Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

205 results about "Protein particles" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Protein particles consist of reversibly or irreversibly associated protein molecules ranging in size from small oligomers to large, extended aggregates of 100s of micrometers long. In well formulated therapeutic proteins, protein particles typically represent an extremely low fraction by mass of the total protein,1 which decreases safety concerns.

Biocompatible protein particles, particle devices and methods thereof

InactiveUS20050147690A1Desired characteristicPromote the remodeling of the particlesOrganic active ingredientsPill deliveryActive agentSolvent

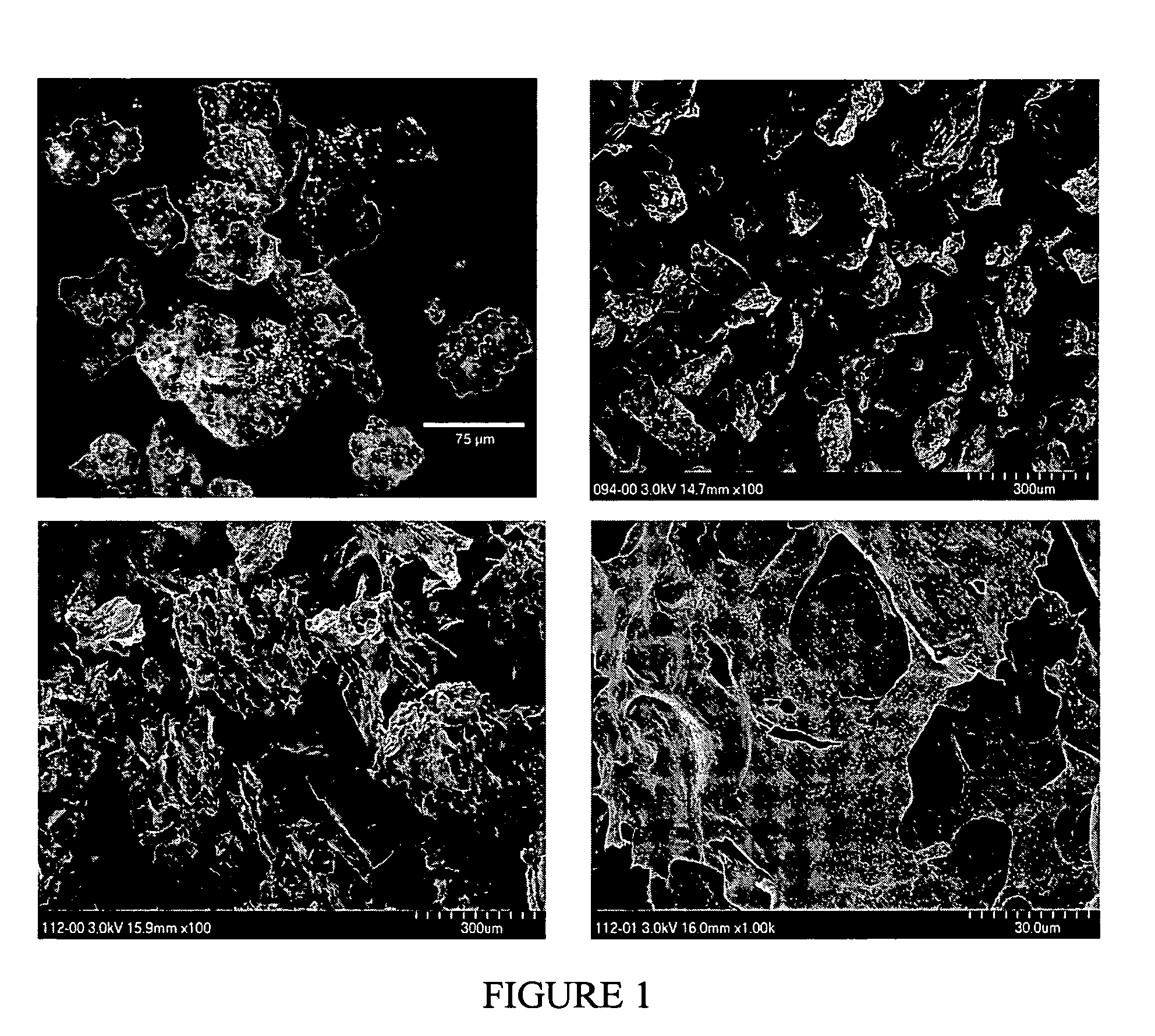

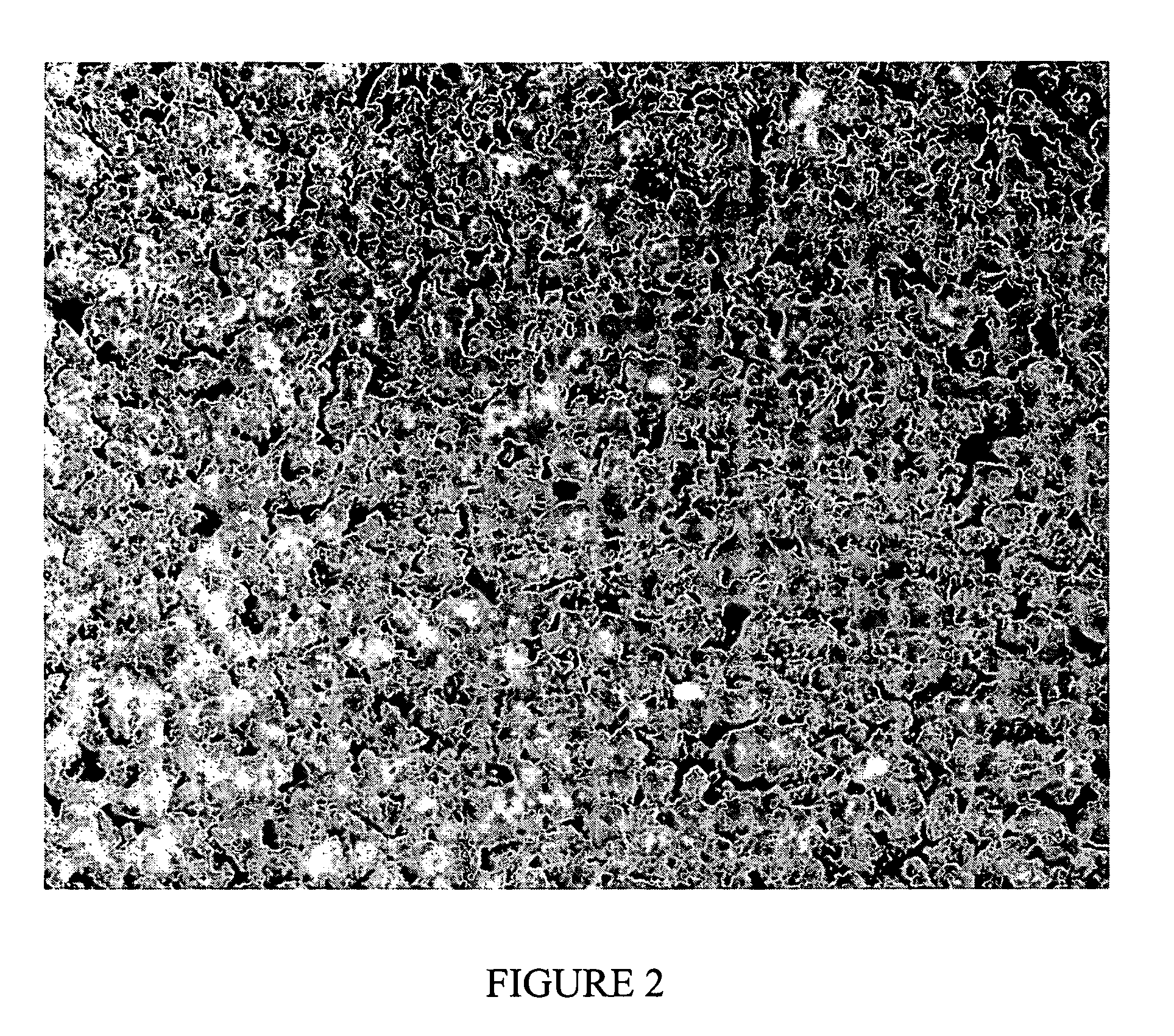

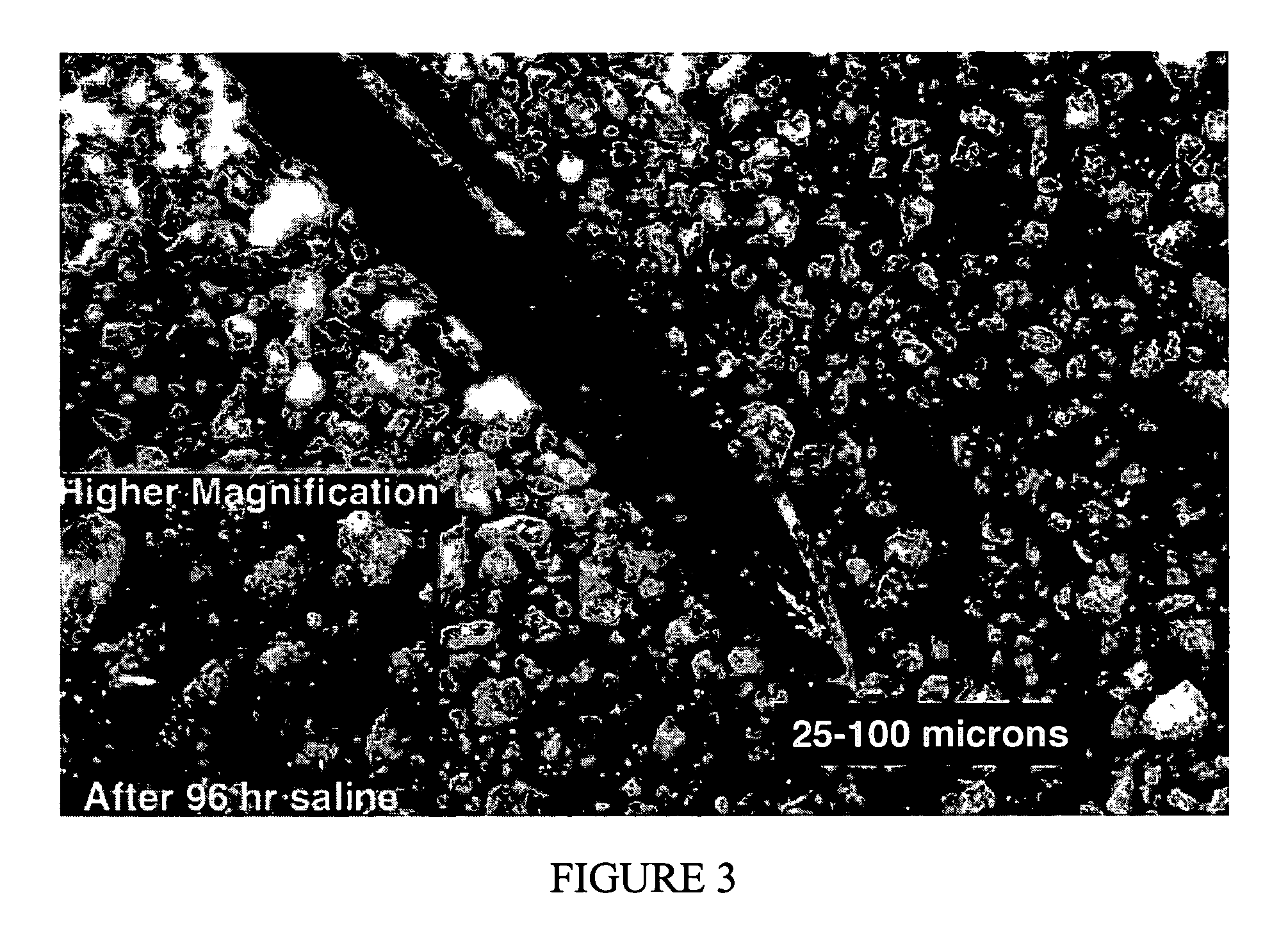

The present invention relates to biocompatible protein particles, particle devices and their methods of preparation and use. More specifically the present invention relates protein particles and devices derived from such particles comprising one or more biocompatible purified proteins combined with one or more biocompatible solvents. In various embodiments of the present invention the protein particles may also include one or more pharmacologically active agents and / or one or more additives.

Owner:GEL DEL TECH

Proteins deposited onto sparingly soluble biocompatible particles for controlled protein release into a biological environment from a polymer matrix

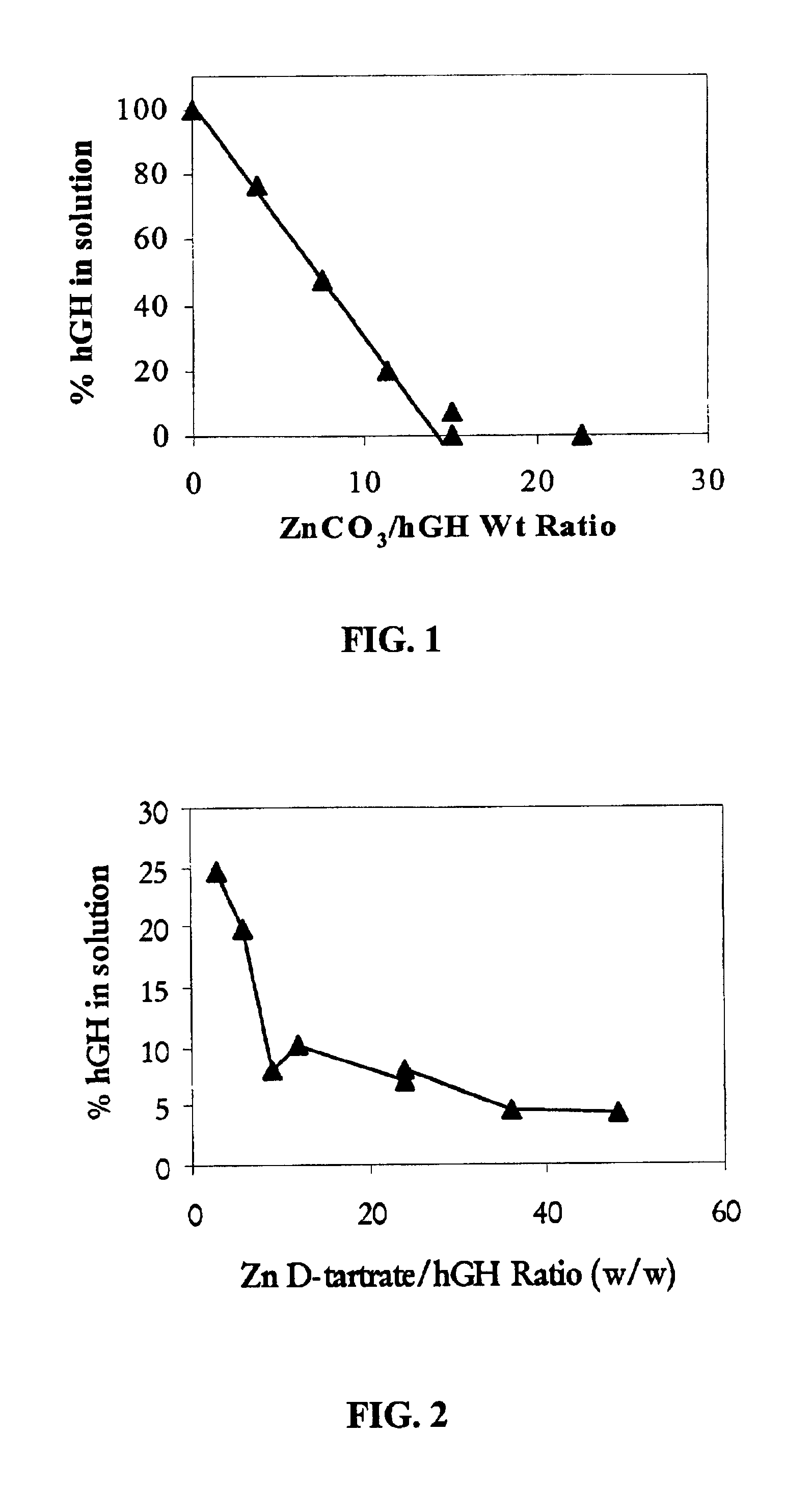

The present invention relates to compositions and methods for the modulated release of one or more proteins or peptides. The composition is comprised of a biocompatible polymeric matrix, a protein and / or peptide, and a sparingly water-soluble or essentially insoluble particle. The protein is deposited by adsorption or some other mechanism onto the sparingly water-soluble biocompatible particle wherein the protein-particle combination is dispersed within the polymeric matrix. The deposition of the protein onto the particle acts to modulate the release of the protein or peptide from dosage forms including long-acting dosage systems.

Owner:BTG INT LTD

Non-carbohydrate foaming compositions and methods of making the same

InactiveUS20060040033A1Improve the immunityMilk preparationOther dairy technologyVitrificationCompound (substance)

A foaming composition includes a powdered carbohydrate-free soluble composition which includes protein particles having a plurality of internal voids containing entrapped pressurized gas. In one form, the foaming composition is produced by subjecting the particles to an external gas pressure exceeding atmospheric pressure prior to or while heating the particles to a temperature of at least the glass transition temperature and then cooling the particles to a temperature below the glass transition temperature prior to or while releasing the external pressure in a manner effective to trap the pressurized gas within the internal voids.

