Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

62 results about "Biphasic calcium phosphate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Biphasic calcium phosphate is a bone substitute which is a mixture of hydroxyapatite and β -tricalcium phosphate in fixed ratios. Studies have demonstrated the osteoconductive potential of this composition.

Biphasic calcium phosphate cement for drug delivery

ActiveUS20110021427A1Provide mechanical strengthSurgical adhesivesPeptide/protein ingredientsBiphasic calcium phosphateMedicine

This invention relates to biomineral-based cements incorporating biopolymer carriers for the site specific introduction of natural or synthetic compounds that influence bone repair and / or patient recovery. The invention further relates to methods for producing such biphasic calcium phosphate cements for drug delivery.

Owner:WARSAW ORTHOPEDIC INC

Calcium phosphate-based materials containing zinc, magnesium, fluoride and carbonate

ActiveUS20090068285A1Promotes bone formationMinimize and prevent bone resorptionBiocideInorganic phosphorous active ingredientsDiseaseAntioxidant

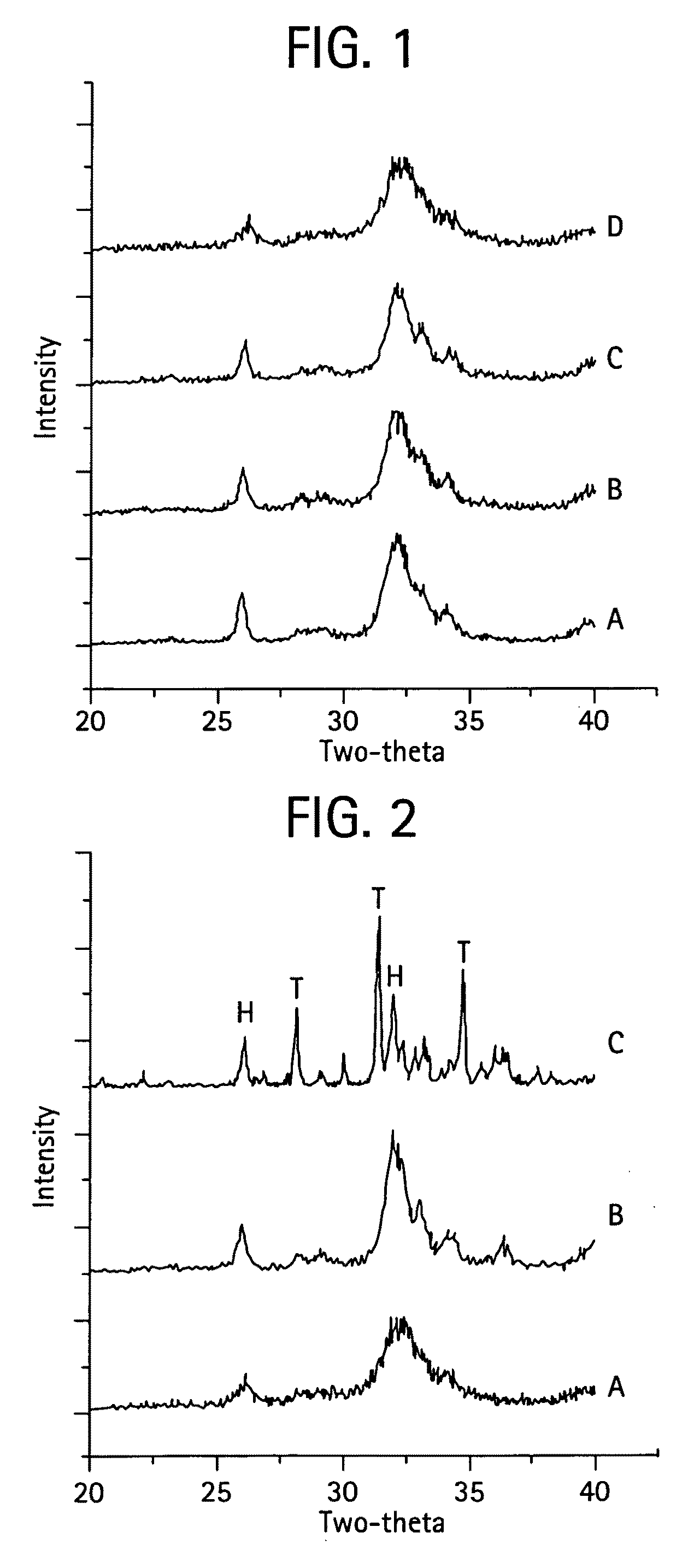

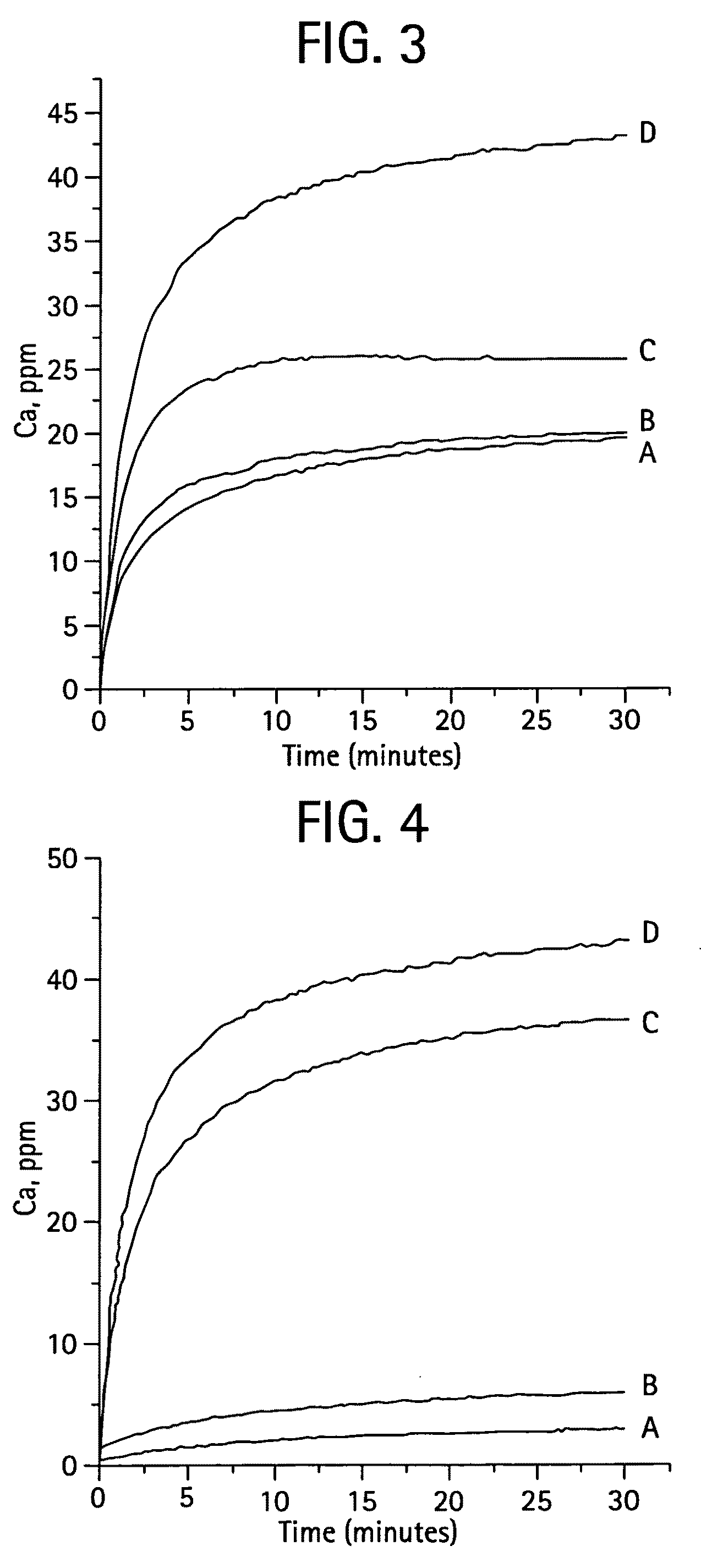

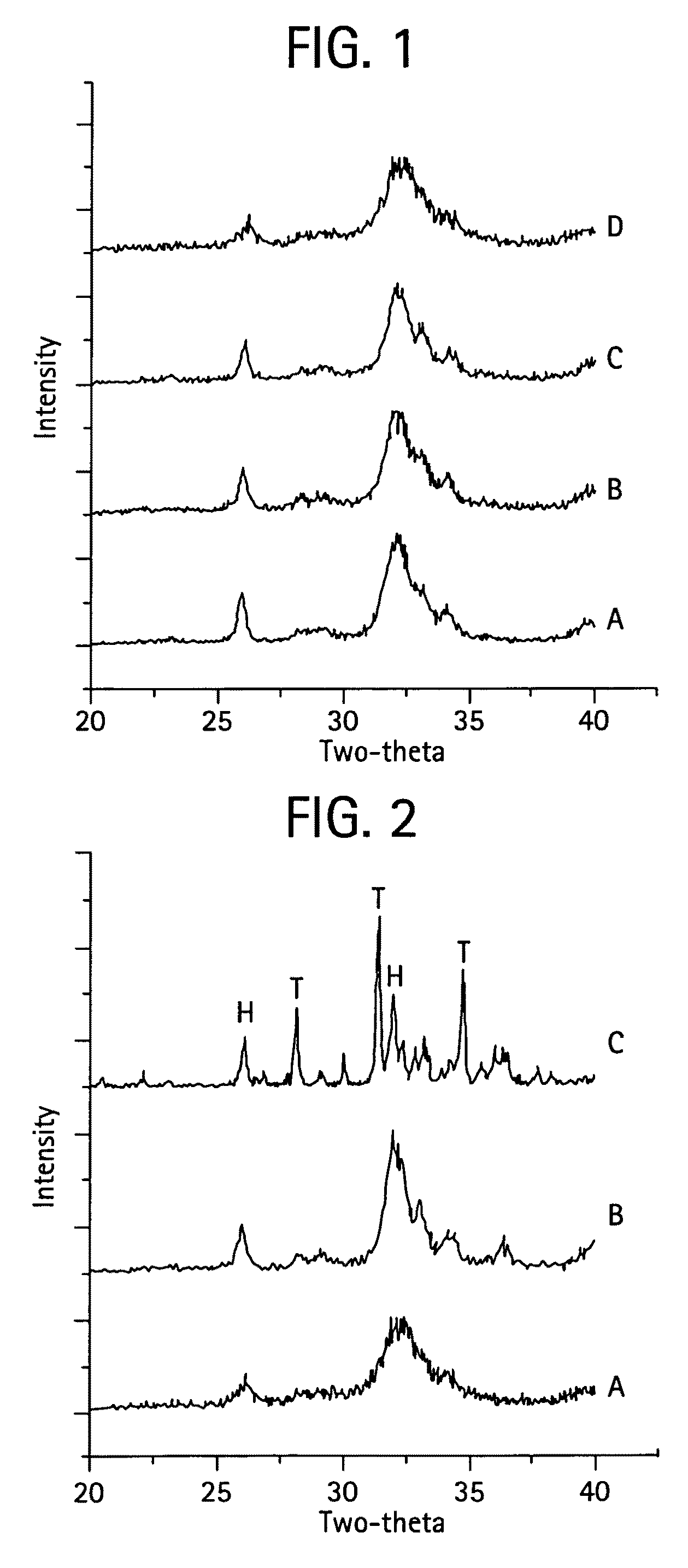

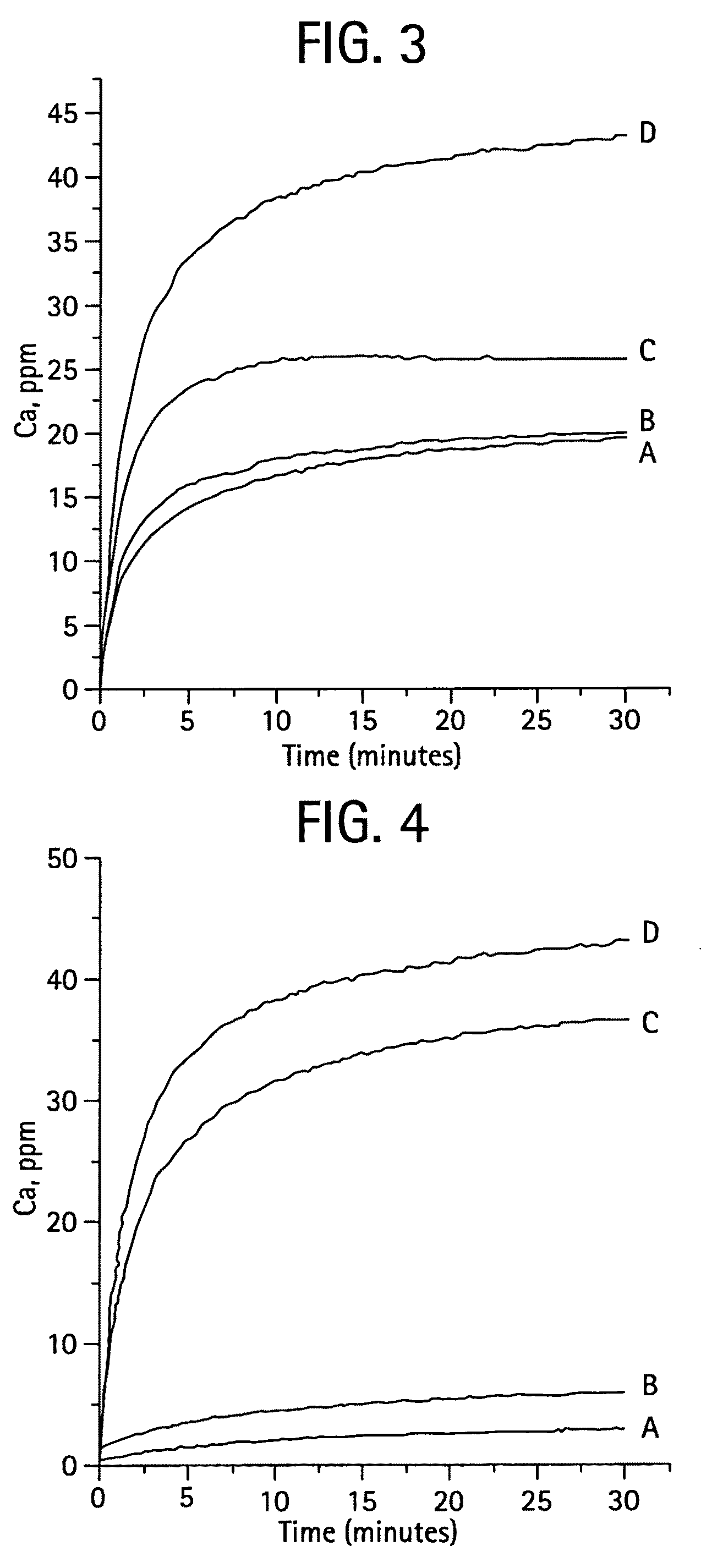

The present invention provides novel biomaterials comprising one or more of Mg, Zn and F ions in a carbonate-containing biphasic calcium phosphate (BCP) system. The biomaterial may contain Mg, Zn, F, Mg and Zn, Mg and F, Zn and F, or Mg, Zn and F. The biomaterial may be substantially similar in composition to bone mineral (a carbonate apatite). The biomaterial may feature slow release of Mg, Zn, F, Ca, and P ions. The biphasic calcium phosphate, BCP, may be a mixture of unsubstituted hydroxyapatite (HA) and unsubstituted .-TCP, Ca3(PO4)2. BCP of varying HA / .-TCP ratios may be produced by sintering calcium-deficient apatite, for instance having a Ca / P<1.5, 1.6, 1.67, 1.75 or 1.8 that has been prepared either by a precipitation or by a hydrolysis method or by a solid-state reaction. The amount of each component (by weight %) present in the biomaterials may be as follows: Mg 0.5 to 12 wt %, Zn 1 to 12 wt %, F 0.1 to 4 wt %, calcium 20 to 40 wt %, phosphate 10 to 20 wt %, and carbonate (CO3) 1 to 20 wt %. The biomaterial may further comprise one or more other ion such as strontium, manganese, copper, boron or silicate, or one or more other organic moiety such as a protein, a peptide, or a nutraceutical which may provide antioxidant, anti-bacterial or anti-inflammatory properties. The invention also provides methods of inhibiting bone resorption, methods of treating osteoporosis or delaying the onset of osteoporosis, methods of treating a bone fracture, and methods of inhibiting osteoclast activity. Further, the invention provides methods of treating or reversing bone deficiencies such as bone loss, similar to osteoporosis, caused all or in part by a mineral deficient diet, a disease such as cancer or osteopenia, a treatment such as steroid therapy or radiation therapy, or a physical condition such as immobilization.

Owner:NEW YORK UNIV

Dual-Phase Calcium Phosphate Cement Composition

ActiveUS20100269736A1Optimize working timeShorten the timeSurgical adhesivesOther chemical processesOrganic acidBiphasic calcium phosphate

Disclosed are dual-phase cement precursor systems and associated methods and kits. The cement precursor systems comprises at least first and second phases each containing a calcium phosphate compound. When mixed, the first and second cement precursor phases form a biocompatible cement. The disclosed systems include an organic acid in an amount effective to enhance the working time of the cement precursor composition, and also include a setting accelerator. In some embodiments, one or more of the calcium phosphate compounds is provided in the form of particles with a nonmonomial particle sized distribution.

