Self-supporting bag and composite film thereof

A composite film, stand-up pouch technology, applied in the direction of synthetic resin layered products, lamination, layered products, etc., can solve the problem of "PE melting out, achieve good stiffness, excellent heat sealing performance, and improve product quality." Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

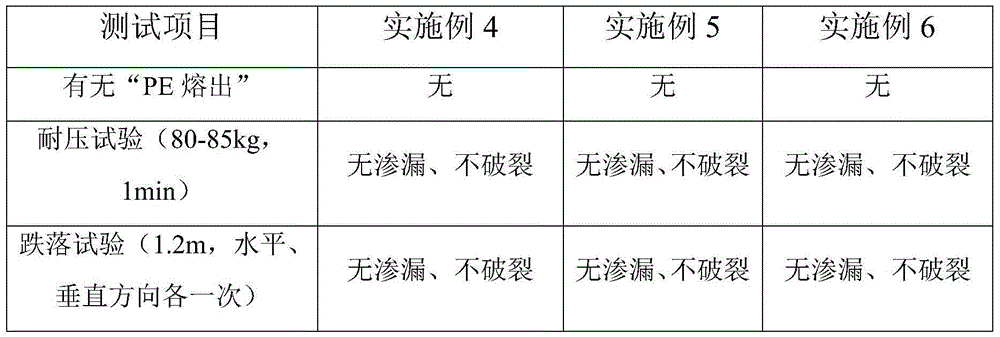

Examples

Embodiment 1

[0029] Example 1, preparing PE film.

[0030] Add composite layer resin raw materials, intermediate layer resin raw materials and heat-sealing layer resin raw materials to the three barrels of the co-extrusion machine respectively. The formula of each resin raw material is as follows:

[0031] Composite layer: 70wt% m-LLDPE and 30wt% LDPE.

[0032] Middle layer: 35wt% HDPE, 30wt% LLDPE, 34.7wt% LDPE and 0.3wt% fluoride additive.

[0033] Heat-sealing layer: 33wt% of LDPE, 65wt% of reinforced polyethylene resin, 0.7wt% of slippery agent and 1.3wt% of opening agent.

[0034] The polymer particles in the above three barrels are melted by the extruder to form a tube blank. After the tube blank is stretched, compressed air is blown out from the center of the extruder die to blow the tube blank into a bubble-like film. The shaped film is cooled and shaped by the air ring cooling air to obtain a PE film.

Embodiment 2

[0035] Example 2, preparing PE film.

[0036] The formula of each resin raw material is as follows: Composite layer: 60wt% m-LLDPE and 40wt% LDPE.

[0037] Middle layer: 30wt% HDPE, 34.8wt% LLDPE, 35wt% LDPE and 0.2wt% fluoride additive.

[0038] Heat-sealing layer: 34.2wt% of LDPE, 63wt% of reinforced polyethylene resin, 0.8wt% of slippery agent and 2.0wt% of opening agent. All the other are with embodiment 1.

Embodiment 3

[0039] Example 3, preparing PE film.

[0040] The formula of each resin raw material is as follows: Composite layer: 66.7wt% m-LLDPE and 33.3wt% LDPE.

[0041] Middle layer: 33.24wt% HDPE, 33.24wt% LLDPE, 33.24wt% LDPE and 0.28wt% fluoride additive.

[0042] Heat-sealing layer: 32.43wt% LDPE, 64.85wt% reinforced polyethylene resin, 0.78wt% slip agent and 1.94wt% anti-opening agent. All the other are with embodiment 1.

[0043] The PE films prepared in Examples 1-3 were tested for their heat-sealing properties and mechanical properties, and the test results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com