A kind of injectable calcium phosphate/natural polymer composite material and its preparation method and application

A technology of natural polymers and composite materials, applied in the field of biomedical materials, can solve the problems of restoring the original state, producing granulomas, and being difficult to remove within 5-1 years, achieving the effect of good clinical application prospects and good shaping effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

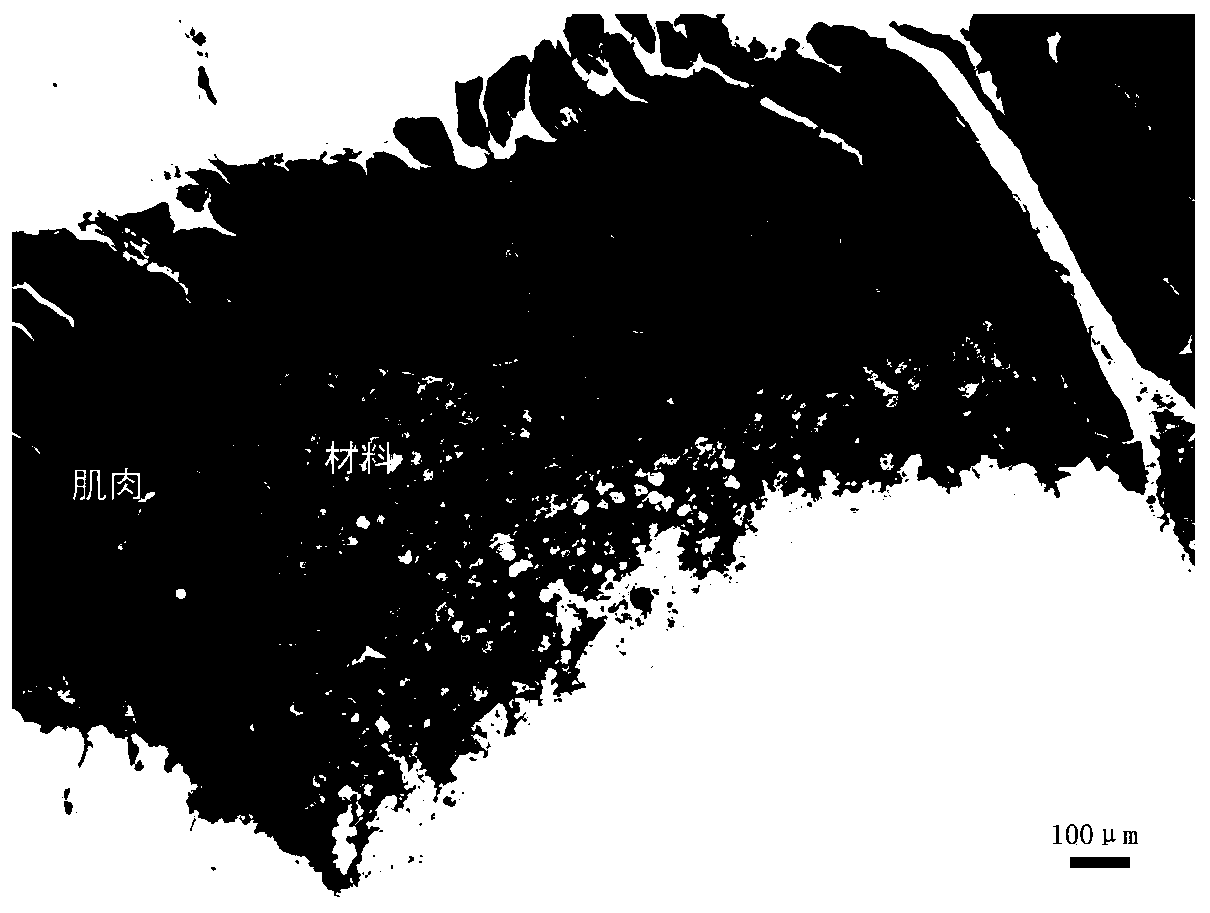

Image

Examples

Embodiment 1

[0025] Embodiment 1 Preparation of injectable calcium phosphate / sodium hyaluronate composite material of the present invention

[0026] 1. Preparation method

[0027] 1) Prepared with sodium hyaluronate (molecular weight 1000kDa, Shandong Huaxi Freda Biomedical Co., Ltd.) modified by 1,4-butanediol glycidyl ether (BDDE) (modification degree 6-10%) into 10ml of 2.5% aqueous solution;

[0028] 2) Take 15g of hydroxyapatite ceramic particles with a particle size of 70-100 μm, add them to the above-mentioned sodium hyaluronate solution and stir evenly to form a paste compound (the solid content of the calcium phosphate ceramic particles is 60 (w / w)%, The solid content of sodium hyaluronate is 1.0 (w / w)%);

[0029] Preparation of hydroxyapatite ceramic particles with a particle size of 70-100 μm: disperse hydroxyapatite micropowder into 1.5% polyvinyl alcohol aqueous solution, transfer to a ball mill and mill for 24 hours to form a slurry with good particle dispersibility. The p...

Embodiment 2

[0031] Embodiment 2 Preparation of injectable calcium phosphate / collagen composite material of the present invention

[0032] 1. Preparation method

[0033] 1) Take medical collagen and prepare 10ml of 1.0% aqueous solution;

[0034] 2) Take 30g of biphasic calcium phosphate ceramic particles (hydroxyapatite / tricalcium phosphate=70 / 30) with a particle size of 40-70 μm, add them to the above collagen solution and stir evenly to form a paste-like composite (calcium phosphate ceramic The solid content of the particles is 75 (w / w)%, and the solid content of the collagen is 0.25 (w / w)%);

[0035] Preparation of biphasic calcium phosphate ceramic particles with a particle size of 40-70 μm: Disperse the biphasic calcium phosphate micropowder into a 1.0% polyvinyl alcohol aqueous solution, transfer to a ball mill and mill for 24 hours to form a slurry with good particle dispersion, through peristaltic The pump is transported to the spray dryer for spray drying treatment, the spray d...

Embodiment 3

[0037] Example 3 Preparation of injectable calcium phosphate / sodium hyaluronate-chondroitin sulfate composite material of the present invention

[0038] 1. Preparation method

[0039] 1) Take sodium hyaluronate (molecular weight 500kDa, Shandong Huaxi Freda Biomedicine Co., Ltd.) and chondroitin sulfate (Shanghai Aladdin Reagent Company) to prepare 10ml of 1.5% sodium hyaluronate and 0.5% chondroitin sulfate Mixed aqueous solution;

[0040] 2) Take 30g of hydroxyapatite ceramic particles containing 5% bioactive glass (45S5 bioglass, Kunshan Huaqiao Technology New Material Co., Ltd.) with a particle size of 20-40 μm, and add it to the above-mentioned sodium hyaluronate-chondroitin sulfate mixture Stir evenly in the solution to form a paste compound (the solid content of calcium phosphate ceramic particles is 75 (w / w)%, and the solid content of sodium hyaluronate and chondroitin sulfate is 0.5 (w / w)%);

[0041] Preparation of hydroxyapatite ceramic particles containing 5% bioa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com