Copolymide nano-fiber non-woven fabric, process for producing the same and the use thereof

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

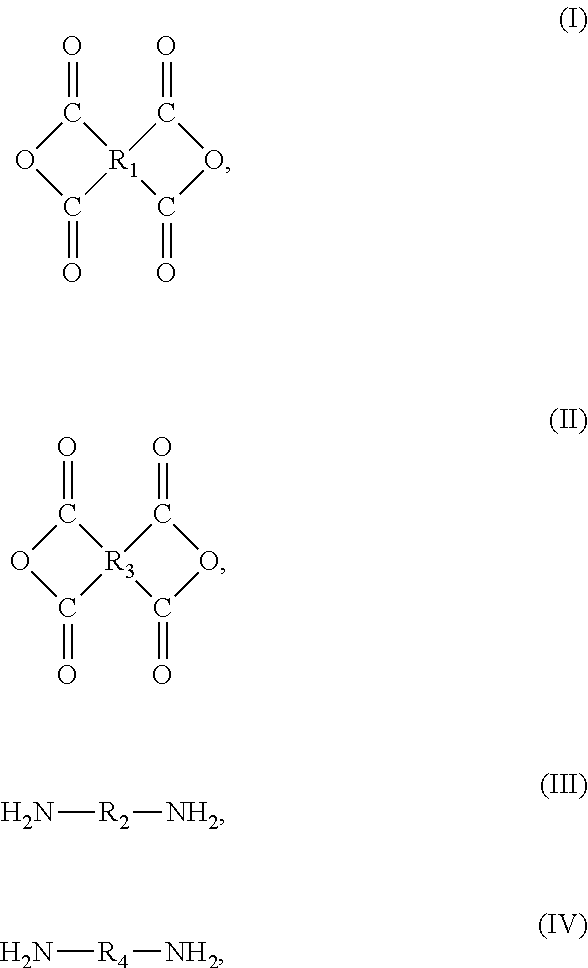

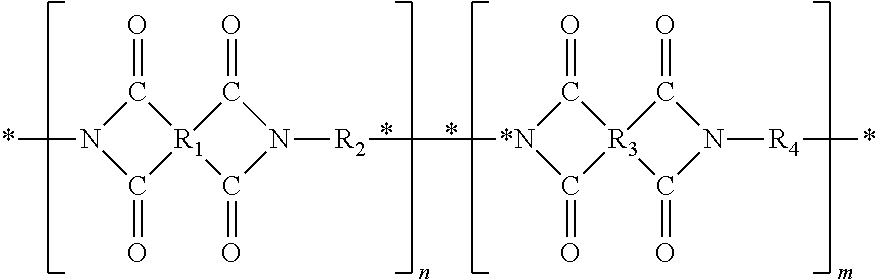

Method used

Image

Examples

embodiment 1

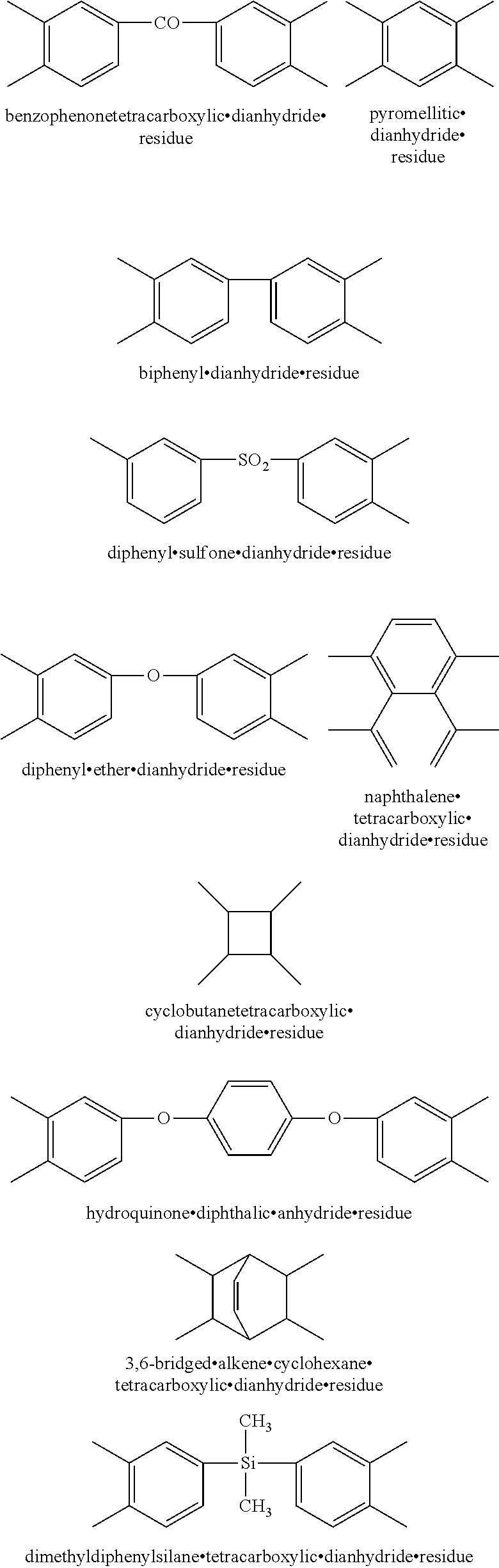

[0032]One tetracid dianhydride monomer and two diamine monomers were selected as the comonomers. Purified biphenyl dianhydride (BPDA), p-phenylenediamine (PPD) and oxydianiline (ODA) were mixed at a molar ratio of 1:0.5:0.5, and reacted in N,N-dimethyl formamide (DMF) as a solvent following the above steps. In reaction step (1), the temperature of the reaction kettle of the example is 10° C., the time of the reaction under agitation is 6 h, and the electric field intensity of the high voltage electric field for the electrostatic spinning is 300 Kv / m; and in reaction step (2), the temperature rise program includes heating from room temperature to 200° C. at a temperature rise rate of 20° C. / min, and maintaining at the temperature for 30 min, heating to 350° C. at a temperature rise rate of 5° C. / min, and maintaining at 350° C. for 30 min, shutting off the power source, and naturally cooling to room temperature.

[0033]Property characterization: the mass concentration of the copolyamic ...

embodiment 2

[0034]One tetracid dianhydride monomer and two diamine monomers were selected as the comonomers. Purified pyromellitic dianhydride (PMDA), oxydianiline (ODA) and Benzidine (Bz) were mixed at a molar ratio of 1:0.6:0.4, and reacted in N,N-dimethyl formamide (DMF) as a solvent following the above steps; in reaction step (1), the temperature of the reaction kettle of the