Owner:ADA FOUND

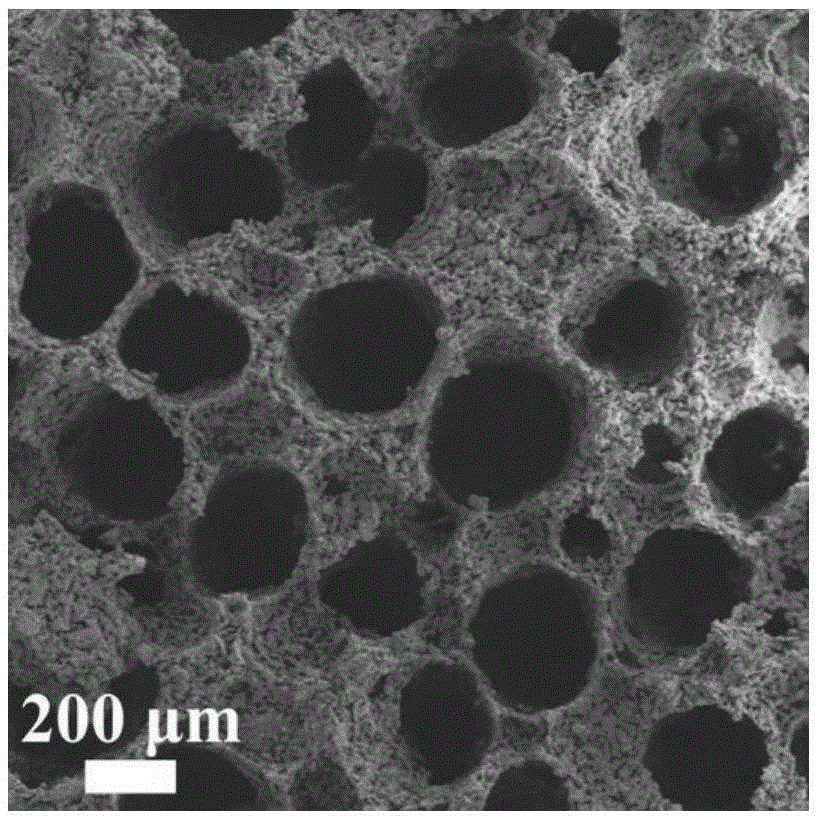

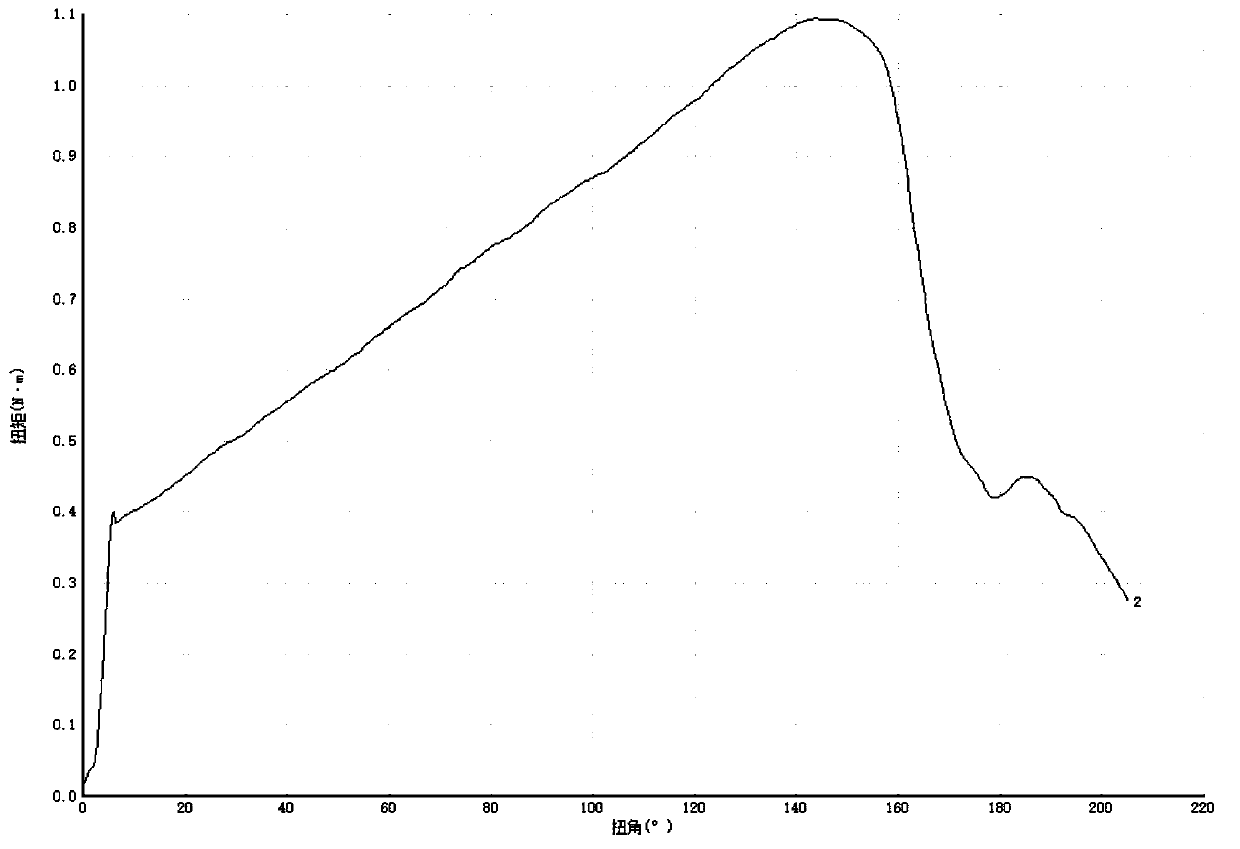

Biodegradable zinc (or zinc alloy) and porous biphase calcium phosphate composite material and preparation method thereof

ActiveCN102727937AGood biocompatibilitySolve the degradation rateProsthesisPorosityBiphasic calcium phosphate

The present invention provides a biodegradable zinc (or zinc alloy) and porous biphase calcium phosphate composite material and a preparation method thereof. The composite material comprises porous biphase calcium phosphate and zinc or a zinc alloy, wherein the zinc or the zinc alloy is arranged in the porous biphase calcium phosphate through suction casting, the porosity of the porous biphase calcium phosphate is 60-95%, the HA content is 10-70%, the beta-TCP content is 30-90%, and the zinc or the zinc alloy is zinc, a zinc-magnesium alloy, a zinc-yttrium alloy, a zinc-calcium alloy, a zinc-magnesium-manganese alloy, a zinc-magnesium-calcium alloy or a zinc-magnesium-yttrium alloy. The composite material is non-porous at the initial stage, and has good mechanical stability and good mechanical strength; after the composite material is implanted a certain time, the composite material is degraded, and the portion which is degraded slowly maintains the mutually-penetrated porous structure so as to prompt the bone to grow in the structure; and the composite material is gradually degraded along with the gradual growth of the bone in the structure, and the composite material is completely degraded when the bone is healed, such that the good coordination of the biodegradability of the composite material and the osteoinductive is provided.

Owner:JIANGYIN BIODEGRADE MEDICAL TECH CO LTD

Dual-phase calcium phosphate cement composition

ActiveUS8557038B2Optimize working timeShorten the timeSurgical adhesivesOther chemical processesBiphasic calcium phosphateCalcium biphosphate

Disclosed are dual-phase cement precursor systems and associated methods and kits. The cement precursor systems comprises at least first and second phases each containing a calcium phosphate compound. When mixed, the first and second cement precursor phases form a biocompatible cement. The disclosed systems include an organic acid in an amount effective to enhance the working time of the cement precursor composition, and also include a setting accelerator. In some embodiments, one or more of the calcium phosphate compounds is provided in the form of particles with a nonmonomial particle sized distribution.

Owner:ADA FOUND

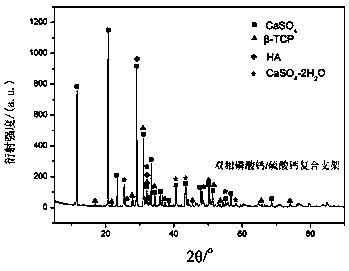

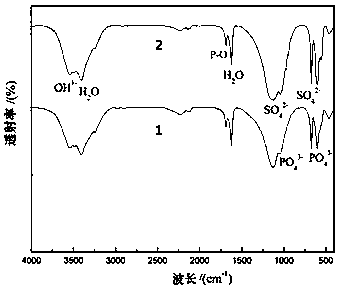

Preparation method of porous bi-phase calcium phosphate/calcium sulfate composite scaffold for bone tissue engineering

InactiveCN107670101AMeet the structureMeet the pore sizeTissue regenerationProsthesisBiphasic calcium phosphateCalcium biphosphate

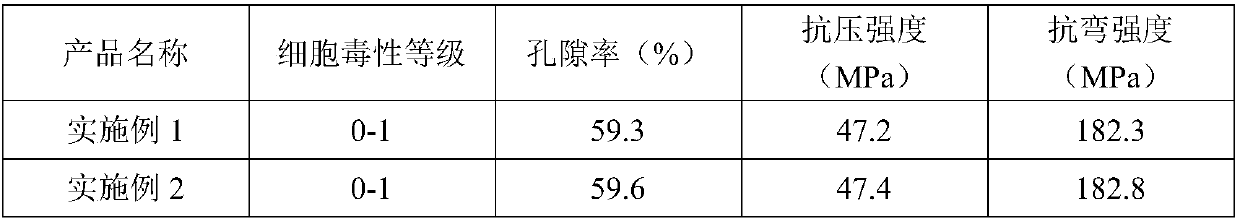

The invention discloses a preparation method of porous bi-phase calcium phosphate / calcium sulfate composite scaffold for bone tissue engineering, and belongs to the field of application of bio-medicalmaterial technologies. The porous composite scaffold is prepared by the following steps: with bi-phase calcium phosphate powder serving as a raw material, adding distilled water and conducting uniformly stirring, so that a dipping slurry is obtained; dipping an organic foam carrier, which is obtained from laser processing and molding, in the slurry, and conducting such processes as microwave heating, drying, heat treatment and the like, so that a porous bi-phase calcium phosphate scaffold that irregular through holes and regular through holes are combined is prepared; and then, dipping the prepared porous bi-phase calcium phosphate scaffold in a calcium sulfate slurry, and conducting hydrating and drying, so that the bi-phase calcium phosphate / calcium sulfate composite scaffold for the bone tissue engineering is finally prepared. The method provided by the invention is simple in process, convenient to operate and stable in yield; the prepared bi-phase calcium phosphate / calcium sulfatecomposite scaffold not only has a porous structure that the irregular through holes and the regular through holes are combined, but also can regulate a degrading rate by adjusting the proportion of the calcium sulfate and the bi-phase calcium phosphate; and the prepared scaffold is qualified in cytotoxicity and good in osteogenesis effect, and the scaffold has a good application prospect.

Owner:KUNMING UNIV OF SCI & TECH

Method for preparation of controlled pore size biphasic calcium phosphate composite ceramic scaffold

InactiveCN105288740AAperture controllableEvenly distributedProsthesisBiphasic calcium phosphateFoaming agent

The present invention discloses a method for preparation of a controlled pore size biphasic calcium phosphate composite ceramic scaffold. Firstly, nano-hydroxyapatite and nano-beta-tricalcium phosphate powder are prepared, the nano powder and a surfactant and a pore-forming agent are uniformly mixed, ground and sieved, added dropwise with a foaming agent solution, stirred into stick viscous slurry, and dried in air at room temperature to obtain a ceramic blank, the ceramic blank is foamed at a certain temperature and dehydrated, and sintered at high temperature, and after removal of the surfactant, the pore-forming agent and the foaming agent, the porous biphasic calcium phosphate ceramic composite scaffold can be obtained. The method is simple in process and strongly practical, by regulating of the use amount of the surfactant, the pore-forming agent and the foaming agent, the porous biphasic calcium phosphate ceramic composite scaffold can be controlled in pore size, even in distribution, and conductive to the practical application in biological medicines.

