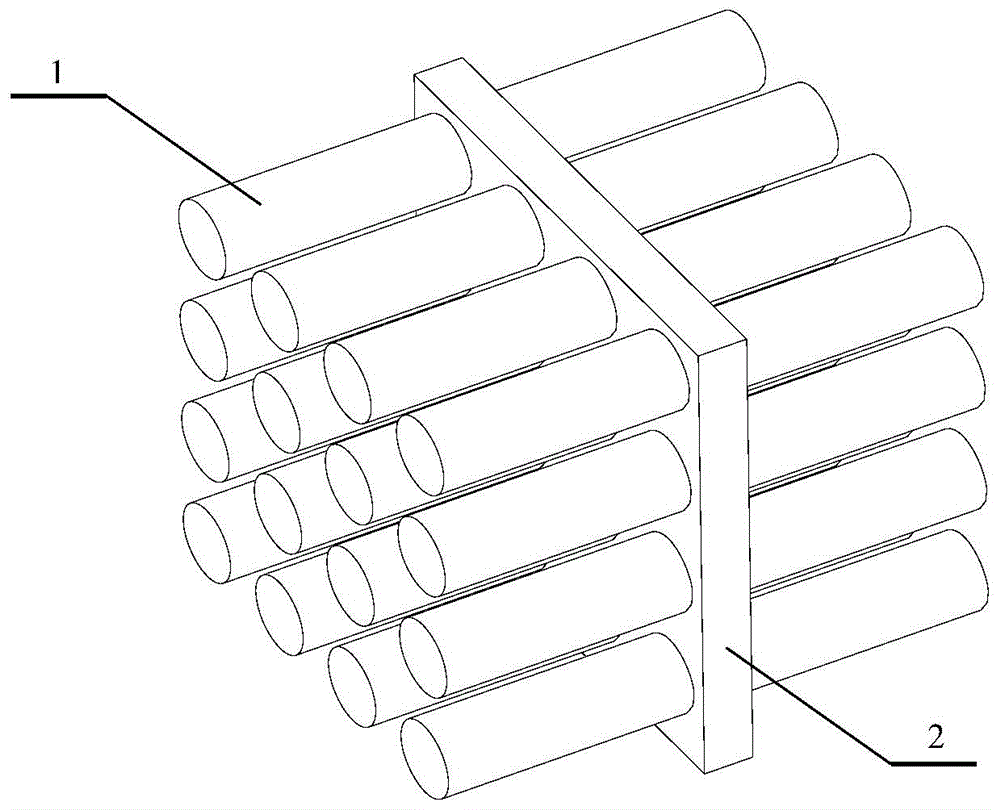

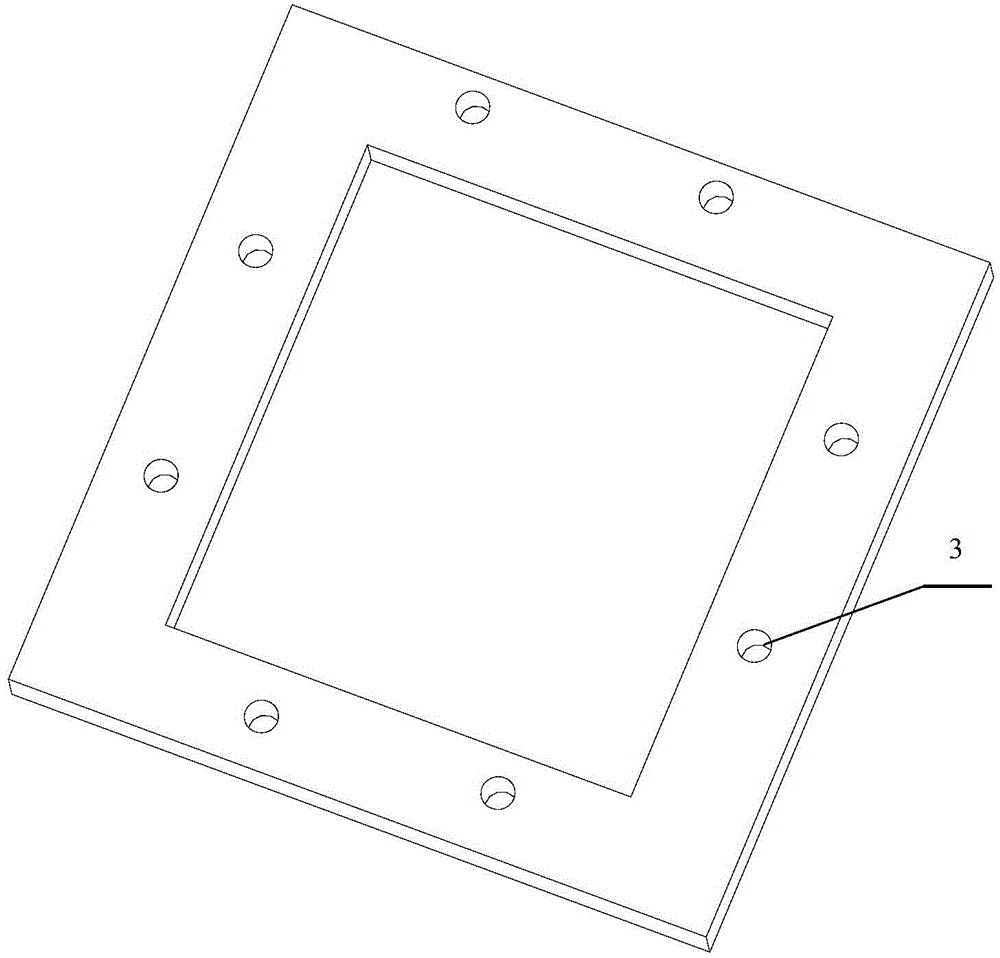

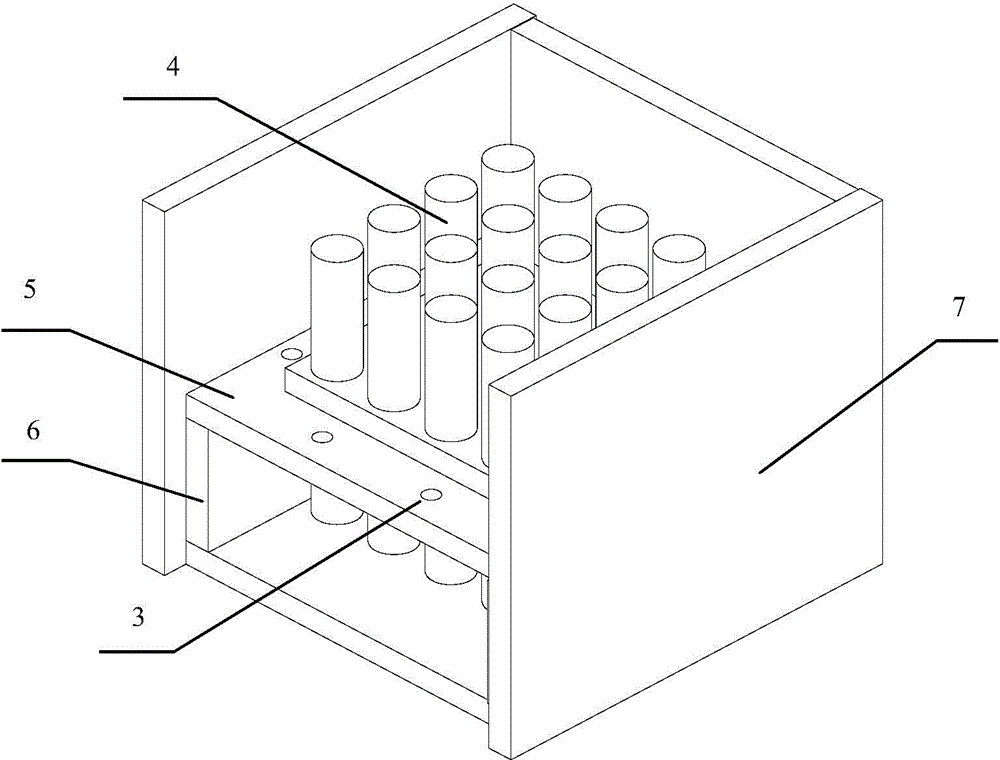

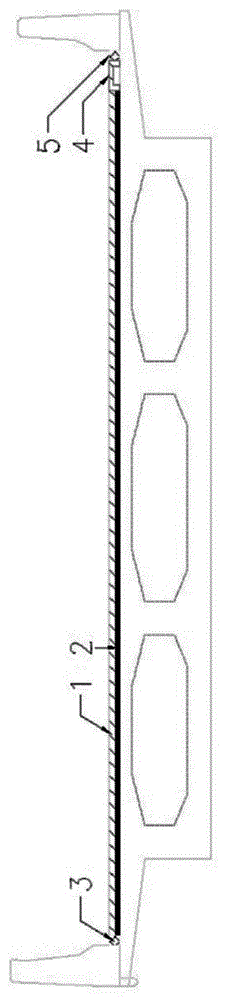

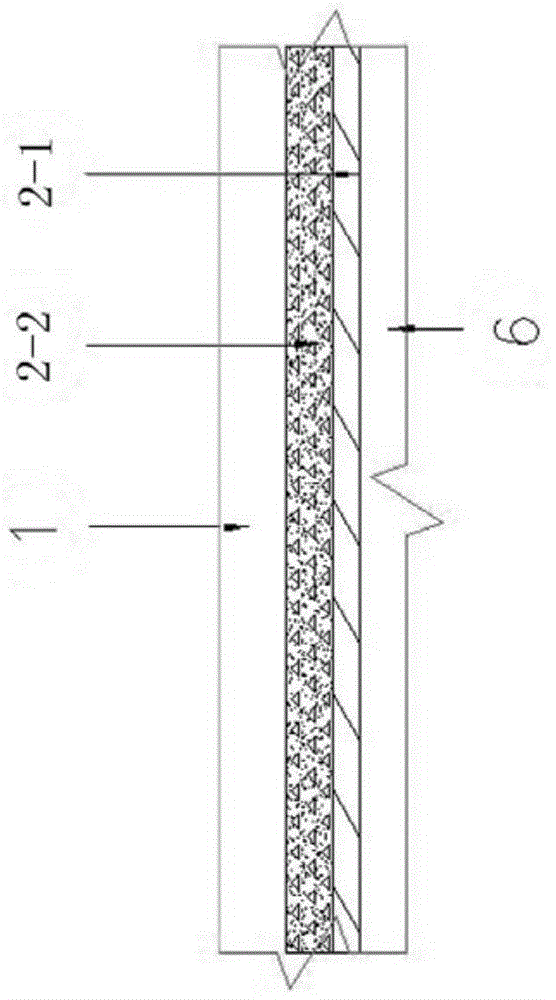

Manufacturing device and method of resin transparent concrete block

The invention discloses a manufacturing device and a method of a resin transparent concrete block, and belongs to the technical field of novel concrete materials. The device used by the method is characterized by comprising a light guide body prototype part, a mold separation piece, cushion plates and a surrounding mold, wherein the light guide body prototype part comprises connecting parts acting a connecting effect, and multiple light guide branches; all the light guide branches can be connected as a whole due to the existence of the connecting parts thereby facilitating demoulding of a silicone mould and facilitating concreting; the mold separation piece is a middle-hollowed rectangular sheet, so that the mold can be naturally divided into two parts of a top mold and a bottom mold, and contact surfaces of the top mold and the bottom mold are smooth and compact in connection; and the cushion plates are two wood plates with the same size to raise the mold separation piece to a needed height. The device can conveniently and quickly apply a mold turning method to manufacture the silicone mold so as to produce resin light guide bodies in batches, so that the production efficiency of resin transparent concrete is improved.

Owner:DALIAN UNIV OF TECH

Thermal spray polymer modified asphalt waterproof adhesive layer paving structure of cement concrete bridge surface and construction method

