Preparing method of metal chalcogenide nanomesh material

A metal sulfide, metal selenide technology, applied in binary selenium/tellurium compounds, molybdenum sulfide, nanotechnology and other directions, can solve problems such as inability to prepare in large quantities, low yield of nanosieves, and restrictions on large-scale production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0068] Preparation of ordered mesoporous silica KIT-6 template material: Accurately weigh 20 grams of triblock copolymer P123 (polyethylene oxide-polypropylene oxide-polyethylene oxide triblock copolymer, PEO- PPO-PEO), transferred into a 1000ml beaker, added 720ml of distilled water, 33.3ml of concentrated hydrochloric acid (36-38%). Stir in a water bath at 35 °C until the P123 is completely dissolved. 20 g of n-butanol were added and stirring was continued for 1 hour. Add 43 grams of tetraethyl orthosilicate, keep the temperature at 35 degrees Celsius, and continue to stir for 24 hours. The mixture in the beaker was transferred to a polytetrafluoroethylene hydrothermal kettle, and kept at a constant temperature of 100 degrees Celsius in an oven for 24 hours. After cooling, take it out, filter it with suction, wash the filter cake three times with distilled water, and wash it once with ethanol to obtain a white powder. After the white powder is completely dry, place it in ...

Embodiment 2

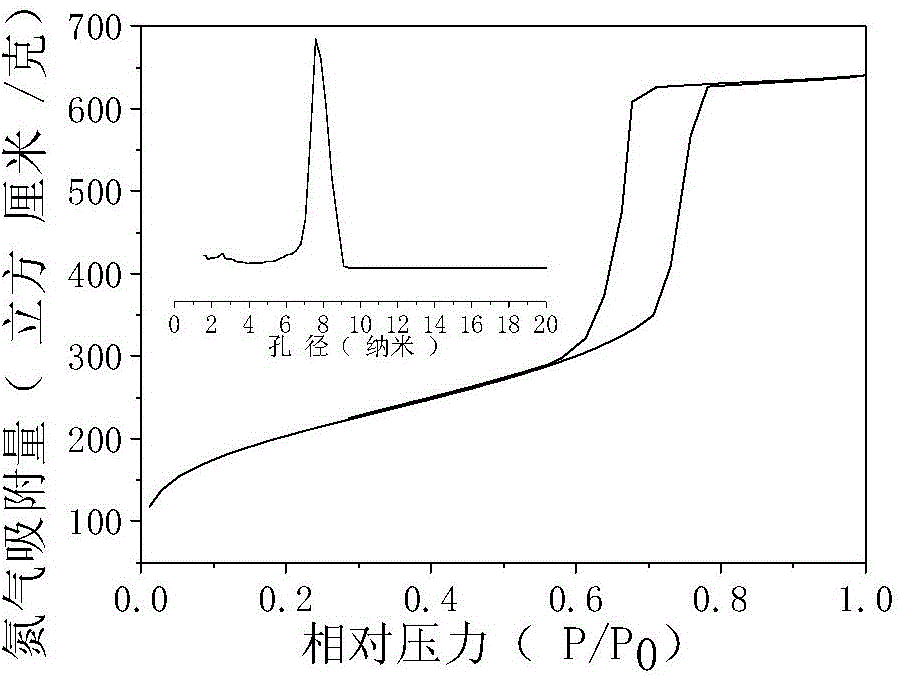

[0072] The ordered mesoporous silica KIT-6 material synthesized according to the method described in Example 1 was further heated in a muffle furnace to 900 degrees Celsius at a heating rate of 2 degrees Celsius / minute, kept for 5 hours and then cooled to room temperature to prepare A white powder was obtained. Weigh 10 grams of KIT-6 material after high-temperature treatment at 900 degrees Celsius, and its total pore volume value is calculated to be 5.3 cubic centimeters according to the nitrogen adsorption test results; add 100 ml of xylene and stir at room temperature for 1 hour to obtain a suspension . Ammonium tungstate ((NH 4 ) 10 W 12 o 41 ) and ammonium paramolybdate ((NH 4 ) 6 Mo 7 o 24 4H 2 O) the mixture was dissolved in 5 ml of a 5% by weight ammonia solution. The ammonia solution of the metal precursor was added to the above mixed suspension of mesoporous silica and xylene. Stirring was continued for 4 hours and then suction filtered. The white KIT-6 p...

Embodiment 3

[0075]2.0 g of phosphomolybdic acid was dissolved in 40 ml of ethanol, and 1 g of the KIT-6 template material prepared by the method described in Example 1 was added. Stir at room temperature until the ethanol is completely volatilized, and an ordered mesoporous silica material loaded with phosphomolybdic acid is obtained. Mix it with 10 grams of sulfur powder evenly, and put it into a quartz boat covered with a quartz plate. Place the quartz boat at the mouth of the tube furnace. A stream of pure hydrogen at a flow rate of 100 ml / min was introduced into the tube furnace. The tube furnace was raised to 400 °C. Use a quartz rod to quickly push the quartz boat into the center of the heating zone of the tube furnace for reaction, and hydrogen gas is continuously injected. After reacting for 600 minutes, it was cooled to room temperature under the protection of hydrogen to obtain a black powder. Put the black powder in a 500ml plastic beaker, add 200ml of distilled water, add ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com