Owner:SHANGHAI JIAO TONG UNIV

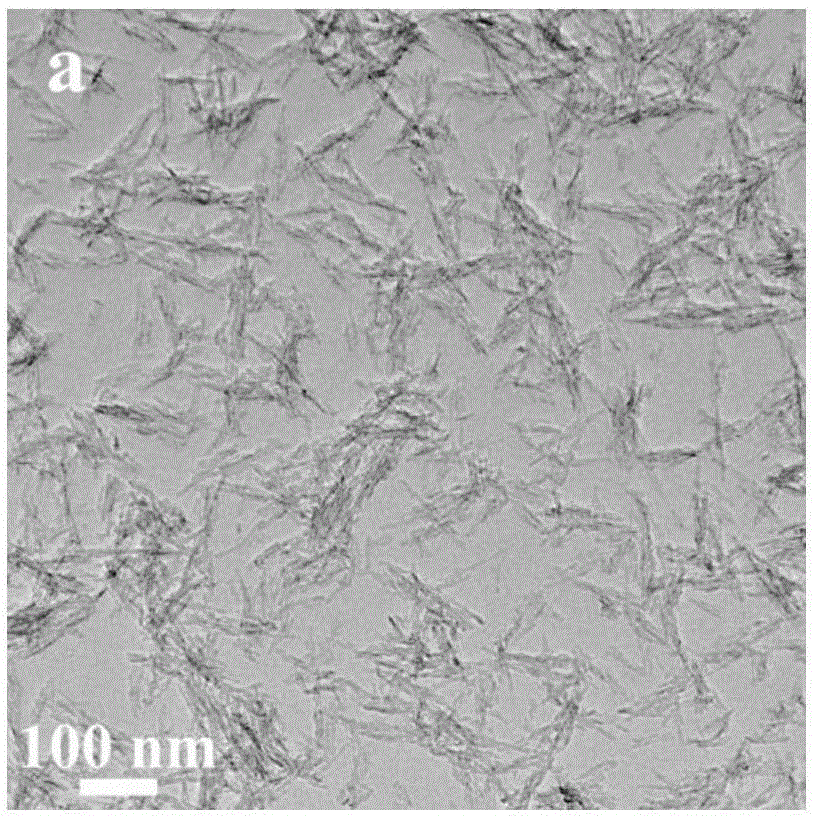

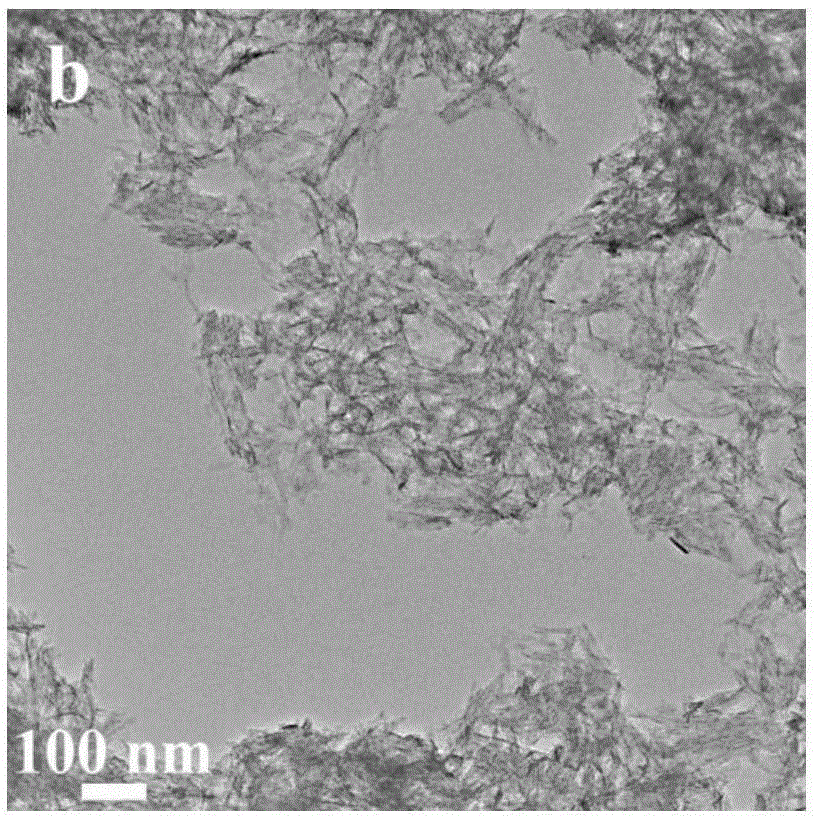

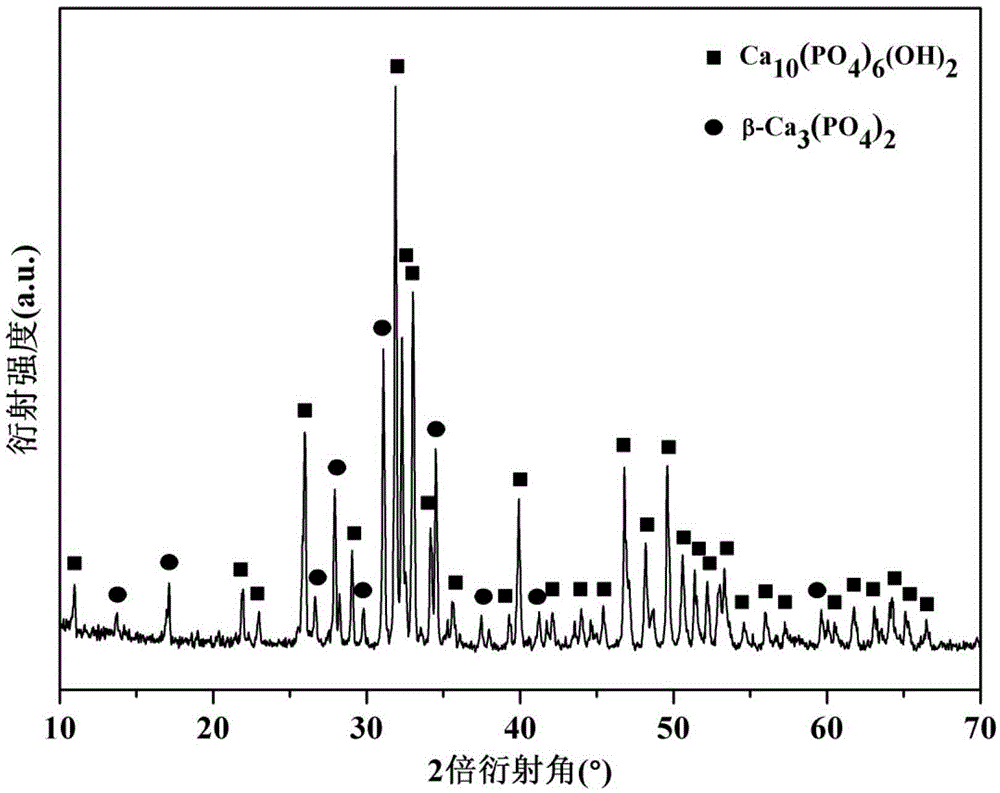

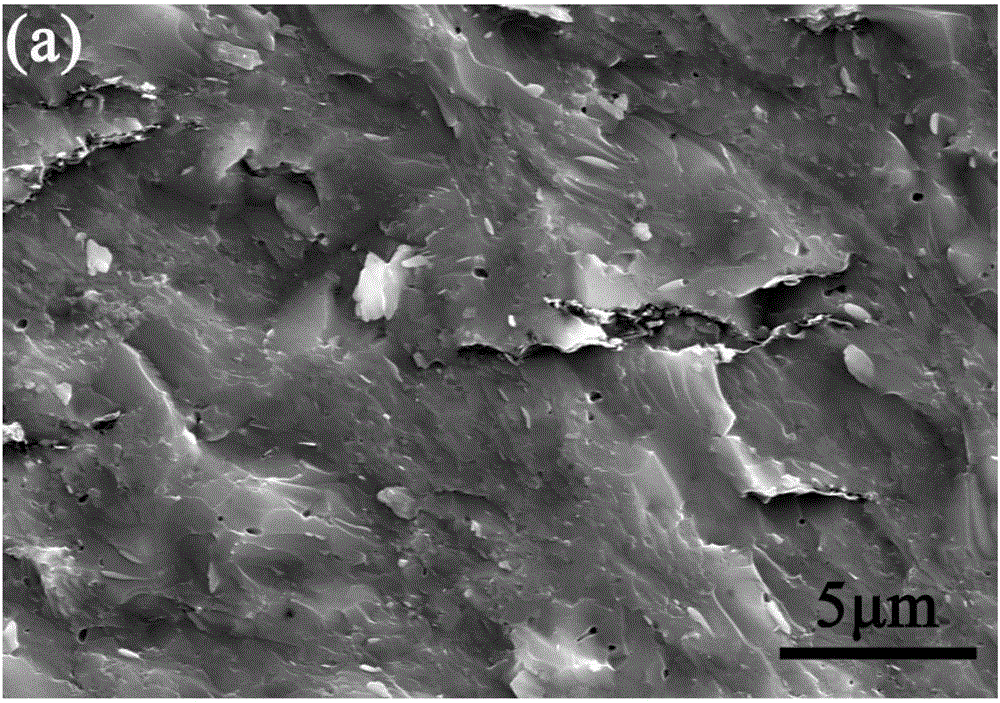

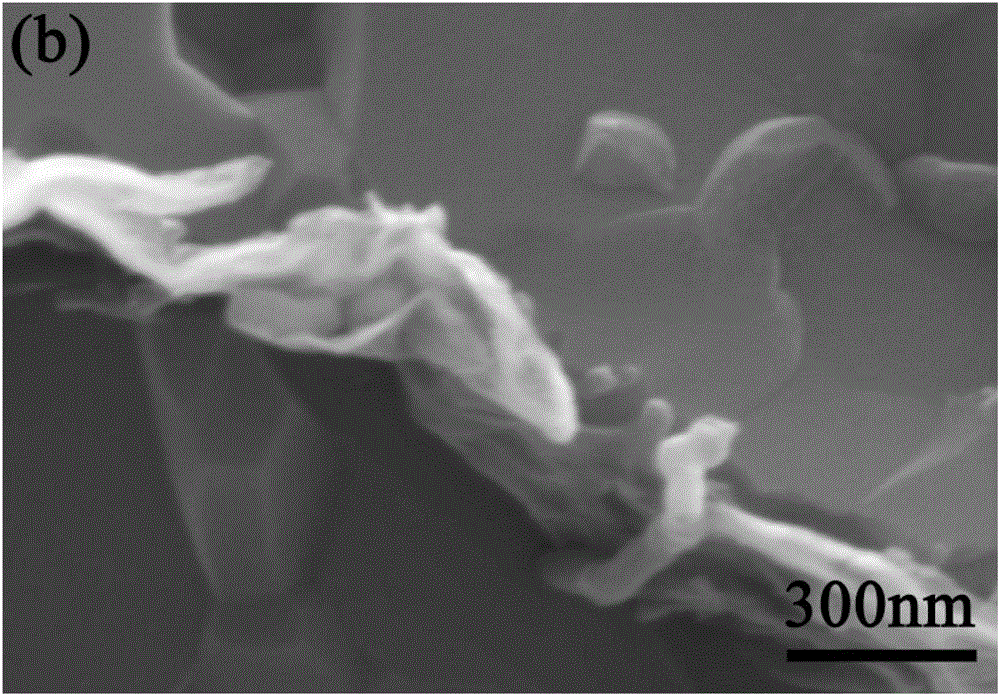

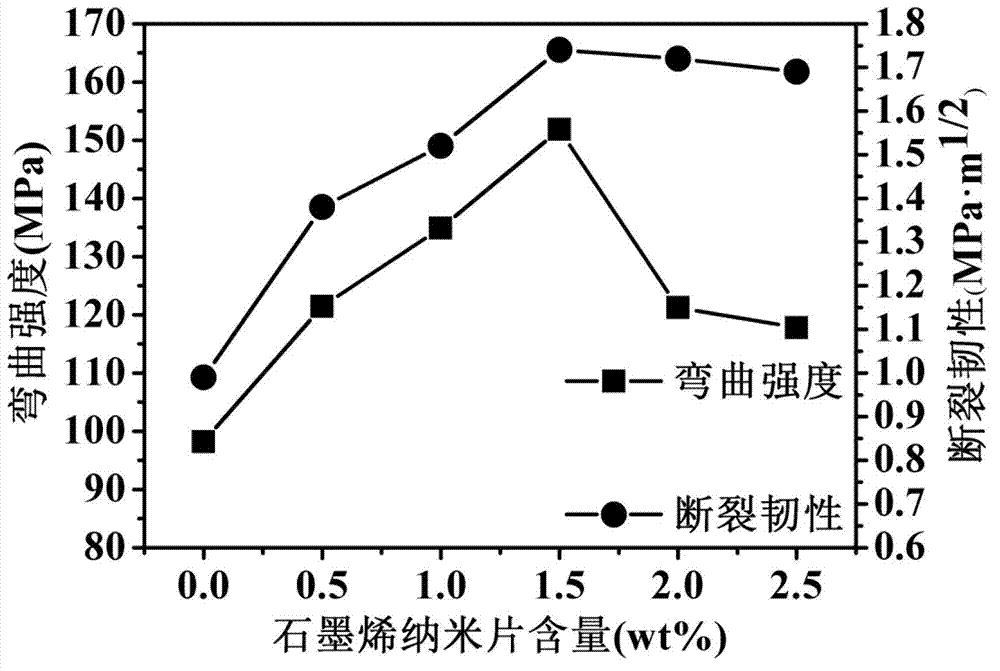

Two-phase calcium phosphate composite material adopting graphene and carbon nano-tube as synergistic toughening phases and preparation method of composite material

The invention discloses a two-phase calcium phosphate composite material adopting graphene and carbon nano-tube as synergistic toughening phases. A weight ratio of graphene to the carbon nano-tube to the two-phase calcium phosphate in the composite material is (0.1-0.5):(0.5-2.5):(97.0-99.4). Graphene and carbon nano-tube are adopted as synergistic toughening phases; the two-phase calcium phosphate is adopted as a substrate; hexadecyl trimethyl ammonium bromide is adopted as a dispersing agent for the graphene and carbon nano-tube; and an ultrasonic process is combined with a ball-milling dispersion process to prepare the two-phase calcium phosphate composite material through hot-pressing sintering. According to the two-phase calcium phosphate composite material and the preparation method of the composite material disclosed by the invention, the selected devices are simple; the cost is low, the preparation process is stable; the toughening phases in the prepared composite material are uniformly dispersed; the toughening phases are well combined with the substrate interface, so that the composite material is excellent in mechanical performances; the bending strength and the breaking toughness respectively reach 166 MPa and 2.13 Mpa.m1 / 2, which are respectively improved by 69% and 115% as compared with those of the two-phase calcium phosphate compositebiological ceramics; and the application prospect is good.

Owner:SHANDONG UNIV

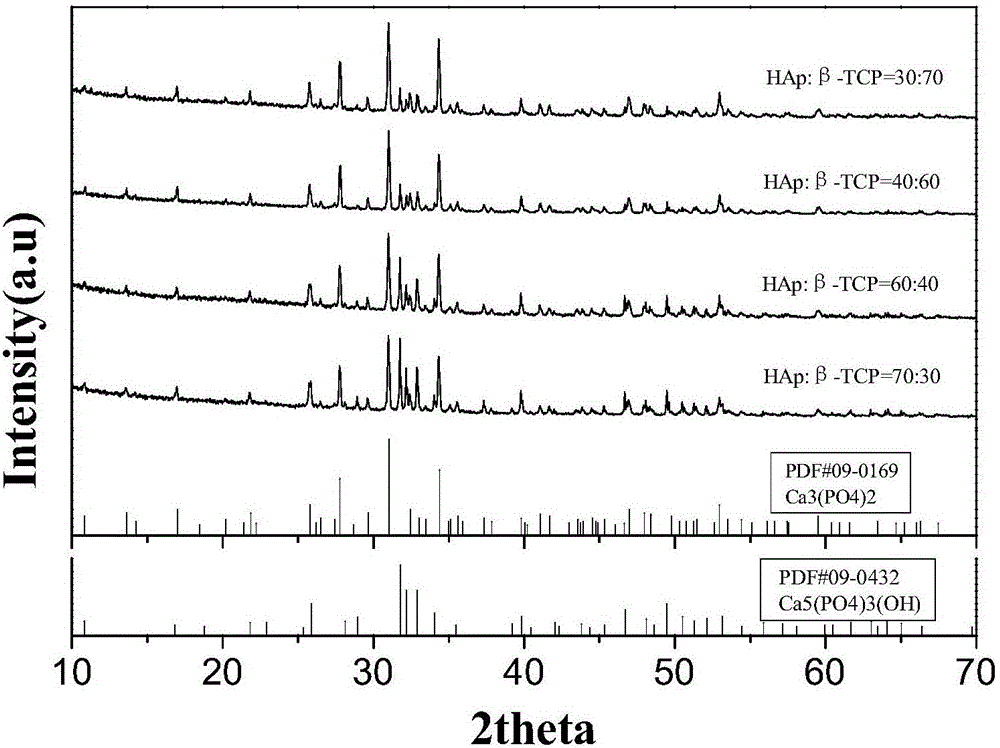

Biphase calcium phosphate (BCP) composite powder synthesized by high-temperature solid phase reaction and preparation method thereof

The invention discloses biphase calcium phosphate (BCP) composite powder synthesized by a high-temperature solid phase reaction. BCP powder is biphase composite powder prepared from hydroxyapatite (HA) and beta-tricalcium phosphate (beta-TCP), in which the molar ratio Ca / P of calcium to phosphorus is 1.5 to 1.67, wherein the value ranges of the relative mass percent of HA and beta-TCP two phases are each 1 to 99 percent; the sizes of crystalline grains of the HA and beta-TCP two phases are 20nm to 300 microns; the crystallinity is 50 to 100 percent. The invention also discloses a preparation method of the BCP composite powder synthesized by the high-temperature solid phase reaction. The BCP composite powder is prepared through the high-temperature solid phase reaction of a calcium-containing solid compound and a calcium-phosphorus solid containing compound. The BCP composite powder has the advantages that a reaction period is short; the costs of raw materials are low; the equipment investment is low; no waste gas and waste water are discharged; further, the proportion of the HA and beta-TCP two phase in the BCP powder is easily regulated and controlled at the same time; the two phases are distributed uniformly; the sizes of the crystal grains and the crystallinity are controllable; finally; the production requirement that the compression strength of BCP biphase composite ceramic is improved or a degradation speed is regulated and controlled is met.

Owner:SUZHOU DINGAN ELECTRONICS TECH

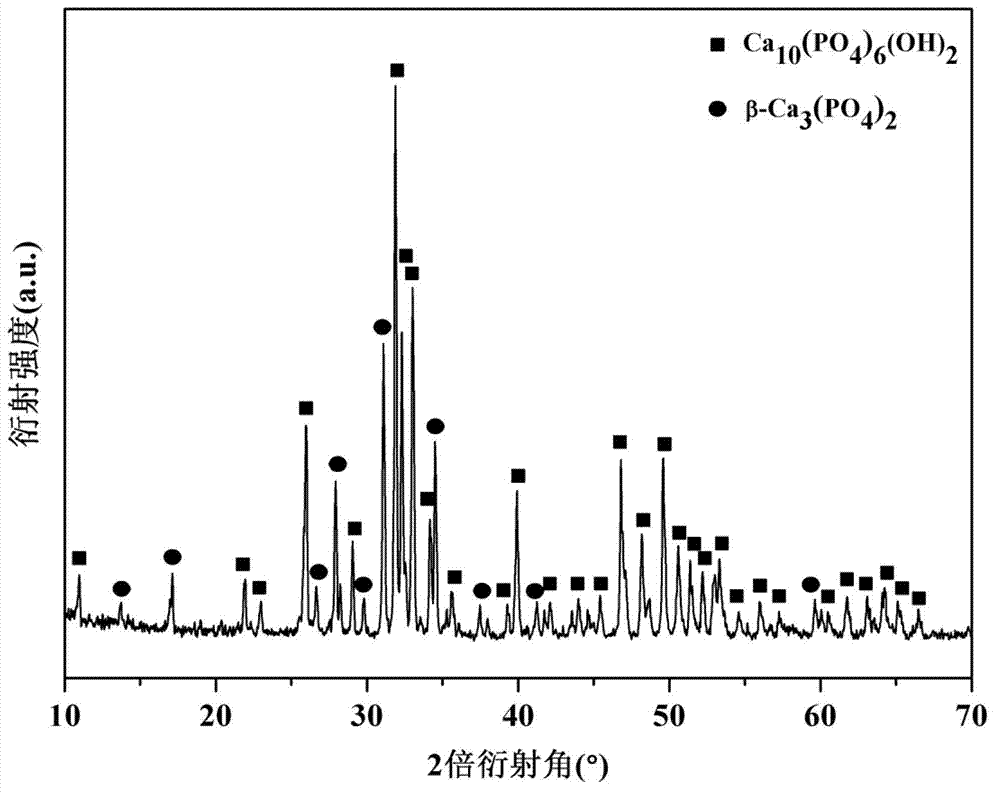

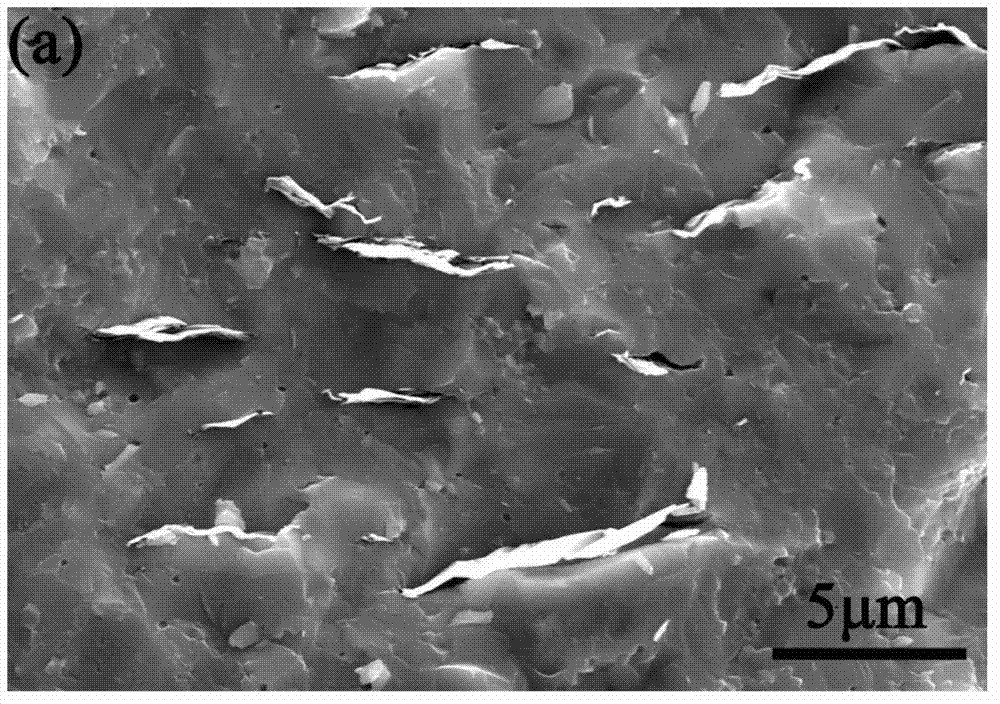

Graphene/dual-phase calcium phosphate composite material and preparation method thereof

InactiveCN102757218AImprove mechanical propertiesEvenly dispersedBiphasic calcium phosphateCalcium biphosphate

The invention discloses a graphene / dual-phase calcium phosphate composite material and a preparation method thereof. The composite material is prepared by performing hot pressing and sintering, taking a graphene nano-sheet as a tough phase, taking biphasic calcium phosphate as a substrate, taking hexadecyl trimethyl ammonium bromide as a dispersing agent of the graphene nano-sheet and adopting an ultrasonic ball-milling dispersing process, wherein the mass ratio of the graphene nano-sheet to the biphasic calcium phosphate is (0.5-2.5):(97.5-99.5). The preparation method has the advantages of simple equipment, low cost and stable preparation process; and the prepared composite material has the advantages of uniform dispersion of the tough phase, high bonding property between the tough phase and the interface of the substrate, high mechanical property, bending strength and fracture toughness being up to 151.82MPa and 1.74MPa.m<1 / 2>, being increased by 55 percent and 76 percent respectively in comparison to biphasic calcium phosphate, and good application prospect.

Owner:SHANDONG UNIV

Apatite super-fine fiber material and its prepn. method

InactiveCN1751745ALarge specific surface areaPromote degradationInorganic material artificial filamentsPhosphorus compoundsTriethylphosphiteApatite

A superfine apatite fiber material used for repairing bone tissue is prepared through proportionally mixing triethyl phosphite with distilled water, hydrolyzing while stirring, adding the aqueous solution of calcium nitrate, stirring, ageing to obtain the gel solution, mixing it with alcohol, adding polyvinyl pyrrolidone to obtain the solution for electrospinning, electrospinning, drying and calcining. Its advantages are nano-class fineness, large specific surface area, high biodegradability and high affinity to cells.

Owner:TIANJIN UNIV

Injectable self-curing artificial bone repair material and preparation method thereof

ActiveCN108553691AGood biocompatibilityImprove support strengthPharmaceutical delivery mechanismTissue regenerationPhosphoric acidBiocompatibility Testing

The invention relates to an injectable self-curing artificial bone repair material and a preparation method thereof. The preparation method comprises the following steps: preparation of two-phase calcium phosphate porous particles, preparation of mineralized collagen porous calcium phosphate composite material and mixing with calcium sulfate hemihydrate. The prepared artificial bone repair material has the following characteristics that: (a) the mineralized collagen is uniformly distributed on the surface and the pores of the two-phase calcium phosphate porous particles, so that the mineralized collagen is uniformly combined with the porous calcium phosphate, thereby having better biocompatibility; (b) the material has a porous structure, not only is favorable for the growth of the bone tissue and the creeping substitution, but also has certain supporting strength; (c) the material can be used as a carrier for growth factors and various antibiotics to carry out anti-inflammatory treatment; (d) the material can be developed under X-ray, which facilitates inspection; (e) the material is degradable, which avoids secondary pain resulting from taking out, and the rate of degradation maybe matched with the new bone growth rate; (f) the material can be injected in situ and has excellent self-curing properties.

Owner:BEIJING ALLGENS MEDICAL SCI & TECH

Process for preparing degradable strontium-doped biphasic calcium phosphate bioactive bone cement

InactiveCN101444638AOvercome Difficulty in FormingOvercome strengthImpression capsDentistry preparationsApatiteMass ratio

The invention discloses a process for preparing degradable strontium-doped biphasic calcium phosphate bioactive bone cement. The cement solid phase adopted by the process is a mixed powder containing Ca4(PO4)2O and Beta-SrxCa3-x(PO4) which are distributed in a certain grain fineness and prepared by a certain molar ratio; the aqueous phase is a water deionized dilute phosphoric acid solution or a dilute phosphoric acid solution with the concentration being lower than 2.0 mol / l; the mass ratio of the reacted solid phase to the reacted aqueous phase is 0.1 to 4.0; and the final products under the physiological environment are strontium-doped hydroxylapatite and residual Beta-SrxCa3-x(PO4). The bone cement has the advantages that the mechanical property is higher; the setting time is proper; the phase composition of the product is changeable; strontium doping content and the calcium strontium / phosphorus ratio are adjustable; the degradation rate is controllable; and the like. Compared with the conventional calcium phosphate bone cement and calcium phosphate bone cement of other types, the biological active bone cement has wider clinical application prospect.

