Two-phase calcium phosphate composite material adopting graphene and carbon nano-tube as synergistic toughening phases and preparation method of composite material

A dual-phase calcium phosphate and carbon nanotube technology, applied in the field of bioceramic composite materials, can solve problems such as poor mechanical properties and limited application, and achieve the effects of low cost, simple equipment and excellent mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

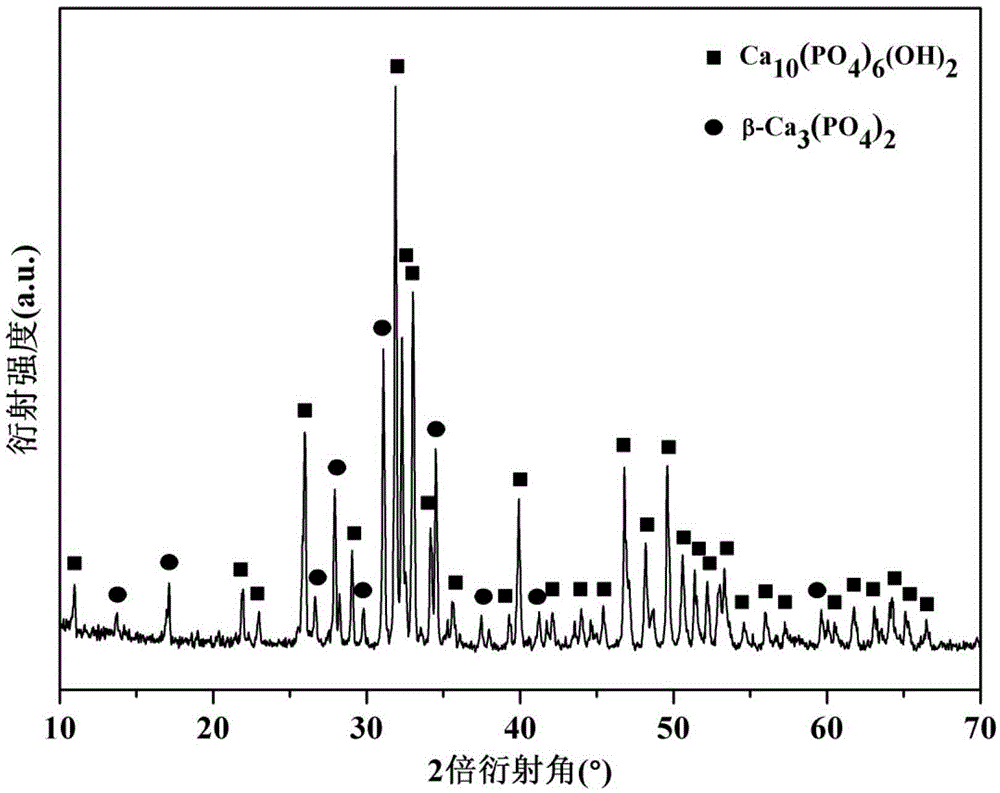

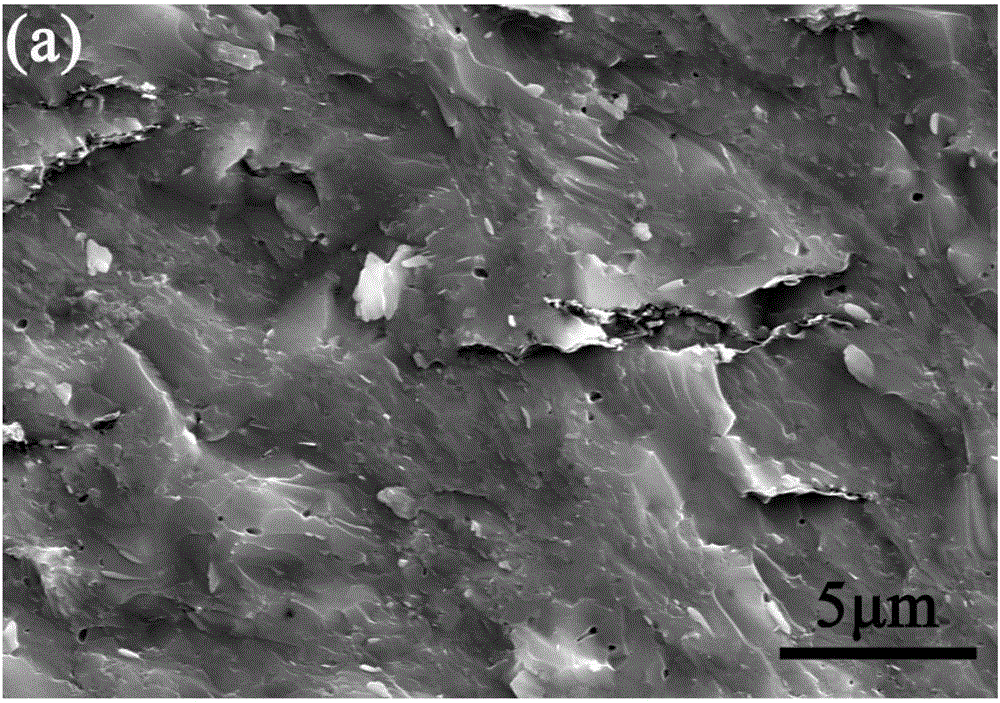

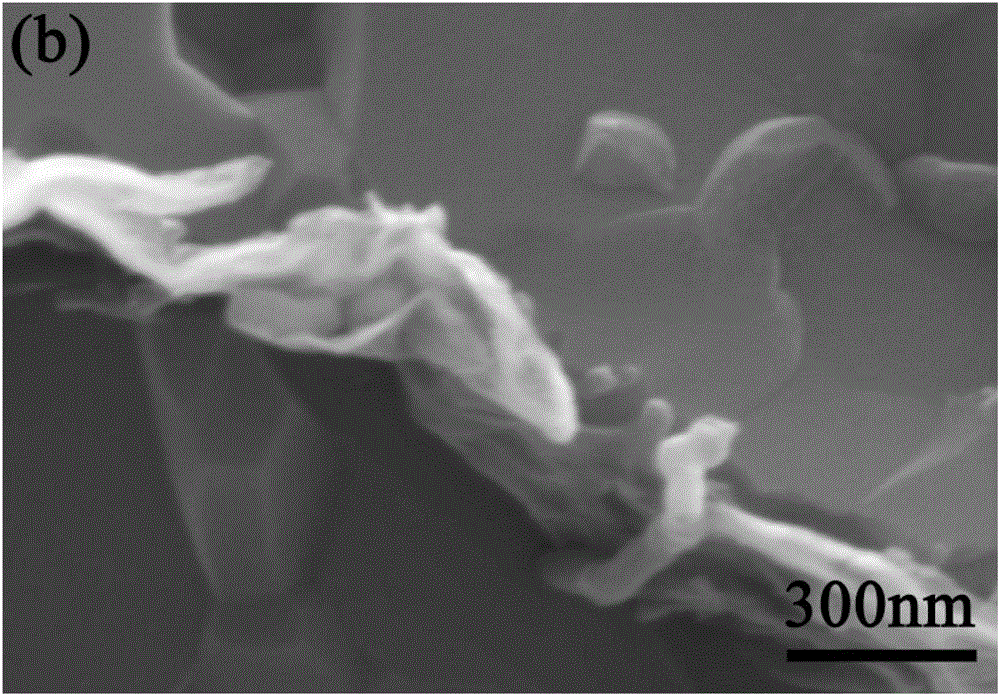

[0026] Example 1: Using graphene and carbon nanotubes as the tough phase and biphasic calcium phosphate as the matrix, a composite material was prepared by hot pressing and sintering.

[0027] First weigh 0.03g graphene, 0.15g carbon nanotube, 29.82g biphasic calcium phosphate with an electronic balance, then weigh 0.003g and 0.0015g hexadecyltrimethylammonium bromide, respectively for dispersing graphene and carbon nanotubes. Graphene and carbon nanotubes were respectively added to 100 ml of distilled water containing a corresponding mass of cetyltrimethylammonium bromide, and ultrasonically dispersed for 1 hour. Add the dispersed solution and the weighed biphasic calcium phosphate into the planetary ball mill tank, and ball mill at 300r / min for 8 hours. The mixed slurry after ball milling was put into a drying oven for drying at 120° C. for 4 hours, and passed through a 100-mesh sieve. Put the dried and sieved mixed powder into a graphite mold with a diameter of 42 mm, use...

Embodiment 2

[0029] Example 2: Using graphene and carbon nanotubes as the tough phase and biphasic calcium phosphate as the matrix, a composite material was prepared by hot pressing and sintering.