ActiveCN104131512AImprove shear resistanceImprove high temperature shear resistanceBridge structural detailsBridge erection/assemblyPolymer modifiedCrack resistance

The invention relates to a thermal spray polymer modified asphalt waterproof adhesive layer paving structure of a cement concrete bridge surface and a construction method. The structure is characterized in that a waterproof adhesive system is arranged on a concrete bridge panel, and an asphalt concrete bridge surface paving layer is also paved on the waterproof adhesive system, wherein the waterproof system consists of a waterproof adhesive layer, an asphalt water sealing band, an antiseptic asphalt layer and a prefabricated drainage groove. The paving layer for paving the asphalt concrete bridge surface consists of a lower paving layer of modified asphalt building mastic macadam SMA-16 and an upper paving layer of modified asphalt building mastic macadam SMA-13. The construction method comprises the following steps: treating the bridge panel, spraying the waterproof adhesive layer, spreading an antisticking crushed stone layer, grinding the waterproof adhesive layer, sticking the asphalt water sealing band, painting the antiseptic asphalt layer and mounting the prefabricated drainage groove. The paving structure disclosed by the invention has very high high-temperature deformation resistance, antifatigue, aging resistance, water damage resistance and low temperature cracking resistance capacity, and has favourable construction workability, so that the structure has a higher industry use value.