Owner:XI AN JIAOTONG UNIV

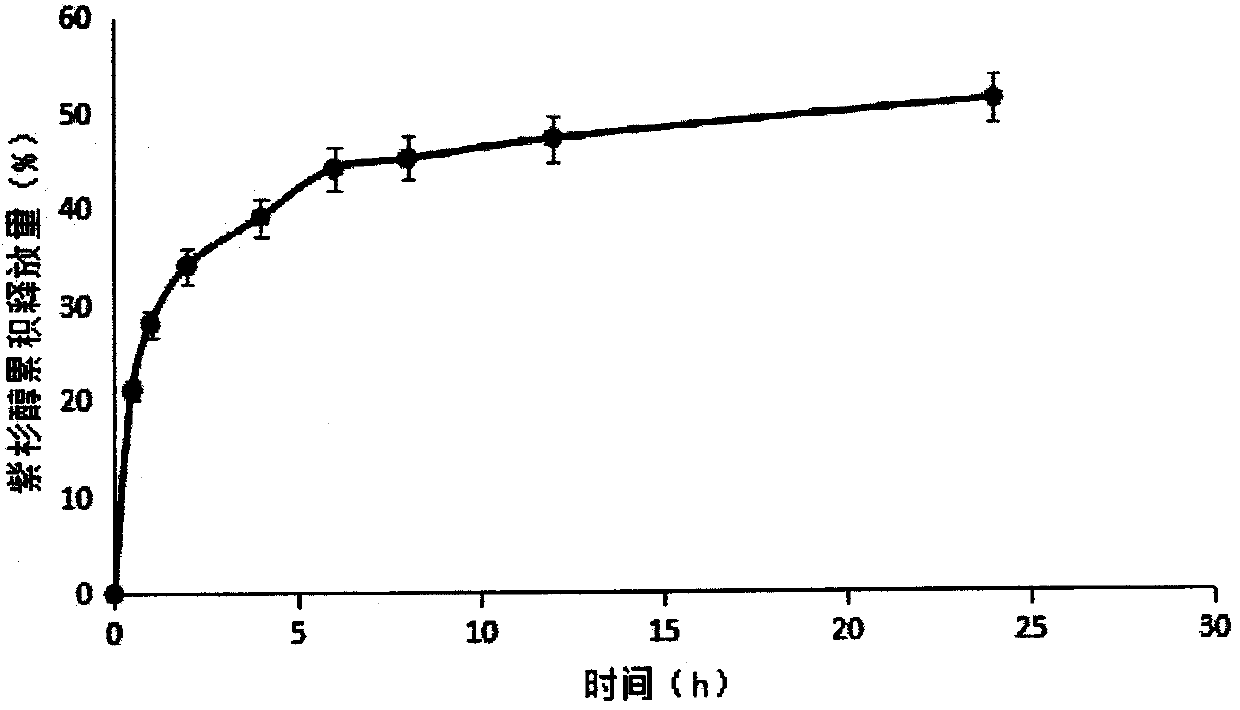

Layer-by-layer self-assembly body having both tumor suppression and bone defect repair functions and preparation method thereof

InactiveCN107596382ASimple preparation processLow costOrganic active ingredientsHeavy metal active ingredientsBiocompatibility TestingLayer by layer self assembly

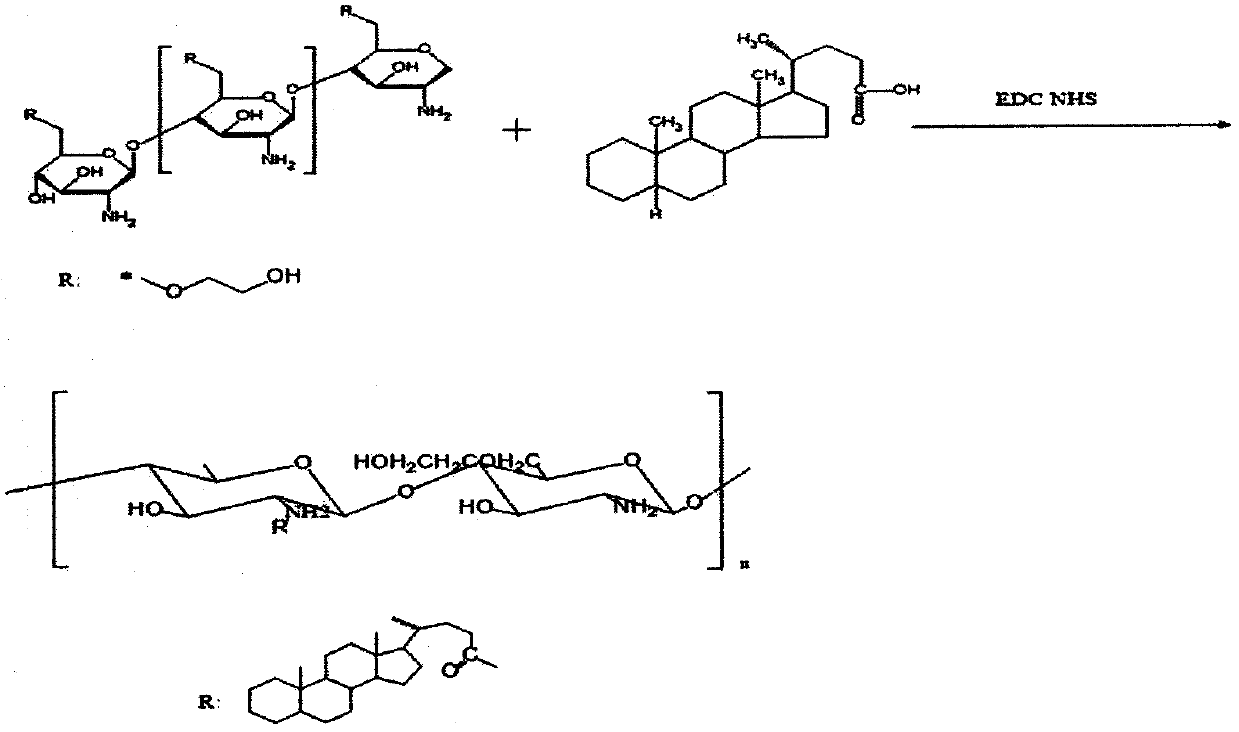

The invention discloses a layer-by-layer self-assembly body having both tumor suppression and bone defect repair functions and a preparation method thereof, and belongs to the field of biomedical materials. In the invention, by means of the layer-by-layer self-assembly technology, a micron / nano-scale biphasic calcium phosphate (BCP) interface is formed, in a layer-by-layer alternating manner, through bionic modification of an adhesion and osteogenesis promoting anionic fusion protein (recombinant fibronectin / cadherin, rFN-CDH) and contains 5[beta]-cholanic acid ethylene glycol chitosan cationic nano-particles supporting an antitumor medicine paclitaxel (HGC-PTX). The structure has physical and chemical properties such as excellent biocompatibility and excellent hydrophilicity, maintains the anti-cancer effect of the HGC-PTX nano-particles and the excellent adhesion and osteogenesis activity promoting of the rFN-CDH protein, so that the layer-by-layer self-assembly body may be used as atumor suppression and bone defect repair material and has a bright future.

Owner:CHINA PHARM UNIV

Calcium phosphate-based materials containing zinc, magnesium, fluoride and carbonate

ActiveUS9199005B2High densityReduce developmentBiocideInorganic phosphorous active ingredientsDiseaseAntioxidant

The present invention provides novel biomaterials comprising one or more of Mg, Zn and F ions in a carbonate-containing biphasic calcium phosphate (BCP) system. The biomaterial may contain Mg, Zn, F, Mg and Zn, Mg and F, Zn and F, or Mg, Zn and F. The biomaterial may be substantially similar in composition to bone mineral (a carbonate apatite). The biomaterial may feature slow release of Mg, Zn, F, Ca, and P ions. The biphasic calcium phosphate, BCP, may be a mixture of unsubstituted hydroxyapatite (HA) and unsubstituted.-TCP, Ca3(PO4)2. BCP of varying HA / .-TCP ratios may be produced by sintering calcium-deficient apatite, for instance having a Ca / P<1.5, 1.6, 1.67, 1.75 or 1.8 that has been prepared either by a precipitation or by a hydrolysis method or by a solid-state reaction. The amount of each component (by weight %) present in the biomaterials may be as follows: Mg 0.5 to 12 wt %, Zn 1 to 12 wt %, F 0.1 to 4 wt %, calcium 20 to 40 wt %, phosphate 10 to 20 wt %, and carbonate (CO3) 1 to 20 wt %. The biomaterial may further comprise one or more other ion such as strontium, manganese, copper, boron or silicate, or one or more other organic moiety such as a protein, a peptide, or a nutraceutical which may provide antioxidant, anti-bacterial or anti-inflammatory properties. The invention also provides methods of inhibiting bone resorption, methods of treating osteoporosis or delaying the onset of osteoporosis, methods of treating a bone fracture, and methods of inhibiting osteoclast activity. Further, the invention provides methods of treating or reversing bone deficiencies such as bone loss, similar to osteoporosis, caused all or in part by a mineral deficient diet, a disease such as cancer or osteopenia, a treatment such as steroid therapy or radiation therapy, or a physical condition such as immobilization.

Owner:NEW YORK UNIV

Composite bioceramic material and preparation method thereof

InactiveCN107602110AGood biocompatibilityImprove mechanical propertiesProsthesisFreeze-dryingFreeze-casting

The invention provides a composite bioceramic material and a preparation method thereof. The preparation method comprises the steps as follows: S1, porous hydroxyapatite, two-phase calcium phosphate ceramic, octacalcium phosphate, calcium pyrophosphate, calcium nitrate, ramie seed gum, carbon spheres, nano titania, chitosan, nano zinc oxide, strontium carbonate and distilled water are mixed, and the mixture is ball-milled in a planetary ball mill; S2, polylactic acid, phenolic epoxy resin and 3,3'-diaminodipropylamine are added, and the mixture is stirred at the rotating speed of 100-200 r / min; S3, a polyoxyethylene-polyoxypropylene copolymer, polyoxyethylene-polyoxypropylene pentaerythrilol ether and polyethylene glycol are added, and the mixture is stirred and then placed in a vacuum drying oven to be vacuumized for defoaming treatment; S4, the obtained mixture is poured in a freeze casting device and a frozen green body is obtained; S5, the green body is placed in a sintering furnace to be sintered for 3-4 h after being freeze-dried, and the composite bioceramic material is obtained. The composite bioceramic material has very good biocompatibility and good mechanical performance.

Owner:WUXI SHENGYA BIOTECH CO LTD FOSHAN BRANCH

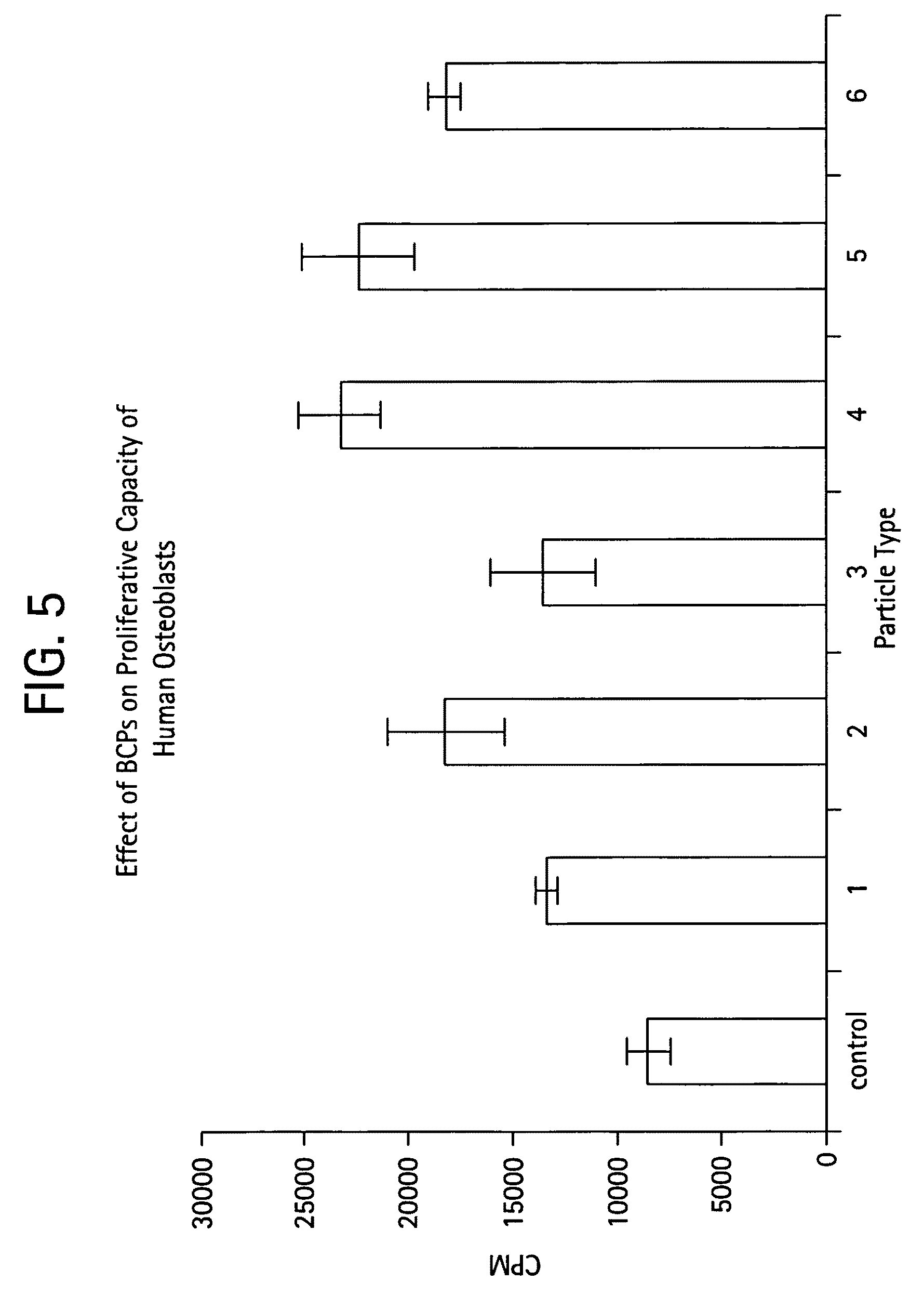

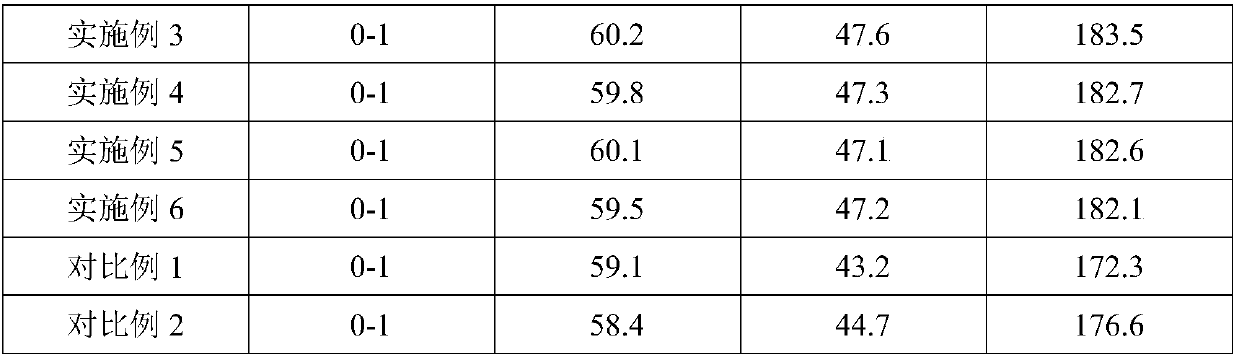

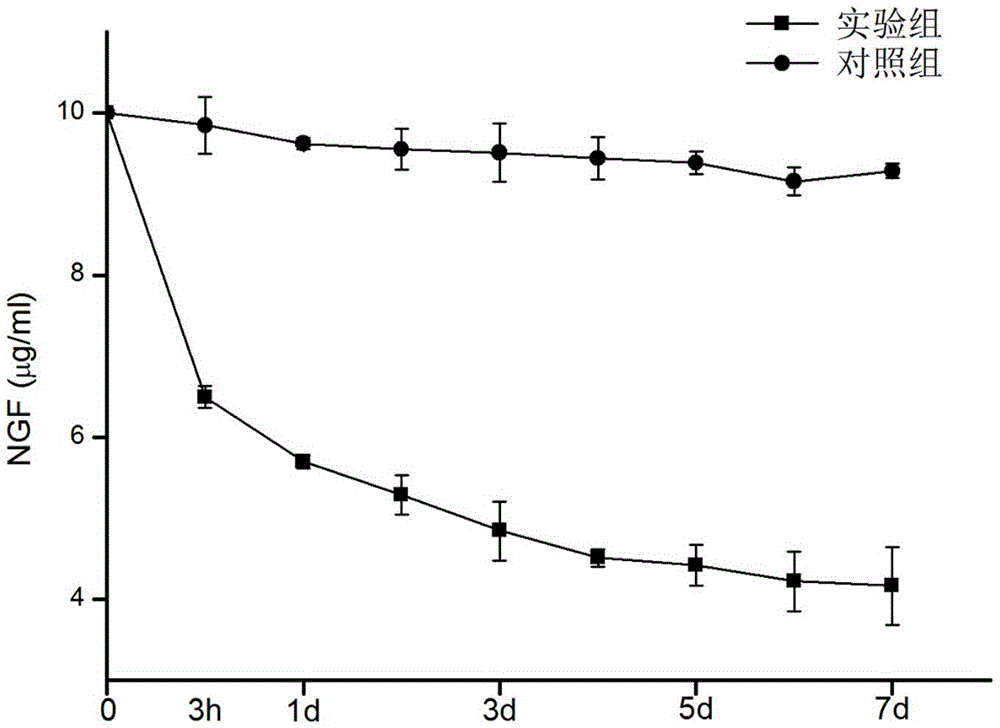

Production method of growth factor supported porous biologic ceramic artificial bone scaffold

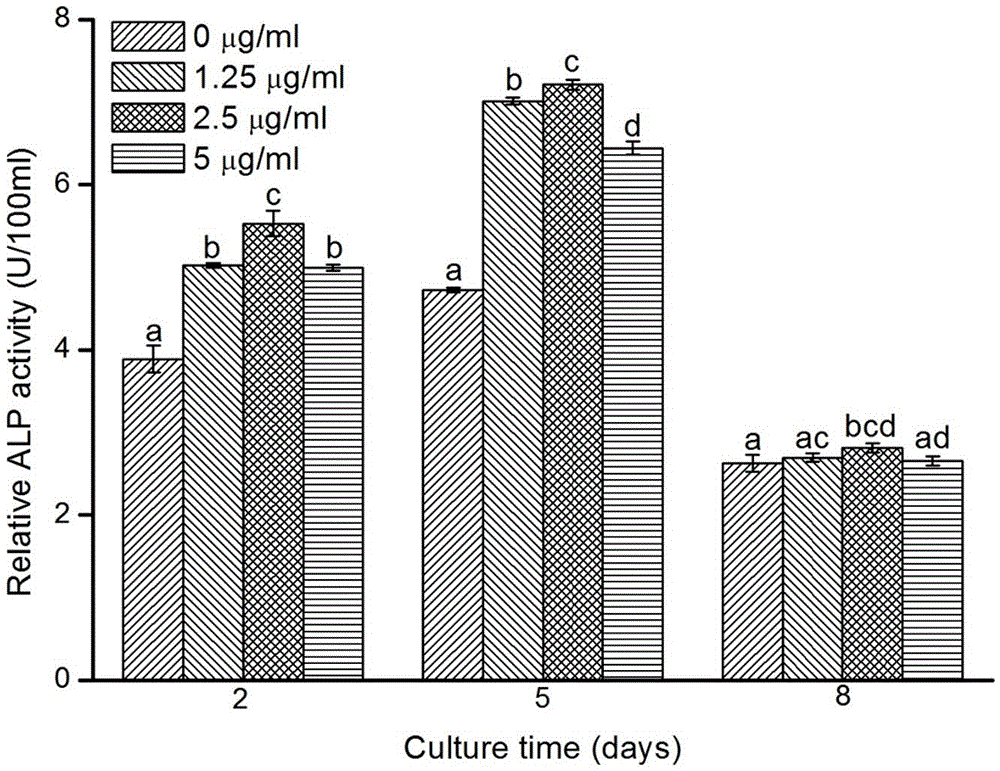

InactiveCN105561397APromote proliferationPromote directed differentiationTissue regenerationProsthesisCobra venomOsteoblast

The invention discloses a production method of a growth factor supported porous biologic ceramic artificial bone scaffold, and belongs to the field of medical science and biomedical engineering. Qualitative and quantitative detection of a cobra venom nerve growth factor (NFG) adsorbed through a biphasic calcium phosphate ceramic (BCP) artificial bone scaffold and artificial bone scaffold function detection prove that the NGF supported BCP is in favor of realizing osteoblast proliferation and directed differentiation. The NGP supported BCP has a good ossification promotion effect, provides a possible method for producing osteoblast in vitro culture scaffolds, and makes researches of bioengineering materials be possible.

