Preparing method for high-strength high-isolation condom comprising modified graphene/latex interlayer

A technology of graphene and condoms, applied in the direction of coating, etc., can solve the problems of easy falling off and damage, poor elasticity, high cost, etc., and achieve the effect of reducing and inhibiting the transmission probability and increasing comfort

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

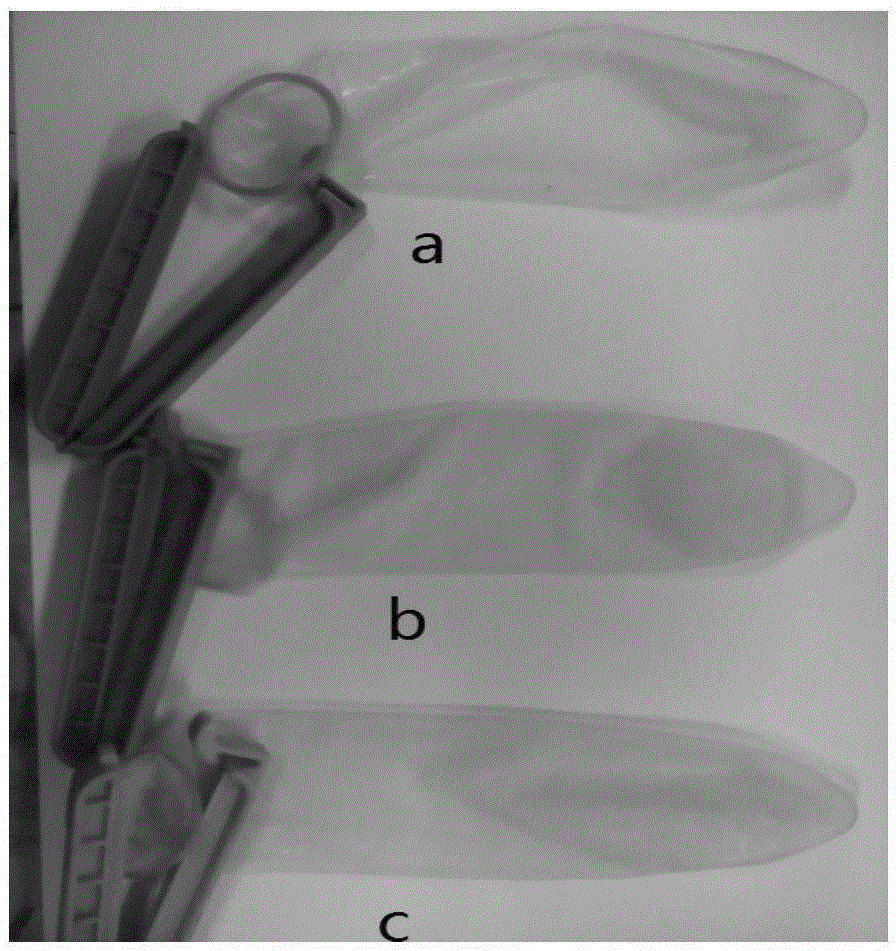

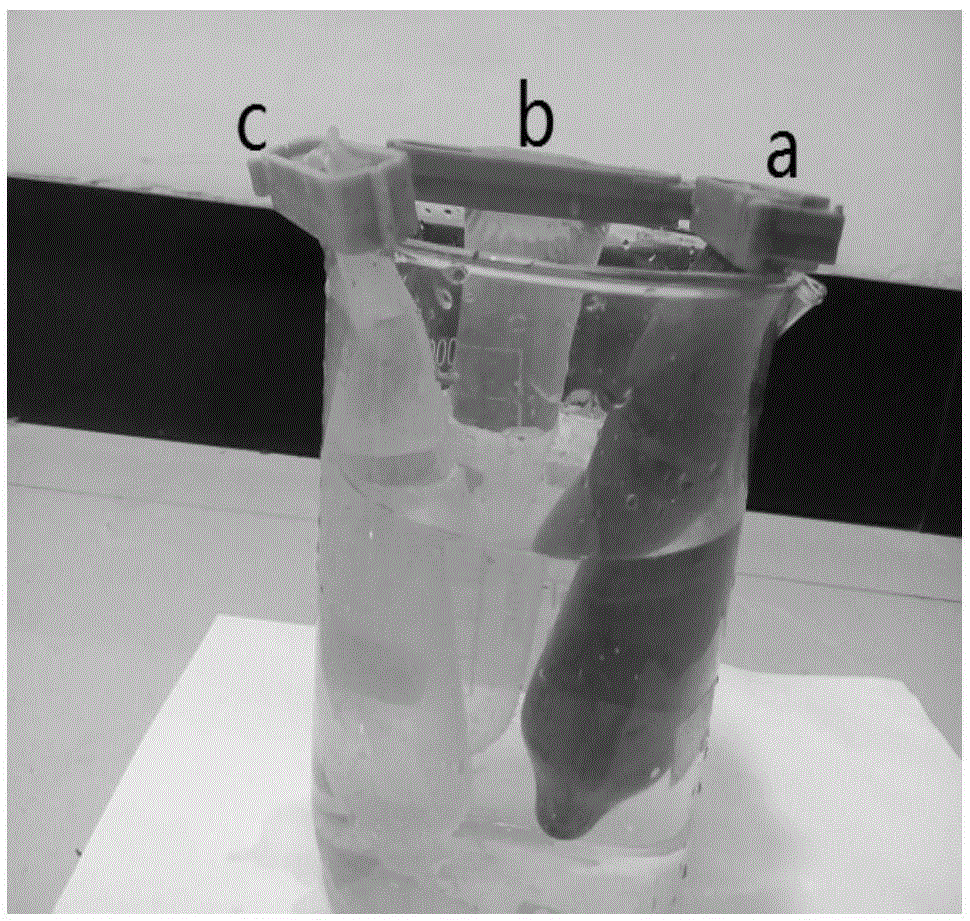

Image

Examples

preparation example Construction

[0044] The preparation methods of modified graphene or graphene derivatives include but are not limited to the following three methods: 1. graphene powder or liquid phase dispersion prepared by expansion and exfoliation of graphite as raw material and subsequent modified products (fluorination, Carboxylation, sulfoylation, amination, oxidation, grafting and other modified derivatives); ② Graphene prepared by chemical vapor deposition (CVD) or physical vapor deposition (PVD) using gaseous carbon source as raw material and its subsequent modification (fluorination, carboxylation, sulfonation, amination, oxidation, grafting and other modified derivatives); ③The powder or liquid phase formed by the aggregation of graphene-like two-dimensional sheet materials formed by chemical polymerization of small molecules Dispersion and its subsequent modification (fluorination, carboxylation, sulfonation, amination, oxidation, grafting and other modification and derivation).

[0045] The ord...

Embodiment 1