Owner:CCCC THIRD HIGHWAY ENG

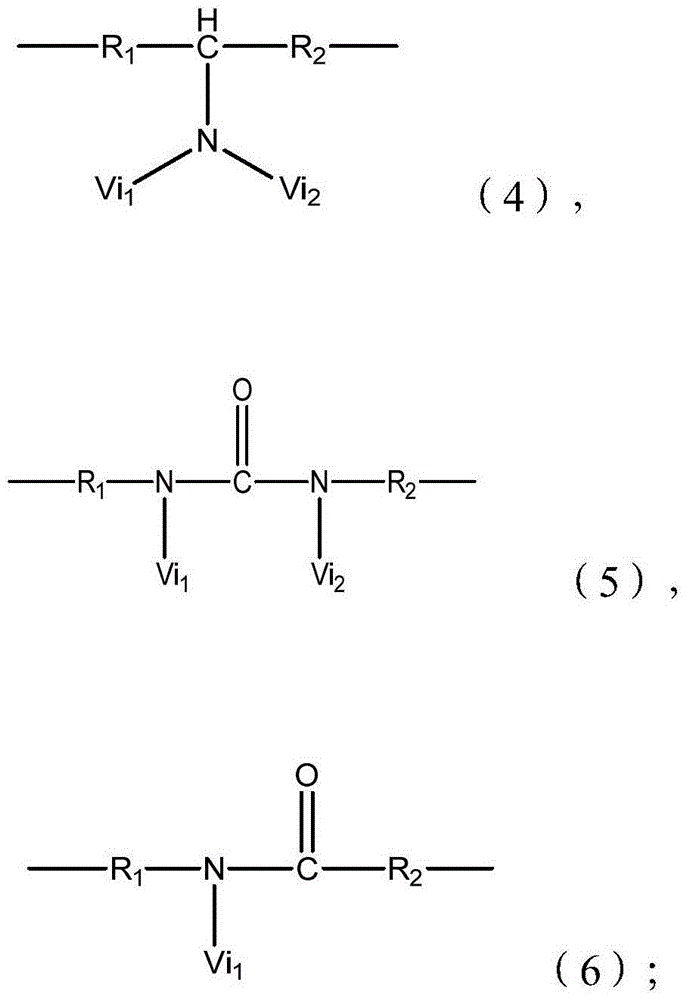

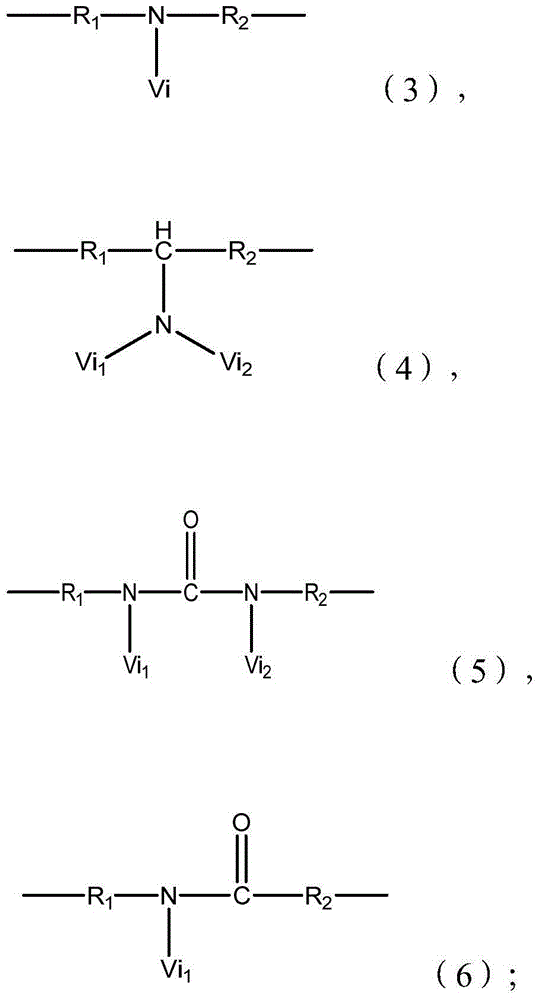

Application of polyurethane catalyst in synthesis of flexible polyurethane foamed plastic

ActiveCN104558469ASmall indentation hardnessGood physical propertiesThermal insulationCatalytic effect

A polyurethane catalyst comprises a sodium compound which is 1-60 wt% of the polyurethane catalyst, and a tertiary amine and / or pyridine compound. The sodium compound and the tertiary amine and / or pyridine compound achieve the synergistic effect; during the catalysis of the polymerization of isocyanate and polyalcohol, the speed of the polymerization reaction is increased; the prepared polyurethane material has excellent physical properties, does not contain any heavy metal element at all, has no volatile organic compound ingredient, is an environment-friendly low-odor catalyst, reduces the catalyst harm while achieving the catalytic effect of a non-environment-friendly catalyst in the prior art, and can be used for preparing a high-resilience polyurethane flexible sponge, a low-resilience polyurethane flexible sponge and other polyurethane flexible sponges; the obtained polyurethane flexible sponge / flexible polyurethane foamed plastic is light in weight, thermal-insulating, sound-absorbing, shockproof, and corrosion-resistant, and can be used as a filtering material, a sound insulation material, a shockproof material, a decoration material, a packaging material, a thermal insulation and a heat preservation material.

Owner:JIANGSU OSIC PERFORMANCE MATERIALS CO LTD

High-strength tear-resistant modified butadiene styrene rubber material

The invention discloses a high-strength tear-resistant modified butadiene styrene rubber material which comprises the following materials in parts by weight: 65-72 parts of butadiene styrene rubber, 33-45 parts of natural rubber, 26-29 parts of neoprene, 35-42 parts of modified graphene, 20-25 parts of white carbon black, 12-16 parts of carbon black, 15-20 parts of blanc fixe, 3-5 parts of silane coupling agent A-151, 4.3-6.5 parts of sulfur, 2.2-2.4 parts of accelerant TMTM, 1.5-2.0 parts of accelerant DM, 3-7 parts of octylated diphenylamine, 2.8-3.3 parts of antiager BLE, 4.3-4.6 parts of antiager OD, 2.6-3.2 parts of coconut oil, 2.5-4 parts of dioctyl phthalate, 3-6 parts of naphthenic oil, 1.2-1.5 parts of phenyl petroleum sulfonate, and 2.3-2.6 parts of epoxy resin. The high-strength tear-resistant modified butadiene styrene rubber material is high in strength and strong in tear resistance.