[0030] Weigh 0.06g graphene, 0.15g carbon nanotubes, 29.79g biphasic calcium phosphate with an electronic balance, and then weigh 0.006g and 0.0015g hexadecyltrimethylammonium bromide, respectively for dispersing graphene and carbon nanotube. Graphene and carbon nanotubes were respectively added to 100 ml of distilled water containing a corresponding mass of cetyltrimethylammonium bromide, and ultrasonically dispersed for 1 hour. Add the dispersed solution and the weighed biphasic calcium phosphate into the planetary ball mill tank, and ball mill at 300r / min for 8 hours. The mixed slurry after ball milling was put into a drying oven for drying at 120° C. for 4 hours, and passed through a 100-mesh sieve. Put the dried and sieved mixed powder into a graphite mold with a diameter of 42 mm, use a...

Embodiment 3

[0032] Example 3: Using graphene and carbon nanotubes as the tough phase and biphasic calcium phosphate as the matrix, a composite material was prepared by hot pressing and sintering.

[0033]Weigh 0.06g graphene, 0.3g carbon nanotubes, 29.64g biphasic calcium phosphate with an electronic balance, and then weigh 0.006g and 0.003g hexadecyltrimethylammonium bromide, respectively for dispersing graphene and carbon nanotube. Graphene and carbon nanotubes were respectively added to 150 ml of distilled water containing a corresponding mass of cetyltrimethylammonium bromide, and ultrasonically dispersed for 1.5 hours. Add the dispersed solution and the weighed biphasic calcium phosphate into the planetary ball mill jar, and ball mill at 350r / min for 10 hours. The mixed slurry after ball milling was put into a drying oven for drying at 130° C. for 4 hours, and passed through a 100-mesh sieve. Put the dried and sieved mixed powder into a conventional graphite mold, use argon as a pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com