Owner:INTERCONTINENTAL GREAT BRANDS LLC

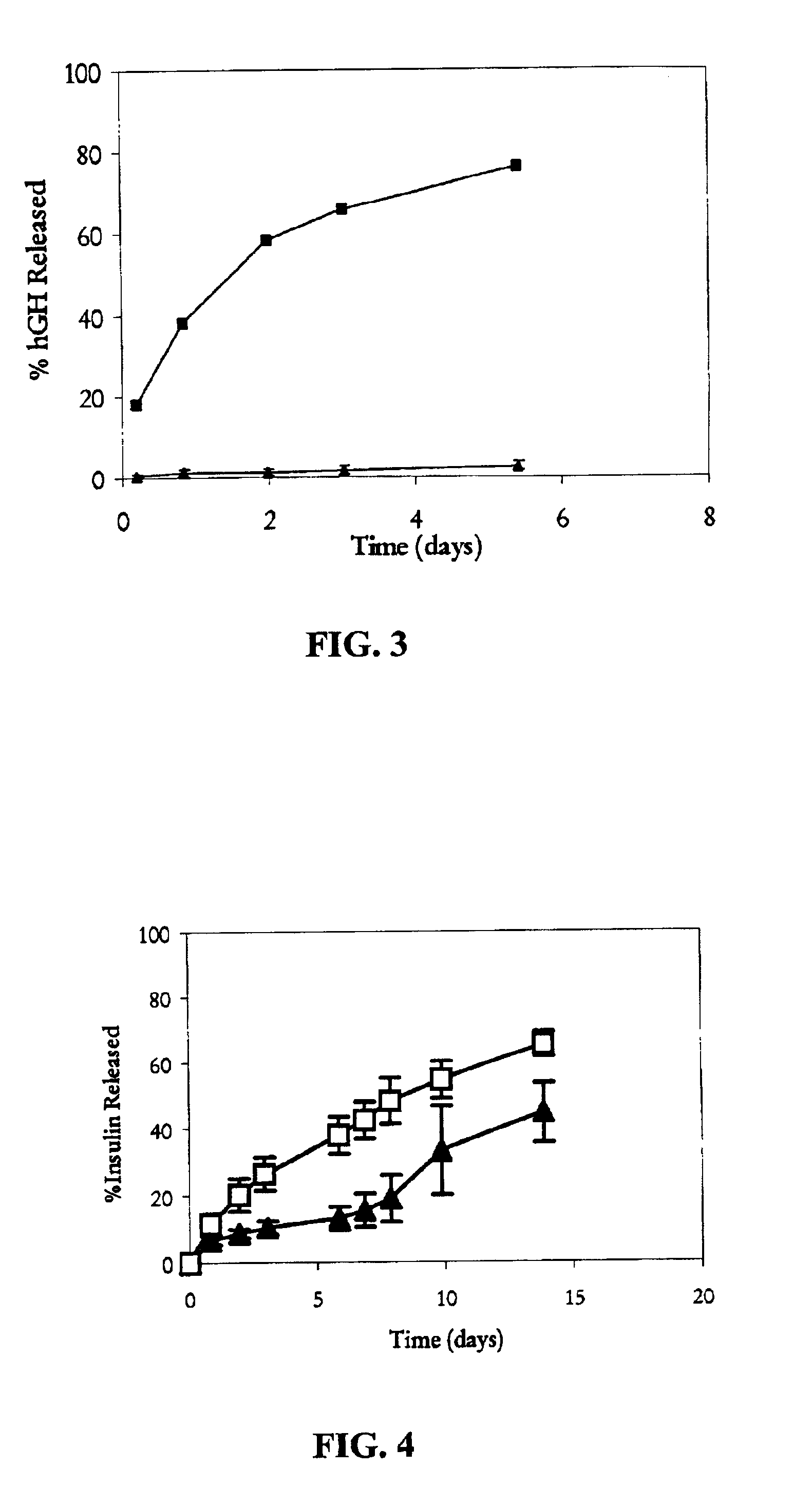

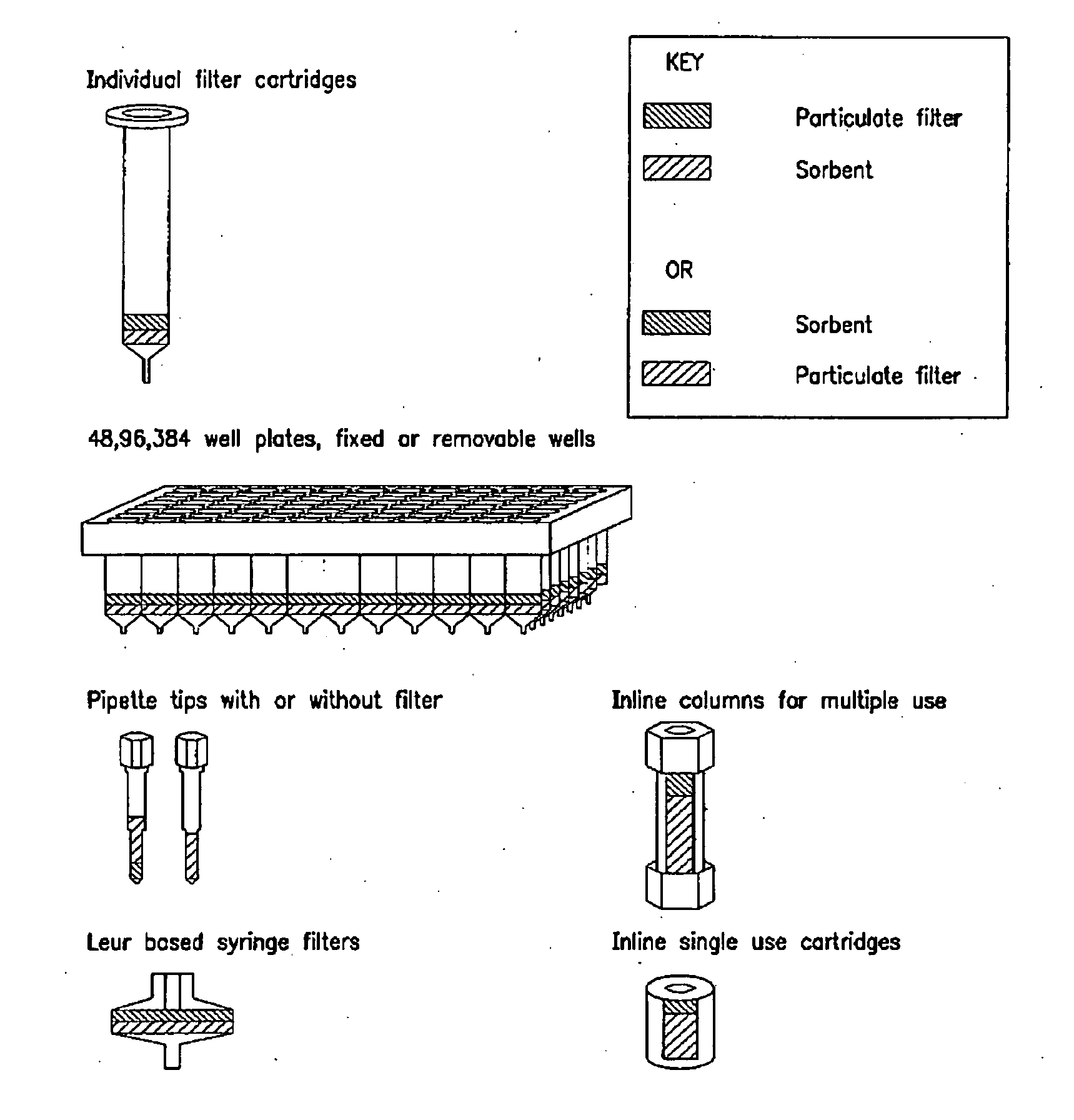

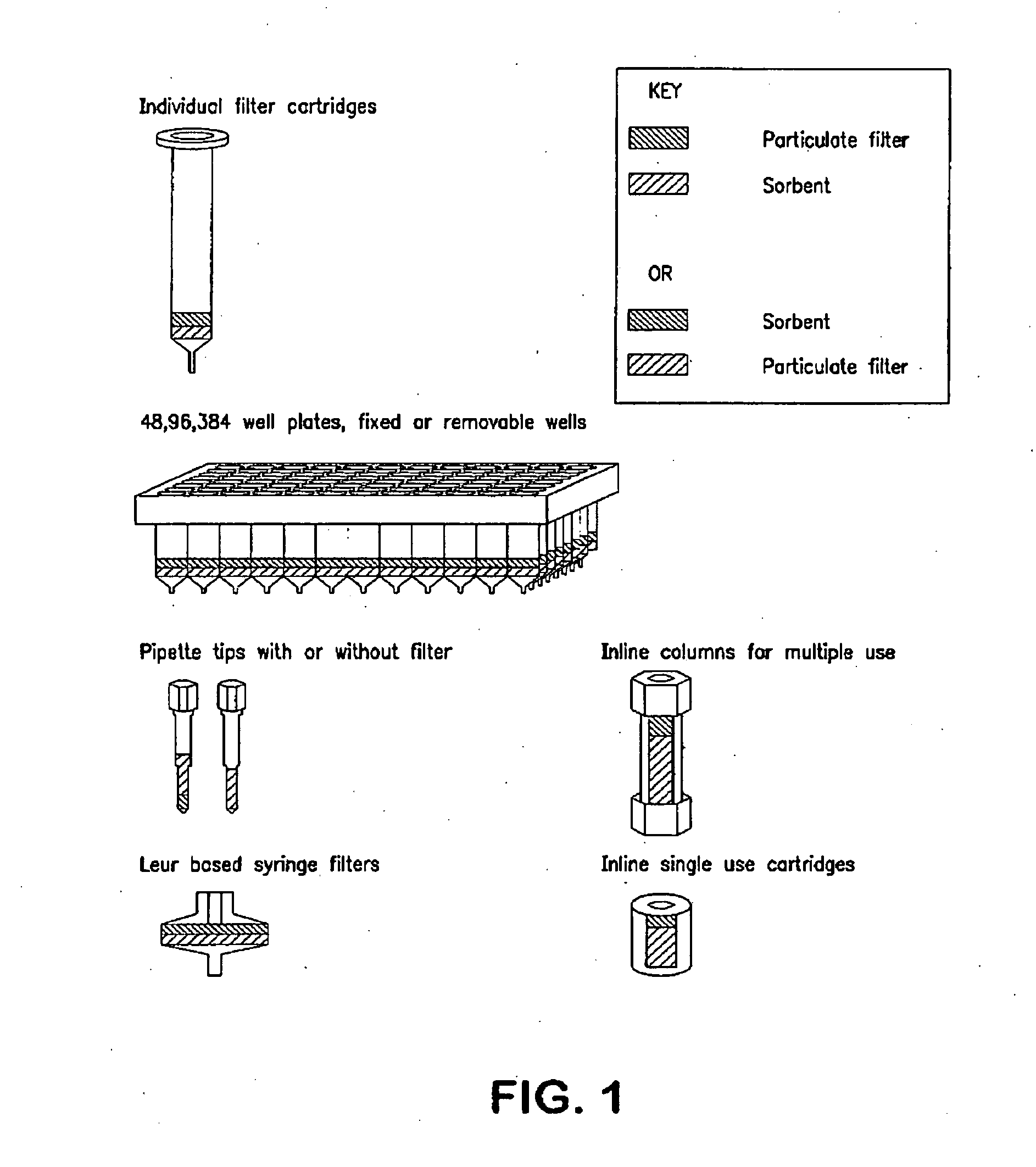

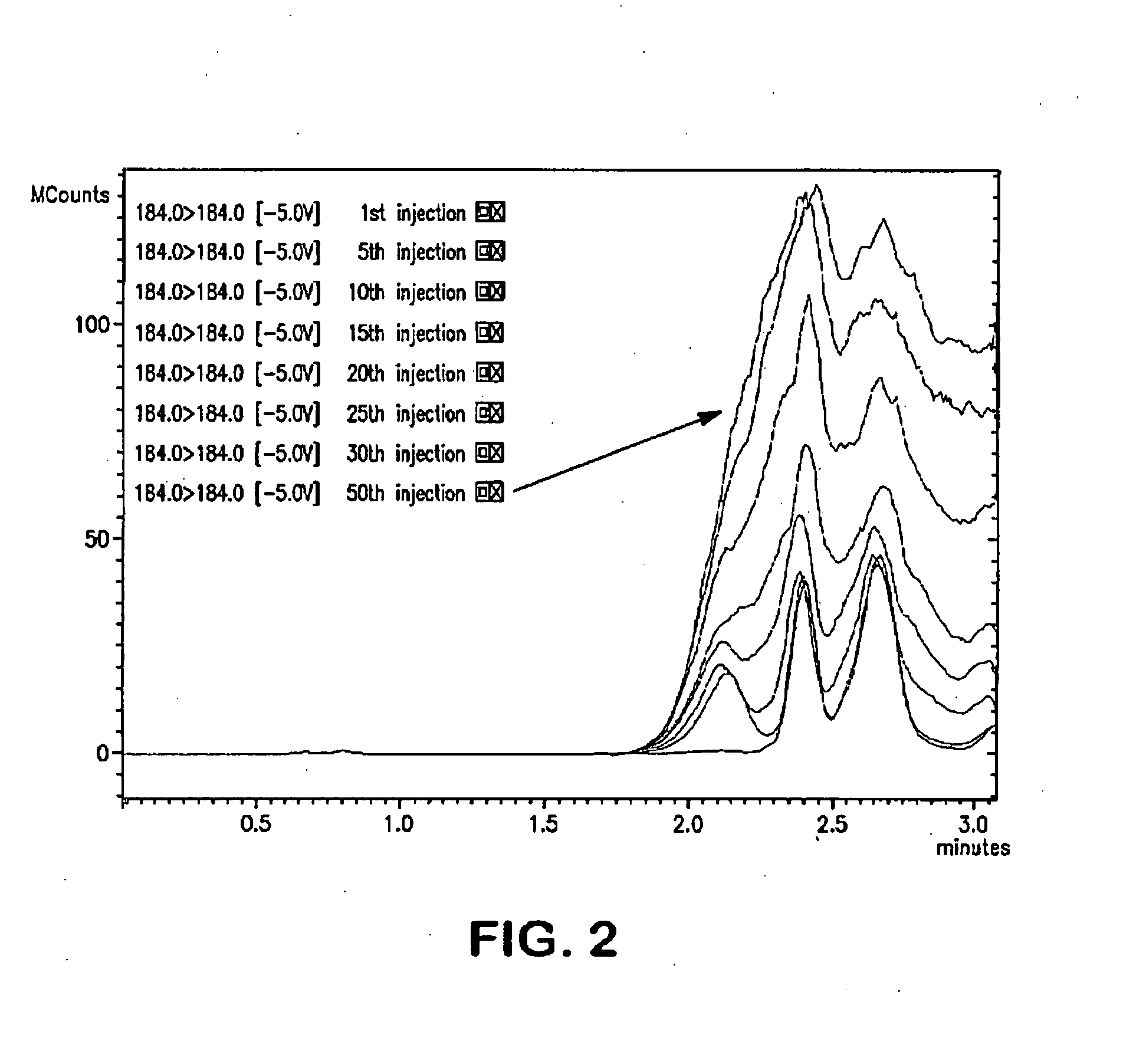

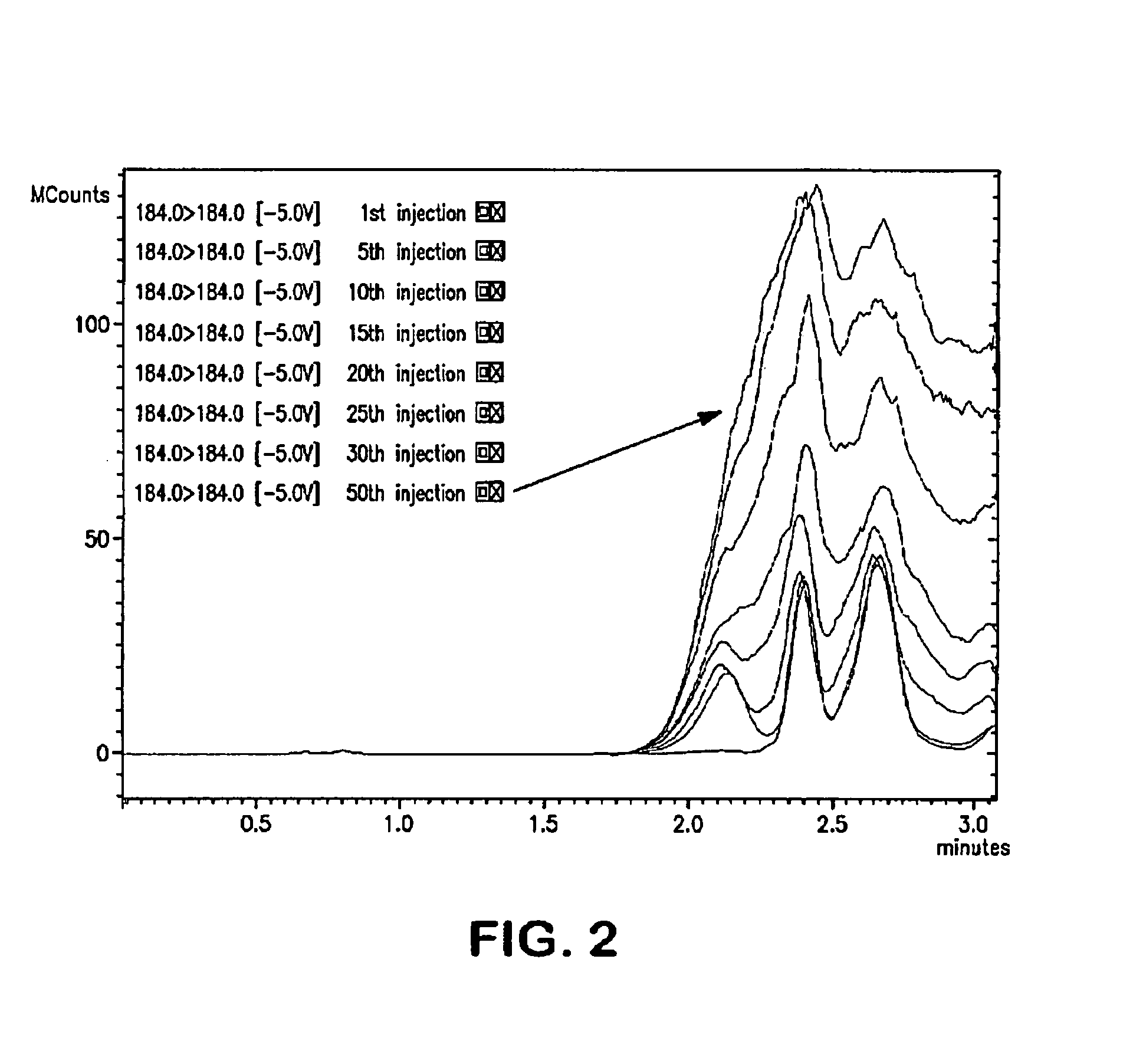

Devices and methods for reducing matrix effects

ActiveUS20080287661A1Reduce matrix effectEasy to makeBioreactor/fermenter combinationsBiological substance pretreatmentsAnalyteSorbent

Devices and methods are provided for reducing matrix effects in protein precipitated bioanalytical samples comprising: a support, and a sorbent associated with the support capable of binding matrix interfering agents present in the bioanalytical sample, wherein the device further comprises filtering means for removing precipitated protein particles. The filtering means is a size exclusion filter or a polymeric or inorganic monolith having a maximum pore size less than or equal to the diameter of the particles to be removed from the sample, and can be integral with the sorbent or associated with the sorbent. The sorbent is characterized by sufficient selectivity between the matrix interfering agents and analytes of interest to provide retention of the matrix interfering agents while providing elution of the analytes of interest (e.g., a reversed phase or a polar modified reversed phase). Typical devices incorporating these features include luer syringe filters, individual filter cartridges, multiwell plates, pipette tips, or inline columns for multiple or single use.

Owner:AGILENT TECH INC

Stable, aerosolizable suspensions of proteins in ethanol

Stable suspensions of a biologically active protein are disclosed that are suited for aerosol delivery to the lungs of a patient in need of treatment, which comprise particles of biologically active protein suspended in ethanol. In a preferred embodiment, the invention describes a stable suspension of insulin useful for aerosol delivery to the lungs of a patient in need of treatment comprising particles of a pharmaceutically effective amount of insulin suspended in ethanol. A method of delivering a therapeutically effective amount of a protein to the respiratory tract of a patient is described which comprises producing an aerosol of a stable liquid suspension of a protein using an electrohydrodynamic spraying means wherein the liquid suspension comprises particles of the protein suspended in ethanol. The stable ethanol suspensions of the invention may optionally contain up to about 20% (V / V) of a pharmaceutically acceptable formulation additive such as glycerol, propylene glycol and polyethylene glycol as well as minor amounts (from about 0.05% to about 5.0% W / V) of a pharmaceutically acceptable excipient.