Owner:GUANGXI MEDICAL UNIVERSITY

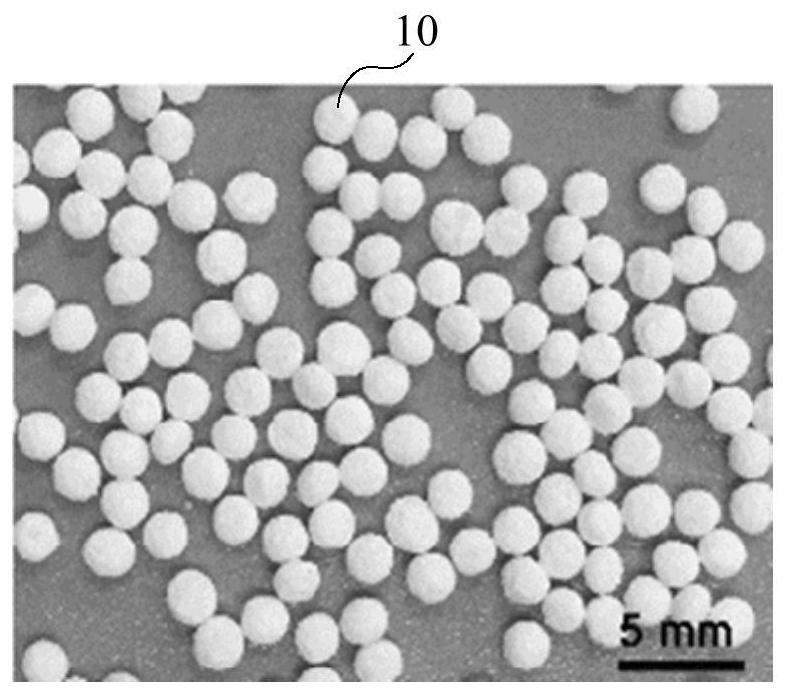

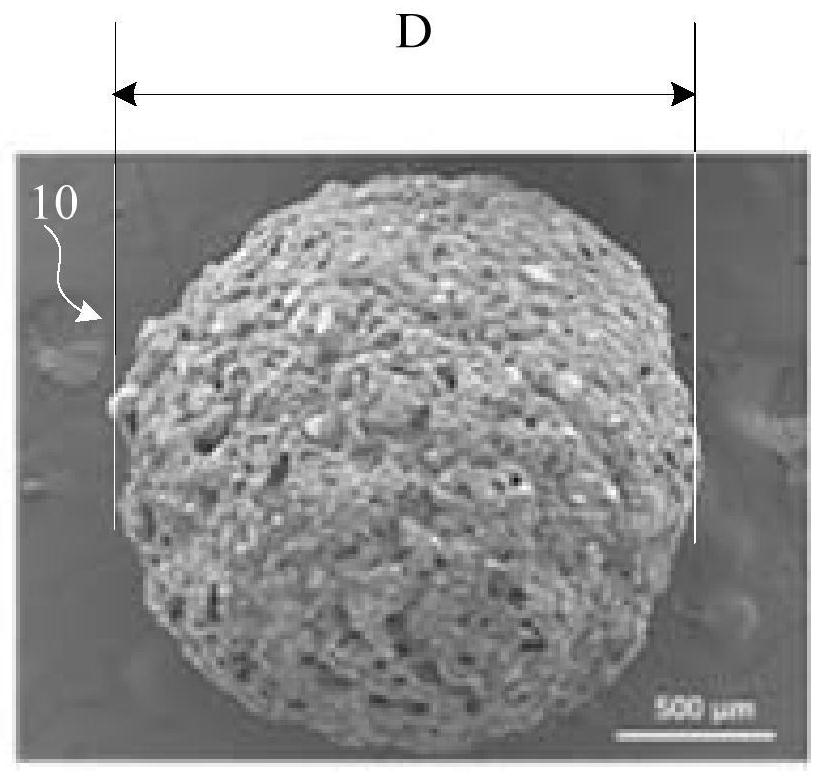

Degradable artificial bone particles with core-shell structure and preparation method thereof

The invention discloses degradable artificial bone particles with a core-shell structure. The particles are characterized in that: the particles have a core-shell structure, the core-shell structure comprises an inner core layer and an outer shell layer coating the outer surface of the inner core layer, the material of the inner core layer is different from that of the outer shell layer, the innercore layer and the outer shell layer are in a ceramic phase, the degradation rate of the inner core layer is smaller than that of the outer shell layer, the outer shell layer is of a porous structure, the porous structure comprises a plurality of through holes with a first hole diameter and a plurality of micropores with a second hole diameter, the through holes are communicated with one another,the inner core layer is selected from at least one of hydroxyapatite, beta-tricalcium phosphate and biphasic calcium phosphate, and the outer shell layer is selected from at least one of hydroxyapatite, beta-tricalcium phosphate and biphasic calcium phosphate. According to the present disclosure, the artificial bone particles which meet the requirements of both osteogenesis, vascularization and degradability of ceramics can be obtained.

Owner:SICHUAN UNIV

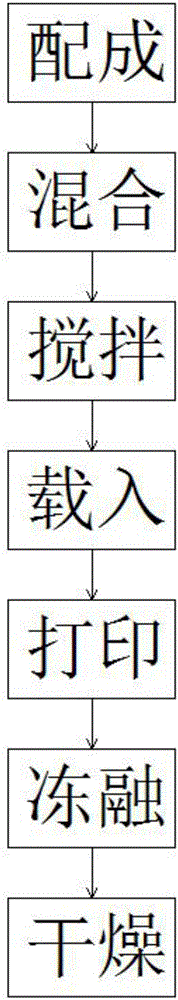

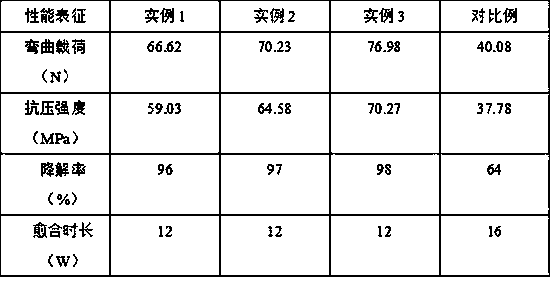

Formula and preparation method of engineered bone scaffold

ActiveCN106620872ATo achieve the effect of sustained releaseSignificant osteogenesisAdditive manufacturing apparatusTissue regenerationCalcium biphosphateBiphasic calcium phosphate

The invention discloses a formula and a preparation method of an engineered bone scaffold. The formula comprises polyvinyl alcohol powder, deionized water and two-phase calcium phosphate. Firstly, 0.15 g / ml of polyvinyl alcohol colloid is prepared by dissolving polyvinyl alcohol in deionized water, then two-phase calcium phosphate-polyvinyl alcohol paste tissue is formed by compounding two-phase calcium phosphate and polyvinyl alcohol colloid, the paste as a raw material is printed by a biological material printer, and a two-phase calcium phosphate-polyvinyl alcohol tissue engineered bone scaffold material with inducing osteogenesis capacity is prepared. The bone tissue engineering scaffold can combine growth factors and medicines, has a slow release effect and has effective potential clinical use value.

Owner:FOURTH MILITARY MEDICAL UNIVERSITY

Nanometer bone repairing material and preparation method thereof

InactiveCN108066817AGood osteoinductivityImprove brittlenessTissue regenerationProsthesisFiberSpatial capacity

The invention relates to a nanometer bone repairing material and a preparation method thereof, and belongs to the technical field of biomedical materials. Bovine bone powder is calcined at high temperature to produce biphasic calcium phosphate in a beta-tricalcium phosphate crystal form, and with the biphasic calcium phosphate as a framework, pearl protein and fish maw collagen are crosslinked andfilled into a porous structure of the biphasic calcium phosphate, so that the brittleness and mechanical properties of the nanometer bone repairing material are improved; in the process of guiding tissue regeneration, the degradation rate of the nanometer bone repairing material is adapted to tissue growth, so that the spatial capacity of a bone defect position is maintained to prevent a fibroustissue from entering a bone defect area, and a degraded product is prevented from quickly entering a body to affect the tissue regeneration at the bone defect position; in addition, the pearl proteinis used for regulating the deposition rate and the surface morphology of CaCO3, a calcium ion binding condition is adjusted, nucleation of calcium carbonate crystals is accelerated, the alkaline phosphatase activity is promoted, osteoblast differentiation is induced, formation of mineralized nodules is promoted, osteoclast differentiation and bone tissue absorption are inhibited, and bone repair is effectively promoted.

Owner:常州琨瑶纺织品有限公司

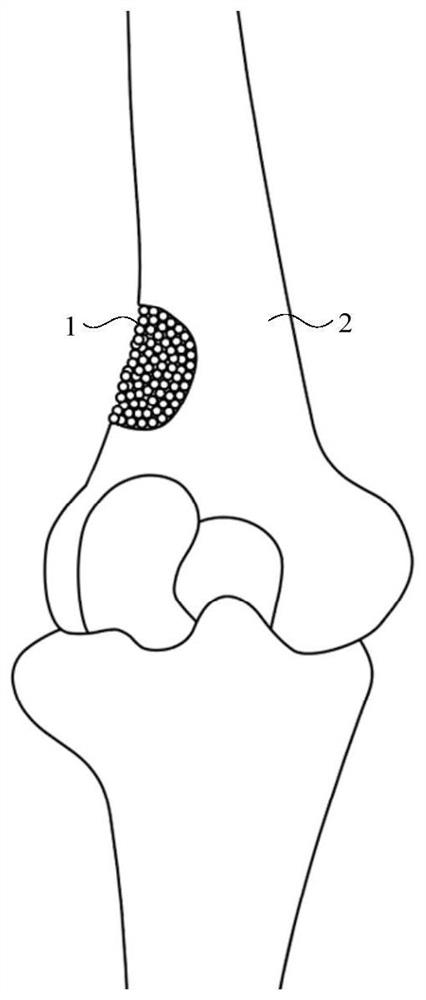

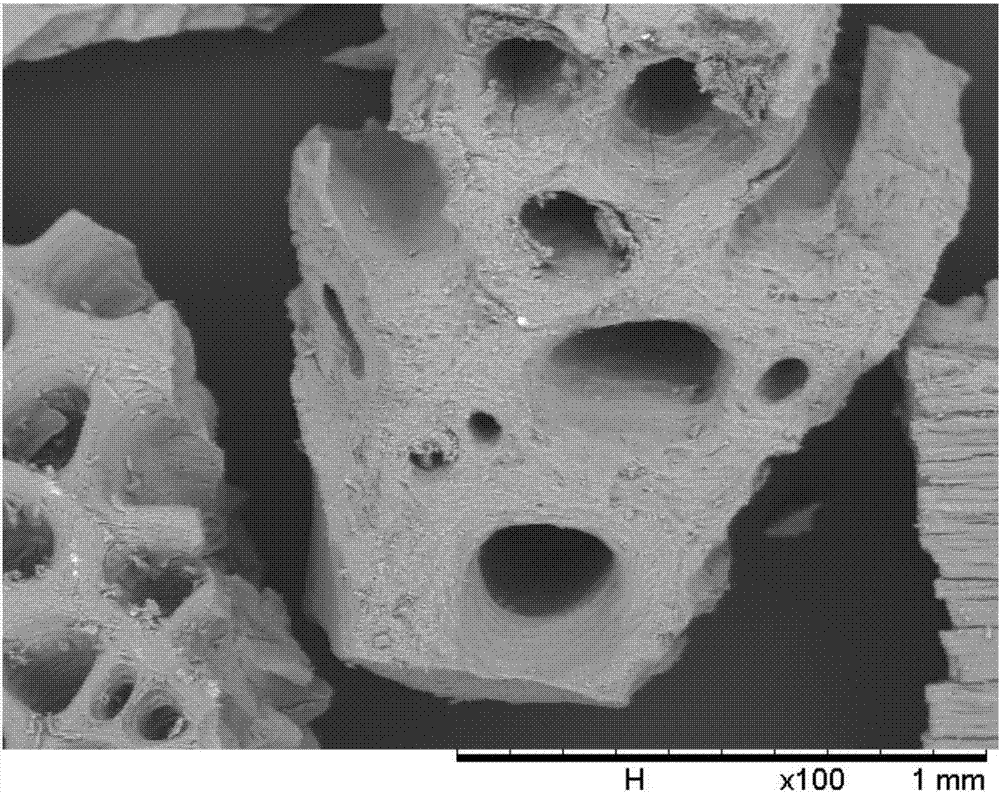

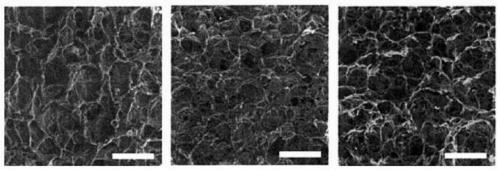

Biphasic calcium phosphate porous bioceramic bone scaffold material and preparation method thereof and application

The invention relates to the field of bioceramic materials, in particular to a biphasic calcium phosphate porous bioceramic bone scaffold material which is prepared from salmon spine as a raw material, is composed of main ingredients hydroxyapatite and beta-tricalcium phosphate , has high porosity, reserves a natural three-dimensional pore structure, has a particle size of 500-1000 [mu]m, and is prepared through steps of washing and drying, high temperature calcination, grinding, sieving and sterilization. The biphasic calcium phosphate porous bioceramic bone scaffold material is rich in sources of raw materials and low in preparation cost, high purity biphasic calcium phosphate ceramic can be prepared without artificial addition of compounds, and the content of hydroxyapatite and beta-tricalcium phosphate can be changed by controlling the calcination temperature in the preparation process, and the biphasic calcium phosphate porous bioceramic bone scaffold material contains a small amount of carbonated hydroxyapatite and various trace elements such as magnesium, potassium and strontium, with the content close to the content in the human body. The calcium phosphate ceramic prepared through the method can serve as a good bone scaffold material to be applied to clinical bone defect repair.