example is 5° C., the time of the reaction under agitation is 6 h, and the electric field intensity of the high voltage electric field for the electrostatic spinning is 250 Kv / m; and in reaction step (2), the temperature rise program includes heating from room temperature to 250° C. at a temperature rise rate of 20° C. / min, and maintaining at the temperature for 30 min, heating to 370° C. at a temperature rise rate of 5° C. / min, and maintaining at 370° C. for 30 min, shutting off the power source, and naturally cooling to room temperature.

[0035]Property characterization: the mass concentration of the copolyamic acid (p...

embodiment 3

[0036]One tetracid dianhydride monomer and two diamine monomers were selected as the comonomers. Purified pyromellitic dianhydride (PMDA), methylene dianiline (MDA) and oxydianiline (ODA) were mixed at a molar ratio of 1:0.5:0.5, and reacted in N,N-dimethyl formamide (DMF) as a solvent following the above steps; in reaction step (1), the temperature of the reaction kettle of the example is 5° C., the time of the reaction under agitation is 10 h, and the electric field intensity of the high voltage electric field for the electrostatic spinning is 250 Kv / m; and in reaction step (2), the temperature rise program includes heating from room temperature to 250° C. at a temperature rise rate of 20° C. / min, and maintaining at the temperature for 30 min, heating to 370° C. at a temperature rise rate of 5° C. / min, and maintaining at 370° C. for 30 min, shutting off the power source, and naturally cooling to room temperature.

[0037]Property characterization: the mass concentration of the copoly...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com