Owner:VENTAIRA PHARMA

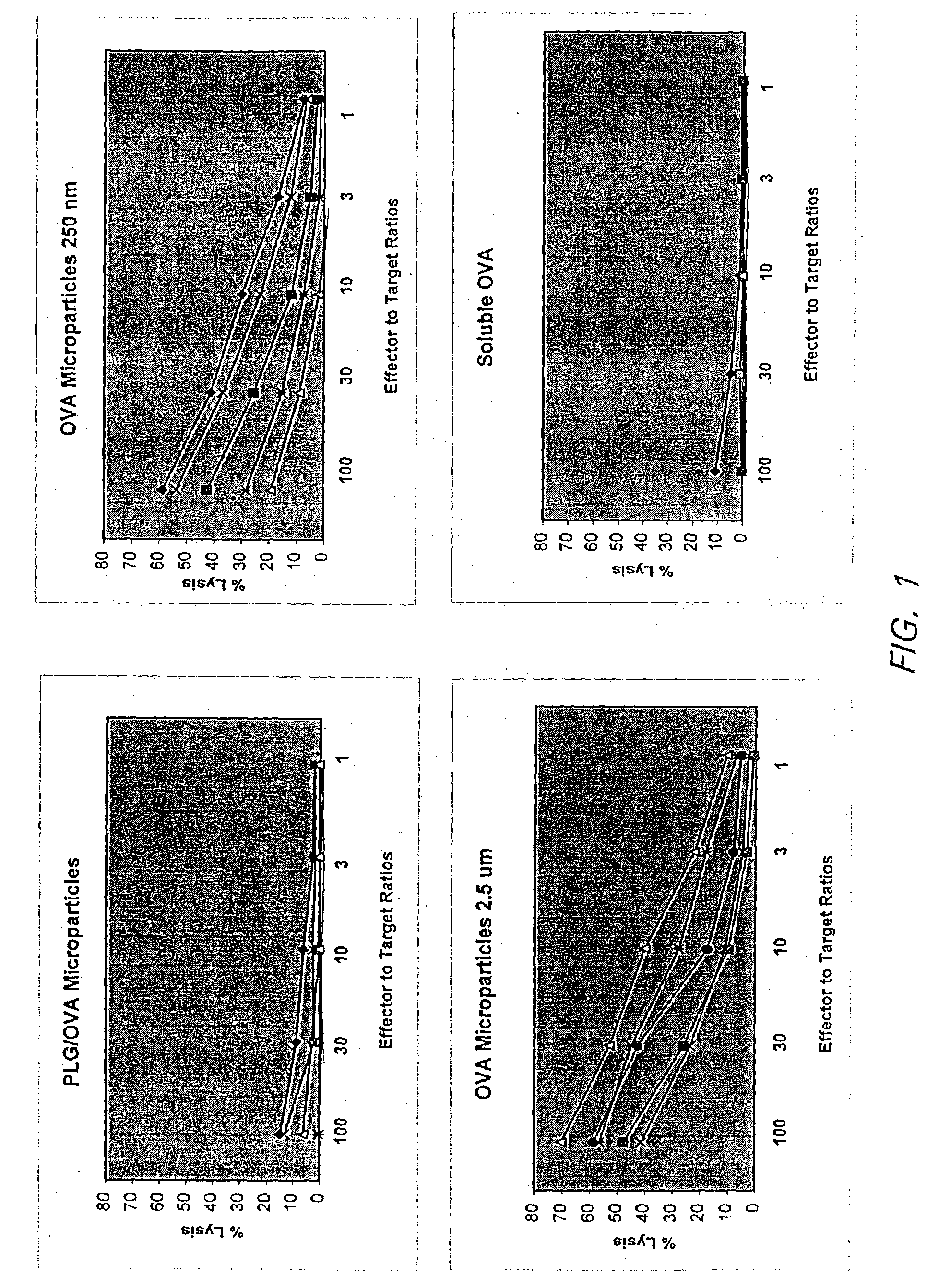

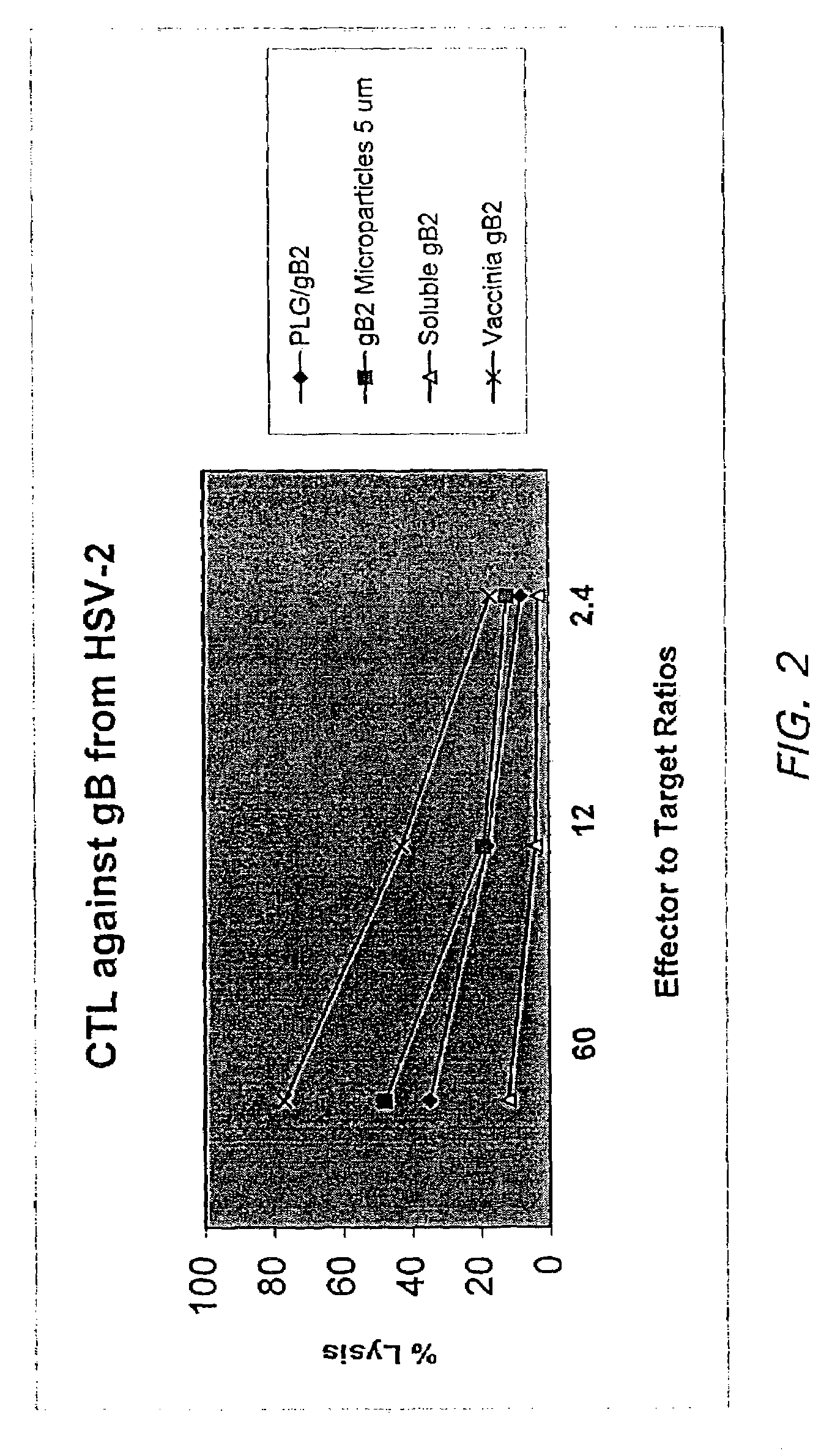

Method of obtaining cellular immune responses from proteins

InactiveUS7604802B2Improving immunogenicityPowerful toolNanotechViral antigen ingredientsExcipientCellular immunity

A method for producing a cellular immune response in a vertebrate subject comprising administering to the vertebrate subject a vaccine composition comprising a protein particle antigen and a pharmaceutically acceptable excipient is disclosed.

Owner:NOVARTIS VACCINES & DIAGNOSTICS INC

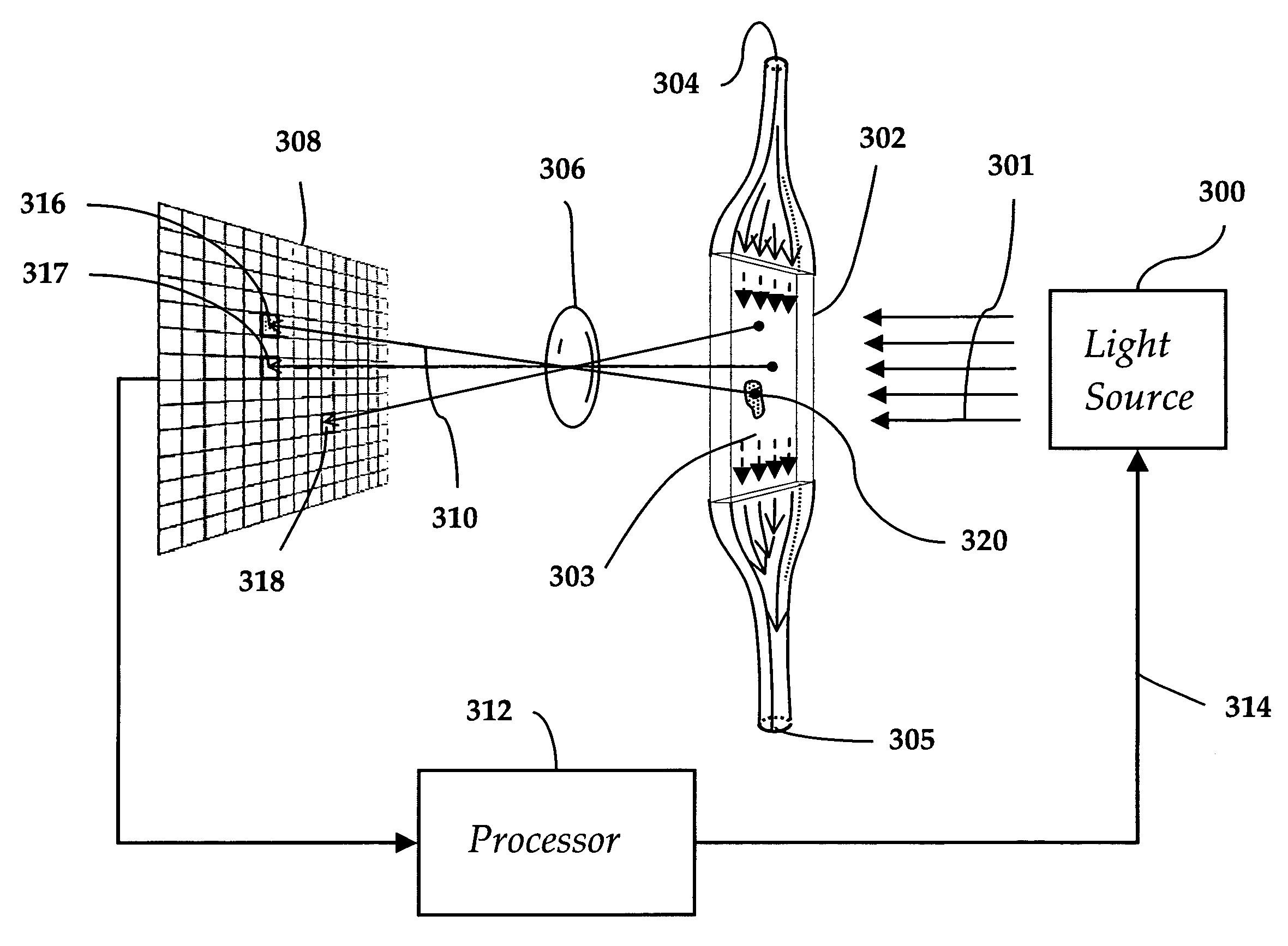

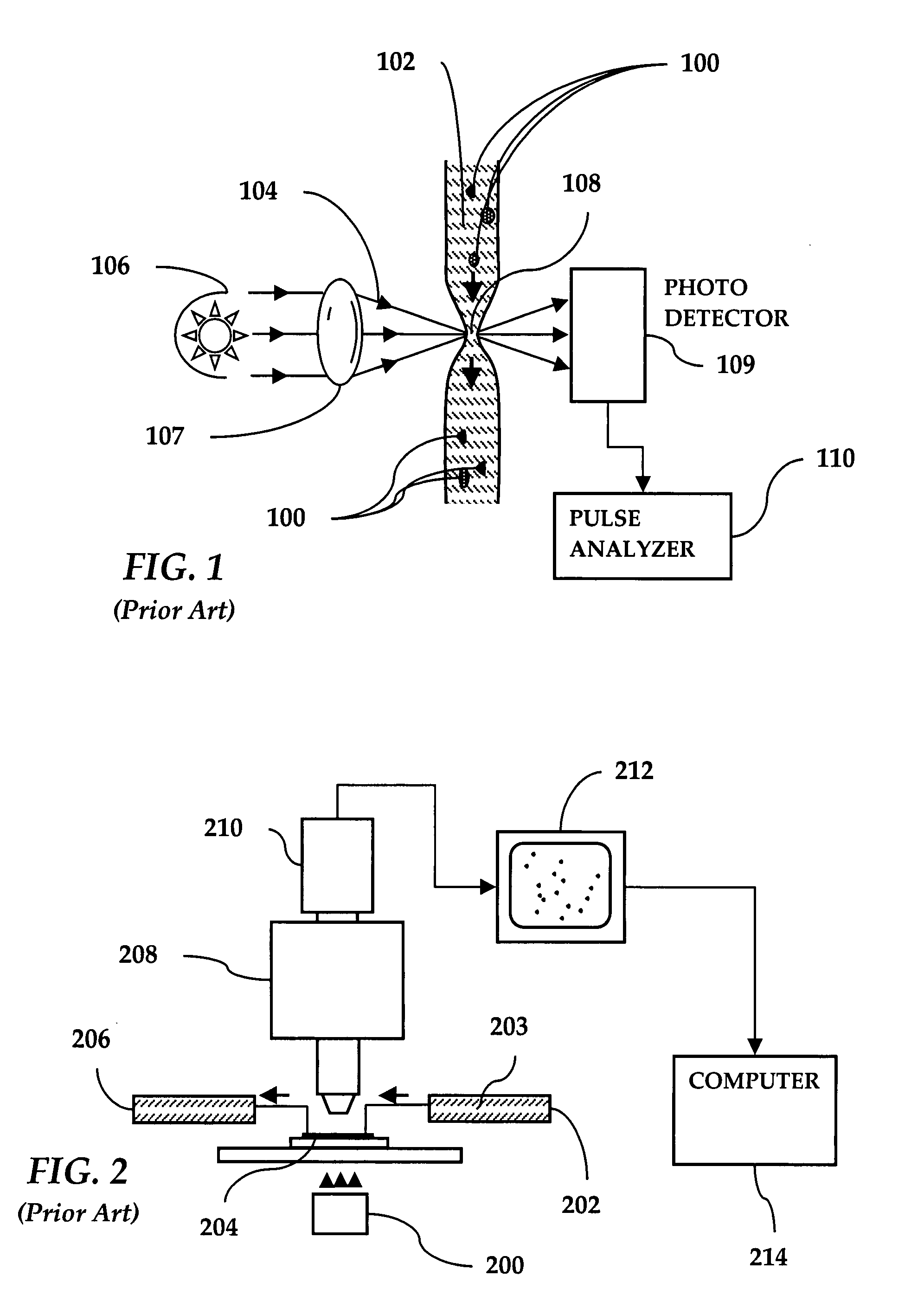

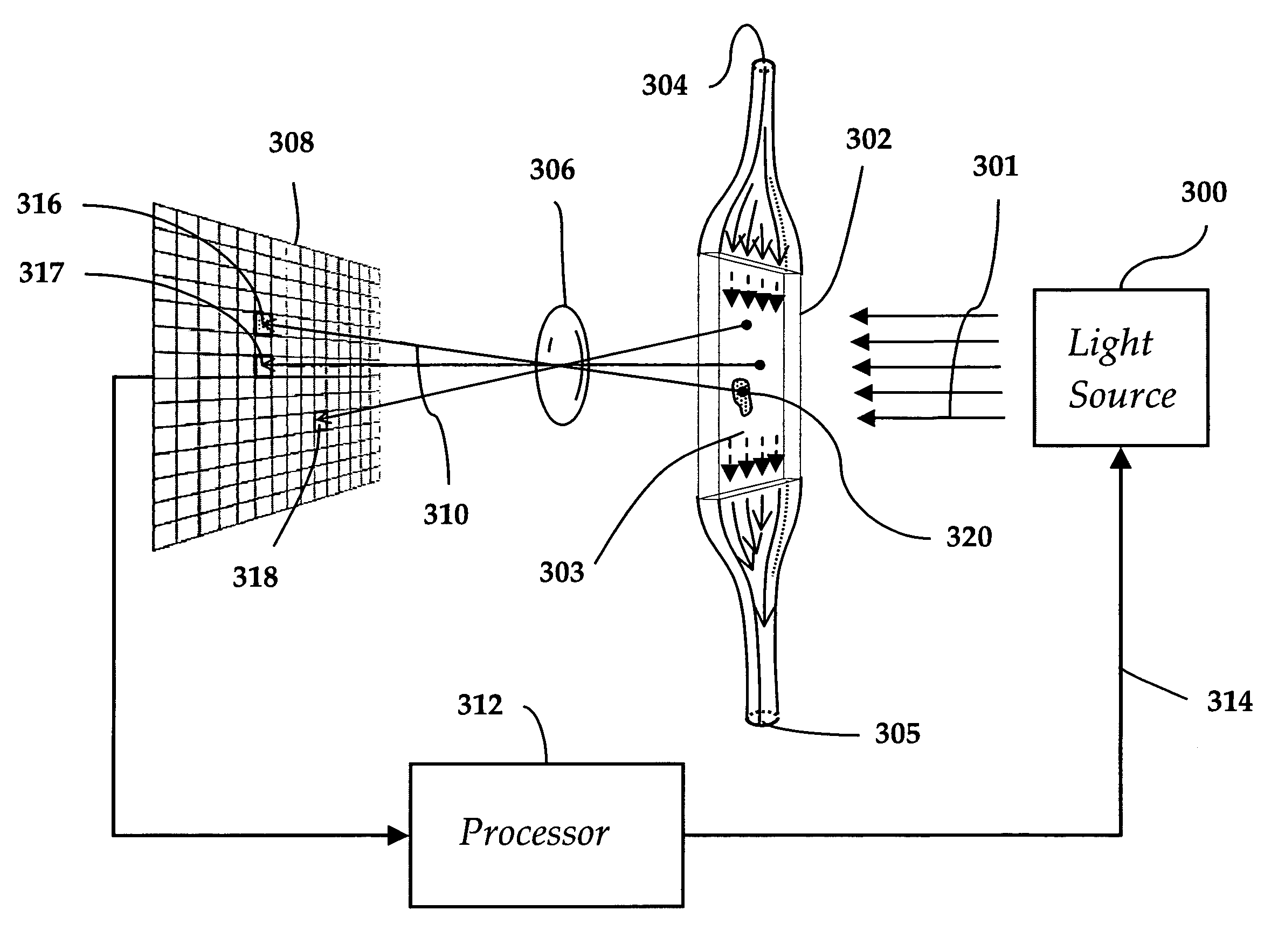

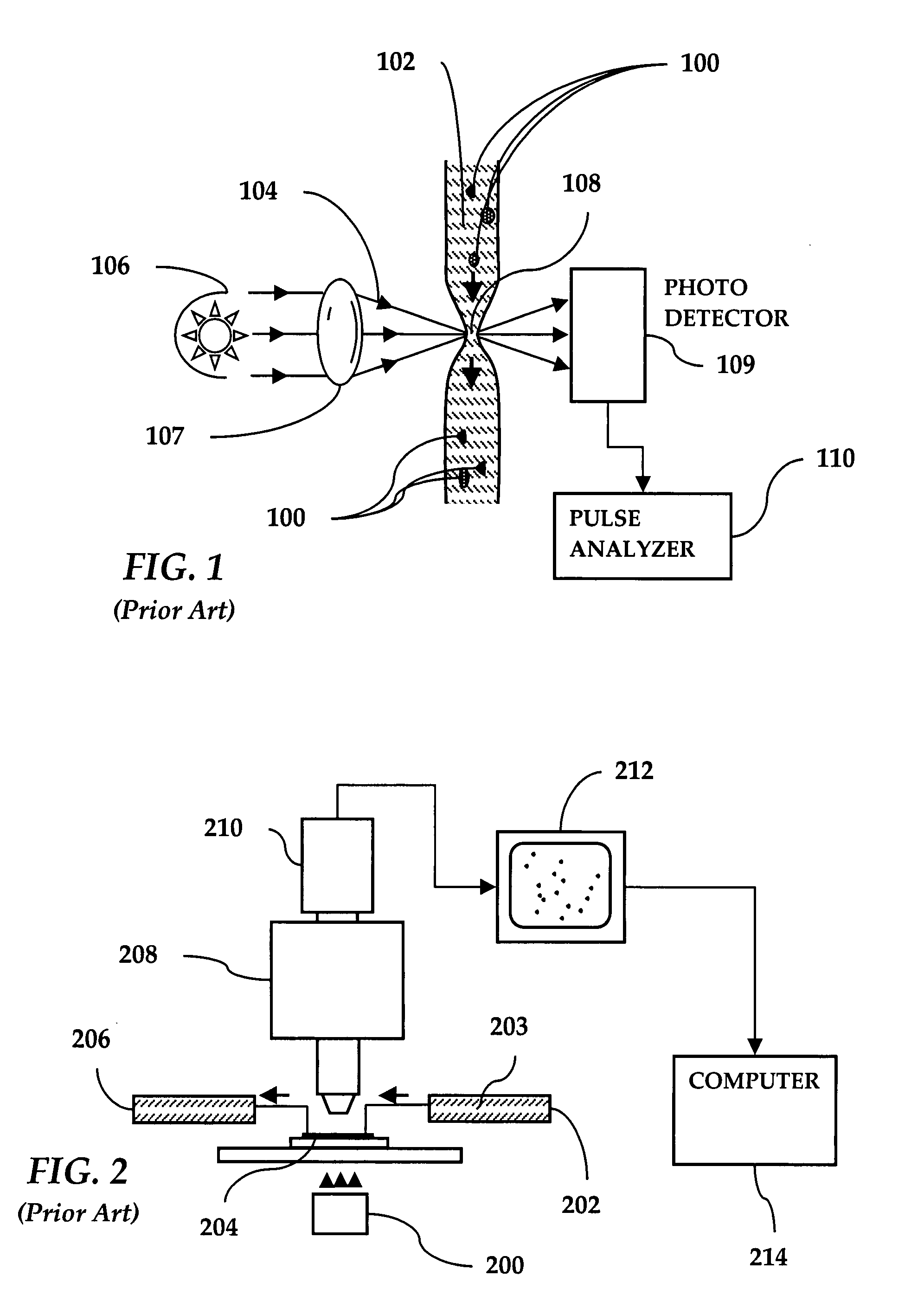

Method and Apparatus for Analyzing Particles in a Fluid

A method and apparatus for analyzing particles in a fluid, such as proteinaceous particles in a pharmaceutical formulation intended for parenteral delivery, are disclosed. The method comprises arranging a fluid to form a wide and shallow stream, acquiring a sequence of magnified still images of the stream, and processing said images, so as to highlight images of particles in the flowing fluid. The apparatus includes a light source, a flow cell, a lens with increased depth of view, a detector array, and a processor for acquiring and processing the images of particles in the fluid stream.