[0058] Adding 200Kg concentration in a clean mixing tank is 60wt% natural rubber latex, and gradually adding 200Kg concentration is 0.5wt‰ graphene aqueous solution after sulfonation under stirring condition, after adding, then add 1wt%~ About 2wt% of dispersion stabilizer (such as: sodium lauricate or F108), keep stirring for 1 hour to make it evenly mixed. At this time, adjust the viscosity to about 15 mPa·s. The compounded glue is left to stand for about 24 hours to allow it to fully mature, and then three dipping productions are carried out as described in the specific implementation mode, and finally the finished product is obtained after the performance test is passed.

[0059] In order to verify the performance advantages of new materials prepared by the present invention and condom products, the inventor prepared batches of graphene-containing / Latex interlayer condom is carried out sampling test, as contrast, sampling test utilizes the pure natural latex condom prepa...

Embodiment 2

[0070]Add 200Kg of natural rubber latex with a concentration of 35wt% in a clean mixing tank, and gradually add 200Kg of graphene oxide aqueous solution with a concentration of 0.05wt‰ under stirring conditions. After the addition, add about 0.5wt% to 1wt% respectively Dispersion stabilizer (such as: sodium lauric acid or F108), keep stirring for 1 hour to make it evenly mixed, and the viscosity is about 8mPa·s. The compounded glue is left to stand for about 24 hours to allow it to fully mature, then it is added to the dipping machine for dipping production as described in the specific implementation method, and finally the finished product is obtained after passing the performance test.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com