Owner:SHANGHAI CHANGHAI HOSPITAL

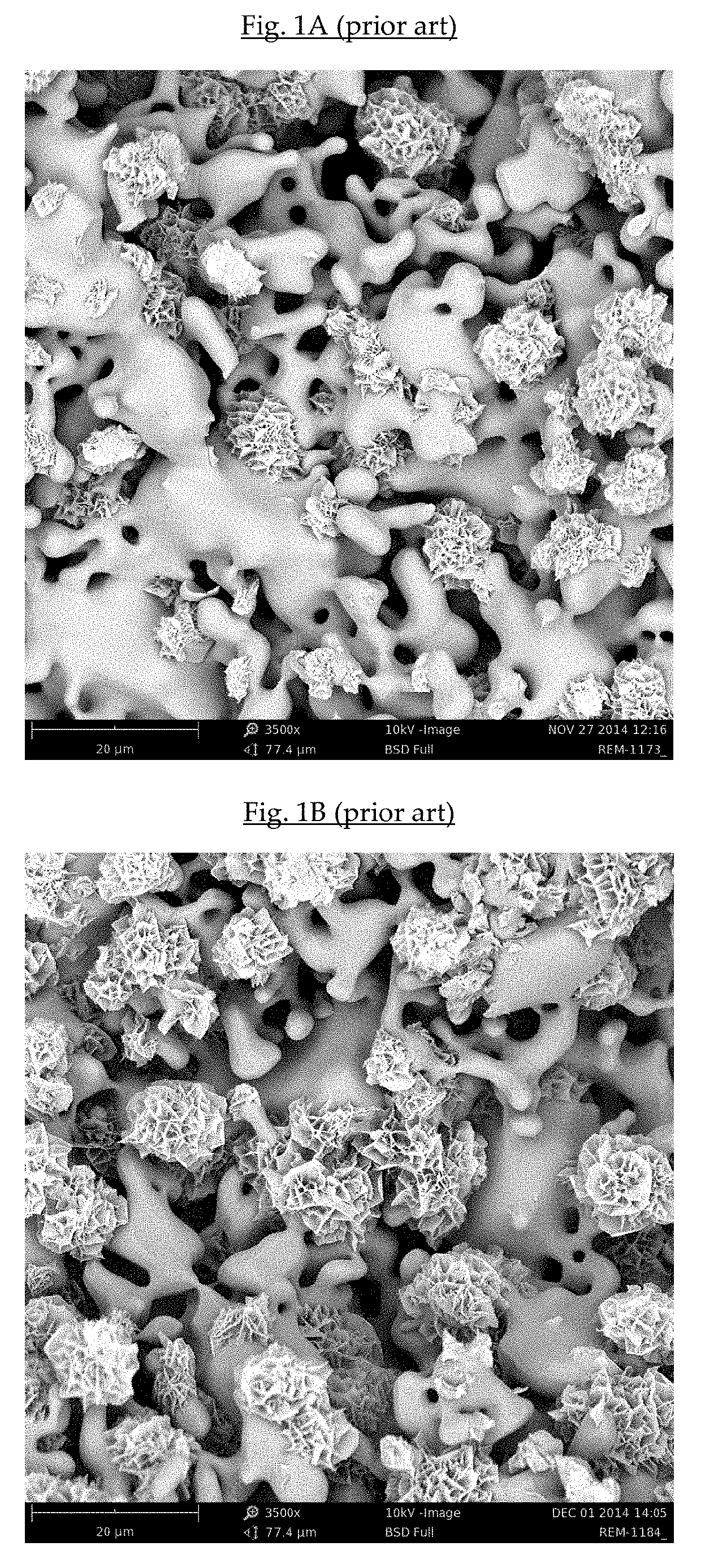

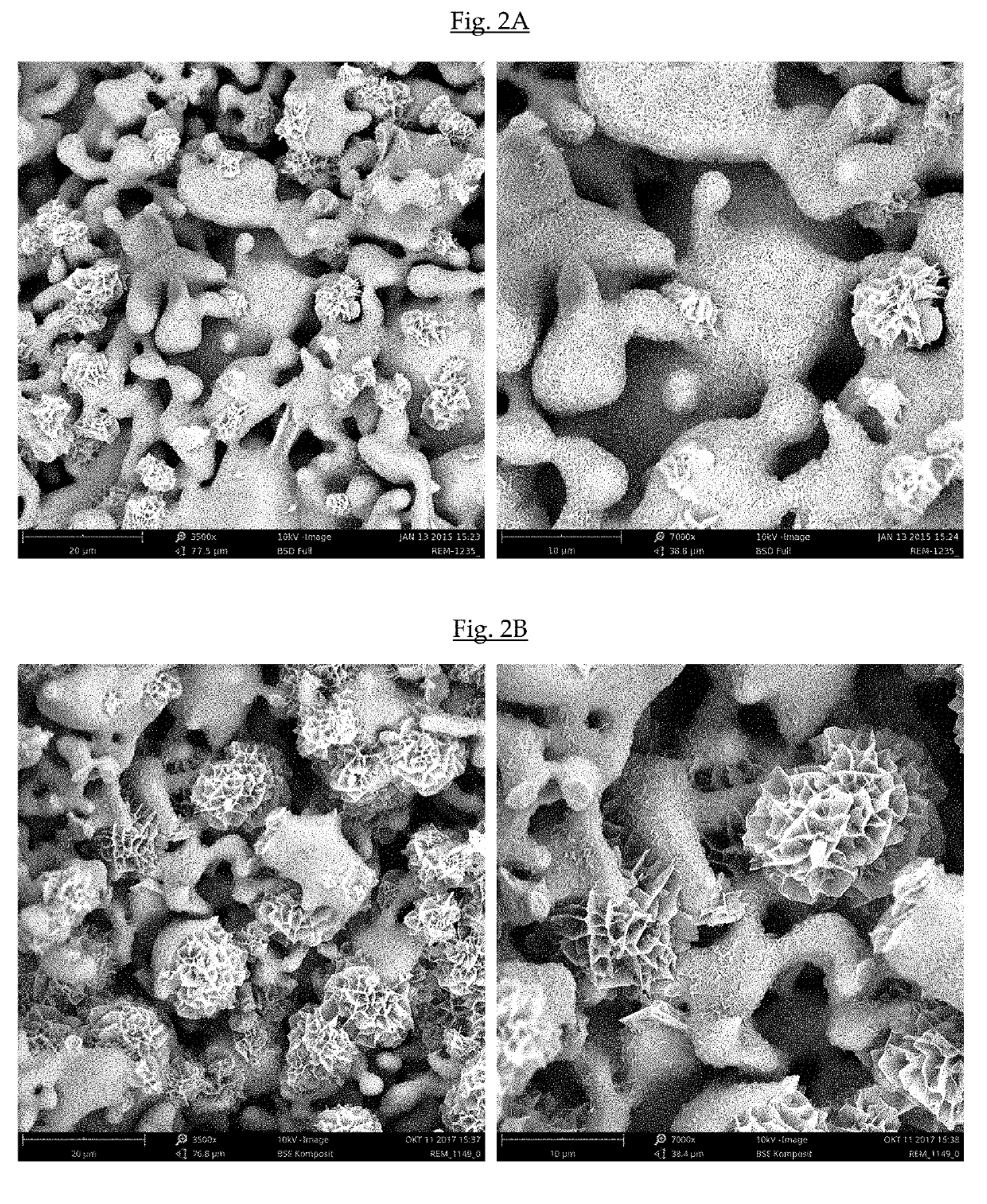

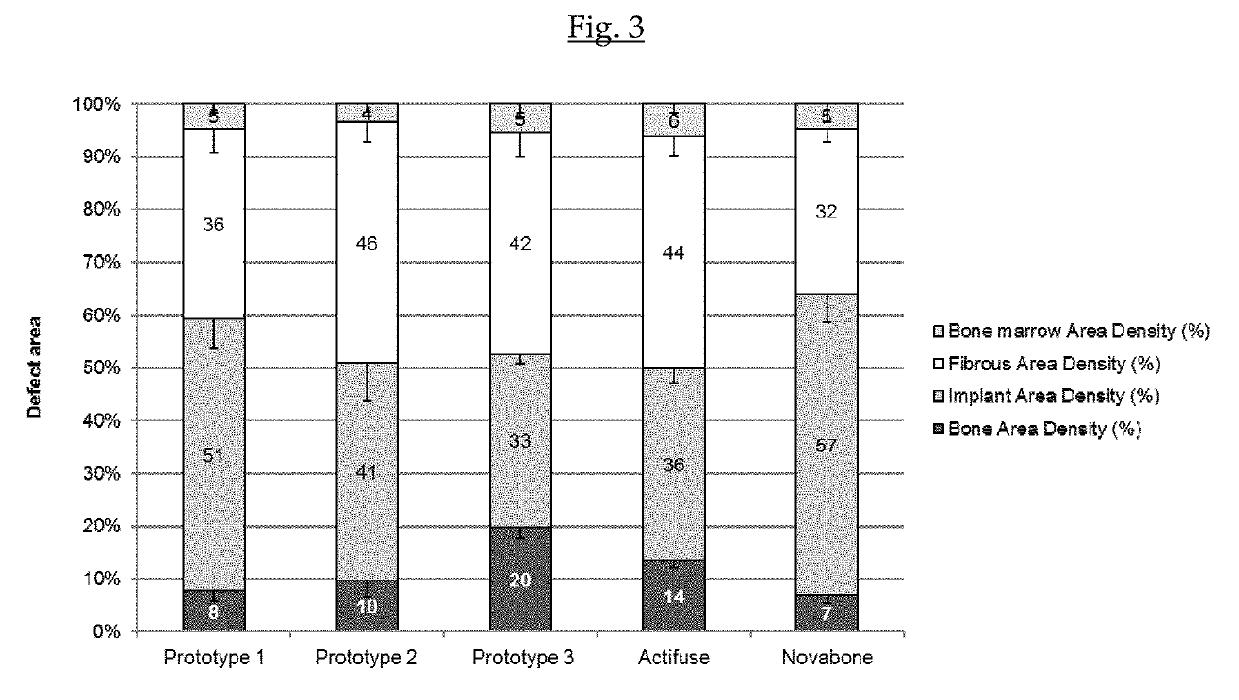

Bone substitute material

ActiveUS20190209737A1Increase capacityImproves osteoblast differentiationSurgical adhesivesBone implantBiphasic calcium phosphateBone formation