Owner:PROTEINSIMPLE

Method and apparatus for analyzing particles in a fluid

A method and apparatus for analyzing particles in a fluid, such as proteinaceous particles in a pharmaceutical formulation intended for parenteral delivery, are disclosed. The method comprises arranging a fluid to form a wide and shallow stream, acquiring a sequence of magnified still images of the stream, and processing said images, so as to highlight images of particles in the flowing fluid. The apparatus includes a light source, a flow cell, a lens with increased depth of view, a detector array, and a processor for acquiring and processing the images of particles in the fluid stream.

Owner:PROTEINSIMPLE

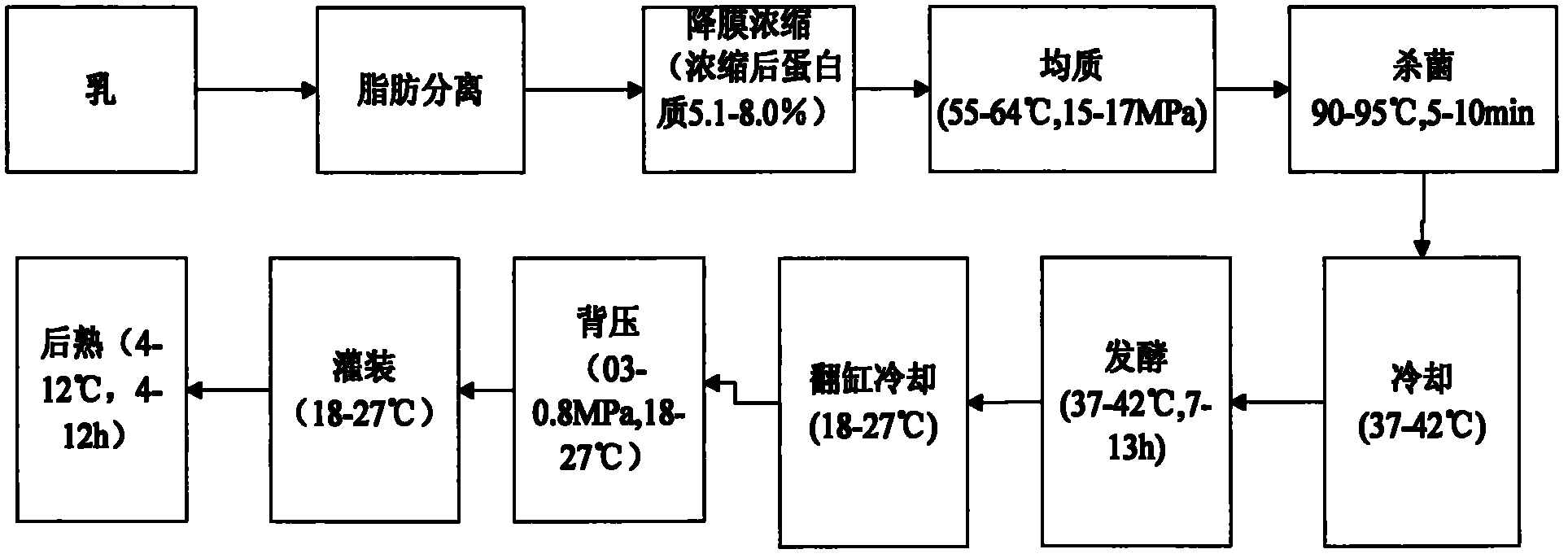

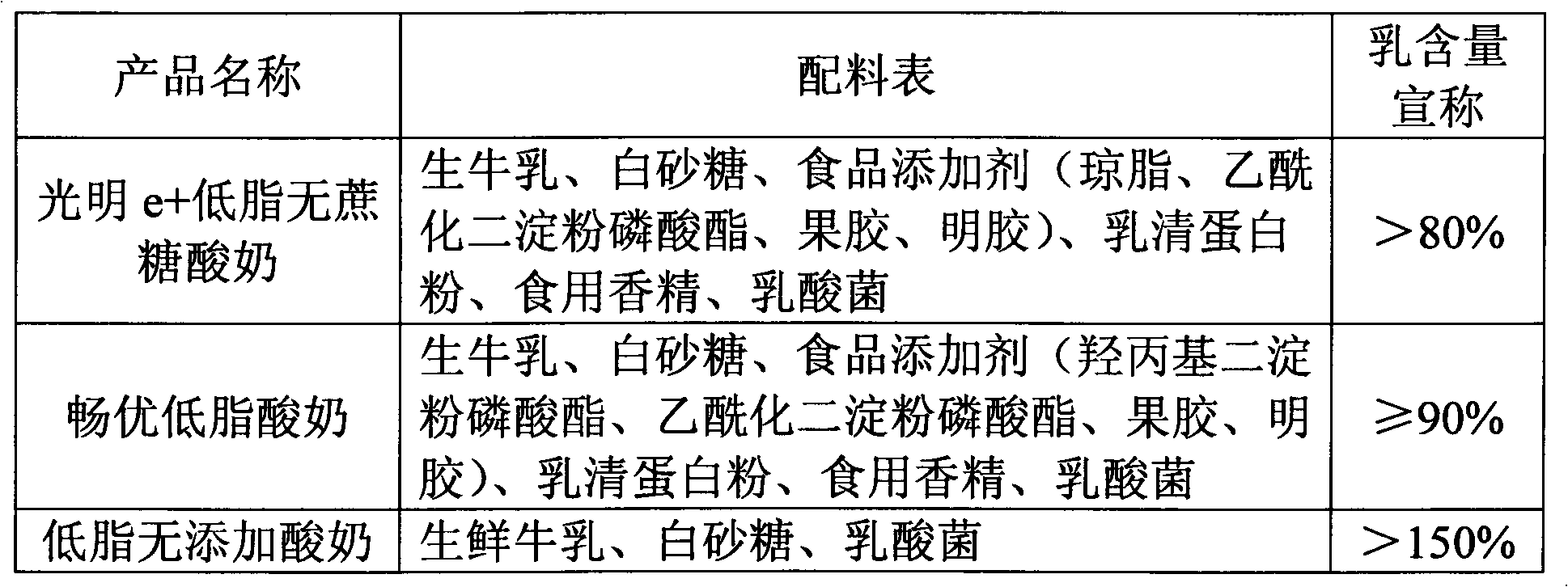

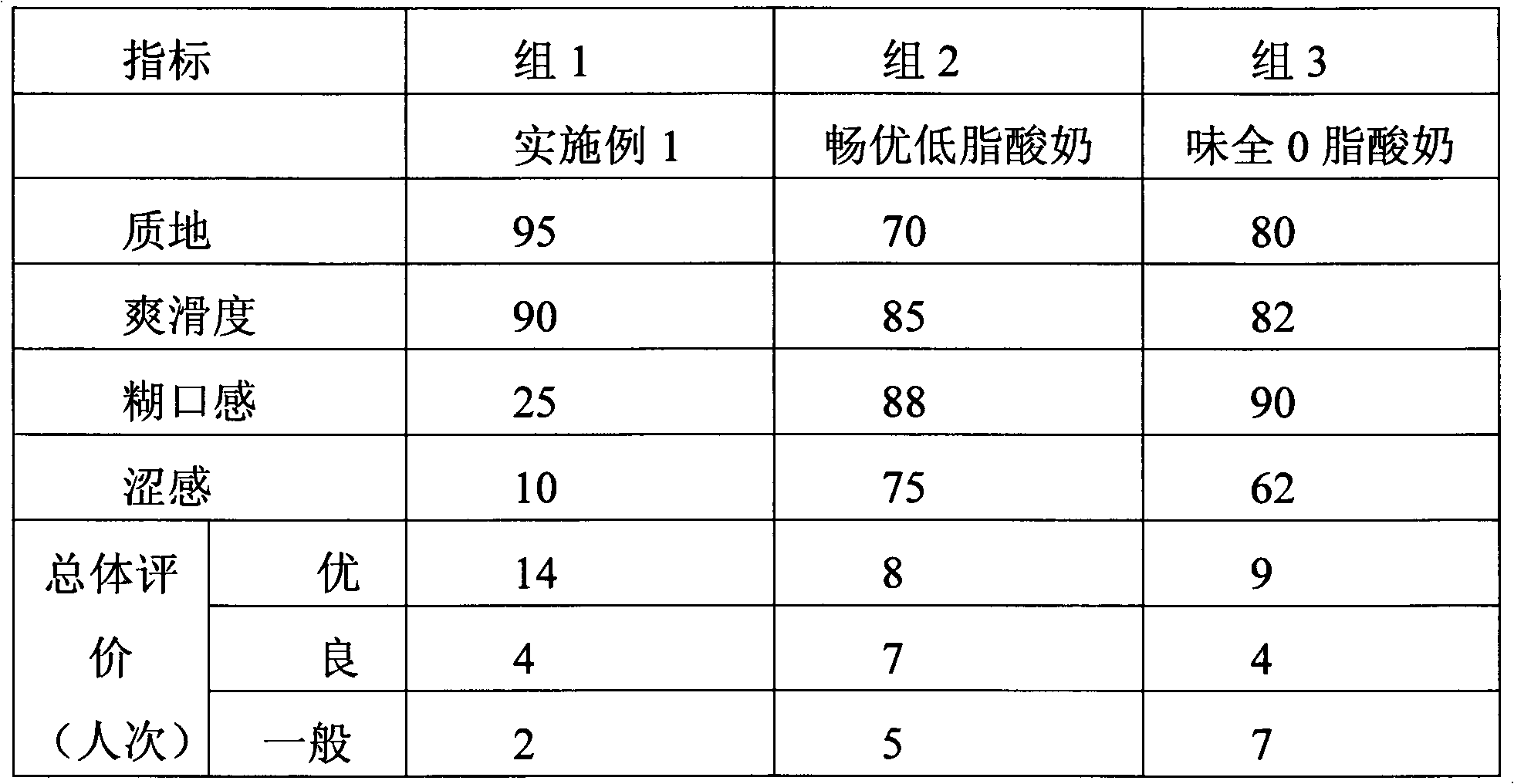

Low-fat additive-free yogurt and preparation method thereof

The invention discloses low-fat additive-free yogurt and a preparation method thereof. The low-fat additive-free yogurt includes main ingredients such as raw milk and fermenting agent, and raw milk is degreased, concentrated, fermented with fermenting culture, cooled, counterbalanced, filled and post-cured to be made into the additive-free yogurt with low content of fat. According to the low-fat additive-free yogurt and the preparation method thereof, by increasing the content of proteins inside the raw milk and prolonging the fermentation time, partial proteins are modified, a substance with the structure and taste being similar to that of the fat is generated, and a taste of smoothness and coolness is applied to the low-fat yogurt; and through the counterbalancing processing technique, protein particles in the yogurt can be eliminated, an exquisite taste is applied to the yogurt, and the viscosity of the yogurt is greatly improved by utilizing the yogurt post-curing technique. On the premise that no external fat substitute is used and no additive such as a thickening agent and essence is utilized, the low-fat additive-free yogurt with a taste being similar to that of whole fermented milk is developed only by improving the raw material and yogurt manufacturing technique conditions.

Owner:BRIGHT DAIRY & FOOD

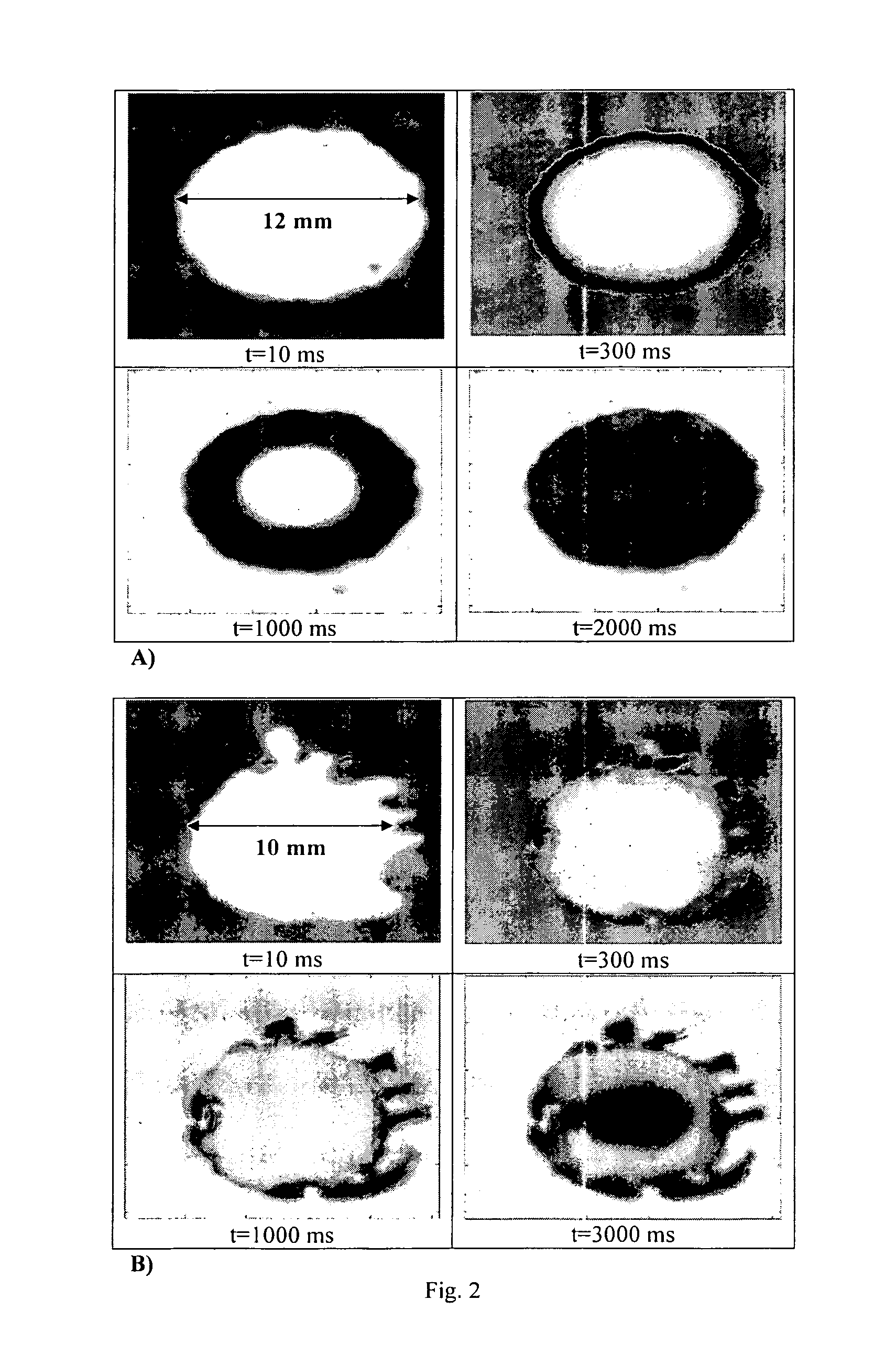

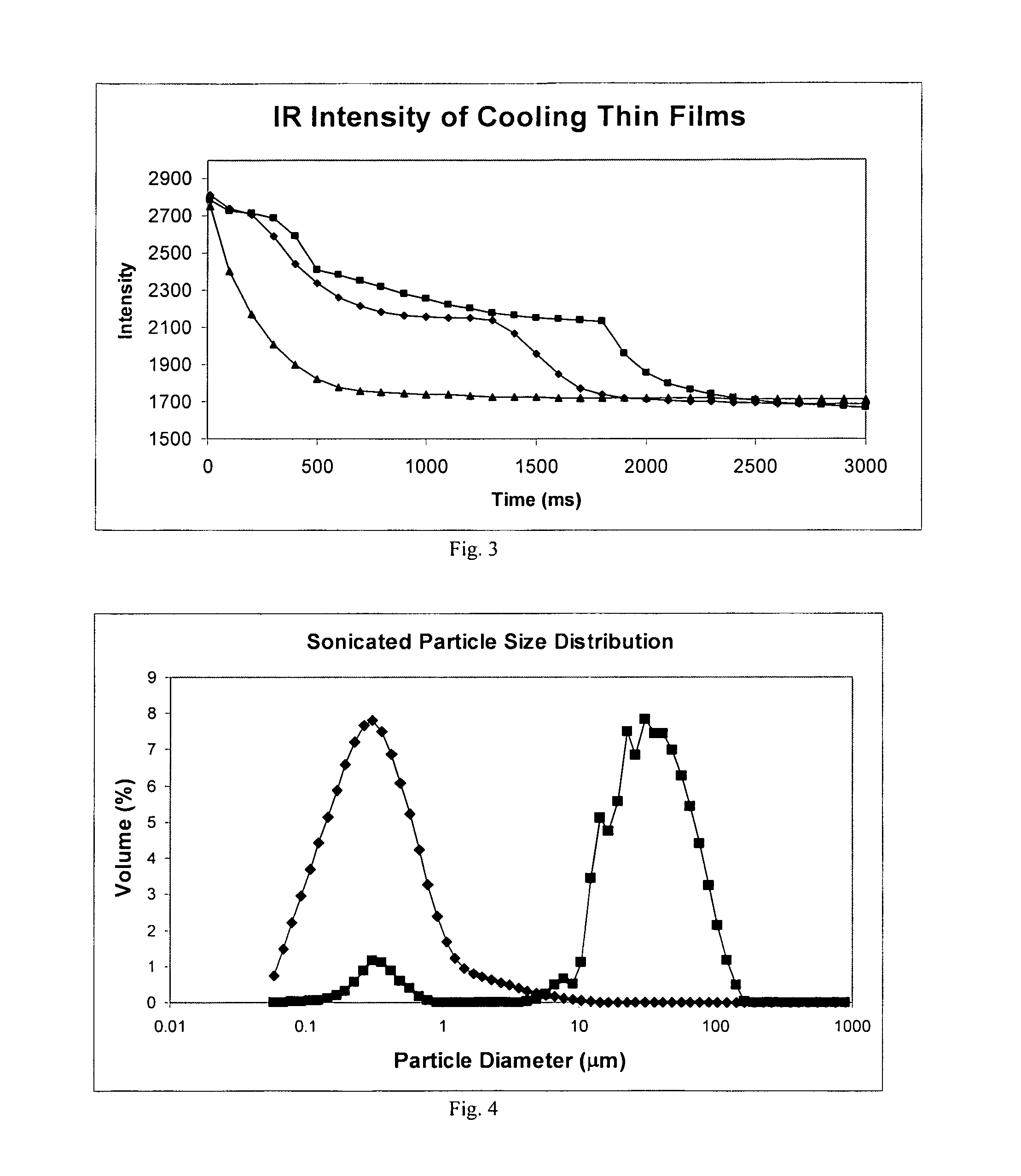

Formation of stable submicron peptide or protein particles by thin film freezing

ActiveUS8968786B2Simple and efficient and robust processPowder deliveryNervous disorderVapor liquidMicrometer

The present invention includes compositions and methods for preparing micron-sized or submicron-sized particles by dissolving a water soluble effective ingredient in one or more solvents; spraying or dripping droplets solvent such that the effective ingredient is exposed to a vapor-liquid interface of less than 50, 100, 150, 200, 250, 200, 400 or 500 cm−1 area / volume to, e.g., increase protein stability; and contacting the droplet with a freezing surface that has a temperature differential of at least 30° C. between the droplet and the surface, wherein the surface freezes the droplet into a thin film with a thickness of less than 500 micrometers and a surface area to volume between 25 to 500 cm−1.

