Method for preparation of controlled pore size biphasic calcium phosphate composite ceramic scaffold

A composite ceramic and calcium-phosphorus technology, which is applied in the field of biomedical nanomaterials, can solve the problem that a dual-phase calcium-phosphorus ceramic stent does not have a better solution, and achieves the effects of strong practicability, controllable pore size, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

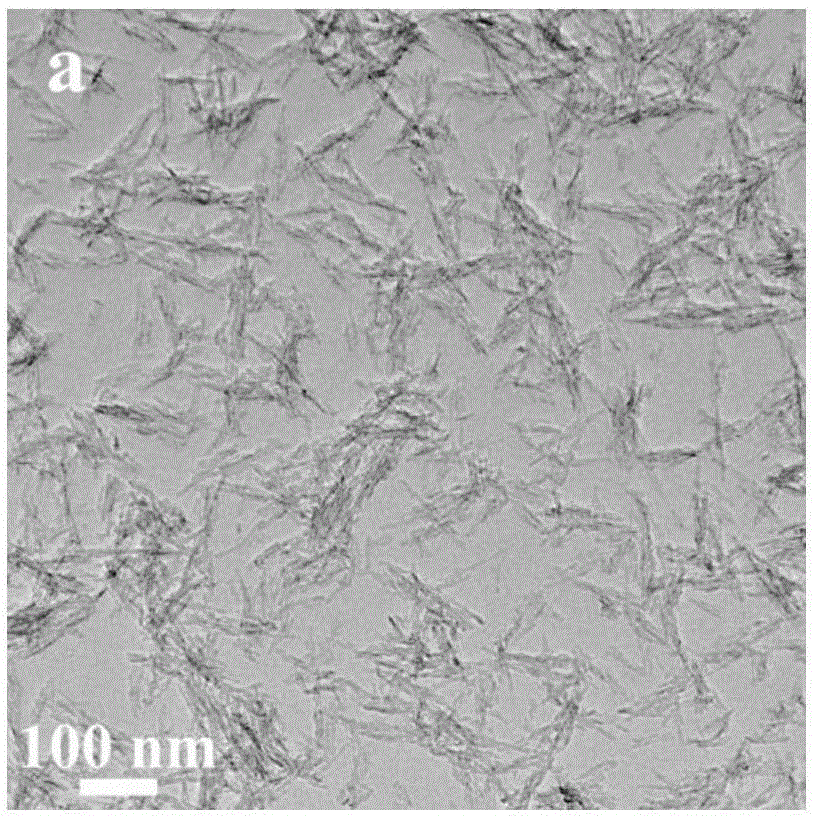

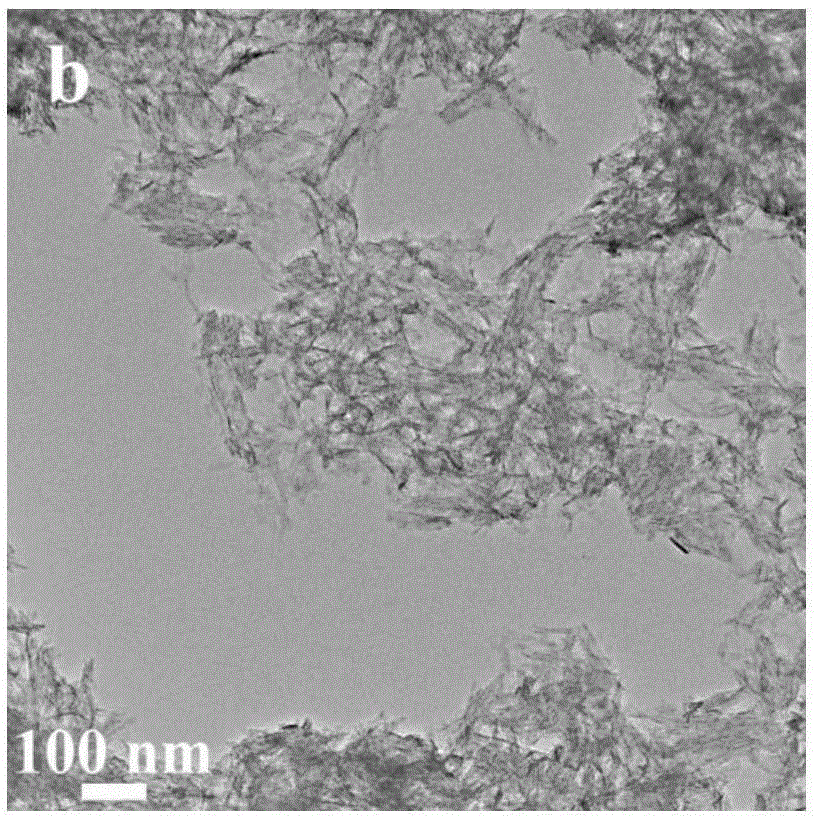

[0026] Step 1, using calcium nitrate as the calcium source, sodium dihydrogen phosphate as the phosphorus source, and the calcium to phosphorus ratio being 1.67 and 1.5, respectively preparing nano-hydroxyapatite and nano-β-tricalcium phosphate powder;