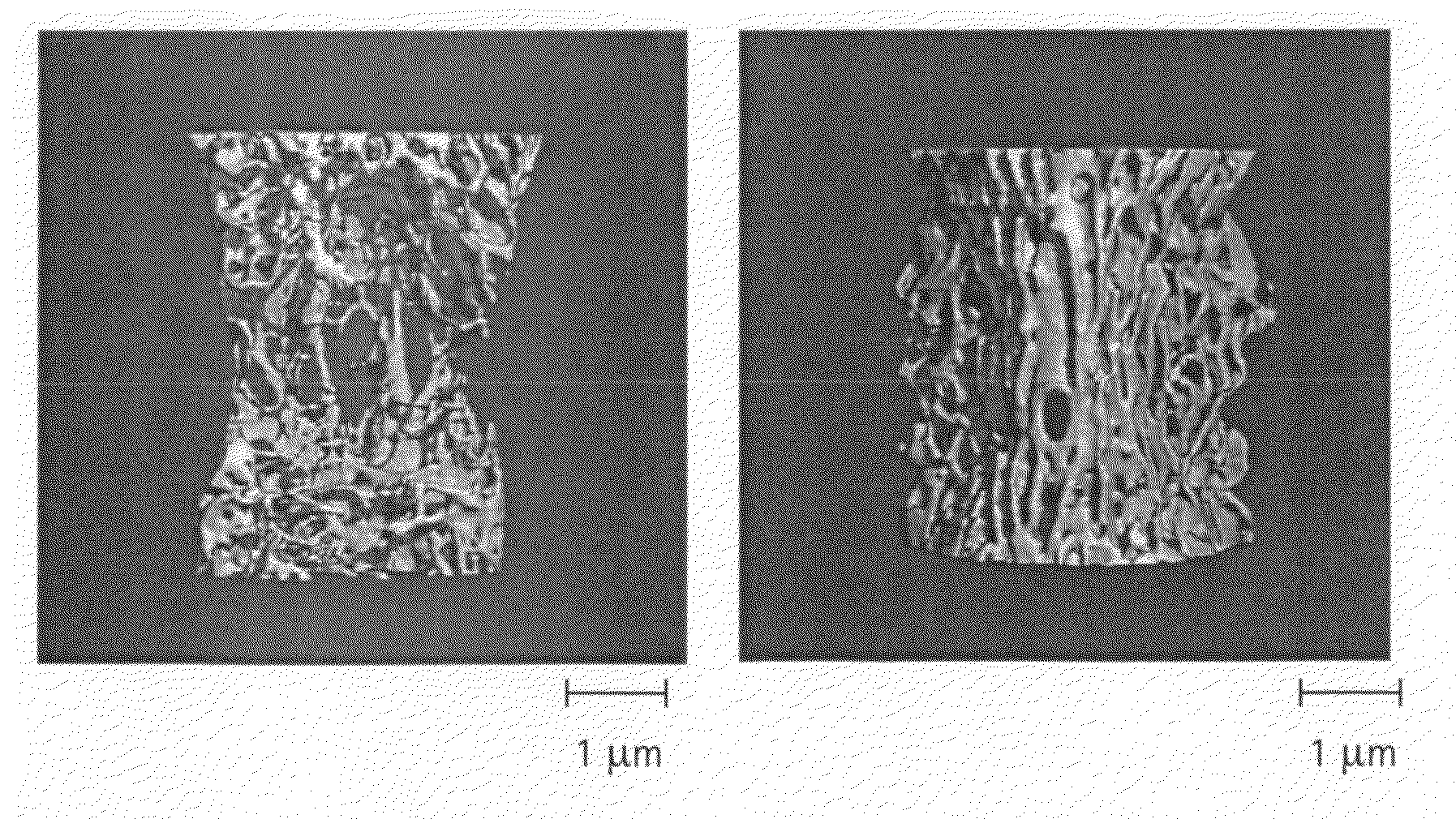

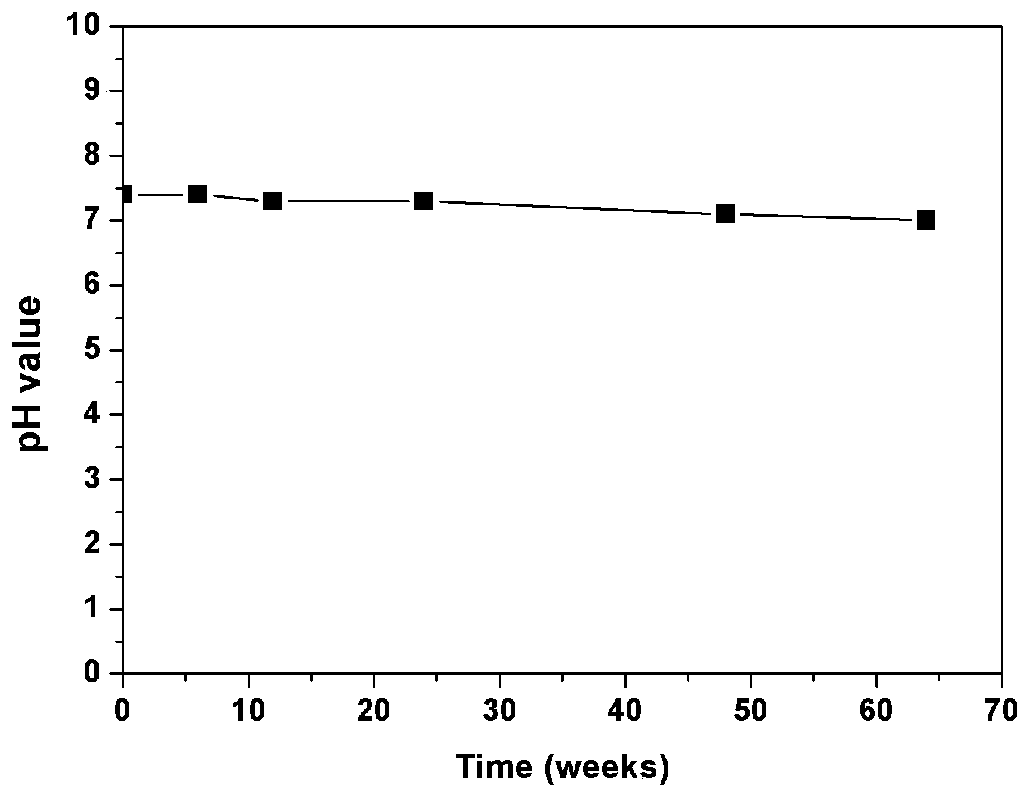

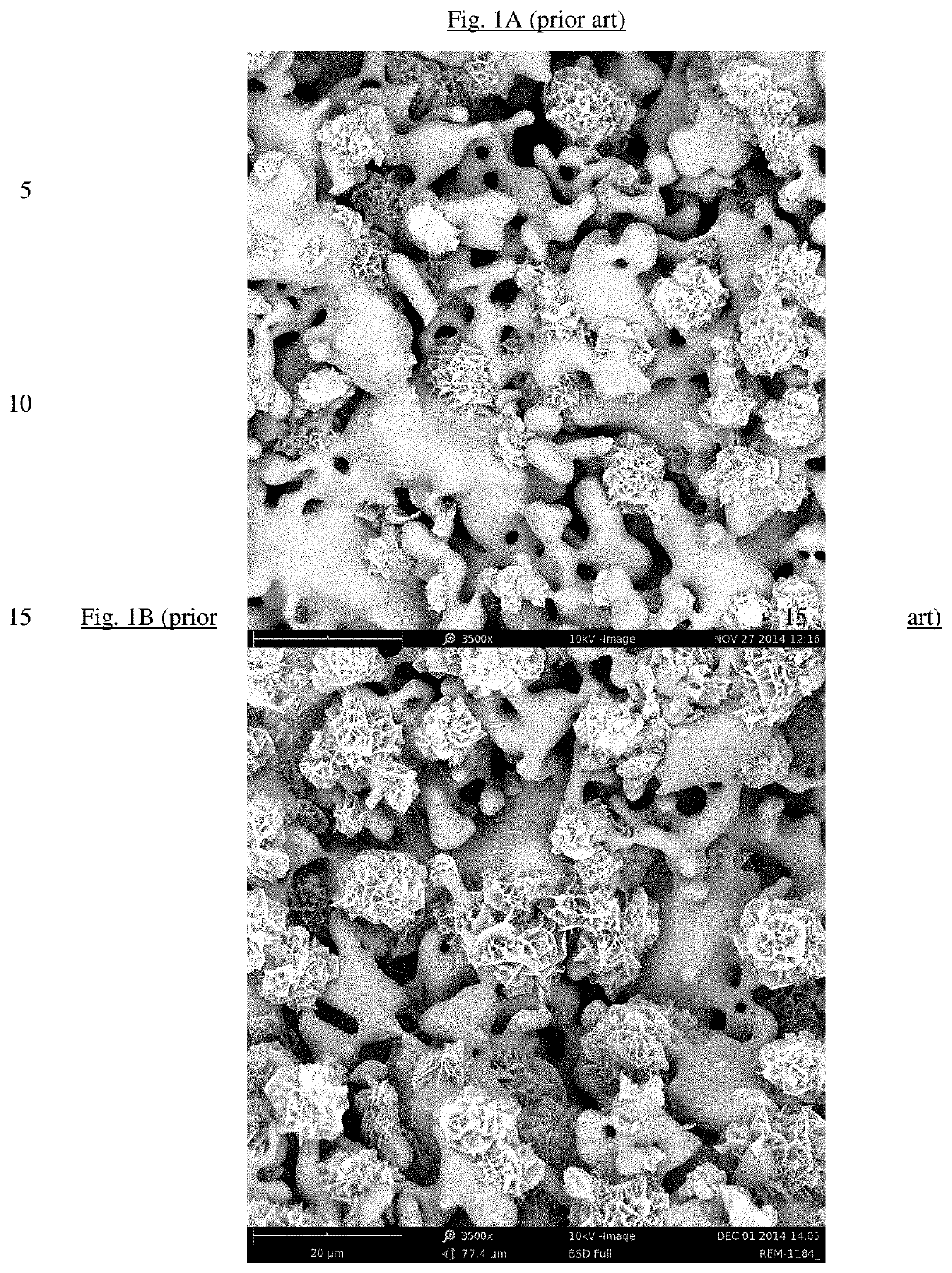

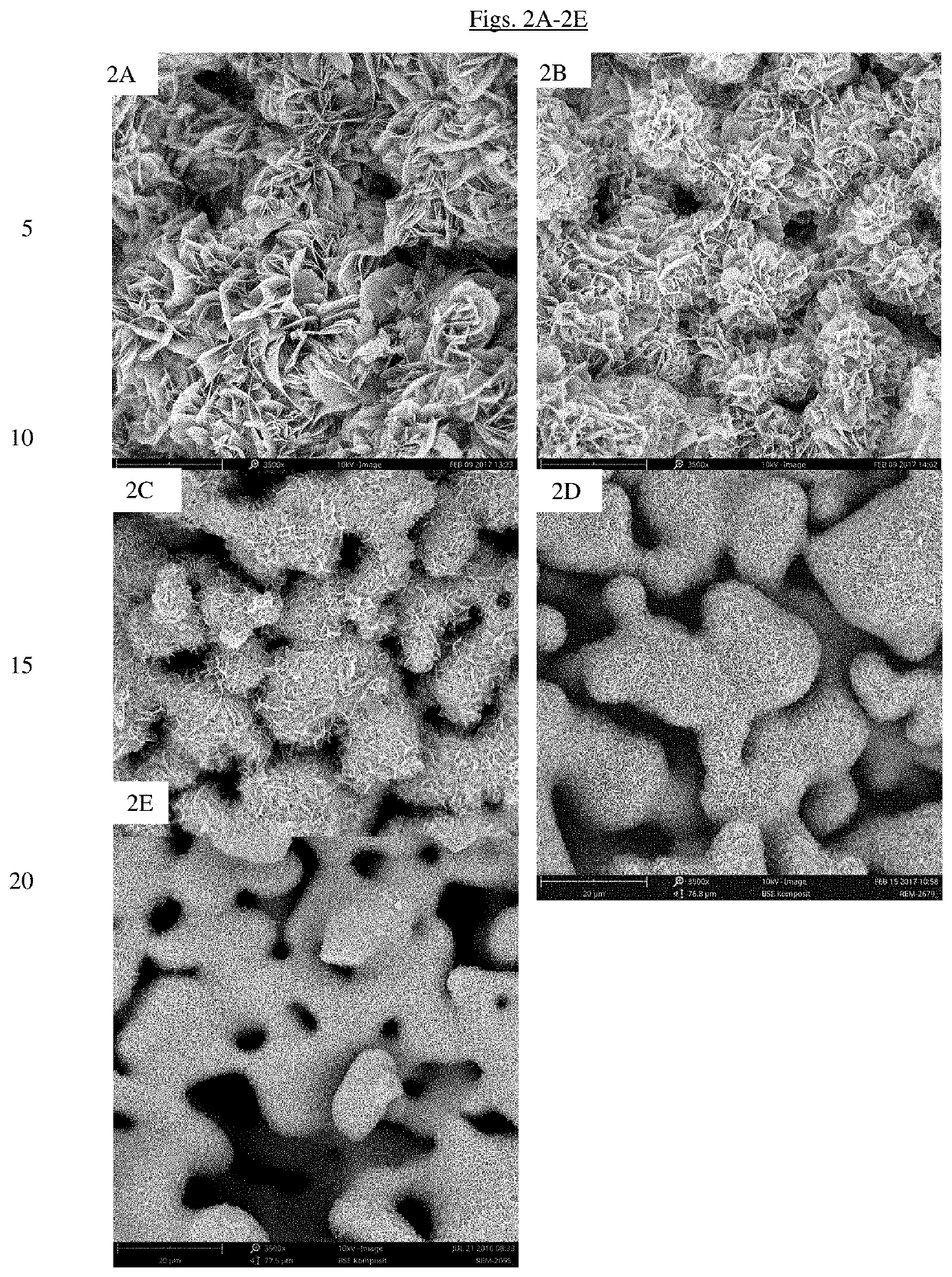

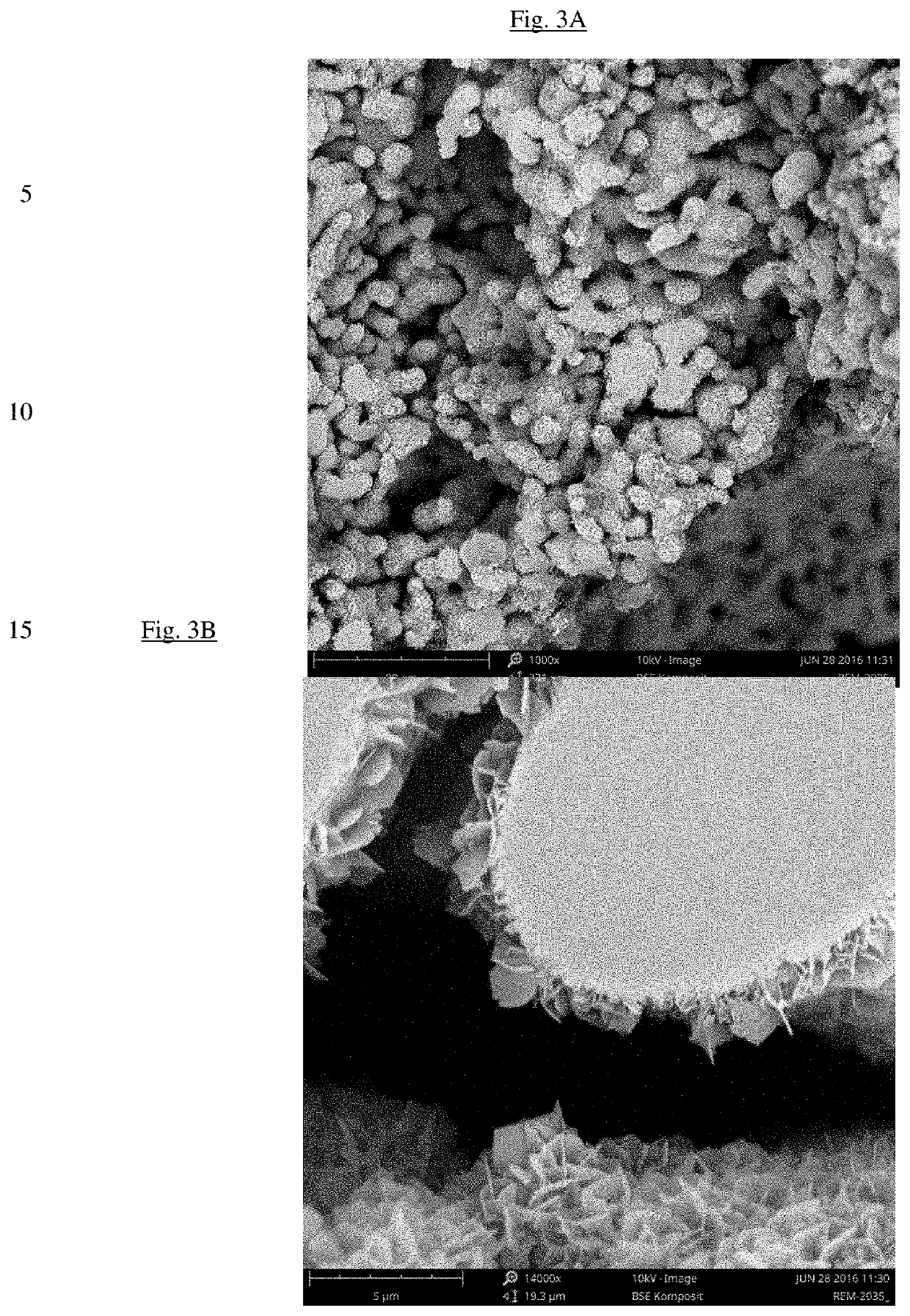

A biphasic calcium phosphate / hydroxyapatite (CAP / HAP) bone substitute material having a sintered CAP core and at least one closed epitactically grown layer of nanocrystalline HAP deposited on the external surface of the sintered CAP core, whereby the epitactically grown nanocrystals have the same size and morphology as human bone mineral, wherein the closed epitactically grown layer of nanocrystalline HAP deposited on the external surface of the sintered CAP core has a non-homogeneous external surface comprising individual clusters of flat crystal platelets consisting of epitactically grown HAP nanocrystals and coarse areas between the individual clusters, whereby the percentage of the coarse areas between the individual clusters as measured by SEM is at least 20% of the total surface, which material shows an increased capacity to induce bone formation, and a process of preparation thereof.

Owner:GEISTLICH PHARMA

Drug-loaded artificial bone material for repairing bone defect and preparation method thereof

ActiveCN108187139APromote repair growthHigh mechanical strengthOrganic active ingredientsPeptide/protein ingredientsTissue repairOsteoblast

The invention relates to the technical field of orthopedic materials, and particularly relates to a drug-loaded artificial bone material for repairing a bone defect and a preparation method thereof. The drug-loaded artificial bone material is prepared from the following raw materials in parts by weight: 5 to 10 parts of drug-loading microsphere, 60 to 70 parts of compound gel particle, 10 to 16 parts of diphase calcium phosphate powder and 2.5 to 4 parts of collagen, wherein the drug-loading microsphere is a complex of hyaluronic acid and modified icariin; the modified icariin is amino modified icariin; the compound gel particle is a complex of modified chitosan and modified retinervus luffae fructus; the mass ratio of the modified chitosan to the modified retinervus luffae fructus is (1 to 2) to 1. According to the drug-loaded artificial bone material provided by the invention, the amino modified icariin for promoting the secretion of the alkaline phosphatase of osteoblast and promoting the skeletal calcification and bone formation is mixed with the hyaluronic acid; the drug property of the drug-loaded artificial bone material is slowly released; the repairing and the growth of defective bone tissue are continuously promoted; in addition, the bacteriostatic and antipyrotic effects are achieved through the modified chitosan, and besides, the artificial bone material is good indegradability and biocompatibility.

Owner:AFFILIATED YONGCHUAN HOSPITAL OF CHONGQING MEDICAL UNIV

Composite absorbable interface screw and preparation method thereof

PendingCN111494724ASimple preparation processImprove reliabilitySurgeryBiphasic calcium phosphatePolymer science

The invention discloses a composite absorbable interface screw and a preparation method thereof. The composite absorbable interface screw is prepared by compounding poly-L-lactic acid (PLLA) and biphasic calcium phosphate, the ratio of hydroxyapatite (HA) to beta-tricalcium phosphate (beta-TCP) in biphasic calcium phosphate is regulated to reach an effect of matching the polylactic acid degradation rate; meanwhile, the preparation process adopts blending granulation by virtue of a simple double-screw blending machine, and then carries out injection molding by virtue of a single-screw injectionmolding machine. The preparation process is simple, high in reliability, does not use organic solvent or acid, and is environment-friendly.

Owner:花沐医疗科技(上海)有限公司

Bone substitute material

ActiveUS20200016293A1Increase differentiationImprove responseAdditive manufacturing apparatusSurgical adhesivesBiphasic calcium phosphateCalcium pidolate

A biphasic calcium phosphate / hydroxyapatite (CAP / HAP) bone substitute material having a sintered CAP core and a closed epitactically grown layer of nanocrystalline HAP deposited on the external surface of the sintered CAP core, wherein the closed epitactically grown layer of nanocrystalline HAP deposited on the external surface of the sintered CAP core has a homogeneous coarse external surface comprising flat crystal platelets, which shows an enhanced osteogenic response, a method of promoting bone formation, bone regeneration and / or bone repair by implanting the biphasic calcium phosphate / hydroxyapatite (CAP / HAP) bone substitute material, and a process of preparation thereof.

Owner:GEISTLICH PHARMA

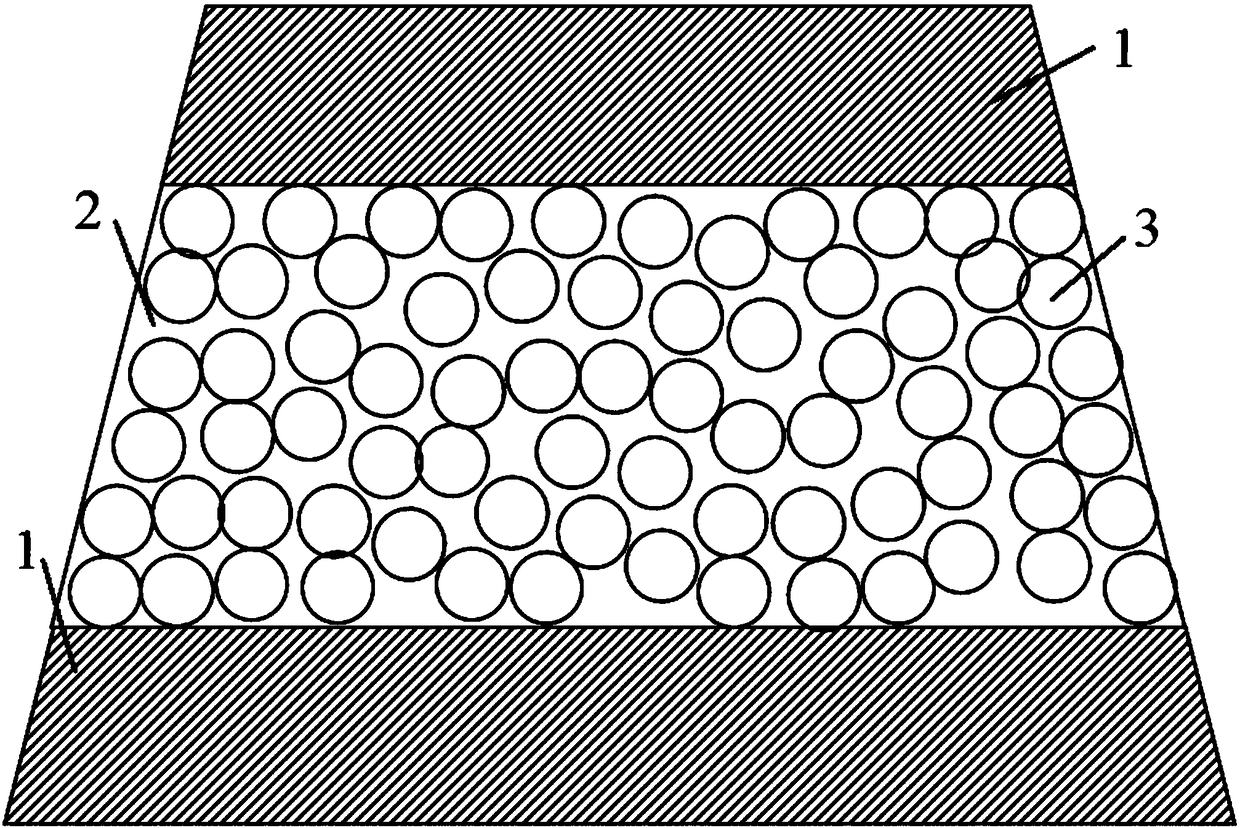

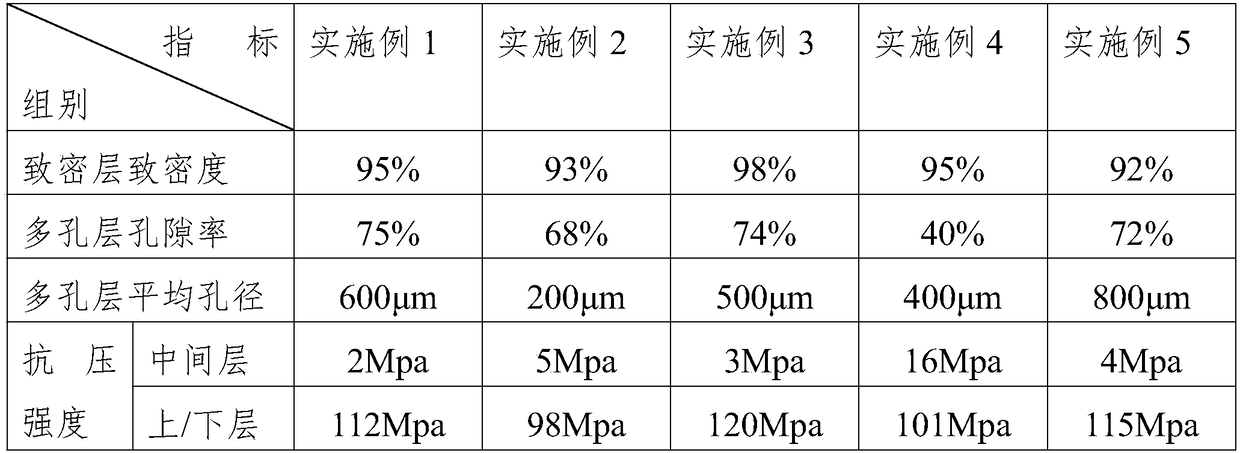

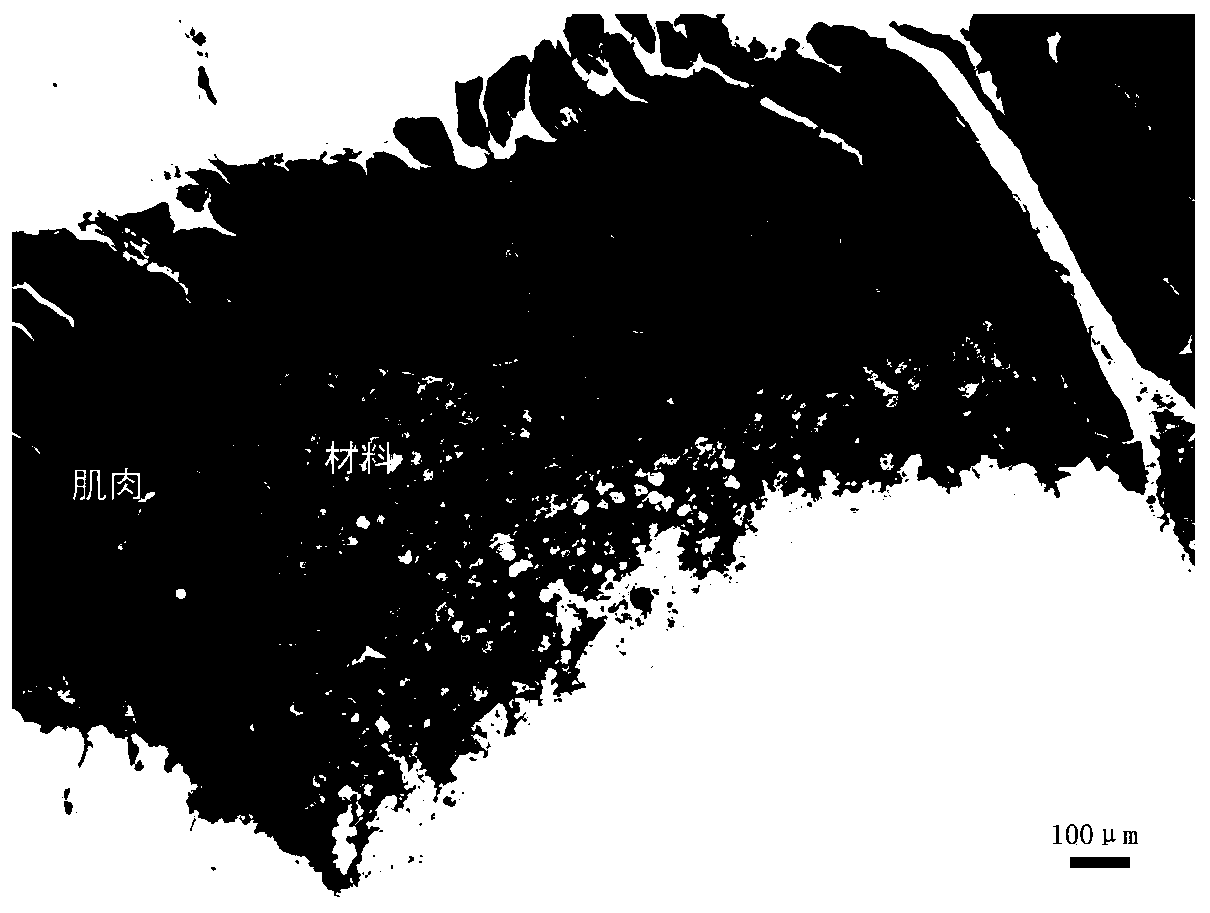

Double-gradient artificial vertebral lamina and preparation method thereof

ActiveCN108379665AAvoid formingInhibit growthTissue regenerationProsthesisDouble phaseTissue Compatibility

The invention belongs to the technical field of biomedical materials and in particular relates to a double-gradient artificial vertebral lamina and a preparation method thereof. The double-gradient artificial vertebral lamina is a base body with a trapezoid cross section and an axial length, wherein the base body is composed of an upper layer, a middle layer and a lower layer; the upper layer andthe lower layer are dense hydroxyapatite ceramic layers; the middle layer is a porous double-phase calcium phosphate ceramic layer. The artificial vertebral lamina provided by the invention has a dense / porous / dense trapezoid sandwich structure; compared with the prior art, the artificial vertebral lamina has higher tissue compatibility and anti-adhesion performance; meanwhile, the artificial vertebral lamina has excellent osteoinduction performance, is simple in structure and convenient to implant and is suitable for being popularized and applied in a large range.