Owner:BOARD OF RGT THE UNIV OF TEXAS SYST

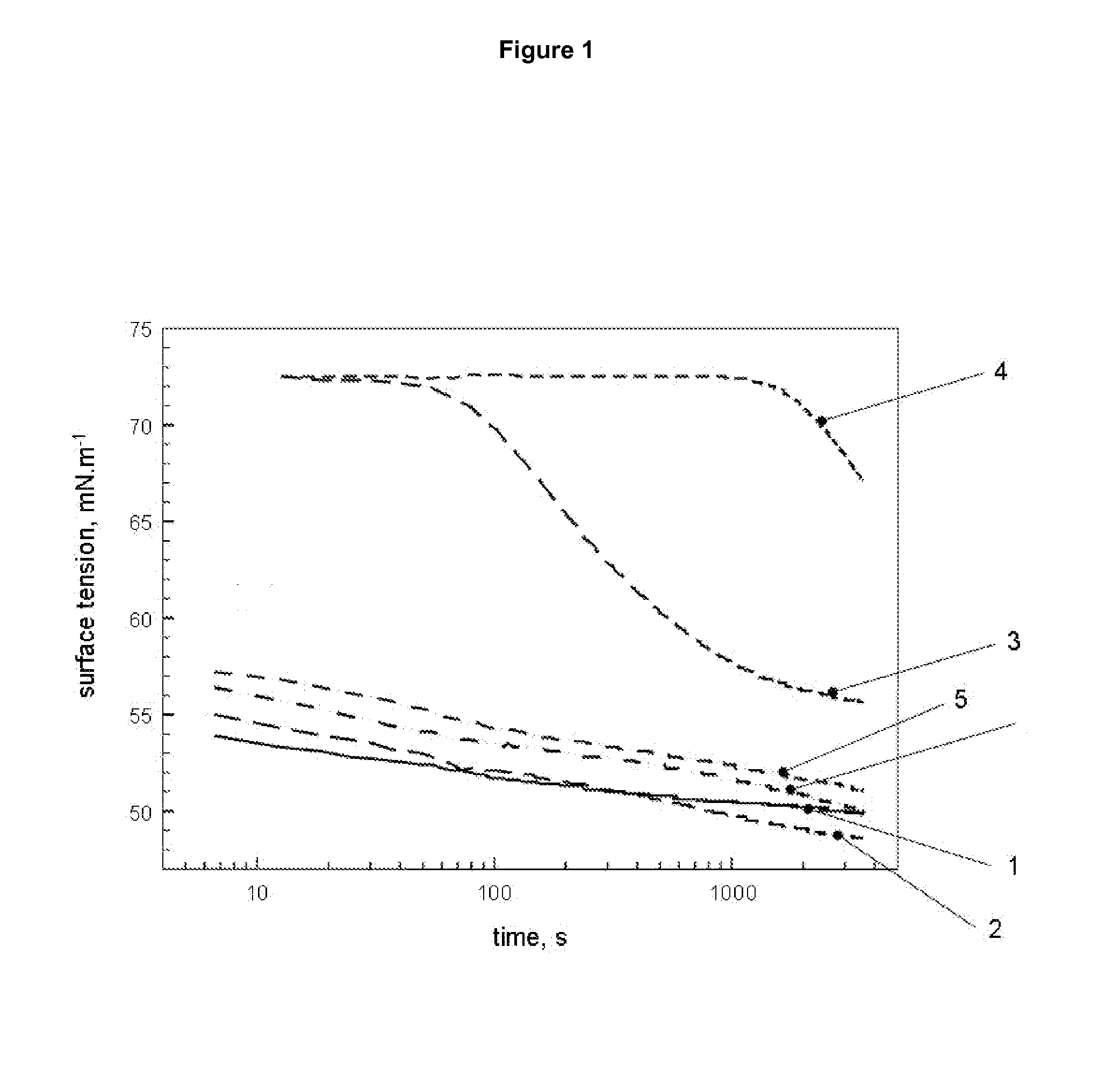

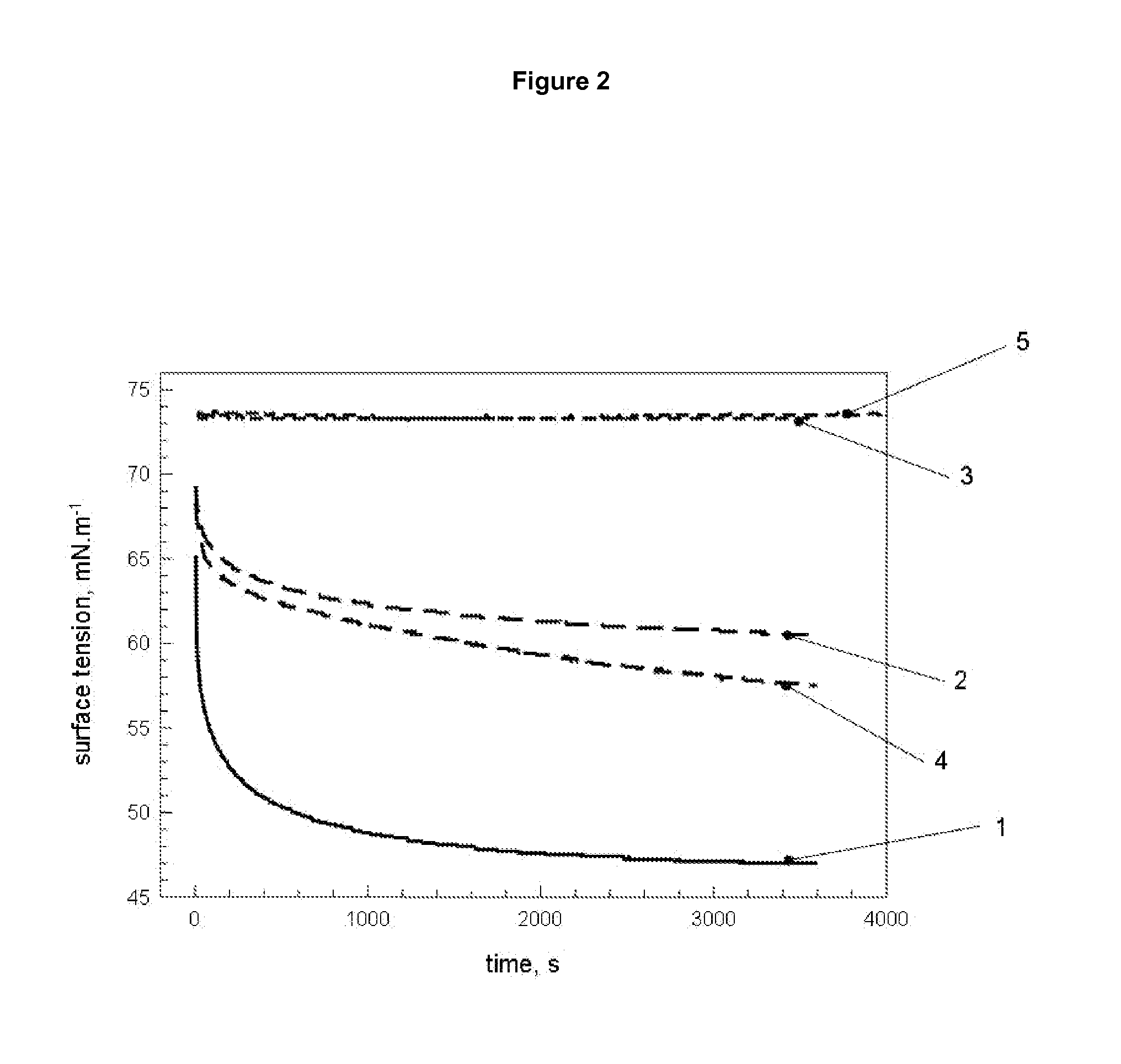

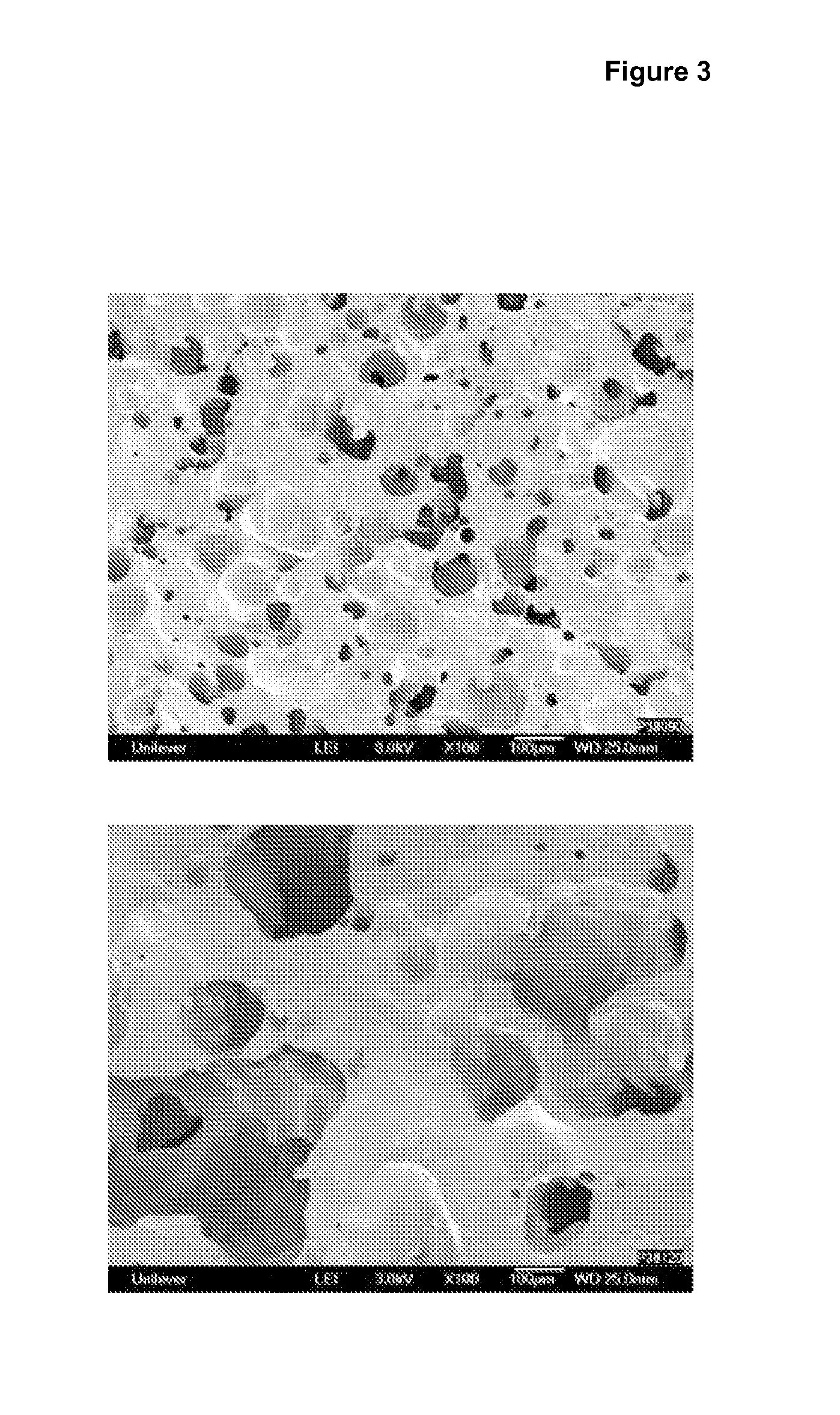

Method for preparing aggregated protein particles

ActiveUS20120121776A1Reduce surface activityReduced stabilityFrozen sweetsAlcoholic beverage preparationCrystallographyAdditive ingredient

The present invention has as an objective to provide protein particles which have strongly reduced surface activity, and can be used as an ingredient in foams and aerated food products while not interfering with stabilisers at the gas bubble interface. This invention provides a method to produce such aggregated protein particles, as well as the aggregated protein particles which have strongly reduced surface activity.

Owner:CONOPCO INC D B A UNILEVER

Formula and production process of dairy cow protein particle feed

InactiveCN101731485AImprove utilization efficiencyIncrease expansionAnimal feeding stuffFiberAntioxidant

The invention relates to a formula of dairy cow protein particle feed which comprises the following components by weigh percent: 15-40 percent of energy feed, 40-80 percent of protein feed, 0-9 percent of oil and fat, 0-18 percent of amino acid, 0-2.3 percent of vitamin, 1.6-2 percent of calcium carbonate, 0-1 percent of adhesive, 0-0.1 percent of antioxidant and 0-0.3 percent of antimold agent. The production process of the dairy cow protein particle feed comprises the following steps: a, weighting the components according to the weight percent thereof; b, grinding the components; c, mixing the ground components; d, tempering the mixture; e, granulating the mixture; f, post-curing the granules; g, drying the granules; and h making the granules into the dairy cow protein particle feed which has the diameter of less than 4 mm and the length of 1 to 2 times of the diameter and contains the dry matter of more than 88 percent. The dry matter contains the crude protein of more than 20 percent and the crude fiber of less than 18 percent. The dairy cow protein particle feed can be kept stable in water for more than 5 min and has the dispersion rate of less than 12 percent in water. The protein in the dairy cow protein particle feed is less degraded by the rumen microorganisms, the rumen bypass efficiency of the protein is improved, the need of the essential amino acids in the nutrient of protein in the dairy cow body is balanced, the efficiency of using the dairy cow protein particle feed by the dairy cow is increased, the health status of the dairy cow body is improved and the pollution of the nitrogen in the excrement of the dairy cow to the environment is reduced.

Owner:ZHEJIANG KESHENG FEED CO LTD

Protein-containing food product and coating for a food product and method of making same

A composition comprising about 10-65 weight % of a protein particulate material, about 35-90 weight % of a lipid-containing material, and no more than small amounts of an emulsifier, can be used as a coating composition for a food product, or as an ingredient in a coating composition for a food product. When used as a coating for a snack food item such as a protein-containing energy bar, the coating can add to the nutritive value of the bar, and maintain the moisture content of the bar. A method for making the composition includes the steps of adding finely ground particulate protein matter to a fat composition with heat and high shear, then cooling the composition.

Owner:BUNGE OILS INC

Devices and methods for reducing matrix effects

Devices and methods are provided for reducing matrix effects in protein precipitated bioanalytical samples comprising: a support, and a sorbent associated with the support capable of binding matrix interfering agents present in the bioanalytical sample, wherein the device further comprises filtering means for removing precipitated protein particles. The filtering means is a size exclusion filter or a polymeric or inorganic monolith having a maximum pore size less than or equal to the diameter of the particles to be removed from the sample, and can be integral with the sorbent or associated with the sorbent. The sorbent is characterized by sufficient selectivity between the matrix interfering agents and analytes of interest to provide retention of the matrix interfering agents while providing elution of the analytes of interest (e.g., a reversed phase or a polar modified reversed phase). Typical devices incorporating these features include luer syringe filters, individual filter cartridges, multiwell plates, pipette tips, or inline columns for multiple or single use.

Owner:AGILENT TECH INC

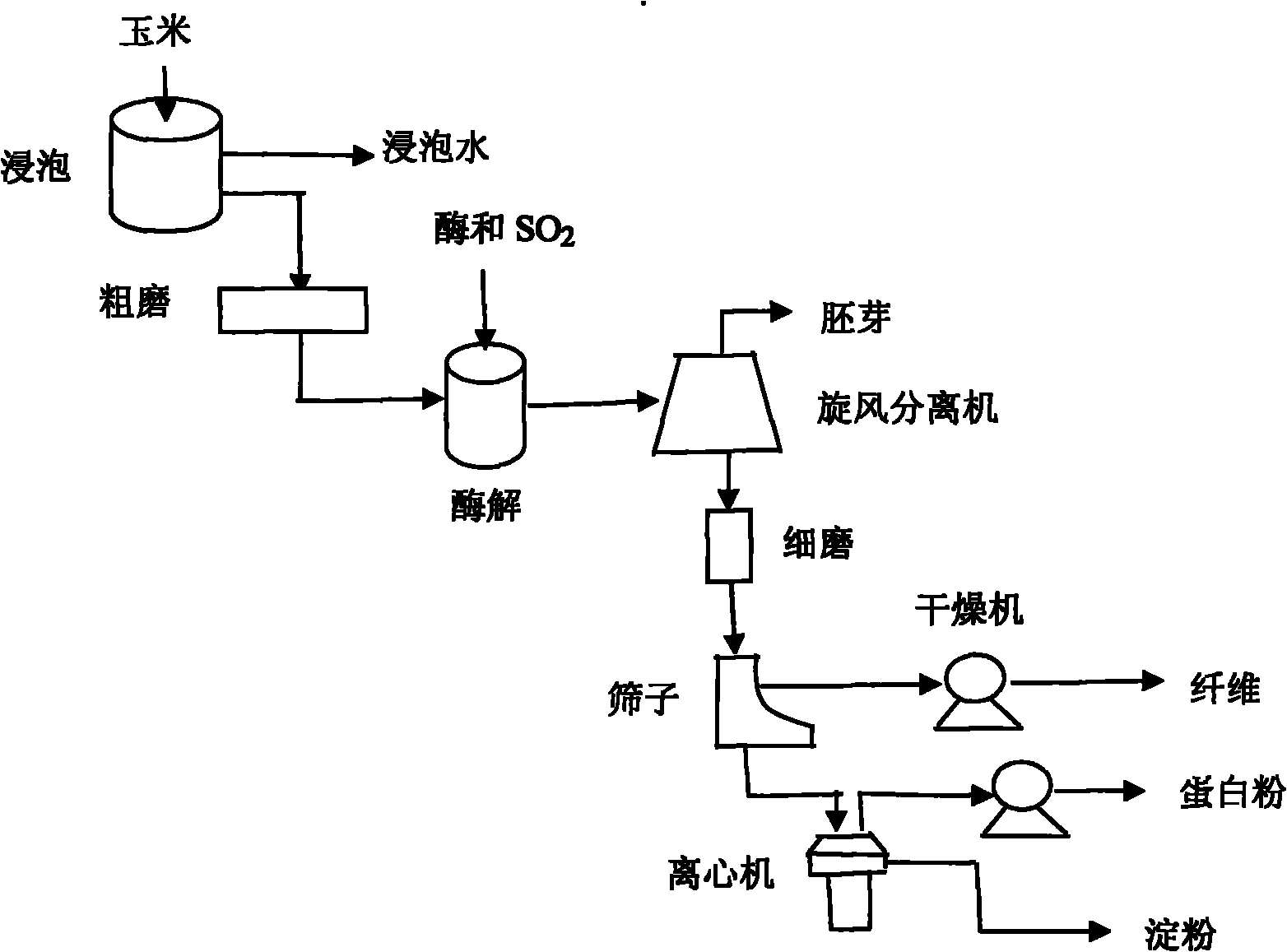

Soaking technology for preparing corn starch

The invention relates to a soaking technology for preparing corn starch, belonging to the technical field of grain deep processing. The technological steps comprise: 1. soaking: corn grains are soaked in water to soften embryos; 2. pulp grinding: the soaked corn grains are coarsely ground to obtain corn pulp; 3. enzymolysis: one of acid protease and pepsin is added in the obtained corn pulp after coarse grinding to conduct enzymolysis to the corn pulp, and SO2 is fed at the same time to mainly take the effect of inhibiting activities of microorganisms on the premise that the enzymatic activity is not affected; and 4. fine grinding, separation and drying to obtain starch finished product. Through shortening soaking time and reducing the used amount of SO2, the invention has the advantages that the corrosion of equipment, the underground water pollution, the residual sulfurous acid in the product and the like are obviously reduced, the obstacles restricting enzyme to enter endosperm to react with protein particles are eliminated, the total soaking time is only 8-12h, the soaking time is shortened, the cost is reduced, the effect is good, and the popularization value and the application value are high.