Owner:ANHUI ELECTRIC GRP SHARES

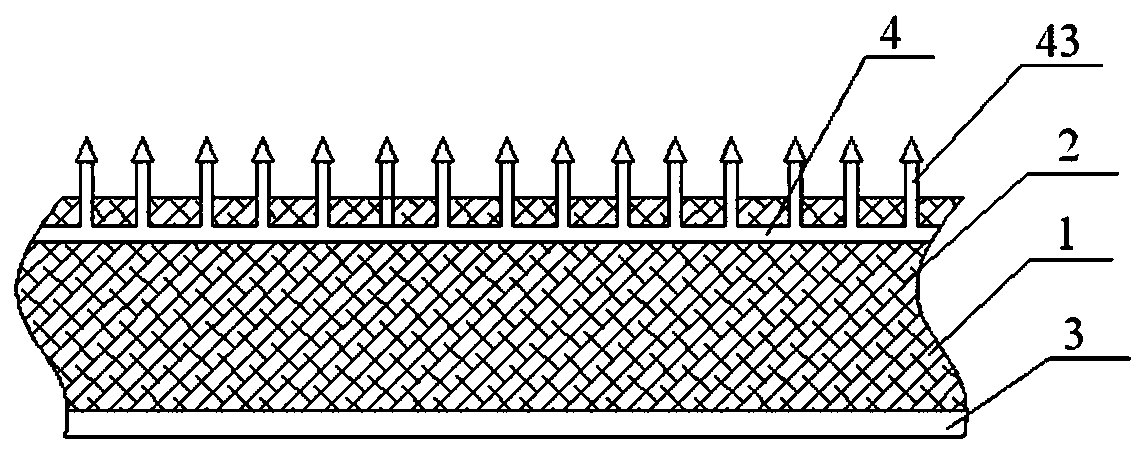

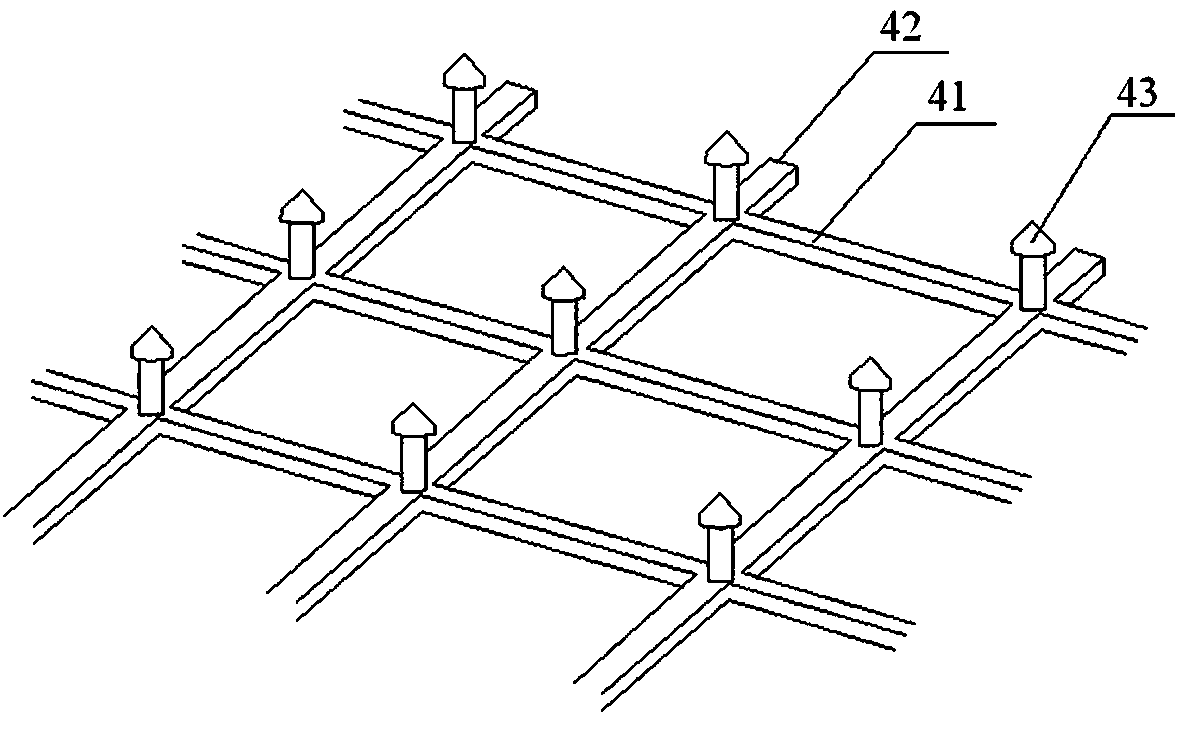

Compound polyurethane sleeper pad and preparation method thereof

PendingCN108660867ASolve the problem of piercingSolve the problem of fast pulverizationBallastwayNonwoven fabricBallast

The invention discloses a compound polyurethane sleeper pad and a preparation method thereof. The sleeper pad comprises a polyurethane foam layer; a plurality of reinforced fibers are embedded in thepolyurethane foam layer; and a non-woven cloth layer for preventing being pierced by ballast gravel is fixedly arranged on the bottom end face of the polyurethane foam layer. The preparation method comprises the steps that a non-woven cloth is laid on a plane worktable with side blocking parts; polyurethane composite materials and the reinforced fibers are evenly poured through a pouring machine with fiber cutting and adding functions, so that poured materials are formed; the poured materials are poured on the plane worktable with the laid non-woven cloth and naturally level; and meanwhile, afoaming reaction is conducted, a fiber compound polyurethane layer with a micropore structure is formed by solidifying, and the fiber compound polyurethane layer and the non-woven cloth on the bottomlayer are pasted closely to form a whole so as to form the compound polyurethane sleeper pad. According to the compound polyurethane sleeper pad and the preparation method thereof, the problem that the sleeper pad is pierced by the ballast gravel can be solved on the basis of solving the problem that the ballast gravel is pulverized quickly, thus the ballast gravel tamping period and the ballast bed hardening time are prolonged, and the railway maintenance cost is reduced.

