Composite absorbable interface screw and preparation method thereof

A technology of interface screws and composite materials, applied in medical science, surgery, etc., can solve problems such as complex process, influence of screw tooth shape, unfavorable clinical application, etc., and achieve the effect of environmental friendliness, high reliability, and simple manufacturing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

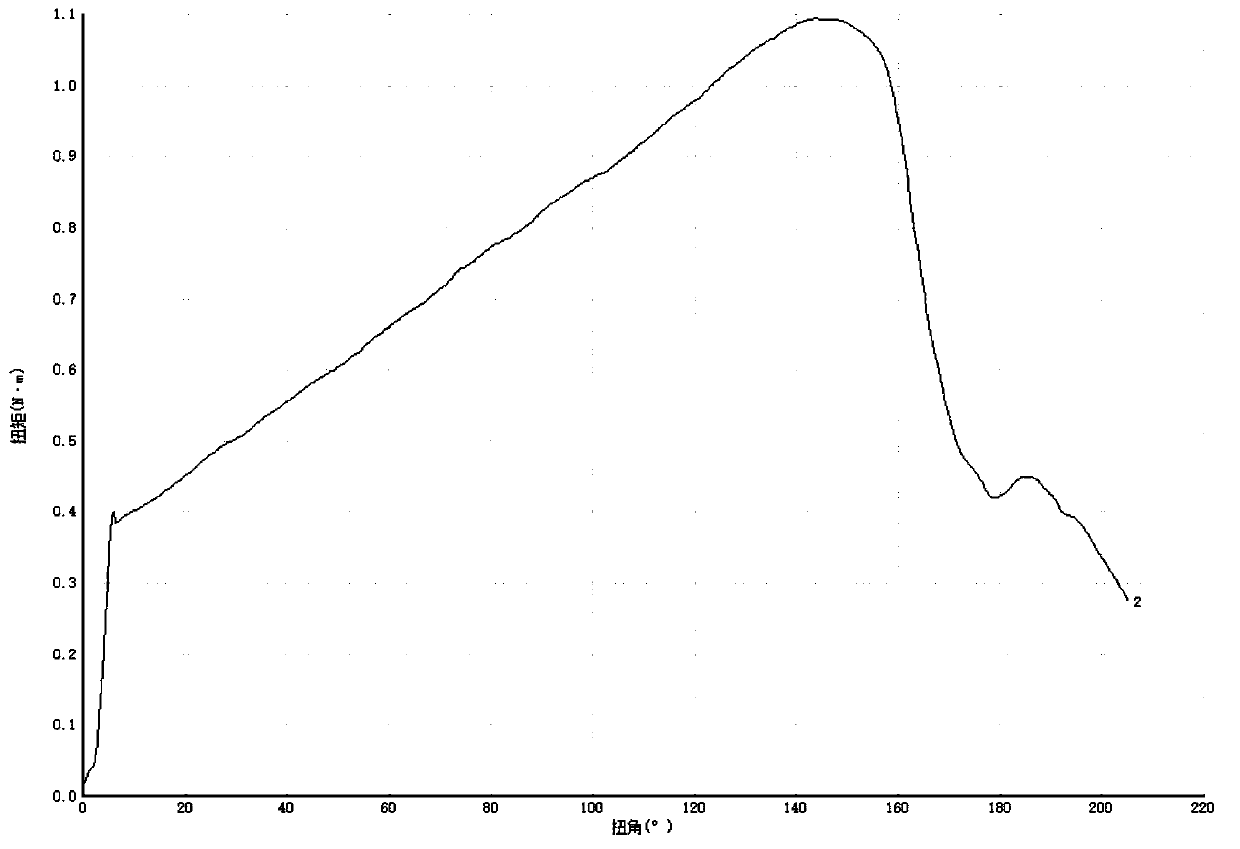

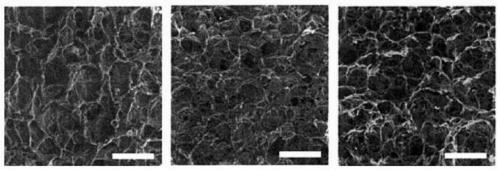

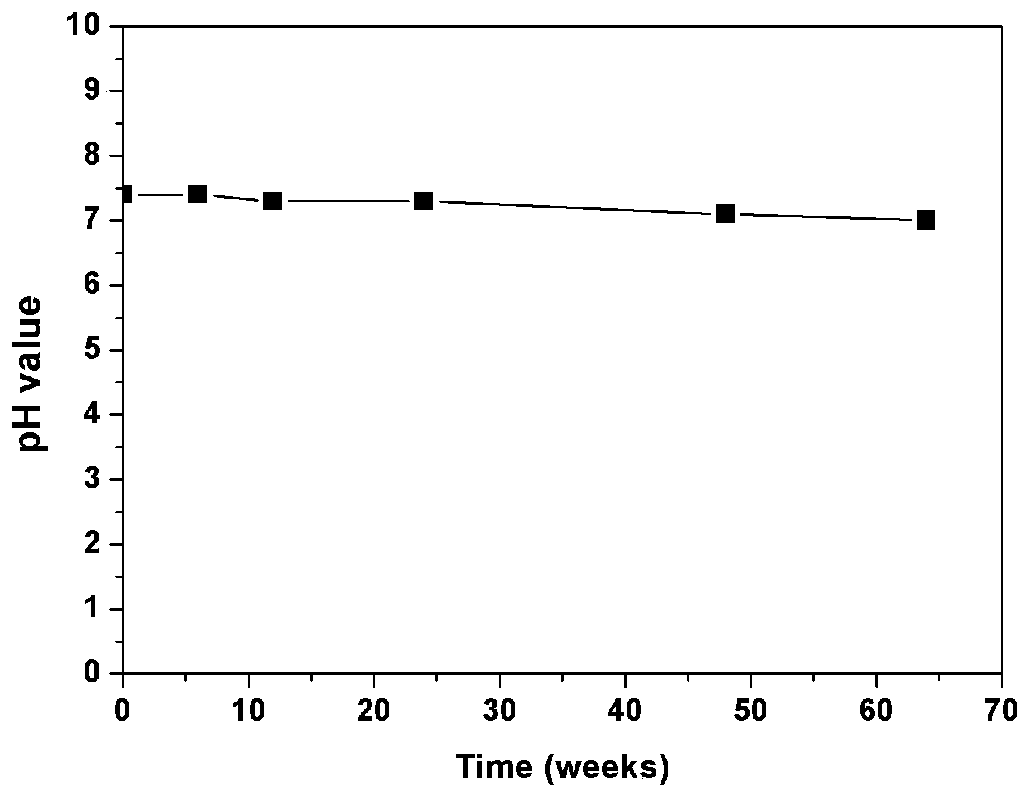

Image

Examples

Embodiment 1

[0025] This embodiment provides a composite absorbable interface screw, which is composed of poly-L-lactic acid (PLLA) and biphasic calcium phosphate; in this embodiment, the biphasic calcium phosphate includes hydroxyapatite (HA) and β - Tricalcium phosphate (β-TCP), by regulating the content of hydroxyapatite (HA) and β-tricalcium phosphate (β-TCP) in the biphasic calcium phosphate, to achieve the early stage of β-tricalcium phosphate (β-TCP) ) fast absorption, and later hydroxyapatite (HA) neutralizes the effect of lactic acid. While obtaining a high-strength composite absorbable interface screw, the preparation process is simple, no organic solvent or acid is needed, and the invention is environmentally friendly.

[0026] In this embodiment, in the material of the composite absorbable interface screw, the weight percentage of poly-L-lactic acid (PLLA) is 60-80%, and the weight percentage of hydroxyapatite (HA) is 15-30%; β- The weight percentage of tricalcium phosphate (β...

Embodiment 2

[0030] This embodiment provides a method for preparing a composite absorbable interface screw, including:

[0031] (1) Dry the PLLA, β-TCP and HA separately, and then mechanically stir and mix the three according to a certain ratio, such as the ratio in Example 1.

[0032] (2) Melt blending the homogeneously mixed materials:

[0033] a. First, set the temperature of the melting zone (upper, middle and lower) of the blender to 190-220°C, the best is 200°C, the screw speed is 10-30 rpm, the best speed is 20 rpm, and then the Mix the uniform material, slowly pour it into the hopper to get the material rod;

[0034] b. Granulating the extruded rod to obtain composite material particles.

[0035] (3) Precision injection molding to obtain interface screws:

[0036] a. Add the composite material particles into the storage tank of the micro-screw precision injection molding machine;

[0037] b. Turn on the temperature of the electric heating system of the micro-screw precision inj...

Embodiment 3

[0040] This embodiment provides a composite absorbable interface screw, the weight percentage of the poly-L-lactic acid (PLLA) is 60%, the weight percentage of hydroxyapatite (HA) (200nm) is 30%, and β-tricalcium phosphate The weight percentage of (β-TCP) (10um) is 10%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com