Owner:山东福田糖醇有限公司

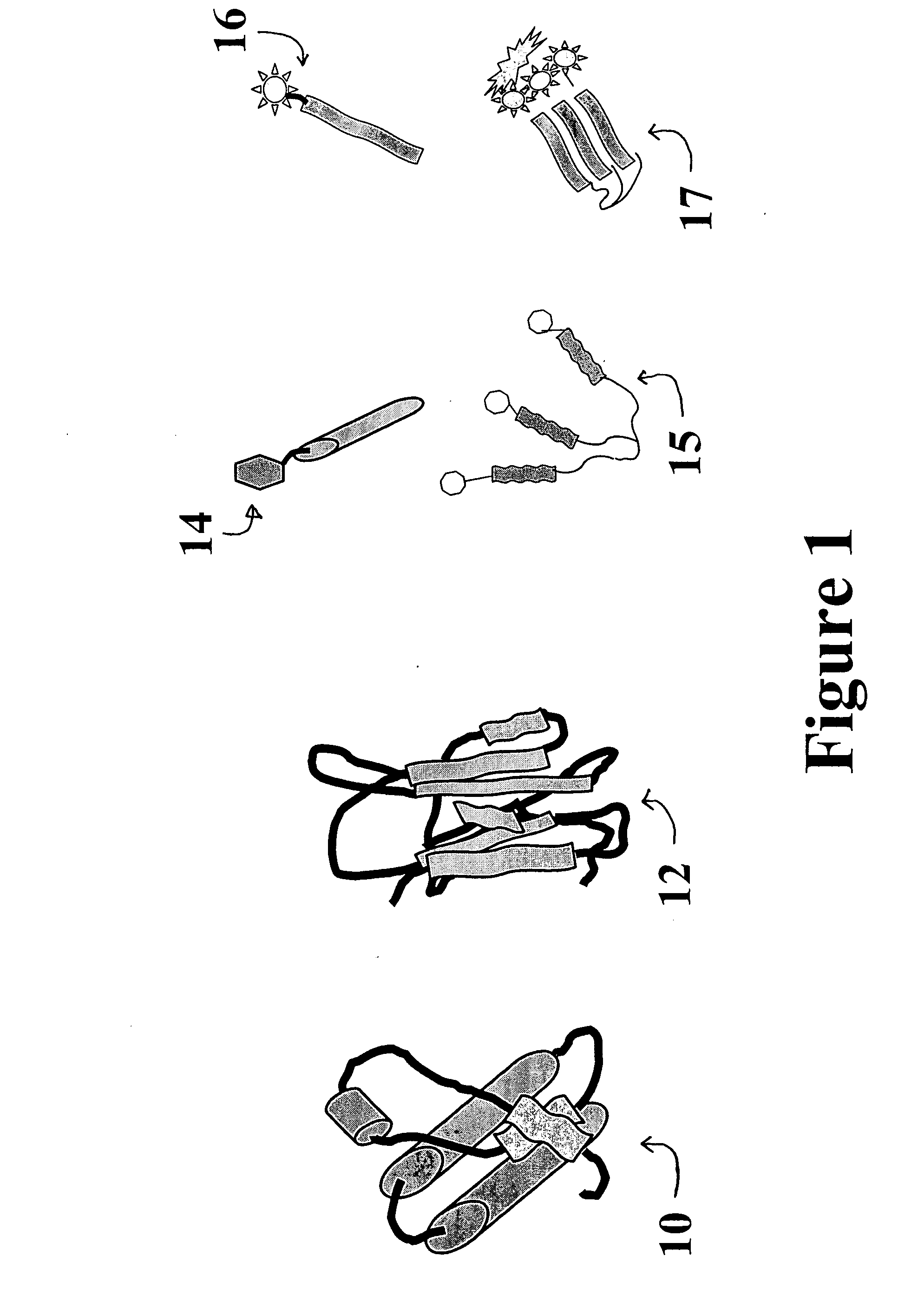

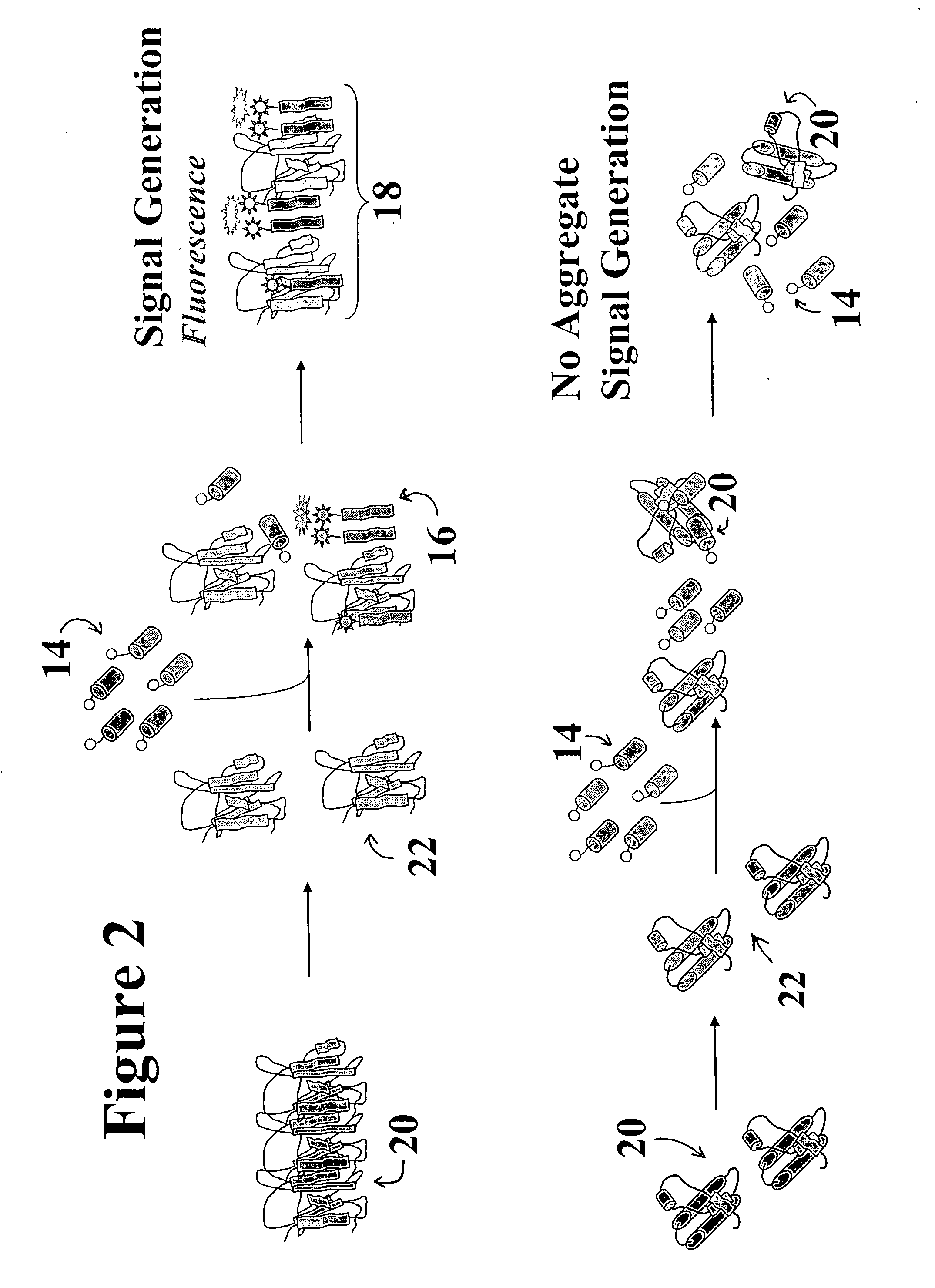

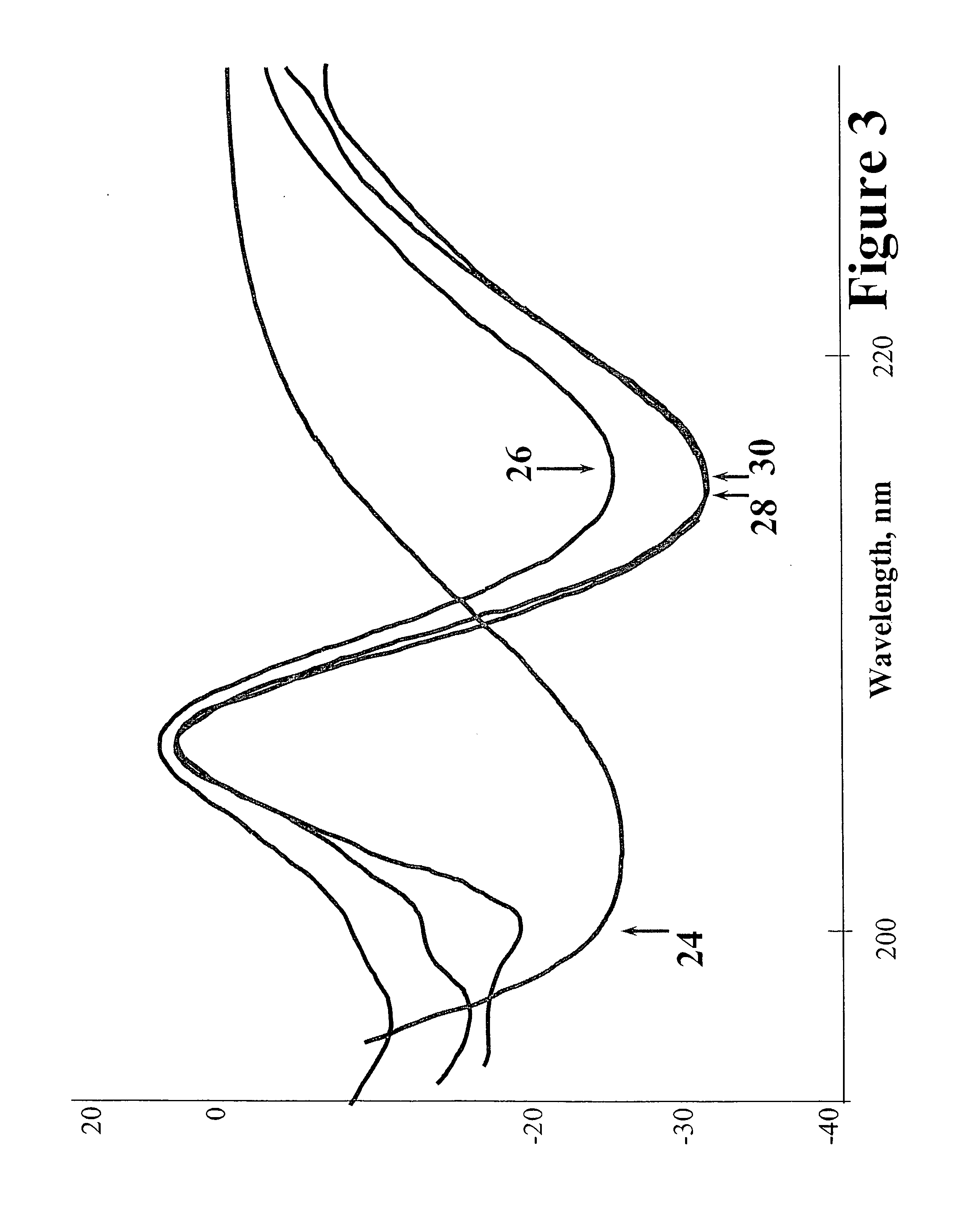

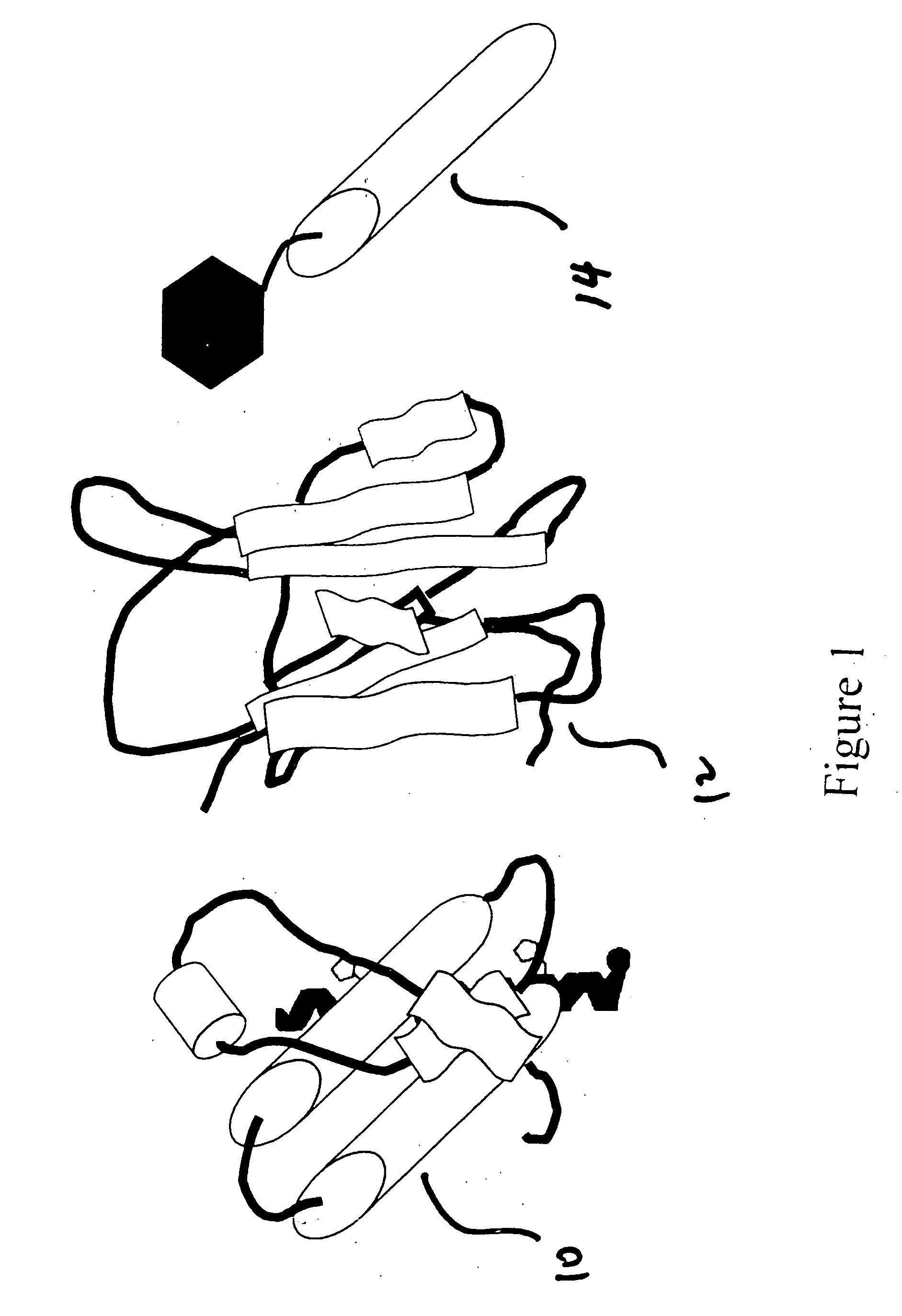

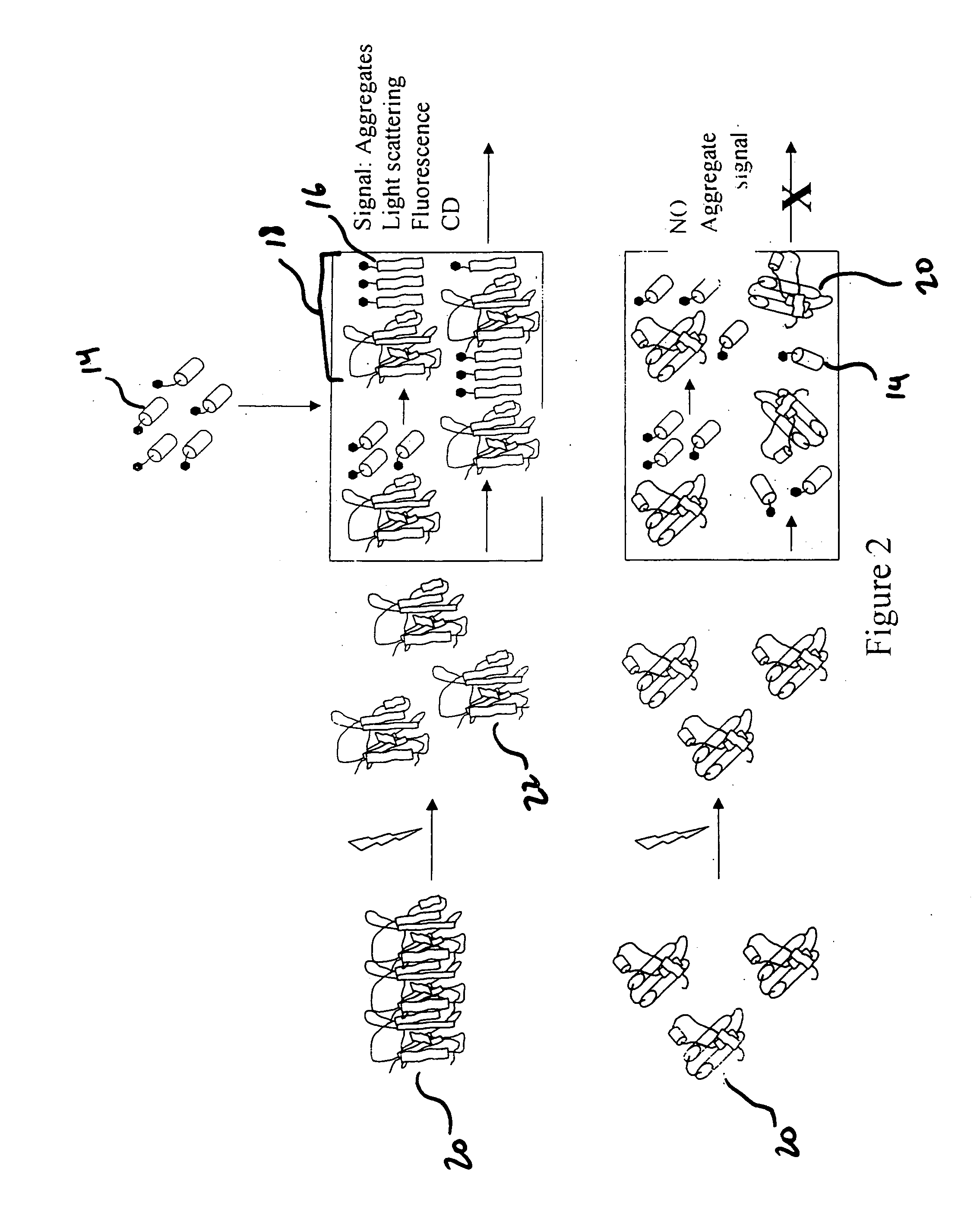

Misfolded protein sensor method

ActiveUS20060286672A1Easy to detectRapid and cost-effectivePeptide preparation methodsDepsipeptidesCrystallographyDendrimer

A catalytic conformational sensor method for detecting abnormal proteins and proteinaceous particles. The method is based on the interaction of a peptide fragment or probe with an abnormal proteinaceous particle. The interaction catalyzes transformation of the probe to a predominately beta sheet conformation and allows the probe to bind to the abnormal proteinaceous particle. This in turn, catalyzes propagation of a signal associated with the test sample-bound probe. As a result signals can be propagated even from samples containing very low concentrations of abnormal proteinaceous particles. The peptide probes can be designed to bind to a desired peptide sequence or can even be based on dendrimer structure to control further aggregate propagation.