Owner:铁科腾跃科技有限公司

Antiskid wear-resistant sole material and preparation method thereof

The invention discloses an antiskid wear-resistant sole material which comprises 15-20% of natural 3L rubber, 10-20% of butyl rubber, 10-15% of styrene butadiene rubber, 5-10% of short fiber, 10-15% of carbon black, 10-15% of white carbon black (SiO2), 1-2% of stearic acid (SA), 2-3% of paraffin oil, 2-3% of bis-silane tetrasulfide (Si-69), 3-6% of sulfur (S), 1-2% of an active agent, 0.5-0.7% of an antioxidant, 3-5% of zinc oxide (ZnO), 0.3-0.5% of magnesium oxide, 1-2% of an accelerant and 1-3% of a filler. According to the antiskid wear-resistant sole material disclosed by the invention, the antiskid coefficient of the sole is improved, the loss index of the obtained material is low, and the abrasion property and tear resistance are strong. The antiskid wear-resistant sole material has relatively good wear resistance and puncture resistance, improves the comfort and safety of the mountain climbing fitness exercise, prolongs the service life of shoes to a certain degree, and has a broad market application prospect.

Owner:朱伟萍

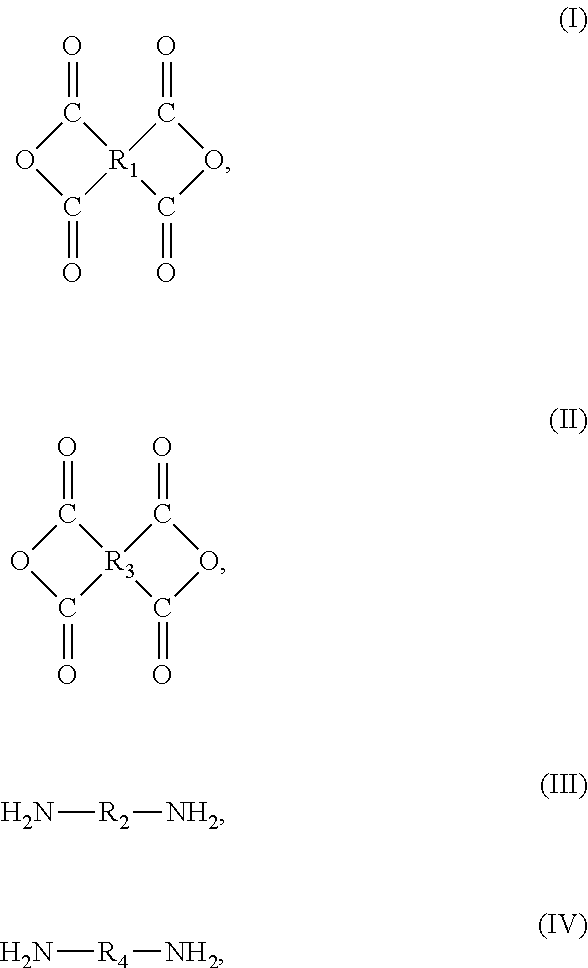

Copolymide nano-fiber non-woven fabric, process for producing the same and the use thereof

InactiveUS20130196562A1High temperature resistanceStrong tear resistanceMonocomponent synthetic polymer artificial filamentCell component detailsElectrospinningChemistry

A copolyimide nano-fiber non-woven fabric, a process for producing the same and the use thereof. The process comprises the following steps: tetracid dianhydride monomer and diamine monomer are polycondensated in the reaction medium of a high polar solvent under mechanical agitation to form a solution of a copolyamic acid; the copolyamic acid solution is electrostatically spinned under a high voltage electric field to give a non-woven fabric of a nano-fiber of the copolyamic acid; and then the non-woven fabric is imidized. The copolyimide nano-fiber non-woven fabric has features of a strong tear resistance, a high porosity, high / low-temperature resistances and excellent mechanical properties, etc., and can be used in battery membrane and capacitor membrane.