[0027] Step 2, uniformly mixing 0.2 g of prepared nano-hydroxyapatite with 0.4 g of nano-β-tricalcium phosphate powder, 0.5 g of sodium lauryl sulfate and 0.2 g of polyethylene, ball milling, and passing through a 100-mesh sieve;

[0028] Step 3, drop 1mL of ammonium bicarbonate aqueous solution into the powder obtained in step 2, stir to make it into a viscous slurry, and dry it at room temperature for 40 minutes to obtain a ceramic embryo;

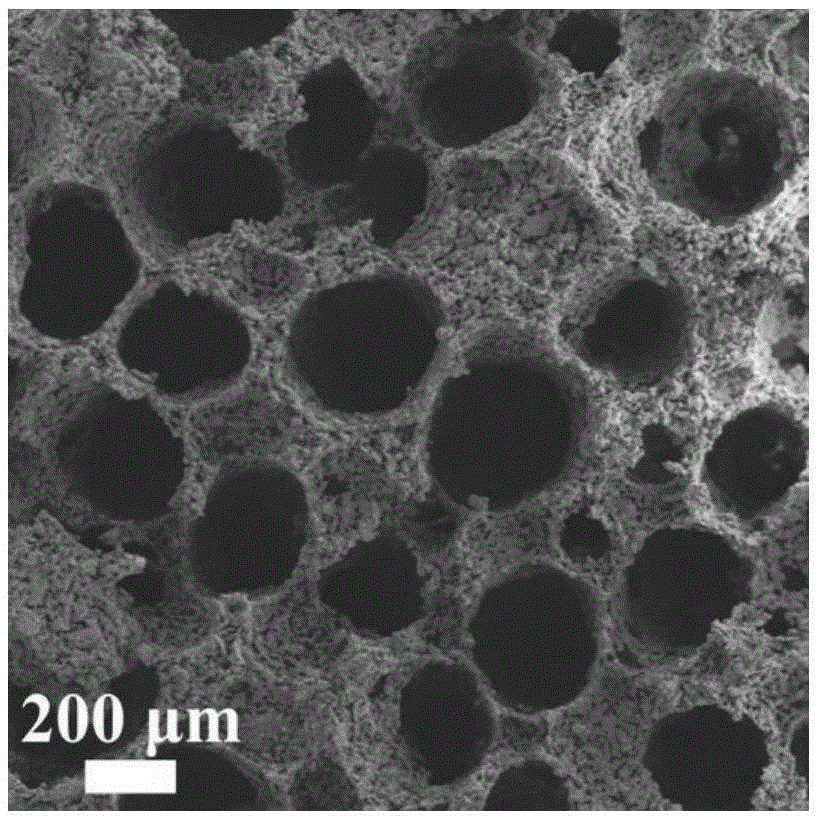

[0029] Step 4: Foam the ceramic body at 45°C for 60 minutes, dehydrate it at 80°C for 120 minutes, then raise the temperature to 1000°C at a rate of 5°C / min, and remove the surfactant, pore-forming agent and foaming agent to obtain Porous biphasic calcium-phosphorus composite ceramic sca...

Embodiment 2

[0031] Step 1, using calcium hydroxide as the calcium source, phosphoric acid as the phosphorus source, and the calcium to phosphorus ratio being 1.67 and 1.5, respectively preparing nano-hydroxyapatite and nano-β-tricalcium phosphate powder;

[0032] Step 2, uniformly mix 0.4g of prepared nano-hydroxyapatite with 0.4g of nano-β-tricalcium phosphate powder, 0.7g sodium dodecylsulfonate and 0.1g polystyrene, grind in a mortar, pass 80 Mesh sieve;

[0033] Step 3, drop 1.5mL ammonium bicarbonate aqueous solution into the powder obtained in step 2, stir to make it a viscous slurry, and dry it at room temperature for 30 minutes to obtain a ceramic green body;

[0034] Step 4: Foam the ceramic body at 40°C for 80 minutes, dehydrate it at 90°C for 100 minutes, then raise the temperature to 900°C at a rate of 2°C / min, and remove the surfactant, pore-forming agent and foaming agent to obtain Porous biphasic calcium-phosphorus composite ceramic scaffold.

Embodiment 3

[0036] Step 1, using calcium chloride as the calcium source, diammonium hydrogen phosphate as the phosphorus source, and the calcium to phosphorus ratio being 1.67 and 1.5, respectively preparing nano-hydroxyapatite and nano-β-tricalcium phosphate powder;

[0037] Step 2, uniformly mix 0.6g of prepared nano-hydroxyapatite with 0.4g of nano-beta-tricalcium phosphate powder, 0.6g sodium lauryl sulfate and 0.3g polymethyl methacrylate, ball mill, pass 80 Mesh sieve;

[0038] Step 3, drop 1mL of ammonium bicarbonate aqueous solution into the powder obtained in step 2, stir to make it into a viscous slurry, and dry it at room temperature for 45 minutes to obtain a ceramic embryo;

[0039] Step 4: foam the ceramic body at 50°C for 30 minutes, dehydrate it at 95°C for 60 minutes, then raise the temperature to 1100°C at a heating rate of 10°C / min, and remove the surfactant, pore-forming agent and foaming agent to obtain Porous biphasic calcium-phosphorus composite ceramic scaffold.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com