Owner:PRESYMPTO INC

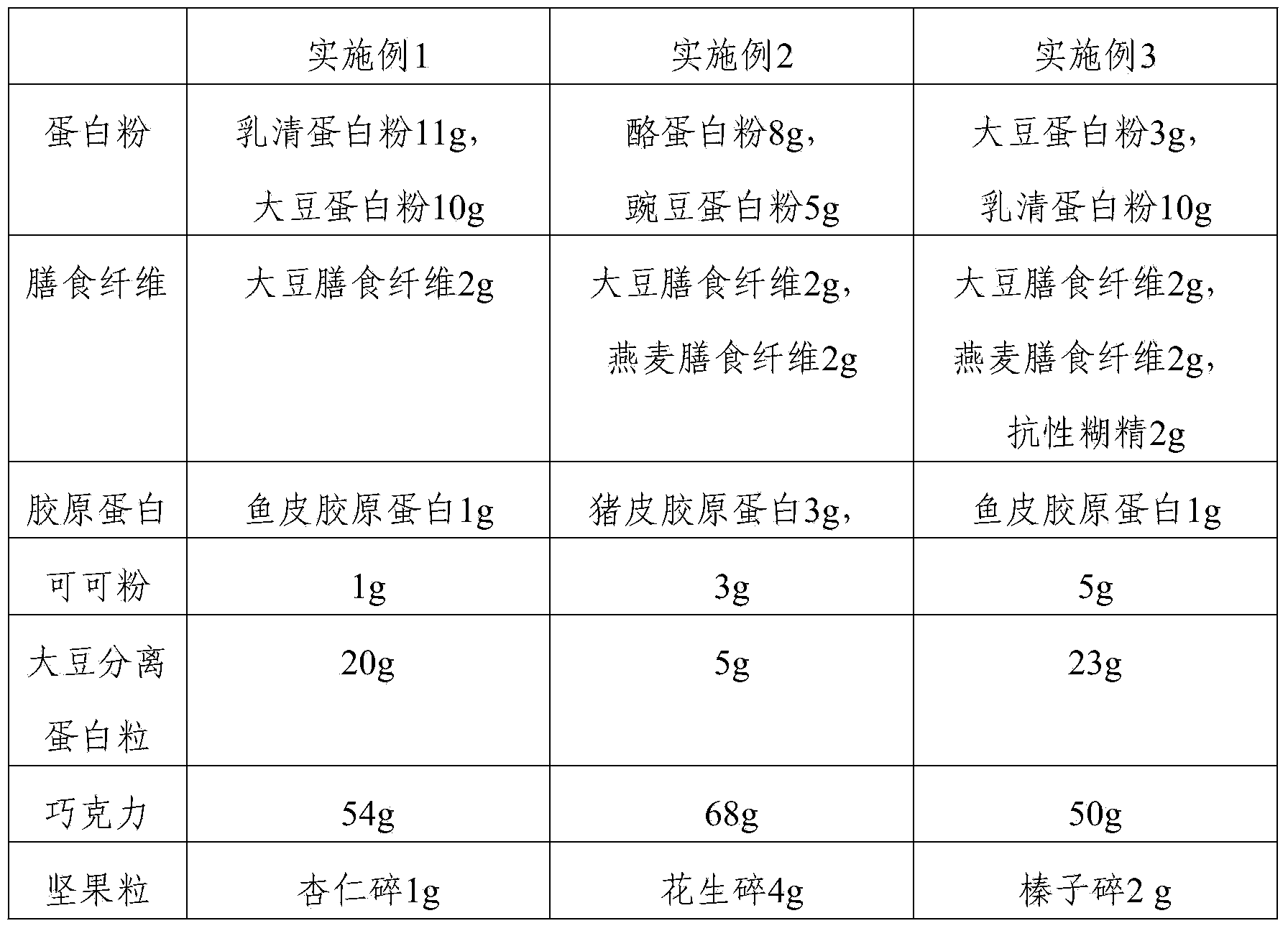

Low-fat, low-sugar and high-protein chocolate product and preparation method thereof

A low-fat, low-sugar and high-protein chocolate product is prepared from the following components in parts by weight: 2-25 parts of protein powder, 1-6 parts of dietary fiber, 1-6 parts of collagen, 1-5 parts of cocoa powder, 5-25 parts of soybean isolate protein particles and 48-88 parts of chocolate. The high-protein, low-fat, low-sugar and frostless chocolate product can be obtained by regulating the components of the conventional chocolate product and improving the preparation process of the conventional chocolate product, and the low-fat, low-sugar and high-protein chocolate product is welcome by consumers.

Owner:BEIJING COMPETITOR SPORTS SCI & TECH

Preparation method of nano pearl proteins

InactiveCN103804468AUniform particlesKeep naturalNanomedicinePeptide preparation methodsCrystallographyHuman body

The invention relates to a preparation method of nano pearl proteins. The preparation method comprises the following steps: crushing pearls into pearl micropowder with the average grain size of 1-4 microns, carrying out acidolysis, filtering, washing the filter residues by purified water to obtain coarse pearl proteins, adding a dispersant into the coarse pearl proteins to grind, and carrying out ultrasonic concussion in the period; and concentrating the grinded liquid by a membrane, and heating, sterilizing and storing to obtain the nano pearl proteins. The preparation method provided by the invention is simple in process, organically combines the nano grinding technology with the emulsifying and dispersing technology, and further enhances the emulsifying and dispersing effect by means of ultrasonic waves, so that the pearl protein particles effectively reach nanoscale. The pure nature and integrity of the pearl protein component can be maintained by pure physical processing, and the nano pearl proteins are uniform in particle and are easily assimilated by human body and further by skins, so that the nano pearl proteins are suitable for being used as an additive of medicines, nutrients and skin care products.

Owner:HAINAN JINGRUN PEARL BIOTECH

Aerated food product and a process for preparing the same

InactiveUS20070178209A1Stabilise the foam structure of aerated food productsFrozen sweetsConfectioneryFood productsProtein particles

An aerated food product comprising at least 0.05 wt %, and preferably at most 50 wt %, of hydrophobic denatured protein particles whereby at least 50% of the number of said protein particles have in a hydrated state a diameter of more than 3 micron, and preferably less than 10% of the number of said protein particles have in a hydrated state a diameter of more than 300 micron.

Owner:CONOPCO INC D B A UNILEVER

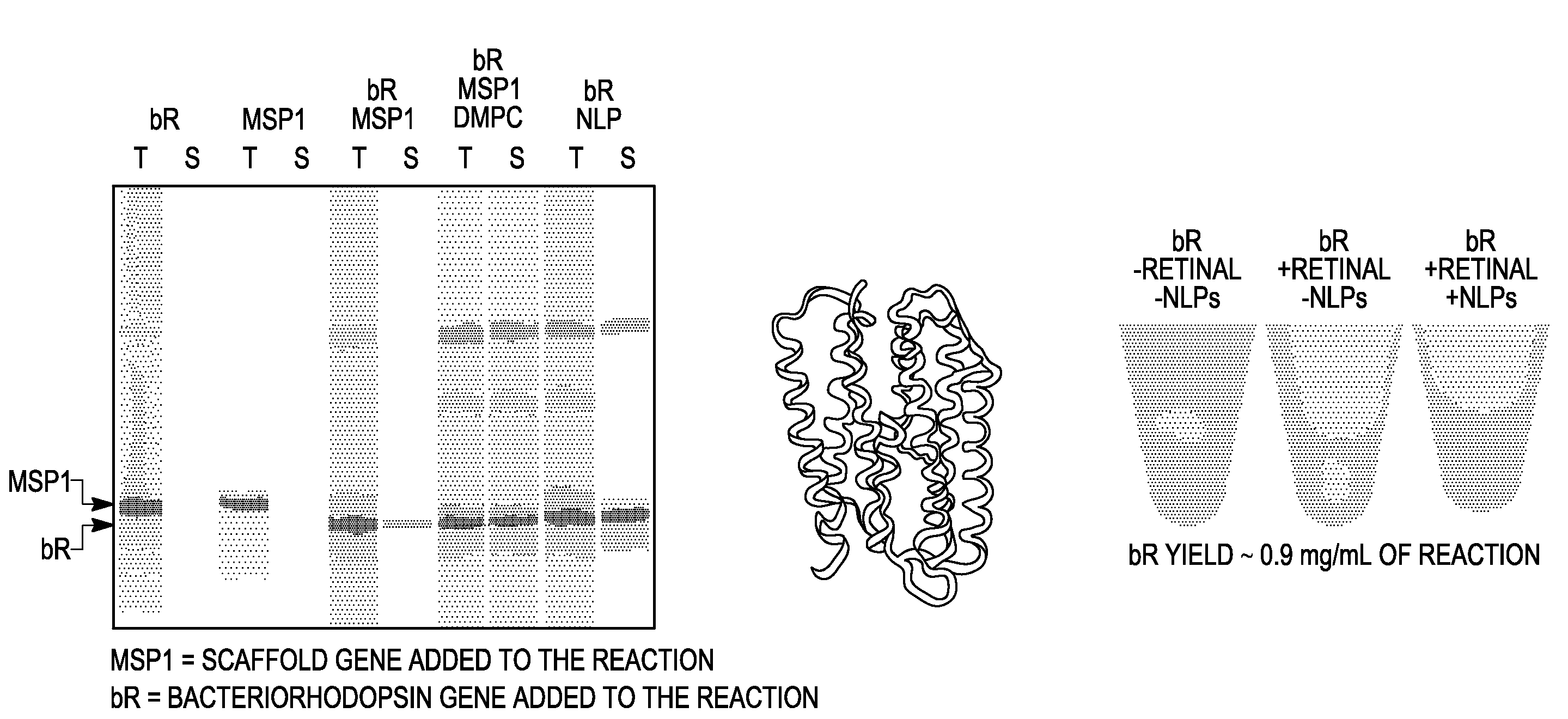

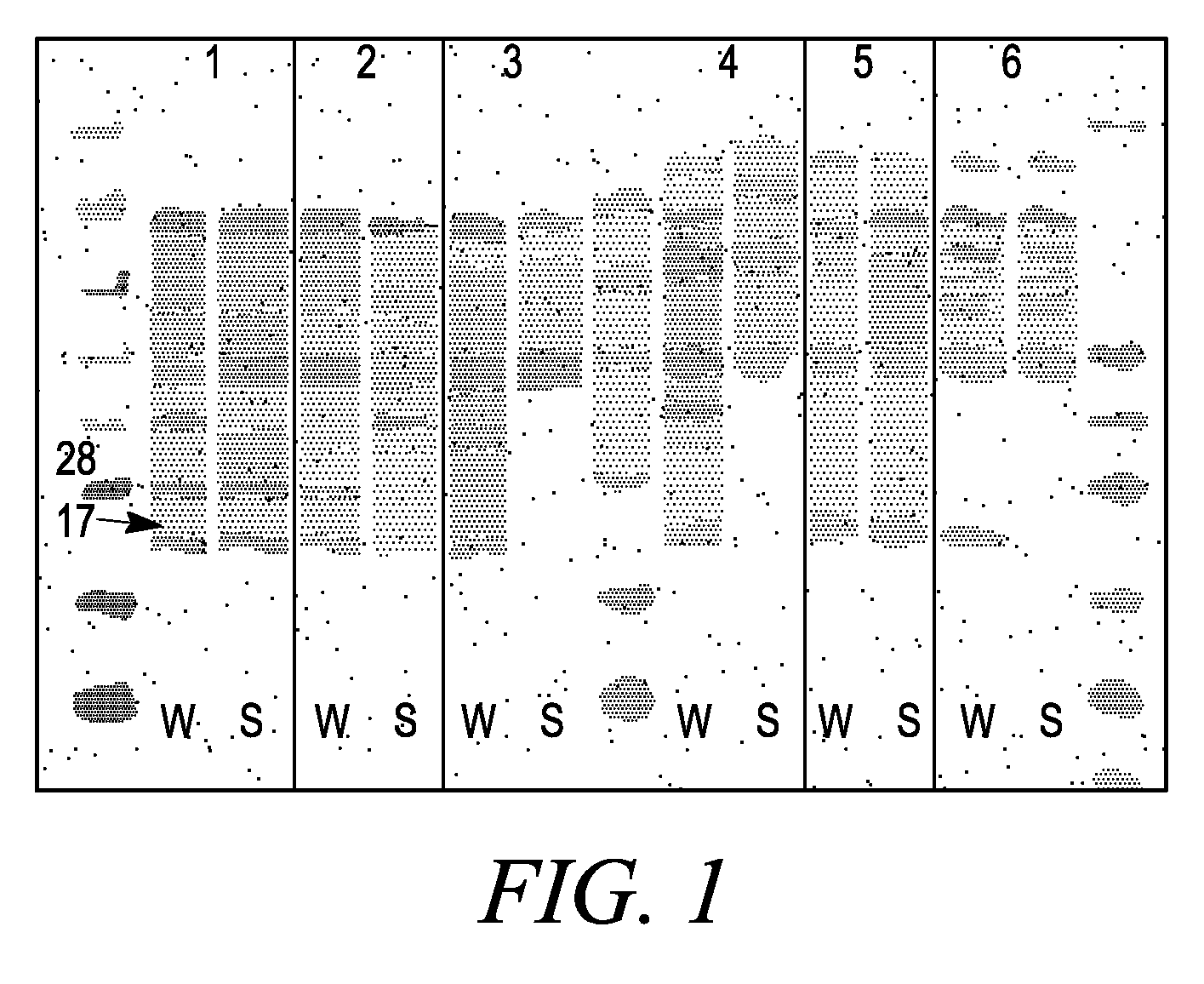

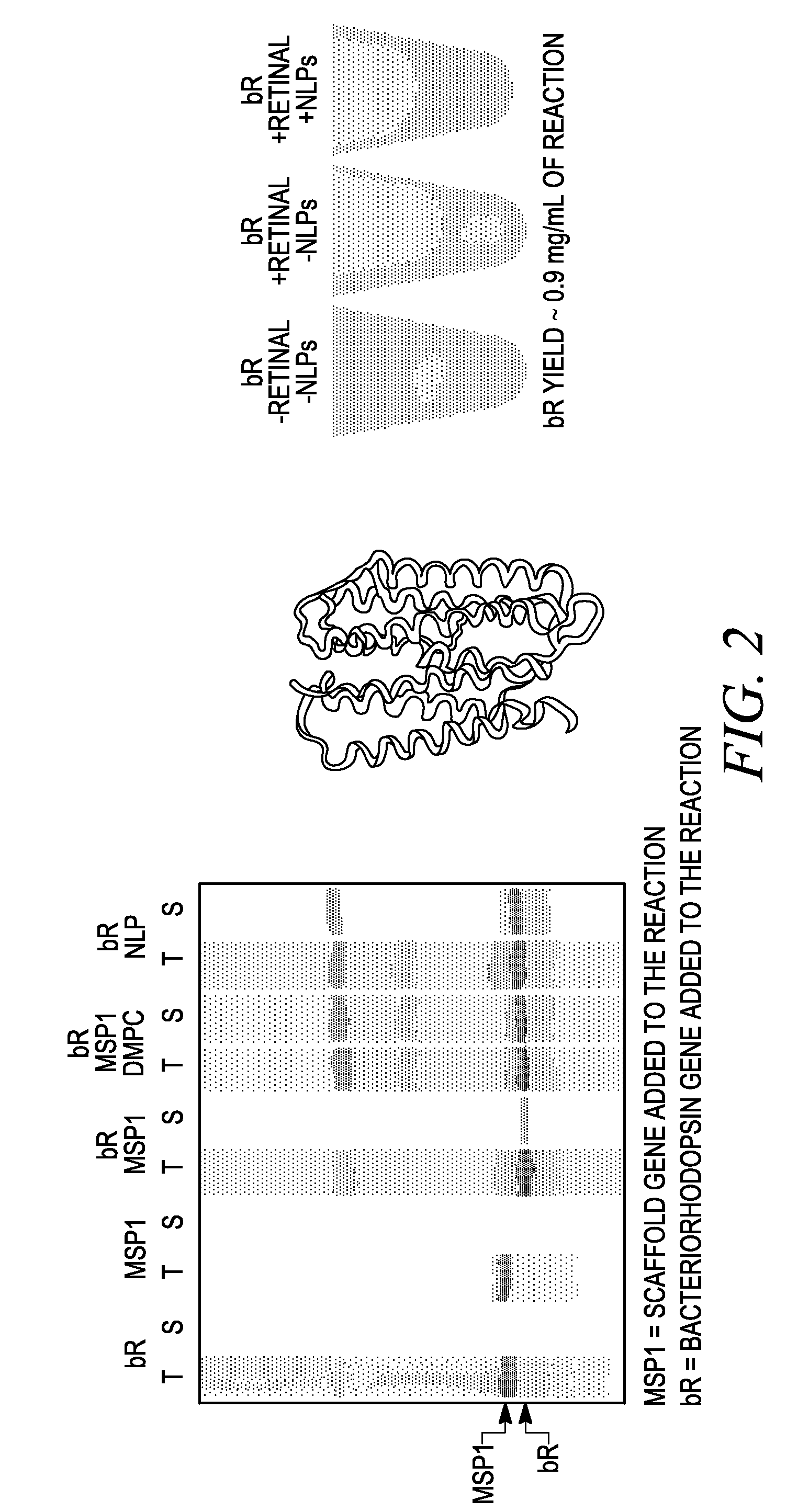

Isolated phospholipid-protein particles

InactiveUS20080248565A1Speed up the processImprove solubilityPeptide preparation methodsDepsipeptidesADAMTS ProteinsApolipoproteins E

Systems and methods are provided for producing a protein of interest that is typically not amenable to expression in soluble form in in vitro expression systems. In some aspects, the invention provides methods of synthesizing proteins using in vitro protein synthesis systems that include a scaffold protein such as apolipoprotein or an amphipathic alpha helix containing (“AAHC”) protein, in which higher yields of soluble protein are produced than in the absence of the scaffold protein. The scaffold proteins may be provided in an in vitro protein synthesis system associated with lipid or not associated with lipid. The scaffold protein may be provided as a protein per se or may be encoded by a nucleic acid template and co-expressed with the protein of interest. The invention also provides compositions and kits for synthesis of proteins in soluble form, in which the compositions and kits include cell extracts for protein expression and isolation.

Owner:LIFE TECH CORP

Formula of peanut paste and preparation method thereof

The invention belongs to the technical field of peanut food deep processing and relates to a formula of peanut paste, which is characterized by comprising pulverized skimmed peanut protein particles, pulverized soybean, pulverized garlic, additive, stabilizer and emulsifier, wherein the mass ratio of the skimmed peanut protein particles to the soybean to the garlic is 10:2:1; and the additive, the stabilizer and the emulsifier account for 1.5 percent, 0.2 percent and 0.1 percent of the mass of the mixture of the peanut protein, the soybean and the garlic respectively. The invention also discloses a preparation method of the peanut paste. The peanut paste prepared by the method has the advantages of preventing the paste from separating from fat and oil, along with fine mouthfeel, pure flavor, high stability, long quality guarantee period and the like. Meanwhile, the peanut paste offers a very excellent mouthfeel and can be spread easily. The production method of the peanut paste is simple and the production cost of the peanut past is low, so the peanut paste is suitable for industrial production and can create obvious economic and social benefit.