Owner:JIANGXI XIAN CAI NANOFIBERS TECH

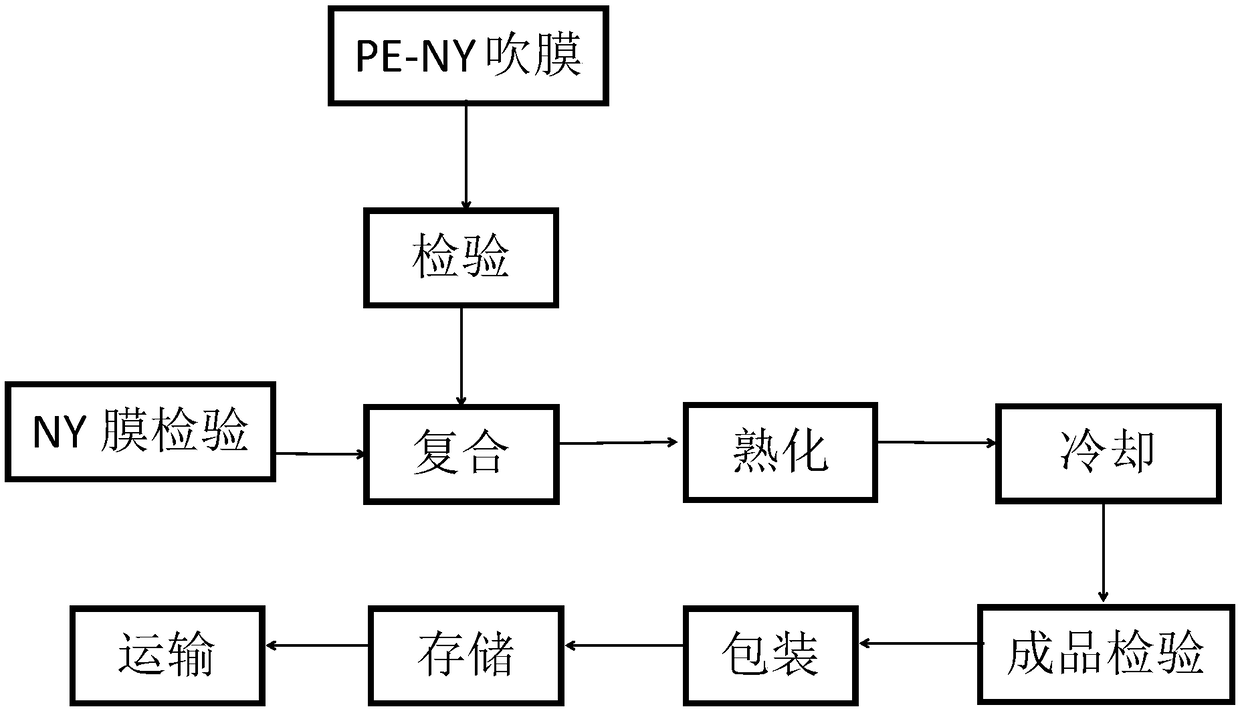

Transparent packaging film and preparation method thereof

PendingCN108790352AHigh solid contentLow viscosityFlexible coversWrappersLow-density polyethyleneLinear low-density polyethylene

