TPE (Thermoplastic Elastomer) yarns for weaving TPE mesh

A yarn and mesh technology, applied in the field of TPE mesh, can solve problems such as poor environmental protection performance, and achieve the effects of strong tear resistance, high resilience, water resistance, oil resistance, and UV resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

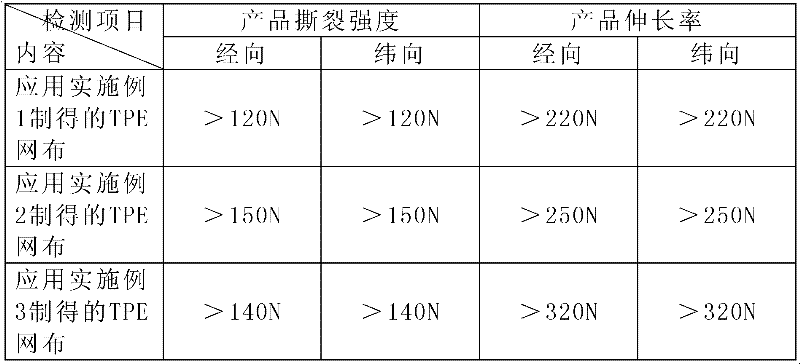

Examples

Embodiment 1

[0025] The TPE yarn of this TPE mesh is a covering structure, in which the core is a high-strength polyester filament, and the surface of the high-strength polyester filament is covered with a TPE composite material, and equipped with a blue dye to make a TPE. Yarn, the TPE composite material is:

[0026] TPO: 40%; HDPE: 13%; LLDPE: 25%; PE rubber master: 10%; PE rubber particles: 12%.

[0027] The specific preparation process is: add the TPE composite material of the above formula and the blue dye to the mixer for thorough mixing, and after mixing evenly, add it to the extrusion system of the extruder to plasticize it into a uniform melt, and pass it through the extruder The continuous screw extruder head, while the above operations, pass the high-strength polyester filament through the head of the plastic extruder, and make the extruded melt wrap the outside of the high-strength polyester filament, and then pass through After the cooling water tank cools down, it is formed ...

Embodiment 2

[0029] The TPE yarn has a covering structure, and its core is high-strength polyester filament. The surface of the high-strength polyester filament is covered with TPE composite material, and equipped with blue dye to make TPE yarn. Described TPE composite material comprises the weight percent of following composition:

[0030] SBC: 38%; HDPE: 10%; LLDPE: 28%; PE rubber master: 12%; PE rubber particles: 12%.

[0031] The specific preparation method is consistent with the method in Example 1, and will not be repeated here.

Embodiment 3

[0033] The TPE yarn has a covering structure, in which the core is high-strength polyester filament, and the surface of the high-strength polyester filament is covered with TPE composite material, and equipped with black dye to make TPE yarn. The TPE composite material includes the weight percentage of the following ingredients:

[0034] TPU: 42%; HDPE: 15%; LLDPE: 23%; PE rubber master: 10%; PE rubber particles: 10%.

[0035] The specific preparation method is consistent with the method in Example 1, and will not be repeated here.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com