Owner:SHANDONG PEANUT RES INST

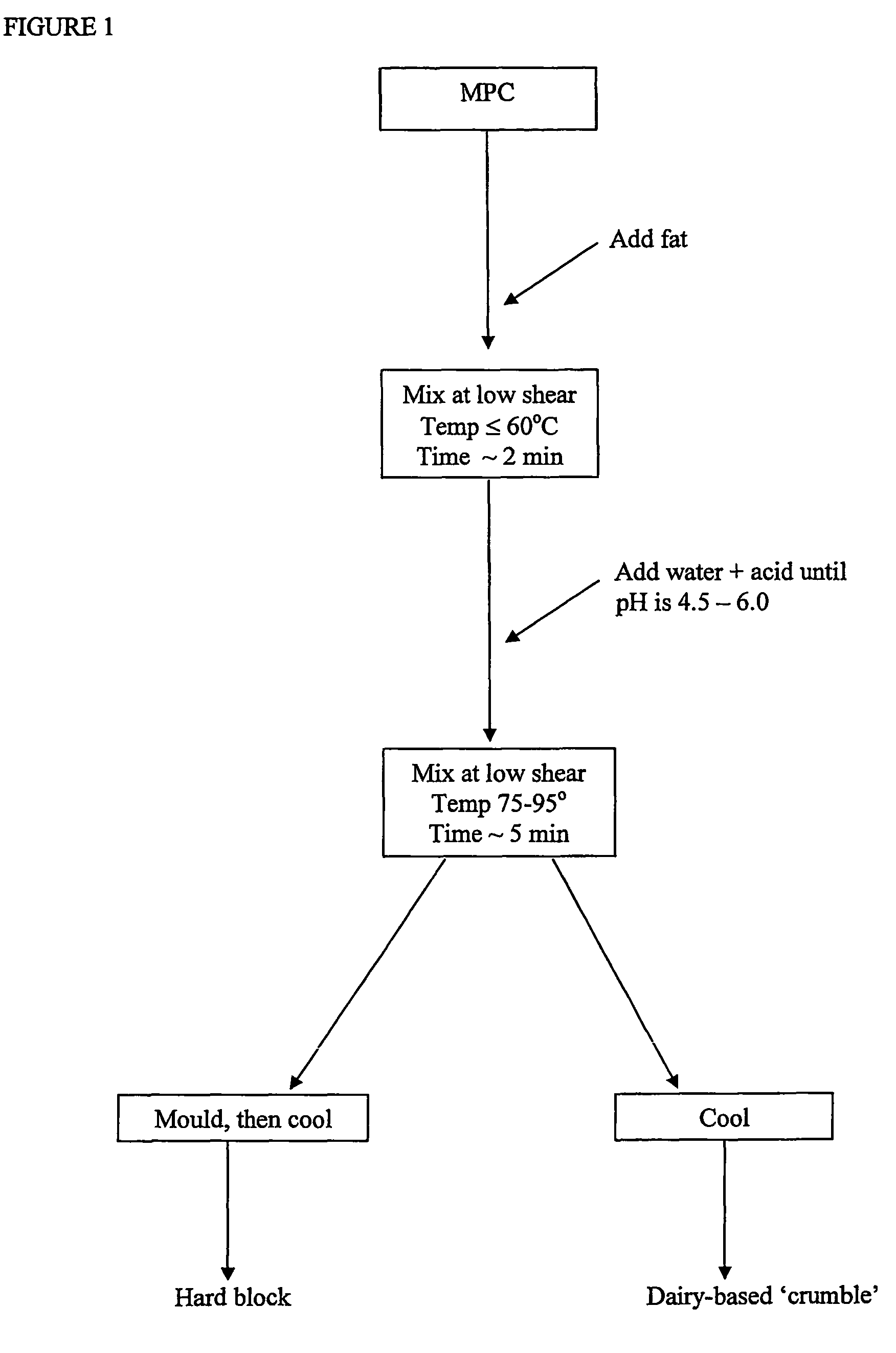

Method of making high solids, high protein dairy-based food

The present invention provides a process for producing a high solids / high protein dairy product wherein an MPC is first mixed with molten fat to produce a mixture of protein particles coated in fat and the mixture hydrated, acidified and heated under low shear to produce a dairy product, preferably a cheese or cheese-like product having a protein to water ratio of between 0.6 and 3.0.

Owner:FONTERRA IP +1

Method for developing a dairy protein cake

ActiveUS20090263553A1Sufficient supplyCheap methodDough treatmentFood ingredientsPotato starchBRAF Protein

A method for producing a shelf-stable protein-based pellet that is capable of expansion into a light, crispy snack cake, while providing a good source of protein and calcium. The method, in preferred embodiments, involves making dough from tapioca and potato starches and a milk protein derivative consisting of whey protein isolate, milk protein isolate or calcium caseinate. The mixture is extruded, sliced and dried in a series of dyers. The method produces a shelf-stable pellet having a moisture level of approximately 9-13% by weight which is further processed to produce a puffed dairy protein snack product, having a moisture level typically less than 2%.

Owner:FRITO LAY NORTH AMERICA INC

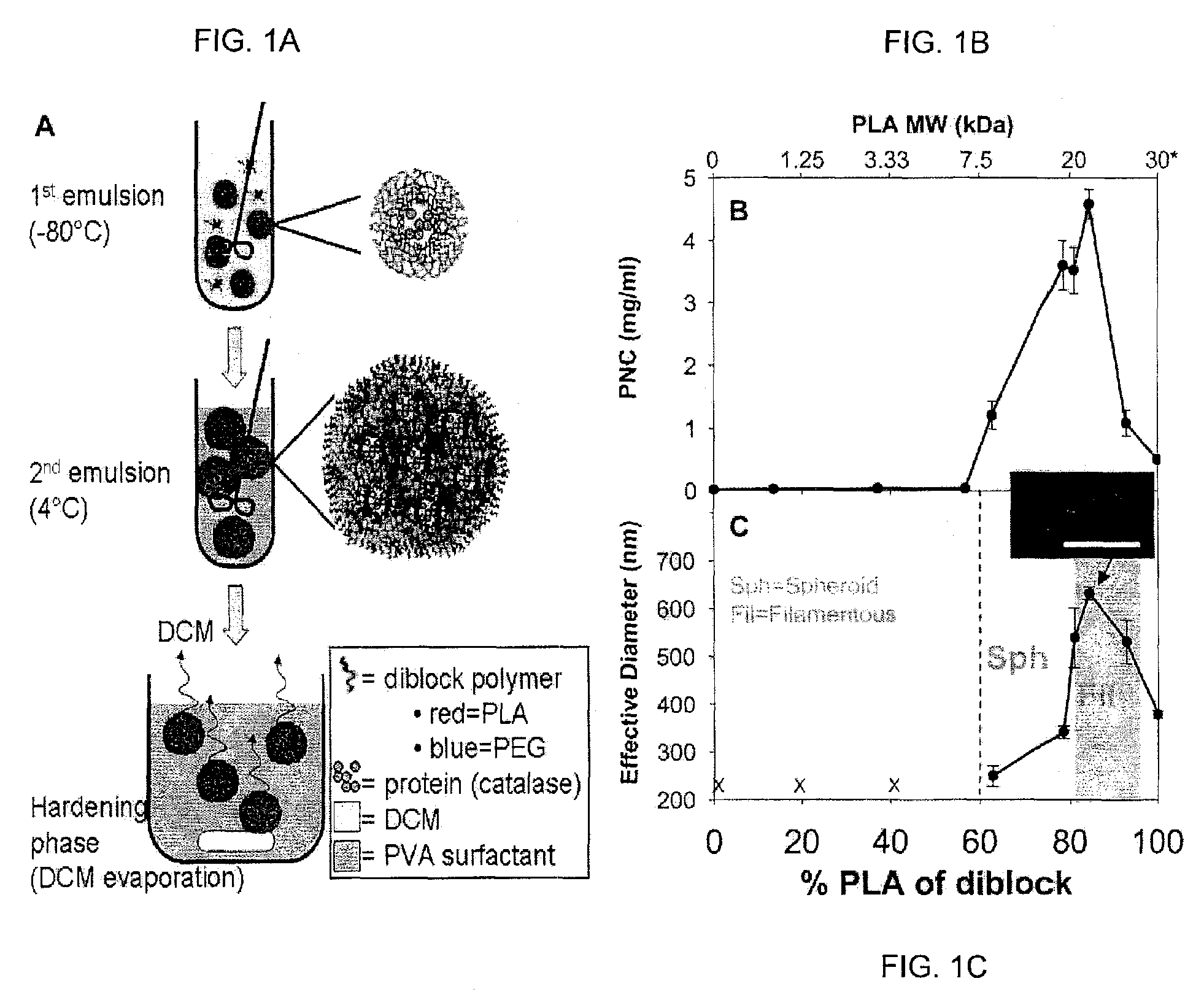

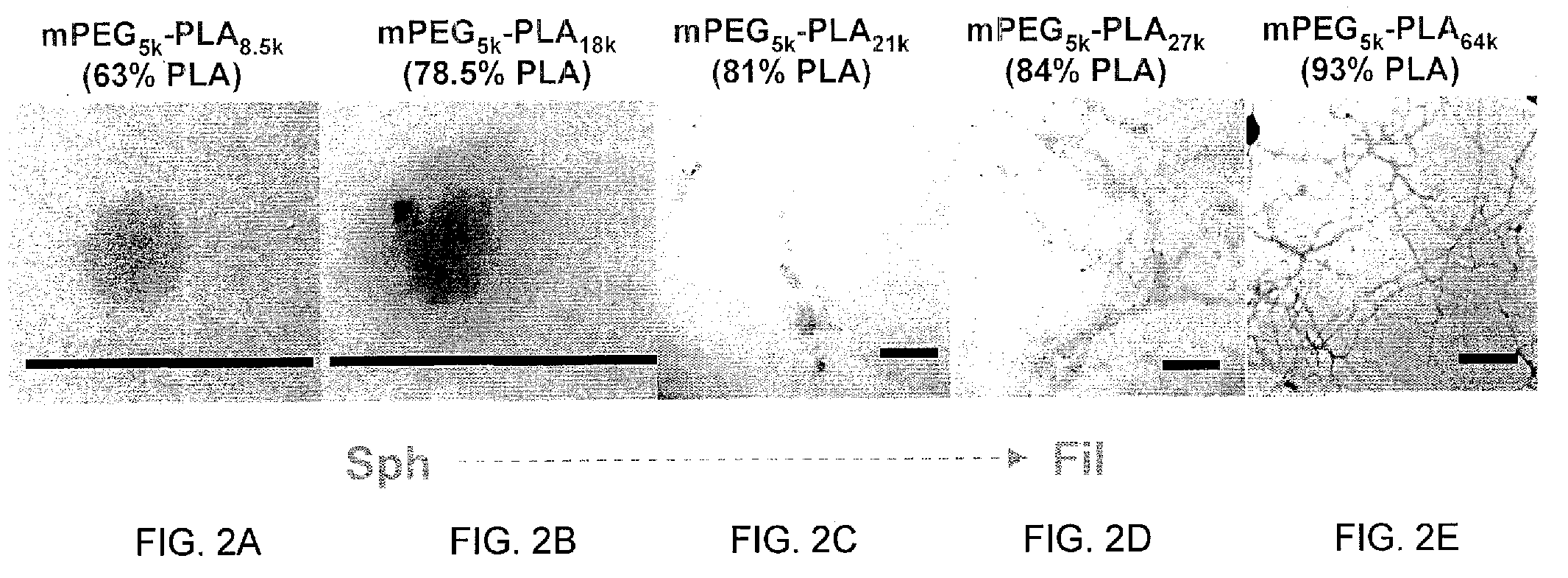

Method and compositions for polymer nanocarriers containing therapeutic molecules

ActiveUS7927629B2Improve enzymatic activityRetain biological activityBiocidePeptide/protein ingredientsFreeze thawingActive enzyme

Owner:THE TRUSTEES OF THE UNIV OF PENNSYLVANIA

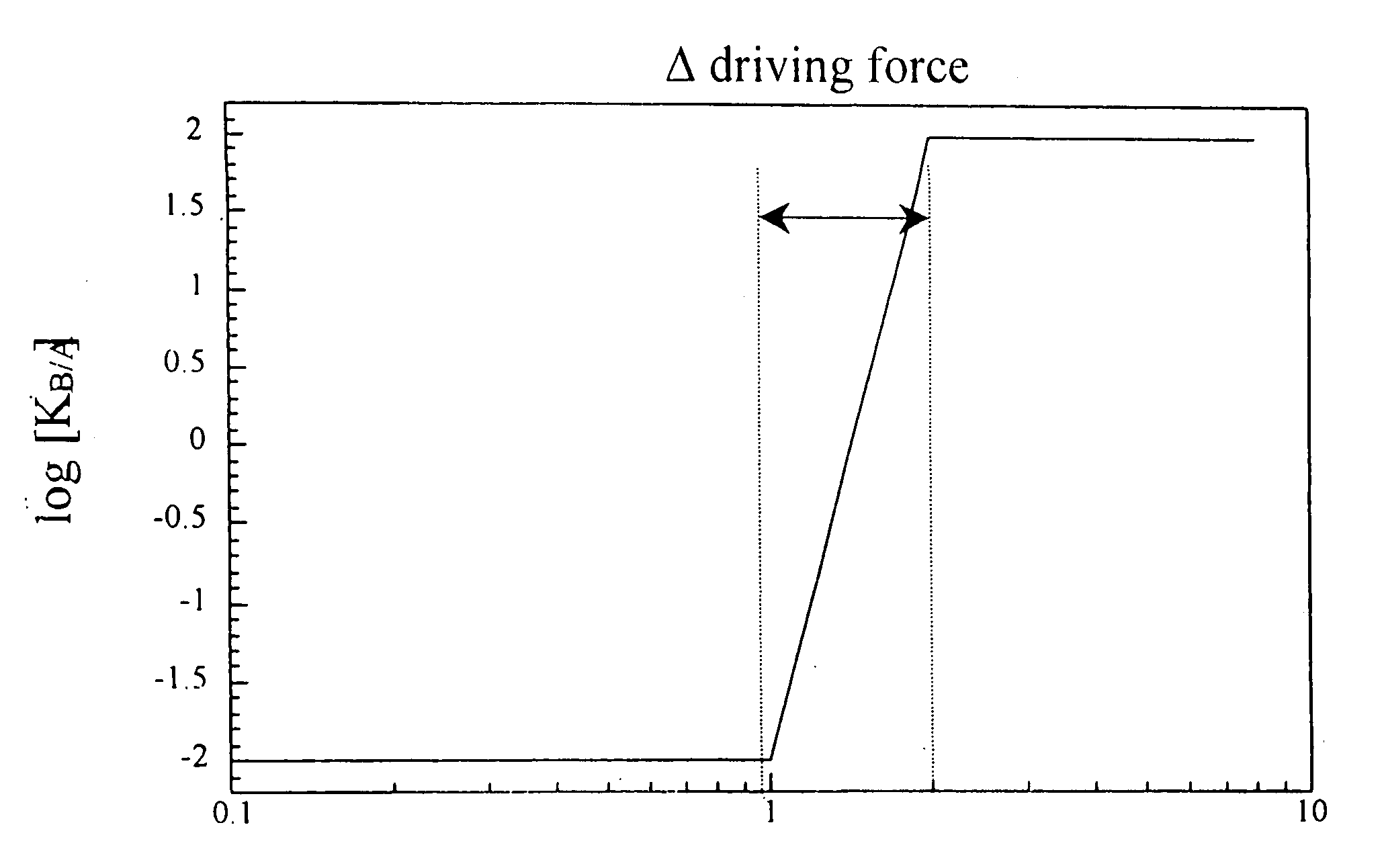

Misfolded protein sensor method in body fluids

InactiveUS20060275910A1Easy to detectRapid and cost-effective analyticalDisease diagnosisBiological testingCrystallographyTest sample

A catalytic conformational sensor method for detecting abnormal proteins and proteinaceous particles. The method is based on the interaction of a peptide fragment or probe with an abnormal proteinaceous particle. The interaction catalyzes transformation of the probe to a predominately beta sheet conformation and allows the probe to bind to the abnormal proteinaceous particle. This in turn, catalyzes propagation of a signal associated with the test sample-bound probe. As a result signals can be propagated even from samples containing very low concentrations of abnormal proteinaceous particles as is the case in many body-fluid derived samples.

Owner:ADLYFE INC

Recombinant fusion protein and use thereof

InactiveCN104341506AAntiviralsAntibody medical ingredientsHepatitis B virus core AntigenAntigen epitope

The invention belongs to the biological medicine field, relates to recombinant fusion protein and use thereof, and in particular relates to recombinant fusion protein carrying hepatitis B virus therapeutic antigen epitopes which are inserted into hepatitis B core antigen protein particles or truncated fragments and use thereof. The recombinant fusion protein contains multiple epitope antigens of hepatitis B virus (HBV) and other immune stimulating epitope antigens and hepatitis B core antigen virus-like particles or truncated fragments thereof for preparation of chimeric antigen, the multiple antigen epitopes can be inserted into same or different sites of hepatitis B virus core antigen HBc or truncated fragments thereof in the manner of single epitope or multi epitope combination, and by combination with different adjuvants, HBV specific humoral and cellular immune functions can be strengthened.

Owner:FUDAN UNIV

Method of making high solids, high protein dairy-based food

The present invention provides a process for producing a high solids / high protein dairy product wherein an MPC is first mixed with molten fat to produce a mixture of protein particles coated in fat and the mixture hydrated, acidified and heated under low shear to produce a dairy product, preferably a cheese or cheese-like product having a protein to water ratio of between 0.6 and 3.0.

Owner:FONTERRA IP +1

Fruit Paste-Based Food Product Incorporating High Protein Particulates

A food product is defined by a moist, fruit-paste matrix, having a water activity level in a range of 0.55 to 0.70, within which protein particulates are intermixed. The protein particulates include protein bits having a bulk density of about 0.4 g / cc and provided with a natural syrup coating. With the added protein bits, the protein level of the food product is at least 10 grams per serving or 10 grams / 50-55 grams of the food product. The food product can be provided in the form of a snack product, such as a bite-sized snack product or a snack bar. The invention also sets forth a method of making the food product wherein provisions are taken to assure that the protein bits are properly coated, separated, sized and added to the fruit-paste matrix under time and other condition constraints to assure the integrity of the protein bits.

Owner:GENERAL MILLS INC

Highly concentrated plant protein preparation and method for producing the same

InactiveUS20090291189A1Reduction of water bindingFeel softProtein composition from vegetable seedsConfectioneryProtein moleculesIncreased saliva

The invention relates to a protein preparation and a method for the production thereof. The protein preparation includes protein particles. A protein particle includes several plant protein molecules with at least one hydrophilic and at least one hydrophobic moiety each. The protein molecules are bound to each other in such a manner that the protein particle has a mainly hydrophobic surface. The preparation allows production of foodstuffs that are rich in protein, that have a pleasant taste, that do not appear to be dry, solid, hard or crumbly, that do not cause increased saliva production and that are easy to swallow.

Owner:ZACHERL CHRISTIAN +3

Extraction of DNA in Pleurotus eryngii by improved CTAB (cetyltrimethylammonium bromide) method

The invention relates to extraction of DNA in Pleurotus eryngii by an improved CTAB (cetyltrimethylammonium bromide) method. 25-35% anhydrous alcohol is added while adding a mixed solution of Tris-phenol, chloroform and isoamyl alcohol, and the OD260 / OD280 values of the extracted DNA are respectively 1.9-2.0, which indicates that the addition of the alcohol is beneficial to removing proteins. Since the alcohol is dissolvable in water and has great affinity for water, the hydration shells of the protein granules can be destroyed, so the proteins precipitate at the isoelectric point; and therefore, the protein precipitate can be removed in the extraction process. When the DNA is subjected to ultraviolet detection by five different methods, the result indicates that only the DNA tape extracted by the invention is the brightest, basically has no degradation trailing phenomenon, and only has few substances detained near the sample charging hole, which indicates that the low-concentration alcohol precipitation method can well remove polysaccharides in the DNA.

Owner:湖南果秀食品有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com