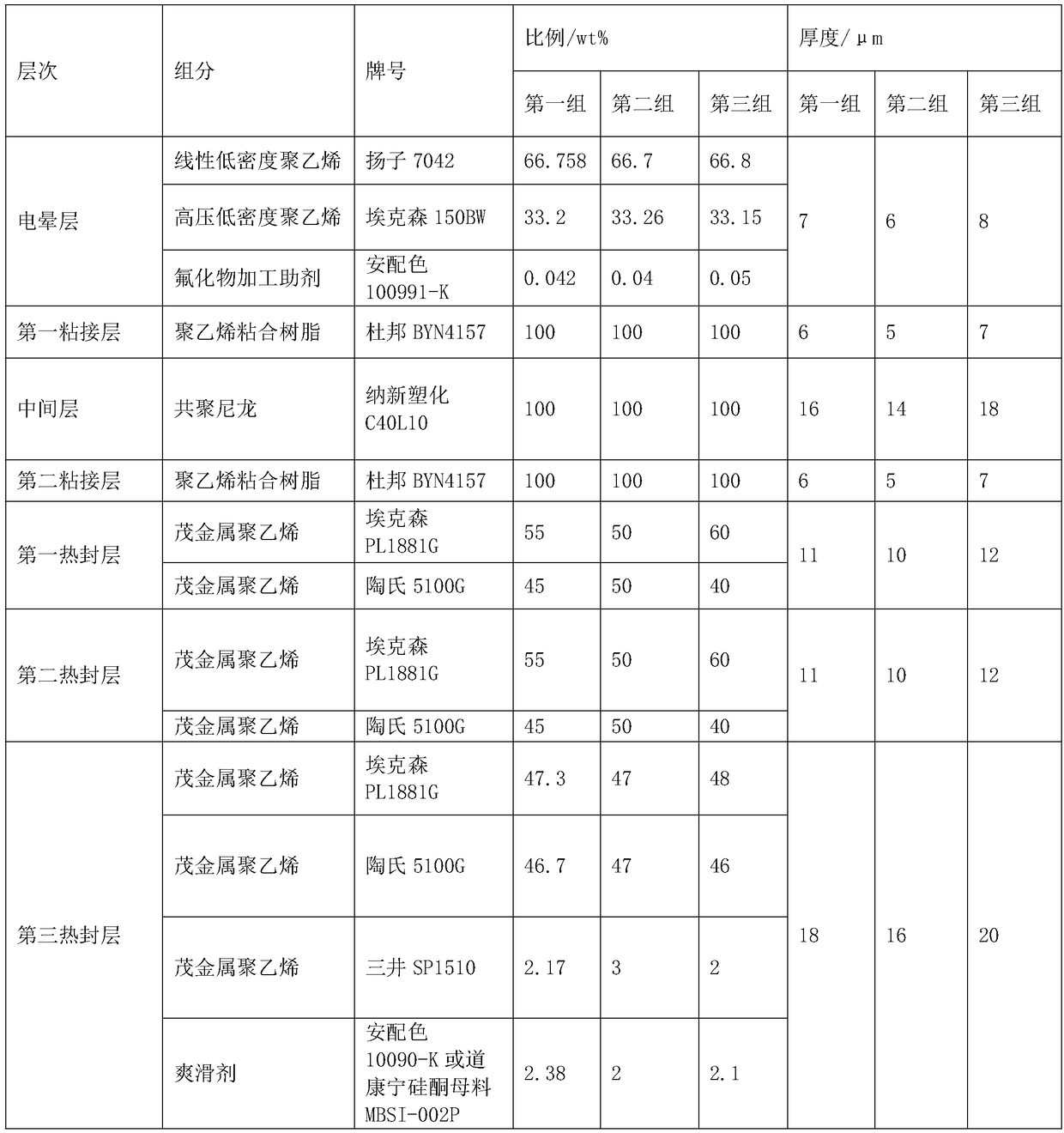

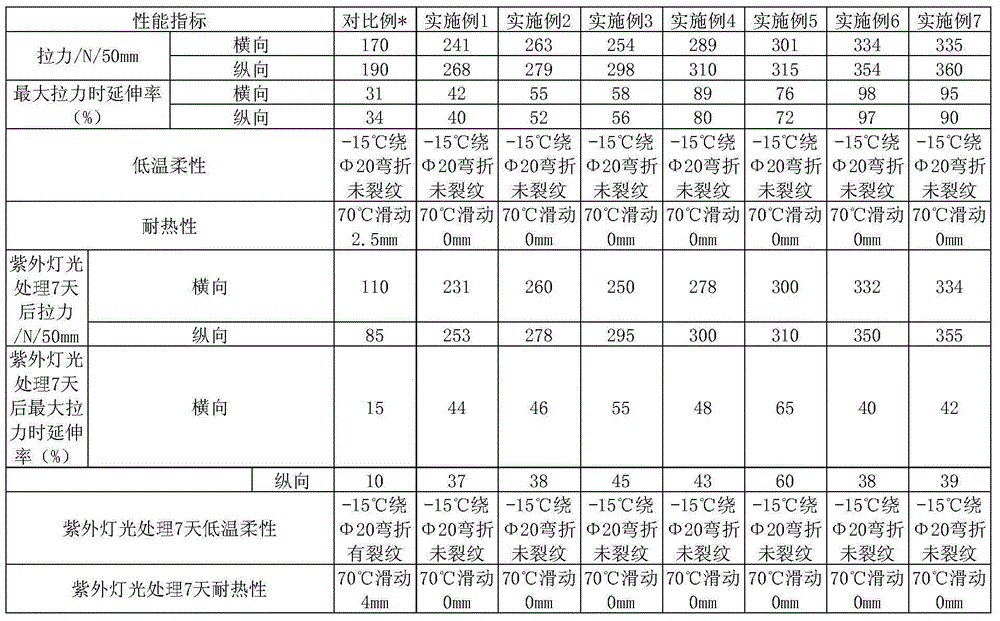

The invention relates to a transparent packaging film and a preparation method thereof. The transparent packaging film comprises an NY (nylon) film layer, an adhesive layer and a PE-NY (polyethylene-nylon) co-extrusion film which are tightly bonded, wherein the PE-NY co-extrusion film layer consists of a corona layer, a first adhesive layer, a middle layer, a second adhesive layer, a first heat sealing layer, a second heat sealing layer and a third heat sealing layer which are sequentially adhered together; the corona layer comprises 66.7 to 66.8wt% of linear low density polyethylene, 33.1 to33.3wt% of high-pressure low density polyethylene and 0.04 to 0.05wt% of fluoride processing additive; the first adhesive layer and the second adhesive layer comprise polyethylene bonding resin; the middle layer comprises copolymerizing nylon; the first heat sealing layer and the second heat sealing layer comprise metallocene polyethylene; the third heat sealing layer comprises 95 to 97wt% of metallocene polyethylene, 2 to 3wt% of smoothing agent and 1 to 2wt% of opening agent. The transparent packaging film is a composite film with good heat sealing and packaging adaptability.

Owner:HUANGSHAN NOVEL

Super weather-proof composite waterproof roll material

InactiveCN104553185AWith super weather resistanceResistant to UV radiationLamination ancillary operationsSynthetic resin layered productsHigh resistanceEnvironmental resistance

The invention relates to the field of waterproof roll materials, and particularly relates to a super weather-proof composite waterproof roll material. The super weather-proof composite waterproof roll material comprises a bonding and sealing adhesive layer and an isolating film protection layer, and also comprises a super weather-proof polymeric film layer, wherein the super weather-proof polymeric film layer, the bonding and sealing adhesive layer and the isolating film protection layer are sequentially arranged from top to bottom and are adhered into a whole in a hot pressing way. The hot pressing temperature is 30 to 220 DEG C, includes but is not limited to 30 to 220 DEG C, and can be adjusted according to factors such as specific production equipment and a hot pressing technology. The bonding and sealing adhesive layer is compounded with the a super weather-proof polymeric film structure, so that the structure has high environmental resistance, corrosion resistance, high strength and high toughness, good dimensional stability, and high impact resistance and puncture resistance, does not need to be protected by cement and mortar, and can be constructed in various environments.

Owner:HANGZHOU FUMO NEW MATERIAL TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com