Owner:SICHUAN UNIV

A kind of injectable calcium phosphate/natural polymer composite material and its preparation method and application

The invention discloses an injectable calcium phosphate / natural polymer composite material. The injectable calcium phosphate / natural polymer composite material is an injectable paste material formed by uniformly dispersing approximately spherical calcium phosphate ceramic particles with the particle size of 20-100 microns in a natural polymer (or its derivative) solution, wherein calcium phosphate is hydroxyapatite or diphasic calcium phosphate, 0-20% of bioactive glass can be added, the natural polymer or its derivative is one or more of sodium hyaluronate, collagen, chitosan, chondroitin sulfate and the like. The invention further discloses a preparation method of an injectable calcium phosphate / natural polymer composite material and a method for performing facial mini-plastic surgery by adopting the method. After the injectable calcium phosphate / natural polymer composite material is implanted in a body by adopting the method, a natural polymer in the material is degraded and absorbed, the calcium phosphate ceramic particles are fused with an autologous bone tissue together, a lasting shaping effect can be achieved, and clinical application prospect is good.

Owner:成都睿漾再生医疗科技有限公司

A kind of bone implant filling material and preparation method thereof

ActiveCN103800944BFast degradationControl to adjust release speedPeptide/protein ingredientsProsthesisBiocompatibility TestingSlow Release Formulation

The invention provides a bone-grafting filling material and a preparation method thereof. The method comprises the following steps: mixing and crushing biphasic calcium phosphates, calcium sulphate and iron oxide into grains of 0.1-1mm, burning at 800 DEG C for 3 hours, taking out to soak in 1M of (NH4)2HPO4 solution for 24 hours; drying two days, and burning at the temperature of 1100 DEG C for 1-2 days; slowly cooling, rinsing and baking, so as to obtain a skeleton structure; spraying a slow release formulation on a layer of collagen surface; spraying a layer of collagen on the surface of the slow release formulation to obtain a compound protein layer; baking the composite protein layer at 30 DEG C, carrying out superfine grinding, so as to obtain protein particles which are 50-100nm in particle size; finally, adding the skeleton structure and the protein particles to absolute ethyl alcohol; placing under the conditions at 1-5 DEG C and -0.01 to -0.05MPa for 2-3 days, so as to obtain the bone-grafting filling material. The bone-grafting filling material disclosed by the invention has biodegradability and biocompatibility, is free of or low in immunogenicity, strong in bone conductibility, bone inductivity, mechanical tolerance and the like, and kinds of performance requirements required by the bone filling material are completely met.

Owner:徐州博创建设发展集团有限公司

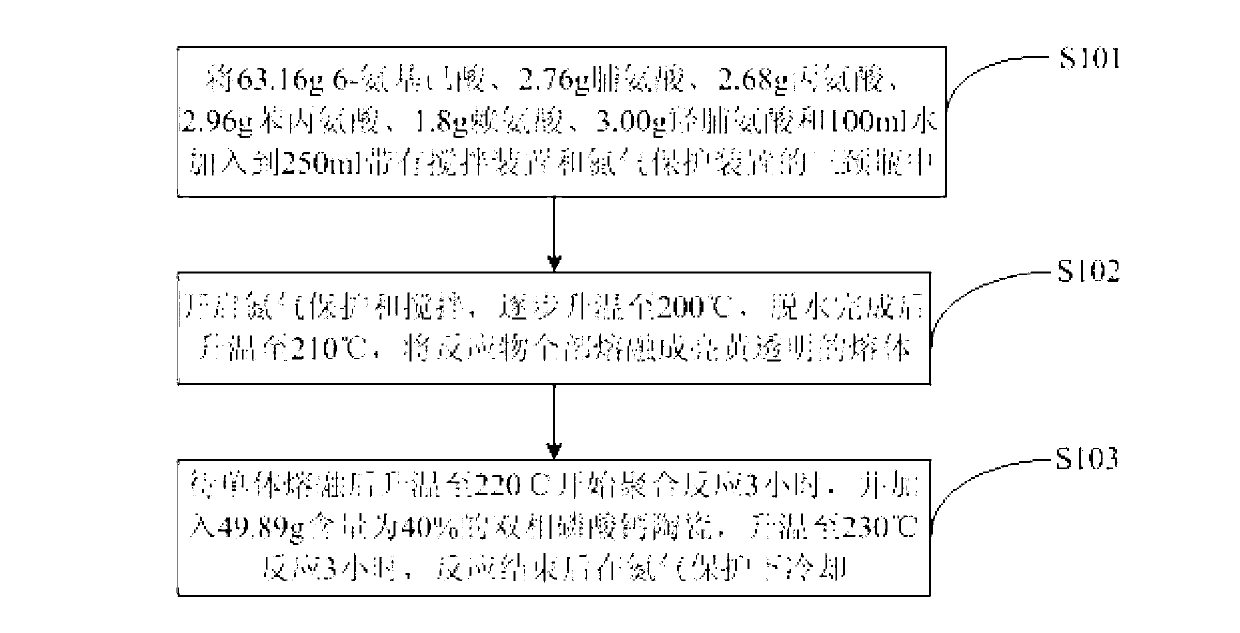

Hard tissue repair and substitute material and preparation method thereof

InactiveCN103007343ALow mechanical strengthPracticalProsthesisBiphasic calcium phosphateUltimate tensile strength

The invention belongs to the technical field of a biological material and provides a hard tissue repair and substitute material and a preparation method thereof. The hard tissue repair and substitute material comprises biphasic calcium phosphate (BCP) in which polyamino acid (PAA) is added. The hard tissue repair and substitute material with good biological activity and enough mechanical strength is obtained by adding the polyamino acid to improve the mechanical strength of the biphasic calcium phosphate, thereby the problem that the single biphasic calcium phosphate has lower mechanical strength, is difficult to serve as the bone repair and substitute material to play a role in a structural support and is largely restricted in clinical application is solved. The preparation method is simple and lower in cost and has stronger practical applicability and higher popularization and application value.

Owner:CHONGQING MEDICAL UNIVERSITY

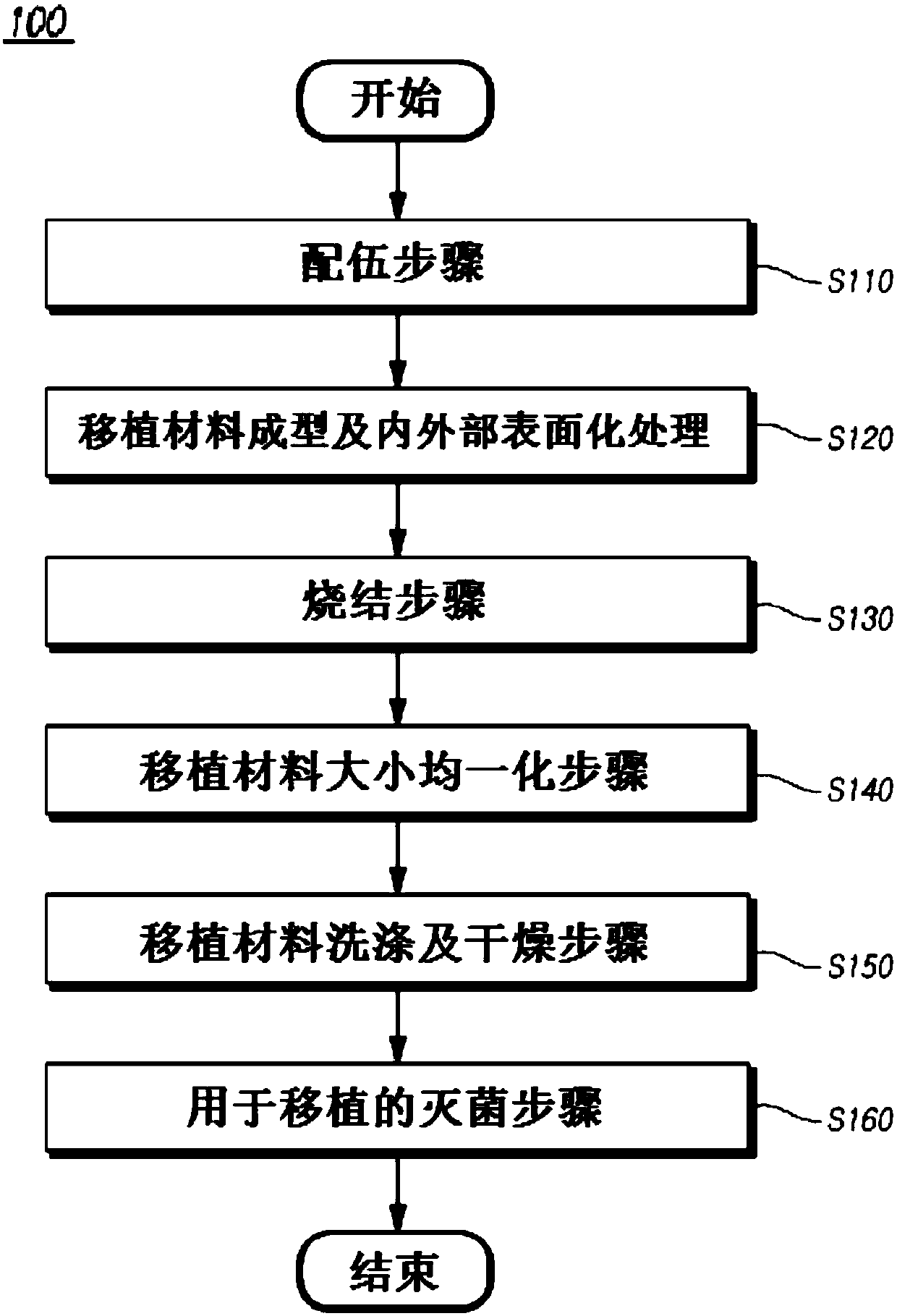

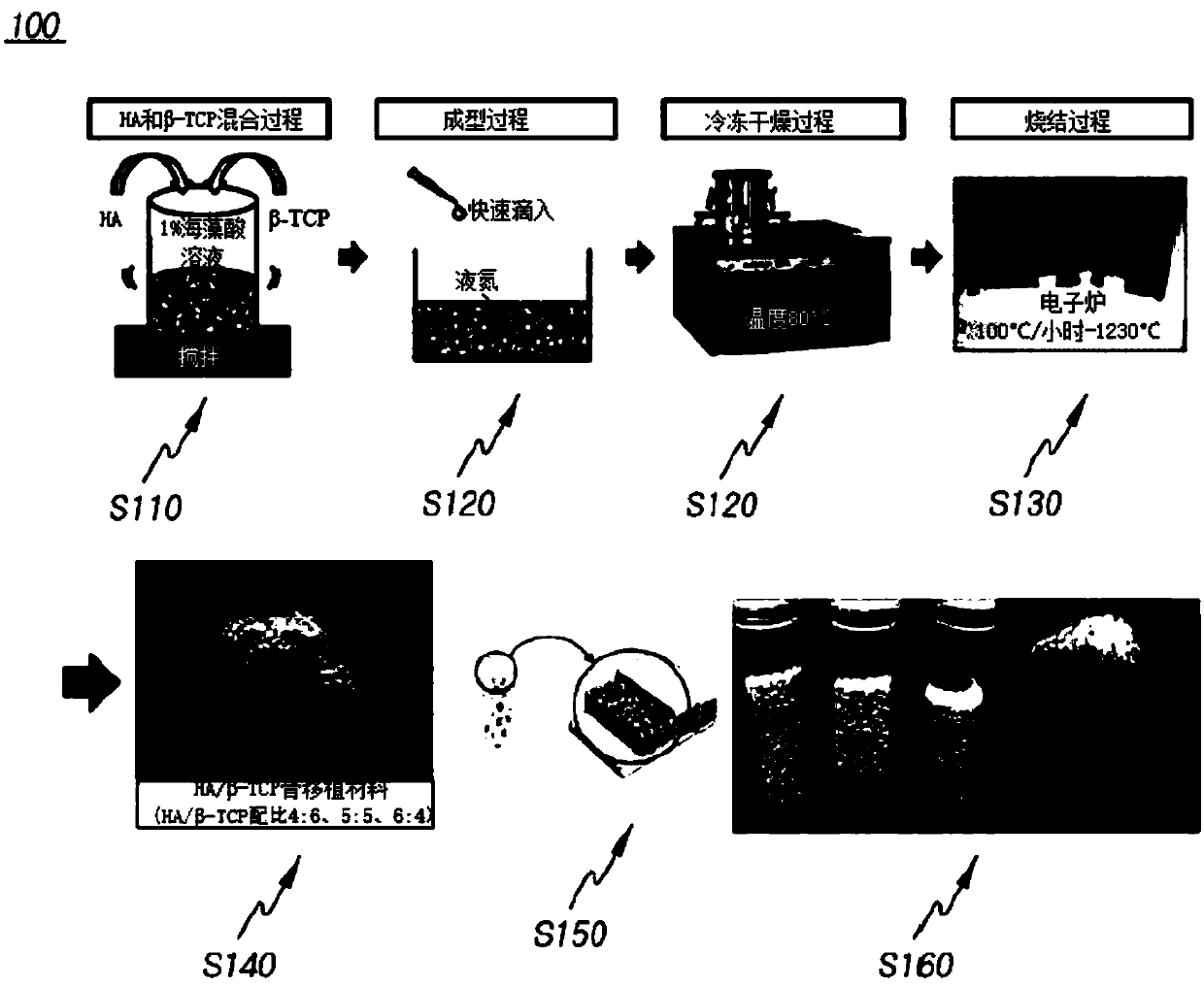

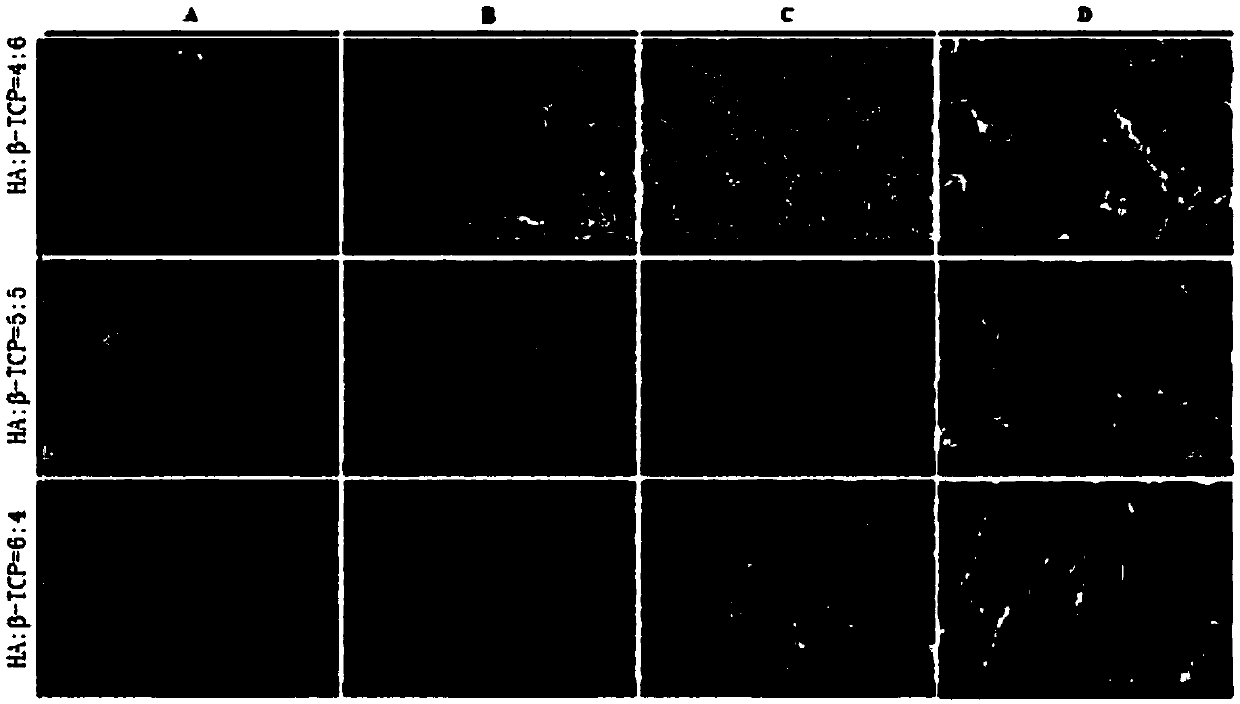

Dental bone graft materials of biphasic calcium phosphate type composed of hydroxyapatite and beta-tricalcium phosphate synthesized from the shell of abalone and preparation method thereof

InactiveCN107670100AExcellent bone formationHigh activityTissue regenerationCeramic materials productionLive donor transplantationSynthetic bone

The invention provides a dental bone graft material of a biphasic calcium phosphate type using abalone shells, and a manufacturing method of the same. The dental bone graft material uses bioceramics for living donor transplantation, that is hydroxyapatite and beta-tricalcium phosphate, synthesized from shells of abalone, which are industrial waste, and is manufactured through an analysis of optimum mixing ratio for alveolar bone regeneration, internal and external surface treatment of the graft material to maximize the induction of bone tissue regeneration for dental and medical use, and biosafety and biocompatibility analysis.

Owner:IND ACADEMIC COOP FOUND CHOSUN UNIV

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com